A method for manufacturing tree ear mushroom lavor improved healthy functionality and expiration date

A manufacturing method and functional technology, which is applied in food preservation, food shaping, dry preservation of meat/fish, etc., can solve the problems of insufficient absorption by consumers, low content of fungus, and short product life, etc., to improve Healthy functionality and shelf life, increased ingredient content, and improved productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

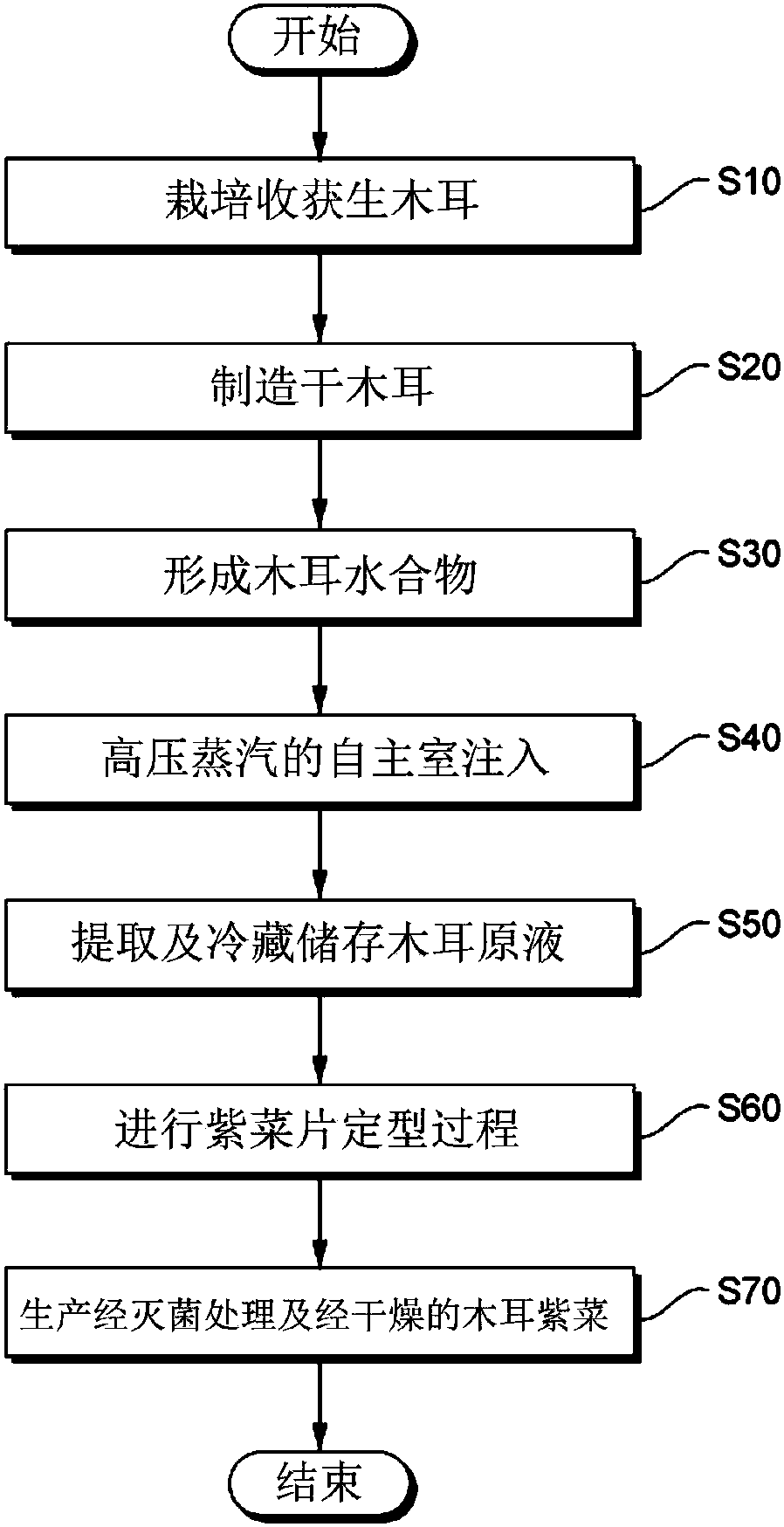

Method used

Image

Examples

Embodiment 1

[0079] Embodiment 1: Use the frame for setting the shape of the seaweed sheet that the fungus powder and the fungus stock solution are mixed together with the original material

[0080] a1) The raw fungus cultivated on the farm can be used directly, but the dried fungus that has been soaked in rock pan water for about 3 hours can be used after drying and storage.

