Direct-fired auto-warming biomass gasifier

A self-heating, gasification furnace technology, applied in the field of gasification furnaces, updraft household gasification furnaces, can solve problems such as blockage, and achieve the effects of improving thermal efficiency, product maturity, and easy ash removal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

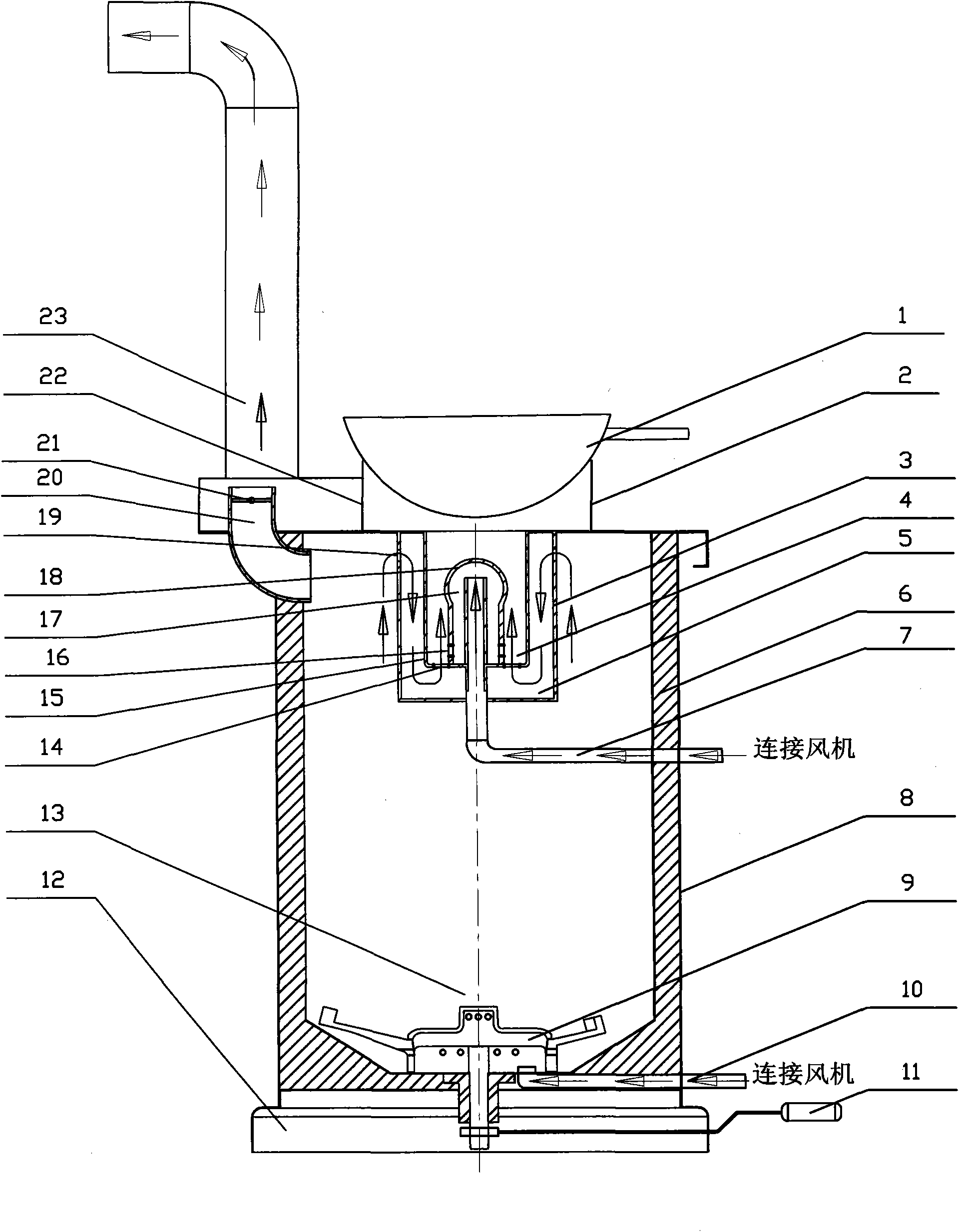

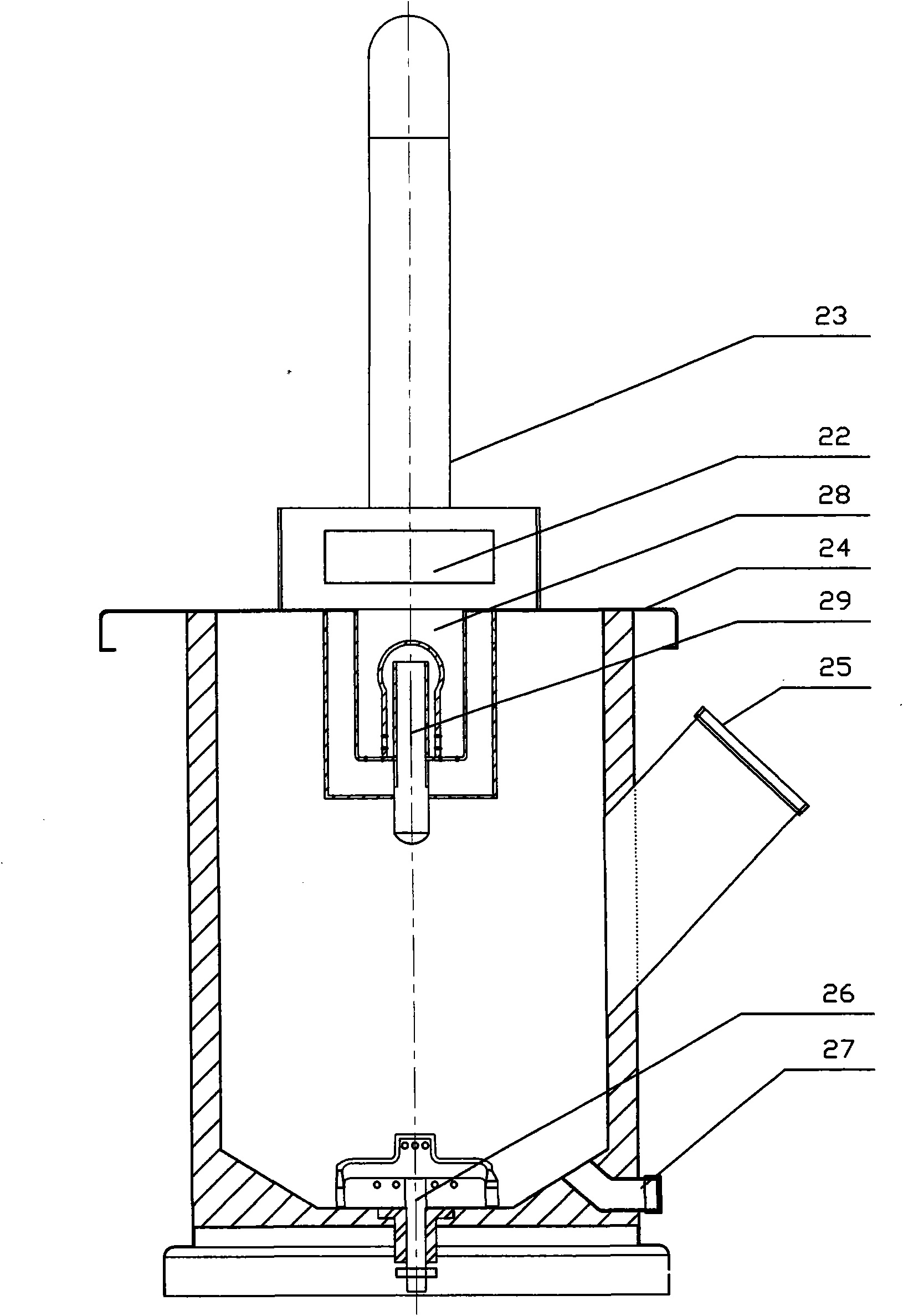

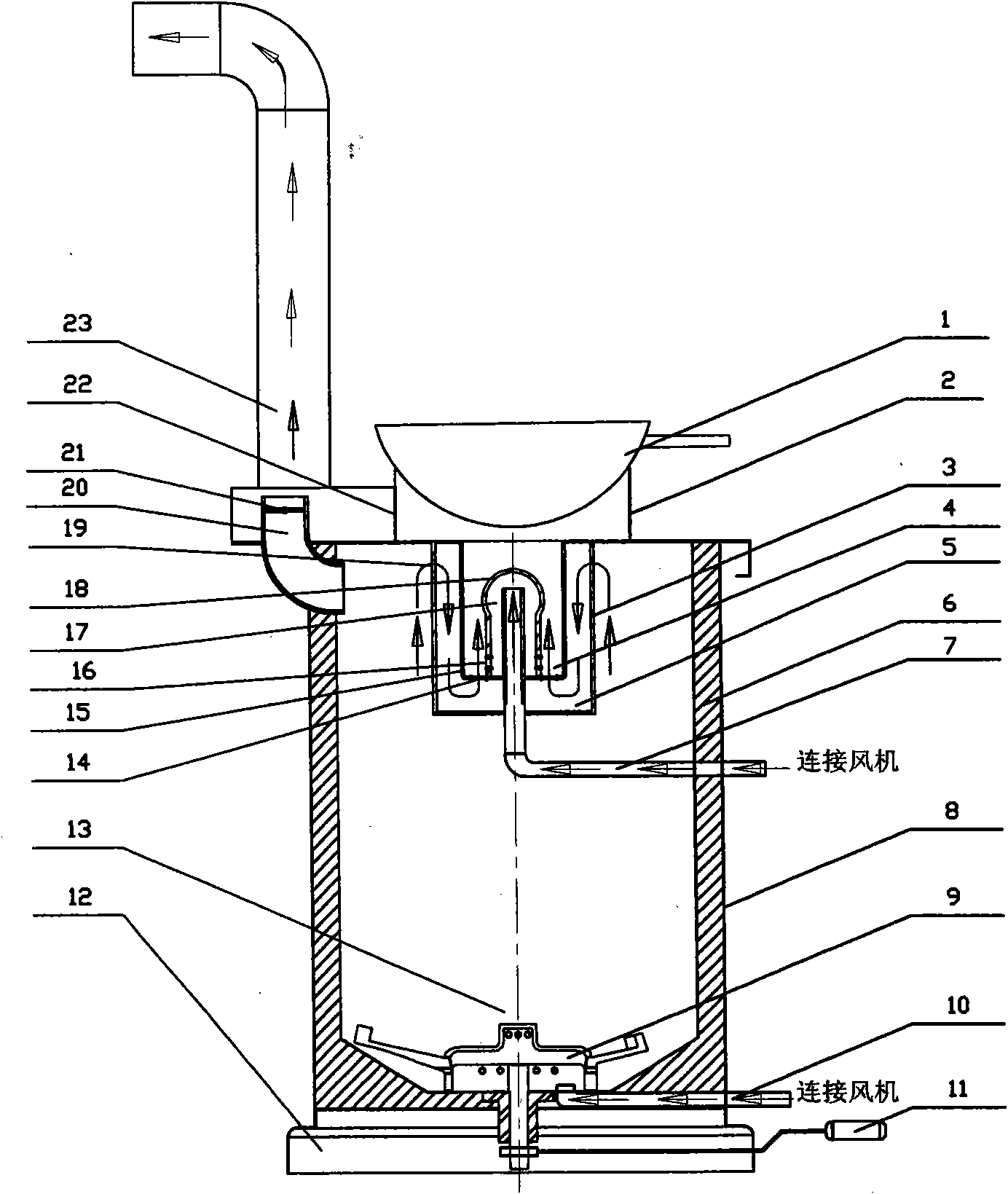

[0012] In the figure, the top of the base (12) is fixed to the body of furnace (8), and the inner wall of the furnace is made of a refractory insulation material layer (6). A manually rotating ash-dispelling and blowing and air-intake device (9) is provided, and its rotating shaft (26) passes through the bottom of the furnace and is connected to the handle of the driving rod (11). The upper part of the furnace (13) is provided with a stove (28), and the stove includes an outer barrel of the stove body (3) and the inner barrel body (15) of the stove head, which are respectively connected and fixed with the stove panel (24), and the combustion-supporting air inlet pipe (7) passes through the stove core (29) and is placed in the center of the air inlet room (17), And cover the heat transfer cup (18), the top side of the furnace is provided with a gas release pipe (20) and a release valve (21) leading to the smoke exhaust pipe (23), and the upper end of the stove top is circled to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com