A kind of corrosion-resistant biological magnesium alloy and preparation method thereof

A magnesium alloy and deformed magnesium alloy technology, applied in the field of biomedical metal materials, can solve the problems of unsatisfactory mechanical properties, accelerated corrosion rate, poor corrosion resistance, etc., and achieves adjustable degradation rate and mechanical properties. Granular tissue, the effect of improving corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

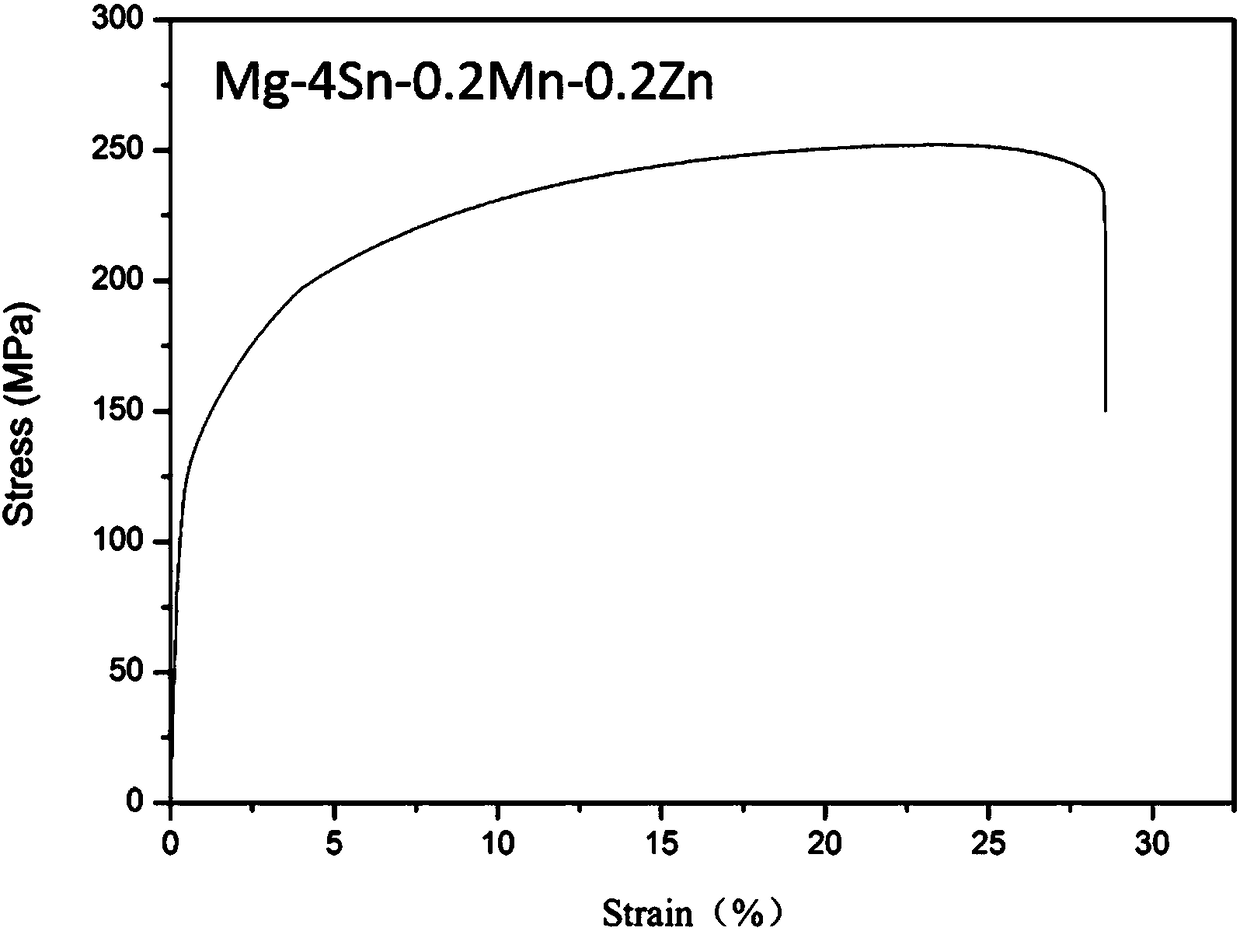

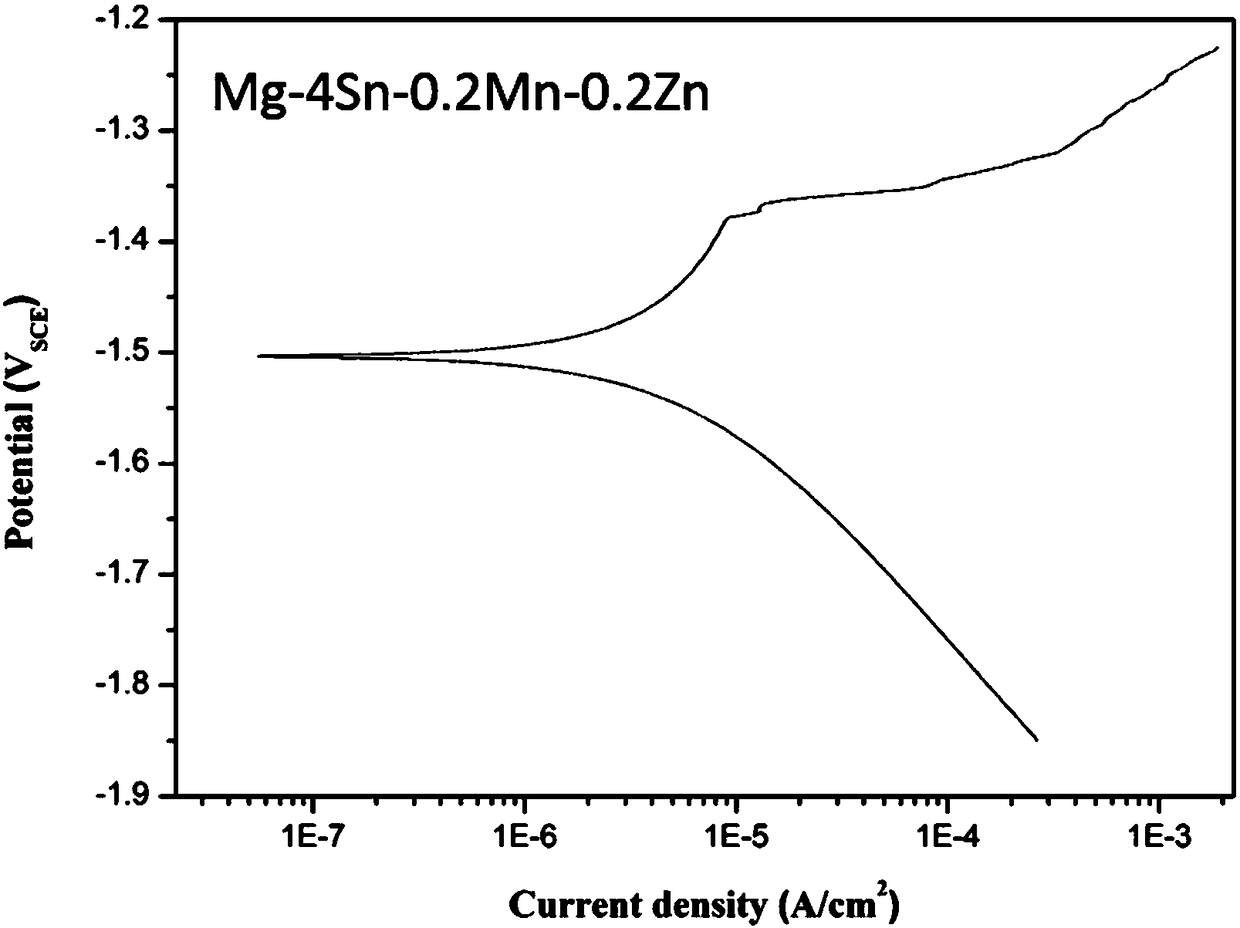

Embodiment 1

[0030] Preparation of Cast Mg-4.0wt%Sn-0.2wt%Mn-0.2wt%Zn Magnesium Alloy

[0031] 1) Raw material preparation: The test raw materials are pure magnesium (99.9wt.%), pure zinc (99.99wt.%) (calculated based on 10% burning loss), pure tin (99.99wt.%) and Mg-7.4wt.% Mn master alloy (calculated on the basis of 30% burning loss), and the raw material is polished with a grinding wheel to remove surface oxides.

[0032] 2) Smelting: In order to prevent the oxidation or combustion of the magnesium alloy melt, N is continuously fed throughout the smelting process 2 +SF 6 The mixed protective gas, where, N 2 and SF 6 The flow ratio is 100:1;

[0033] a) Dry the crucible, slag removal tool, stirring rod and mold in an oven at 200°C for use;

[0034] b) Put the treated crucible into a resistance furnace, set the temperature to 300°C, and when the furnace temperature reaches, pass in protective gas;

[0035] c) After feeding the protective gas for 5-8 minutes, add the polished high-pu...

Embodiment 2

[0042] Preparation of Cast Mg-3.0wt%Sn-0.01wt%Mn-0.5wt%Zn Magnesium Alloy

[0043] 1) Raw material preparation: The test raw materials are pure magnesium (99.9wt.%), pure zinc (99.99wt.%) (calculated based on 10% burning loss), pure tin (99.99wt.%) and Mg-7.4wt.% Mn master alloy, and the raw material is ground with a grinding wheel to remove surface oxides.

