3D printing biphase calcium phosphate stent and preparation method thereof

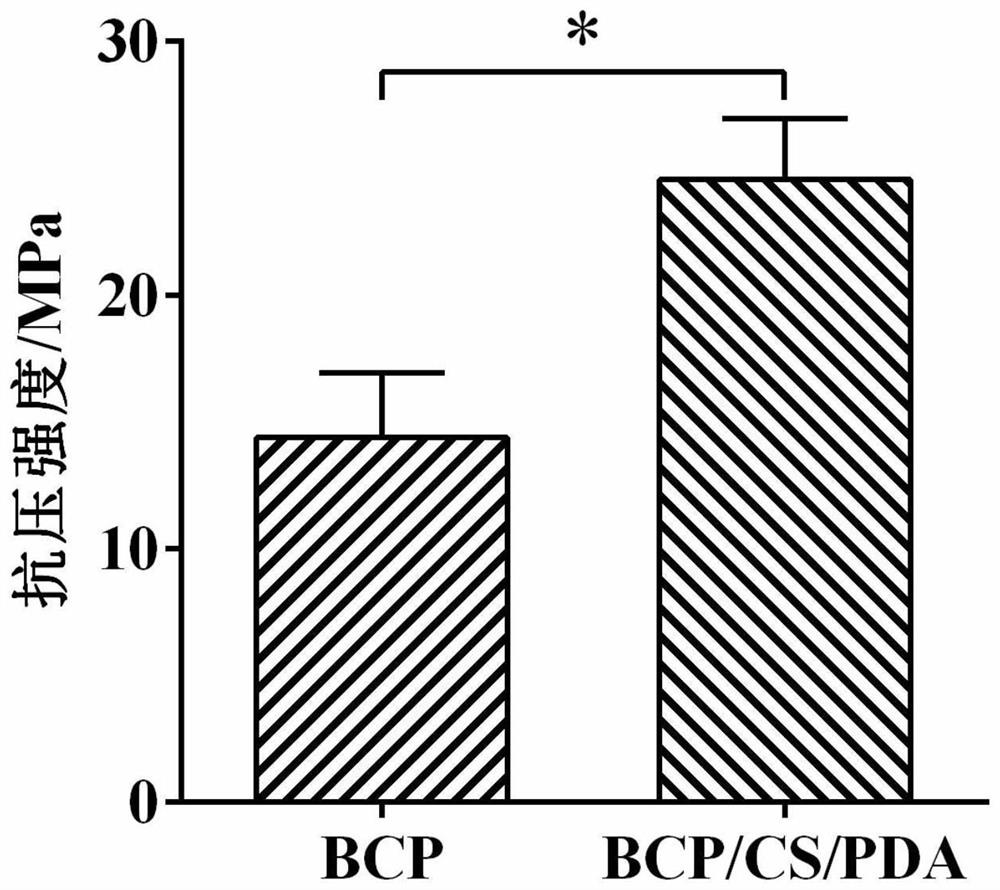

A biphasic calcium phosphate, 3D printing technology, applied in medical science, surgery, coating and other directions, can solve the problems of poor osseointegration of scaffolds, poor promotion of osteogenic differentiation, and unfavorable osteocytes, and achieve the coating preparation method. Simple, effective in improving osseointegration and compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] In a first aspect, the present invention provides a method for preparing a 3D printed biphasic calcium phosphate scaffold, comprising the following steps:

[0032] Prepare a slurry with hydroxyapatite, β-tricalcium phosphate, hydroxypropyl methylcellulose and deionized water according to the set mass ratio, and the solid-liquid ratio of the slurry is 1:0.96-1.01;

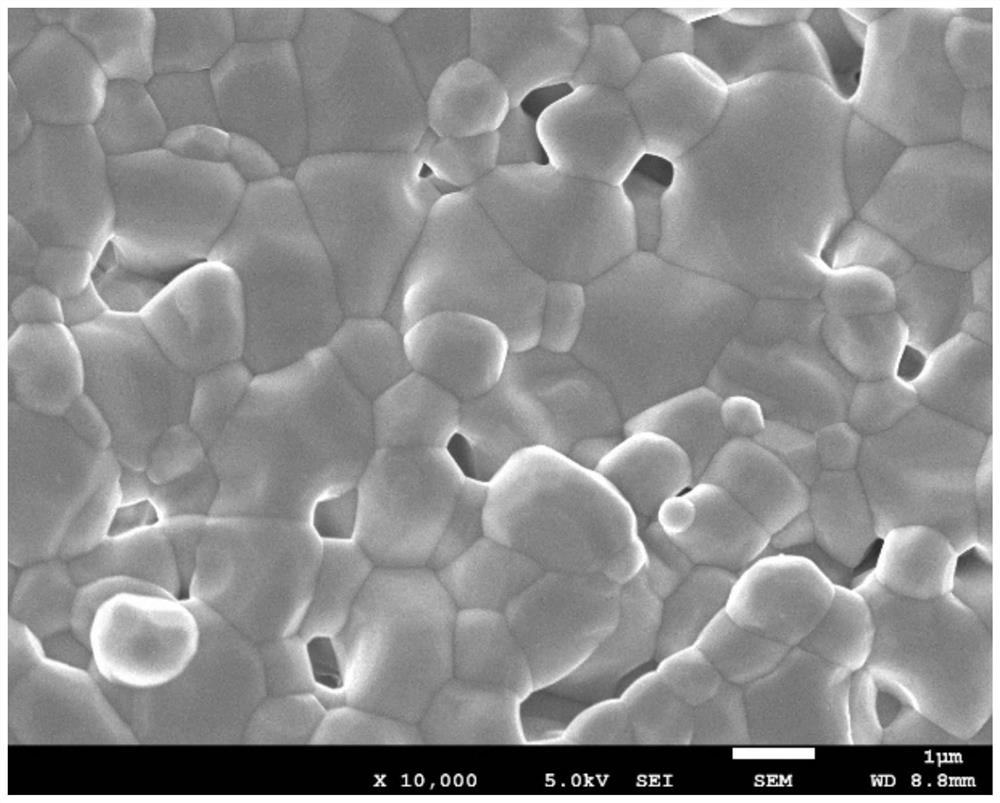

[0033] Using 3D printing technology to print the biphasic calcium phosphate scaffold with the prepared slurry, and sintering the printed biphasic calcium phosphate scaffold;

