Wood-like building and steel-wood connecting structure thereof

A technology for connecting structures and steel structures, applied in the field of imitation wood buildings, can solve the problems of difficult insertion of tools, inconvenience in installation or disassembly, inconvenience in installation or disassembly of imitation wood buildings, etc. And the effect of easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

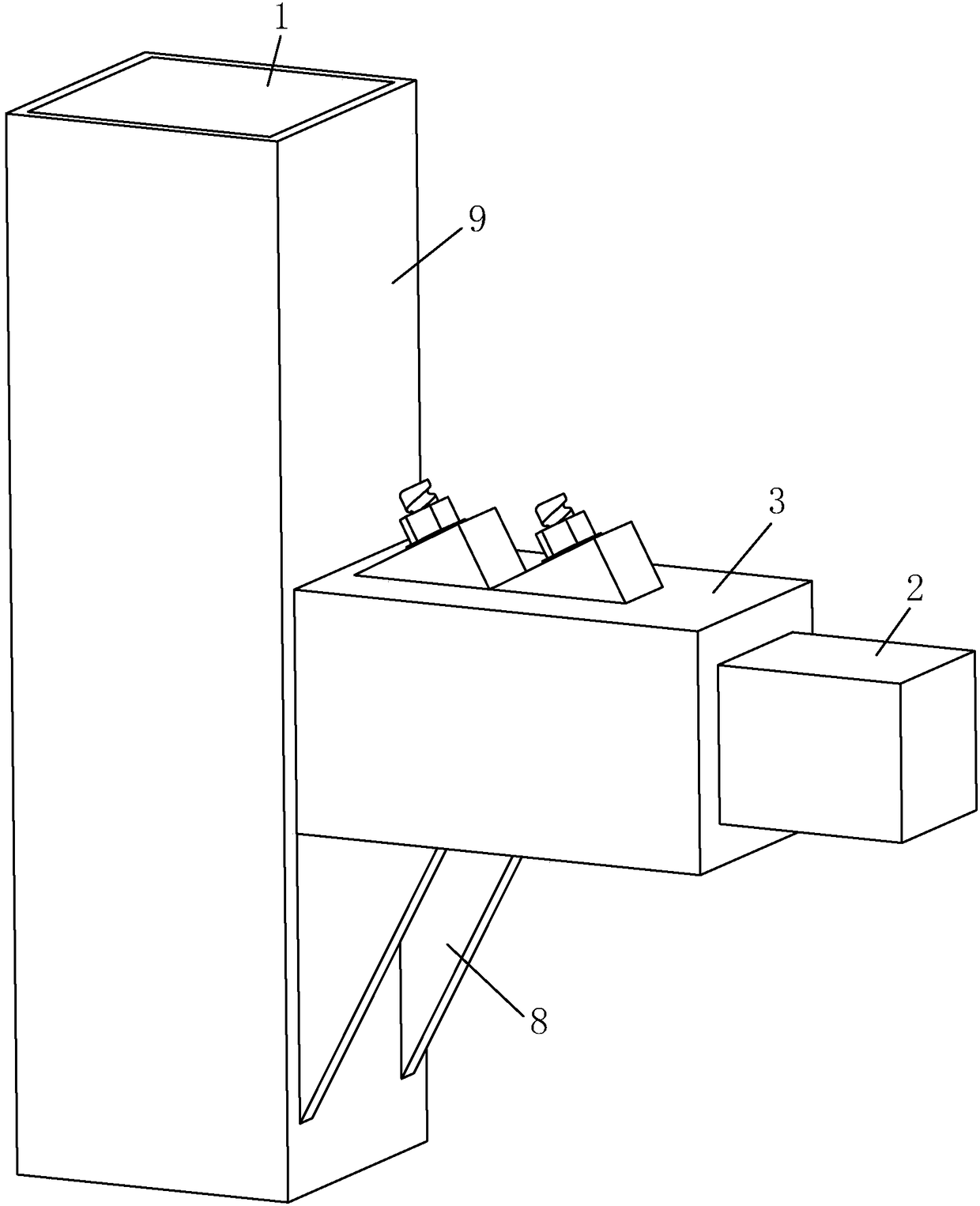

[0037] Embodiment 1: a steel-wood connection structure, see figure 1 , including a steel structure support column 1 and a wooden beam 2, a steel sleeve 3 is welded on the steel structure support column 1, the steel sleeve 3 is arranged perpendicular to the length direction of the steel structure support column 1, and the end of the wooden beam 2 is inserted into the steel sleeve within 3. Two right-angled triangle ribs 8 are welded between the lower surface of the steel sleeve 3 and the steel structure support column 1 . The ribs 8 can improve the bearing effect of the steel sleeve 3 on the wooden beam 2, and the bearing strength is higher. In addition, the outer wall of the steel structure support column 1 is glued and coated with wooden boards 9 . The planks 9 make the appearance of the steel structure support column 1 more beautiful, and improve the aesthetics of the whole imitation wood building.

