Test method and apparatus for pin element

A test method and technology of a test device, applied in the direction of measurement device, measurement of electricity, measurement of electric variables, etc., can solve the problems of poor contact, large application, pressure damage to the object 9 under test, etc., to reduce pressure and improve contact. , the effect of reducing the probability of damage due to pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

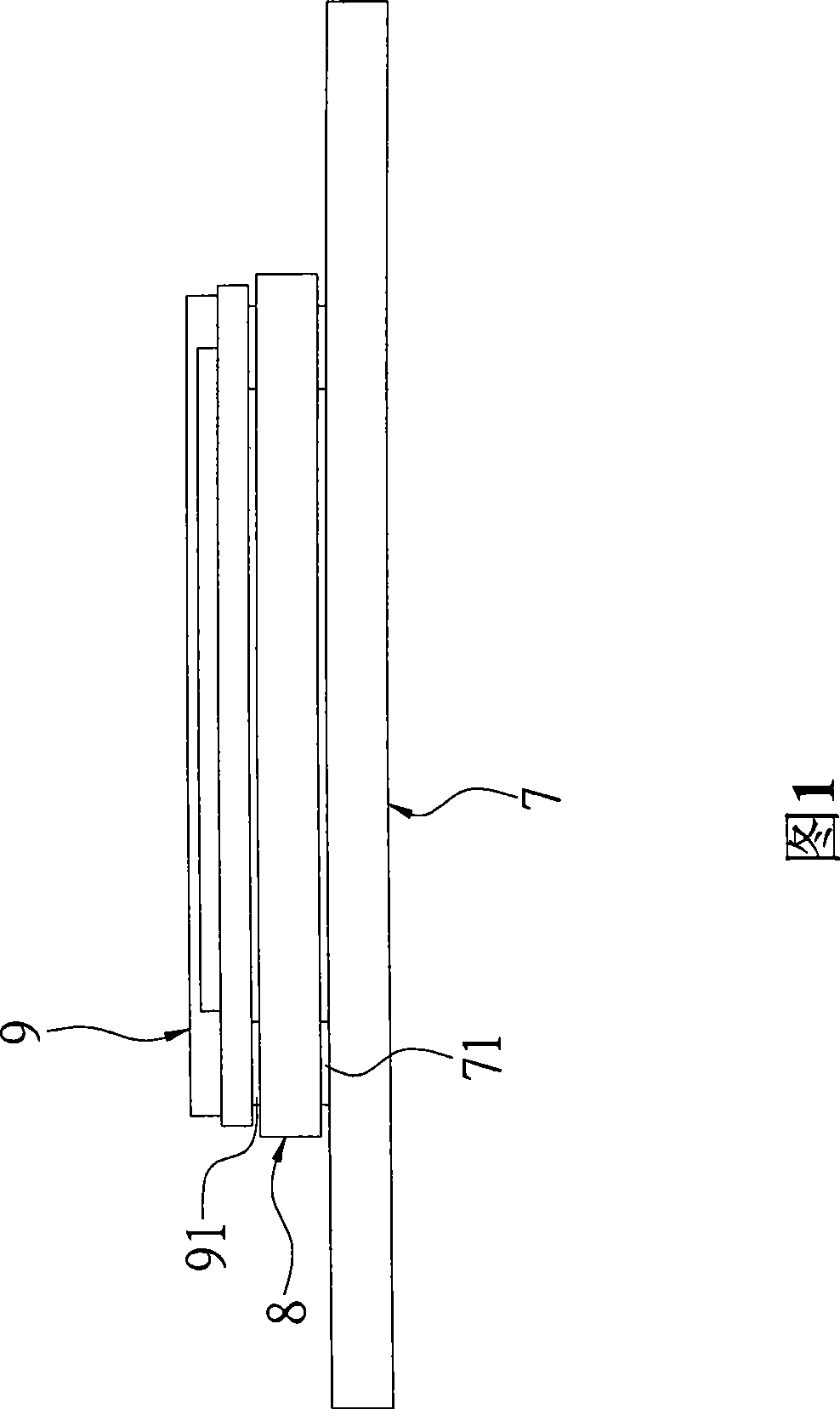

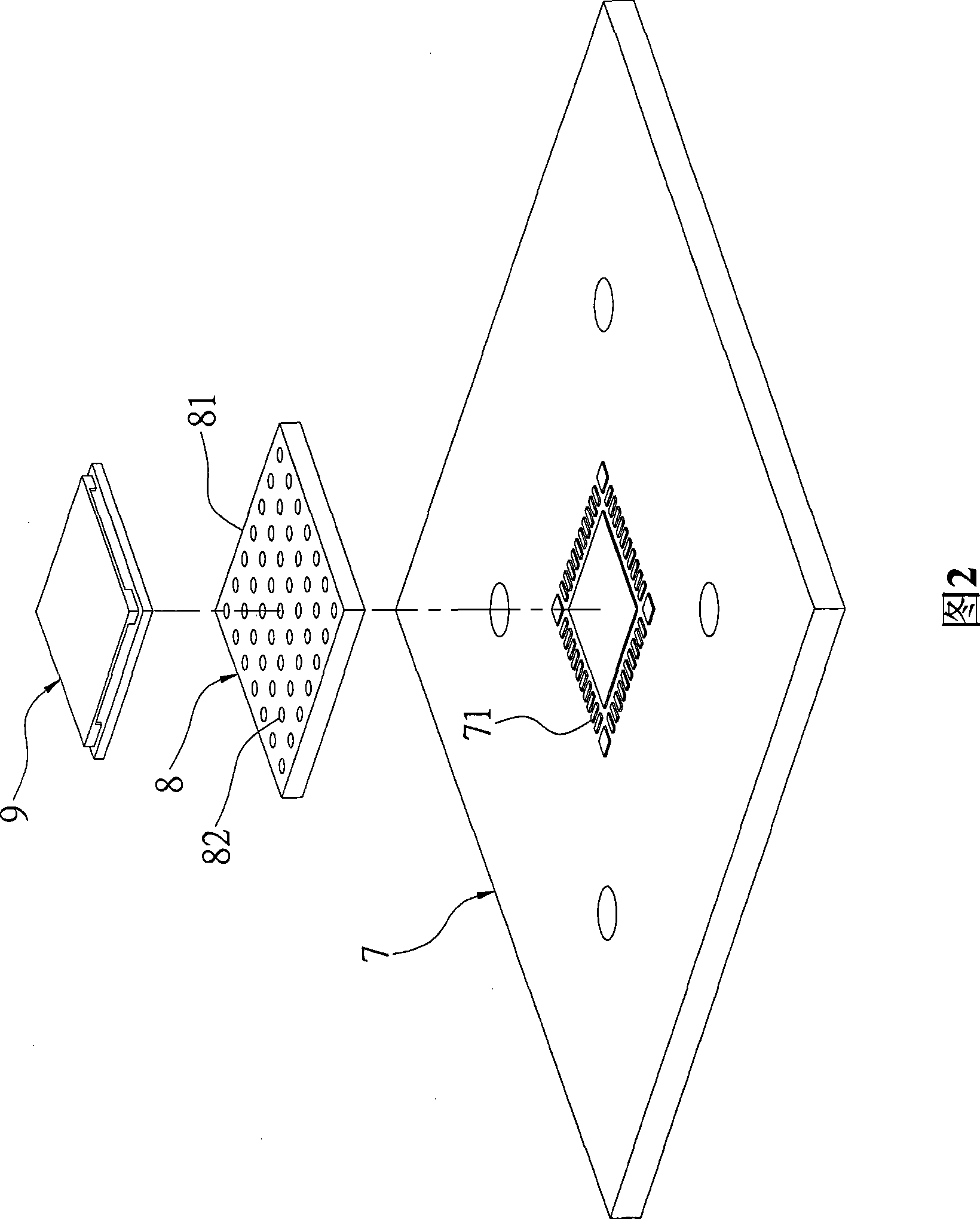

