Patents

Literature

60results about How to "Improve contact" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

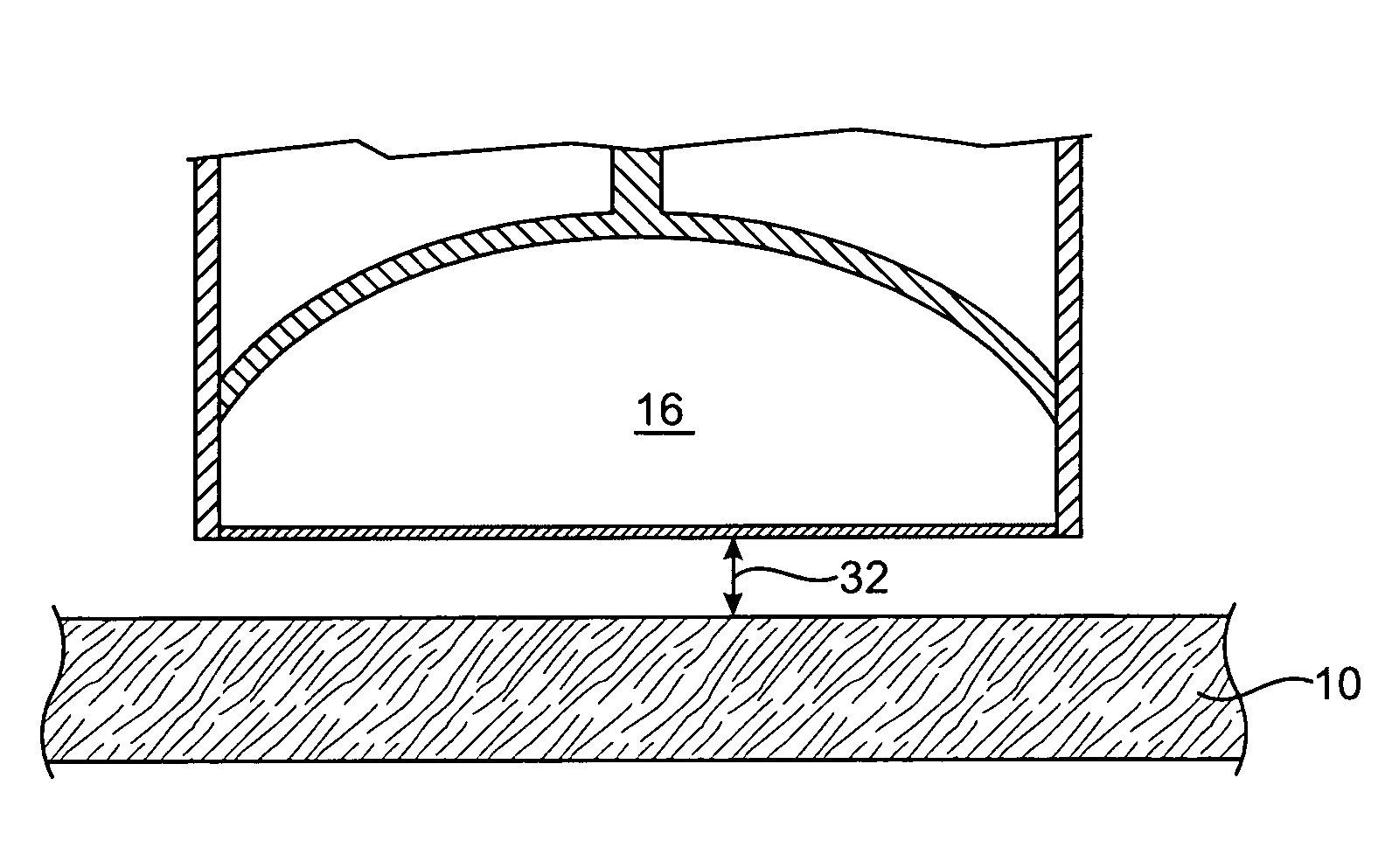

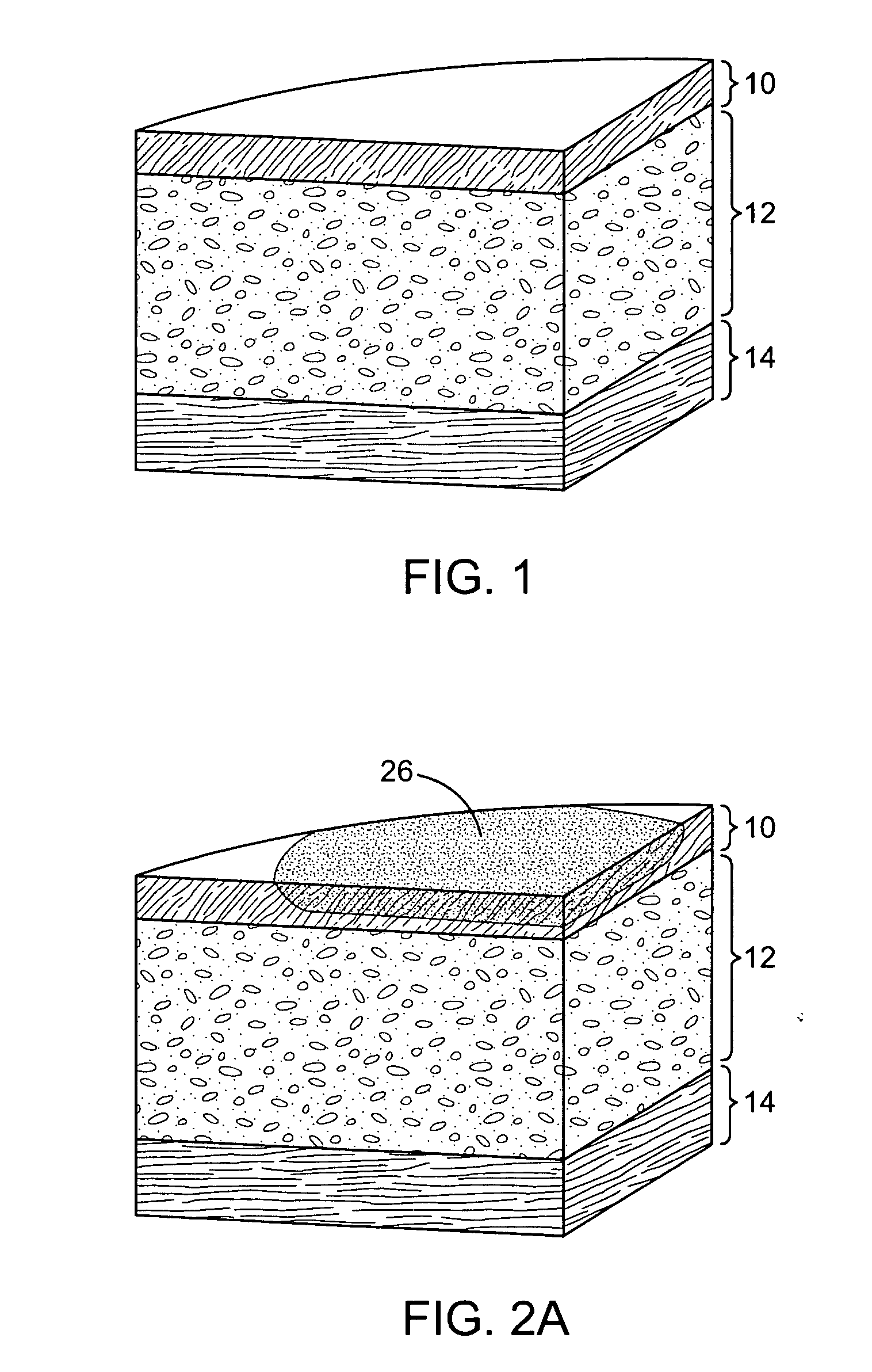

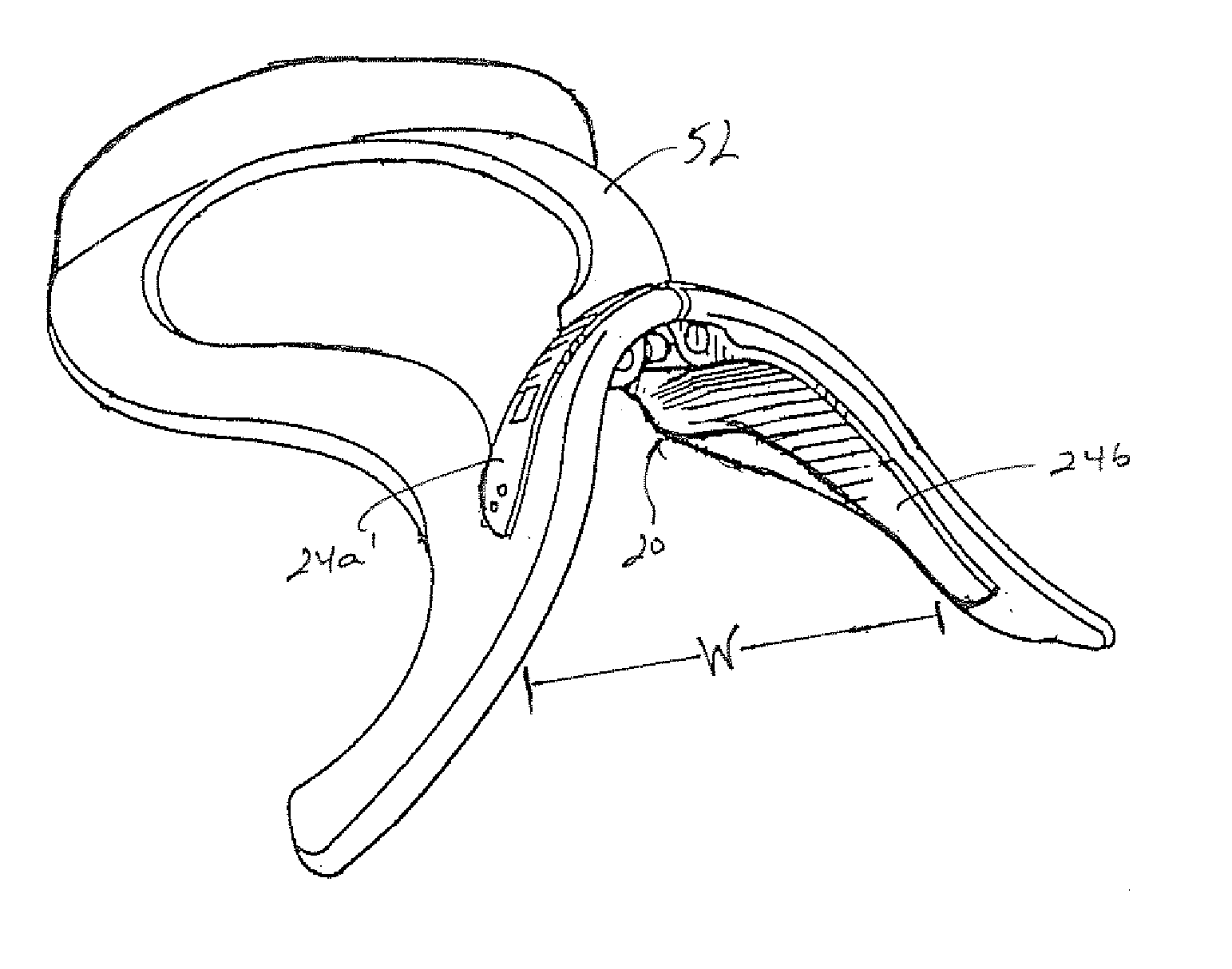

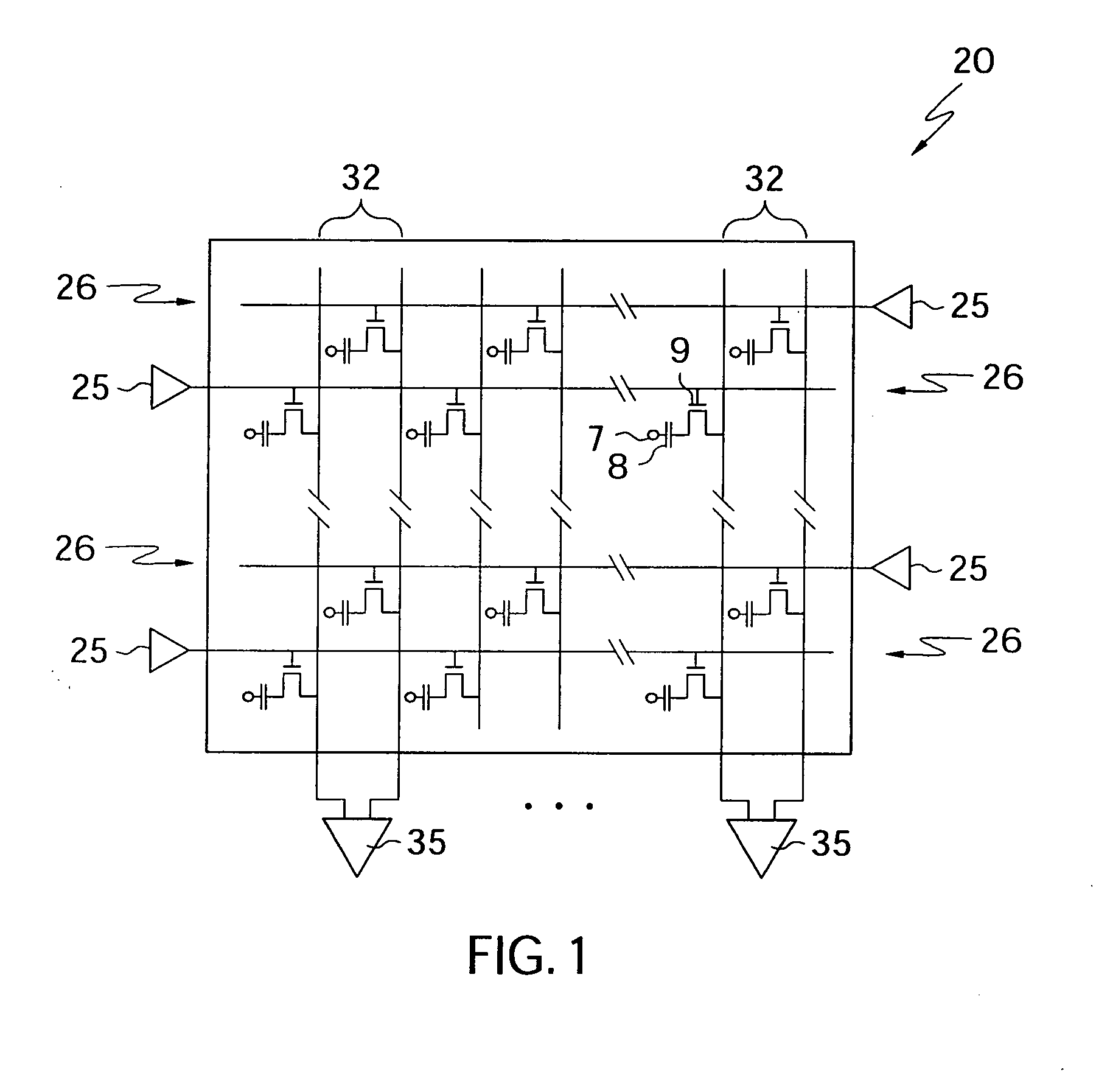

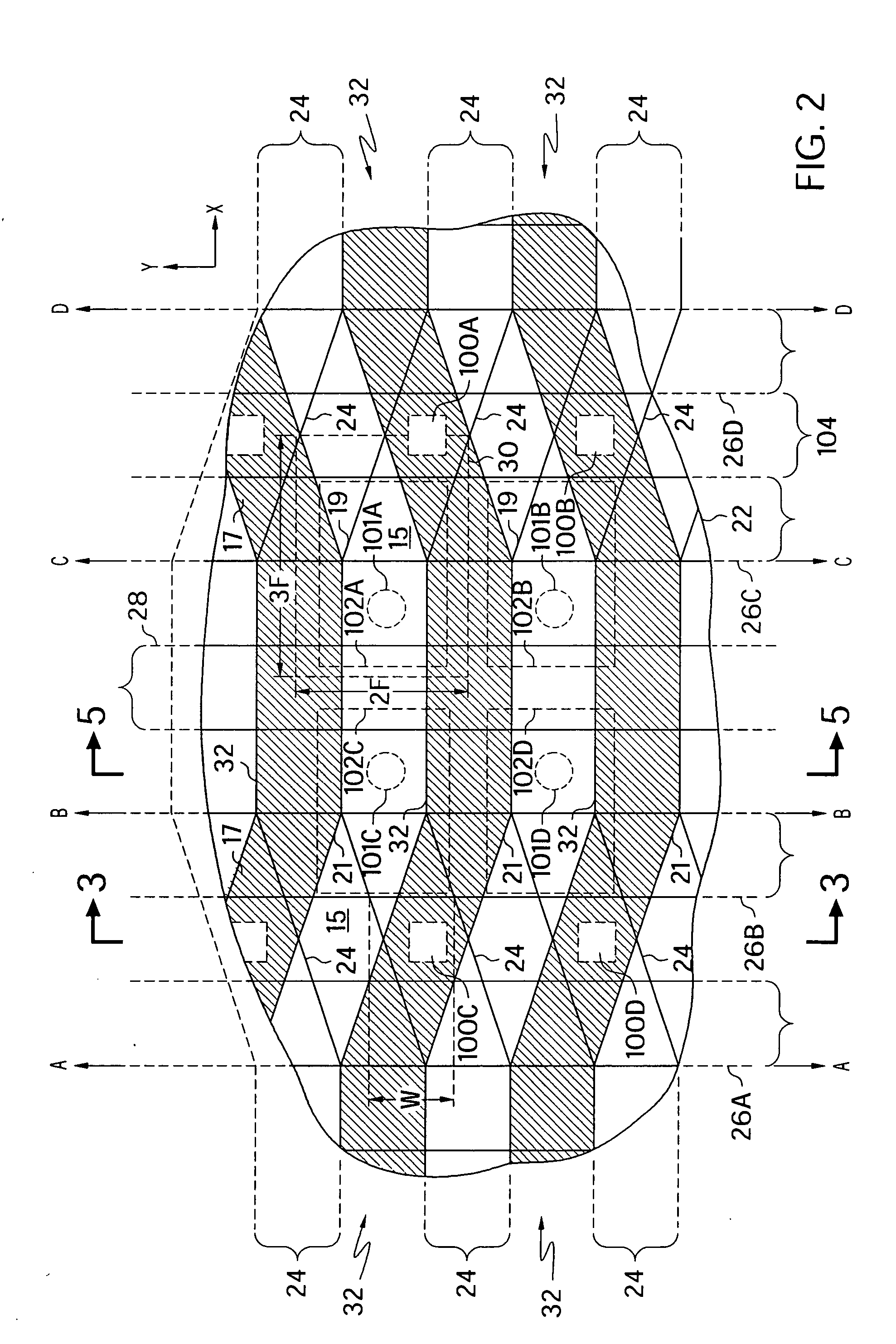

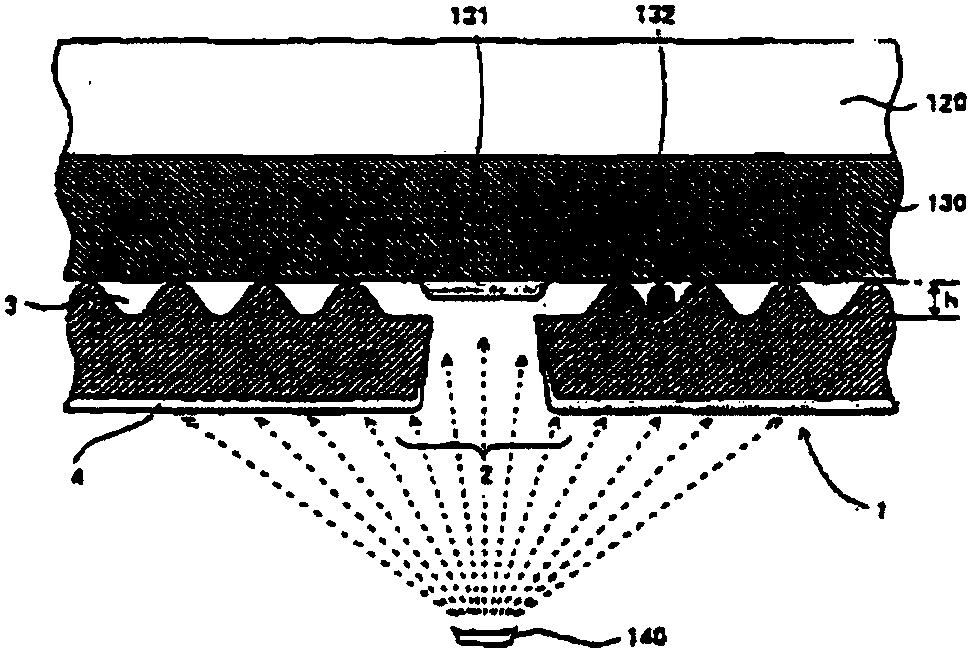

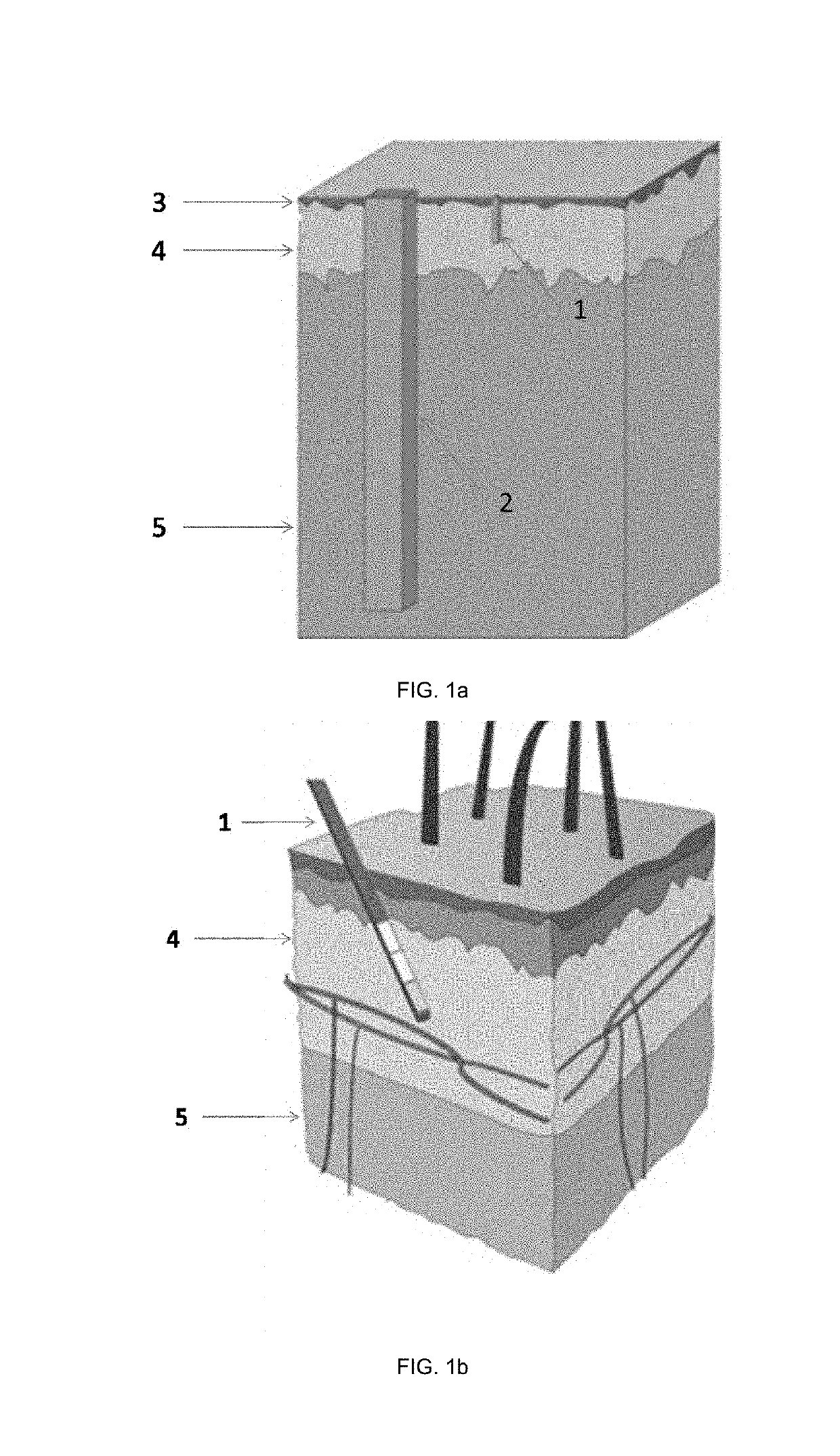

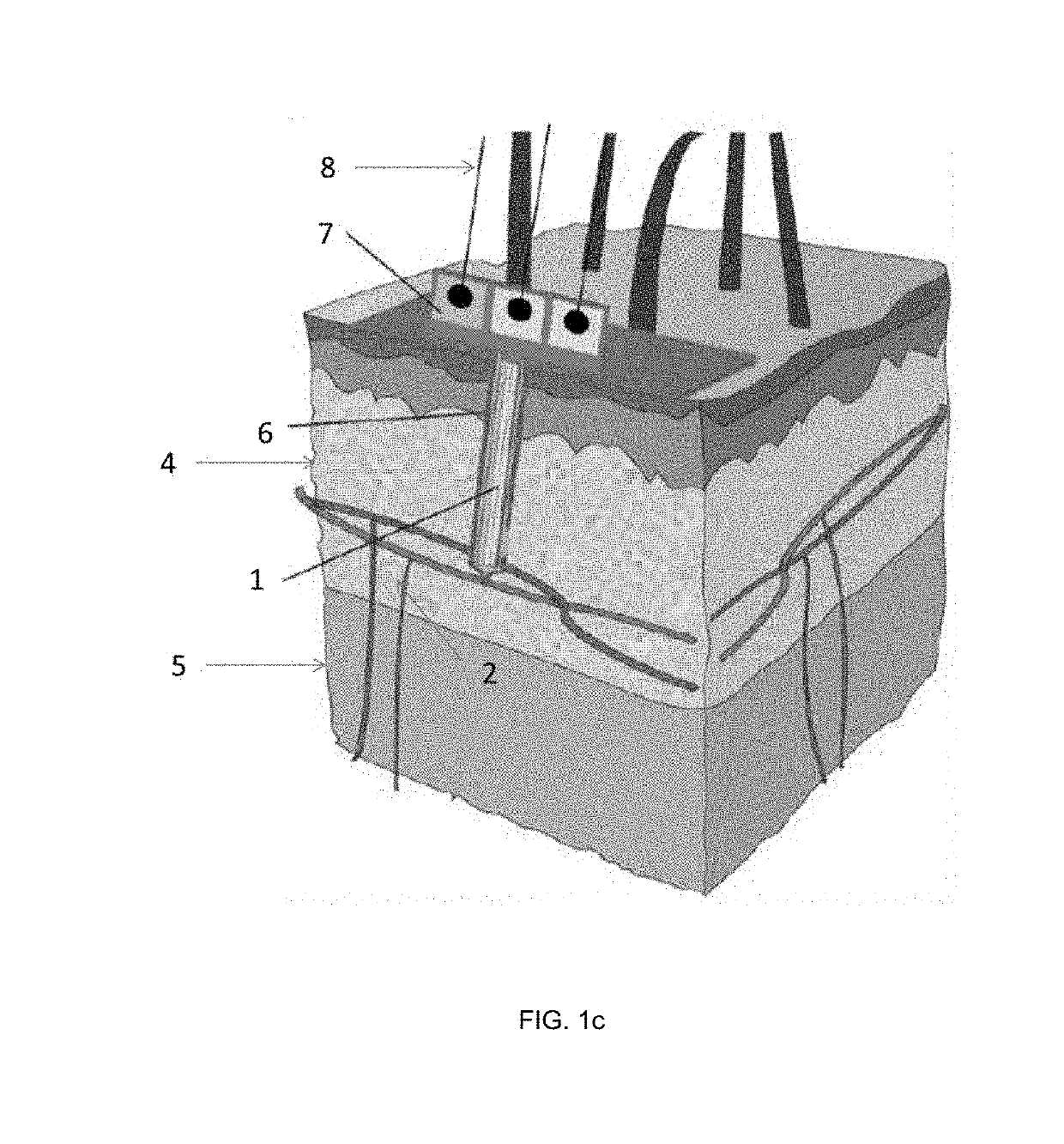

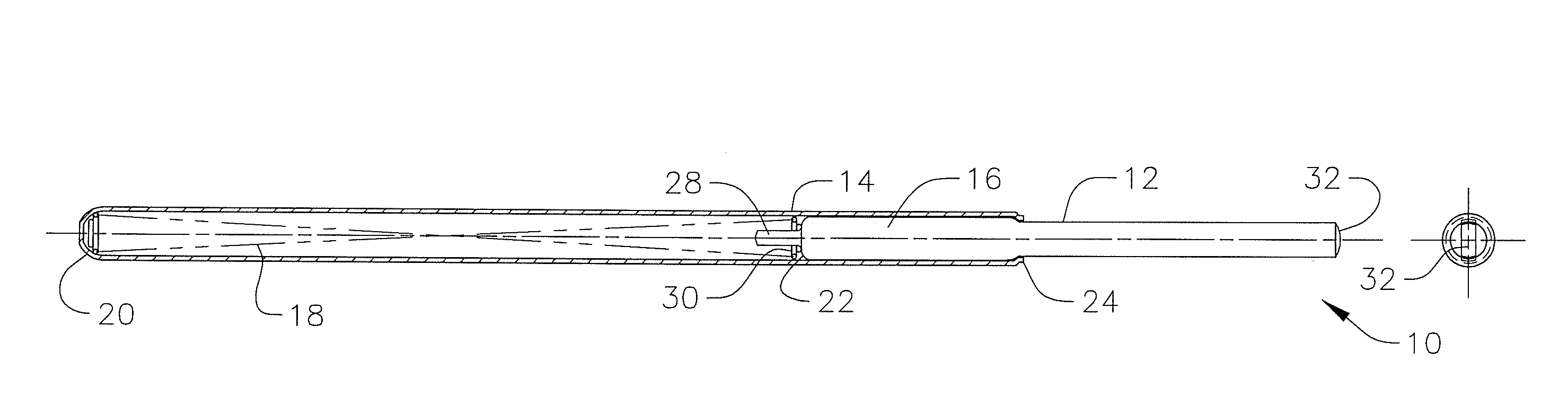

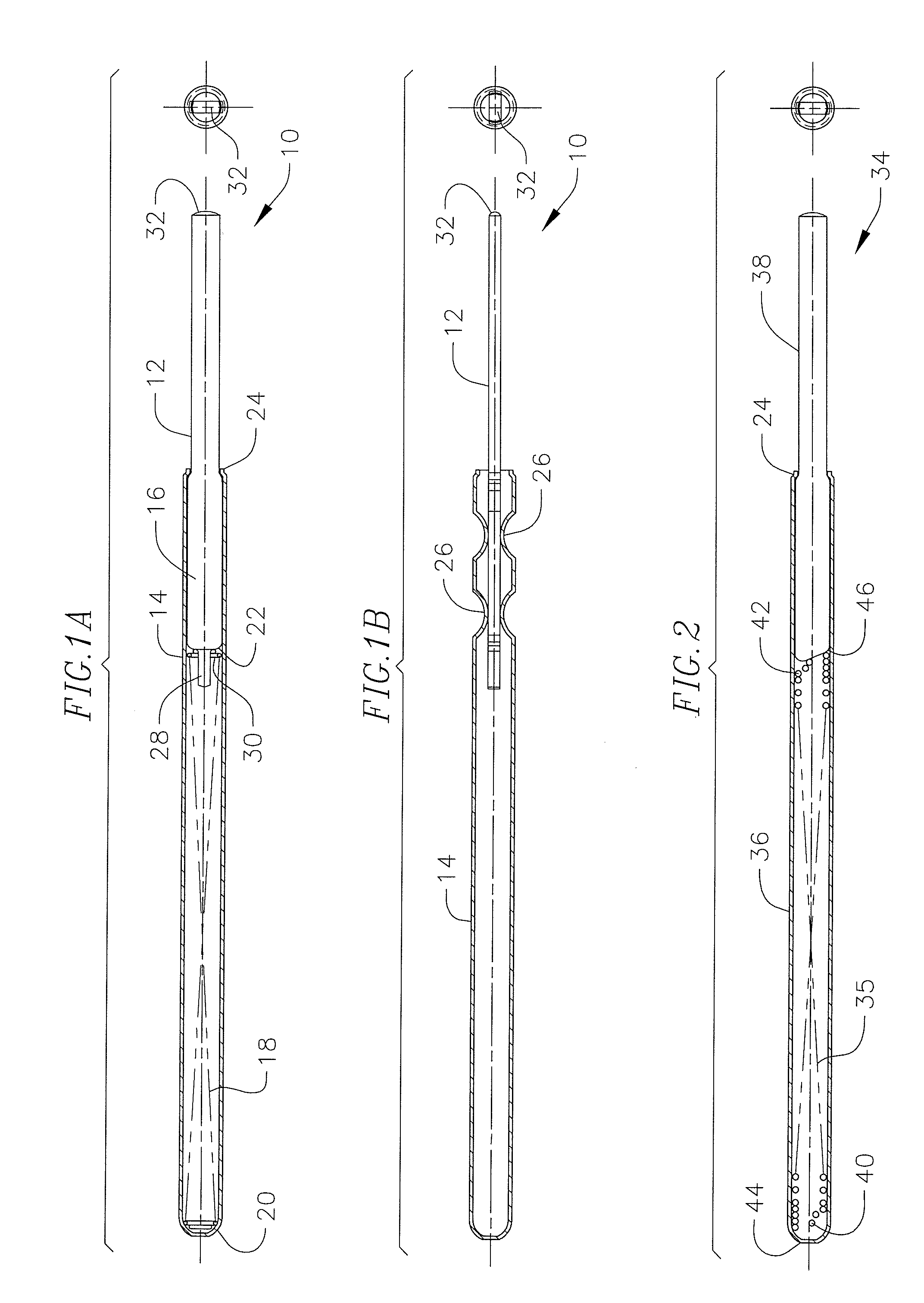

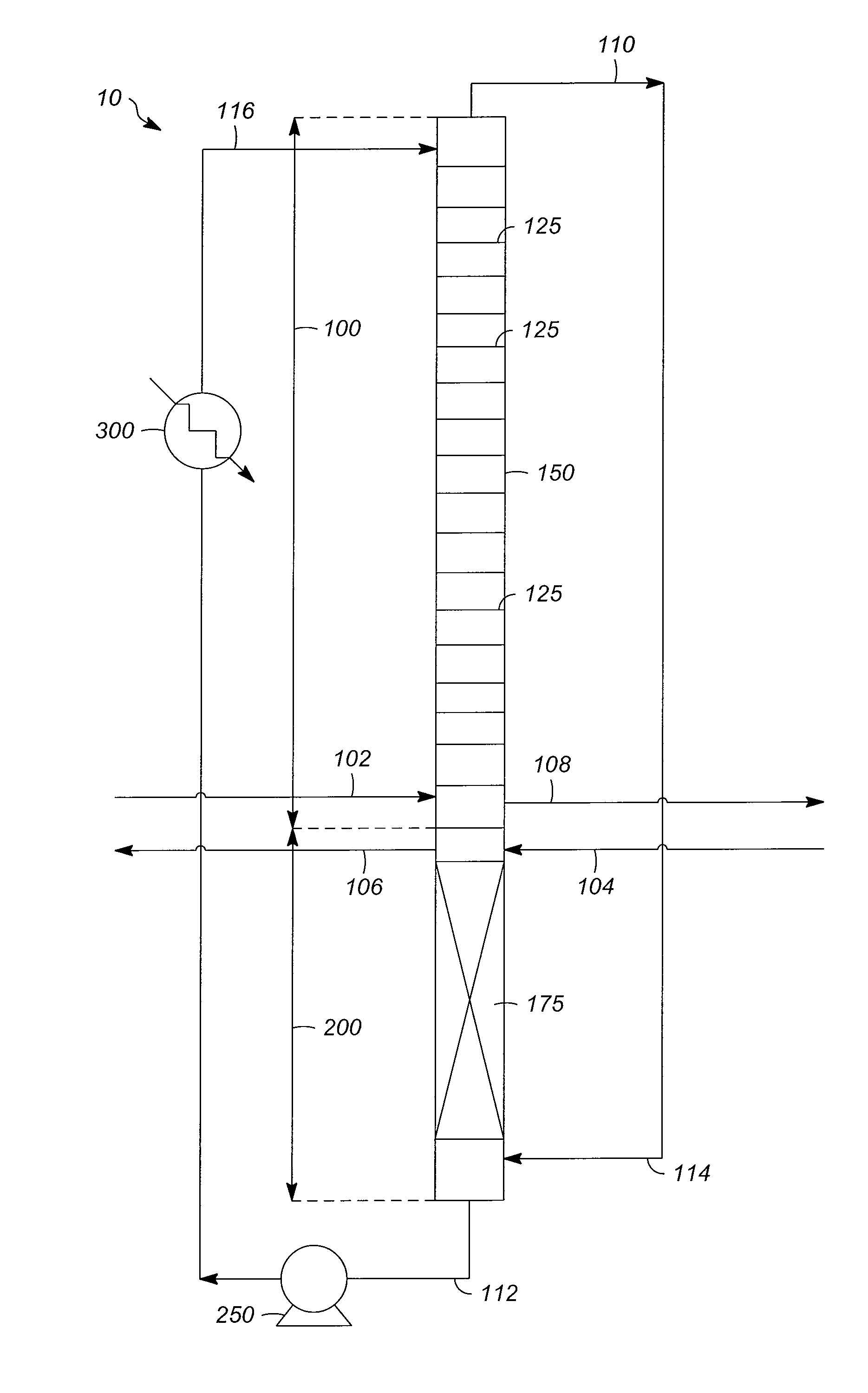

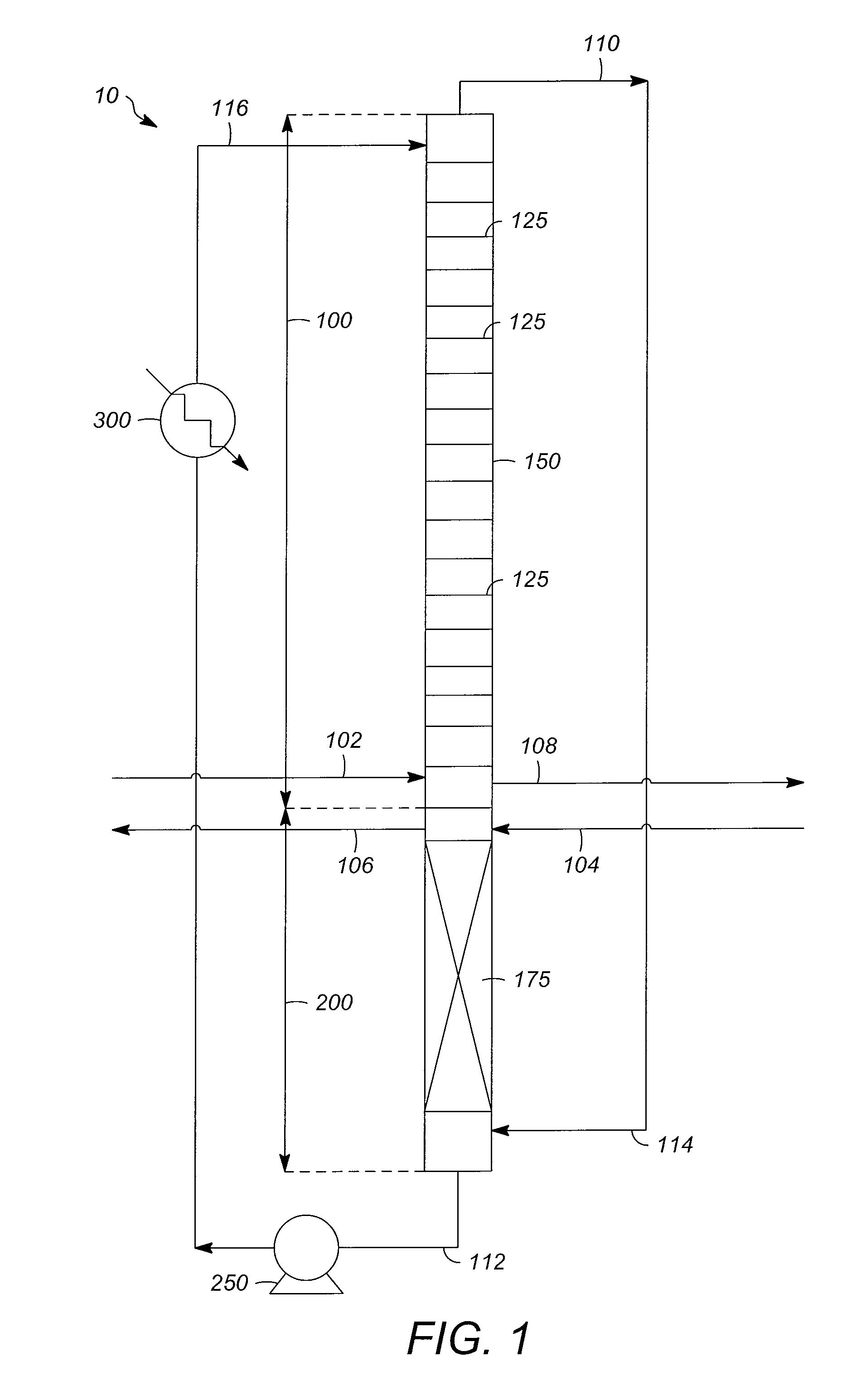

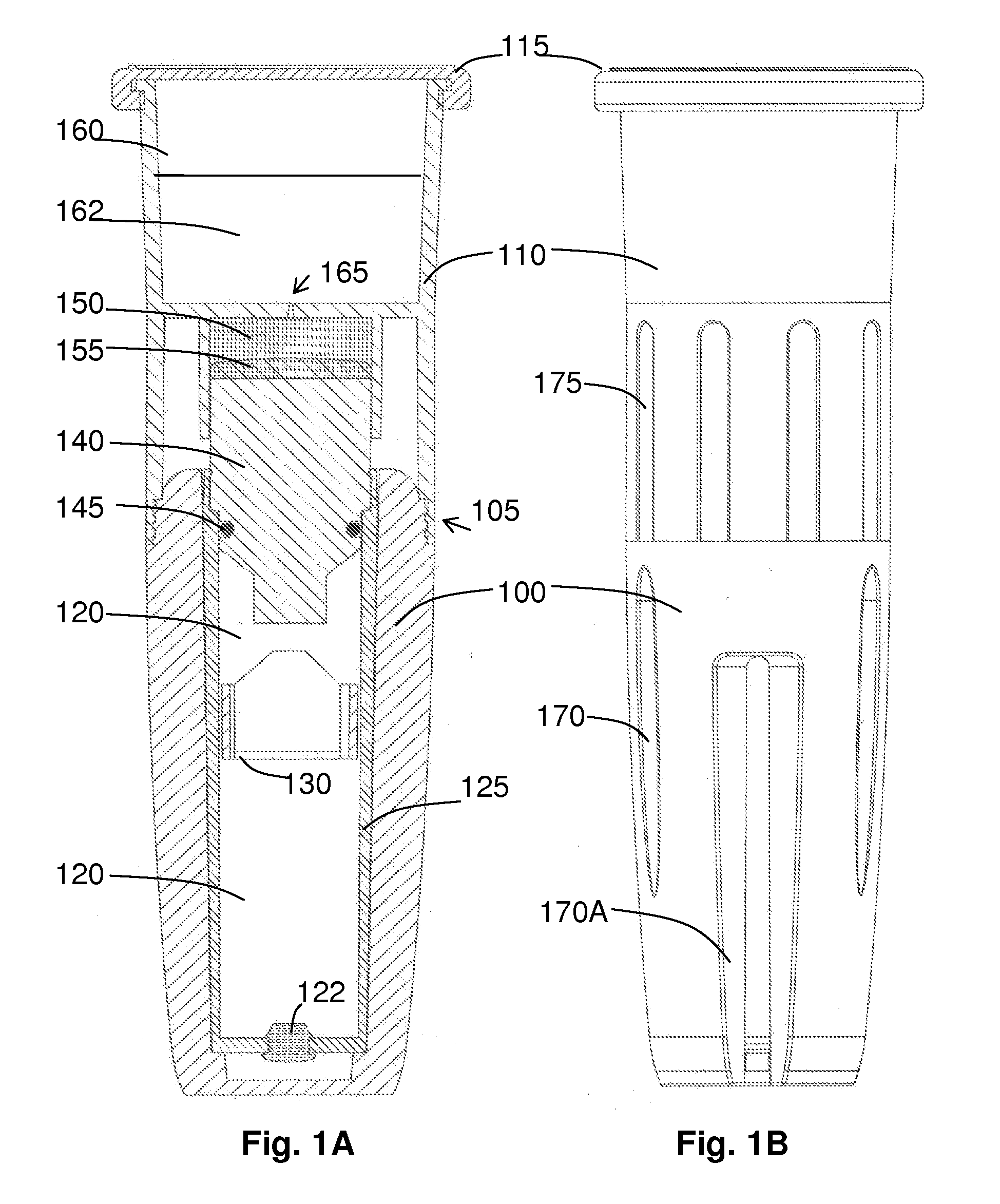

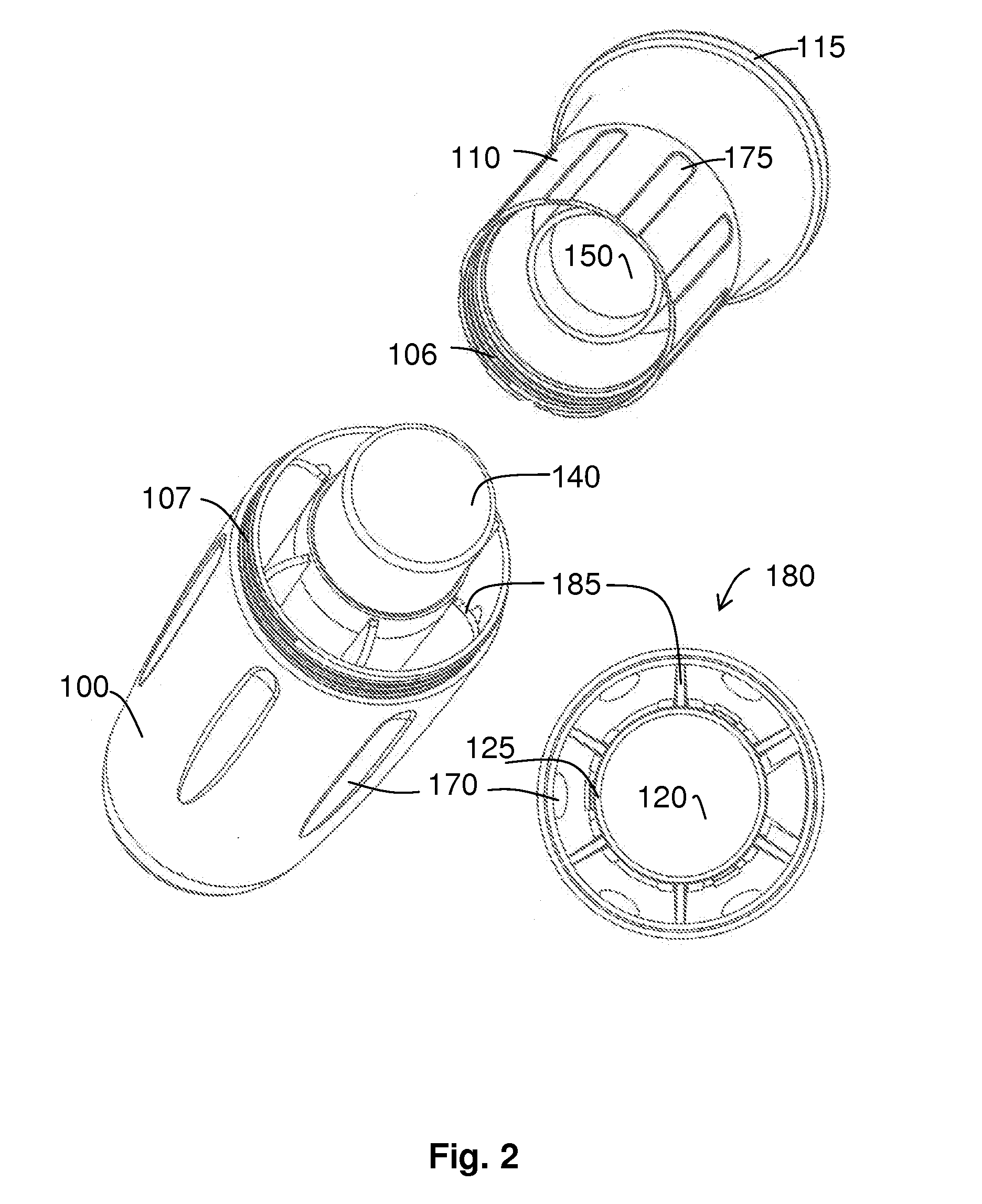

Methods and apparatus for coupling a HIFU transducer to a skin surface

ActiveUS20070238994A1Improve contactMinimizing attenuationUltrasonic/sonic/infrasonic diagnosticsUltrasound therapyHigh-intensity focused ultrasoundHigh intensity

Methods and apparatus are described for coupling a high intensity focused ultrasound transducer to a skin surface using water as a coupling agent.

Owner:SOLTA MEDICAL

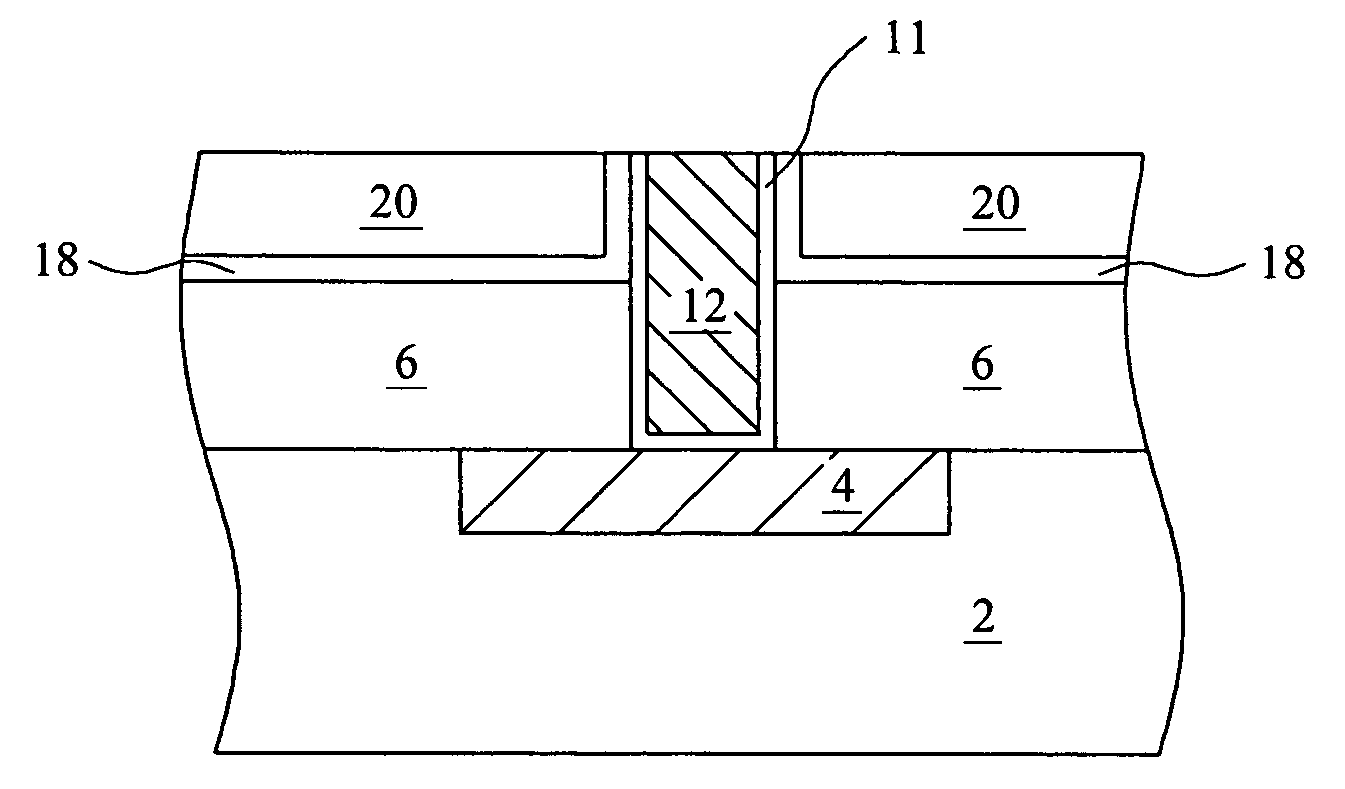

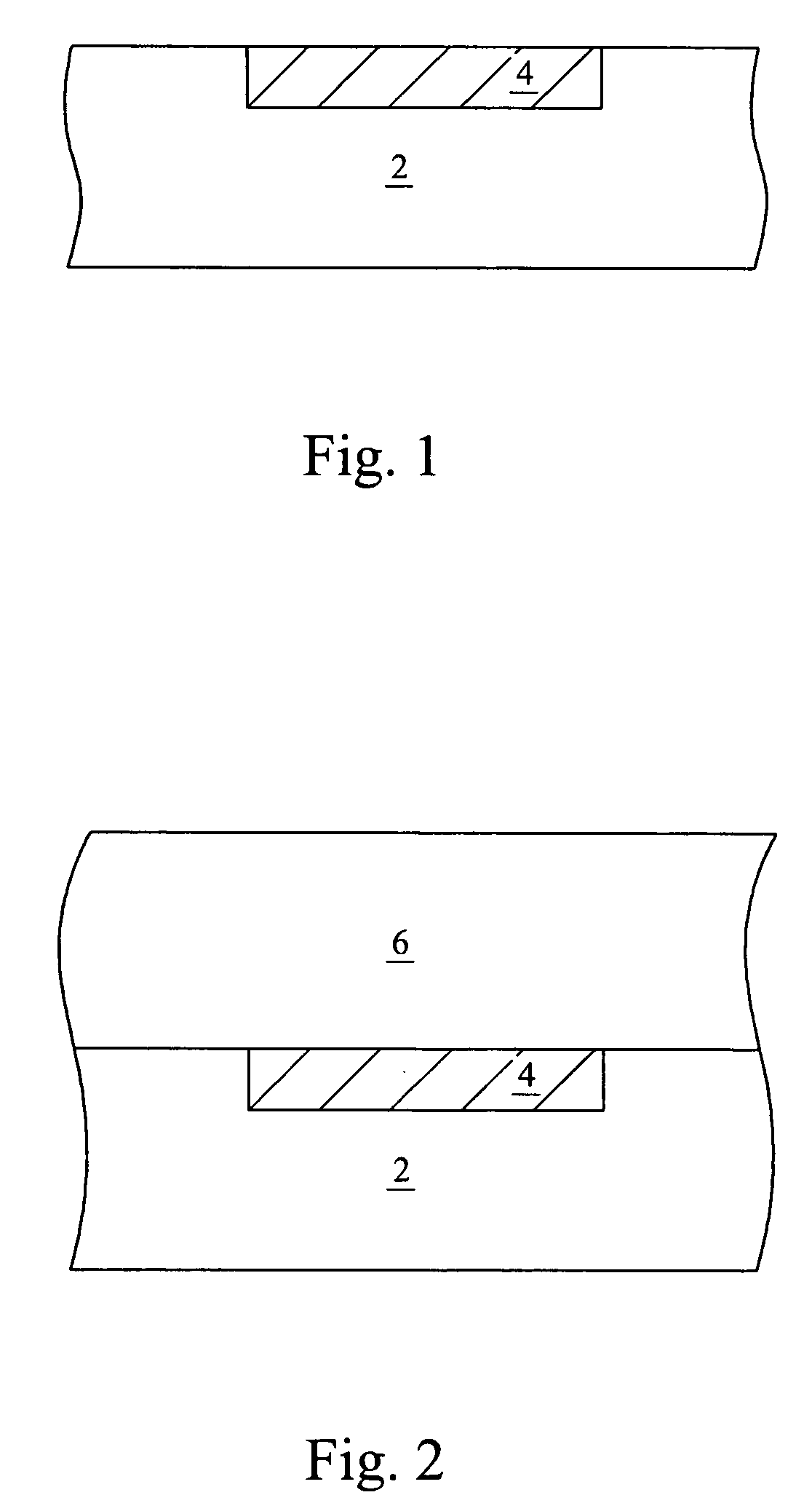

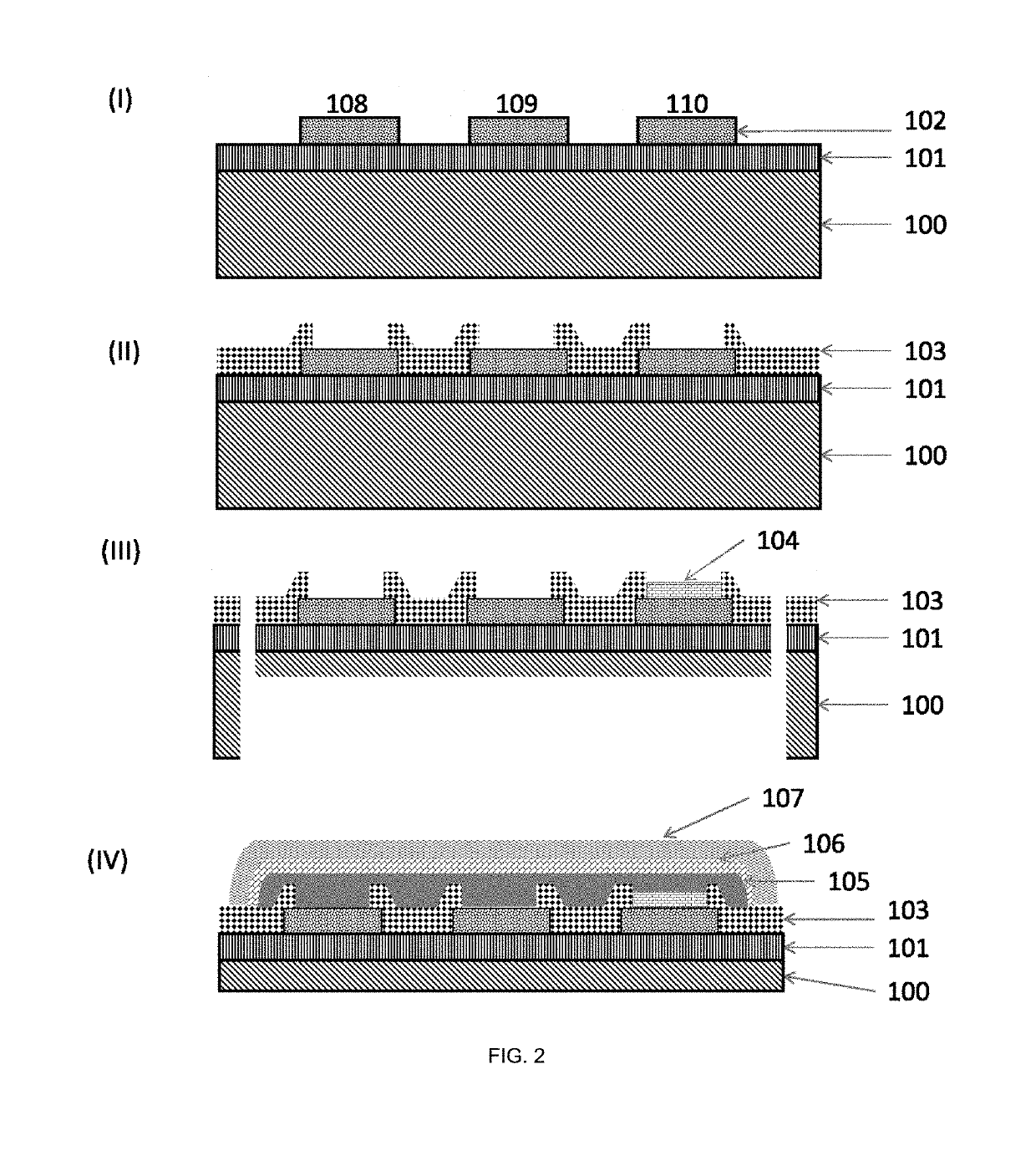

Stable metal structure with tungsten plug

ActiveUS20050224986A1Improve contactImprove adhesionSemiconductor/solid-state device detailsSolid-state devicesLow-k dielectricTungsten

