Patents

Literature

293results about How to "Solve your worries" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for recycling lithium carbonate from lithium iron phosphate waste material

ActiveCN102903985ASolve the problem of resource recyclingSolve your worriesWaste accumulators reclaimingBattery recyclingIron sulfateWaste material

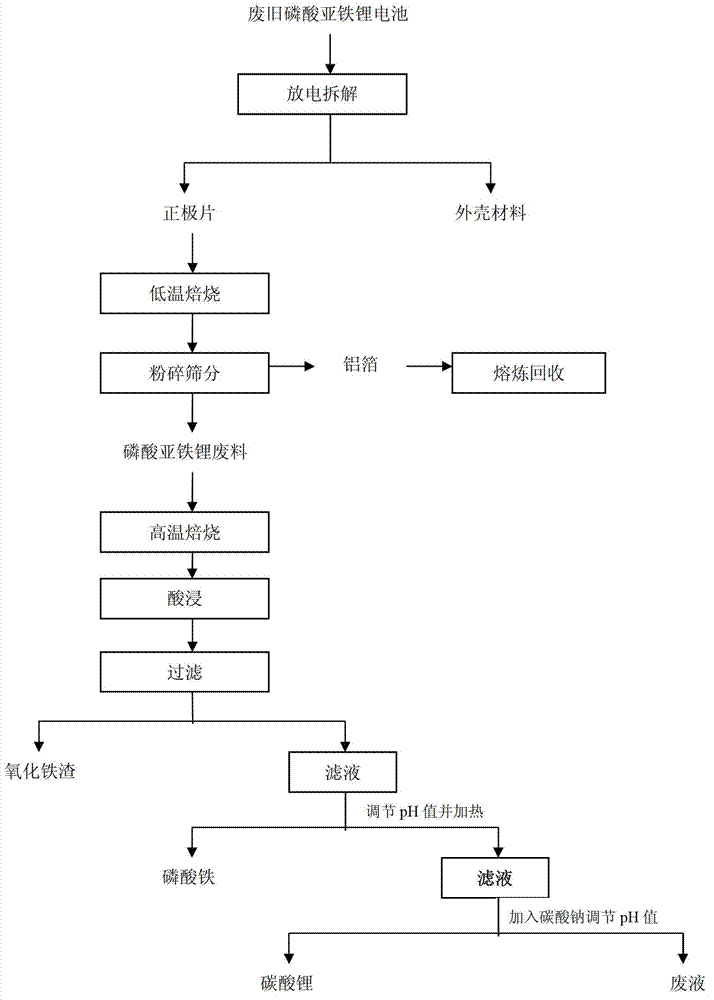

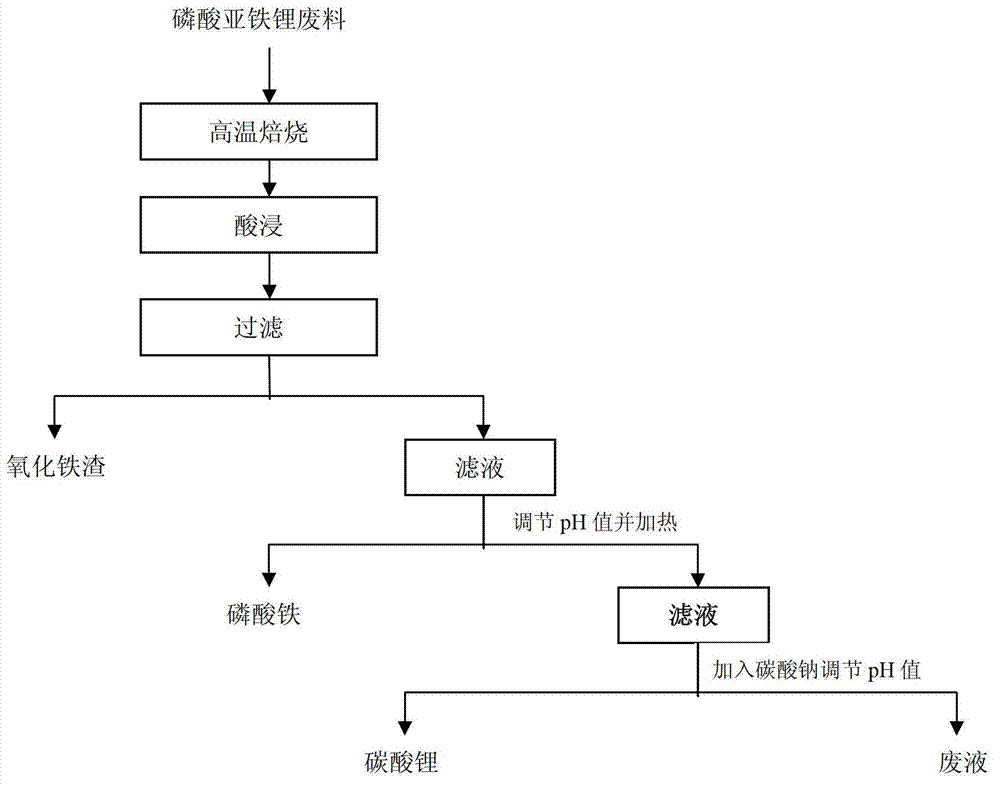

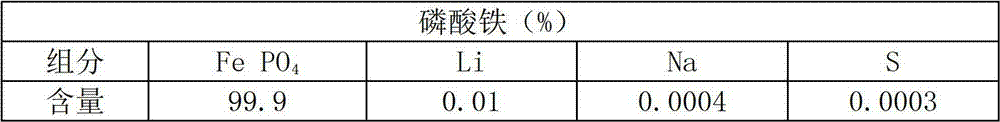

The invention relates to a method for recycling lithium carbonate from a lithium iron phosphate waste material, and belongs to the technical field of waste lithium oil battery recycling. The technical problem to be solved by the invention is that a method for recycling lithium carbonate from the lithium iron phosphate waste material is provided. The method provided by the invention comprises the following steps of: roasting the lithium iron phosphate waste material at 500-800 DEG C for 1-4 hours; adding sulfur into the roasted waste material and leaching, and filtering so as to obtain a mixed solution of lithium phosphate, iron phosphate and ferric sulfate; heating the mixed solution to 80-100 DEG C, and adjusting the pH value to 2-2.5, reacting for 1-4 hours, filtering, washing, and drying to obtain iron phosphate; adjusting the pH value of a filtrate obtained by filtering to be 6-7, adding calcium chloride and dephosphorizing, and filtering; and adjusting the pH value of the filtrate obtained by filtering to be 10-12 by sodium carbonate, reacting for 0.5-2 hours, filtering, washing, and drying so as to obtain battery grade lithium carbonate.

Owner:天齐锂业(江苏)有限公司 +2

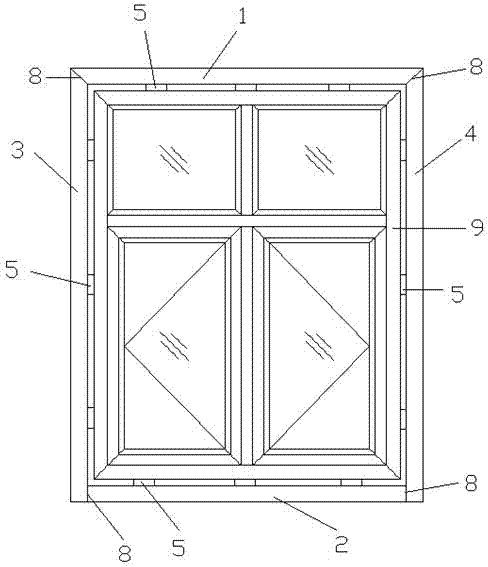

Energy-saving door and window attached frame and door and window installation method

ActiveCN102777103AAvoid installationSolve the connection waterproof problemFrame fasteningWindow/door framesBuilding energyConstruction engineering

Owner:JIANGSU HONGSHA DOOR & WINDOW +1

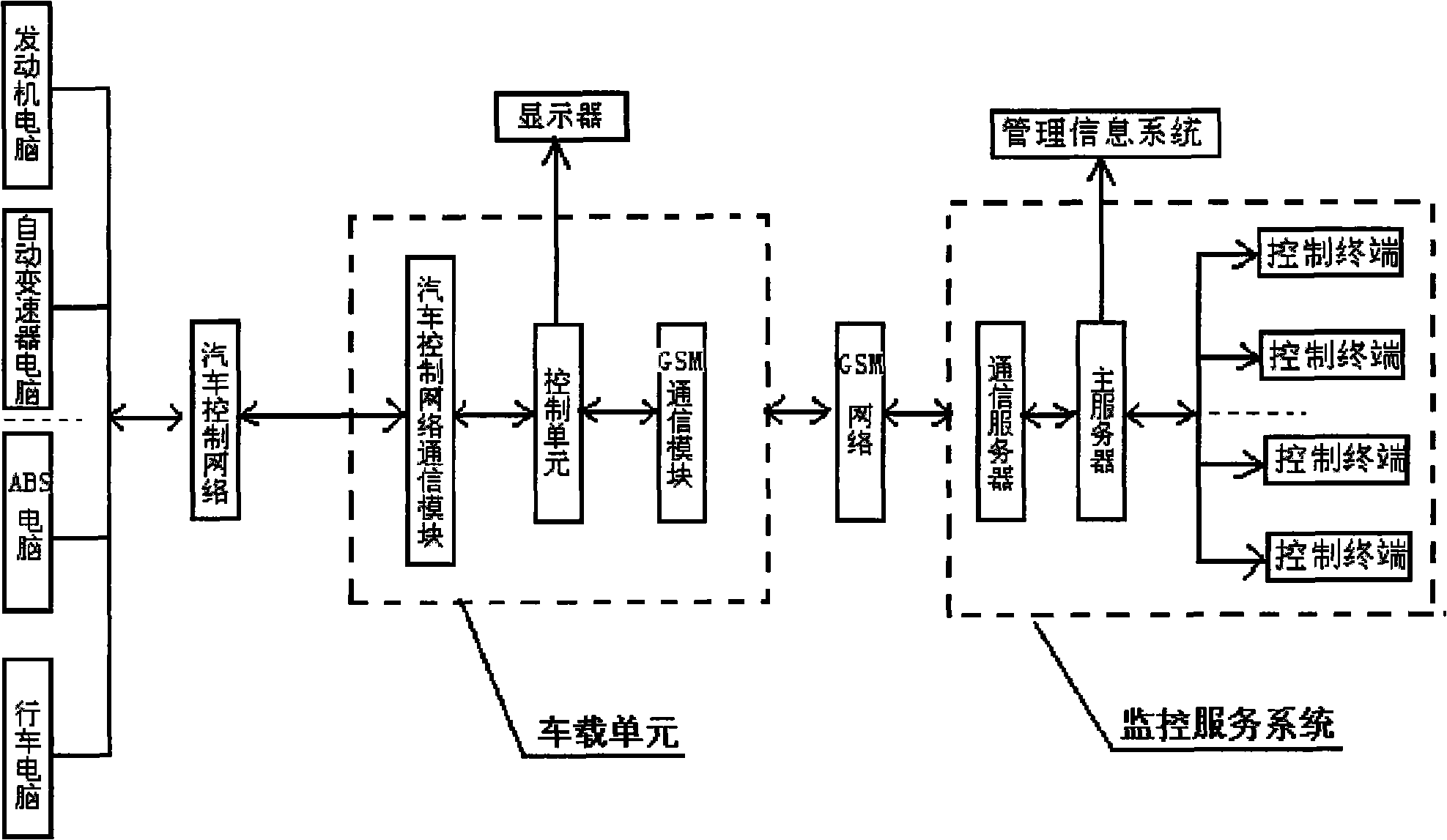

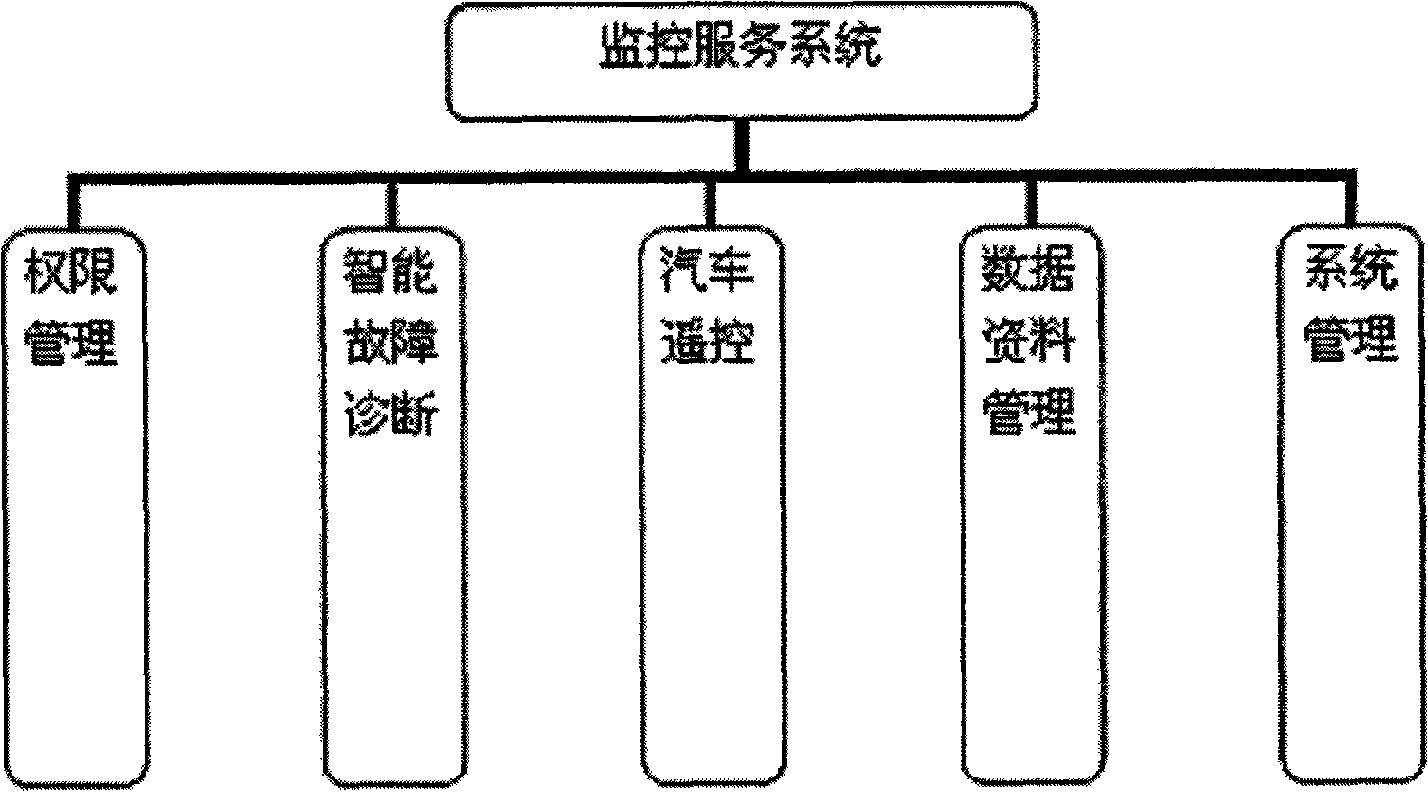

Vehicle detecting and maintaining intelligent control device

InactiveCN101272427AHumanized maintenance service supportRealize remote guidanceComputer controlSimulator controlRemote controlMotor control

The invention relates to an intelligent control device for inspection and maintenance of automobile, which belongs to a technical field of communication and artificial intelligence. The intelligent control device for inspection and maintenance of the automobile comprises a vehicle-mounted unit connected with a motor control network which is connected with a monitoring service system of a motor repair center (comprising a communication gateway) in a wireless way by a GSM network. The vehicle-mounted unit is arranged on the controlled automobile and is communicated with the monitoring service system through the GSM network; the communication gateway takes charge of the wireless communication of the vehicle-mounted unit and the monitoring service system; the monitoring service system is the core of the system, which can carry out human-computer interaction, intelligent fault diagnosis, remote control, etc. The device has the advantages of carrying out failure warning, maintenance suggestion, remote control, fault diagnosis, etc., thus providing various fast, convenient and more humanized services for users.

