Sand wind preventing pedal of railway vehicle

A railway vehicle, anti-wind and sand technology, applied to railway car body components, transportation and packaging, etc., can solve the problems of severe longitudinal vibration and insufficient rigidity, and achieve the effects of increased rigidity, optimized cross-sectional form, and good manufacturability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

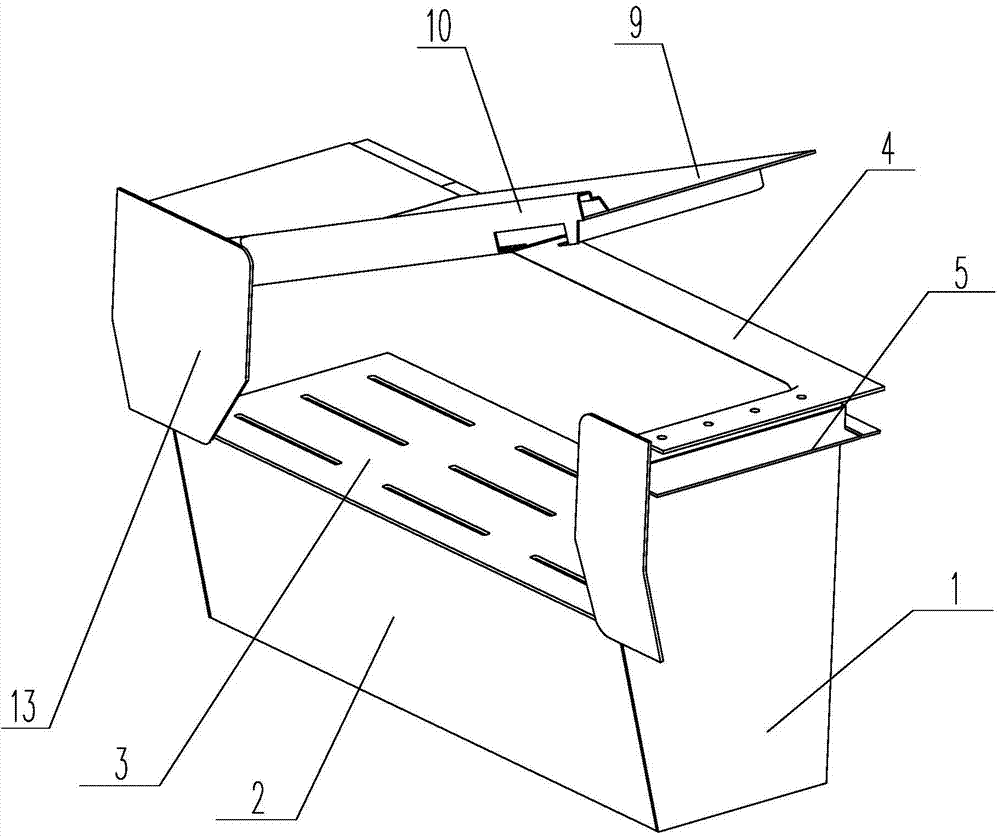

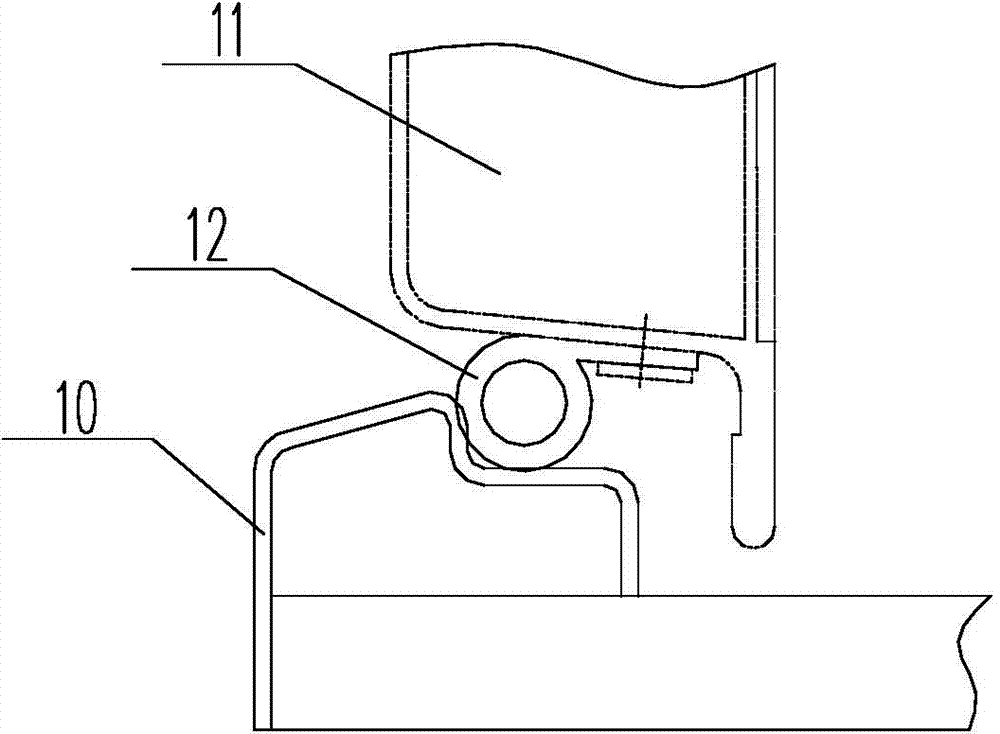

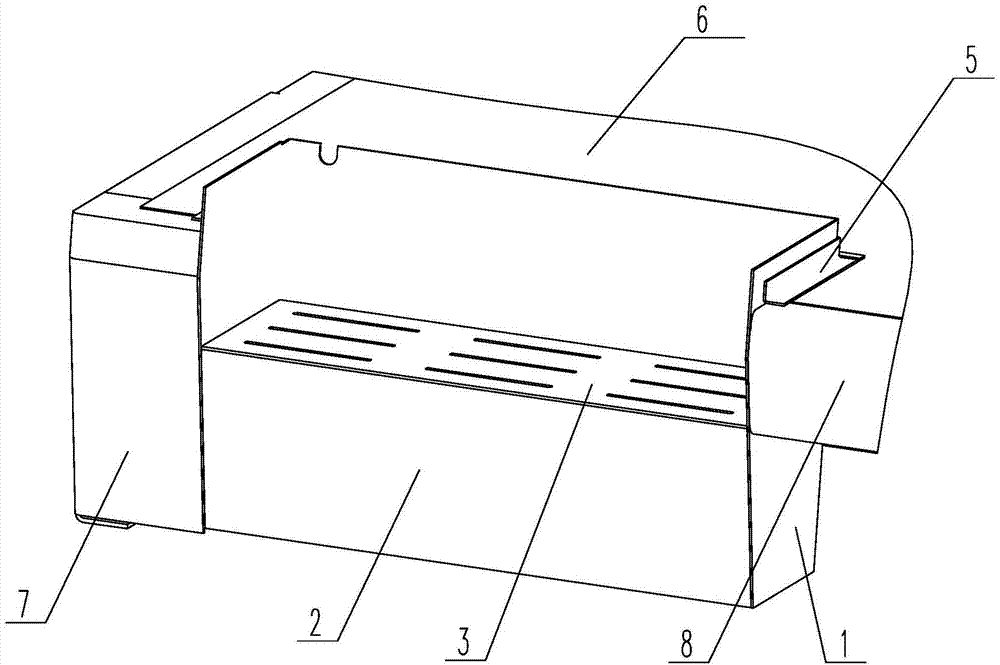

[0018] Such as figure 1 , figure 2 , image 3 As shown, the anti-wind sand pedal of the railway vehicle in this embodiment includes a box-type box body composed of a coaming plate 1 and a sealing plate 2. A pedal 3 is welded in the coaming plate 1. The pedal 3 is a lentil pattern steel plate. The pedal 3 is provided with several An oblong hole for preventing deposition of rainwater and sand; a frame 4 is fixed on the upper edge of the hoarding plate 1, and an L-shaped connecting iron 5 welded to the hoarding plate 1 is provided under the frame 4, and the connecting iron 5 is welded and fixed to the iron floor 6; near the end beam 7- The coaming 1 on the side is welded and fixed to the end beam 7, and the coaming 1 on the side away from the end beam 7 is welded and fixed to the side beam 8; the upper side of the coaming 1 is connected with a flap 9 through a hinge, and the front end of the replica is welded with a threshold 10. The inner side of the door sill 10 has an L-sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com