In the preferred embodiment, a thick regular-k dielectric is formed on a substrate. A tungsten plug is formed in the thick regular-k dielectric. The thick regular-k dielectric is recessed and a thin low-k dielectric is formed on the thick regular-k dielectric. The thin low-k dielectric acts as a glue layer and as an etch stop layer. A thick low-k dielectric is formed on the thin low-k material. Optionally, an opening is formed through the thick low-k dielectric to expose the tungsten plug. The opening is then filled with copper or copper alloys.

Owner:TAIWAN SEMICON MFG CO LTD

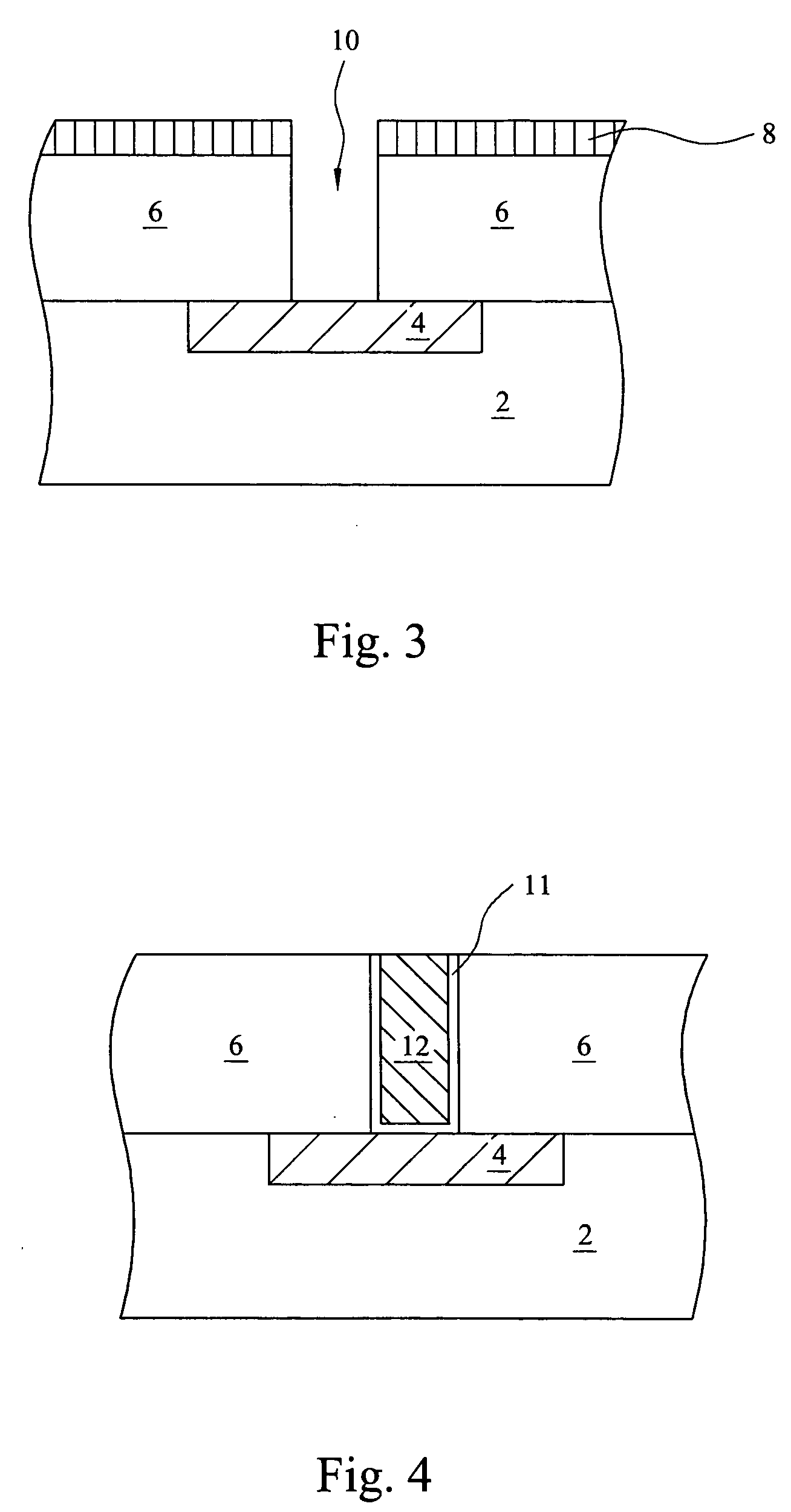

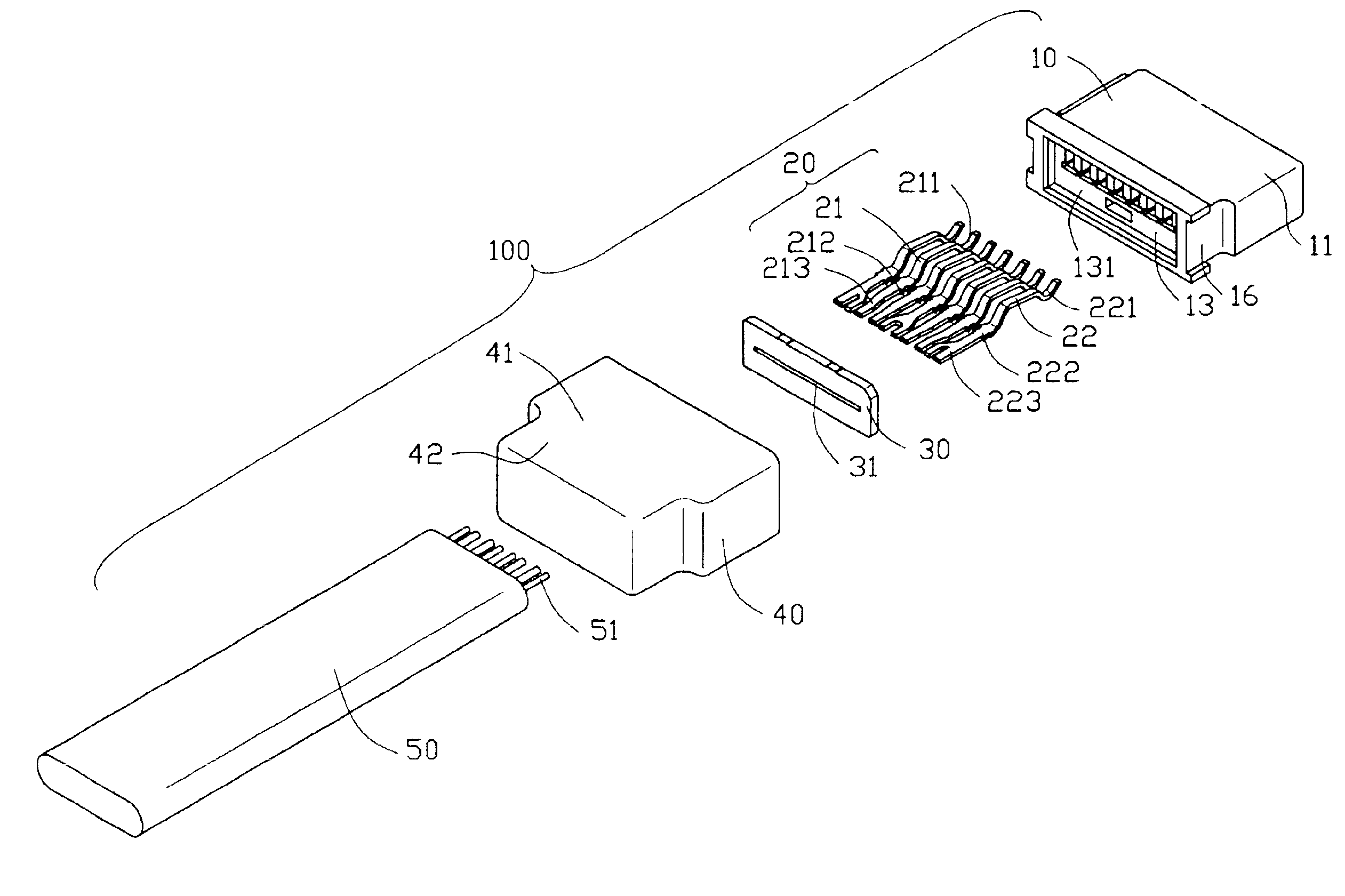

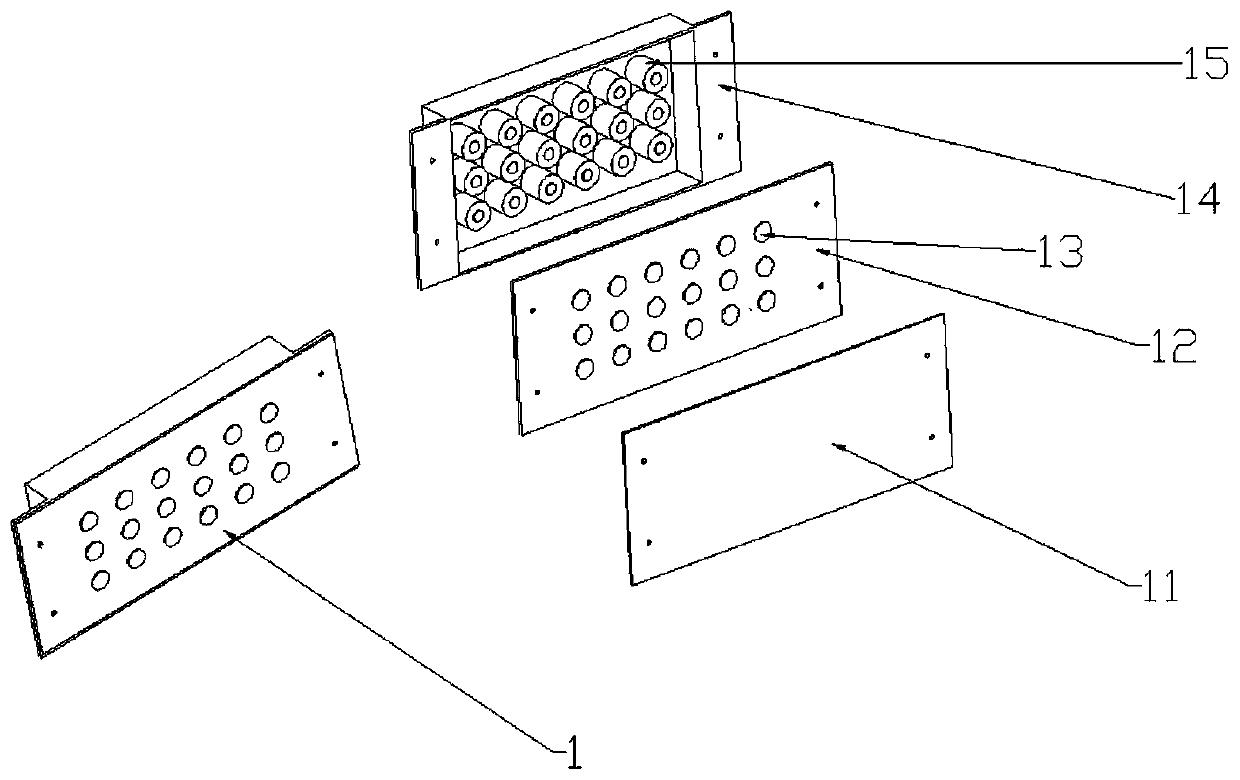

Power connector with improved contacts

InactiveUS20090215315A1Improve contactGood ESD performanceCoupling protective earth/shielding arrangementsSolderingEngineering

An electrical connector includes an insulative housing, a plurality of terminals in the housing and a shield assembled on the housing. The terminals include a conductive grounding contact with separated first grounding contact and second grounding contact. The first grounding contact and second grounding contact respectively includes at least one soldering tail electrically connected to the shield for being electrically connected to each other.