Owner:于京诺

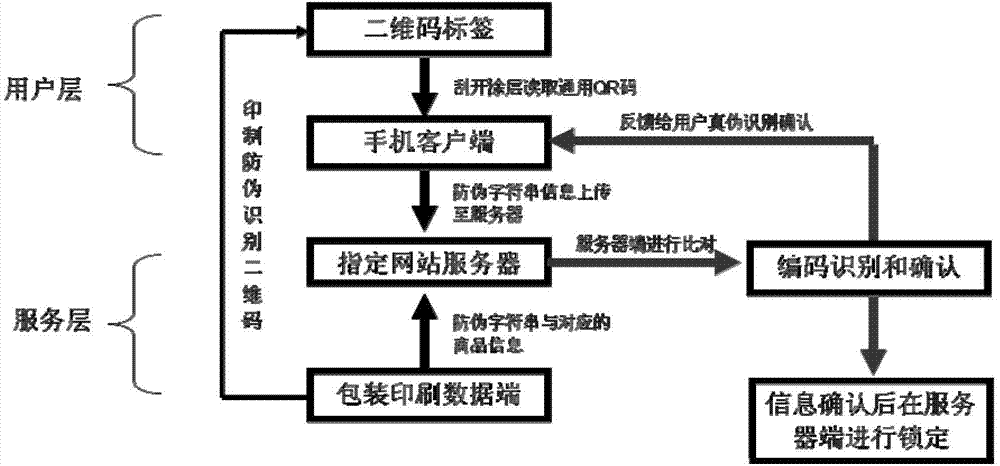

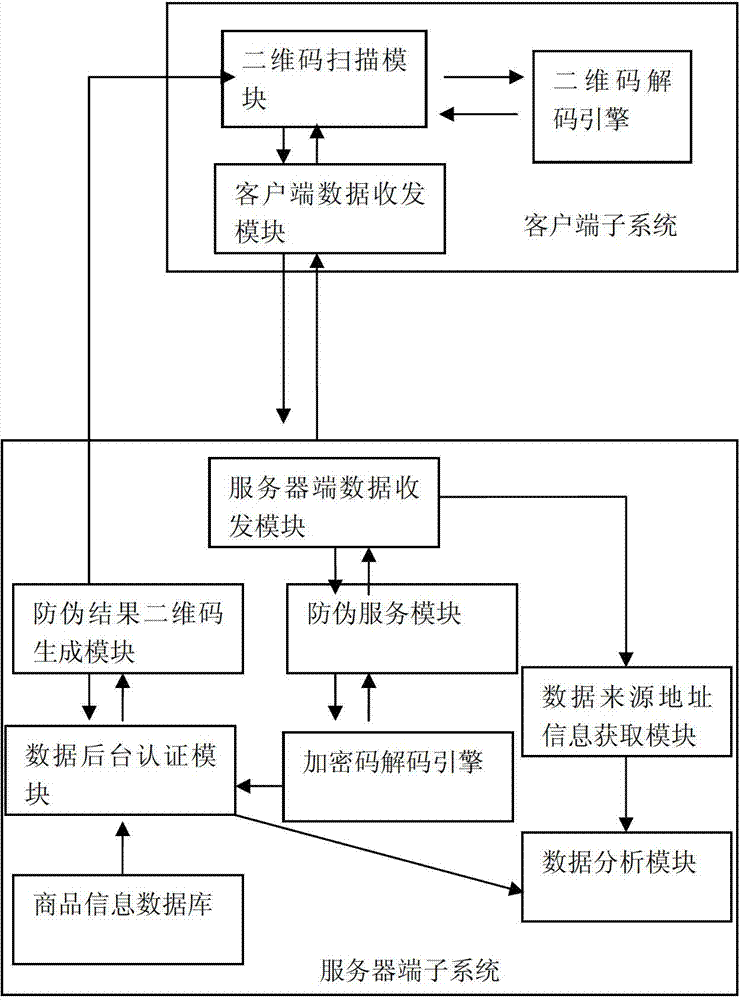

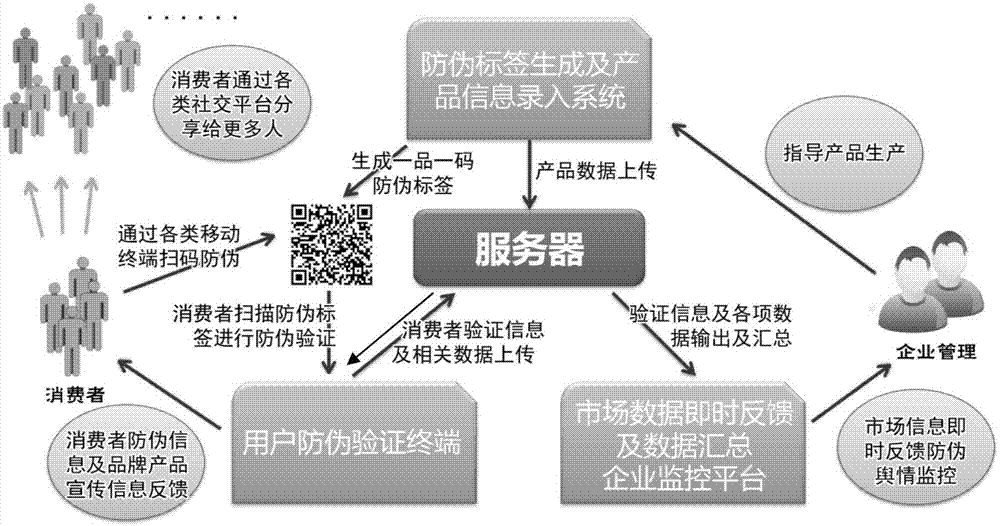

Tracing anti-fake market interaction integration system and method

ActiveCN103325042AAnti-counterfeiting is the most detailedGuarantee the strength of anti-counterfeiting certificationCommerceSoftware engineeringAuthentication

The invention discloses a tracing anti-fake market interaction integration system and method. The tracing anti-fake market interaction integration system and the tracing anti-fake market interaction integration method break through limitation on the cover degree of an existing tracing anti-fake system, achieve the purpose that one product is provided with one code, and put anti-fake into practice for every consumer. The anti-fake method that one product is provided with one code is adopted in the whole process of product delivery and sale. The method includes the steps of correspondence of identification codes to goods and correspondence of the identification codes to spraying in the process of anti-fake code generation and subsystem generation, then based on identification code scanning and network transmission, the most detailed anti-fake is achieved under the condition of little expenditure, and anti-fake and authentication effort for each product is guaranteed.