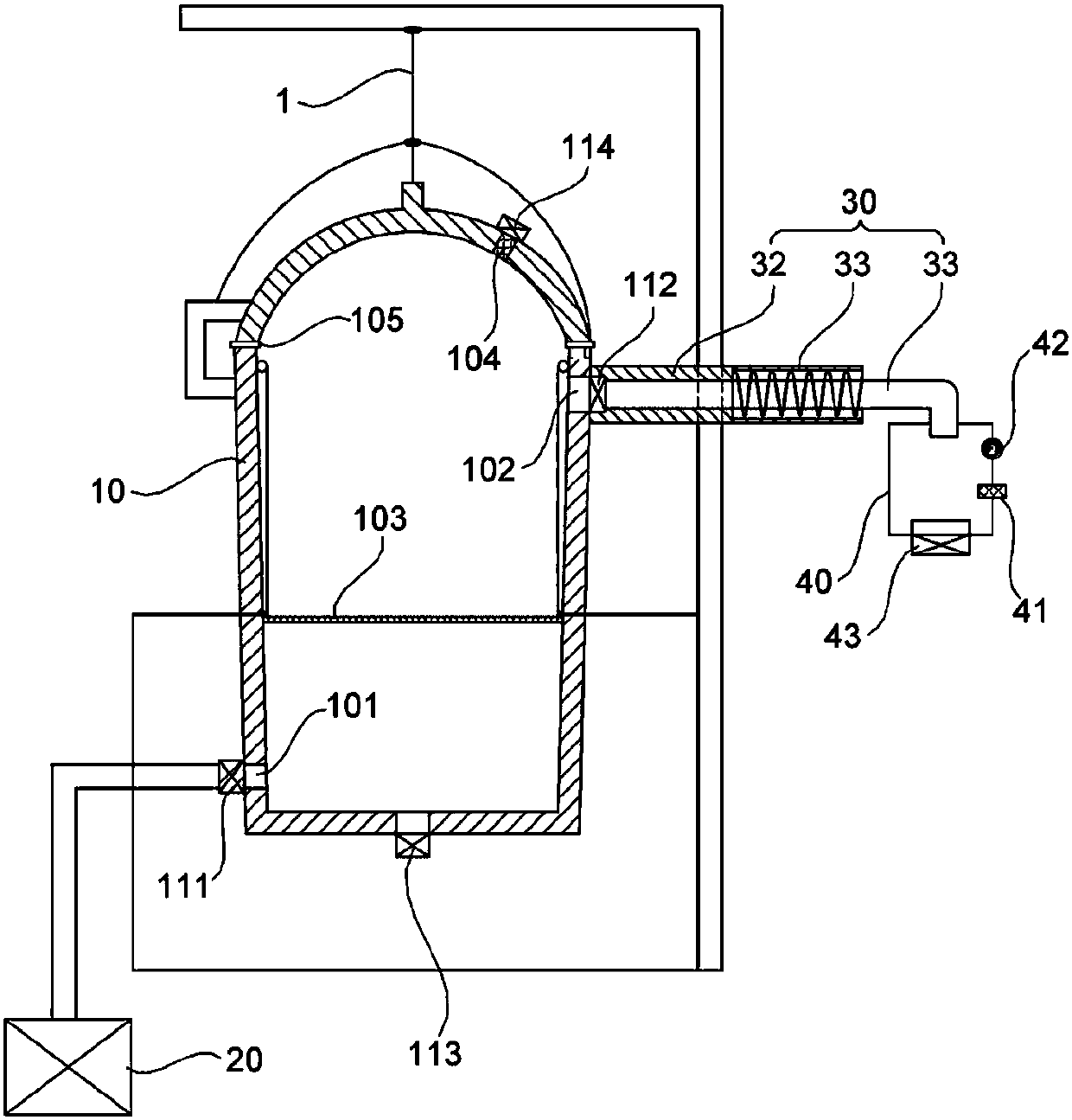

[0081] b1) Put the green fungus cultivated in the natural environment into the independent chamber connected with the high-pressure steam engine [pressure is 5-10kg / cm 2 , the operating weight is 450kg], open the inlet valve and close the outlet valve (but depending on the length of the exhaust pipe or the surrounding temperature, there may be some gaps in the time) for about 30 minutes to about one hour, then open the outlet valve and collect Steam is used for cooling, while the fungus stock solution can be extracted. The stock solution storage temperature can be between 5°C and 15°C.

[0082] c1) Stir the washed...

Embodiment 2

[0084] Embodiment 2: Under the situation of using no fungus powder, only use the fungus stock solution and the laver sheet sizing frame that is mixed with the original material

[0085] a2) The raw fungus cultivated on the farm can be used directly, but the dried fungus that has been soaked in rock pan water for about 3 hours can be used after drying and storage.

[0086] b2) Put the green fungus cultivated in the natural environment into the independent chamber connected with the high-pressure steam engine [pressure is 5-10kg / cm 2 , the operating weight is 450kg], open the inlet valve and close the outlet valve (but depending on the length of the exhaust pipe or the surrounding temperature, there may be some gaps in the time) for about 30 minutes to about one hour, then open the outlet valve and collect Steam is used for cooling, while the fungus stock solution can be extracted. The stock solution storage temperature can be between 5°C and 15°C.

[0087] c2) Stirring the wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com