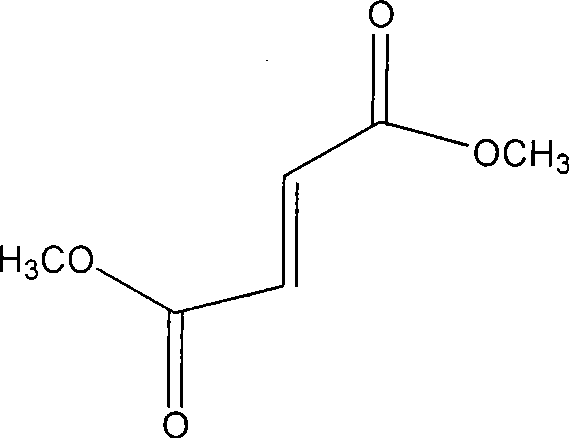

Preparation method of dimethyl fumarate

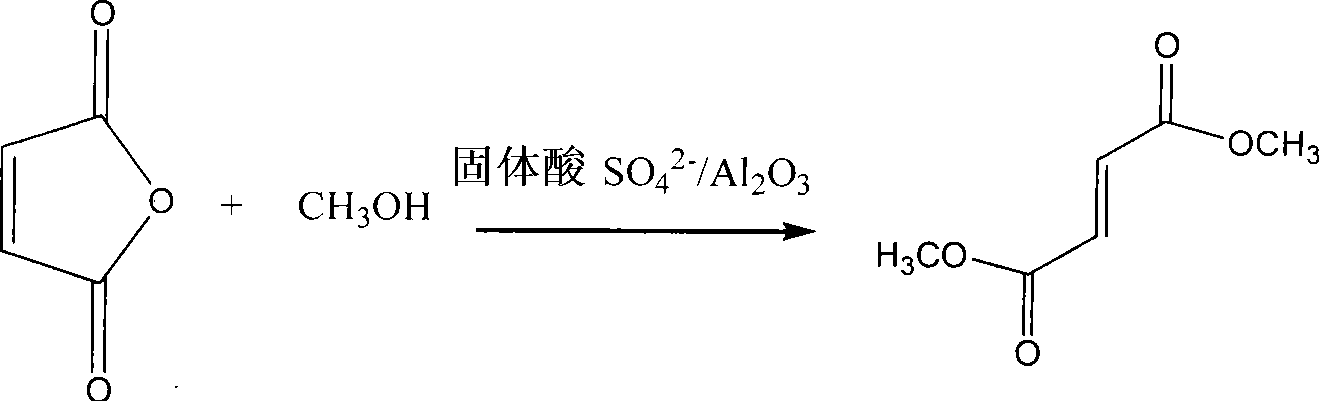

A technology for dimethyl fumarate and dimethyl fumarate is applied in the field of preparation of catalyzed synthesis of dimethyl fumarate, and can solve the problems of complicated post-processing operations, difficult recovery of catalysts, and equipment corrosion. and other problems, to achieve the effect of stable product quality, environmental improvement, and reduction of equipment corrosion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] In a reactor equipped with heating, stirring, thermometer, and reflux condensing device, 125ml of methanol, 49g (0.5mol) of maleic anhydride and 2.5g of solid acid SO were added at room temperature. 4 2- / Al 2 o 3 Catalyst, while stirring, gradually heat up to reflux, control the reaction temperature at 60°C, react for 5.0 hours, cool the reaction solution to room temperature, filter, dissolve the precipitate with ethyl acetate, filter to remove solid acid SO 4 2- / Al 2 o 3 Catalyst (can be recycled after recovery), the ethyl acetate layer is washed with 100ml 8wt% NaOH solution, the separated ethyl acetate layer is washed with water to neutrality, and the solvent ethyl acetate is evaporated (recovered and reused) to obtain a white solid The product dimethyl fumarate was 62.91 g, and the yield was 87.34%. Melting point: 103.1-103.5°C. Purity: 98.7% (HPLC).

Embodiment 2

[0022] In a reactor equipped with heating, stirring, thermometer, and reflux condensing device, add 150ml of methanol, 49g (0.5mol) of maleic anhydride and 5g of solid acid SO at room temperature. 4 2- / Al 2 o 3 Catalyst, gradually heat up to reflux while stirring, control the reaction temperature at 65°C, cool to room temperature after 10 hours of reaction, filter, dissolve the precipitate with ethyl acetate, filter to remove solid acid SO 4 2- / Al 2 o 3 Catalyst (recycling after recovery), ethyl acetate layer uses 125ml 9wt%Na 2 CO 3 The solution was washed, and the separated ethyl acetate layer was washed with water until neutral, and the solvent ethyl acetate was evaporated (recovered and reused) to obtain 64.88 g of dimethyl fumarate as a white solid product, with a yield of 90.11%. Melting point: 102.9-103.3°C. Purity: 97.9% (HPLC).

Embodiment 3

[0024] In a reactor equipped with heating, stirring, thermometer, and reflux condensing device, 175ml of methanol, 49g (0.5mol) of maleic anhydride and 8g of solid acid SO were added at room temperature. 4 2- / Al 2 o 3 Catalyst, the reaction temperature is controlled at 70 °C, after 8 hours of reaction, cool to room temperature, filter, dissolve the precipitate with ethyl acetate, and filter to remove solid acid SO 4 2- / Al 2 o 3 Catalyst (recycling after recovery), ethyl acetate layer uses 140ml 10wt%NaHCO 3 The solution was washed, and the separated ethyl acetate layer was washed with water until neutral, and the solvent was evaporated (recovered and reused) to obtain 66.97 g of dimethyl fumarate as a white solid product, with a yield of 93.01%. Melting point: 102.8-103.1°C. Purity: 98.2% (HPLC).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com