Owner:黄梅

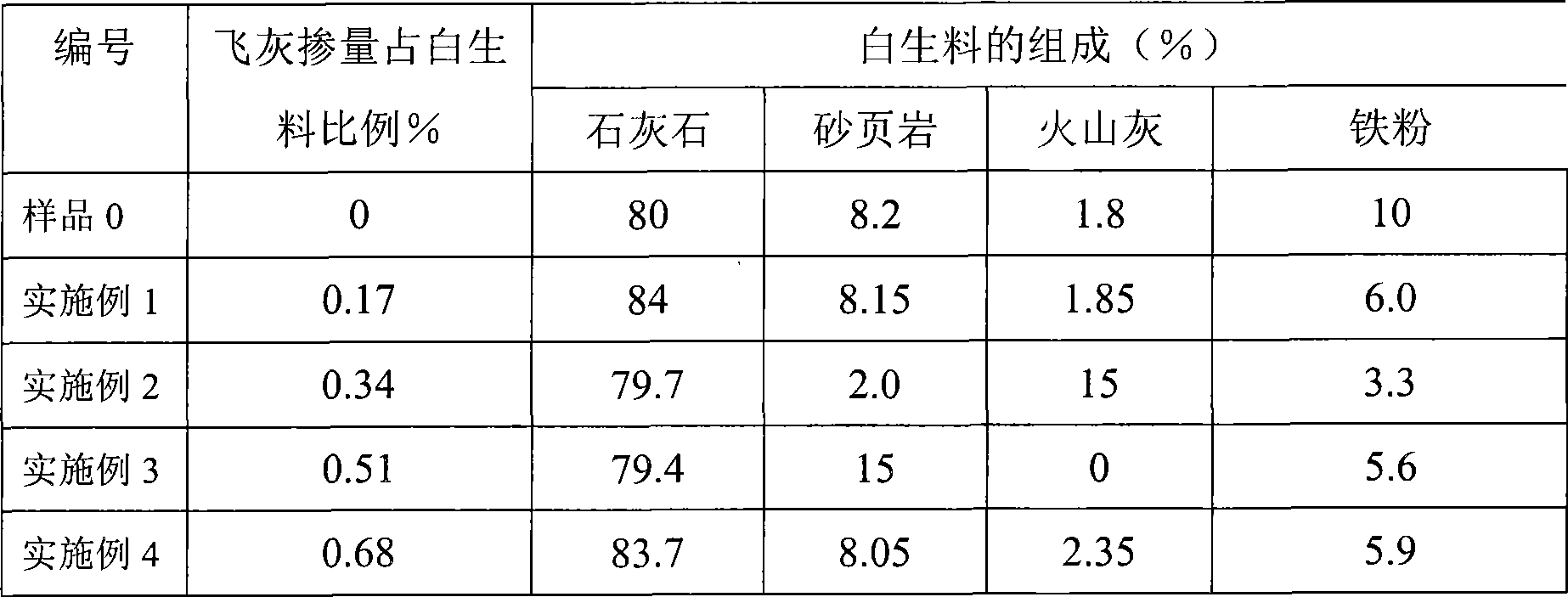

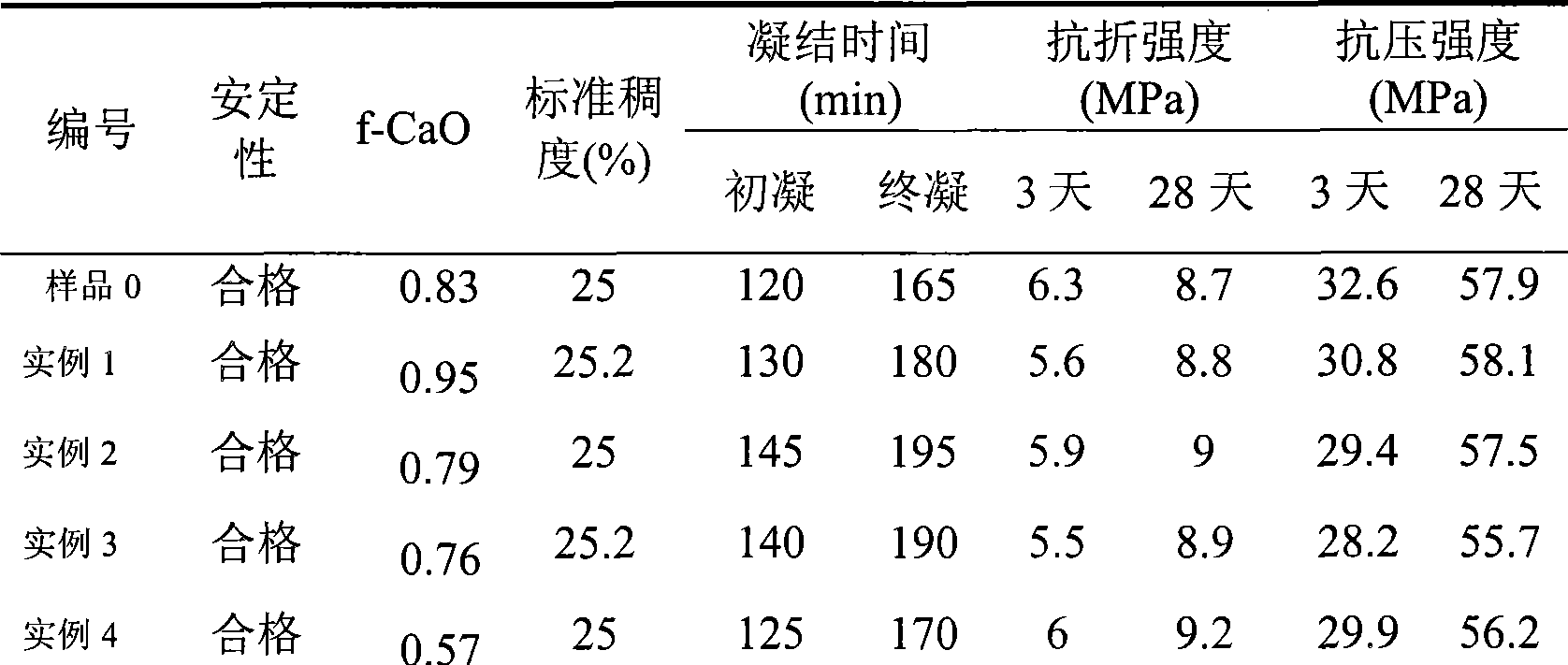

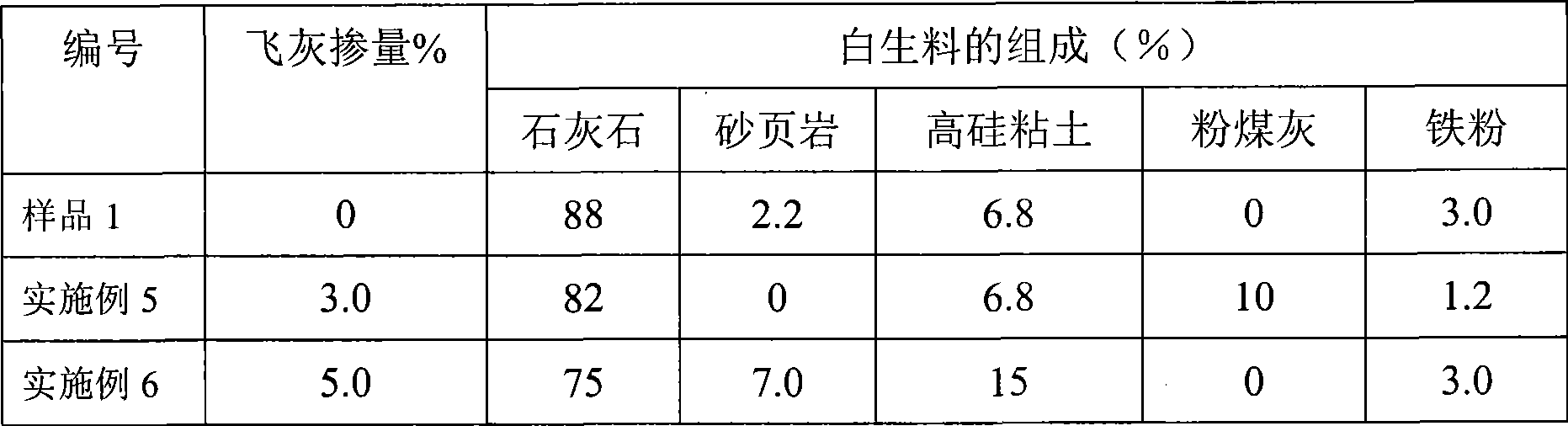

Method for producing portland cement clinker using domestic waste flying ash

The invention relates to a method for producing Portland cement clinker with incineration slag of municipal solid waste. The method solves the problem of crust and blockage caused by chlorine through the reconstruction of the prior kiln which is realized by mounting a by-way air exhaust device. For a kiln system with a kiln row and a furnace row which are independent from each other, the by-way air exhaust device is arranged in an uptake of a kiln end gas chamber in the kiln row close to a five-stage cylinder; while for common industrial kiln, the air exhaust device is arranged between an outlet of decomposing furnace and an inlet of the five-stage cylinder or arranged at an uptake of an outlet of the five-stage cylinder; the fly ash passes through a kiln head, the kiln end gas chamber, or the decomposing furnace and then is sprayed into the kiln. The use frequency of the by-way air exhaust device is between once per four hours and once per three days, the temperature of the air entering the by-way air exhaust device is controlled to be more than 950 DEG C. the method has the advantages of small reconstruction investment, low treatment cost, production of Portland cement clinker having wide application range and meeting JC / T853-1999 standards of Portland Cement Clinker, realization of reclamation, contribution to the development of cyclic economy, and reduction in consumption of natural resources and energy of the cement industry.

Owner:SOUTH CHINA UNIV OF TECH

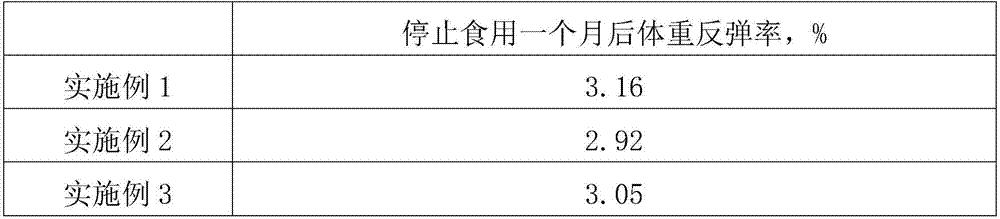

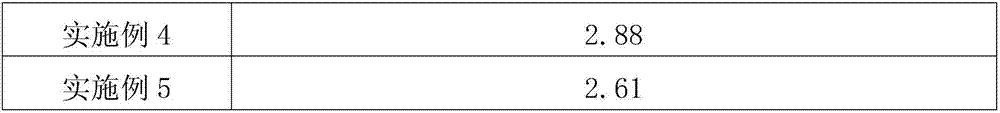

Cereal diet meal replacement powder and making method thereof

PendingCN106889521AKeep the tasteRetain nutrientsFood mechanical treatmentFood dryingMeal replacementRed bean

The invention discloses cereal diet meal replacement powder and a making method thereof. The cereal diet meal replacement powder includes raw materials yam, red dates, Chinese wolfberry fruits, oats, red beans, black beans, black sesame, walnut kernels, dried apples, chia seeds, quinoa and probiotics. The cereal diet meal replacement powder has the effects of moderating, nourishing and tonifying qi, nourishing the kidney, nourishing the blood, nourishing the intestines and detoxifying the intestines and expelling toxin, is suitable for all people, is homological in medicine and food, natural and health-care and can replace the three meals.

Owner:北京幸福人生健康科技发展有限公司

Chinese medicament for treating flu caused by influenza A(H1N1) and the like

InactiveCN101708275AEasy to buy and decoctSolve your worriesAntipyreticAnalgesicsMedicinal herbsBaical Skullcap Root

The invention discloses a Chinese medicament for treating the flu caused by influenza A(H1N1) and the like, which belongs to the technical field of Chinese medicament. The Chinese medicament is prepared from the following raw material medicaments: mix-fried ephedra herb, gypsum, honeysuckle flower, weeping forsythiae capsule, baical skullcap root, common anemarrhena rhizome, thunberg fritillary bulb, toasted almond, great burdock achene, sweet wormwood herb, peppermint, and raw licorice root. The Chinese medicament of the invention not only can have obvious healing effect on classical symptoms of the flu, such as fever, discomfort or soreness of the throat, cough and the like, has broad spectrum antibacterial effect, and is convenient for purchasing, decoction and administration because the raw medicinal materials are all common medicinal materials.

