Novel mask film and evaporation device

A mask and a new type of technology, applied in the field of new masks and evaporation devices, can solve the problems of mask substrate damage, mask pollution, difficult processing, etc., to reduce the possibility of damage, optimize contact methods, and prevent pollution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

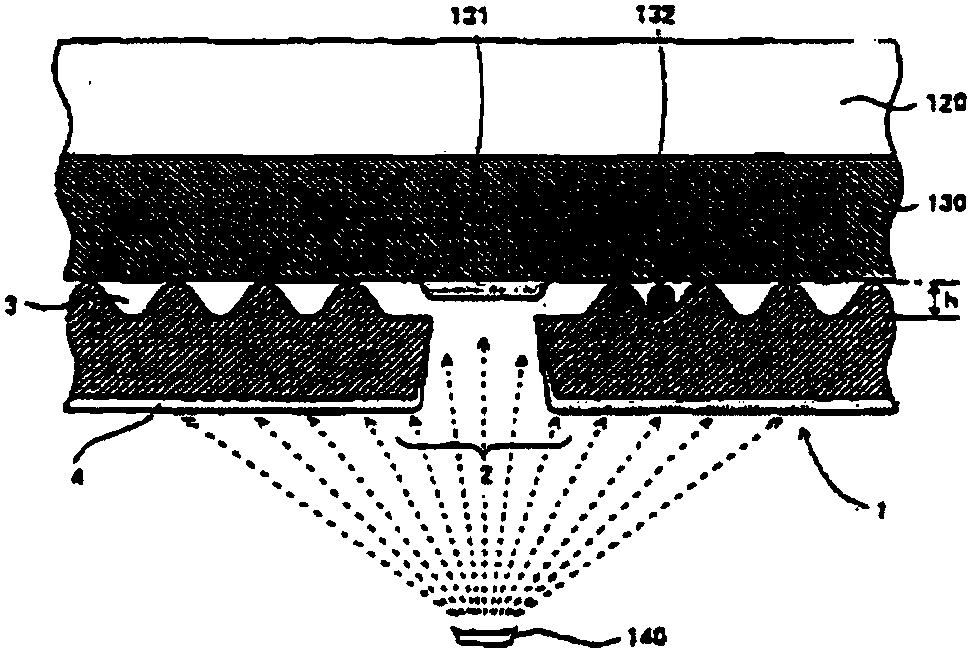

[0035] see Figure 4 A novel mask disclosed.

[0036] The new mask includes: a mask main body 1 and a mask frame 2 designed integrally with the mask main body 1 and surrounding the mask main body 1, and a specified pattern is formed on the mask main body 1; the mask Mounting holes are distributed on the membrane frame 2 and a supporting structure 3 is arranged in the mounting holes.

[0037] The new mask includes: a mask main body 1 and a mask frame 2 integrally designed with the mask main body 1 and surrounding the mask main body 1, which is the main structure of the mask in this embodiment.

[0038] in:

[0039] The mask main body 1 has a specified pattern formed thereon.

[0040] The mask frame 2 has mounting holes distributed thereon and a supporting structure 3 is arranged in the mounting holes.

[0041] The top of the support structure 3 is in contact with the substrate, which optimizes the contact mode between the substrate and the mask frame. On the one hand, a gap...