Owner:HON HAI PRECISION IND CO LTD

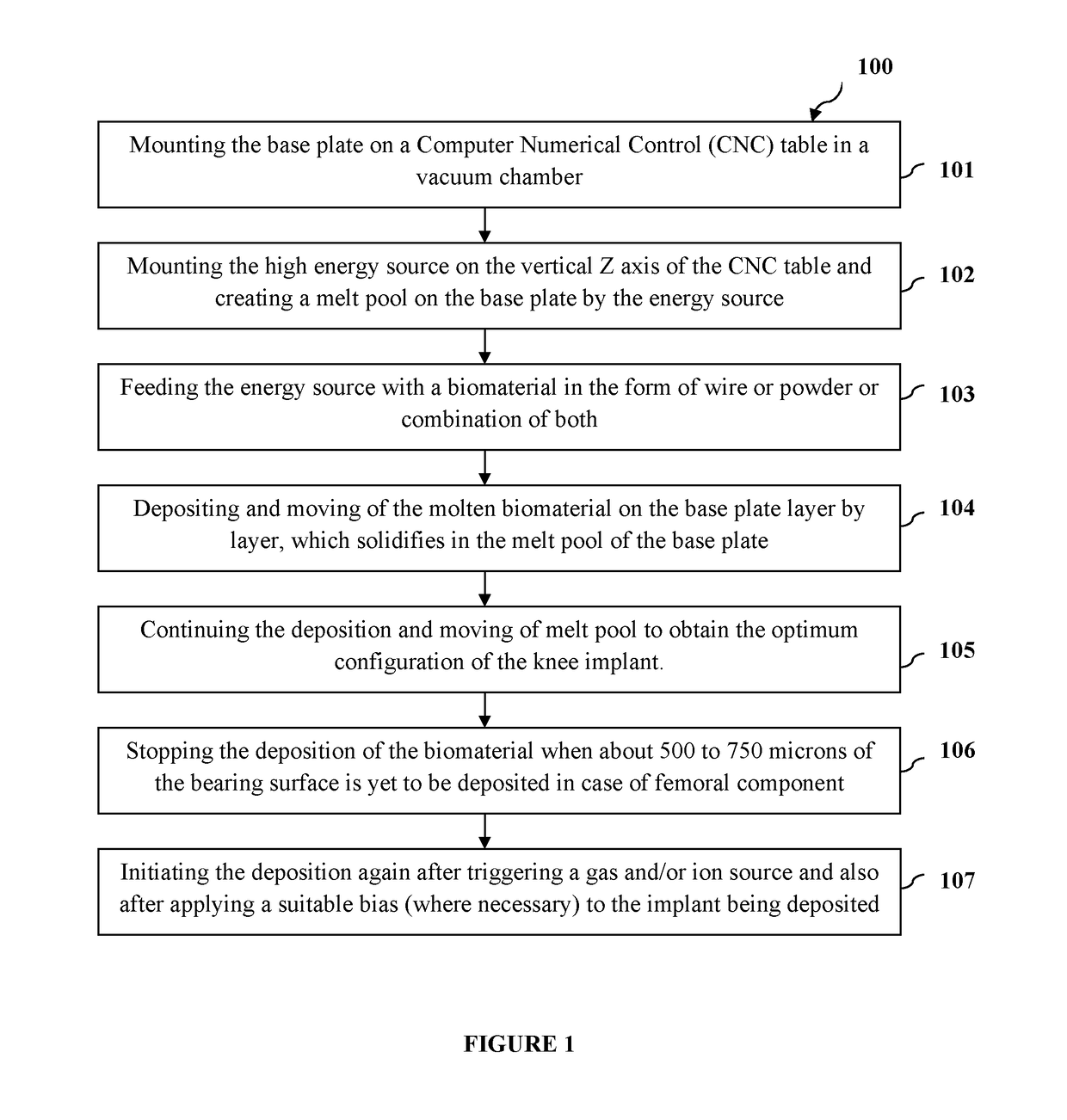

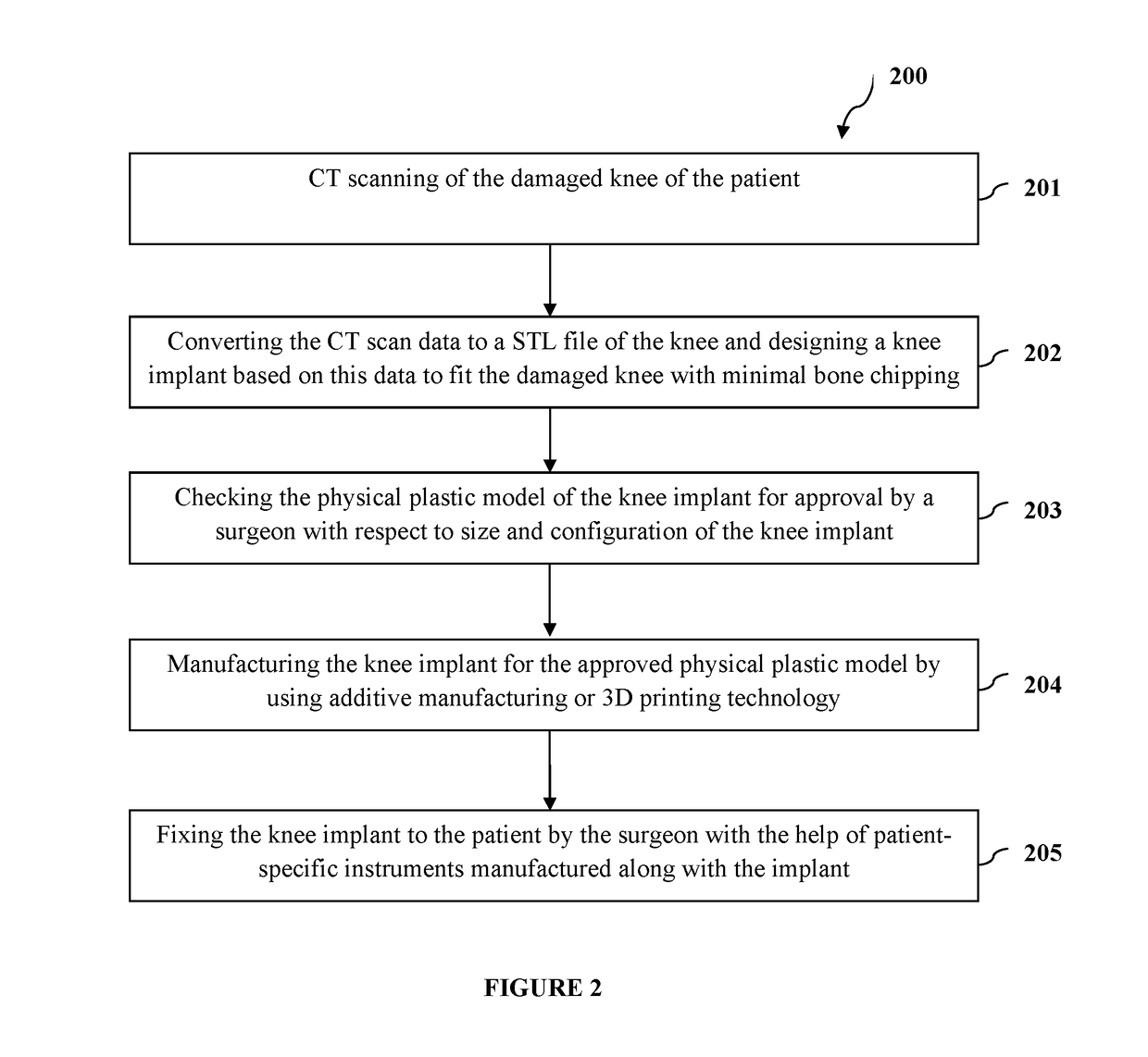

Composition of orthopedic knee implant and the method for manufacture thereof

InactiveUS20170071744A1Reduce coefficient of frictionImprove contactPharmaceutical delivery mechanismJoint implantsPatient specificBiomedical engineering

The present invention discloses a composition of a knee implant comprising biomaterials such as combination of Ti—Nb—Zr alloy and tantalum to support osseointegration. The present invention further discloses a method of manufacturing customized patient-specific knee implant using 3D printing technology to suit the patient. The method involves the use of high energy source such as fiber laser or electron-beam. The base plate is mounted on the CNC. The energy source creates a melt pool on the base plate and the energy source is fed with a biomaterial in the form of wire or powder. The biomaterial is deposited on the base plate layer by layer, which solidifies in the melt pool of the base plate. The knee implant thus fabricated suits the elastic modulus of the bone and is useful as customized implant in patient undergoing replacement surgery.

Owner:BALI SULZHAN +1

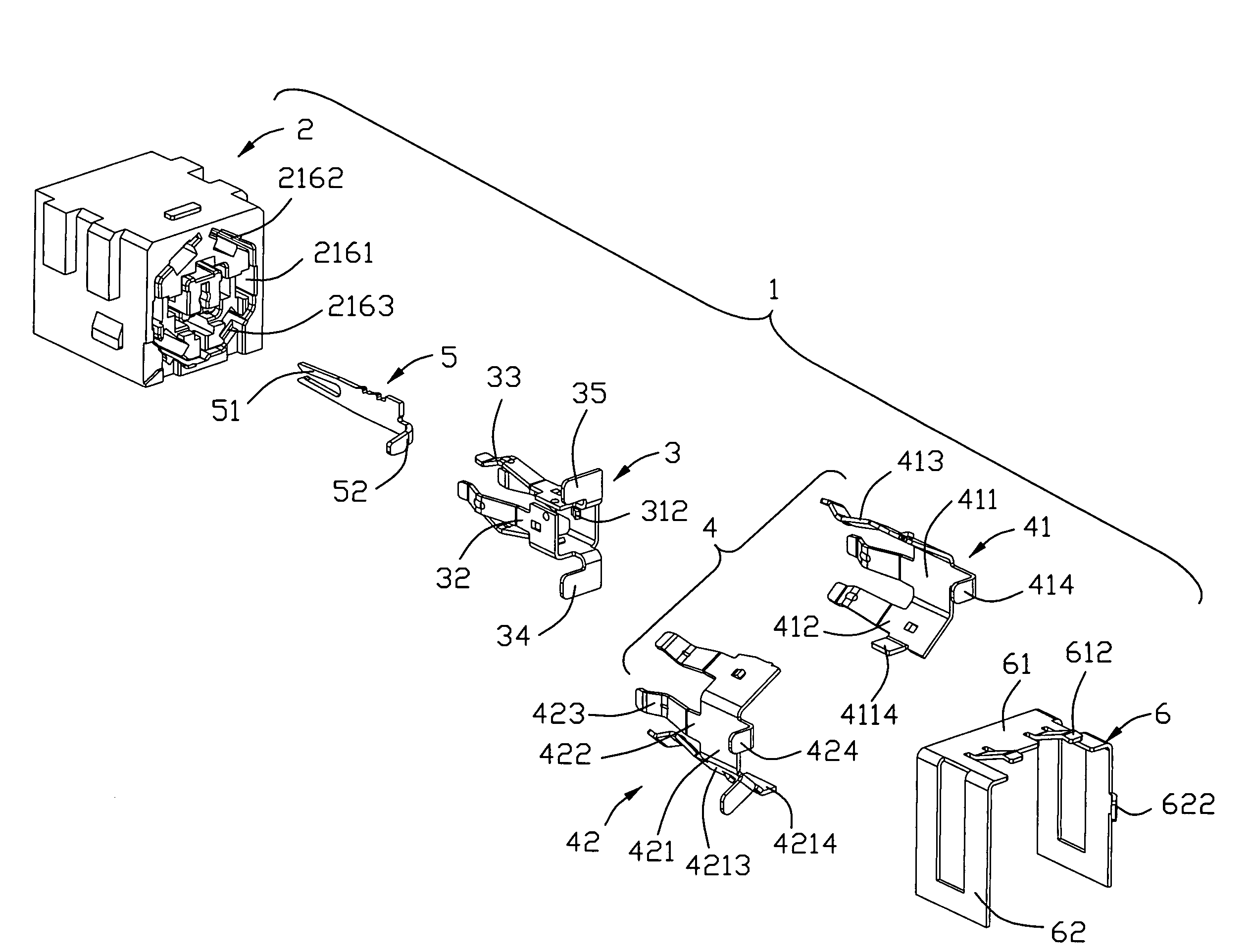

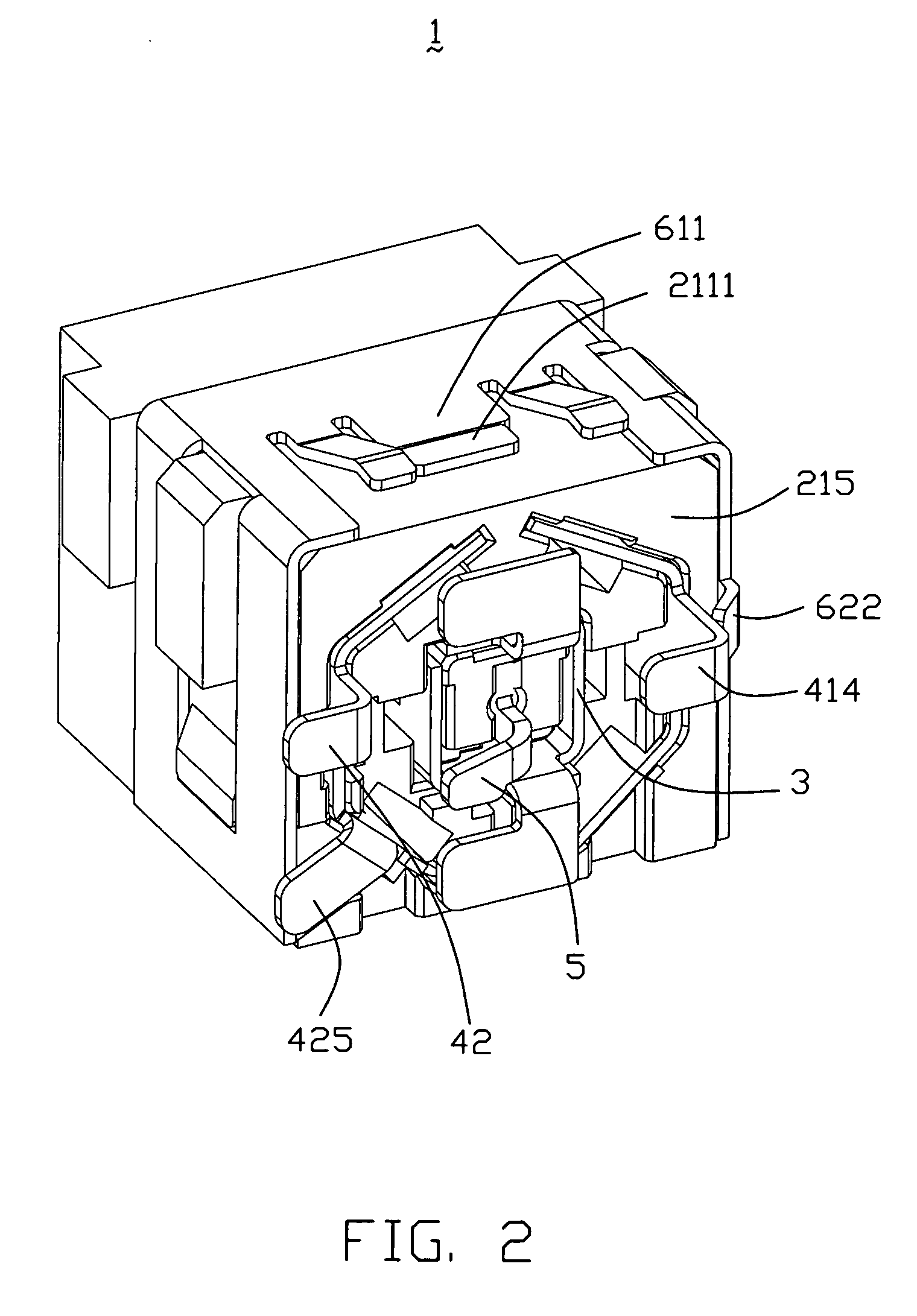

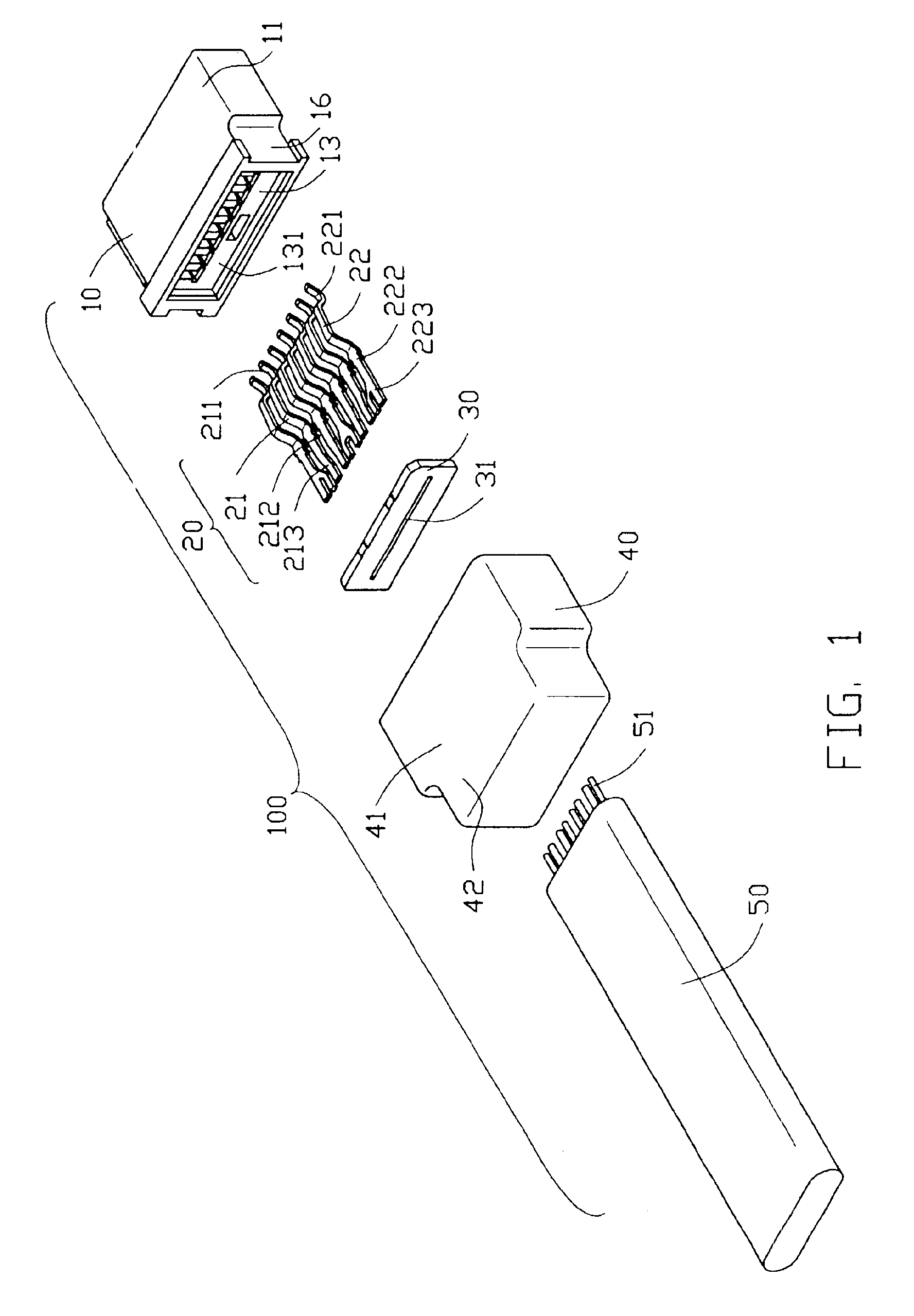

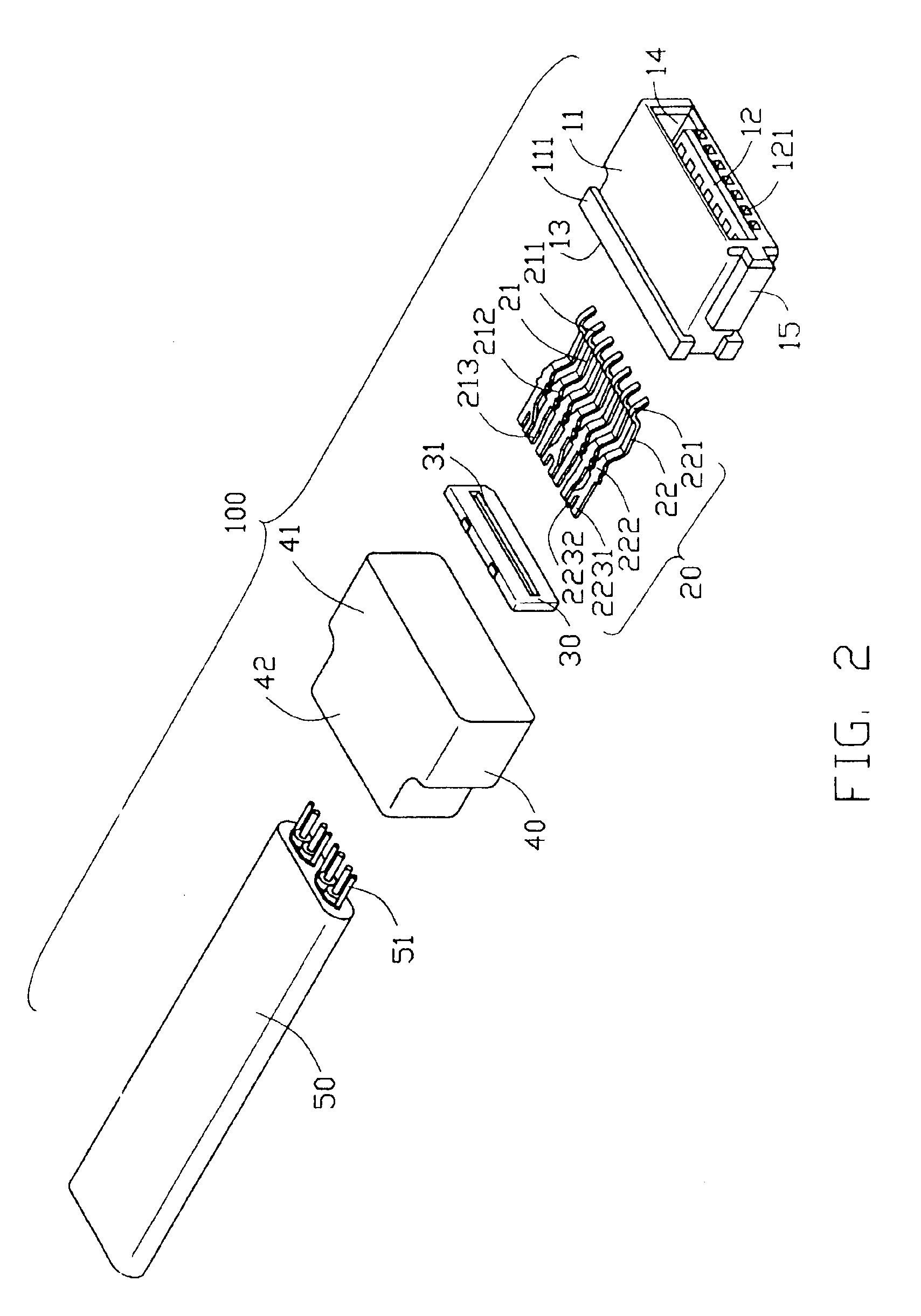

Cable end connecotr assembly with improved contact

InactiveUS6875048B2Improve contactSmooth connectionRelieving strain on wire connectionCoupling protective earth/shielding arrangementsGround contactEngineering

A cable end connector assembly including an insulative housing (10), a plurality of signal and grounding contacts (21), (22), a spacer device (30), a cable (40), and an over-molding cover (50). The insulative housing has a base, the base having a mating section defining a receiving space therein adapted for receiving a mating portion of the complementary connector. The signal and grounding contacts are mounted in the housing, each contact has an engaging portion, a rear connecting portion, and a tail portion extends rearwardly from the connecting portion, at least one tail portion of the grounding contact has a fork-shape. The cable has a number of conductors each electrically connecting a corresponding contact. The cover is over-molded with and encloses a rear end of the housing and the front end of the cable.