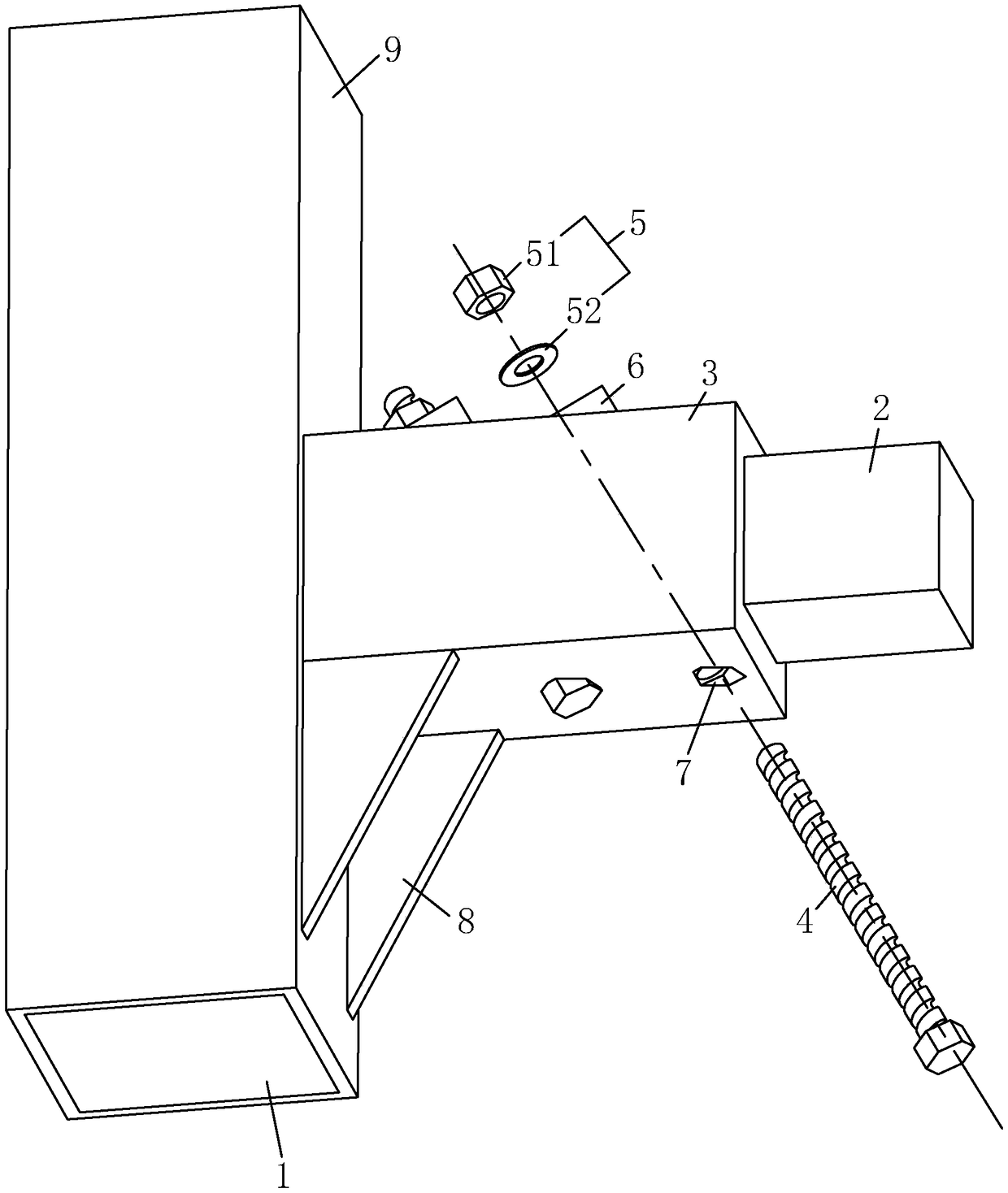

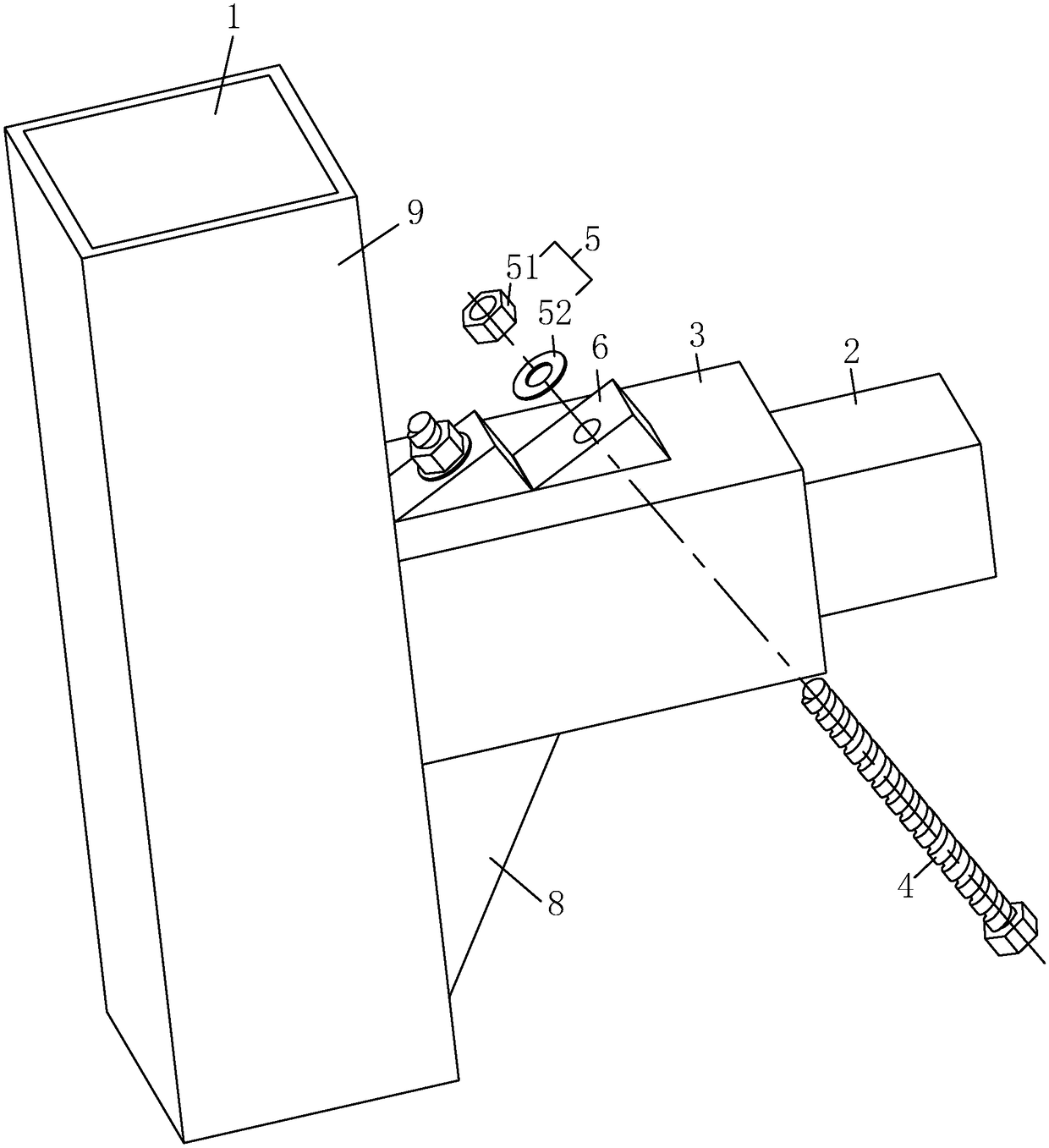

[0038] see figure 2 and image 3 , the upper and lower surfaces of th...

Embodiment 2

[0044] Embodiment two: a kind of wood-like building, see Figure 4 and Figure 5 , including four steel structure support columns 1 fixedly installed on the ground and sequentially connected to form a rectangle, and a top cover 10 fixedly installed directly above the four steel structure support columns 1 . Wherein, the ground is a level and poured concrete ground, and the top cover 10 is a laminated explosion-proof glass top cover 10 .

[0045] It also includes the steel-wood connection structure described in any one of claims 1 to 7; the tops of the four steel structure support columns 1 are sequentially connected with wooden beams 2 perpendicular to the steel structure support columns 1, and the wooden beams 2 and the steel structure support A steel-wood connection structure is fixedly installed between the columns 1 .

[0046] When installing or dismantling the imitation wood building, the steel structure support column 1 and the wooden beam 2 connected by the steel-wood...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com