[0044] 2) Smelting: In order to prevent the oxidation or combustion of the magnesium alloy melt, N is continuously fed throughout the smelting process 2 +SF 6 The mixed protective gas, where, N 2 and SF 6 The flow ratio is 100:1;

[0045] a) Dry the crucible, slag removal tool, stirring rod and mold in an oven at 200°C for use;

[0046] b) Put the treated crucible into a resistance furnace, set the temperature to 300°C, and when the furnace temperature reaches, pass in protective gas;

[0047] c) After feeding the protective gas for 5-8 minutes, add the polished high-purity magnesium ingot, and at the same time, the...

Embodiment 3

[0054] Preparation of Cast Mg-1.0wt%Sn-1wt%Mn-0.05wt%Zn Magnesium Alloy

[0055] 1) Raw material preparation: The test raw materials are 820g of pure magnesium (99.9wt.%), 10.9g of pure zinc (99.99wt.%) (calculated according to 10% burning loss), 0.54g of pure tin (99.99wt.%) (according to 30% burning loss calculation) and Mg-7.4wt.%Mn master alloy 174.9g (calculation is based on 30% burning loss), and the raw material is polished with a grinding wheel to remove surface oxides.

[0056] 2) Smelting: In order to prevent the oxidation or combustion of the magnesium alloy melt, N is continuously fed throughout the smelting process 2 +SF 6 The mixed protective gas, where, N 2 and SF 6 The flow ratio is 100:1;

[0057] a) Dry the crucible, slag removal tool, stirring rod and mold in an oven at 200°C for use;

[0058] b) Put the treated crucible into a resistance furnace, set the temperature to 300°C, and when the furnace temperature reaches, pass in protective gas;

[0059] c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com