Owner:HON HAI PRECISION IND CO LTD

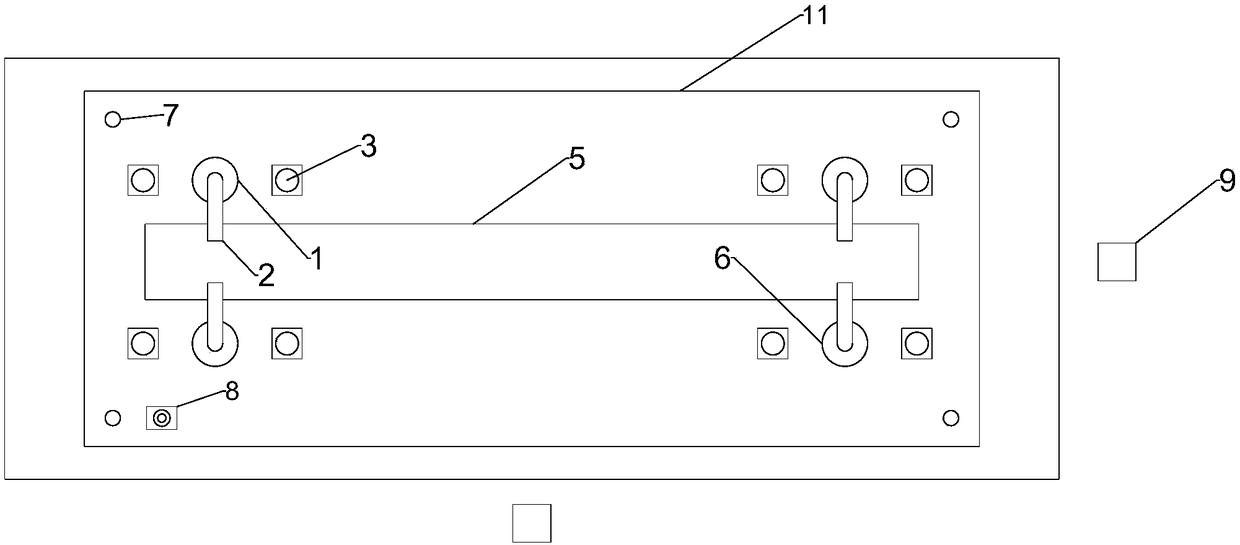

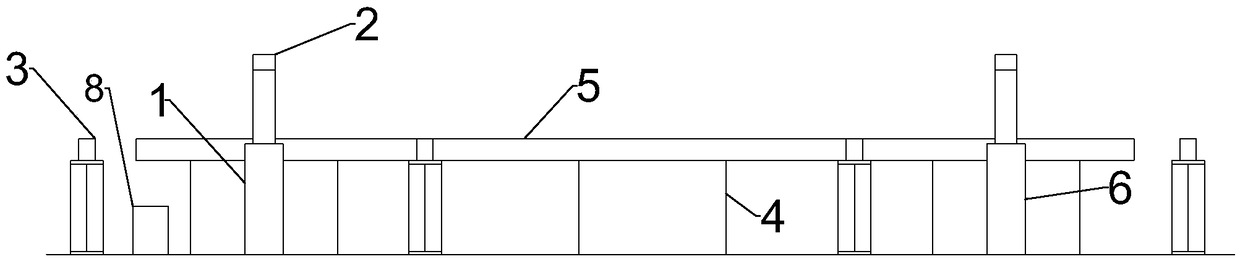

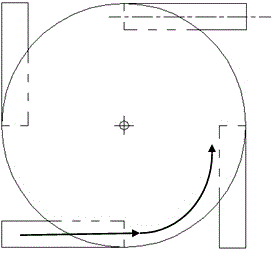

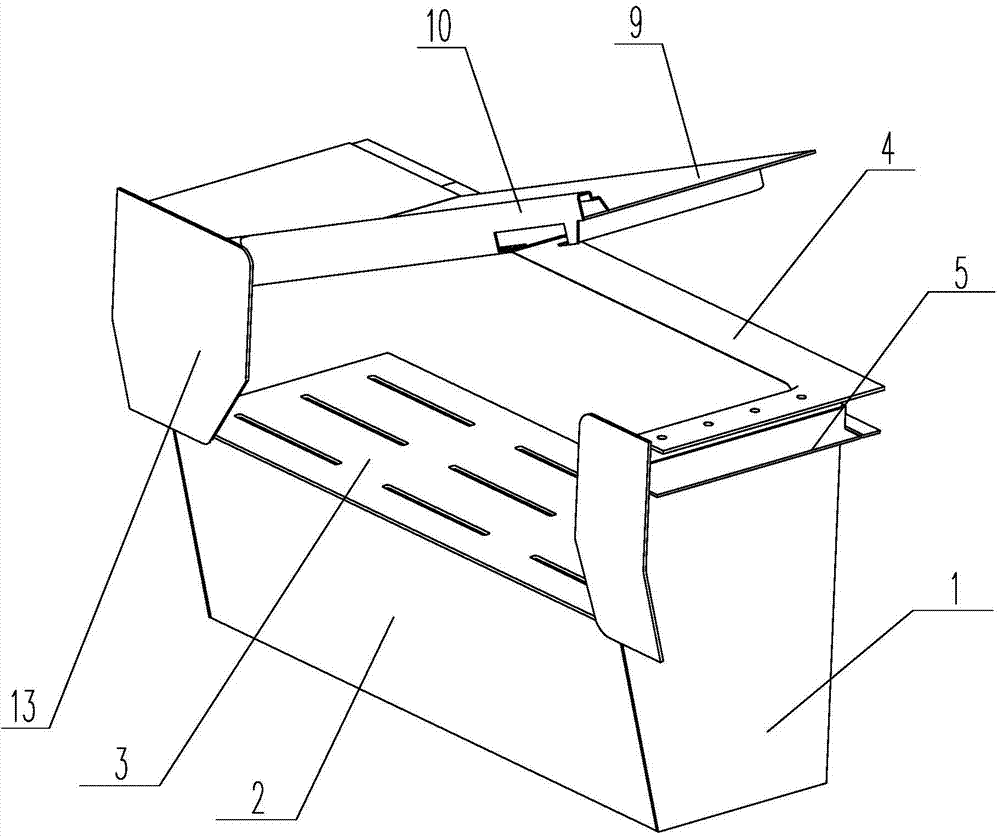

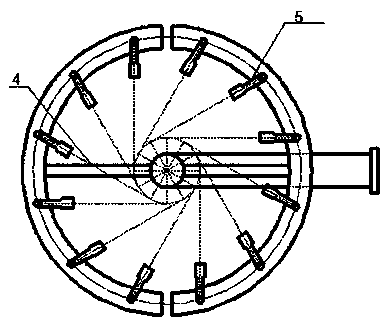

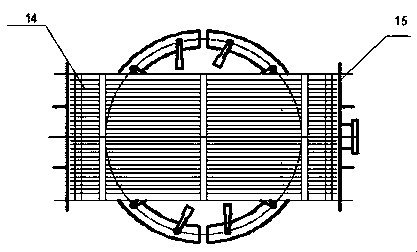

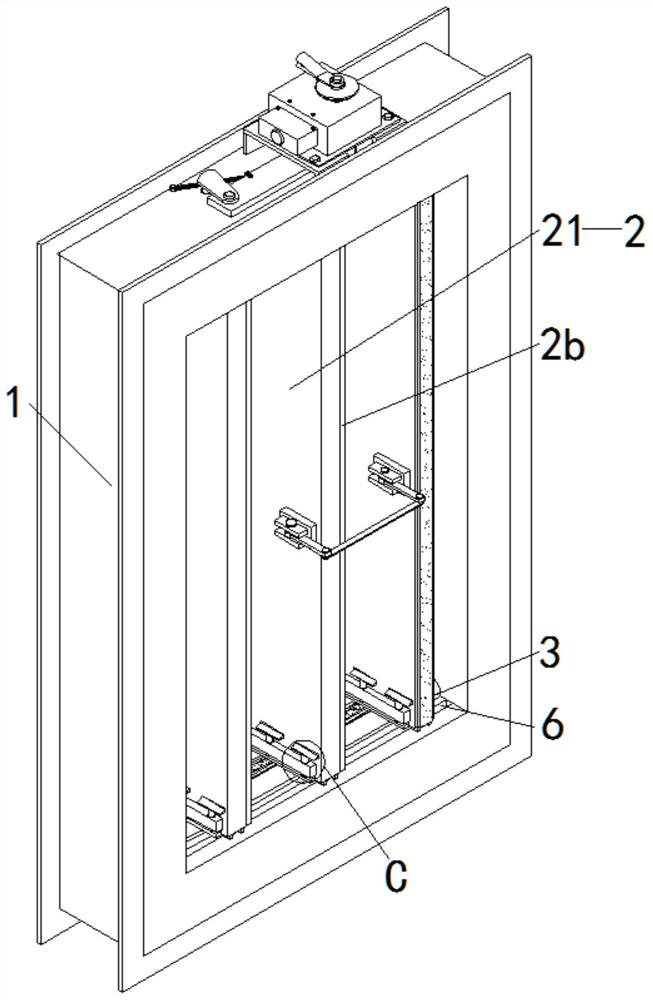

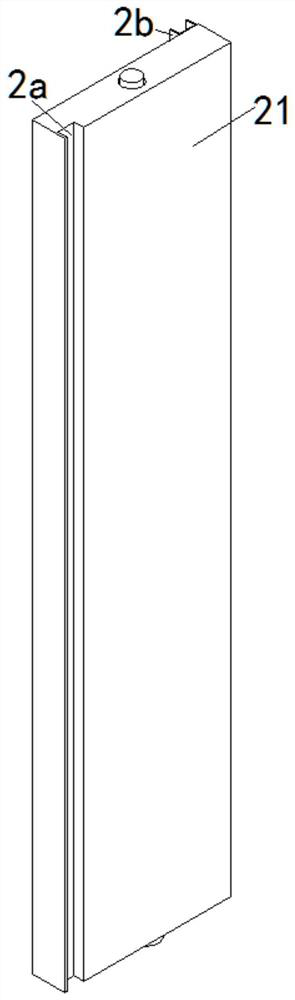

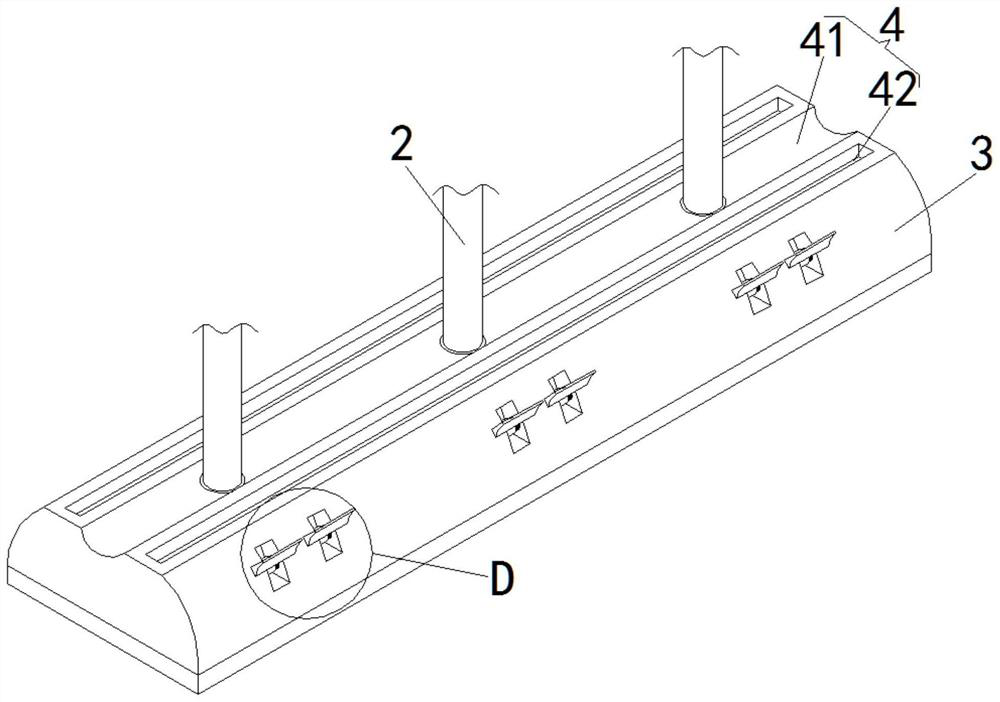

Aviation structural part automatic avoiding clamp device

InactiveCN108857506AImprove contactEliminate machining errorsWork clamping meansMeasurement/indication equipmentsAirplaneMachine tool

The invention discloses an aviation structural part automatic avoiding clamp device. The device comprises a bottom plate, a clamping unit, a detection unit, a supporting unit and a tool setting element. The clamping unit comprises four rotary clamping air cylinders, every two rotary clamping air cylinders form a group, and the rotary clamping air cylinders are divided into a first rotary clampingair cylinder group and a second rotary clamping air cylinder group. The supporting unit comprises at least three supporting plates which are arranged on the bottom plate, and a straight line is evenlydistributed under a clamped part. By means of multi-point clamping, the contact mode of a clamp and the part is improved, and machining errors caused by most of the clamping factors are effectively eliminated. A sensor is used for accurate positioning and pneumatic element control, so that a machining tool is automatically avoided, and machining efficiency and the machining errors caused by repeated clamping are greatly improved. According to the device, machining requirements of the whole structural part of an aircraft can be efficiently met at high quality, and the operation is convenient and fast.

Owner:四川铭利达科技有限公司

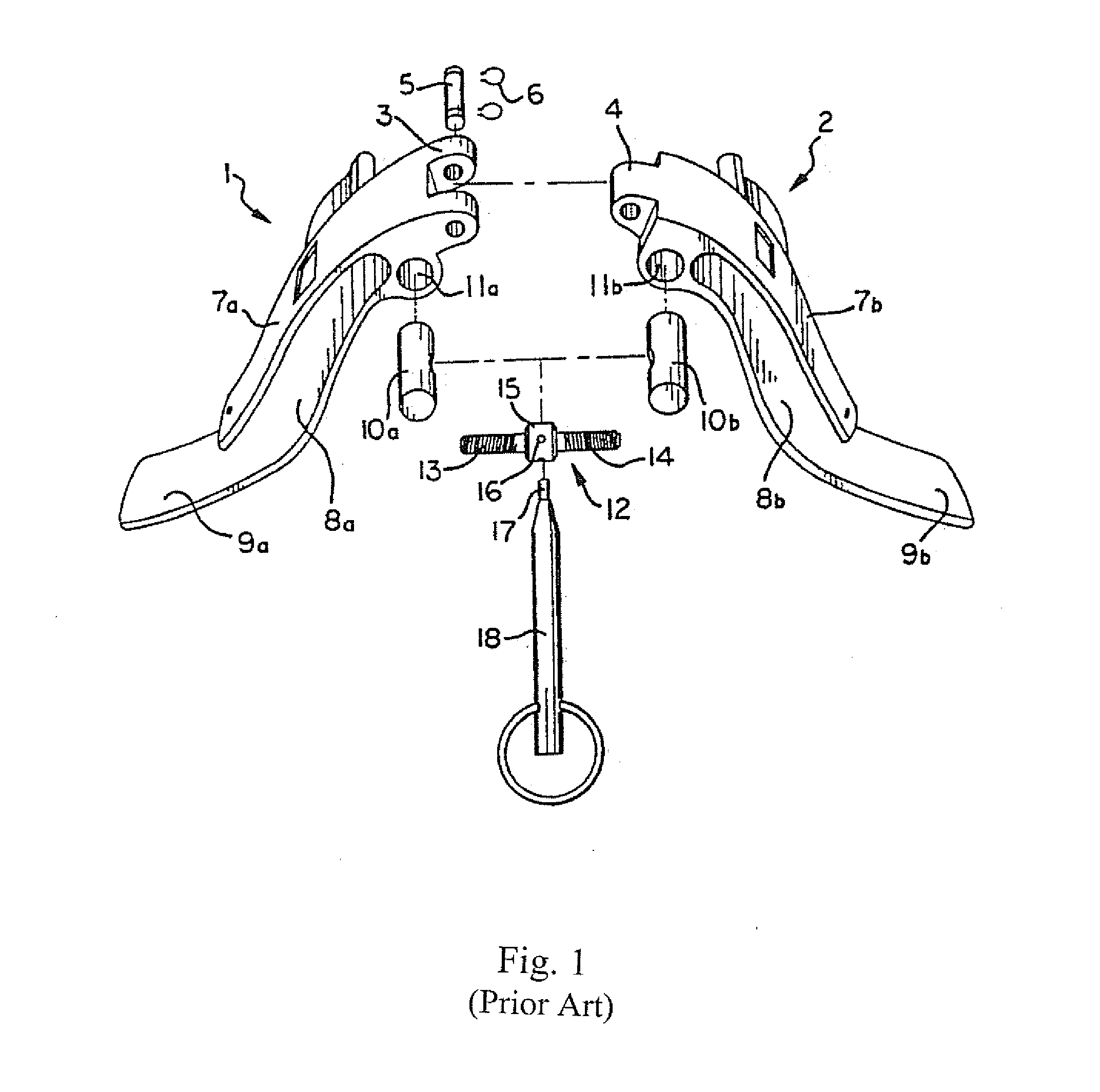

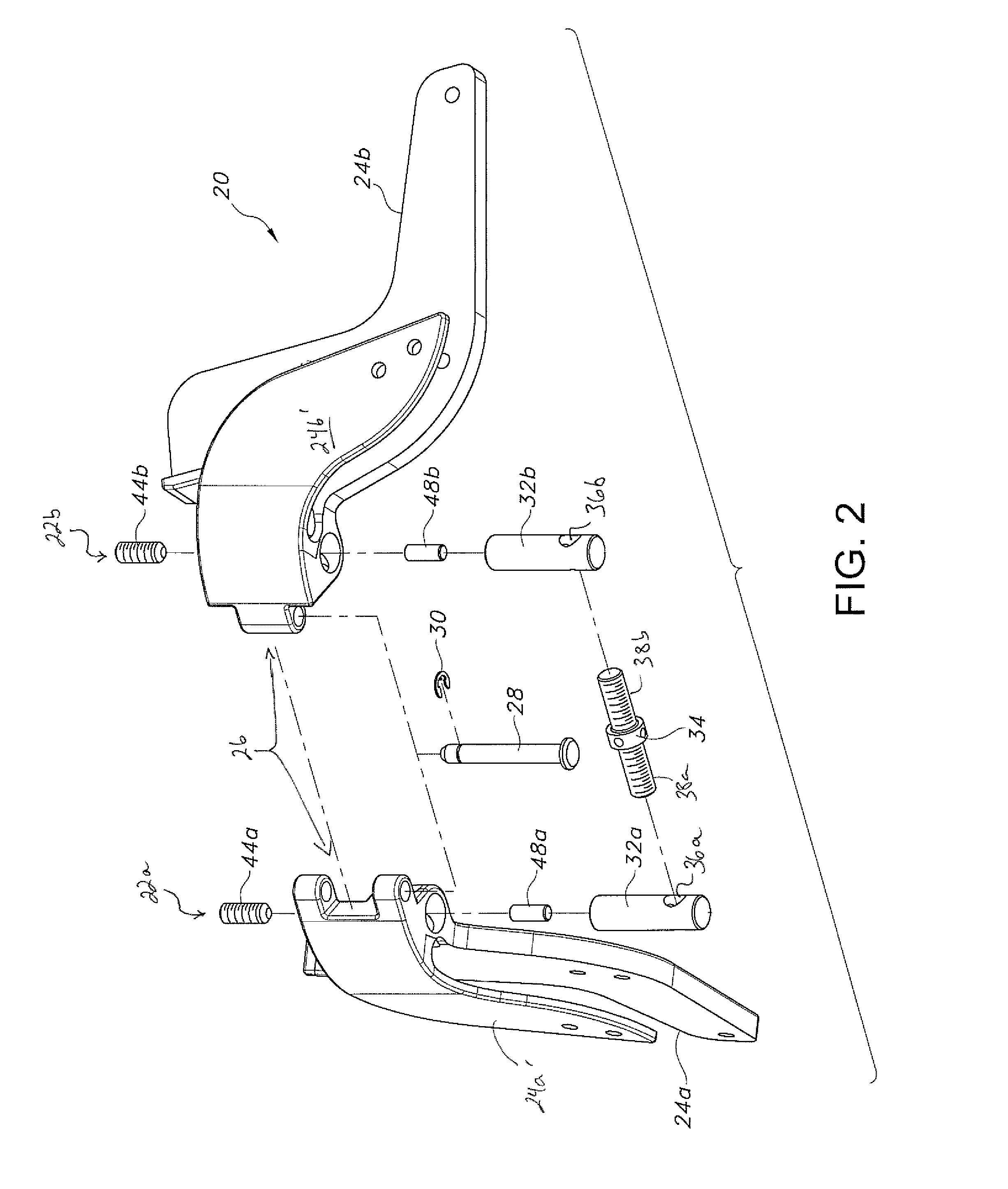

Locking headplate for adjustable saddle tree

ActiveUS20100229507A1Improve contactImprove efficacyFastening devicesSaddlesThreaded fastenerScrew thread

A locking headplate for an adjustable saddle tree includes opposed, hingedly connected elements for securing to a saddle tree head portion, a rotatable displacing element for displacing the hingedly connected plates inwardly or outwardly, and an engaging element for selectively preventing rotation of the rotatable displacing element. The engaging element includes at least one insert and a threaded fastener for compressing the insert against the rotatable displacing element to selectively prevent rotation thereof. A portion of the rotatable displacing element may be made of a material having a first hardness, and the insert may be made of a material having a second hardness which is less than the first hardness whereby a portion of the rotatable displacing element impinges into the material of the insert. Saddle trees and saddles incorporating the locking headplate are provided.

Owner:INT RIDING HELMETS

Cement-containing compositions and method of use

InactiveUS20090229492A1Improve contactImproved support characteristicSolid waste managementCeramicwareWater solublePortland cement

The invention provides a system comprising two components to be mixed together to form a settable cementitious composition wherein a first component comprises: (a) Portland cement; (b) calcium sulphate; and (c) water in a weight ratio of water to Portland cement and calcium sulphate solids of from 0.5:1 to 5:1; and a second component comprises: (d) a water soluble silicate; and (e) water, in a weight ratio of water to silicate solids of from 1.5:1 to 25:1; which cementitious composition has a higher early strength than known compositions.

Owner:MINOVA INT

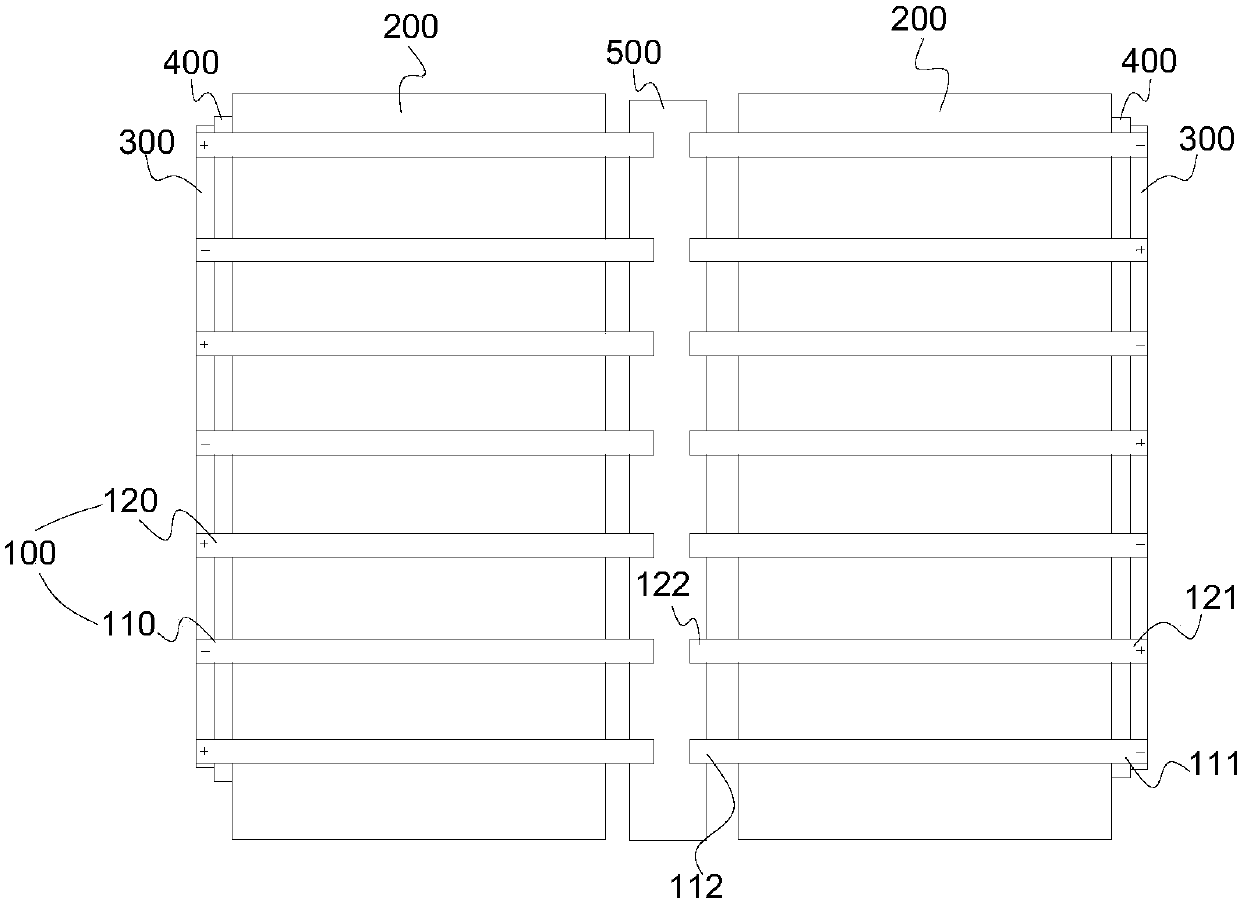

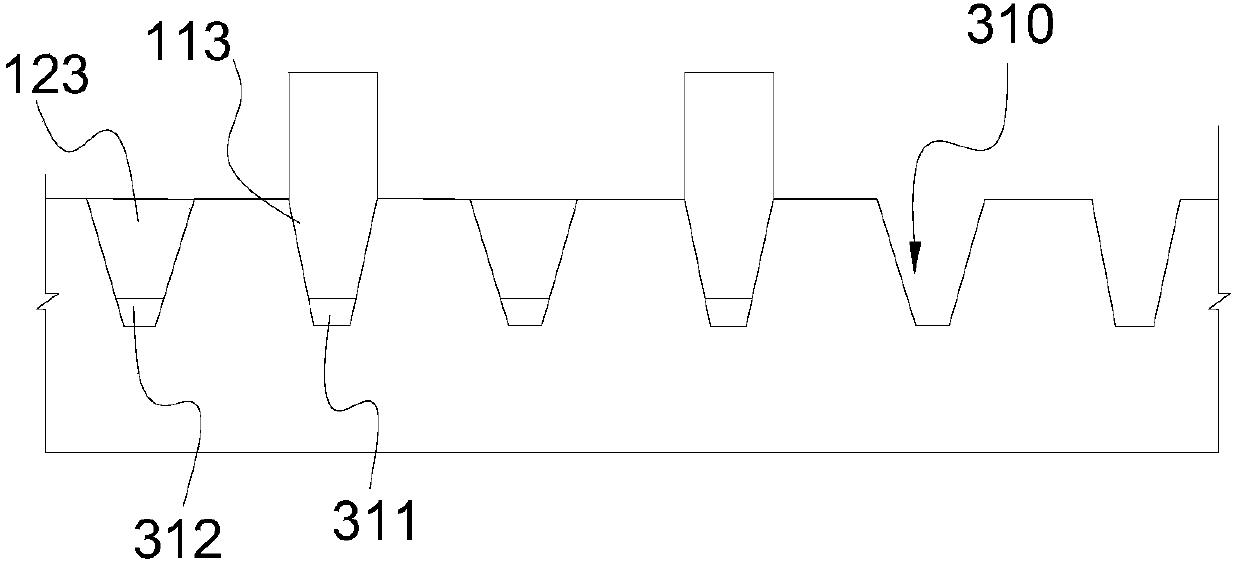

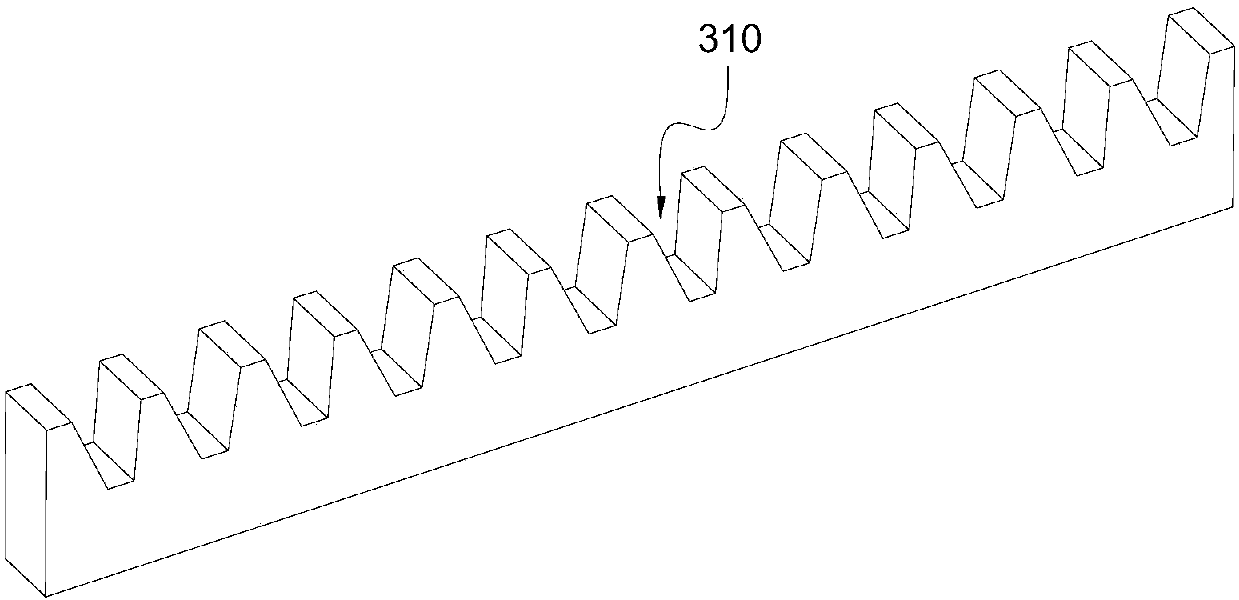

Method for improving contact resistance reduction caused by conductive contact means during zinc electrolysis

InactiveCN107916440AImproving the conductive contact mode of zinc electrolysisImprove contactPhotography auxillary processesProcess efficiency improvementElectrical resistance and conductanceElectrolysis

The invention belongs to the technical field of improvements on electrolysis equipment, and provides a method for improving a contact resistance reduction caused by a conductive contact means during zinc electrolysis. According to the method, the conventional single-sided contact is changed into the inter-groove copper-bar grooved contact, and the wedged double-sided contact is adopted for both electrode plates; and the grooved conductive copper bar and wedged conductive head design is converted from the original horizontal contact into the bevel contact. By adoption of the method, the technical problem that a lap conductive head is high in contact resistance, high in temperature, easy to oxidize and easy to deform during a conventional process of zinc electrodeposition based on wet zinc smelting can be solved; meanwhile, the total voltage of electrodeposition and the waste of electric energy can be reduced; and furthermore, the contact resistance can be greatly reduced, the easy cleaning operation and the low dirt adhesion possibility can be achieved, and the electric energy consumption can be greatly reduced.

Owner:四川四环锌锗科技有限公司

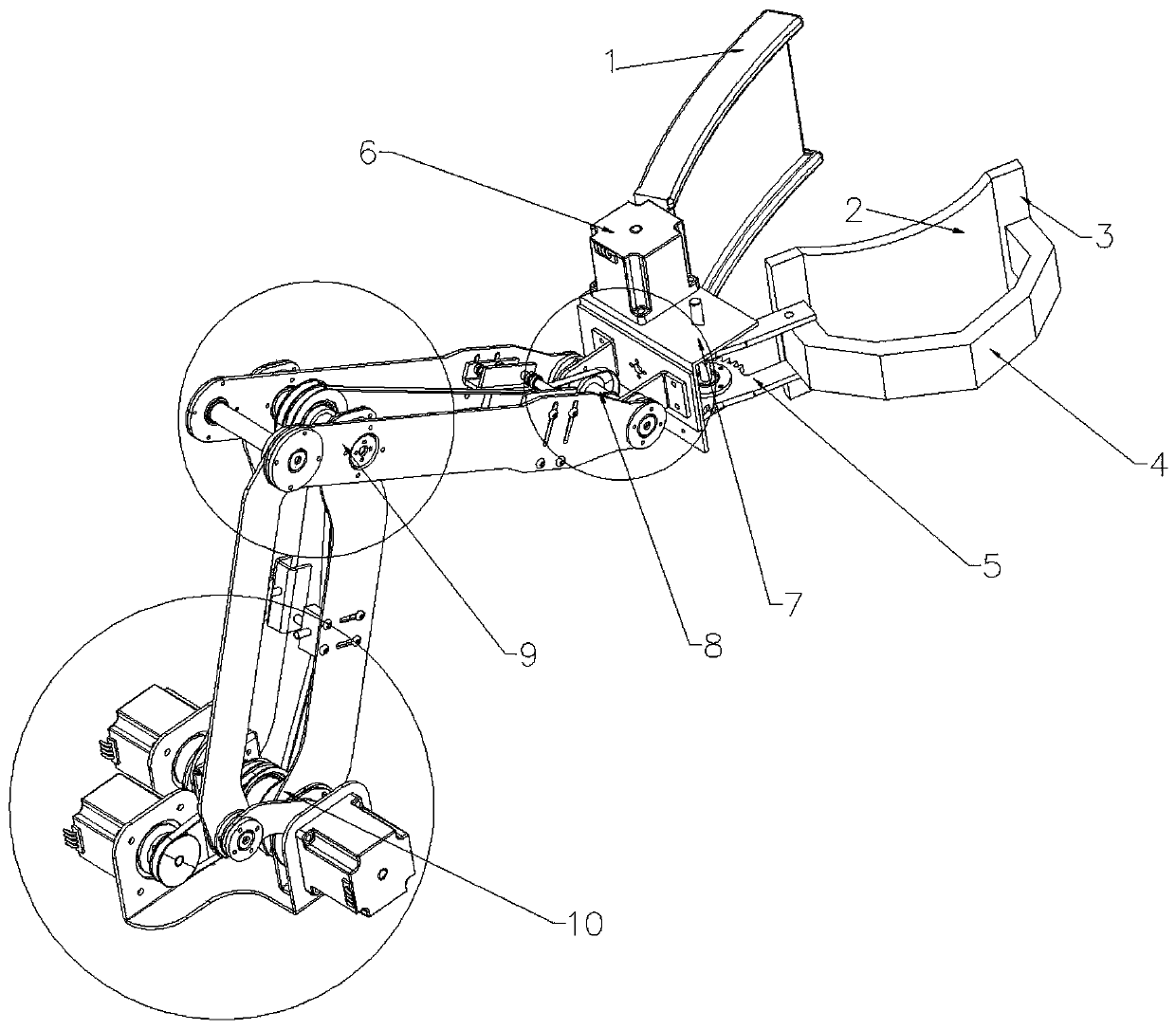

Flexible magnetic net type mechanical grabbing device

PendingCN110238869ANo reduction in gripping forceEasy to controlProgramme-controlled manipulatorGripping headsGravity centerEngineering

The invention discloses a flexible magnetic net type mechanical grabbing device, and relates to the technical field of mechanical grabbing. The flexible magnetic net type mechanical grabbing device can adapt to the appearances of objects different in shape and can firmly grab objects. Meanwhile, the structure is simpler, and control is more convenient. The flexible magnetic net type mechanical grabbing device comprises an arm and a clamping structure, wherein the clamping structure is arranged at the tail end of the arm and comprises two clamping faces, the clamping faces are a magnet plate and a flexible net correspondingly, and the edge of the flexible net and a positioning magnet block are fixedly connected. According to the flexible magnetic net type mechanical grabbing device, the contact manner of a mechanical claw and a grabbed object is optimized, meanwhile, force application control during grabbing is improved, feedback force application control is achieved, and the advantages that better attachment to the grabbed object is achieved, the object is not damaged during clamping, force application is more uniform, control owning feedback can be achieved, the device is simple, mechanical arm position control is convenient and accurate, and the gravity center of the device is stable are achieved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

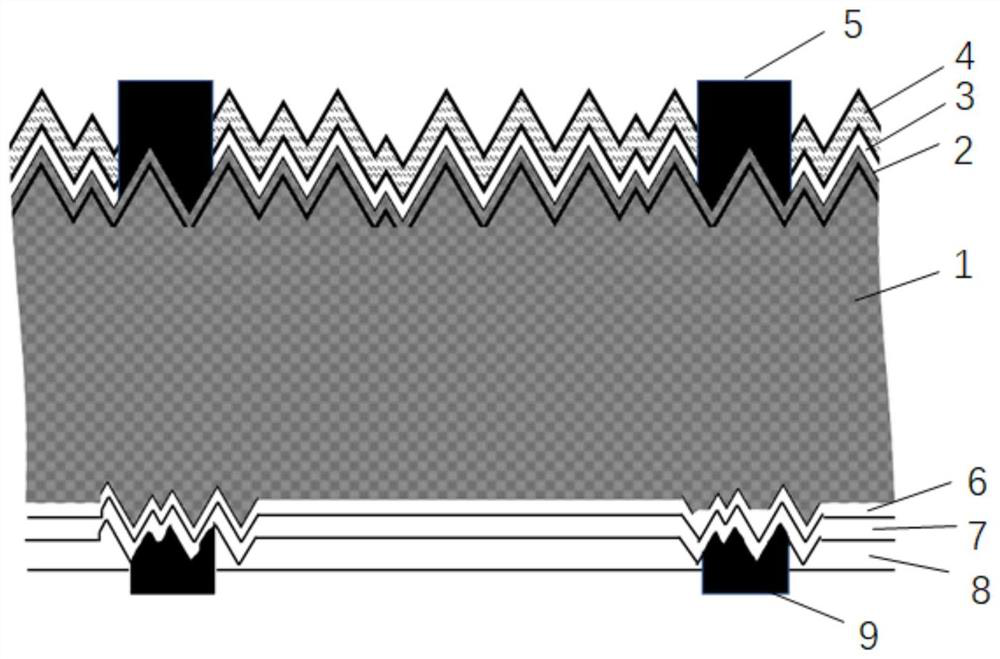

N-type battery structure and preparation method thereof

PendingCN113078232AImprove contactEasy to fillFinal product manufacturePhotovoltaic energy generationEngineeringElectric current flow

The invention discloses an N-type battery structure and a preparation method thereof. The structure comprises an N-type silicon body material and a metal grid line electrode formed on the surface of the N-type silicon body material, and is characterized in that the back surface of the N-type silicon body material is provided with a suede part and a polished surface part, and the contact position of the metal grid line electrode and the N-type silicon body material is located in the suede part. The back metal grid line electrode adopts a suede structure, so the contact area between the metal grid line and silicon is increased, and the contact resistance is improved; the flat surface of the polished area can improve the back passivation effect, reduce the surface recombination rate, enhance the internal reflection of long waves and improve the front current.