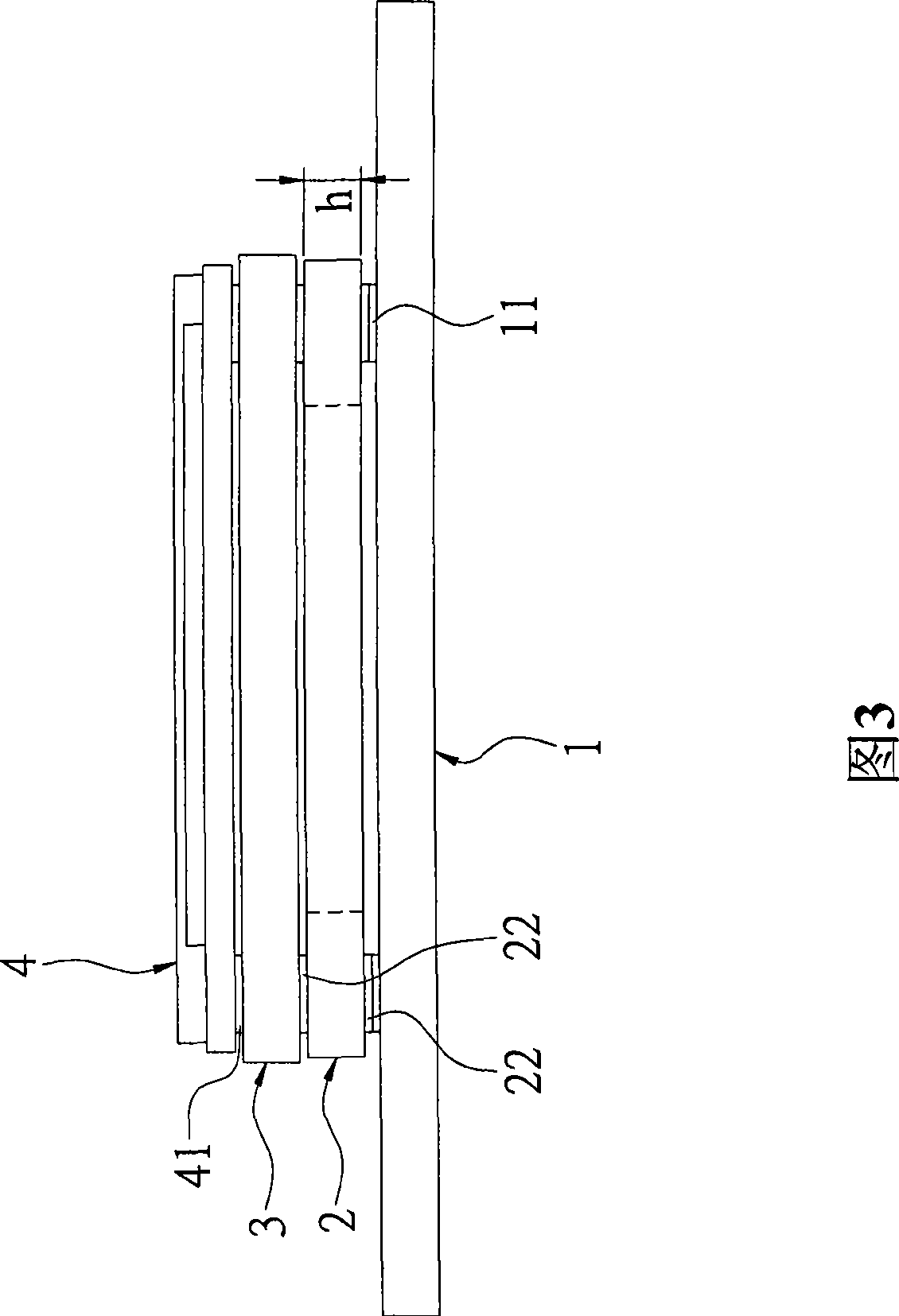

[0034] Please refer to Fig. 3 to Fig. 5, the present invention provides a kind of testing method of pin component, especially a kind of testing method suitable for the electronic part (under test) of LGA pin form, comprise steps as follows:

[0035] (1) Firstly, a test carrier board 1 is provided. The top surface of the test carrier board 1 has a plurality of test contacts 11 corresponding to the plurality of pins 41 on the bottom surface of the object under test 4 .

[0036] (2) A test sub-board 2 is provided. A square hollow part 21 is formed inside the test sub-board 2. The hollow part 21 penetrates from the top surface of the test sub-board 2 to the bottom surface. The test sub-board 2 is placed on the hollow part. 21 is provided with a plurality of conductors 22 at the periphery, the conductors 22 correspond to the test contacts 11, and the conductors 22 penetrate from the top surface of the test sub-board 2 to the bottom surface; in this embodiment, The test sub-board 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com