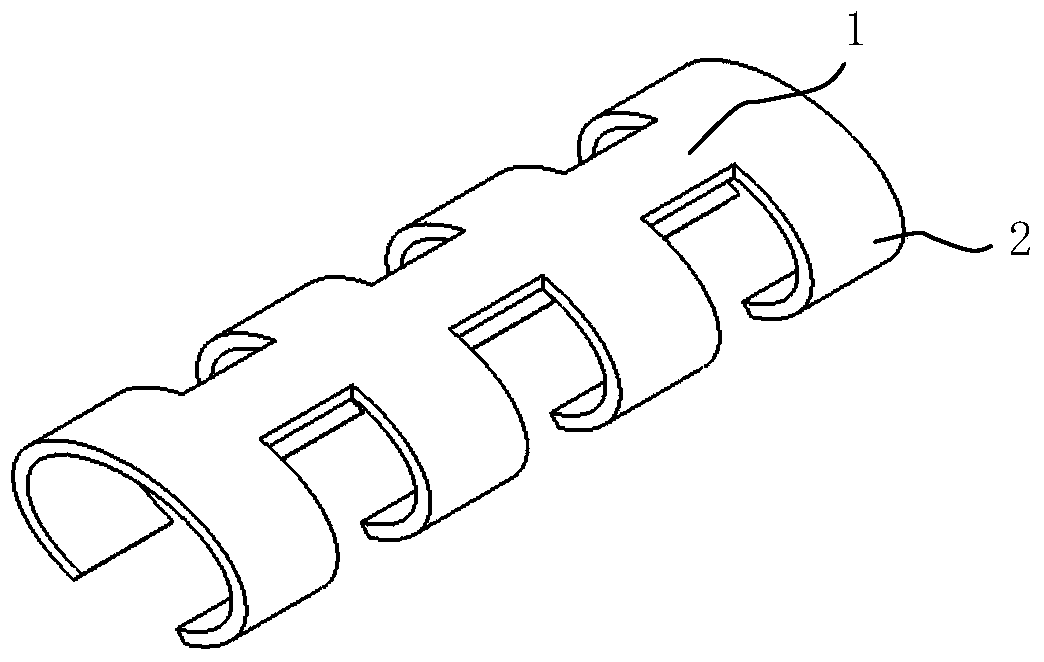

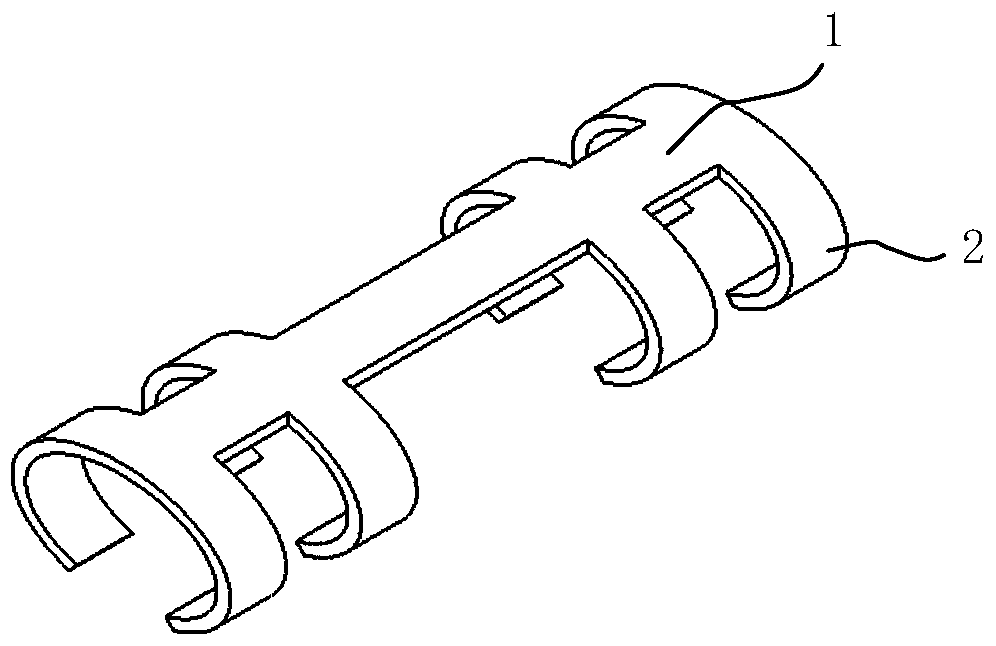

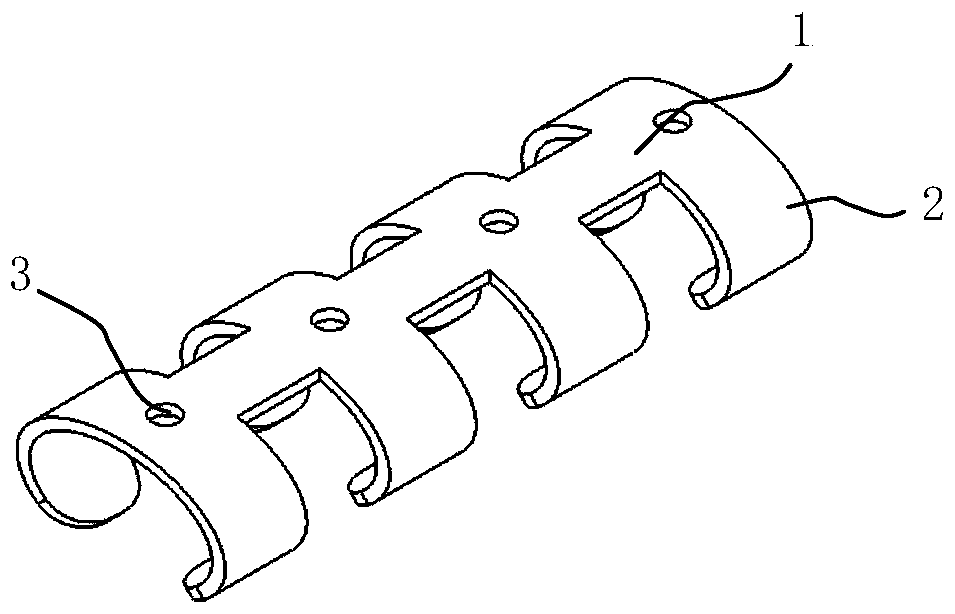

An encircling fracture internal fixation device and its preparation method

A fixed device, embracing technology, applied in medical science, surgery, etc., can solve the problems of non-degradable metal materials, non-degradable, and inconvenience for patients, achieve excellent biocompatibility, reduce pain and inflammation, and accelerate clinical healing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0060] The preparation method of the embracing fracture internal fixation device of the present invention can be a conventional processing and molding method in the polymer field, including but not limited to injection molding, injection molding-laser cutting molding, hot pressing-laser cutting molding, extrusion molding, extrusion- Laser cutting molding, etc.

[0061] For the processing and molding of cross-linked polymers, the cross-linking reaction of the polymer can occur during processing or after processing. The crosslinking reaction adopts crosslinking methods such as ultraviolet irradiation crosslinking or thermal polymerization.

[0062] Optionally, during the processing and molding process, an orientation force is applied to the polymer melt to orient the molecules of the degradable polymer material, so that the obtained polymer has higher mechanical properties; or the device is heated and stretched after molding The copolymer molecules are oriented at a temperature...

Embodiment 1

[0066] Preparation of linear degradable polymer embracing fracture internal fixation device with shape memory function

[0067] (1) Synthesis of degradable polymers