Owner:CSI CELLS CO LTD +1

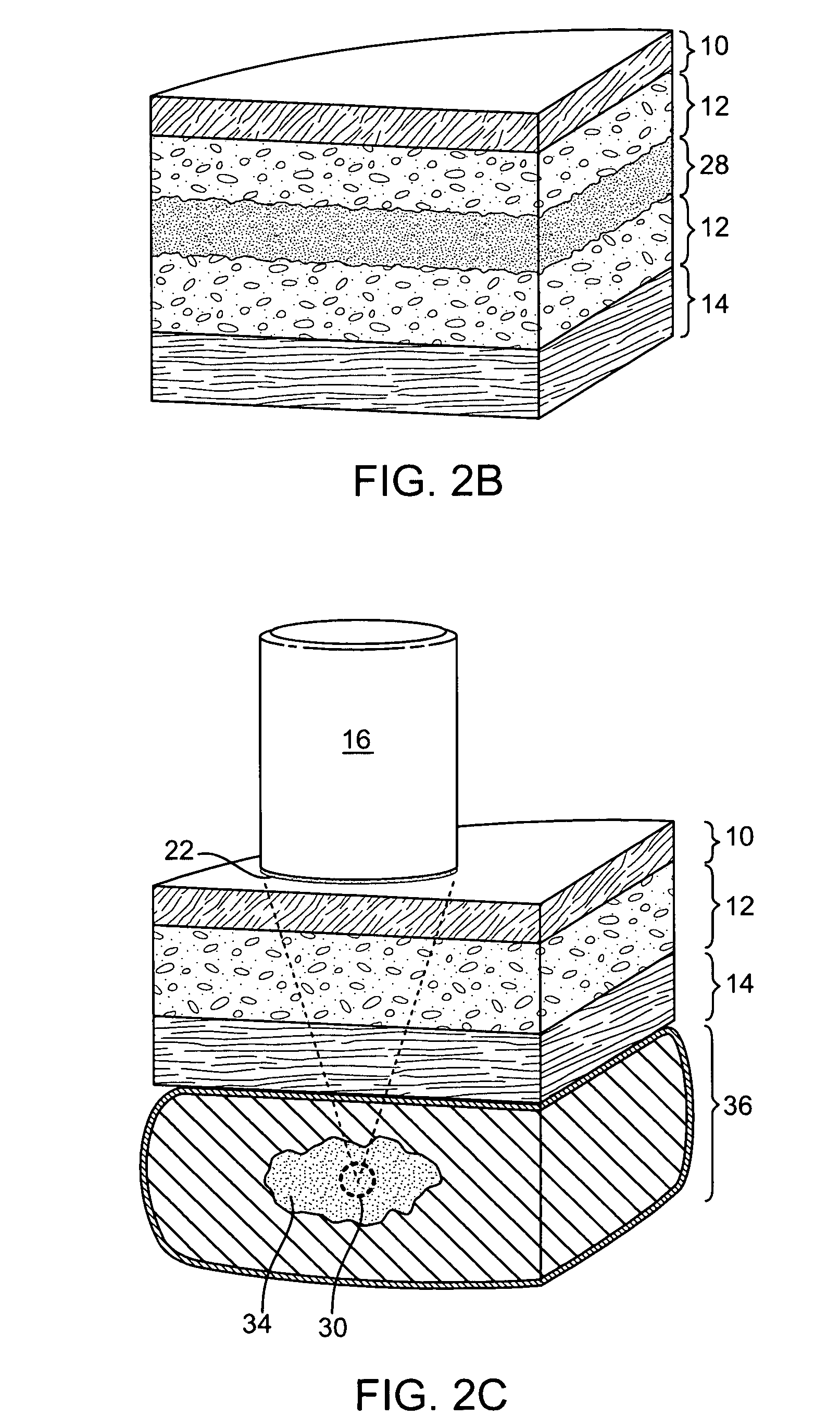

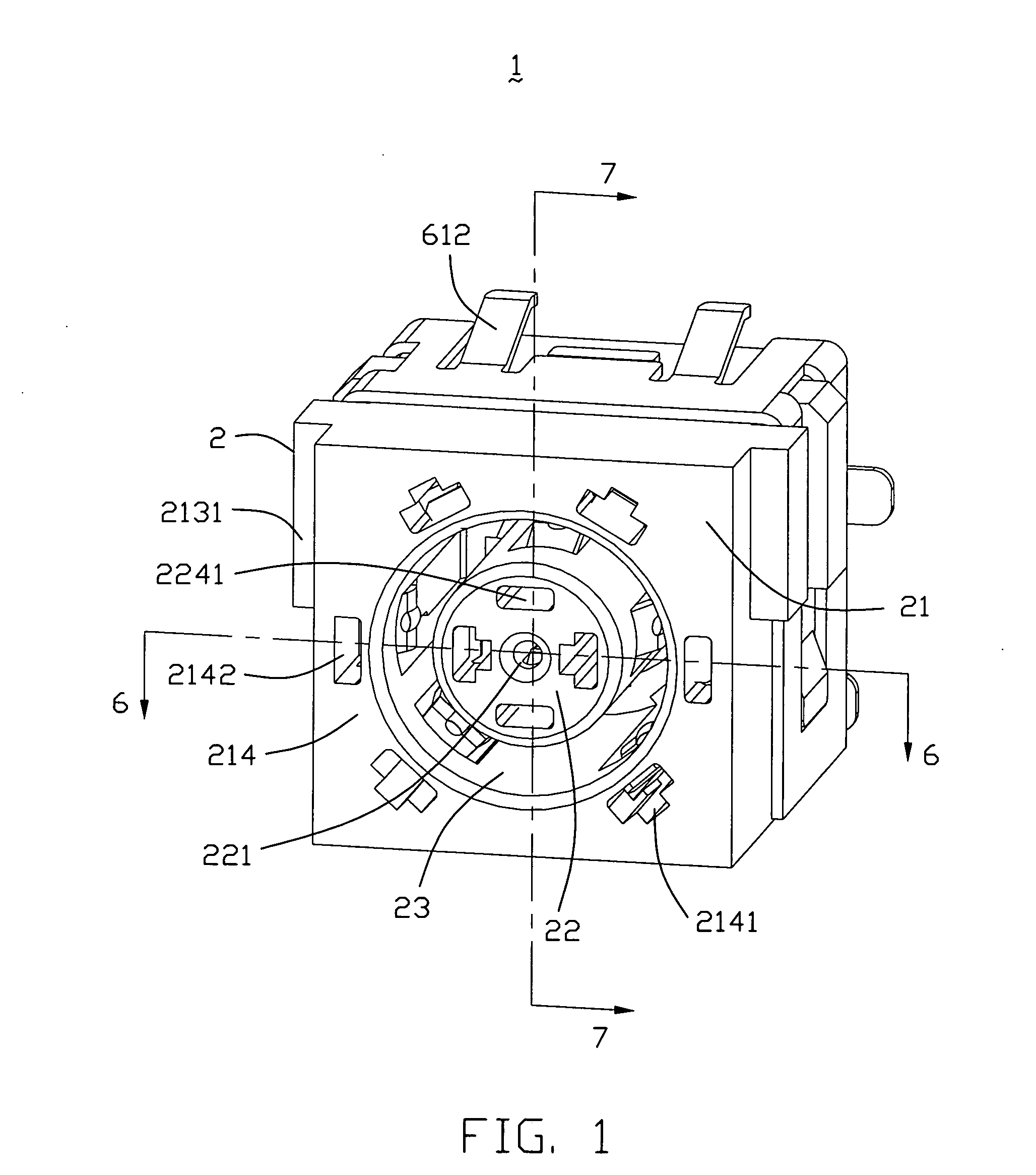

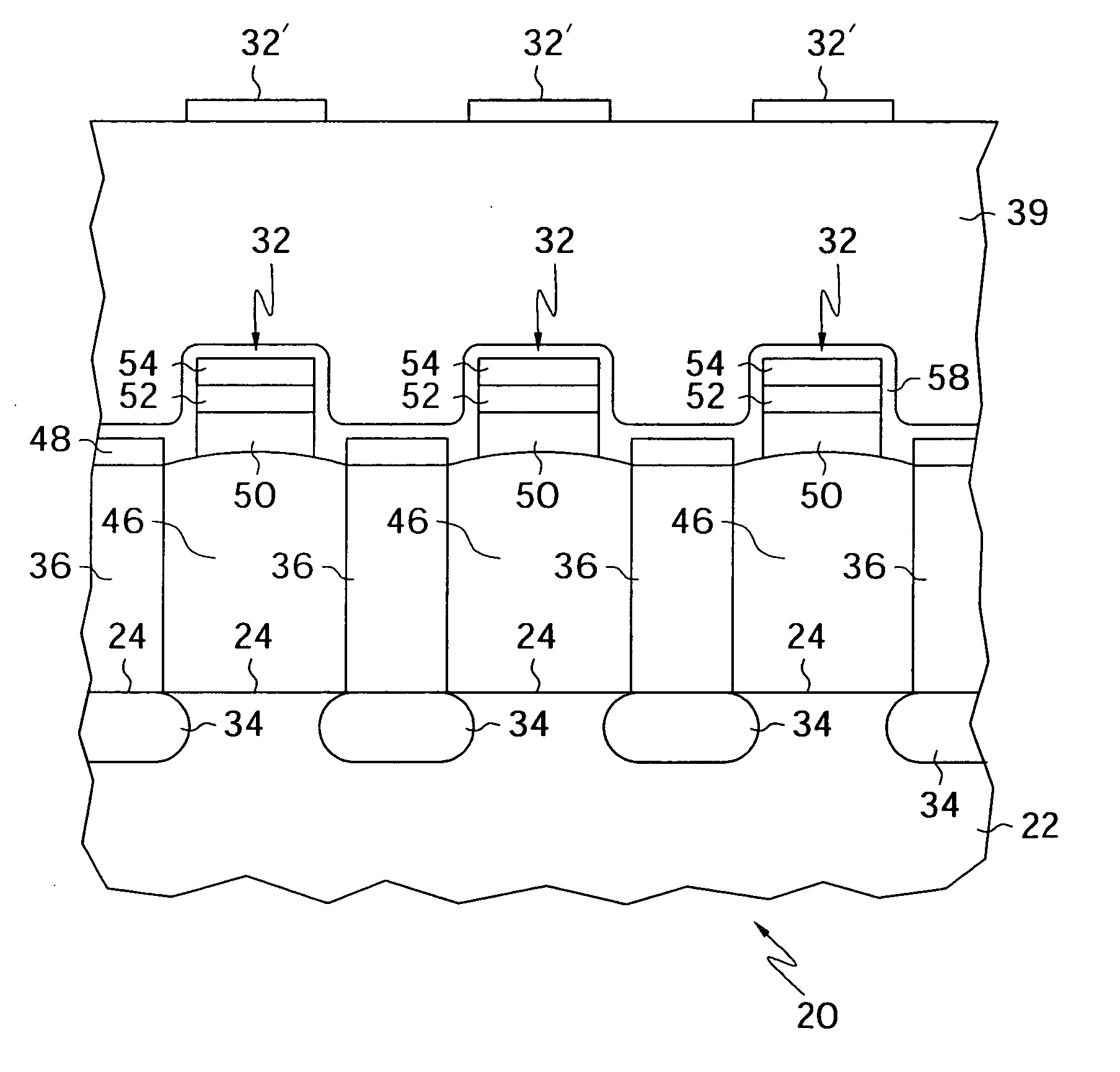

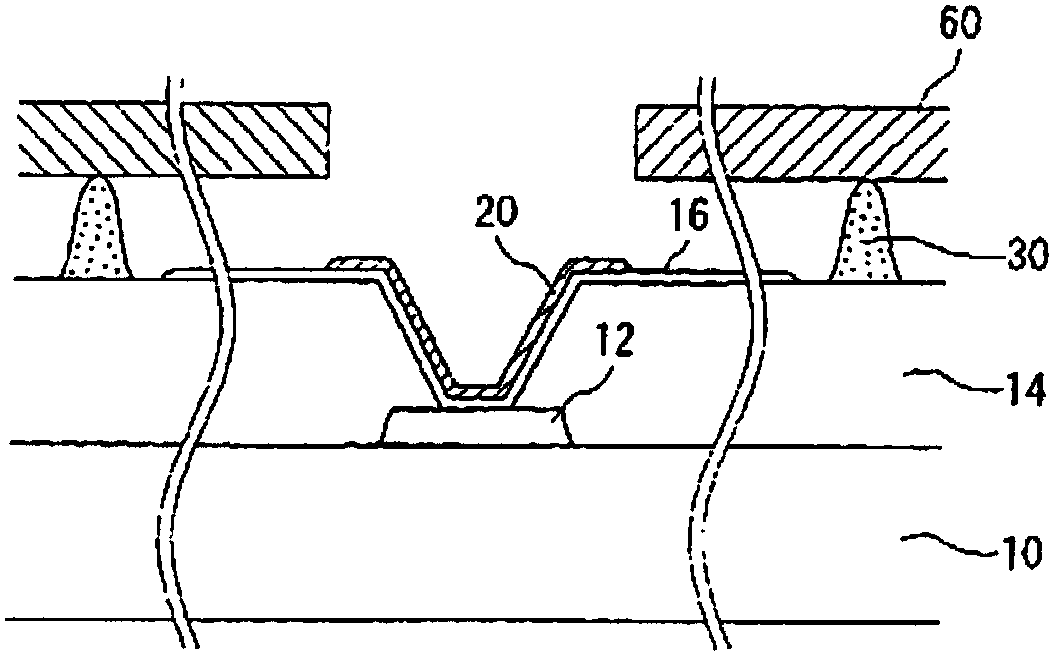

Selective polysilicon stud growth

ActiveUS20050124108A1Improve processingImprove contactTransistorSolid-state devicesPolycrystalline siliconContact hole

A memory cell having a bit line contact is provided. The memory cell may be a 6F2 memory cell. The bit line contact may have a contact hole bounded by insulating sidewalls, and the contact hole may be partially or completely filled with a doped polysilicon plug. The doped polysilicon plug may have an upper plug surface profile that is substantially free of concavities or substantially convex. Similarly, a storage node contact may comprise a doped polysilicon plug having an upper plug surface profile that is substantially free of concavities or that is substantially convex. Additionally, a semiconductor device having a conductive contact comprising a polysilicon plug may is provided. The plug may contact a capacitor structure.

Owner:MICRON TECH INC

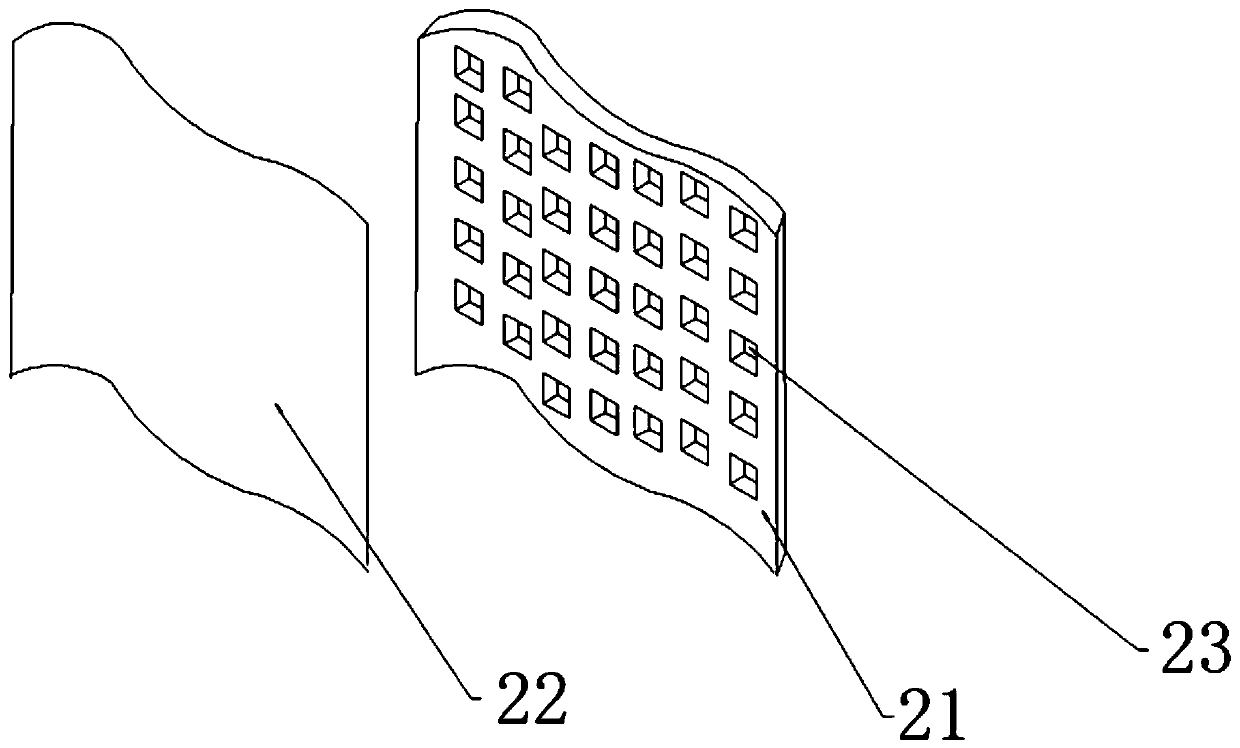

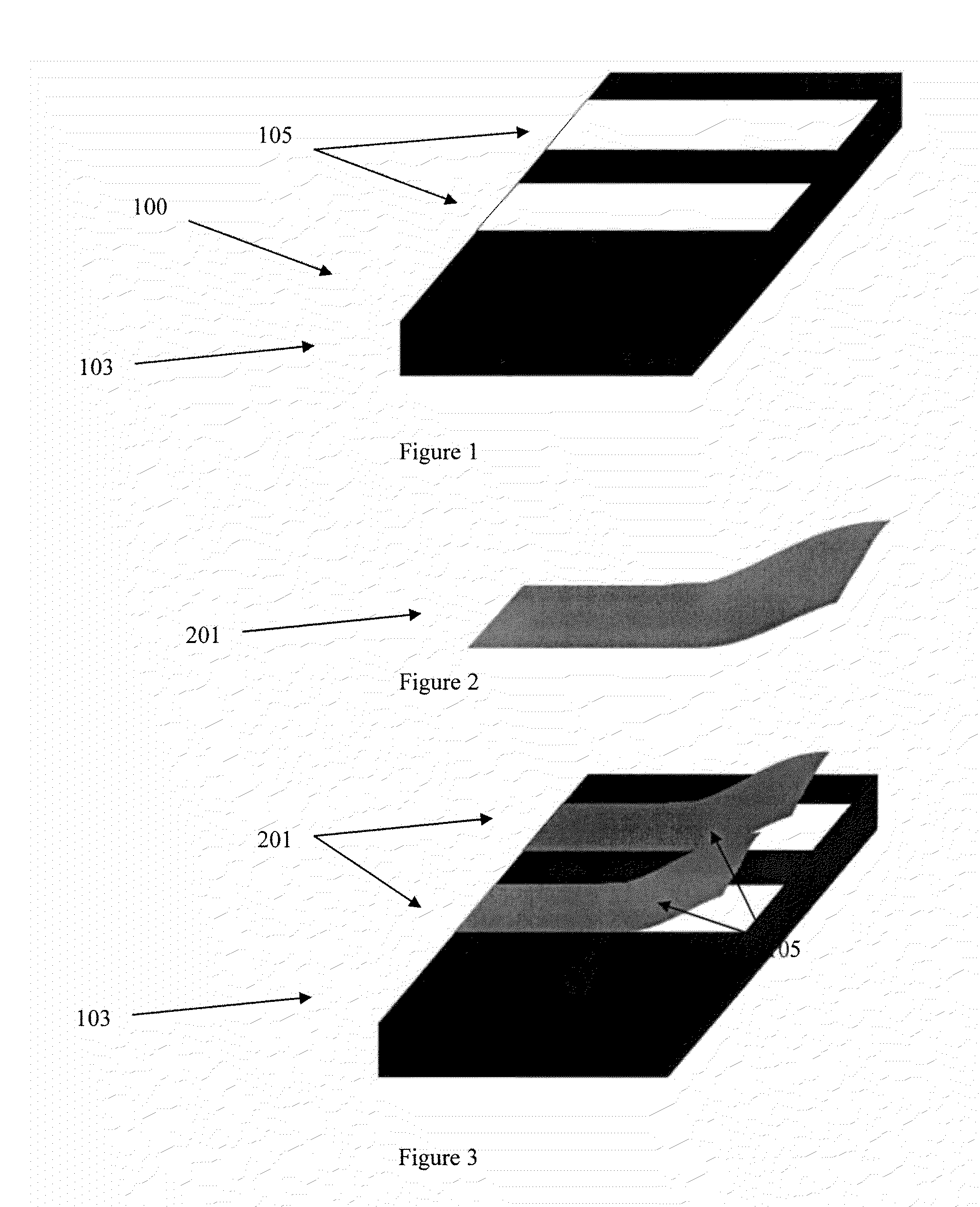

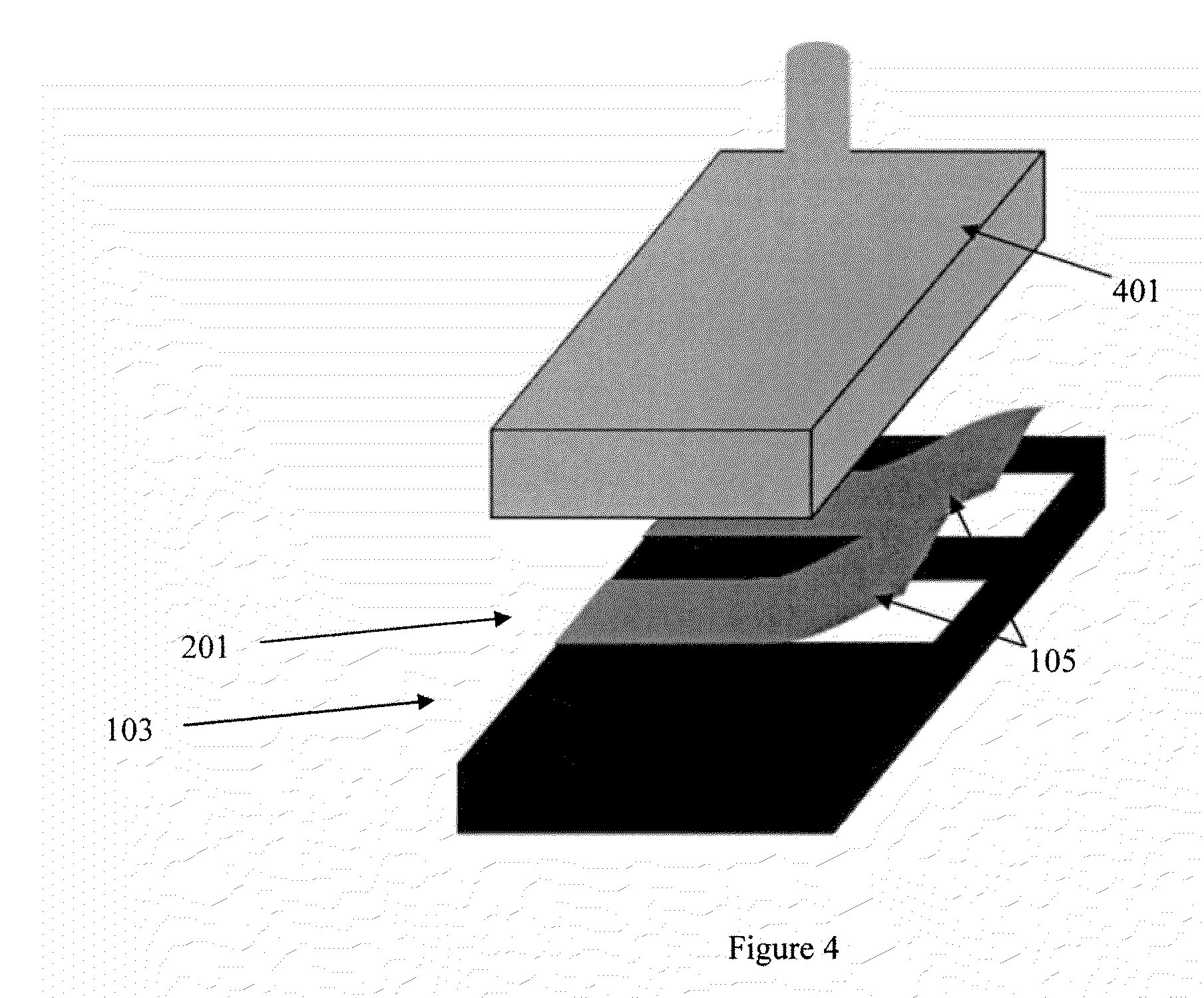

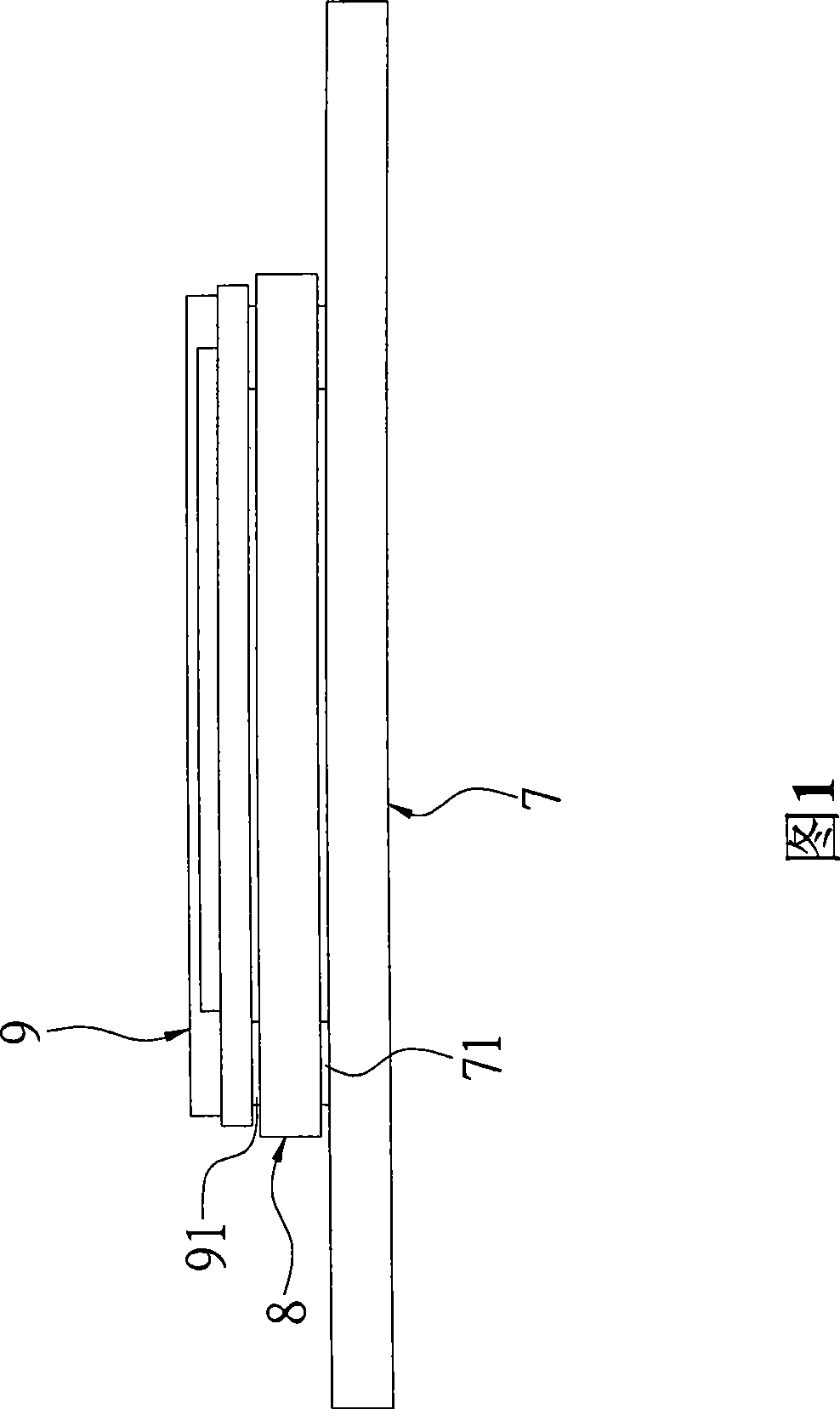

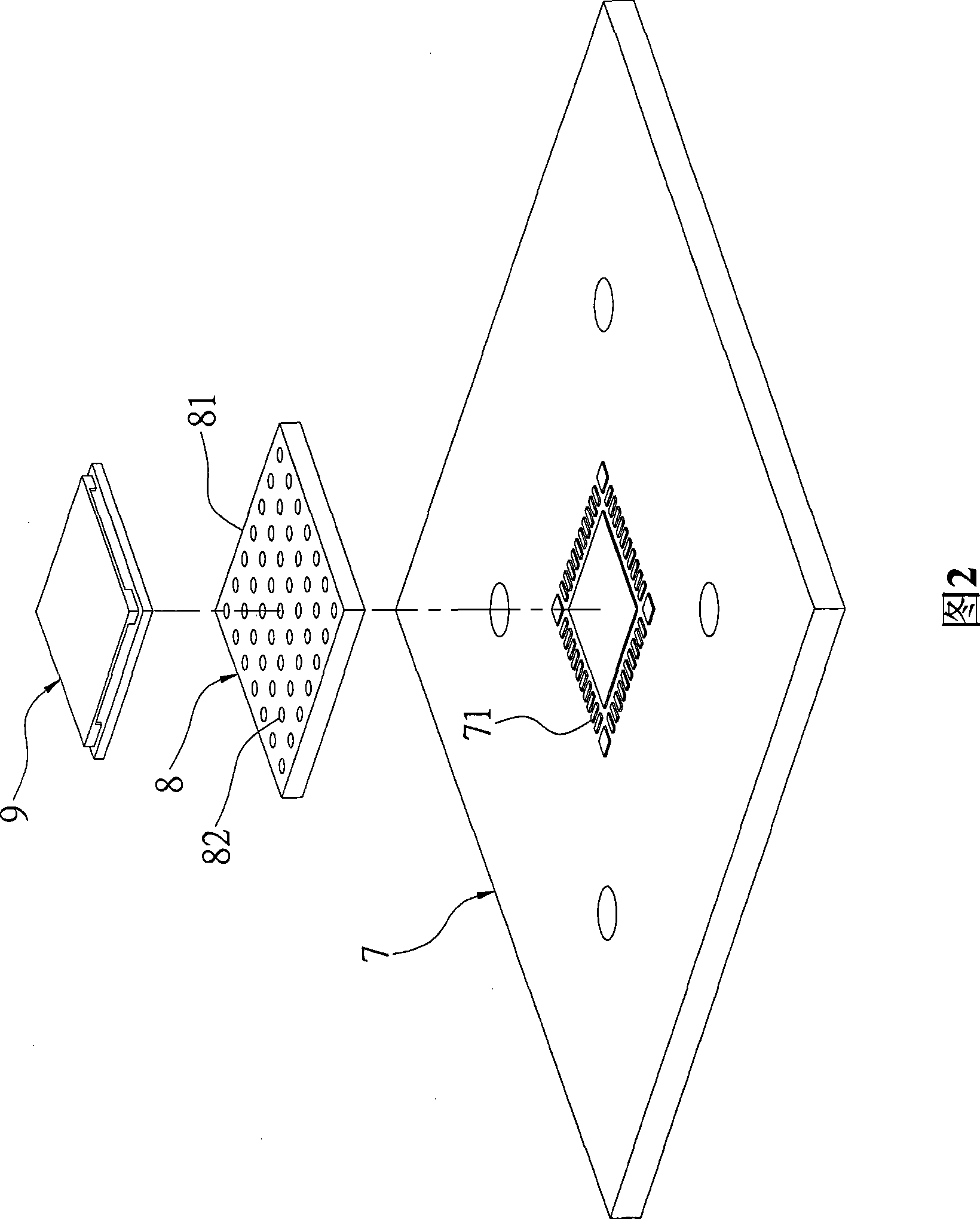

Novel mask film and evaporation device

InactiveCN108149191AAvoid pollutionImprove contactVacuum evaporation coatingSputtering coatingFilm frameEngineering

The invention discloses a novel mask film which comprises a mask film main body and a mask film frame integrally designed with the mask film main body and surrounding the mask film main body. A designated pattern is formed on the mask film main body, mounting holes are distributed in the mask film frame, and supporting structures are arranged in the mounting holes. Compared with the prior art, according to the technical scheme, the mask film main body is not modified, and the influence on the evaporated pattern can be avoided accordingly; and on the basis of further improvement on the technical scheme, the heights of the supporting structures can be adjusted, the situation that fragmenting or cracking occurs to a substrate due to the problem of the lateral flatness of the mask film or thesubstrate is avoided, and pollution on the mask film can be reduced to the largest extent as well.