Owner:聚协昌(北京)药业有限公司

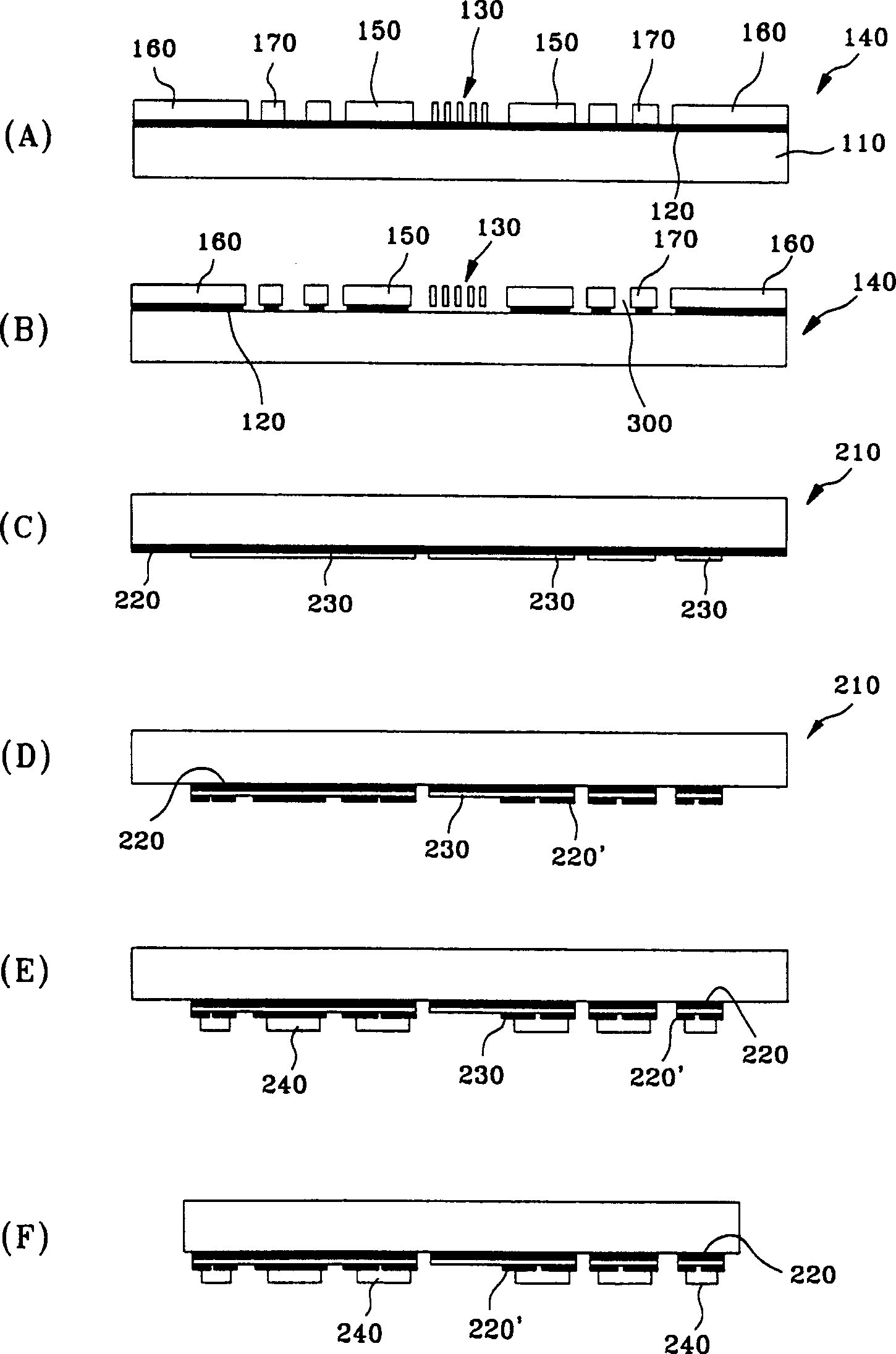

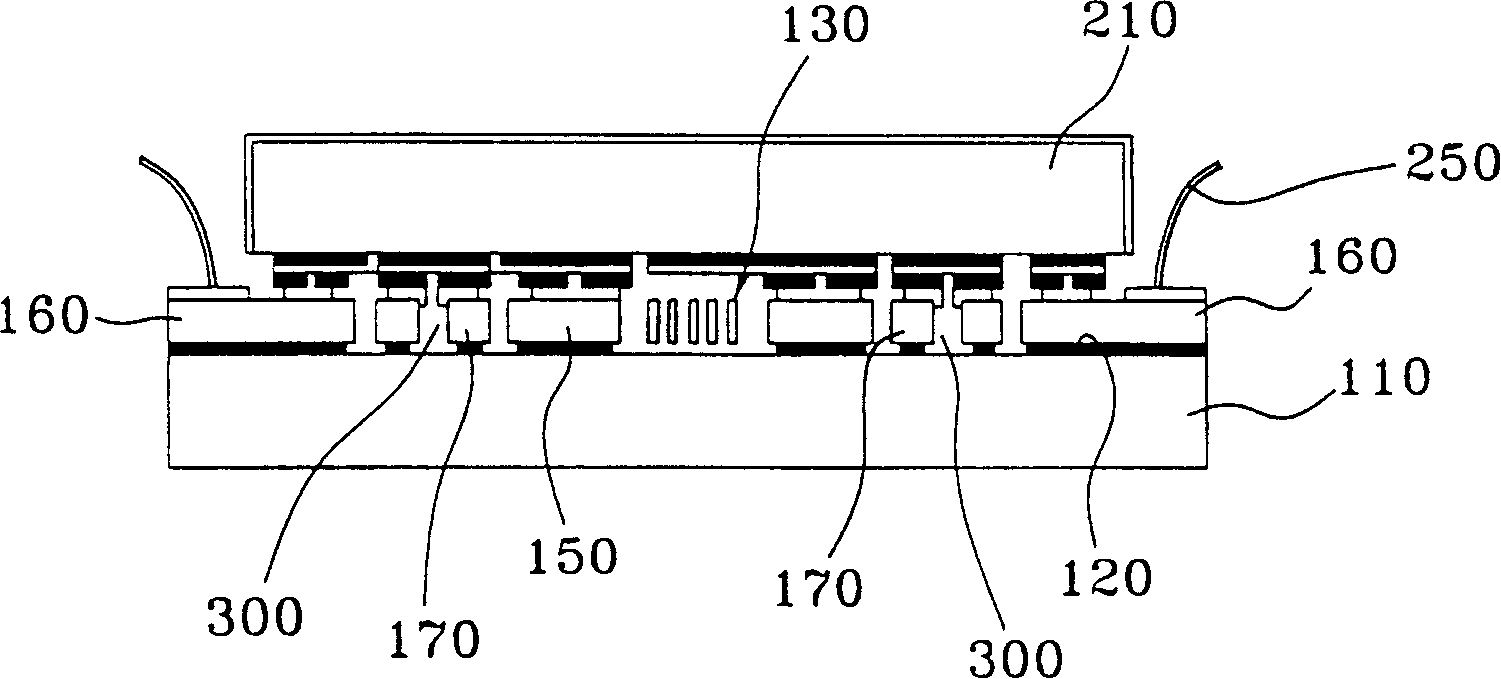

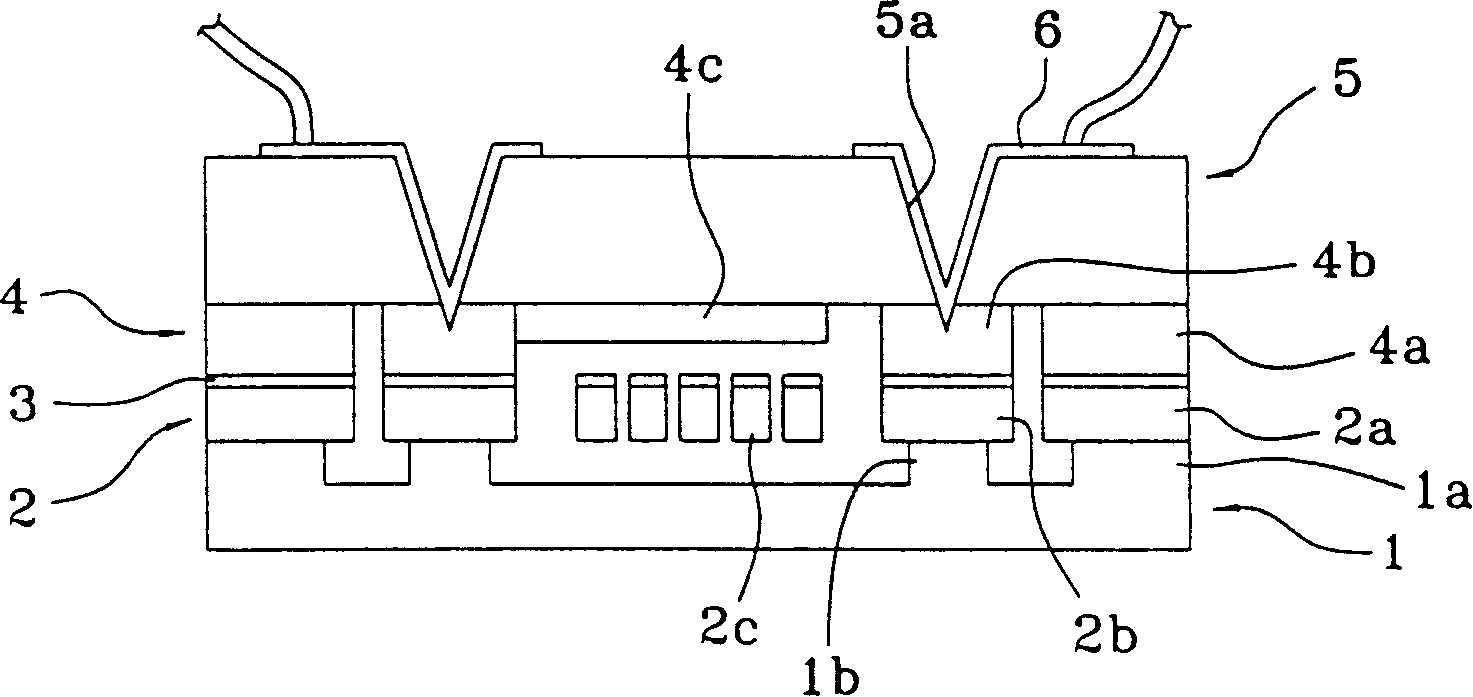

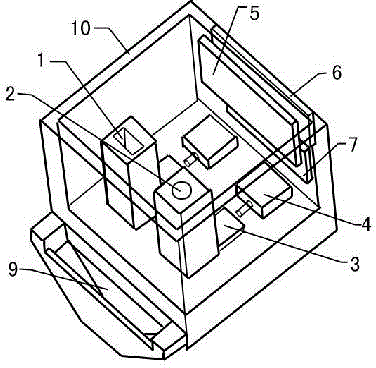

Micro inertia sensor and its mfg. method

InactiveCN1447093ASolve wiring difficultiesSolve your worriesAcceleration measurement using interia forcesDecorative surface effectsCapacitanceMiniaturization

The present invention will provide a micro-inertial sensor characterized by the following content, which includes: a lower glass substrate; a lower silicon substrate on the lower glass substrate for detecting the first edge and the first fixed point and side motion detection structures Layer; including the first edge portion corresponding to the above-mentioned lower silicon layer, the first fixed point and the second edge portion of the side motion detection structure, the second fixed point bonded by the through-hole with the built-in metal line, and the above-mentioned side motion The upper silicon layer including the second detection electrode used to detect the capacitance in the vertical direction between the detection structures; the eutectic bonding layer between the above-mentioned upper silicon layer and the lower silicon layer; located on the upper part of the above-mentioned upper silicon layer, and An upper glass substrate having through-holes provided with metal wiring. In addition, the present invention provides a micro inertial sensor manufacturing method, and the purpose of the present invention is to realize the miniaturization of the product and the simplification of the process.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

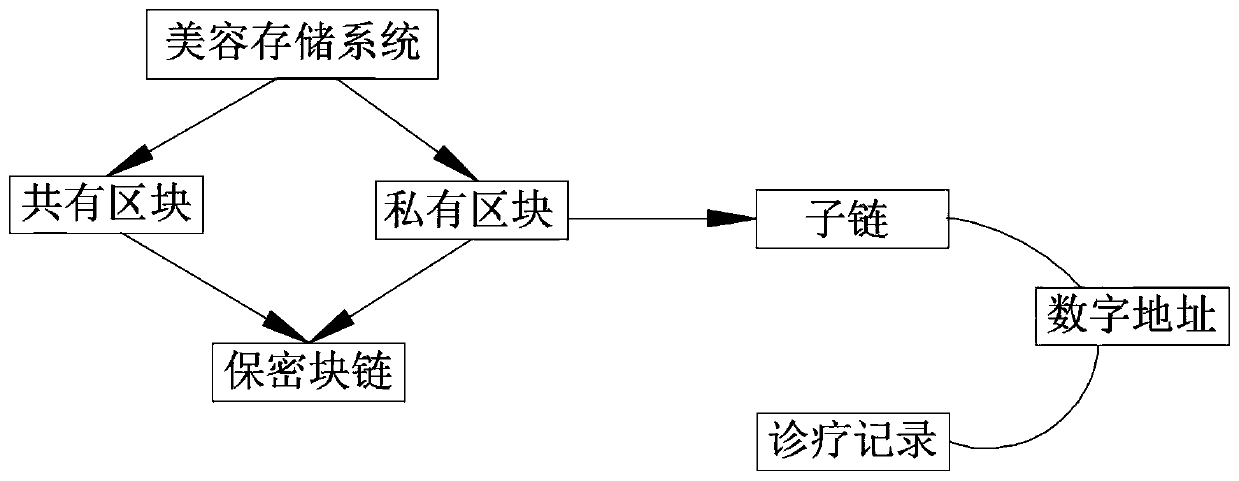

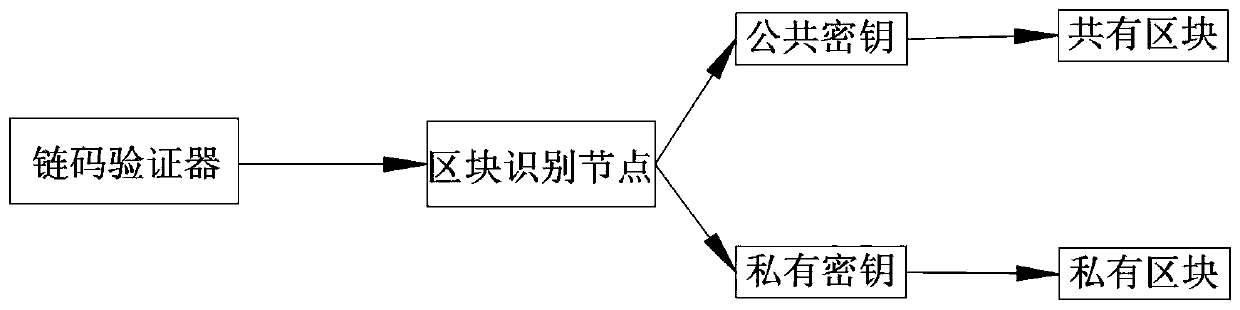

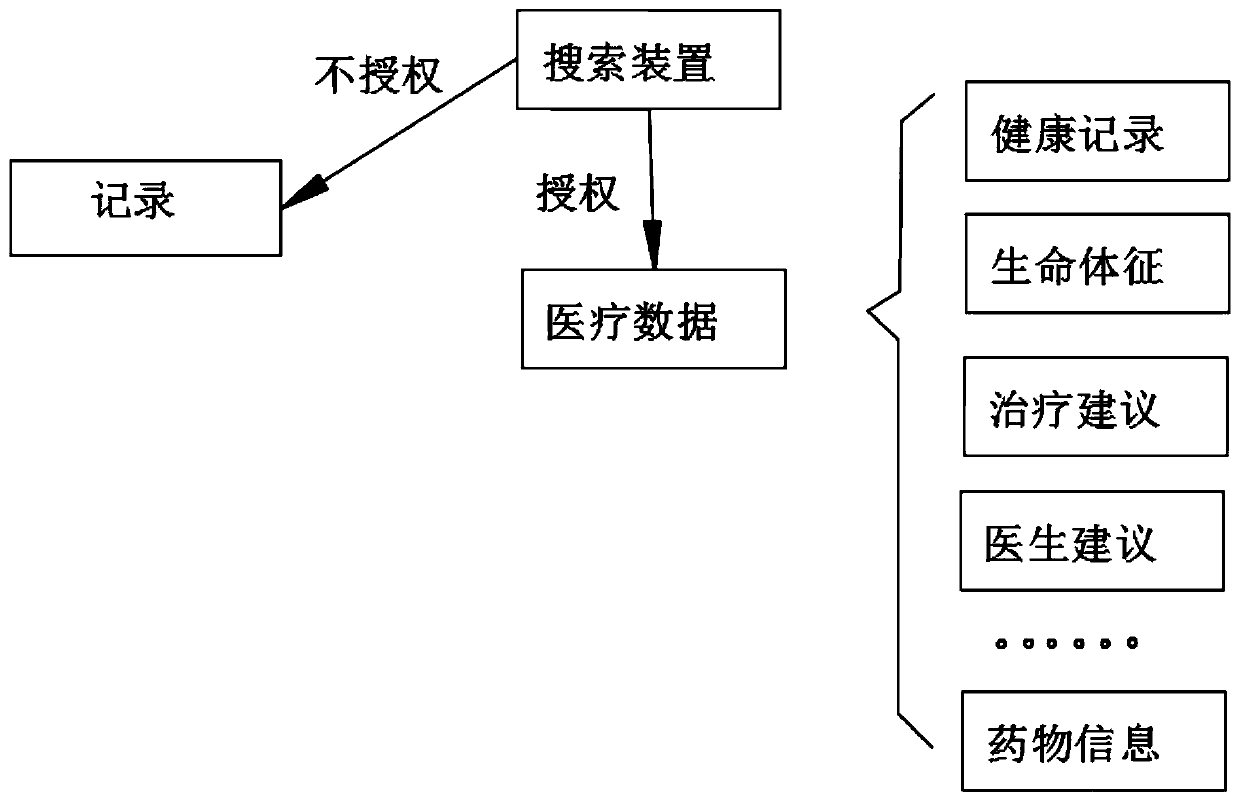

Beauty data storage system based on block chain

ActiveCN110929293AProtection securityOvercome leakageDigital data protectionPatient-specific dataData storage systemBlockchain

The invention provides a beauty data storage system based on a block chain. The beauty data storage system based on a block chain comprises a public block, a private block and a confidential block chain, wherein the public block is used for storing diagnosis and treatment operation and diagnosis and treatment information; the private block is configured to store a patient personal diagnosis and treatment record; the confidential block chain is configured to be used for verifying identities of the public block and the private block; and both the public block and the private block are connectedwith the secret chain. Personal information of a patient is stored by adopting a private block chain, so that the risk of leakage of traditional electronic archive information is overcome, and sensitive personal information of the patient is protected, and the worry that the patient worries about plastic surgery information leakage is solved.

