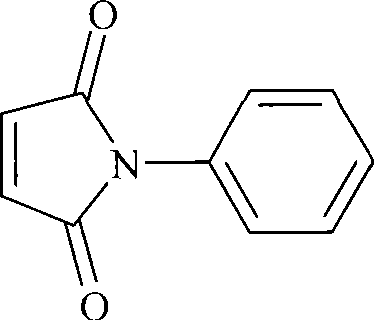

Preparation of N-phenyl maleimide

A technology of maleimide and phenyl, which is applied in the field of preparation of N-phenylmaleimide, can solve the problems of long preparation cycle, high energy consumption, high cost, etc., achieve stable product quality, reduce three wastes, The effect of reaction time reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

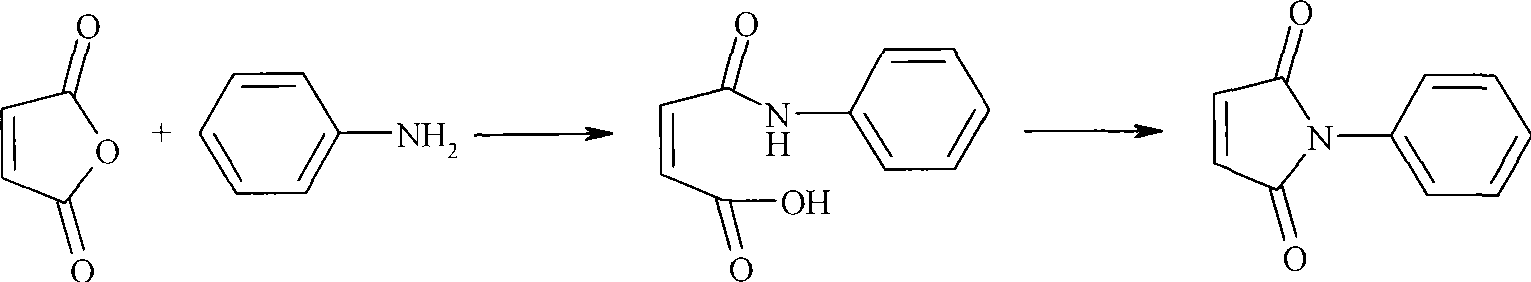

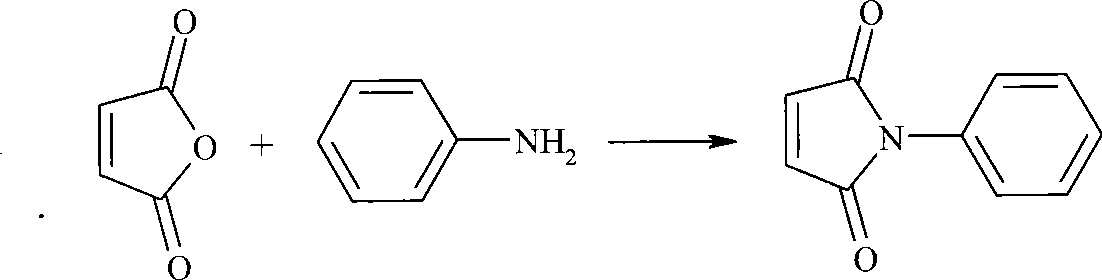

Method used

Image

Examples

Embodiment 1

[0024] Add respectively 100ml dimethylbenzene, 0.2g 2,6-di-tert-butyl p-cresol, mixed dehydration catalyst 4g (concentrated sulfuric acid and hydrogensulfate The mass ratio of sodium is 1.0:1.0, g / g). Heat up to reflux under stirring, the temperature is 140°C, drop into ① the mixed solution containing 58.8g (0.6mol) maleic anhydride-100ml xylene-10ml DMF through the dropping funnel within 0.5 hours, ② 46.5g (0.5mol) Aniline was continued to reflux for 1 hour, and 9ml of water was separated. The reaction solution was cooled to 60°C, 55ml of 15wt% sodium carbonate solution was slowly added, stirred for 5 minutes, left to stand, the organic phase was separated, the solvent was evaporated under reduced pressure, and 174ml of the solvent was recovered to obtain the yellow solid product N-phenylmaleimide Amine 77.9g, yield 90%, purity: 98.7% (HPLC). Melting point: 88.6-90.1°C.

Embodiment 2

[0026] Add respectively 100ml toluene, 0.2g pyrocatechol, and 3g of mixed dehydration catalyst (the mass ratio of concentrated sulfuric acid and sodium dihydrogen phosphate is 5.0 in the reactor with heating, thermometer, dropping funnel, reflux water separation condenser tube: 1.0, g / g). Heat up to reflux under stirring, the temperature is 110°C, drop into ① a mixture containing 56.35g (0.575mol) maleic anhydride-100ml toluene-8ml DMF, ② 46.5g (0.5mol) aniline through the dropping funnel within 0.5 hours , continue the reflux reaction for 2 hours, and separate 9ml of water. The reaction solution was cooled to 60°C, 75ml of 10wt% sodium carbonate solution was slowly added, stirred for 5 minutes, left to stand, the organic phase was separated, the solvent was evaporated under reduced pressure, and 162ml of solvent was recovered to obtain the yellow solid product N-phenylmaleimide Amine 79.2g, yield 91.5%, purity 99.0% (HPLC). Melting point: 89.2-90.1°C.

Embodiment 3

[0028] Add respectively 100ml toluene, 0.2g hydroquinone, mixed dehydration catalyst 5g (the mass ratio of concentrated sulfuric acid and p-toluenesulfonic acid is 1.5:1.0, g / g). Heat up to reflux with stirring, the temperature is 110°C, drop into ① a mixture containing 53.9g (0.55mol) maleic anhydride-100ml xylene-7.5ml DMF, ② 46.5g through the dropping funnel within 1.0 hour under reflux (0.5mol) aniline, continued to reflux for 2.5 hours, and separated 9ml of water. The reaction solution was cooled to 50°C, 100ml of 8wt% sodium carbonate solution was slowly added, stirred for 5 minutes, left to stand, the organic phase was separated, the solvent was evaporated under reduced pressure, and 158ml of the solvent was recovered to obtain the yellow solid product N-phenylmaleimide Amine 79.5g, yield 92%, purity: 98.9% (HPLC). Melting point: 88.7-90.3°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com