Owner:GUAN YEOLIGHT TECH CO LTD

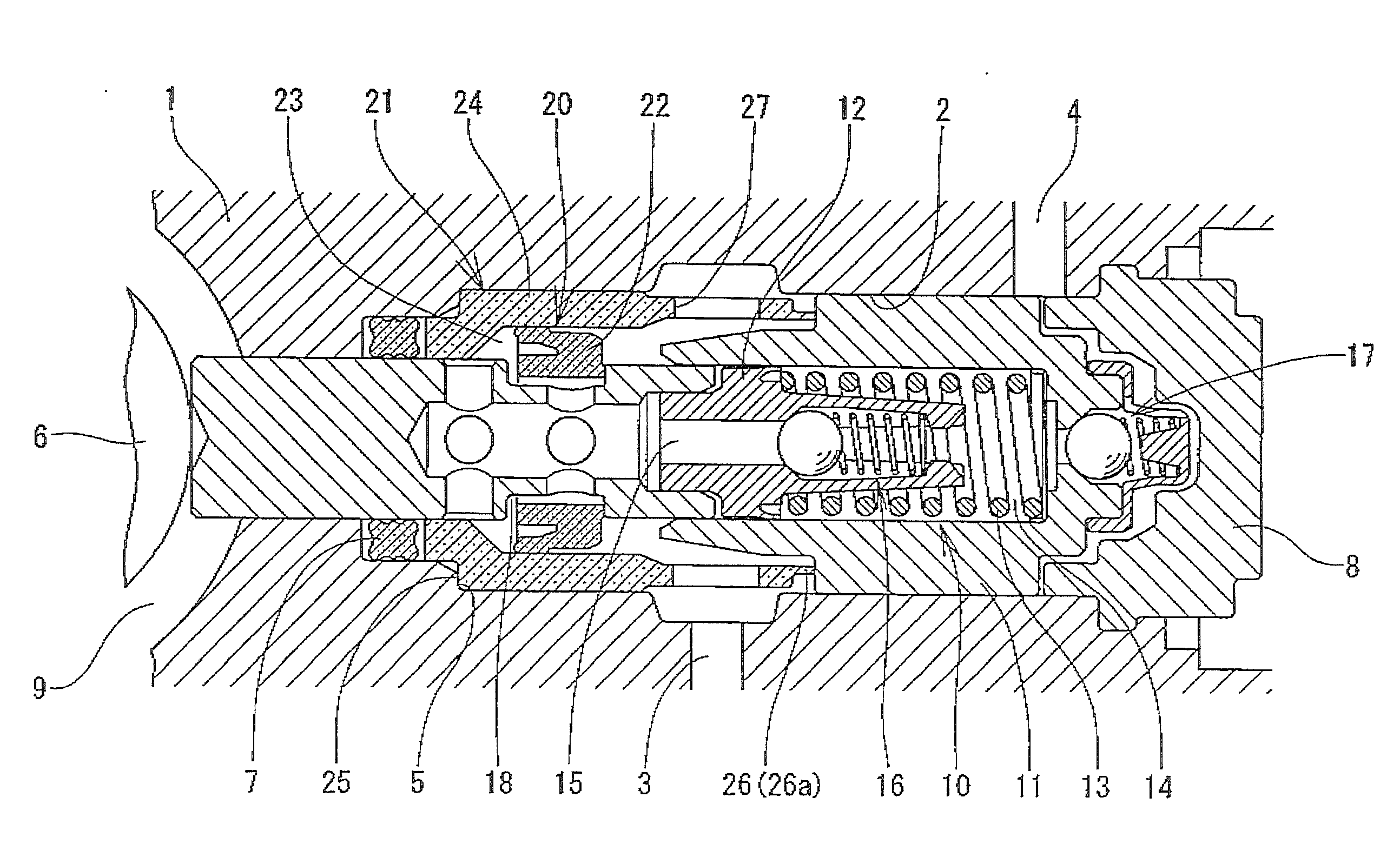

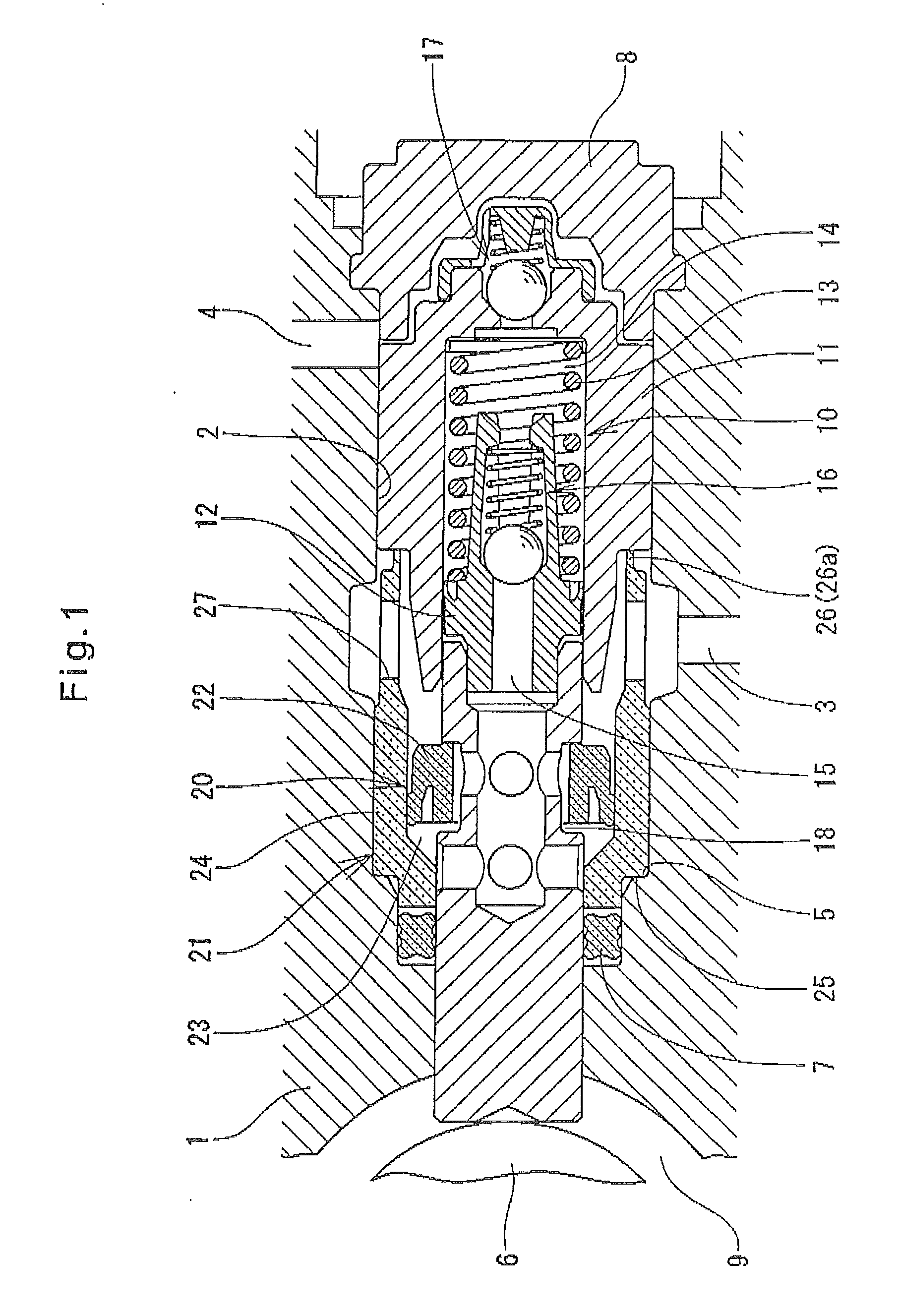

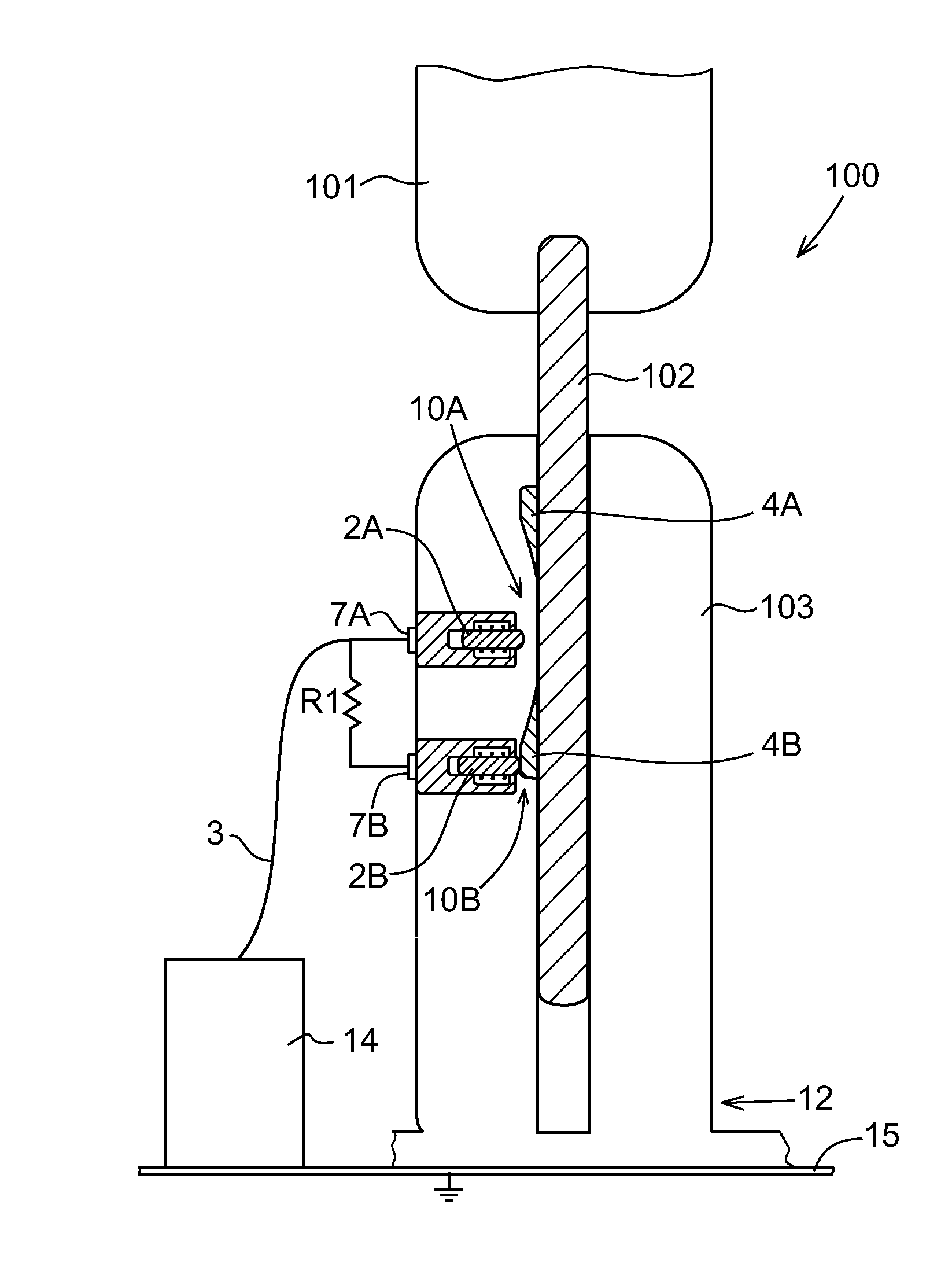

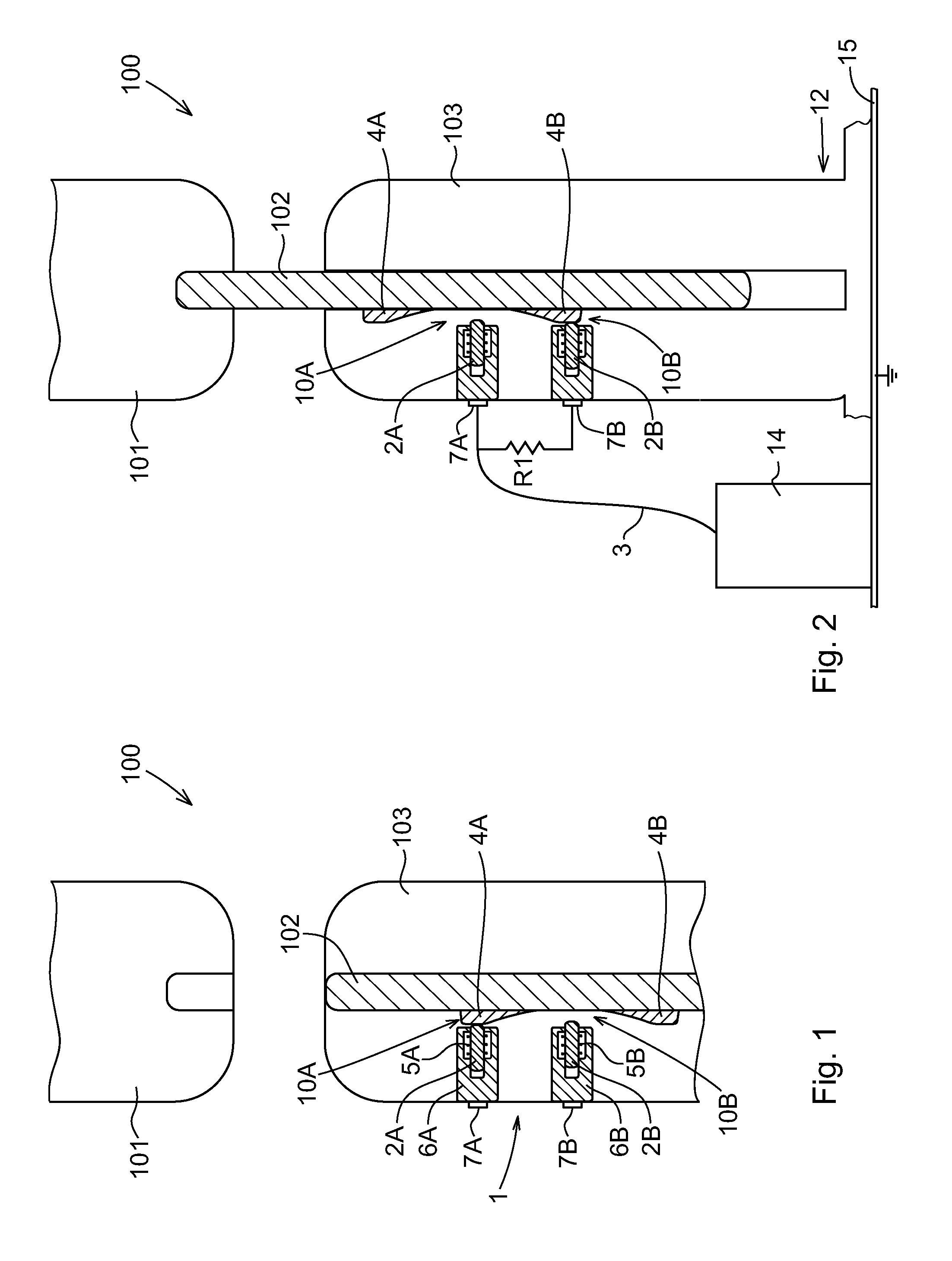

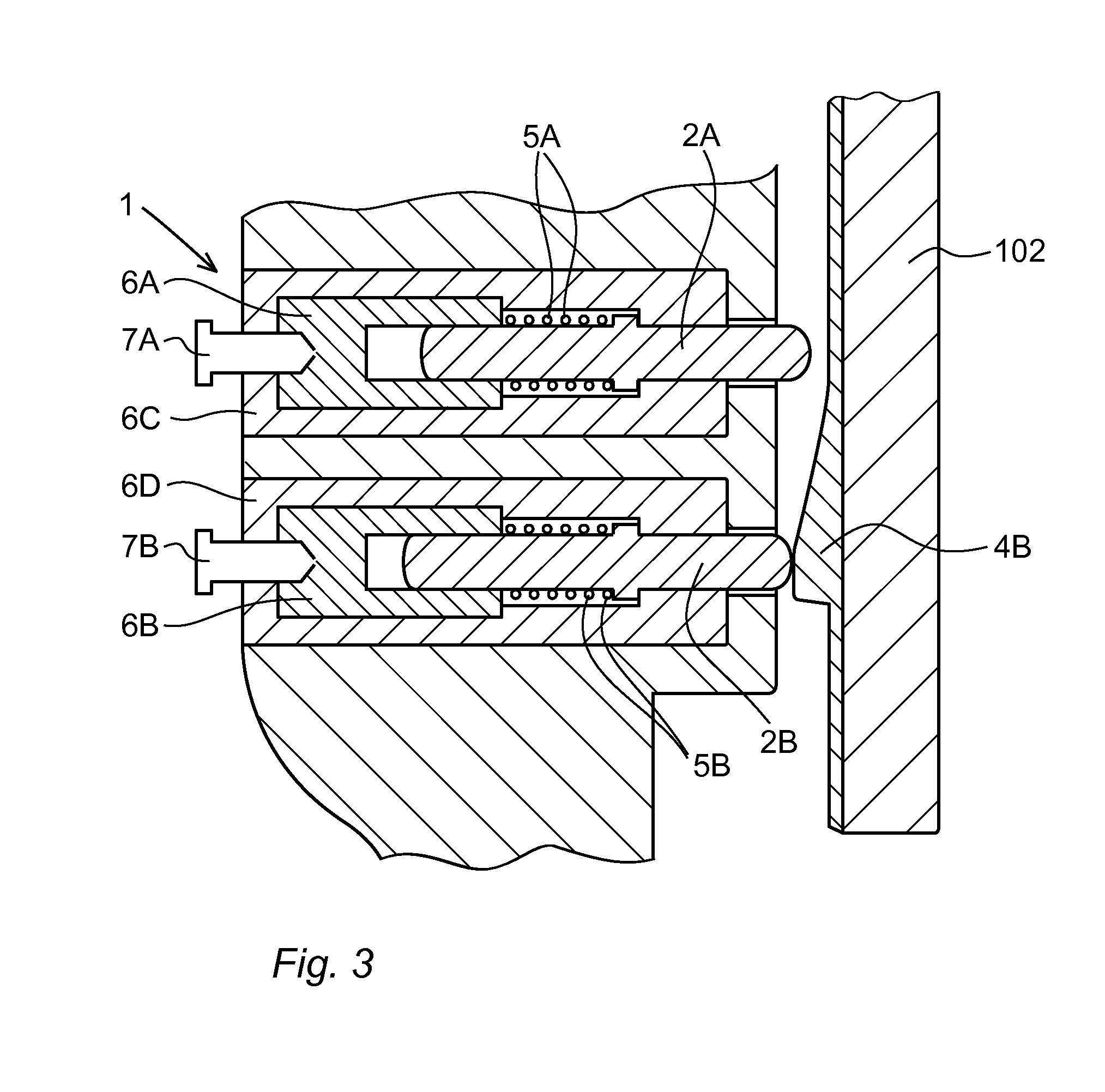

Piston pump assembly

ActiveUS20110070112A1Improve contactImprove discharge capacityPositive displacement pump componentsCylindersEngineeringPiston pump

A piston pump assembly includes a first pump having a first cylinder member inserted in a piston hole of a pump housing, and a first piston inserted in the first cylinder member, and a second pump having a second cylinder member inserted in the piston hole, and an annular second piston slidably fitted in an annular groove formed in the outer periphery of the first piston, and also axially slidably inserted in the second cylinder member. The first cylinder member axially presses the second cylinder member, thereby preventing the second cylinder member from being dropped out of the piston hole. The second cylinder member has an annular seal surface in contact with a shoulder surface formed on the inner periphery of the piston hole. Strain-absorbing protrusions are formed on the end of the second cylinder member in abutment with the first cylinder member. The protrusions are compressed when they are pressed by the first cylinder member.

Owner:ADVICS CO LTD

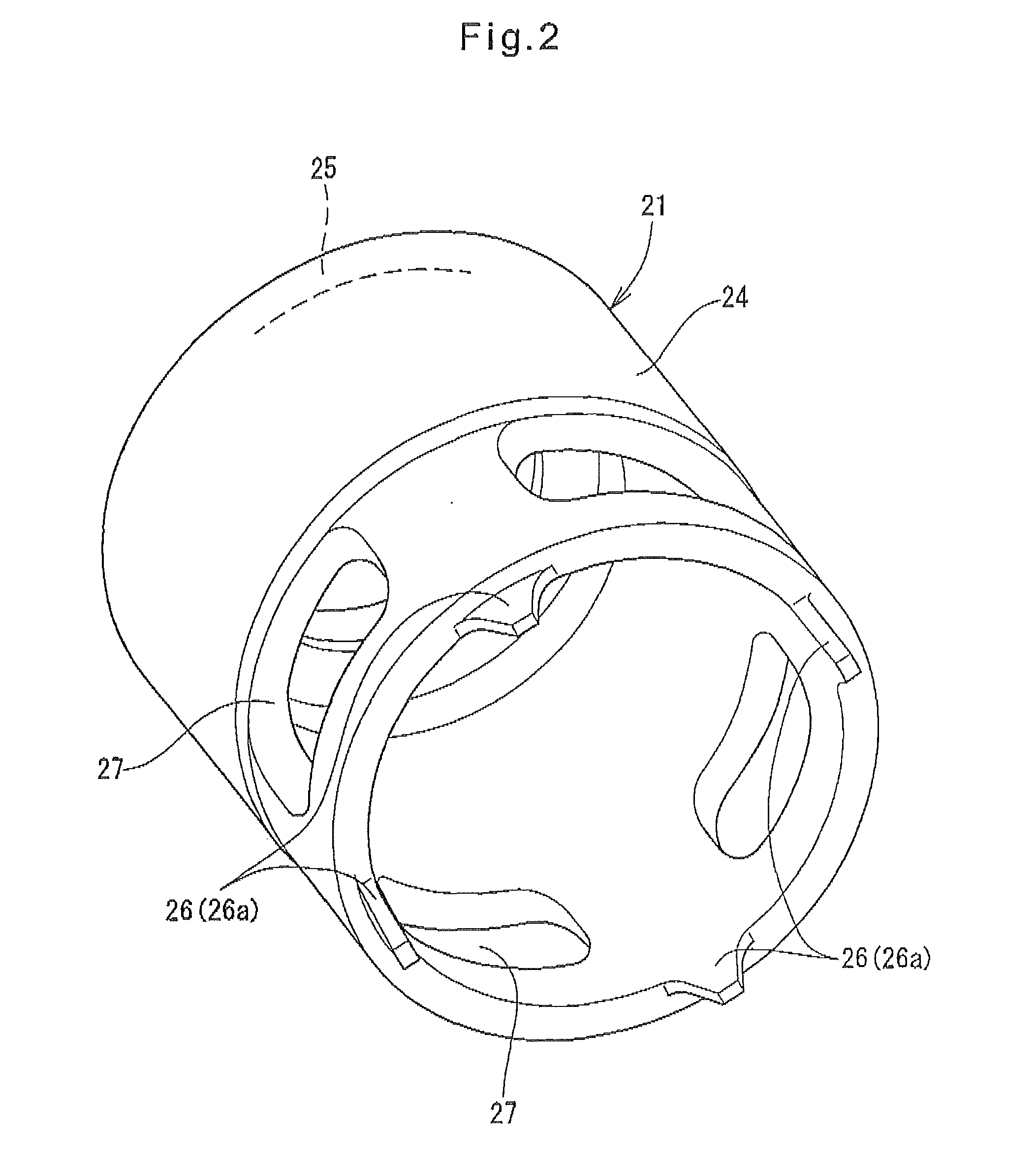

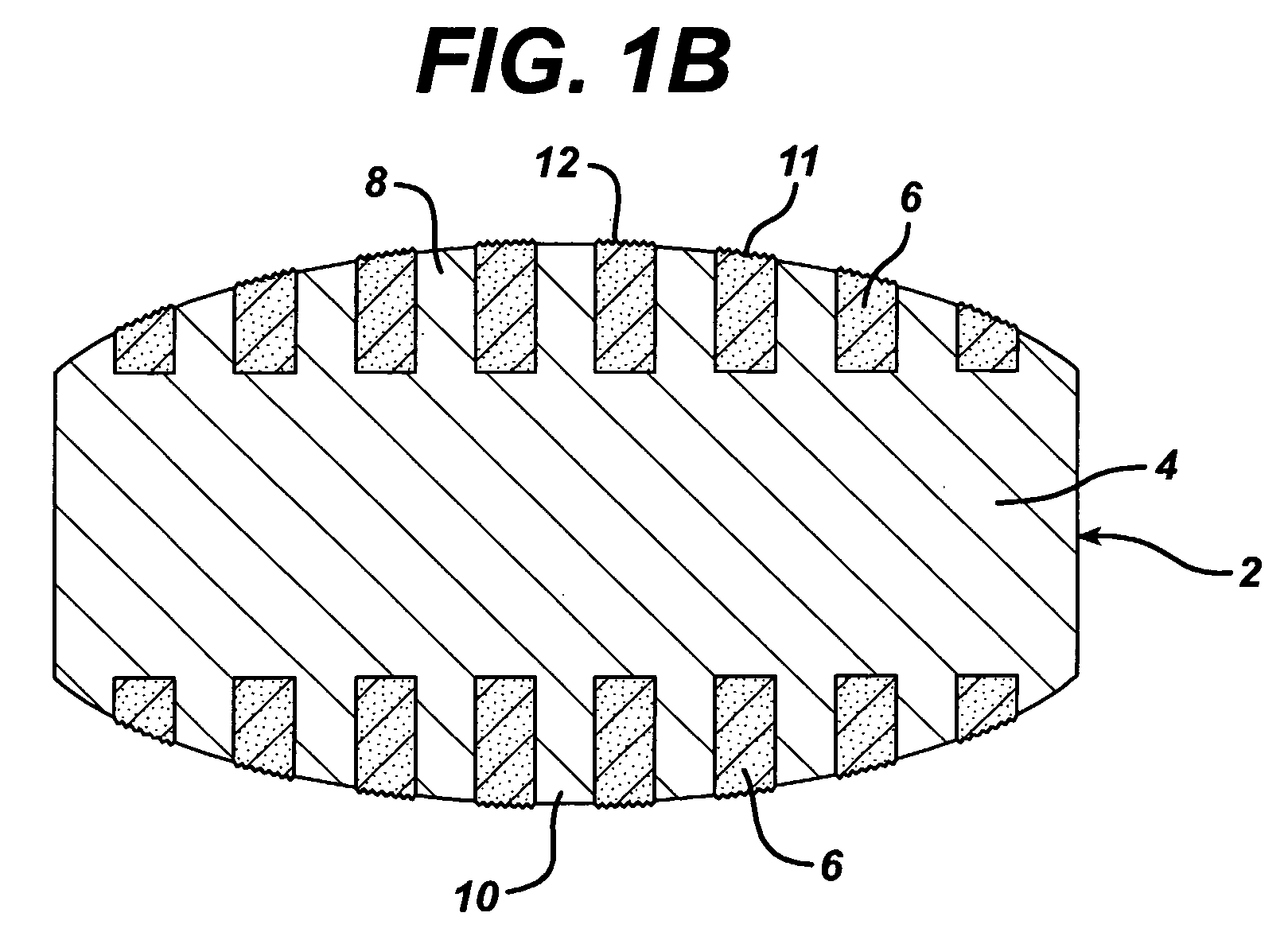

Dosage forms having a microreliefed surface and methods and apparatus for their production

The present invention provides an edible dosage form that incorporates optical elements (e.g., printed patterns, microrelief gratings, and / or macrorelief gratings), capable of producing unique optical effects and images in order to enable a user to better identify and differentiate the dosage forms, as well as to improve the detection of counterfeit production thereof, wherein the edible dosage forms may be made in a variety of ways to incorporate the optical elements therein.

Owner:JOHNSON & JOHNSON CONSUMER COPANIES

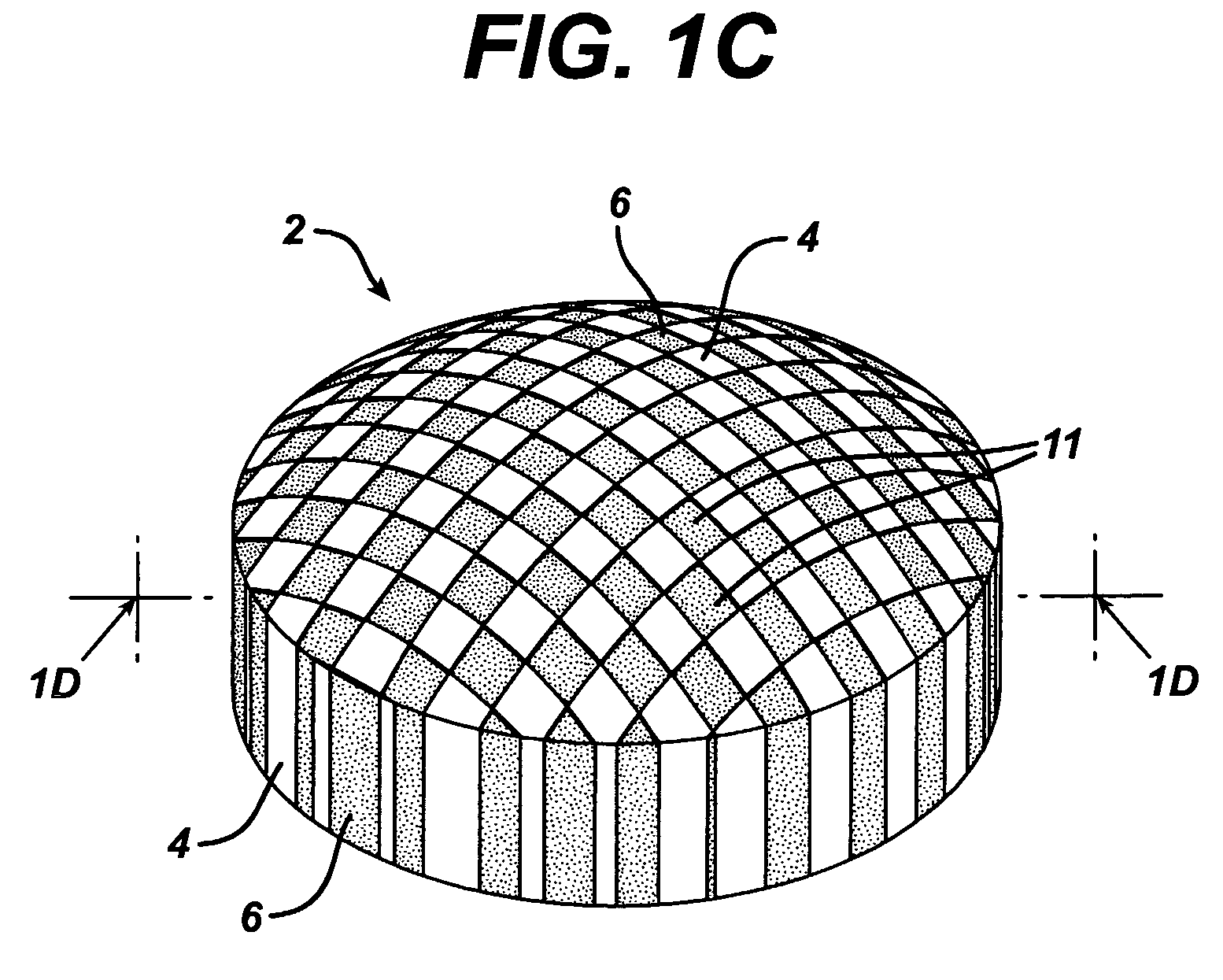

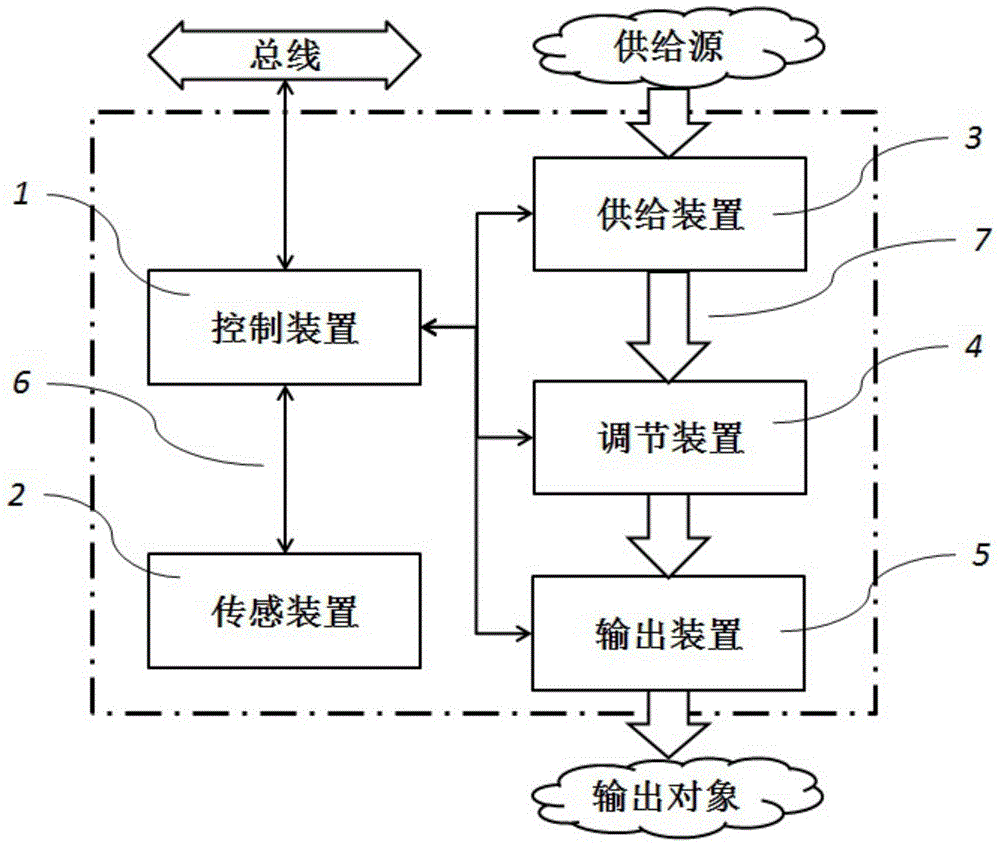

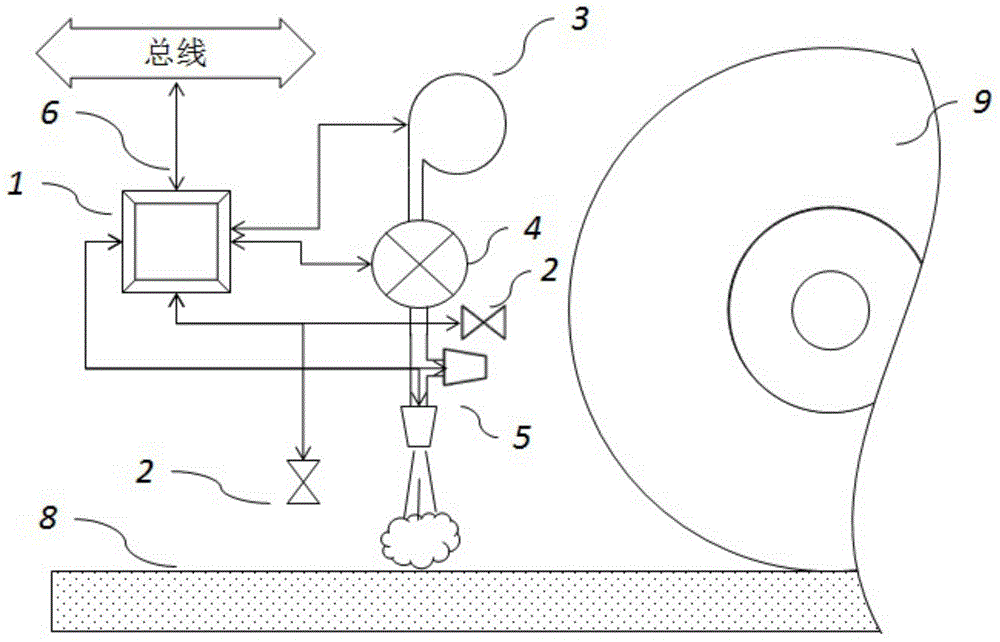

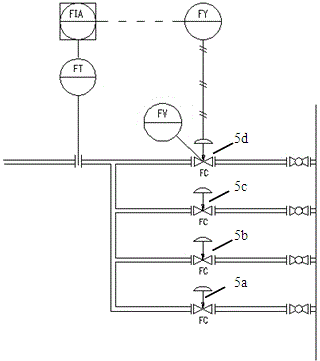

System for improving operating environment between operating body and carrying base plane and application thereof

ActiveCN104816586AImprove contactGreat tractionWheel adhesionInformation transmissionResource consumption

The invention relates to a system for improving an operating environment between an operating body and a carrying base plane and application thereof. The system comprises a control device, a sensing device, a supplying device, an adjusting device and an output device, wherein the control device receives detection information and feedback information of the system and an instruction of an operator, performs judgment and sends an execution command, the sensing device detects operating information of the operating body and the carrying base plane and transmitting the information to the control device, the supplying device obtains and stores a flowing medium from the outside or a carrying body, receives the execution command of the control device to release the flowing medium and sends the feedback information to the control device, the adjusting device receives the flowing medium released from the supplying device and processes and delivers the flowing medium to the output device, the output device receives the flowing medium delivered and processed by the adjusting device and sprays the flowing medium to the operating body and / or the carrying base plane. Compared with the prior art, the system for improving the operating environment between the operating body and the carrying base plane has the advantages of being advanced in method, simple in structure, low in cost, wide in application range, low in resource consumption and the like.

