Multilayer composite film

A composite film, multi-layer technology, applied in the direction of layered products, synthetic resin layered products, flexible coverings, etc., can solve problems such as pollution, user pollution, and harm to the human body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

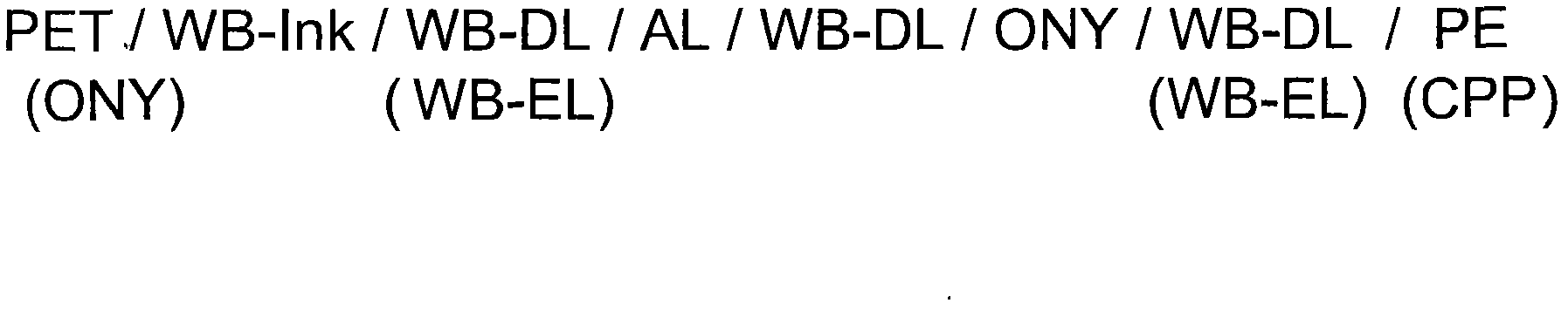

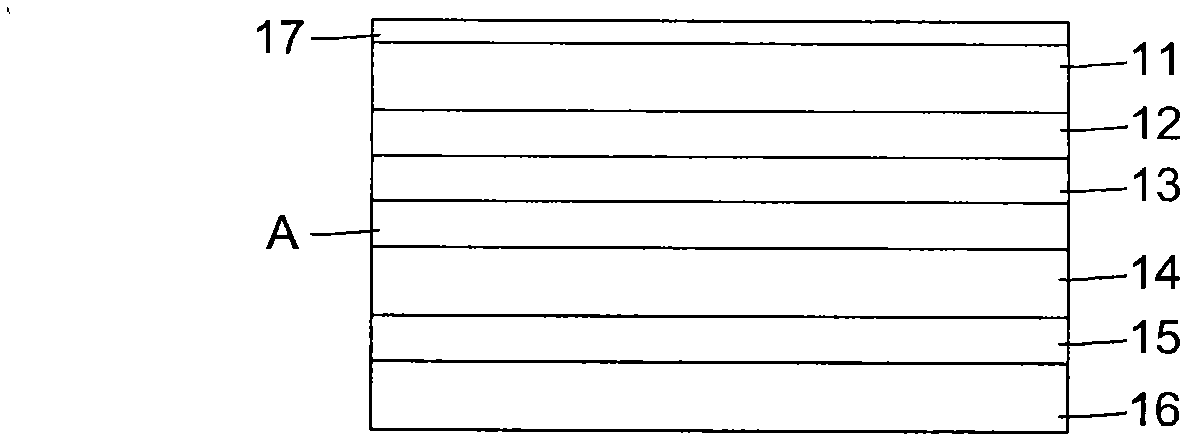

[0102] First of all, a kind of multi-layer composite membrane of the present invention, the first embodiment, such as figure 2 As shown, the substrate uses a plastic film such as a layer of PET (polyester film) or ONY (nylon film) on the outer layer, or paper made of pulp that can be used as an outer layer, etc., on the inner surface of the outer layer Or surface printing patterns, printing is printed on the outer layer with water-based ink-WB-Ink (Water Base Ink), and then water-based adhesive-WB-DL (Water Base Dry Lamination) or water-based solvent two-component thermal Extrusion film-WB-EL (Water Base Extrusion Lamination) is attached to an AL aluminum material, and then a water-based adhesive-WB-DL (Water Base Dry Lamination) is used to adhere to ONY (Orient Nylon through alignment stretched nylon film), and another water-based adhesive Adhesive-WB-DL (Water Base Dry Lamination) or water-based solvent two-component hot extrusion film-WB-EL (Water Base Extrusion Lamination...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com