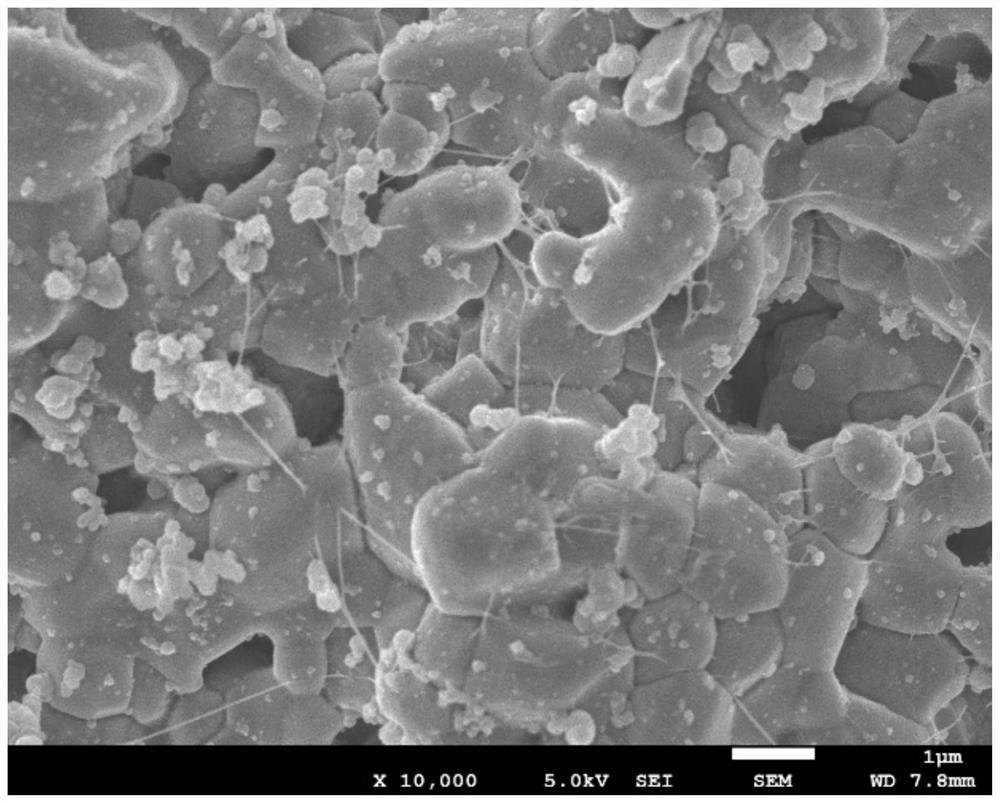

[0034] The sintered scaffolds are soaked in chitosan solution in vacuum to obtain biphasic calcium phosphate scaffolds modified on the surface of chitosan;

[0035] The biphasic calcium phosphate scaffold modified on the surface of the dried chitosan is placed in a polydopamine solution, coated, dried, washed and dried again to obtain a chitosan / polydopamine composite surface-modified biphasic phosphate calcium scaffold.

[0036] In s...

Embodiment 1

[0049] (1) Preparation of biphasic calcium phosphate ceramic slurry

[0050] Weigh 3g hydroxyapatite, 2g β-tricalcium phosphate and 0.2g hydroxypropyl methylcellulose, measure 5.2mL deionized water, and mix them to prepare biphasic calcium phosphate ceramic slurry;

[0051] (2) 3D printed porous biphasic calcium phosphate scaffolds

[0052]Use a direct-write molding printer, put the ceramic slurry into the printer barrel, select a needle with an inner diameter of 0.6mm, set the air pressure of the air pressure valve to 0.3MPa, the printing speed is 10mm / s, and the printing size is 14mm×14mm×2.5mm and 14mm×14mm×10mm porous biphasic calcium phosphate scaffold with a filling rate of 60%;

[0053] (3) Sintering bracket

[0054] Put the printed and dried brackets into the muffle furnace, and use the original sintering procedure of the muffle furnace for sintering, where the maximum temperature is 1245°C;

[0055] (4) Surface modification of chitosan

[0056] Prepare 5 mg / mL chi...

Embodiment 2

[0060] The sintering process of setting the muffle furnace in step (3) of this embodiment is to heat up at a rate of 5°C / min, then keep the temperature at 1200°C for 2 hours, and then cool with the furnace;

[0061] In step (4) of this example, a 5 mg / mL chitosan solution was prepared with 1% (v / v) acetic acid as a solvent, and the stent was soaked in a vacuum environment for 2 hours;

[0062] 10mmol·L was used in the step (5) of this example -1 , pH 10 Tris-HCl solution to prepare 5mg / mL polydopamine solution; set the temperature of the shaker to 37°C, the rotation speed to 160r / min, and the coating time to 2h.

[0063] Others are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Average compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com