Embodiment 2

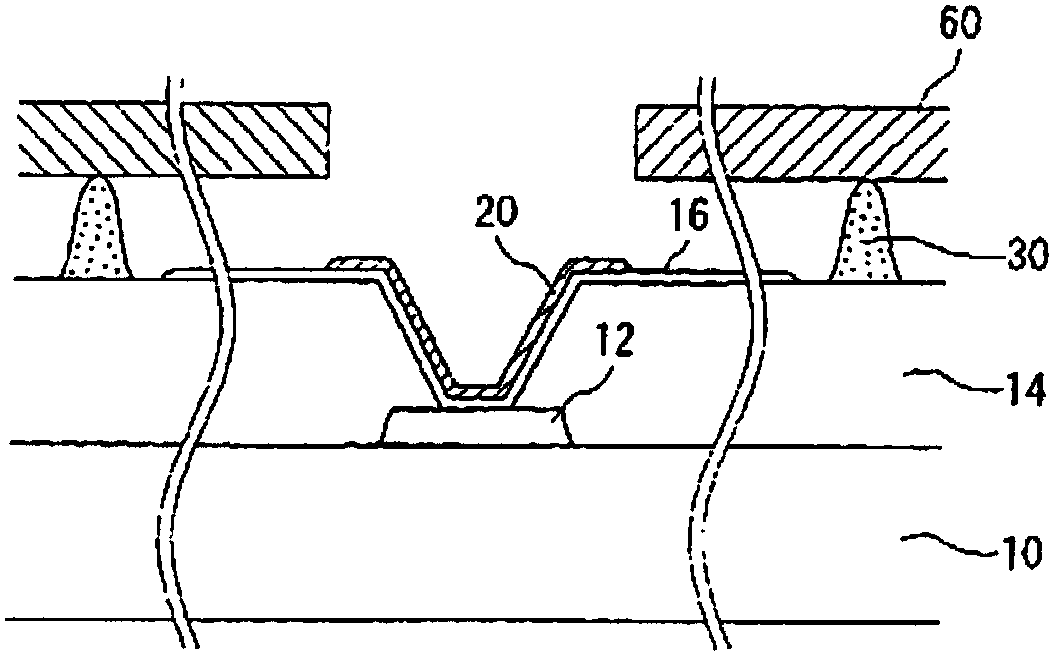

[0047] see Figure 5 A novel mask disclosed.

[0048] Different from Embodiment 1, in this embodiment, the support structure 3 includes: a support member 5 disposed in the installation hole and a pad 4 installed at the free end of the support member 5 .

[0049] Based on the above design, the support structure 3 is composed of two parts, namely the support 5 and the liner 4, the support 5 is arranged in the installation hole for supporting the liner 4; the liner 4 is installed At the free end of the support 5 there is direct contact with the substrate 6 .

[0050]Based on the above design, the support member 5 of the support structure 3 and the liner 4 can be fixedly connected or detachably connected, and the liner can be replaced during long-term use.

[0051] Based on the above design, support members 5 or pads 4 with the same height or different heights can also be provided at different positions on the mask frame.

[0052] In the case of high flatness on the side of the...

Embodiment 3

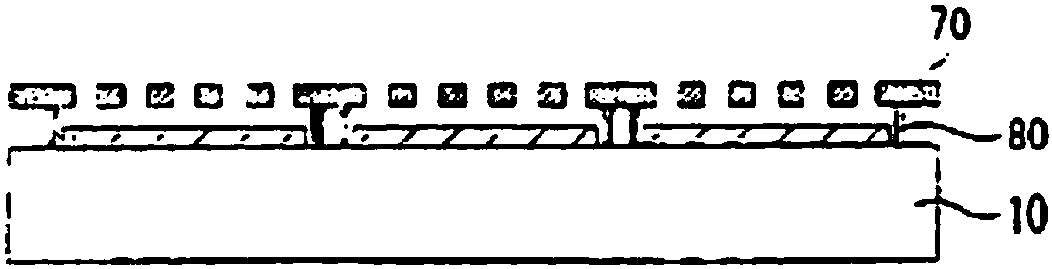

[0055] see Image 6 with Figure 7 A novel mask disclosed.

[0056] Different from the second embodiment, in this embodiment, the support member 5 is elastic.

[0057] Image 6 , the elastic support member is in a compressed state, and at this time, the distance between the substrate and the mask frame is relatively small.

[0058] Figure 7 , the elastic support is in a stretched state, and at this time, the distance between the substrate and the mask holder is relatively large.

[0059] Based on the above design, in order to be able to adapt to the substrate, the specific adjustment method of the height of the support structure 3 still depends on the mask holder.

[0060] However, different from Embodiment 2 and Embodiment 1, in this embodiment, the support structures 3 at different positions on the mask frame will have different heights. In the case of uneven masks, elastic supports of different heights can be used The components are used for height compensation, so t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com