Descaling agent

A descaling agent, mass percent technology, applied in descaling and water softening, complex/solubilizer treatment, special treatment targets, etc., can solve problems affecting safe use, shortening service life, easily causing accidents, etc. Thorough descaling, energy saving, good cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

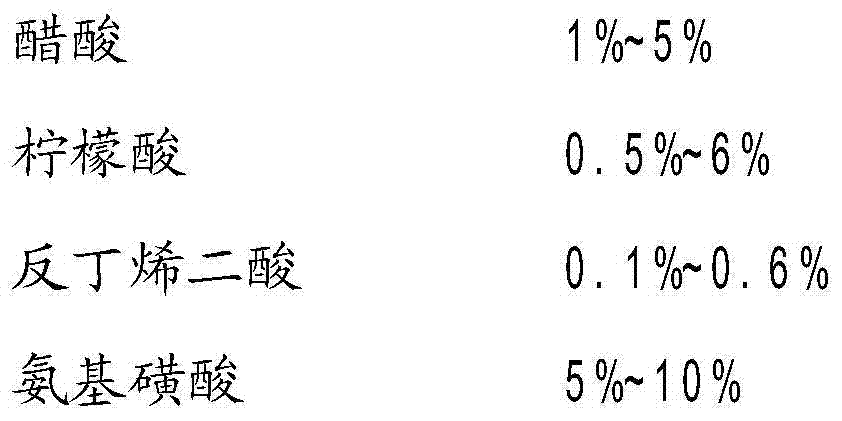

[0022] The invention provides a kind of descaling agent, and described descaling agent is made up of following components by mass percentage:

[0023]

[0024] The metal corrosion inhibitor is a combination of four kinds of glucose, starch, pectin and sodium gluconate. The auxiliary material is food-grade essence. The antirust agent is a combination of triethanolamine and sodium nitrite.

[0025] A kind of preparation method of described descaling agent of the present invention, in step (1), with solid material citric acid, sulfamic acid, fumaric acid, maleic acid, sodium dodecylbenzene sulfonate Sequentially add to the chemical reactor, then add water and stir evenly to dissolve the solid material; the stirring speed during stirring is 500r / min.

[0026] In step (2), the liquid materials acetic acid, hydrochloric acid, lactic acid and corrosion inhibitor are added into the chemical reactor and stirred evenly to make them fully dissolved; the stirring speed during stirrin...