Owner:FOSHAN UNIVERSITY

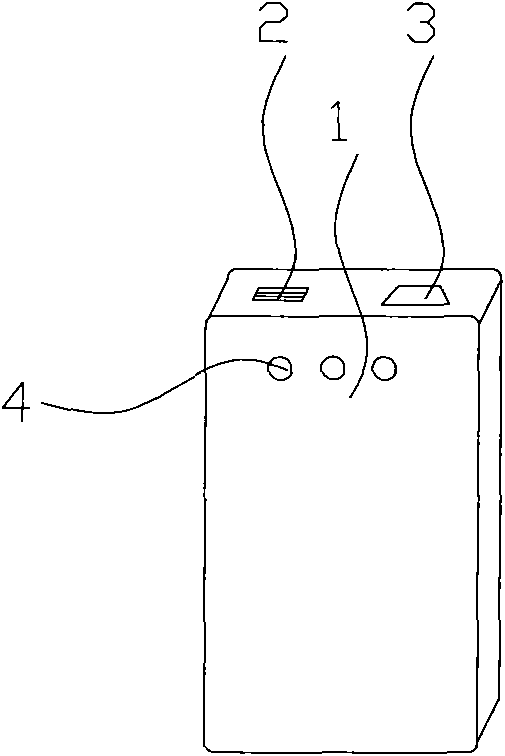

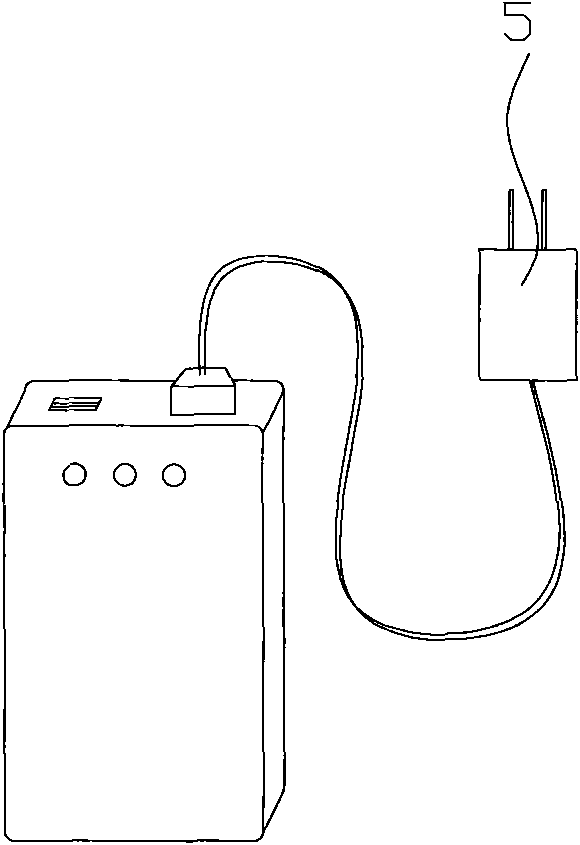

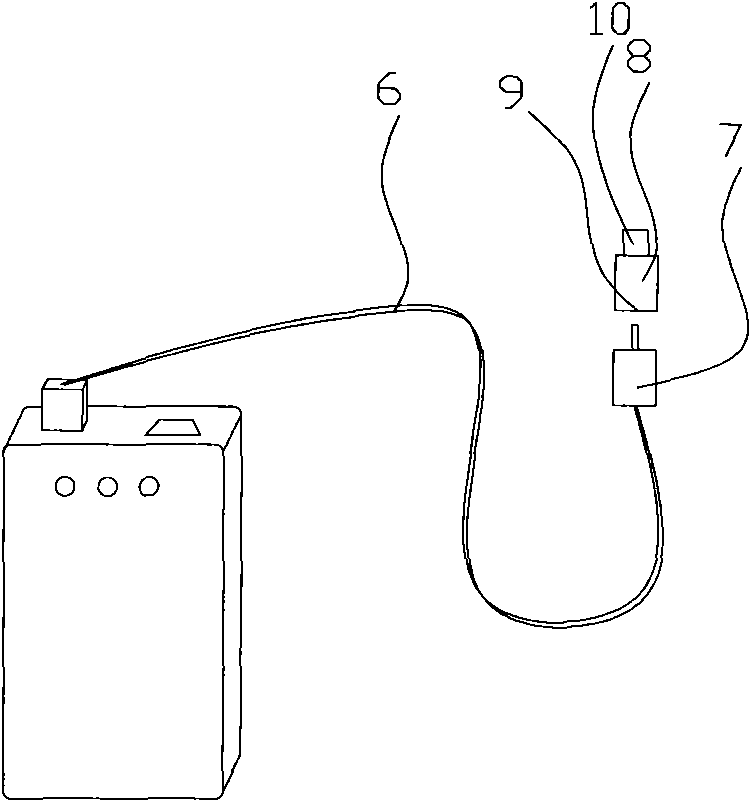

Multifunctional portable power supply device for mobile phone

InactiveCN102142696ASolve the inability to meet the requirements of power supply for mobile phones produced by different manufacturers at the same timeEasy to carryBatteries circuit arrangementsSecondary cells charging/dischargingElectricityMemory chip

The invention relates to a portable power supply device, which aims to solve the problems of single product function and inconvenience for use of the prior art. The invention provides a multifunctional portable power supply device for a mobile phone, which integrates charging, power supply and information storage and exchange to be convenient for trips of people. The portable power supply device comprises a shell body, a control circuit board and a charger, wherein the control circuit board is installed in the shell body, and the charger is connected with the shell body and is electrically connected with the control circuit board. A lithium battery is also arranged in the shell body, and the control circuit board comprises a voltage converting circuit which is used for converting the voltage of the lithium battery into the voltage of a mobile phone power source. A memory chip is also arranged in the shell body. The device is integrated with the charging and uninterrupted power supply of the mobile phone and a mobile hard disk, has several purposes, is convenient for people to carry, and eliminates the trouble of people out of home.

Owner:NINGBO VEKEN BATTERY

Method for cultivating mechanized transplanted seedlings of rice by use of organic medium production line in gutter-connected plastic greenhouse

InactiveCN104663230ASmall qualityRapid emergenceFlowers cultivationGrowth substratesPlant diseaseSeed treatment

The invention discloses a method for cultivating mechanized transplanted seedlings of rice by use of an organic medium production line in a gutter-connected plastic greenhouse. The method comprises the following steps of 1), arrangement of cultivating seedling materials, namely a medium, a seedling disk, a dome-shaped steel-structure plastic film gutter-connected glasshouse facility, and a finishing seedbed; 2), seed treatment, namely choosing seeds, soaking the seeds and accelerating germination; 3), medium treatment and disk loading, namely firstly loading a bottom-layer medium, then seeding, finally covering the seeds with the medium and watering; 4) seeding and bud promotion, namely seeding dry rice and bud rice in each disk, stacking the disks and promoting bud, moisturizing, warming, arranging the disks, and performing atomizing spray, wherein the disk stacking height is 20 layers; and 5) seedling stage management, namely attentively managing the temperature and moisture and controlling diseases. The method has the advantages of good technical effect, obvious social benefit and prominent economical and ecological benefits and the like, and the method has preferable popularization prospect.

Owner:贵州卓豪农业科技股份有限公司

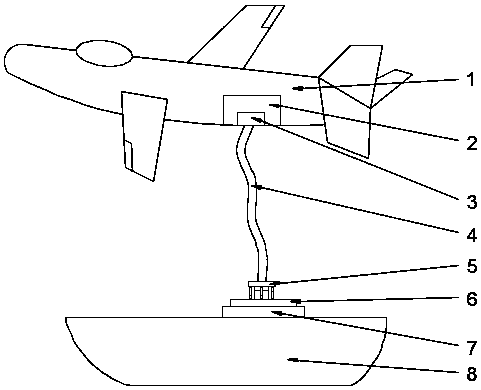

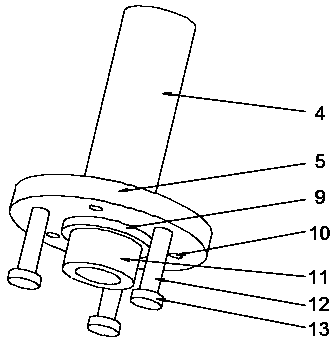

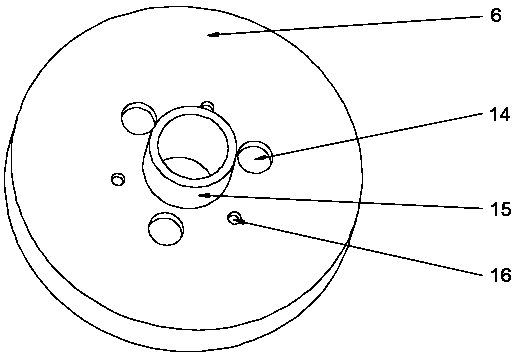

Marine inflight refuelling system and method of unmanned ship

ActiveCN108820130AReasonable designSimple structureAircraft componentsUnmanned surface vesselsMarine engineeringFuel tank

The invention relates to a marine inflight refuelling system and method of a unmanned ship. The marine inflight refuelling system of the unmanned ship comprises an unmanned aerial vehicle and the unmanned ship; a make-up oil tank, an oil pipe contraction and release device, an oil conveying pipe and a three jaw sucker are arranged on the unmanned aerial vehicle; and a plane sucker and an oil tankto be made up are arranged on the unmanned ship. The marine inflight refuelling system of the unmanned ship has the advantages that the design is reasonable, the structure is simple, the operation isstable, the system is convenient and rapid, the whole refuelling process of the system is completely autonomous without manual intervention, the refuelling effectiveness of the unmanned ship can be enhanced, and the marine manual refuelling risk can also be avoided. The two ends of refuelling are tightened and fixed to act through positioning so that the refuelling operation realizes higher connection stability; and meanwhile, through combination between the unmanned aerial vehicle and the unmanned ship, the refuelling unmanned and autonomation degree is further enhanced, the problem of poor endurance of the unmanned ship is solved, the acting area of the unmanned ship is enlarged, and precondition and guarantee are provided for multifunctionality of marine operation of the unmanned ship.

Owner:SHANGHAI UNIV

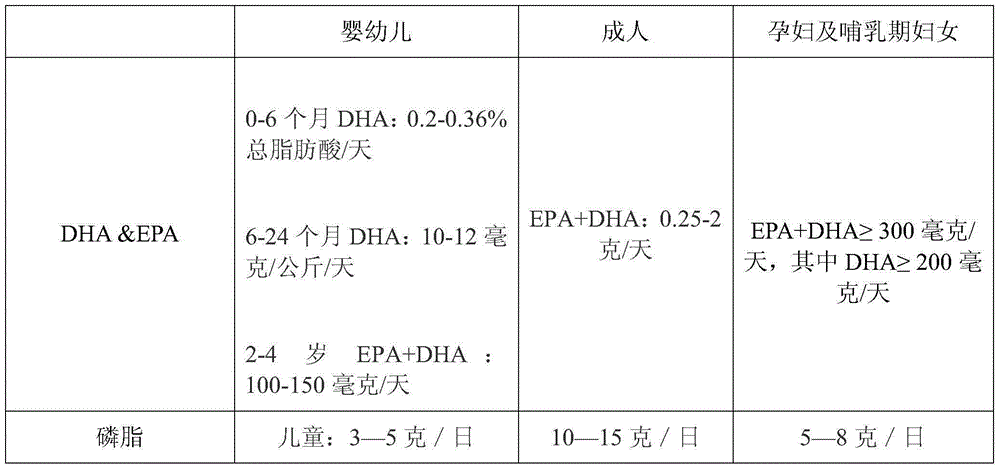

Fish oil and phospholipid milky and concentrated beverage production method

The present invention belongs to the technical field of food, relates to a fish oil and phospholipid milky and concentrated beverage, and specifically relates to a DHA and EPA high content deep sea fish oil and phospholipid high content milky beverage. The technical scheme provides a fish oil and high-purity phospholipid concentrated beverage. The contained DHA and EPA content accounts for 10-90% of the total amount of the deep sea fish oil with a content ratio of the DHA and EPA being 9 : 1 to 1 : 9. According to different administration individuals, the content ratio of the DHA and EPA is preferably 7 : 3 or 7 : 7, and the content of soybean lecithin or egg yolk lecithin phosphatidylcholine (PC) content is more than 50%. By taking advantage of the characteristic of using lecithin as an emulsifier, the fish oil and the phospholipids are scientifically combined, and the mixture is subjected to a high speed shearing and low pressure homogenizing, and become a comfortable and tasty milky beverage which can be directly taken. The traditional ways of respective administrations of the phospholipids and the fish oil as capsules are changed, and the absorption rate and the efficacies of disease treating and preventing are increased.

Owner:SHENYANG TIANFENG BIOLOGICAL PHARMA

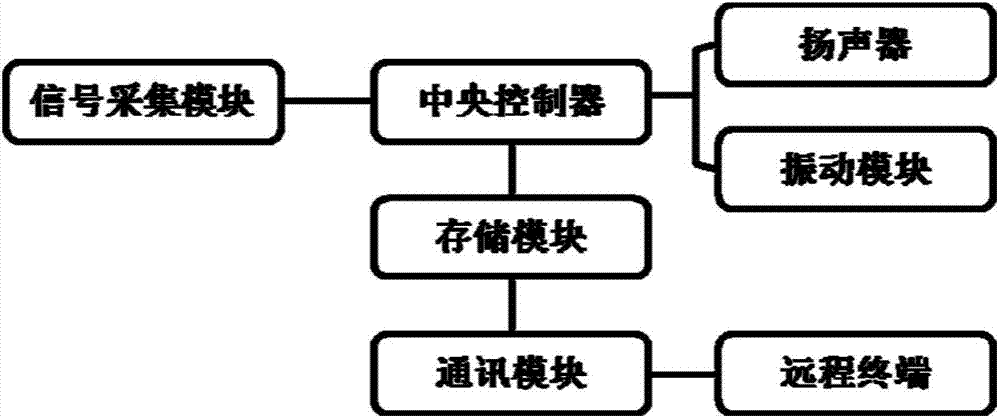

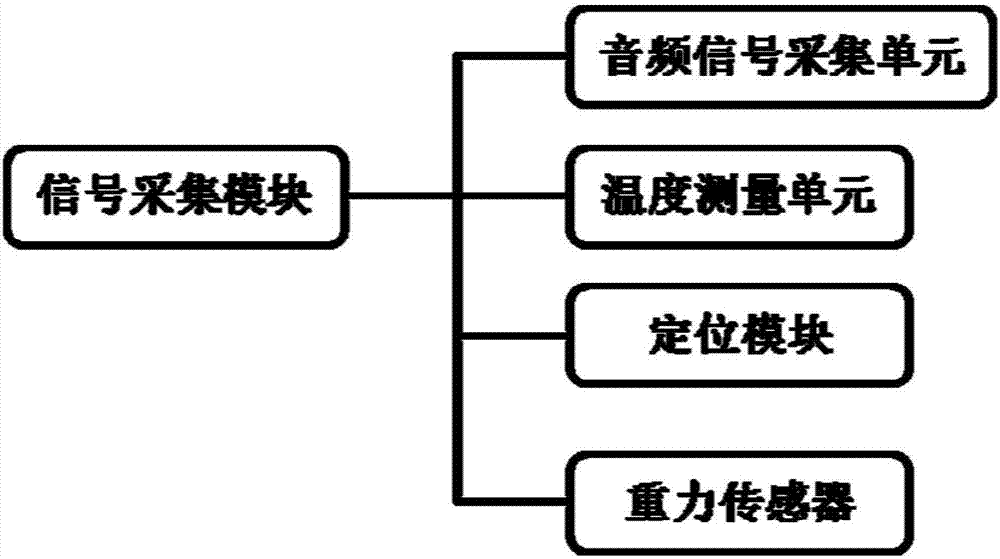

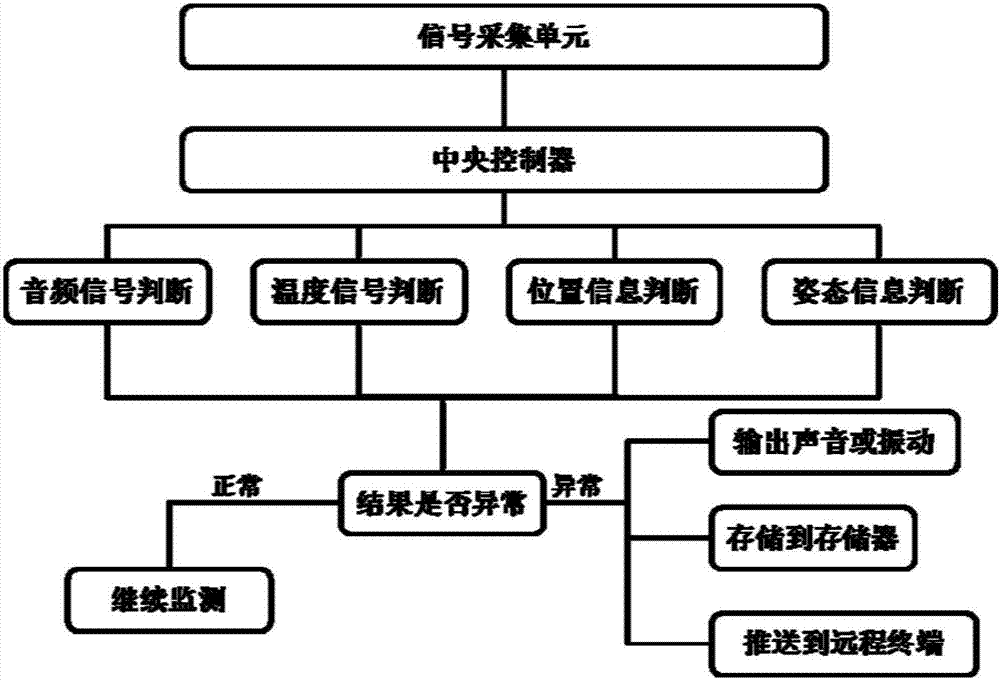

Remote intelligent monitoring system for children

InactiveCN107277164ASimple device structureMiniaturizationSpeech analysisDiagnostic recording/measuringE communicationLoudspeaker

