Interface convection inducing bioreactor and applications thereof

A bioreactor and induced interface technology, applied in biological water/sewage treatment, waste fuel, chemical instruments and methods, etc., can solve the problem of high equipment investment and maintenance costs, limited processing capacity, and no real operation of continuous fermentation devices, etc. problems, to achieve the effect of improving the efficiency of sewage treatment and renewable energy, reducing the use and investment and operation costs, and speeding up the start-up and operation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

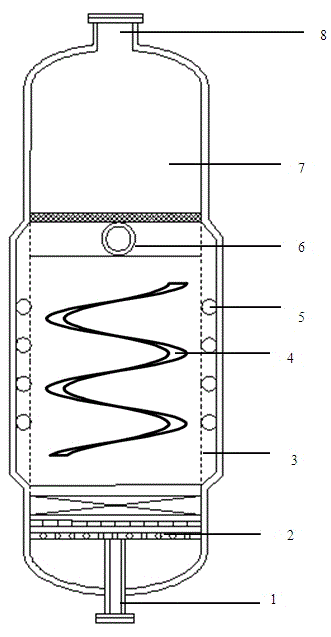

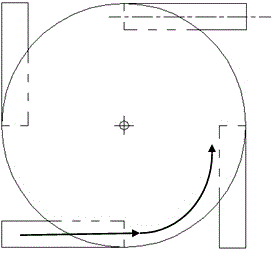

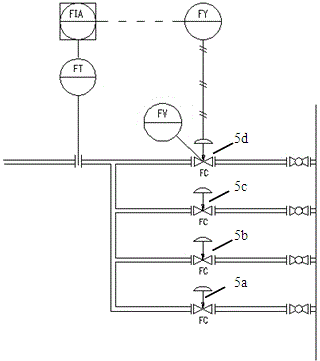

[0033] Such as figure 1 As shown, the main body of the reactor is mainly composed of eight parts, which are in order from bottom to top: inlet pipe 1, water distribution device 2, diversion belt 4, pulse tube 5, purified water outlet 6, gas collection bag 7 and gas discharge Pipe 8, the water distribution device 2 is composed of distributors and structured packing, the guide zone 4 and the pulse tube 5 are the main components of the induced fermentation zone 3, the guide zone 4 is a helical coiled metal component, and the pulse The tube 5 is introduced along the tangential direction of the inner wall of the induced fermentation zone, and is distributed in four positions, and the angle between any two pulse tubes is 90° or 180°. The diameter D5 of the diversion zone 4 is equivalent to the inner diameter D1 of the induction zone, the bandwidth D6 is 15% of the diameter D5 of the diversion zone, and the height difference H4 between layers of rotation is 1 / 4 of the height H1 of th...

Embodiment 2

[0041] An induced interface convection bioreactor, the reactor is in order from bottom to top: inlet pipe, water distribution device, induced fermentation area, purified water outlet, gas collection bag and gas discharge pipe, the water distribution device consists of distributor and Structured packing, the induced fermentation zone is equipped with diversion belts and pulse tubes, the guide zone is a helical coiled metal member, and the pulse tubes are introduced along the tangential direction of the inner wall of the induced fermentation zone, distributed in four positions, any The angle between the two pulse tubes is 90° or 180°. The height (H3) of the water distribution device generally does not exceed 1 / 5 of the inner diameter (D1) of the induction zone. The diameter D5 of the diversion zone is equivalent to the inner diameter D1 of the induction zone, and the bandwidth D6 is 10% of D5. The interlayer height difference H4 of the helical rotation of the diversion zone is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com