Embodiment 2

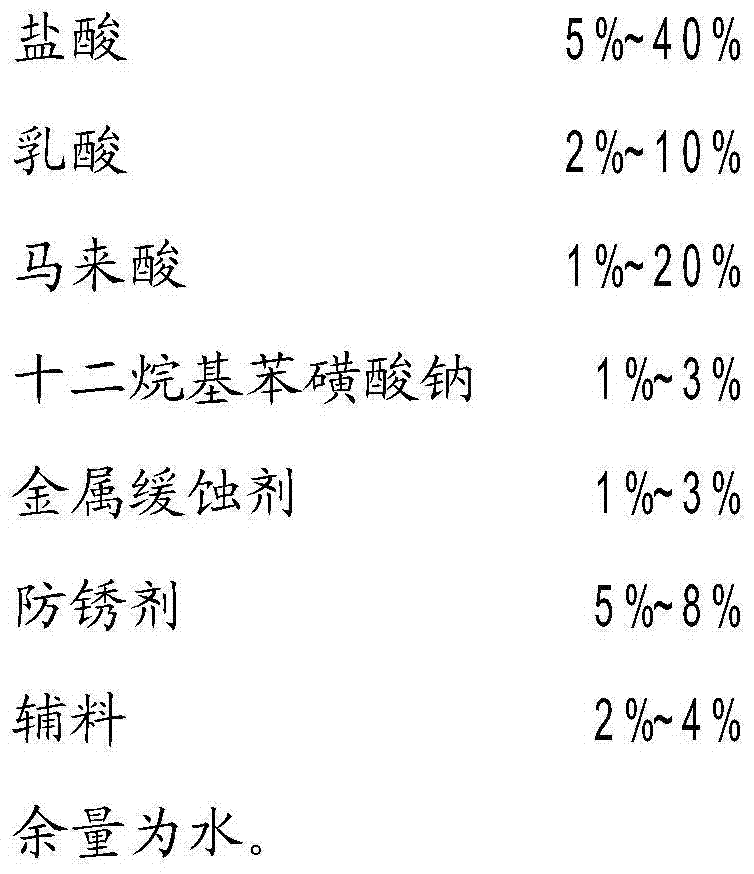

[0033] The difference between embodiment 2 and embodiment 1 is: the present invention provides a kind of descaling agent, and described descaling agent is made up of following components by mass percentage:

[0034]

[0035]

[0036] The metal corrosion inhibitor is a combination of glucose, starch and vitamin C. The auxiliary material is a combination of food-grade essence or food-grade colorant. The rust inhibitor is sodium nitrite.

[0037] A preparation method of the descaling agent of the present invention, in step (1), the stirring rate during stirring is 800r / min. In step (3), the mesh number of the stainless steel screen is 100 mesh.

[0038] Put the weighed stainless steel standard corrosion test piece, carbon steel alloy steel standard corrosion test piece, copper standard corrosion test piece, aluminum standard corrosion test piece, magnesium standard corrosion test piece into 6 beakers, and time it. After 8 hours, take out the test piece, dry it, weigh it,...

Embodiment 3

[0044] The difference between embodiment 3 and embodiment 1 is:

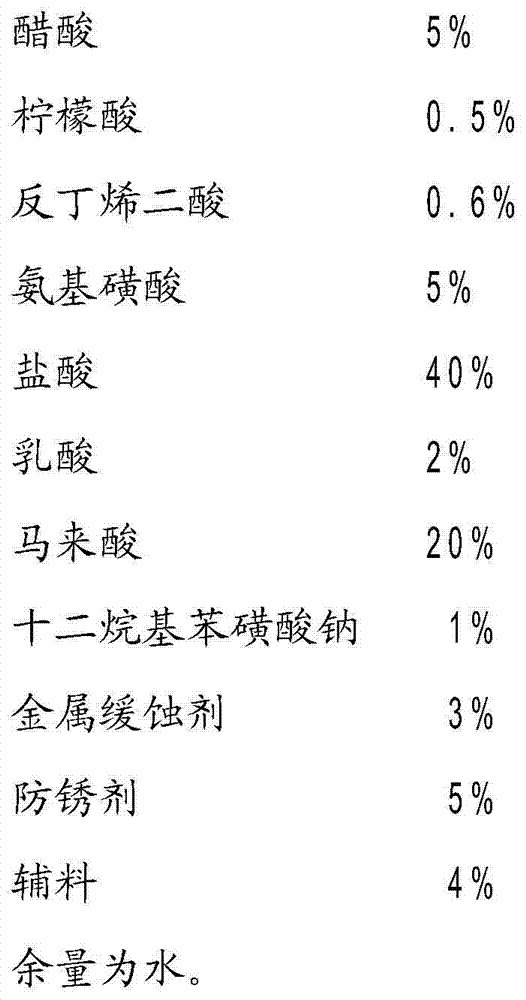

[0045] The invention provides a kind of descaling agent, and described descaling agent is made up of following components by mass percentage:

[0046]

[0047] The metal corrosion inhibitor is sodium gluconate. The auxiliary material is one or a combination of food-grade essence or food-grade colorant. Described antirust agent is triethanolamine.

[0048] A preparation method of the descaling agent of the present invention, in step (1), the stirring rate during stirring is 800r / min. In step (3), the mesh number of the stainless steel screen is 200 mesh.

[0049] Put the weighed stainless steel standard corrosion test piece, carbon steel alloy steel standard corrosion test piece, copper standard corrosion test piece, aluminum standard corrosion test piece, magnesium standard corrosion test piece into 6 beakers, and time it. After 8 hours, take out the test piece, dry it, weigh it, and calculate the corrosi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com