The invention relates to a remote intelligent monitoring system for children. The remote intelligent monitoring system for children comprises a signal acquisition module, a memory module, a central controller, a communication module, a loudspeaker module, a vibration module and a remote terminal; wherein the signal acquisition module comprises an audio signal acquisition unit, an infrared temperature measurement unit, a position measurement unit and a gravity sensor, respectively used for collecting audio signals, temperature signals, position information and gesture information; the central controller comprises a processor, and the central controller processes the collected signals to accurately determine the status of a child; the signal acquisition module collects signals once every other time T1 and transmits to the central controller; the central controller analyzes and determines whether the state of the child is abnormal or not; and the central controller carries out corresponding emergency treatment according to different abnormal states, and transmits the abnormal state information to the remote terminal through the communication module and sends an alarm signal to the remote terminal user.

Owner:重庆市端峰科技有限公司

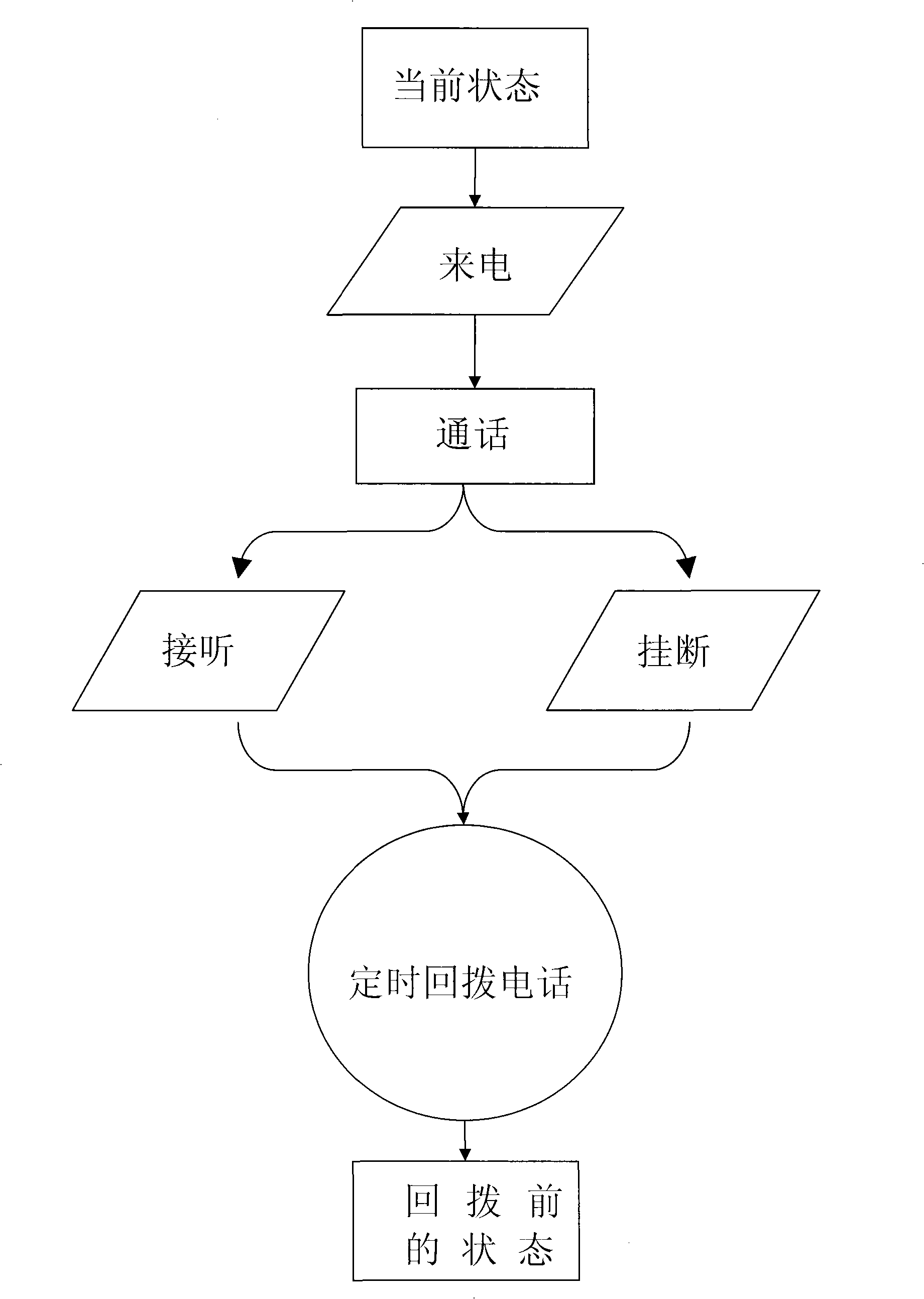

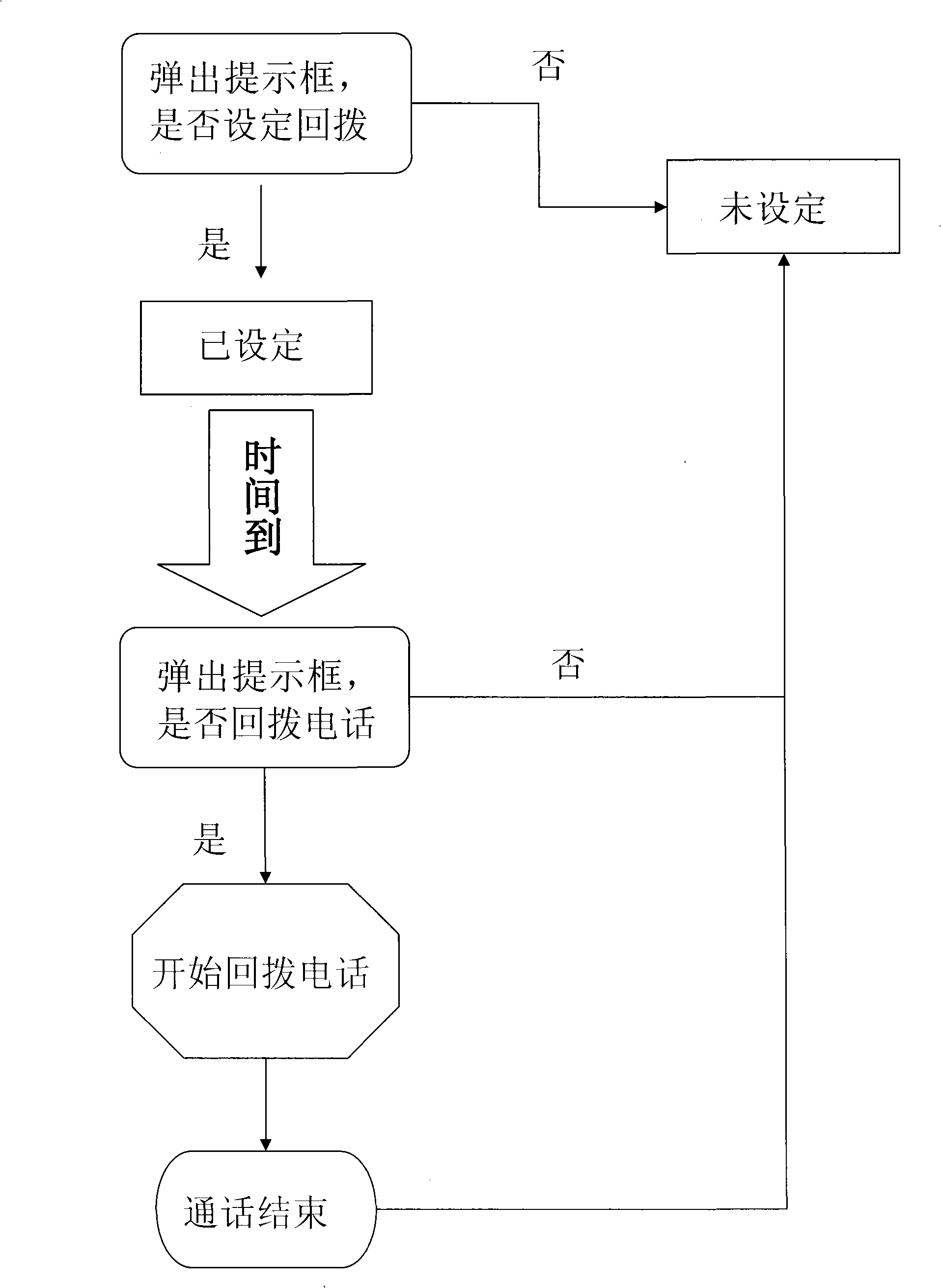

Method for timed calling applied in mobile phone

InactiveCN101340483ASolve your worriesSubscriber signalling identity devicesTelephone sets with user guidance/featuresUser FriendlyMobile phone

The invention relates to a method for timely dialing back a call, and the method is applied to a mobile phone. When an incoming call is got through or hung up by a user, a system can prompt the user whether timely dialing back the call needs to be set or not. The time for timely dialing back is set up, when the time is up, the system can make an automatic response and prompts the user whether the telephone number needs to be dialed back or not. The call with the preset dialing back time can be successfully made only by confirmation of the user. Furthermore, a timely dialing back option is also existed in call records, phone book and other menu options, thereby leading the user to select manually. The method can greatly facilitate the use of the people. Especially for business people, even in a very busy work, the business people can not forget the important call by using the method. The intelligent and user-friendly design causes the method to be more applicable to the market demand.