Owner:上海昊洛电子科技有限公司

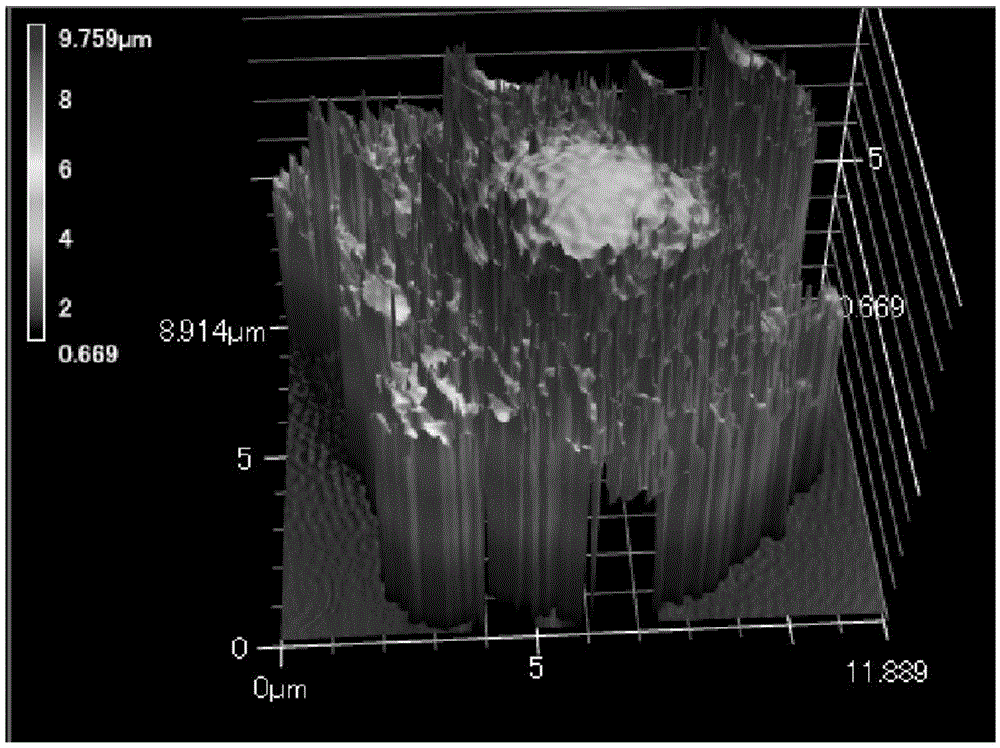

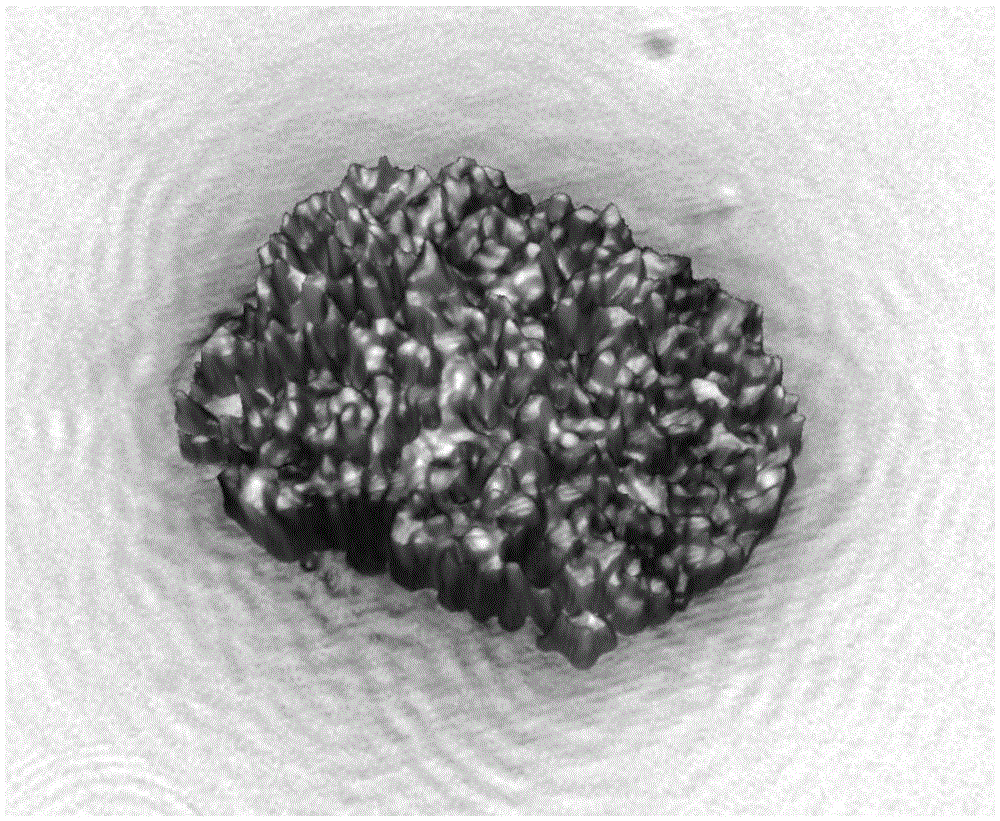

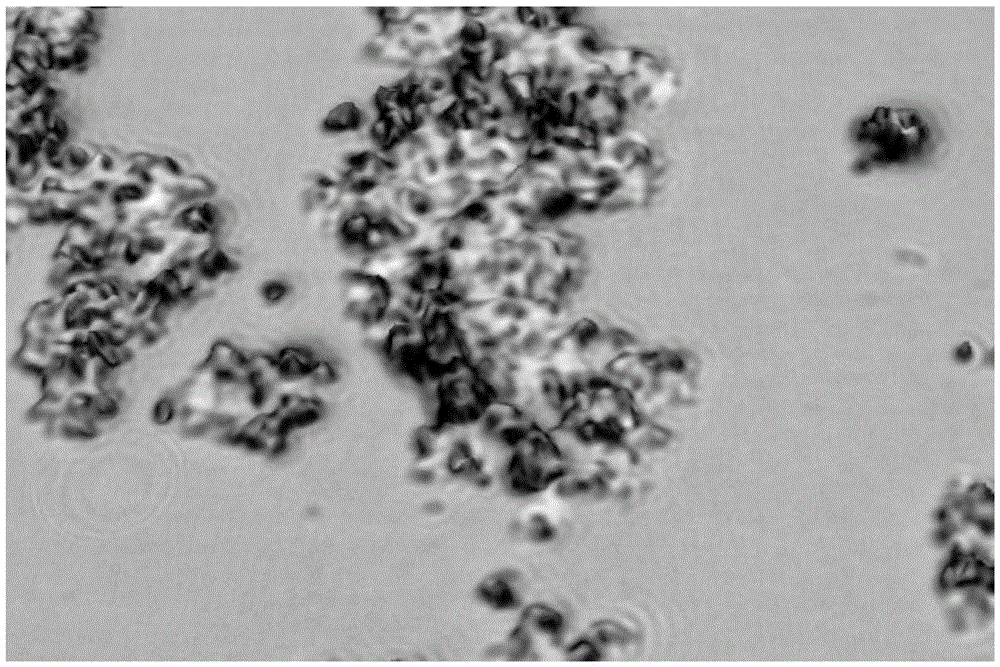

Raw material for high-speed growth of silicon carbide crystals and silicon carbide crystal growing method

InactiveCN105603530AIncrease the amount of sublimationGood suspensionPolycrystalline material growthFrom condensed vaporsCrucibleSemiconductor

The invention relates to a raw material for high-speed growth of silicon carbide crystals and a silicon carbide crystal growing method, and belongs to the technical field of semiconductors. The raw material for high-speed growth of the silicon carbide crystals and the silicon carbide crystal high-speed growing method are provided for solving the problem that existing silicon carbide crystals are small in growing speed and low in efficiency. The raw material contains silicon carbide particles, the average particle size of the silicon carbide particles is smaller than 5 mum or at least two types of silicon carbide particles which are in different shapes and / or have different particle sizes are mixed to form a mixed raw material, and the raw material at last contains a type of silicon carbide particles with the average particle size smaller than 5 mum. The silicon carbide crystal growing method comprises the following steps: placing the raw material in a crucible; and heating the crucible and enabling the raw material in the crucible to be recrystallized after sublimating so as to obtain the silicon carbide crystals. The purpose of increasing sublimating speed and efficiency can be achieved.

Owner:TAIZHOU BEYOND TECH

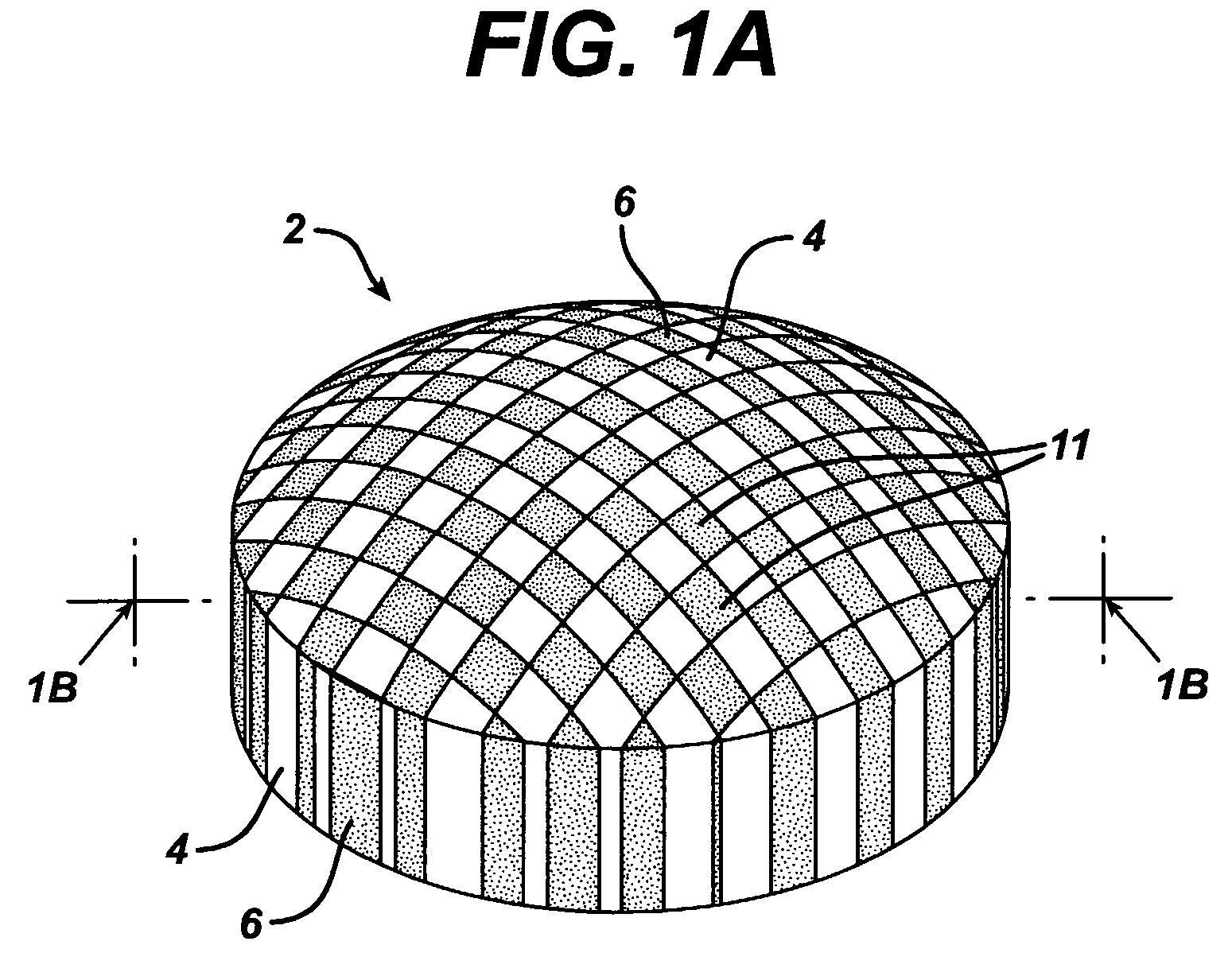

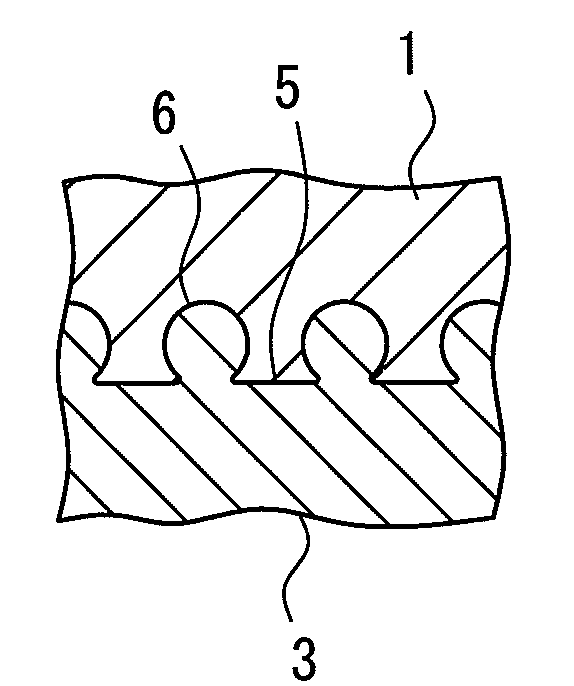

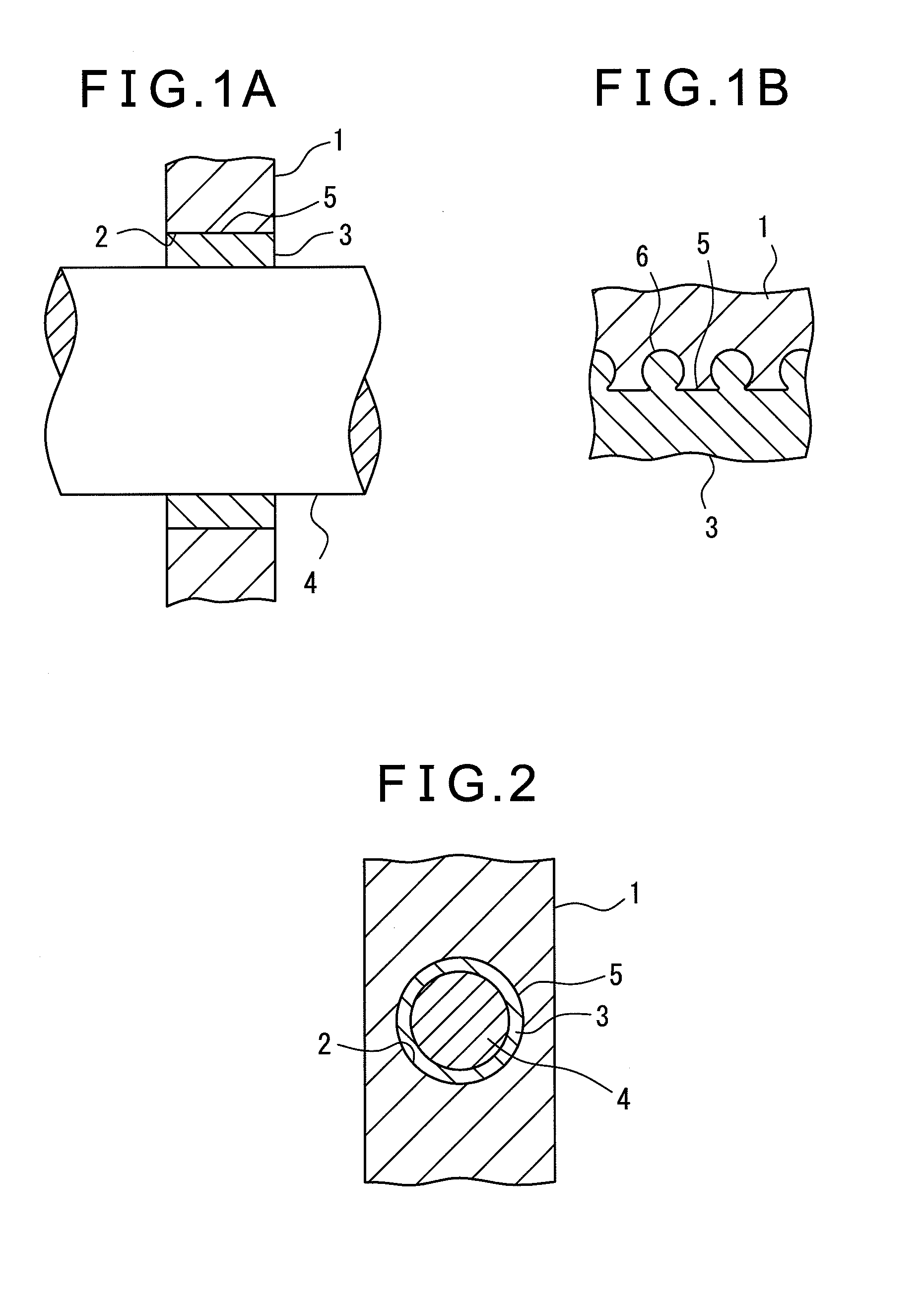

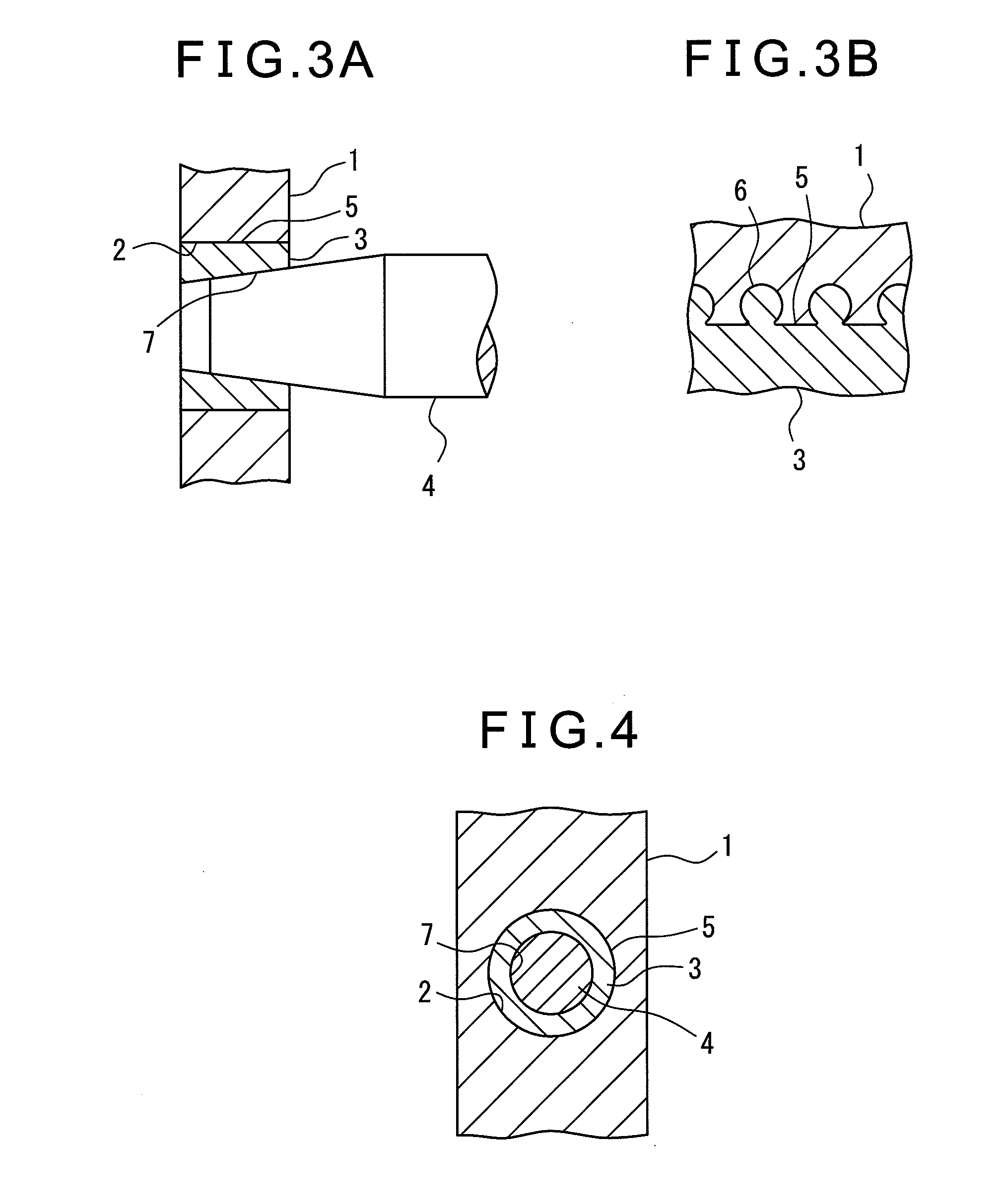

Support member

ActiveUS20120224798A1Improve contactIncrease contactConnecting rod bearingsBearing assemblyEngineeringMechanical engineering

A support member with excellent contact with the member to which the support member is attached, that is, a metal support member which supports a shaft directly or through a bearing and which has a plurality of the projections at its outer circumferential surface, wherein the plurality of the projections are formed at the outer circumferential surface as a whole at the time of casting of the support member and wherein at least part of the projections have thin-waisted shapes or a plastic support member which supports a shaft directly or through a bearing and which has a plurality of the projections at its outer circumferential surface, wherein the plurality of the projections are formed at the outer circumferential surface as a whole at the time of molding of the support member and wherein at least part of the projections have thin-waisted shapes.

Owner:TEIKOKU PISTON RING CO LTD +1

Micro sensor

A micro sensor for sensing at least one analyte from a biological fluid of a patient, the micro sensor comprises a probe and at least two electrodes arranged on the probe. The probe comprises a longitudinal body and the at least two electrodes are arranged in the width or in the length of the longitudinal body of the probe.

Owner:DEBIOTECH SA

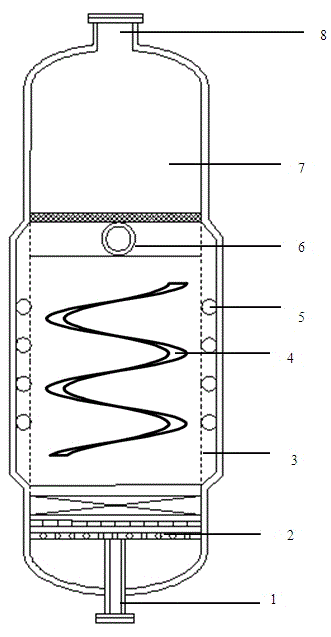

Interface convection inducing bioreactor and applications thereof

ActiveCN104591400ARegulatory processingRegulation efficiencyWaste based fuelMultistage water/sewage treatmentSludgeDistributor

The present invention discloses an interface convection inducing bioreactor and applications thereof. The interface convection inducing bioreactor comprises an inlet pipe, a water distribution device, a fermentation induction zone, a purified water outlet, a gas collection bag and a gas discharge pipe, wherein the water distribution device comprises a distributor and a structured filler, the fermentation induction zone is provided with a diversion belt and pulse pipes, the diversion belt is a helical and coiled metal member, the pulse pipe is introduced along the tangential direction of the inner wall of the fermentation induction zone, the included angle between any two pulse pipes is 90 DEG or 180 DEG, the diameter D5 of the diversion belt is equivalent to the inner diameter D1 of the induction zone, the belt width D6 is 10-20% of the D5, the height difference H4 between the layers formed through helical rotation of the diversion belt is 1 / 10-1 / 4 of the height H1 of the induction zone. According to the present invention, the regulation on the granular sludge interface morphology and the self-coagulation effect are utilized to reduce the biomass loss along with the liquid removing so as to reduce the use of the subsequent sedimentation tank, the aeration tank and the related equipment and the investment operating cost.