[0068] The reaction kettle was vacuum-dried at 60°C for 1 hour, and L-lactide (L-lactide) was added to the reaction kettle under nitrogen protection, vacuum-dried for 1 hour, and then 1,4-butanediol (M / I = 54.9), 100ppm of stannous octoate, heated to 140°C for 10h through ring-opening polymerization to synthesize polylactic acid PLLA-diol with terminal hydroxyl groups, dissolved the obtained solid in dichloromethane, filtered through anhydrous ethanol precipitation, and vacuum-dried. The final product was obtained with a number average molecular weight of about 8000.

[0069] The reaction kettle was vacuum-dried at 60°C for 1 hour, caprolactone was added to the reaction kettle under nitrogen protection, and vacuum-dried for 1 hour, then 1,4-butanediol (M / I=69.3), 100ppm octanoic acid sulfide Tin, heat up to 120...

Embodiment 2

[0076] Preparation of cross-linked degradable polymer embracing fracture internal fixation device with shape memory function

[0077] (1) Synthesis of degradable polymer prepolymer

[0078] Reactor was vacuum-dried at 60°C for 1 hour, and L-lactide (L-lactide), glycolide (glycolide) and initiator trimethylolpropane (TMP) were added to the reactor under nitrogen protection (lactide) The lactide / glycolide molar ratio is 90 / 10, the weight ratio of TMP to monomer lactide and glycolide is 0.9%), and vacuum-dried at 60° C. for 1 hour. Then add stannous octoate (100ppm, weight sum of monomer lactide and glycolide and initiator), heat up to 145°C and react for 3 hours to obtain star-shaped polylactic acid prepolymer PLGA90 / 10, with a number average molecular weight of 15,000 . Then add methacryloyl chloride (-COCl and -OH molar ratio is 1:1), free radical inhibitor p-hydroxyanisole (4-Methoxyphenol) 300ppm (monomer lactide and glycolide and initiator weight and ) and 1wt% (monomer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com