Owner:飞图科技(北京)有限公司

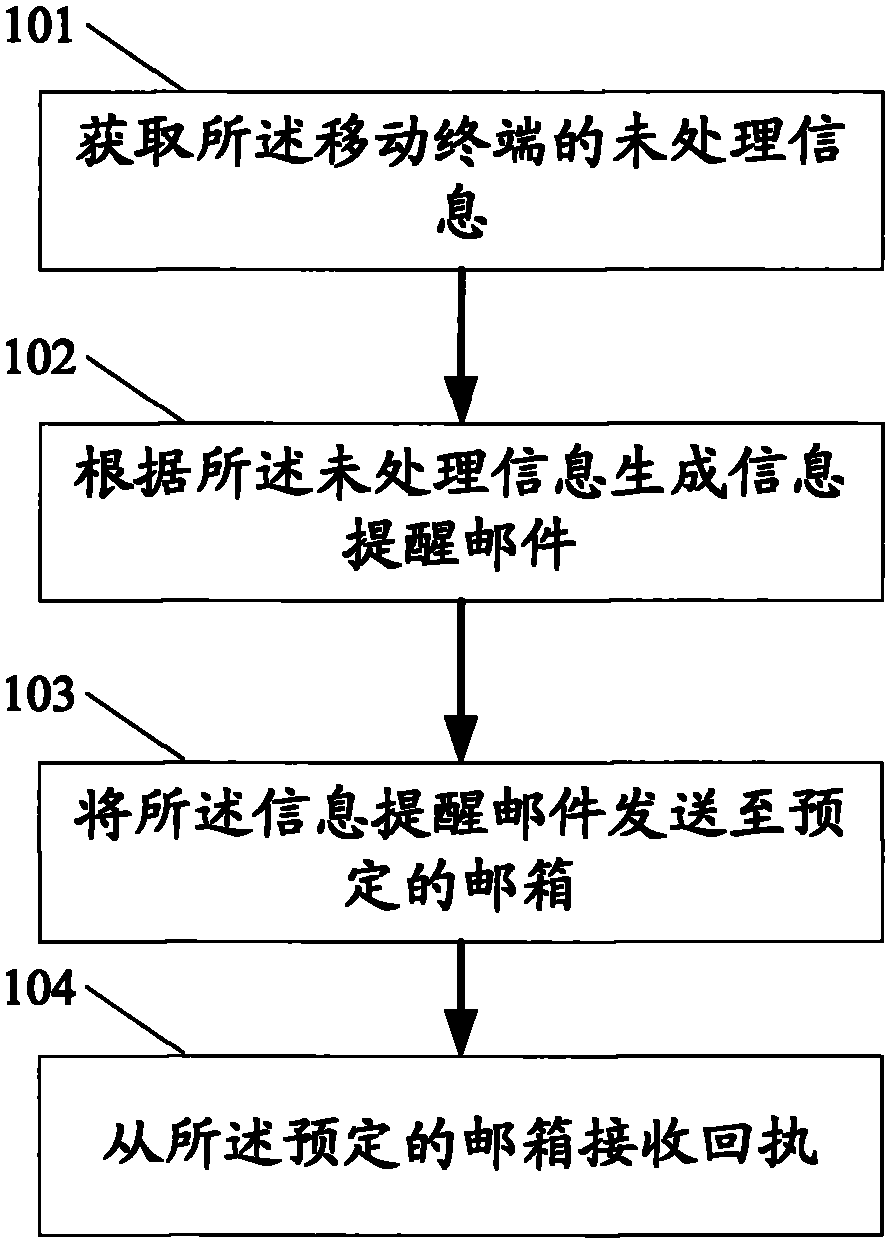

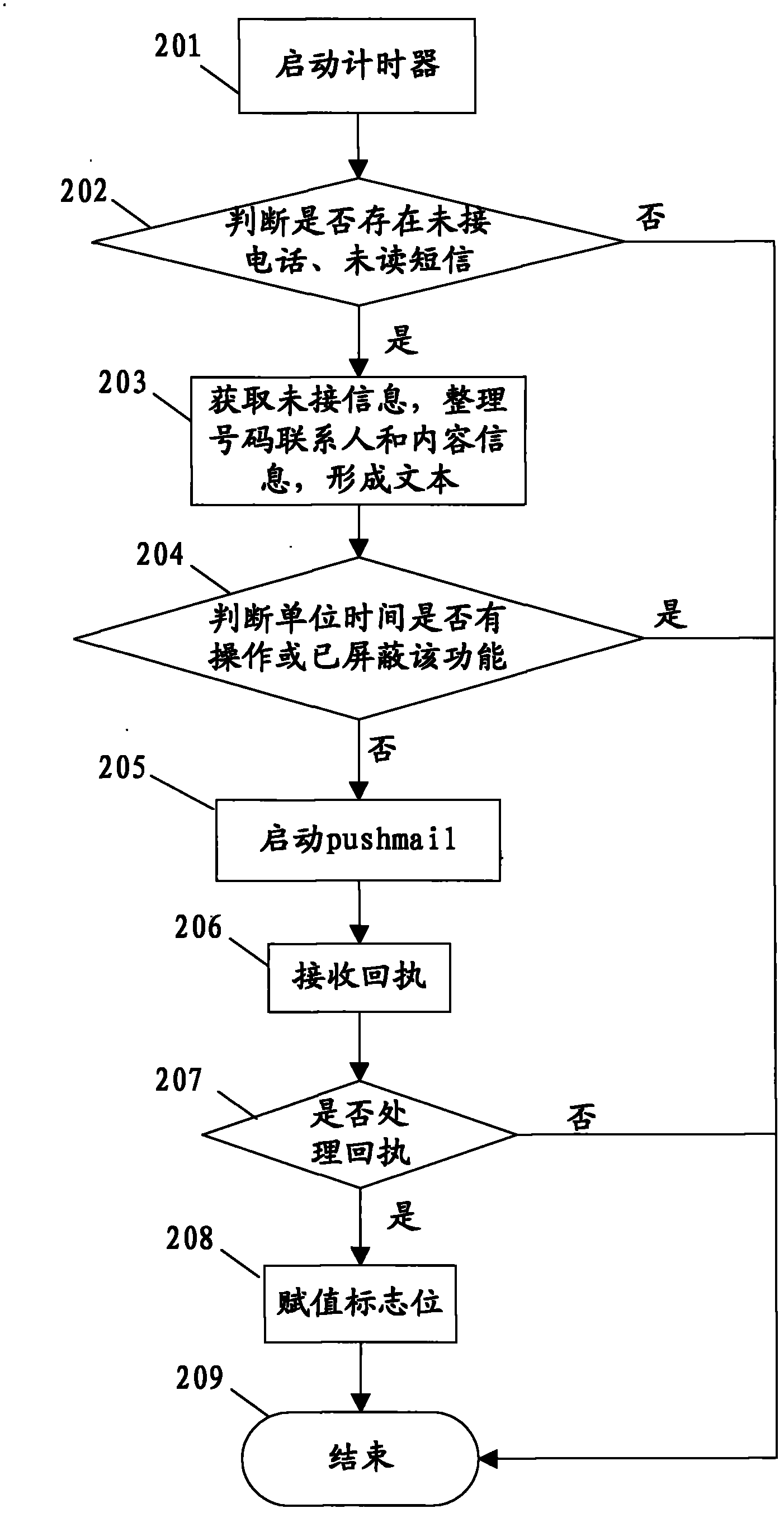

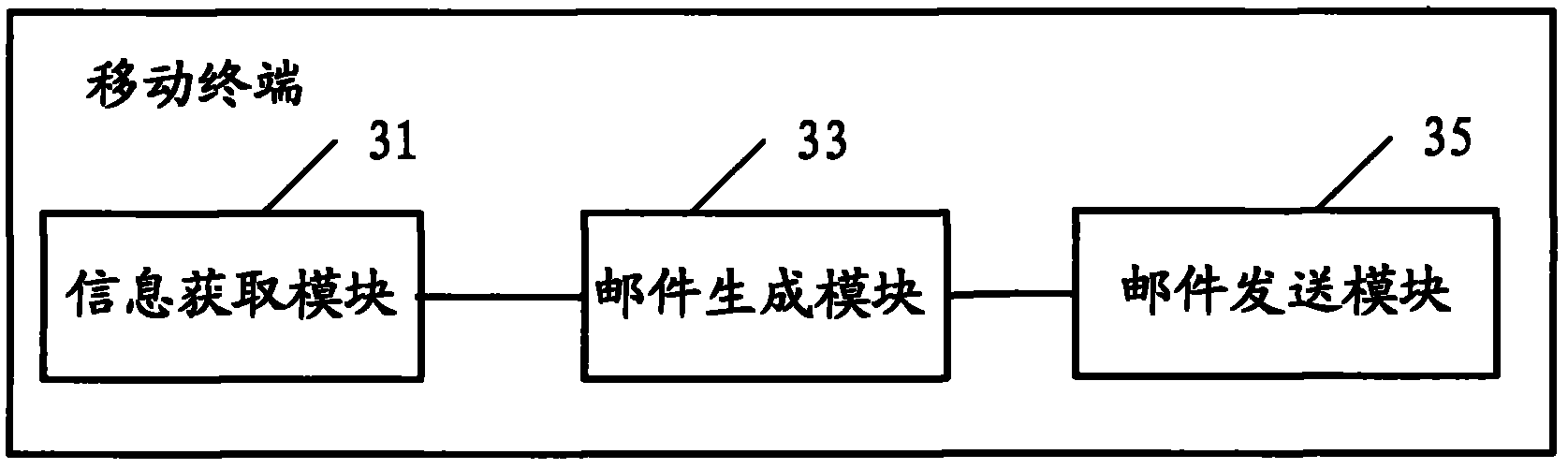

Mobile terminal information processing method and mobile terminal

InactiveCN101917680ASolve your worriesReduce the impactMessaging/mailboxes/announcementsLocation information based serviceInformation processingProcess information

The embodiment of the invention discloses a mobile terminal information processing method and a mobile terminal. The method comprises the following steps of: acquiring unprocessed information of the mobile terminal, wherein the unprocessed information comprises one or more of missed call, unread short message, unread mail information and event reminding information in a predetermined time; generating information reminding mails according to the unprocessed information; and sending the information reminding mails to the predetermined mail boxes. In the embodiment of the invention, when a user leaves the mobile terminal at home or in a car, the missed information can be acquired at any time in the office or at other places with networks by mail reminding so as to solve later troubles, reduce the influence and bring convenience to the user. Particularly, the user incapable of using the mobile terminal during working can acquire the information on a mobile phone at any time through the mail box and the like.

Owner:YULONG COMPUTER TELECOMM SCI (SHENZHEN) CO LTD

Inorganic abradant cleaning paste

InactiveCN101205509ANo pollutionSolve your worriesInorganic/elemental detergent compounding agentsPigmenting treatmentOrganic matterCleaning product

The invention relates to the cleaning product field, in particular to abio-abrasive cleansing paste. The components by weight percentage of the cleansing paste are: 35 to 50 percent of abio-abrasive, 15 to 35 percent of humectant, 15 to 30 percent of deionized water, 2 to 3 percent of sodium lauryl sulfate, 0.1 to 0.3 percent of triethanolamine, and 1 to 2 percent of chitosan germicide. The invention takes the abio-abrasive as the main component of dishware cleanser to replace the prior petroleum base compound; moreover, organic matter of other components are nontoxic raw materials, which ensures that the abio-abrasive cleansing paste has excellent decontamination ability and does not pollute the environment or affect the health of people. In addition, the invention has the advantages of convenient use and transportation, low cost of production and water economization. Therefore, the invention can be the environmental substitute of the prior dishware and cooker cleanser.

Owner:苏伟光

Intelligent medicine box

InactiveCN104146866ASolve your worriesTake medicine on timePharmaceutical containersMedical packagingMicrocomputerMicrocontroller

The invention provides an intelligent medicine box which comprises at least one medicine storing hole, a pushing plate, a relay, a single chip microcomputer, a medicine box shell and a button area. The medicine storing holes are formed in the medicine box shell, the relay and the pushing plate are arranged at the inner bottom of the medicine box shell, the single chip microcomputer is embedded in the inner rear wall of the medicine box shell, the relay is connected with the pushing plate, and the button area is arranged on the outer rear wall of the medicine box shell. Information of the number of times of medicine taking, the time of medicine taking and / or medicine taking dose of medicines in different medicine storing holes of each day is preset in the single chip microcomputer, according to the preset information, the single chip microcomputer controls the relay to push out and draw back the pushing plate at preset time points, and the single chip microcomputer controls the relay to accurately push out medicines, so that automatic medicine dispensing is achieved.