Owner:深圳市山水乐环保科技有限公司

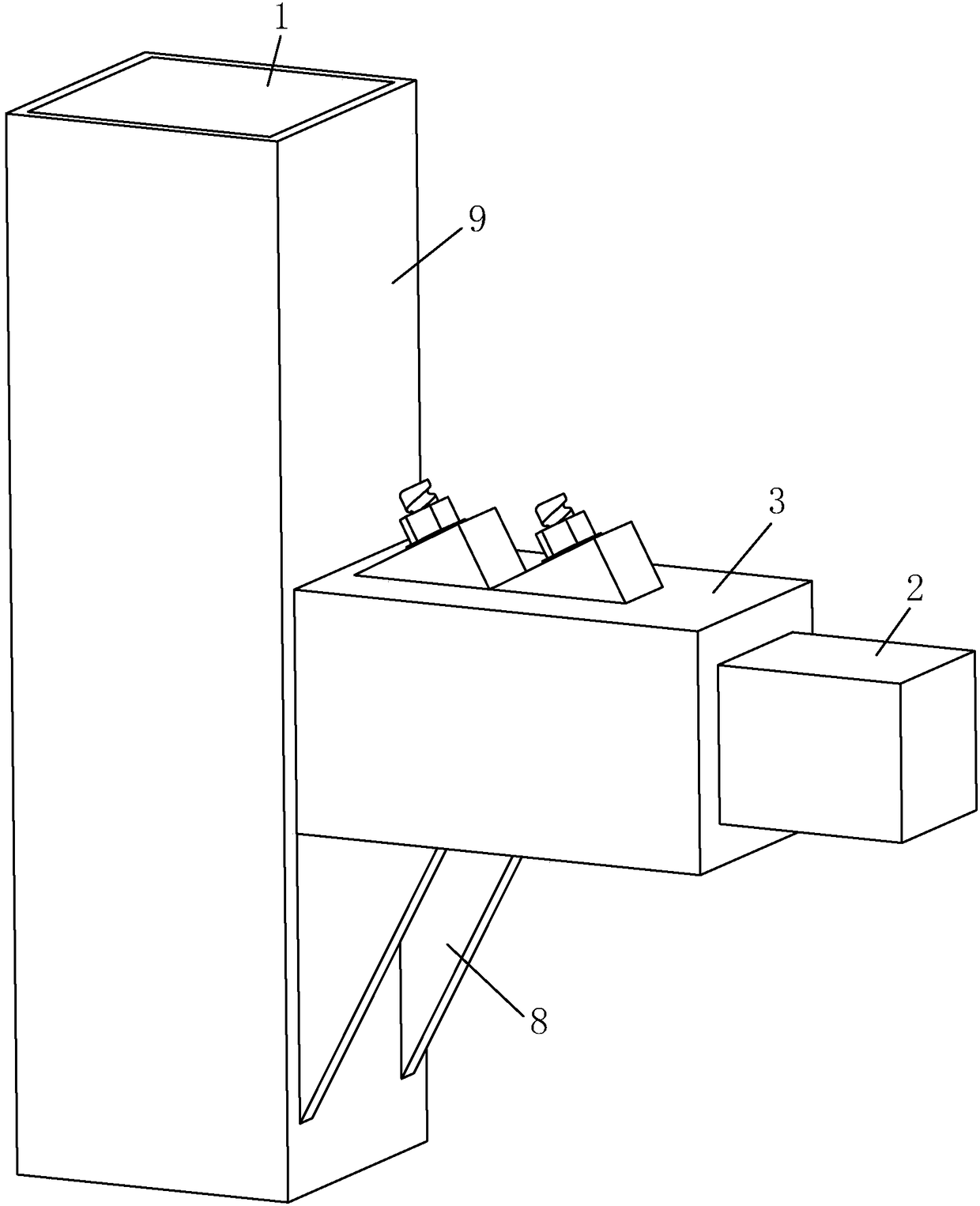

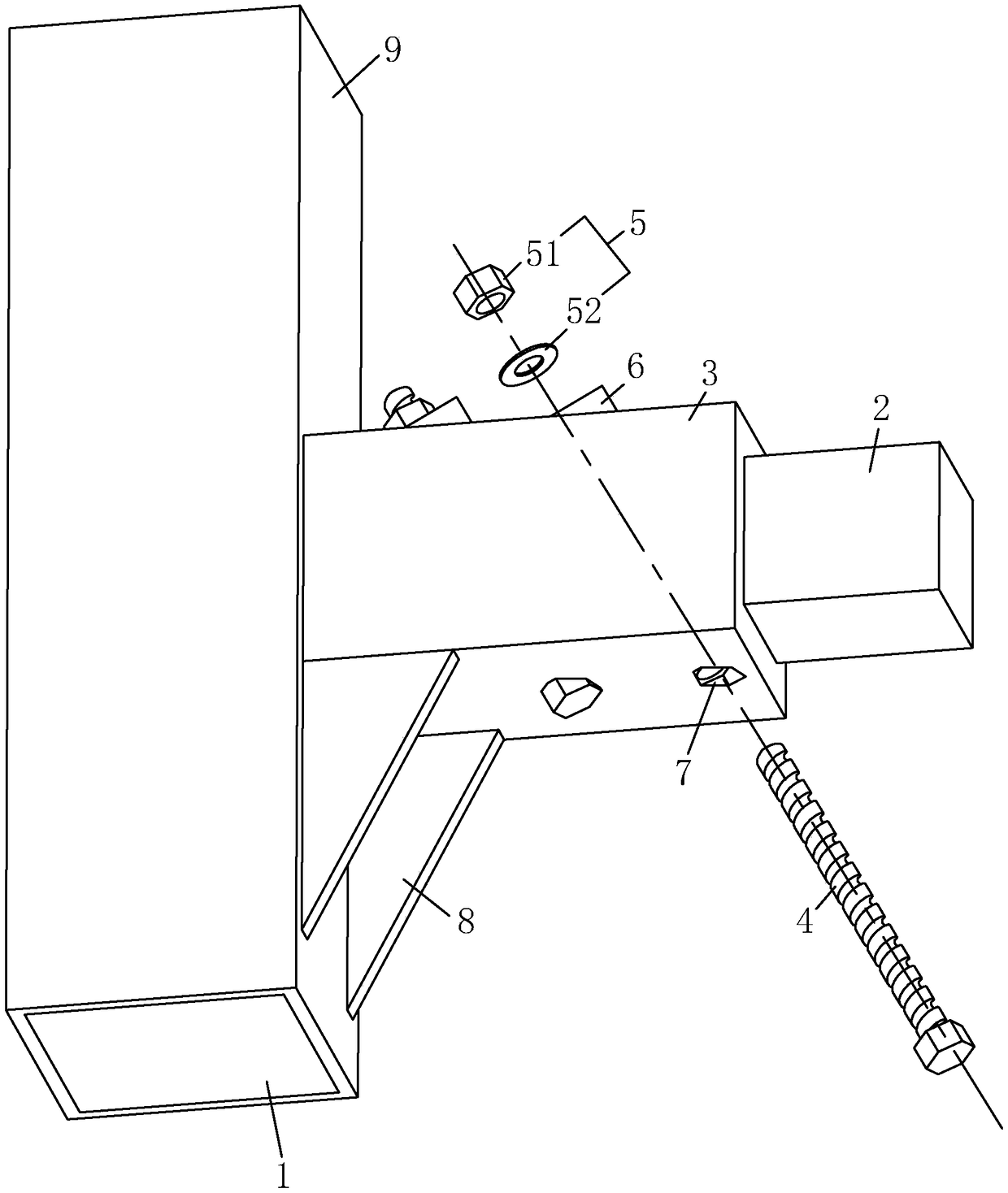

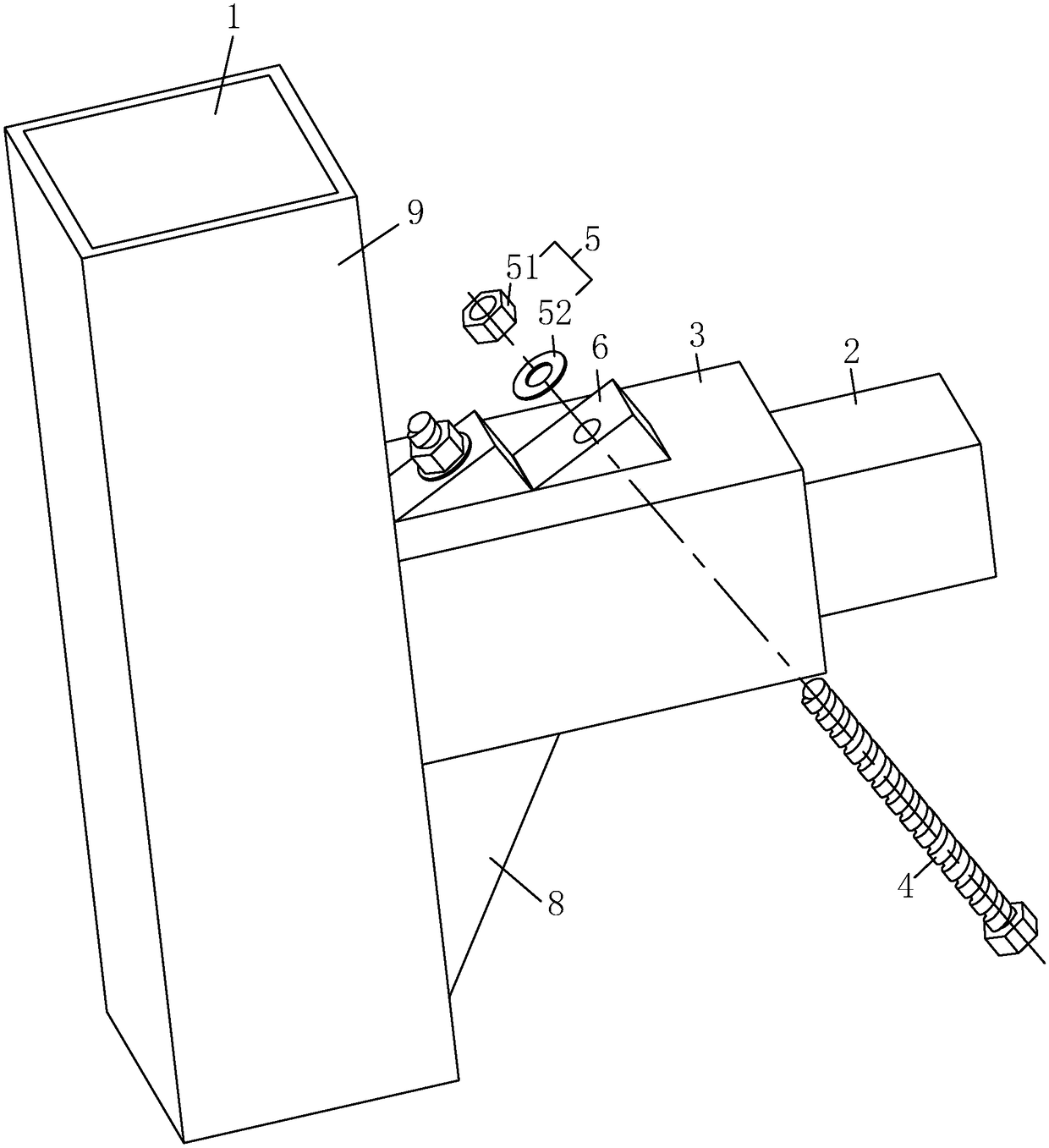

Wood-like building and steel-wood connecting structure thereof

ActiveCN108517972ALarge operating spaceIncrease contact areaBuilding constructionsSteel jacketFastener

The invention relates to the technical field of wood-like buildings, in particular to a wood-like building and a steel-wood connecting structure thereof, which comprises a steel structure supporting column and a wood beam. A steel jacket is welded on the steel structure supporting column and is arranged along the length direction of the steel structure supporting column. The end part of the wood beam is inserted into the steel jacket, a screw penetrating through the wood beam is arranged on the steel jacket, the screw is obliquely arranged with the head of the screw far away from the steel structure supporting column and the bottom of the screw close to the steel structure supporting column, the bottom of the screw is connected with a fastener in screw mode, the outer surface of the steeljacket is fixedly provided with an embossment which is abutted and matched with the fastener, and the embossment is parallel with the surface on which the fastener is abutted and matched. The embossment enables easier disassembly and assembly due to larger operation space of tightening or loosen the fastener, compared with the fastener being directly arranged on the steel jacket, so that the worker can disassemble and assemble the wood-like building more conveniently.

Owner:广东大喜装饰设计工程有限公司

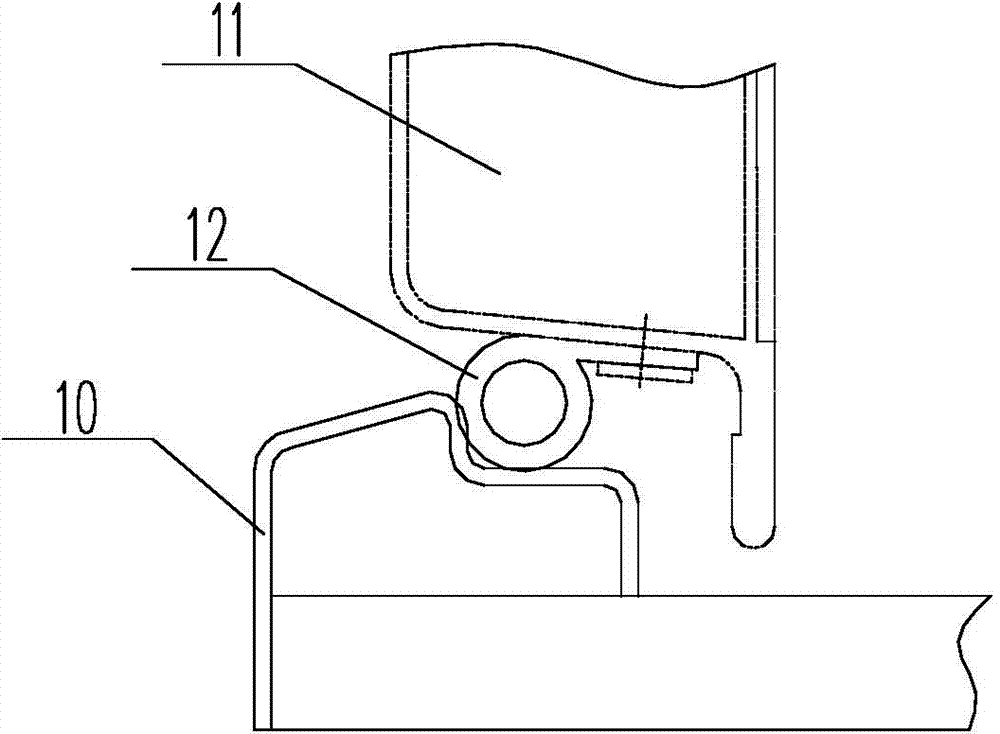

Sand wind preventing pedal of railway vehicle

The invention relates to a sand wind preventing pedal of a railway vehicle. The pedal comprises a case type box composed of an enclosure plate and a sealing plate, a pedal body is arranged in the enclosure plate in a welded mode, a frame is fixed to the upper edge of the enclosure plate, an L-shaped connecting iron part welded to the enclosure plate is arranged below the frame and fixedly welded to an iron floor, the side, close to an end beam, of the enclosure plate is fixedly welded to the end beam, the side, away from the end beam, of the enclosure plate is fixedly welded to an edge beam, a turnover plate is connected to the position above the enclosure plate through a hinge, a doorsill is welded to the front end of the turnover plate, an L-shaped groove is formed in the inner side of the doorsill, and the two groove walls of the L-shaped groove are suitable for abutting against a sealing rubber strip on a lower opening of a side door of the vehicle. According to the sand wind preventing pedal of the railway vehicle, the section form of the doorsill is optimized, contact with the side door is improved, and a good sealing effect is achieved; due to the fact that the enclosure plate and the pedal body are of an integrated case type structure, the side outline of the enclosure plate is consistent with the structure of a vehicle body, and the rigidity of the pedal is obviously improved.

Owner:CRRC NANJING PUZHEN CO LTD

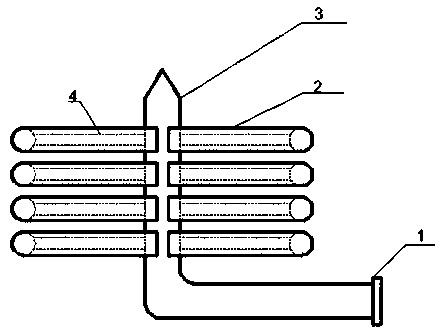

Air inlet device for variable-diameter carbonization tower

ActiveCN109775728AImprove air intake efficiencyImprove uniformityProductsReagentsSpray nozzleCarbonization

The invention discloses an air inlet device for a variable-diameter carbonization tower. The air inlet device comprises a main air inlet pipe which extends into the carbonization tower, multiple branch air pipes evenly distributed in the axial direction of the main air inlet pipe in a layer shape and an air blowing device arranged at the bottom of the carbonization tower. Multiple spray nozzles are evenly distributed on the branch air pipes, and gas discharged into the carbonization tower from the spray nozzles spirally ascends under the effect of the air blowing device. According to the air inlet device for the carbonization tower, the distribution uniformity of gas discharged into the carbonization tower is improved, the gas discharged out from the spray nozzles does not directly impacta heat exchange water tank above the air inlet device, impact and wear of a tube bundle in the heat exchange water tank are reduced, and the service life of the device is prolonged.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

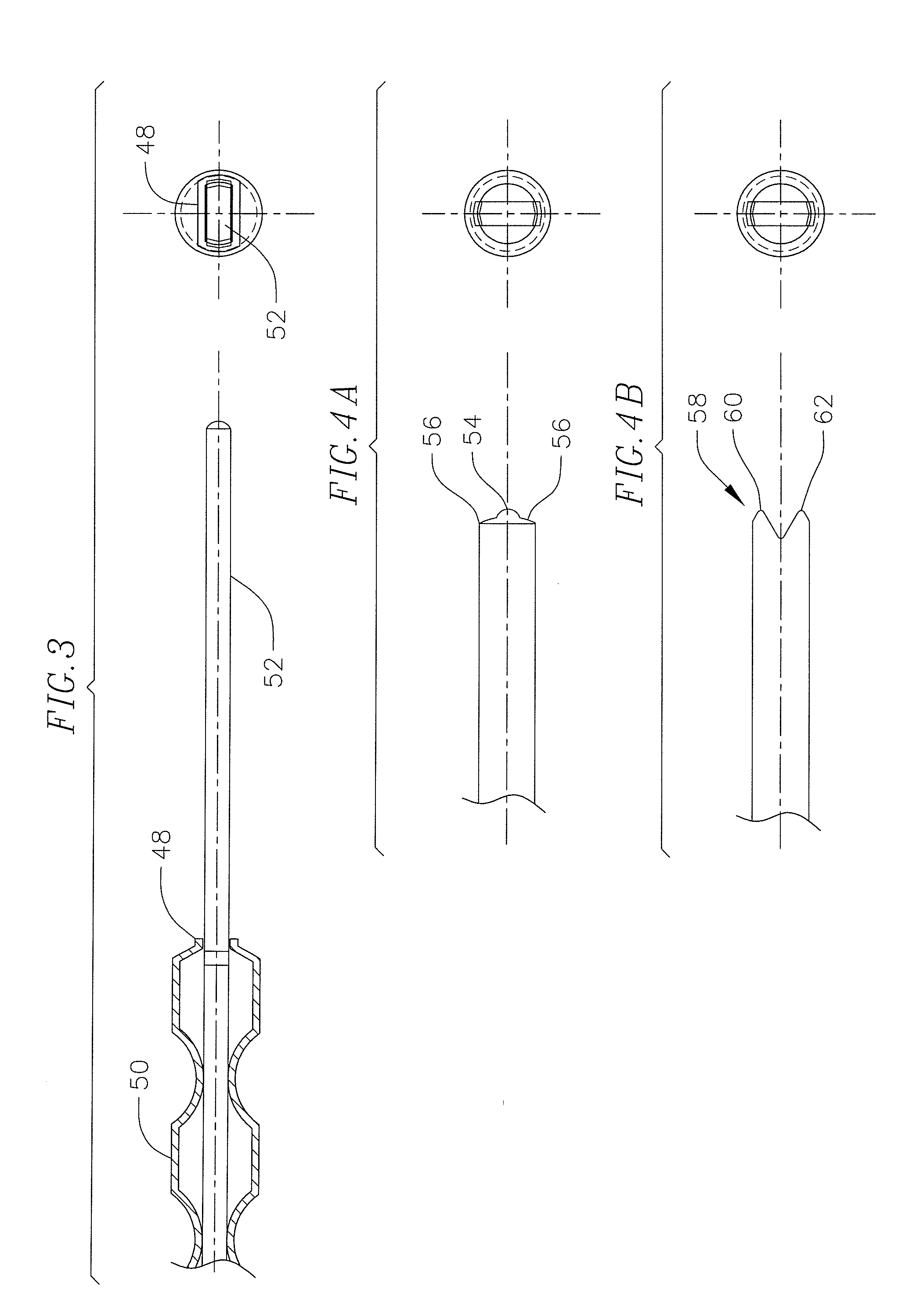

Flat plunger round barrel test probe

InactiveUS20100197176A1Improve contactImprove internal contactElectrical measurement instrument detailsElectric connection basesTorsion springBiomedical engineering

Owner:XCERRA

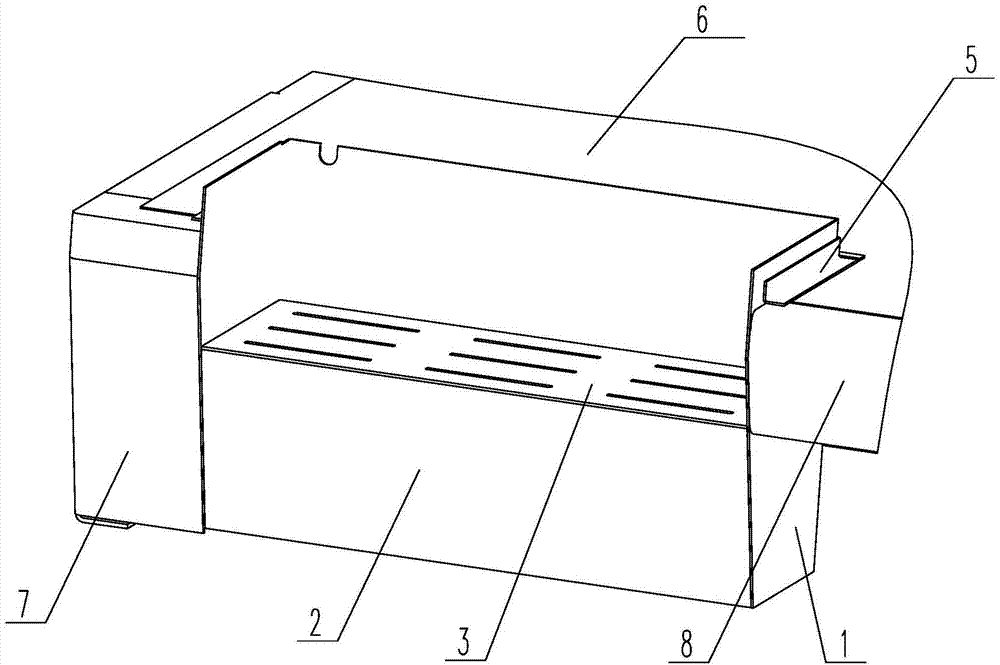

Smoke exhaust fireproof valve

The invention relates to a smoke exhaust fireproof valve. The smoke exhaust fireproof valve comprises a valve body and a fireproof blade assembly arranged in the valve body, and further comprises two sealing seats oppositely arranged on the inner side wall of the valve body, the fireproof blade assembly is arranged between the two sealing seats, and sealing grooves are formed in the sealing seats. Telescopic sealing parts used for being inserted into the sealing grooves are arranged on the side, close to the sealing seats, of the fireproof blade assembly. The traditional contact mode of blades and a valve body when the blades are in a closed state is improved, hard contact type closing is converted into soft contact type closing, rollers roll on the arc-shaped side edges of the sealing seats and cooperate with stretching and retracting of first springs, and damage to fireproof blades can be reduced in the closing process; and the service life of the fireproof blades is prolonged, due to soft contact type closing, through matched use of the sealing seats and the sealing parts, in the closing process of the fireproof blades, the sealing effect on the closing position of the valve body is achieved, and the fireproof effect of the fireproof blades on high-temperature smoke is improved.

Owner:顺达空调设备集团有限公司

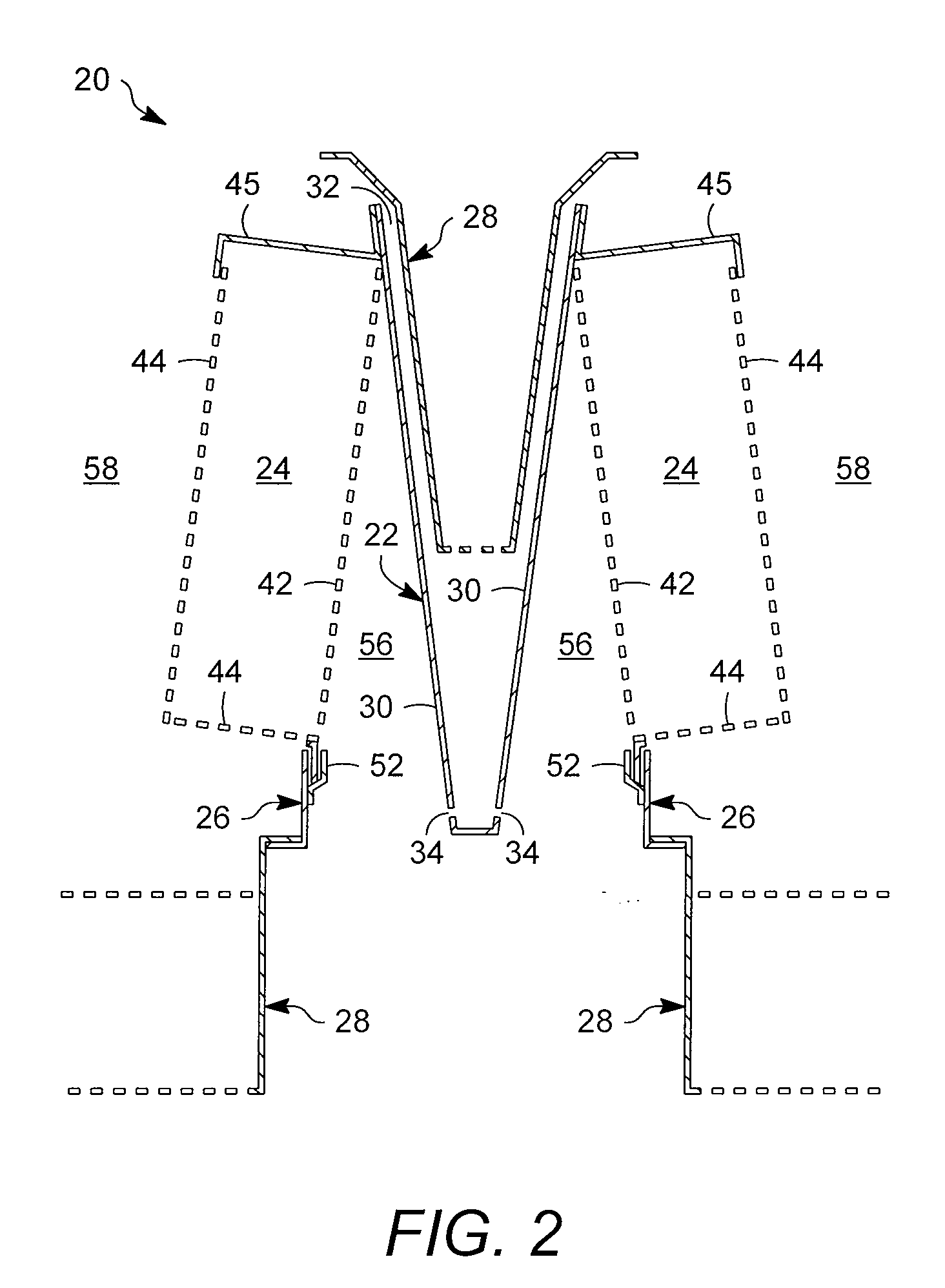

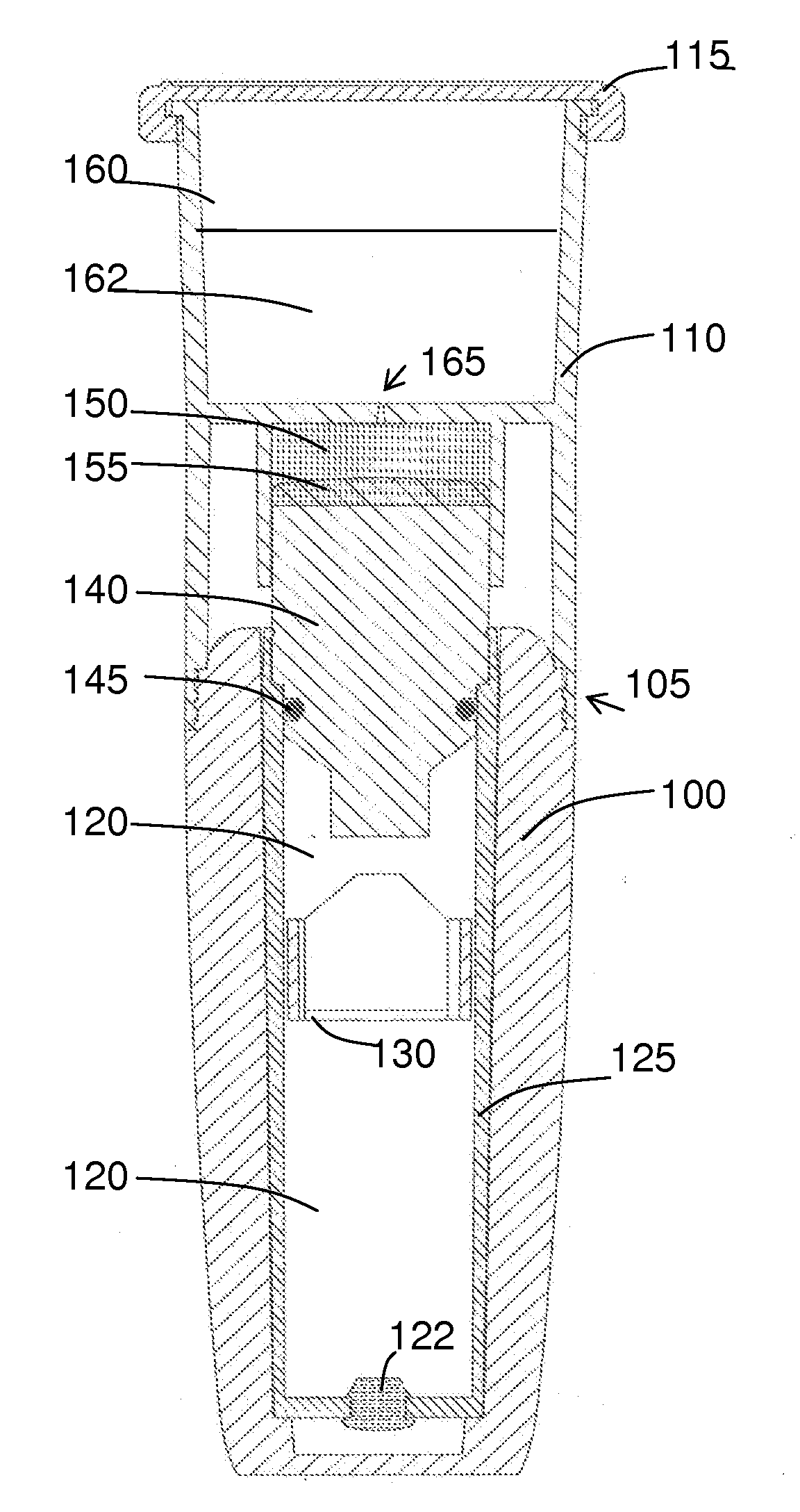

Configuration of contacting zones in vapor liquid contacting apparatuses

ActiveUS20110305616A1Improve contact efficiencyImprove contactRespiratorsCarburetting airChemistryPRIMARY CONTACT

Vapor-liquid contacting apparatuses comprising a primary contacting zone and a secondary contacting zone are disclosed. A representative secondary contacting zone is a secondary absorption zone, such as a finishing zone for subsequent contacting of the vapor effluent from the primary contacting zone to further remove impurities and achieve a desired purity of purified gas exiting the secondary absorption zone. The secondary contacting zone is disposed below the primary contacting zone, such that the secondary contacting zone, which must operate efficiently in removing generally trace amounts of remaining impurities, is more protected from movement than the more elevated, primary or initial contacting stages for bulk impurity removal. The apparatuses are therefore especially beneficial in offshore applications where they are subjected to rocking.

Owner:UOP LLC

Cooling device for locally anesthetizing an area on the surface of the body

InactiveUS20090254158A1Improve contactAvoid coldness injuryDomestic cooling apparatusLighting and heating apparatusChillerWarming up

A cooling device for locally and superficially anesthetizing an area on the surface of the body comprising a coolant fluid contacting a cooler. The cooler is moistened by a disinfection fluid. The cooling device is held in a refrigerator till use, then allowed to warm up to operation temperature. Then, the cooler is applied to the area on the surface of the body.

Owner:SHAPIRO OLEG

Device for indicating the state of a switching apparatus

ActiveUS20150194276A1Improve contactSimple and robust and reliable indicationContact testing/inspectionSwitch condition indicationElectrical switchingElectricity

A device for indicating the state of an electrical switching apparatus includes a movable contact arranged movable between a first and a second position. The device includes at least one protruding contact element arranged on the movable contact, at least one contact pin arranged in the close vicinity to the movable contact such that said contact element abuts the contact pin when the movable contact is in the first position and said contact element is at a distance from the contact pin when the movable contact is in the second position. The contact element and the contact pin form an electrical switch and a detector arrangement configured to detect when said electrical switch is closed and by that detect when the movable contact is in the first position.

Owner:HITACHI ENERGY SWITZERLAND AG

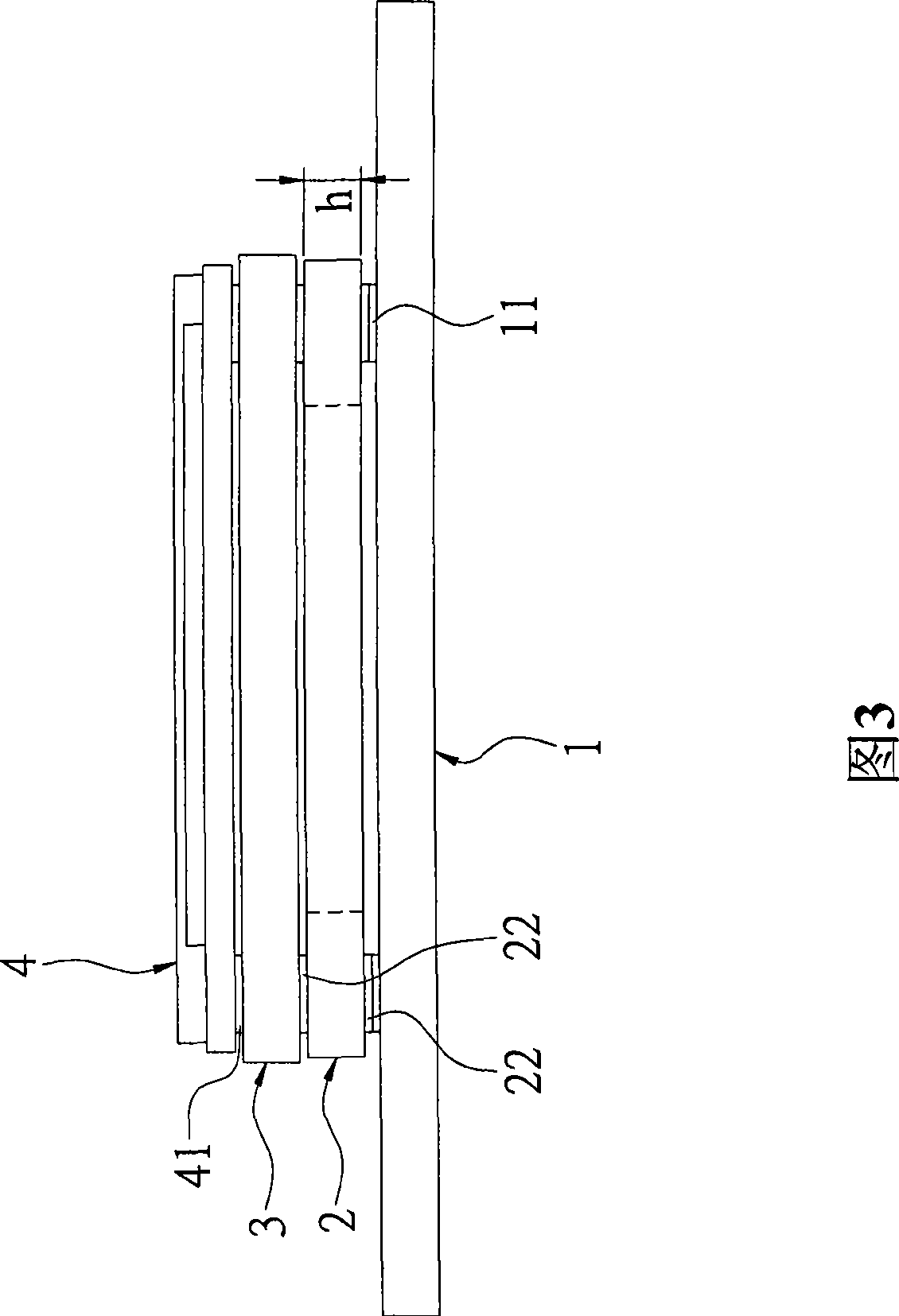

Test method and apparatus for pin element

ActiveCN101430354AImprove contactRelieve pressureElectrical testingMeasurement leads/probesTest fixtureEngineering

The invention relates to a test method of a pin element. The method comprises the following steps: providing a test support board which is provided with a plurality of test contacts; providing a test daughter board which is provided with a plurality of conductors throughout the top surface of the test daughter board to the bottom surface of the test daughter board, wherein, drop height forms on the test daughter board, and the test daughter board is arranged on the test support board, and the conductors are correspondingly contacted with the test contacts; arranging a conductive gasket on the test daughter board, wherein, the conductive gasket correspondingly contacts the conductors of the test daughter board; and arranging an object to be tested on the conductive gasket, wherein, the object to be tested is provided with a plurality of pins which contacts the conductive gasket, the object to be tested is pressed so that the pins of the object to be tested, the conductive gasket, the conductors of the test daughter board are electrically connected with the test contacts of the test support board to test the object to be tested. The invention further provides a test device for the pin element.

Owner:UNIVERSAL SCIENTIFIC INDUSTRIAL (SHANGHAI) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com