Piston pump assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

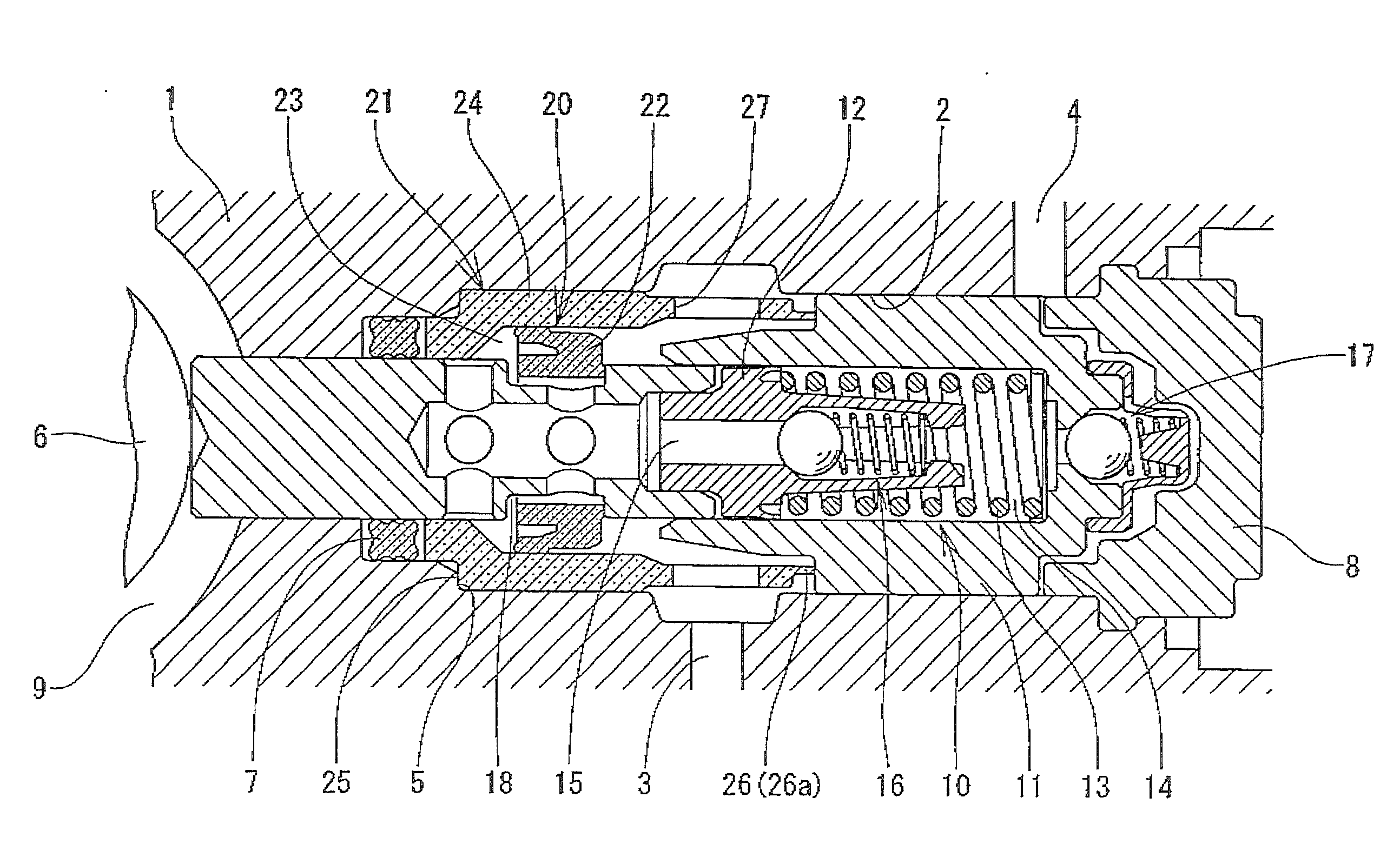

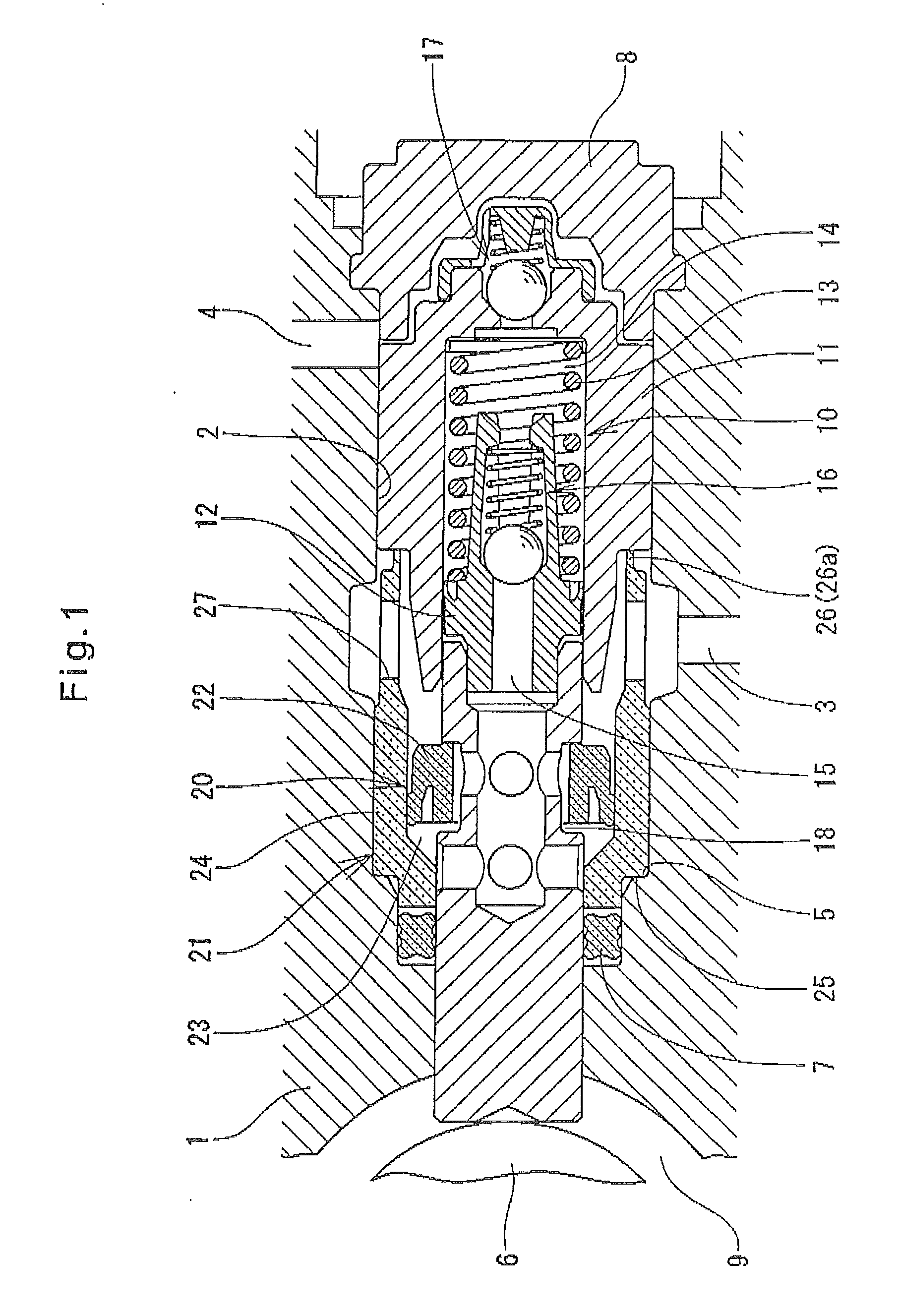

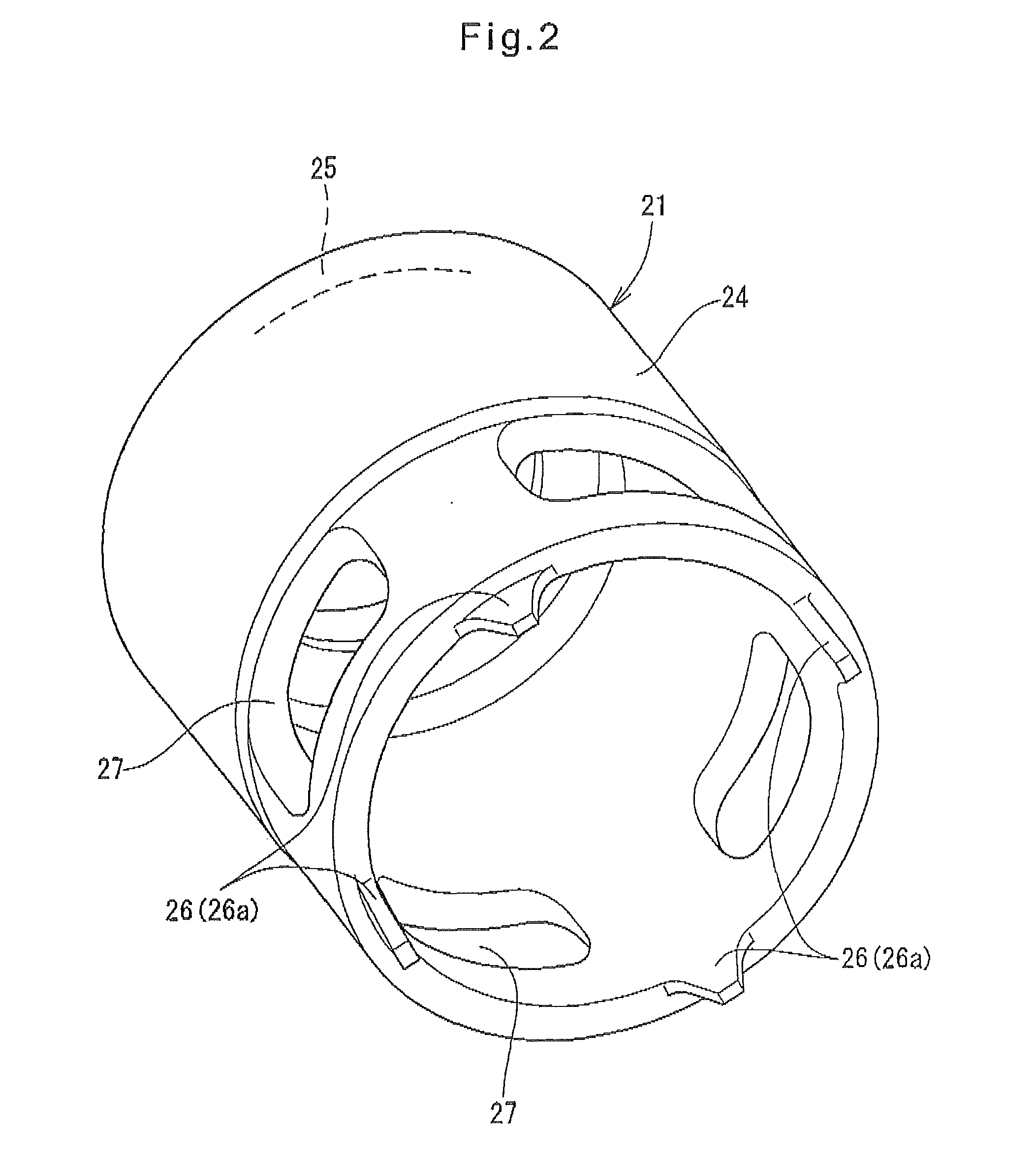

[0045]Now the piston pump assemblies embodying the present invention are described with reference to FIGS. 1 to 4.

[0046]The piston pump assembly shown in FIG. 1 comprises a pump housing 1, a first pump 10, a second pump 20, an eccentric cam 6 for driving the first and second pumps, and an annular seal member 7, which is described below.

[0047]The pump housing 1 is formed with a piston hole 2, a fluid inlet port 3 communicating with the piston hole 2, and a discharge port 4 through which fluid drawn by the pumps are discharged. The first and second pumps 10 and 20 are mounted in the piston hole 2. The inlet of the piston hole 2 is liquid-tightly sealed by an end plug 8. The outlet of the first pump 10 communicates with the discharge port 4 through a chamber defined by the inner surface of the end plug 8.

[0048]The first pump10 includes a first cylinder member 11 mounted in the piston hole 2, a first piston 12 having one end thereof slidably inserted in the first cylinder member 11, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com