Travelling case shell material and its preparation method

A shell material and luggage technology, applied in the field of luggage, can solve the problems of honeycomb core rupture, poor ductility, shape defects, etc., and achieve the effects of good impact resistance, good product quality and high cost performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A preparation method for a suitcase case material, comprising the steps of:

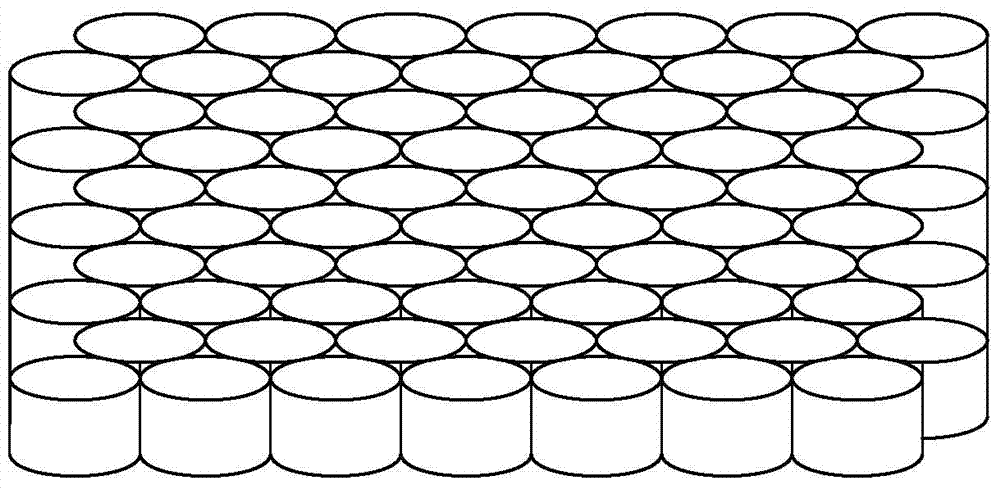

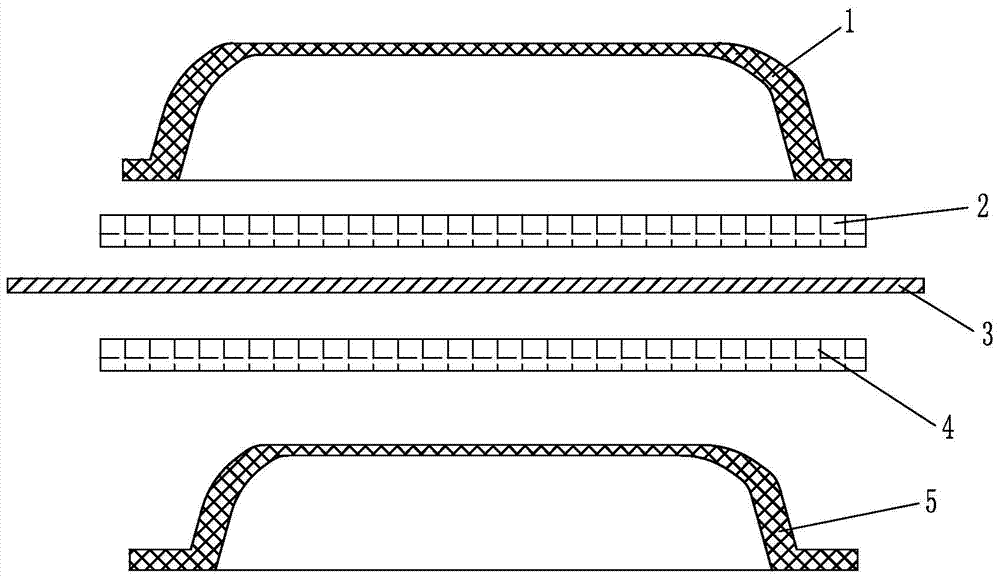

[0030] 1) Choose a thickness of 6-10mm and a density of 60-120kg / m 3 The polypropylene honeycomb core is used as the skeleton, such as figure 1 As shown, the preparation method of the polypropylene honeycomb core material refers to the patent document with the publication number CN102689458A, that is, the polypropylene honeycomb core is: a plurality of double-layer composite pipes are spliced into a honeycomb shape, and the adjacent double-layer composite pipes are closely attached. The outer layers of the polypropylene honeycomb core are bonded together, and the end faces of the inner layers of the adjacent double-layer composite pipes are fused to form glue bumps; the upper and lower sides of the polypropylene honeycomb core respectively refer to the two ends of the multiple double-layer composite pipes. surface; use a melting point higher than 200 ° C, heat shrinkage rate of 4% to 8% at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com