Owner:QILU UNIV OF TECH

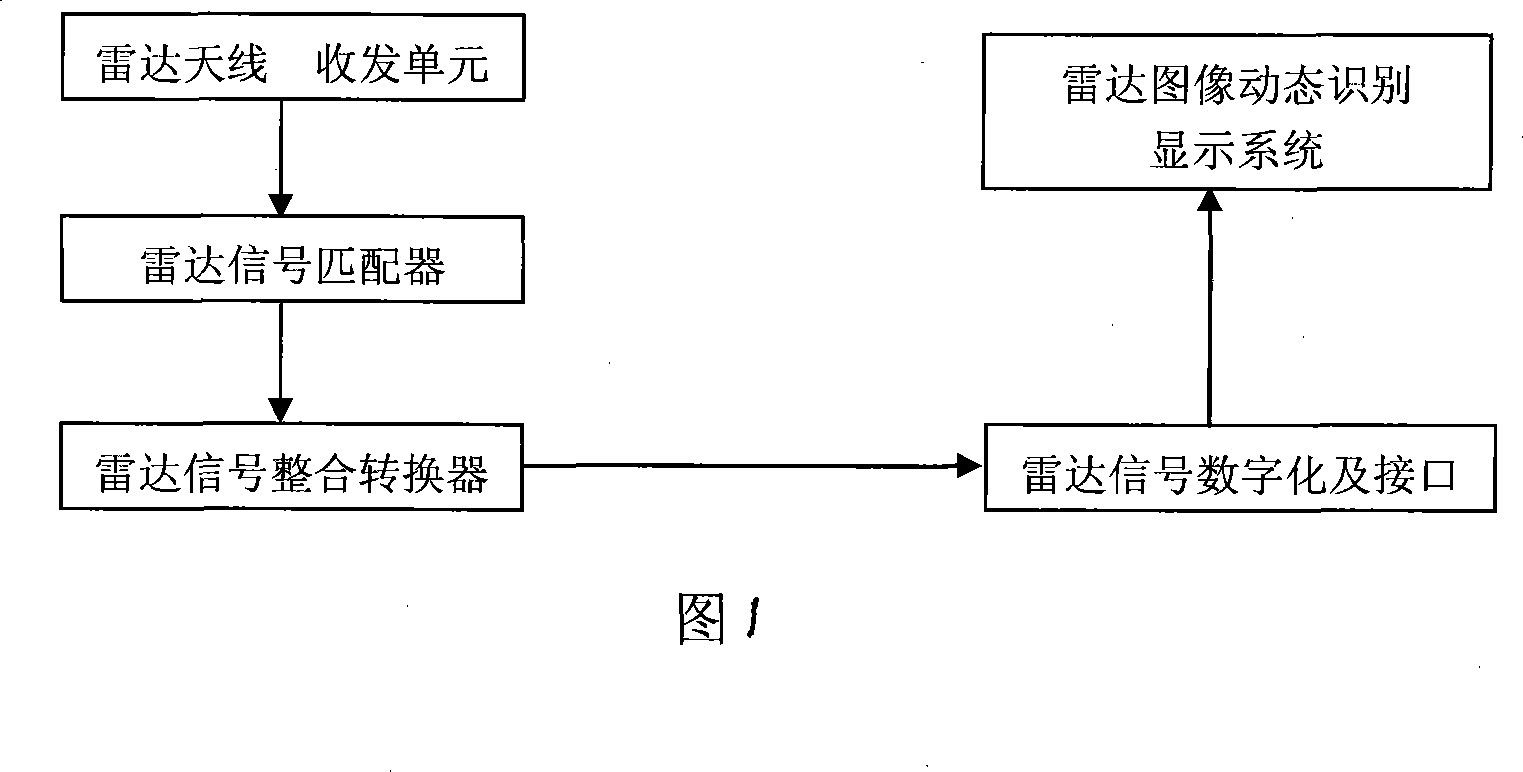

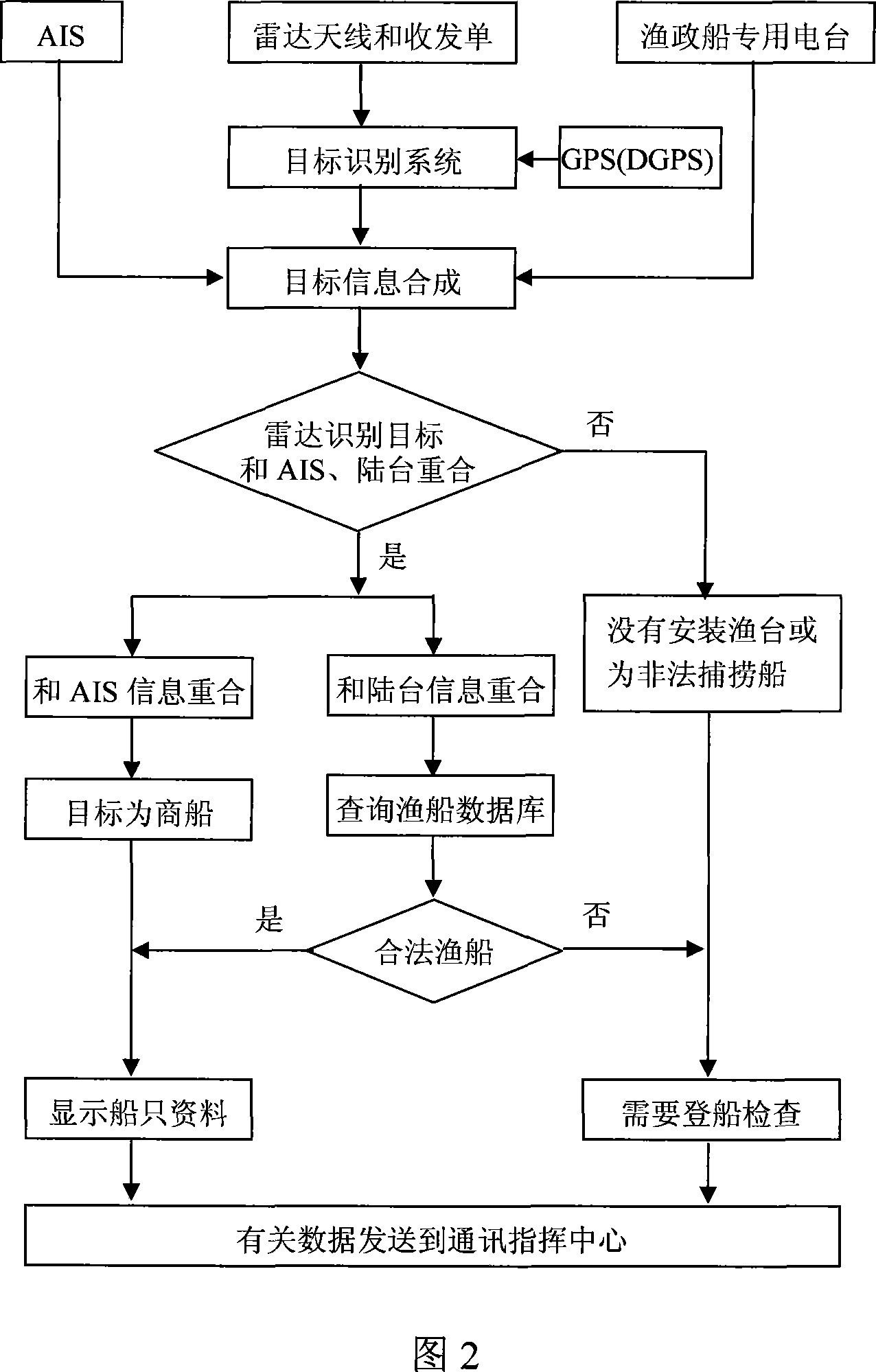

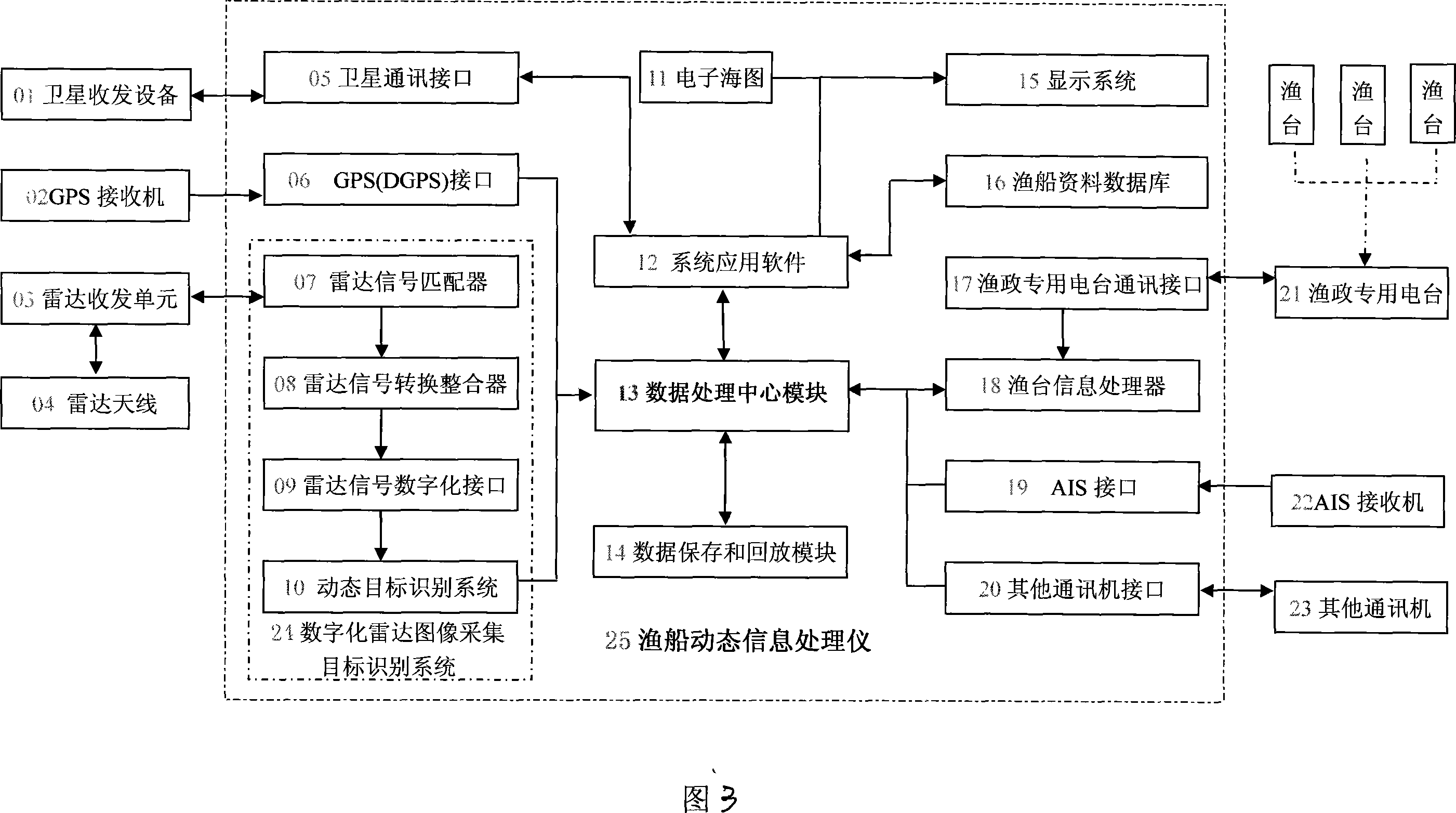

Fishing boat dynamic monitoring and inquiry validation system

ActiveCN101145037AAccurate positioning and rescueSolution by itemProgramme control in sequence/logic controllersRelevant informationCost effectiveness

The present invention relates to a dynamic monitoring, inquiring and verifying system for fishing boats, and is used for monitoring verification management and wreck salvage of fishing boats at sea; the system consists of an input / output interface part, a data-processing part, a data storage part and a display part; the interface part can be used to receive the signal of a fishing boat; then through module analyzing, judging and processing the signal by the data processing center, the system can realize the remote electron-monitoring, inquiring and verifying for fishing boats in a larger area around the fishing boat, can inquiry and trace the relevant information of other fishing boats and vessels, and can transmit the relevant data real time to the land command center completely; the dynamic monitoring, inquiring and verifying system for fishing boats of the present invention is designed according to the fisheries management requirements of the marine fisheries management department; the present invention has the advantages of novel structure, rapid verification and accurate monitoring, easy management, low cost as well as good effect, etc. and thereby, the present invention belongs to novel dynamic monitoring, inquiring and verifying system for fishing boats, and combines cost-effectiveness and practicability into a whole.

Owner:DALIAN HAOYANG TECH DEV CO LTD

Method for producing 2,4-dichloroacetophenone by using solid waste chlorobenzene tar as raw material

InactiveCN101898947ASolve your worriesAlleviate supply and demand pressureCarbonyl compound preparation by condensationAcetyl chlorideM-dichlorobenzene

The invention discloses a method for producing 2,4-dichloroacetophenone by using solid waste chlorobenzene tar as a raw material. The method mainly comprises the following steps of: extracting m-dichlorobenzene from the solid waste chlorobenzene tar, and then performing five steps of acylation, washing, distillation, crystallization and packing in the 2,4-dichloroacetophenone production process. The method is characterized in that: the acylation reaction comprises that: the m-dichlorobenzene and acetyl chloride undergo the acylation reaction under the action of anhydrous aluminum trichloride, the dripping temperature of the acetyl chloride is kept between 50 and 60 DEG C during reaction, the temperature is gradually raised to between 90 and 95 DEG C after the dripping is finished, and reflux stirring reaction is performed for about 4 hours to obtain the 2,4-dichloroacetophenone. The method has the advantages that: the m-dichlorobenzene is reclaimed from the solid waste chlorobenzene tar during production, and the reclaimed m-dichlorobenzene is used as the raw material for producing the 2,4-dichloroacetophenone, so by the method, the 2,4-dichloroacetophenone is produced by using the m-dichlorobenzene as the raw material while extra worries of m-dichlorobenzene and o-dichlorobenzene production enterprises are solved, the supply and demand pressure of chlorobenzene markets is relieved and extended products are further developed and utilized.

Owner:JIANGSU LONGCHANG CHEM

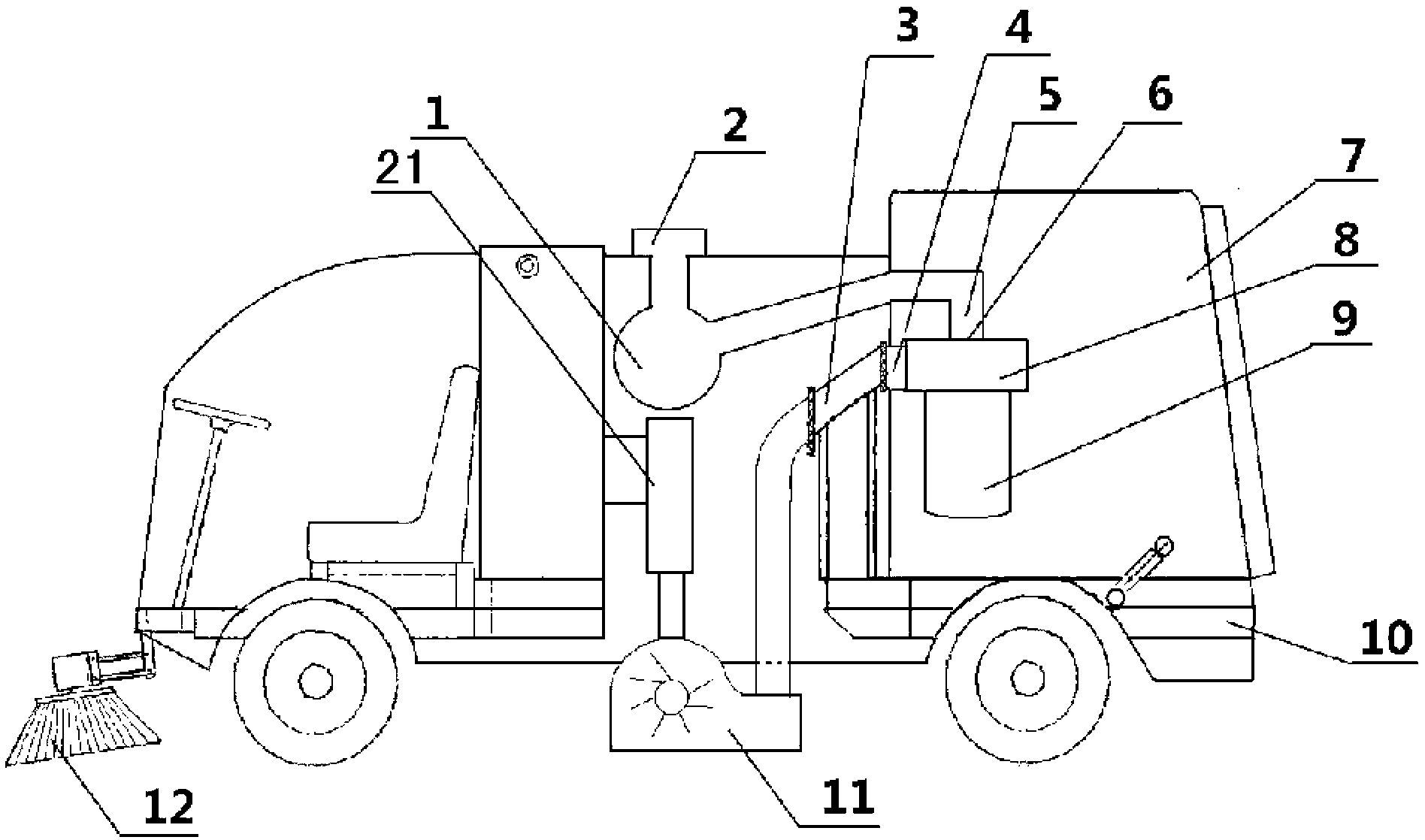

Electric dust-free solar energy sweeping vehicle

InactiveCN102797235AQuick installationEasy to removeDispersed particle filtrationRoad cleaningWind drivenVehicle frame

An electric dust-free solar energy sweeping vehicle comprises a vehicle frame, a storage battery, an exhaust blower, a trash box, a rotary brushing plate and a solar photoelectric conversion plate which is arranged on a vehicle body; and the storage battery is mounted at the bottom of the vehicle frame and serves as a main power source for driving vehicles to drive and a sweeping system, and the trash box is mounted at the rear part of the vehicle frame and is used for storing trash. The electric dust-free solar energy sweeping vehicle is characterized in that a no-dust-escape dedusting device is further arranged in the trash box; the no-dust-escape dedusting device comprises a swirler and a combined filter cylinder; the upper end of the swirler is connected with the exhaust blower arranged outside the trash box through an exhaust pipe and forms a wind-driven power passage together with a dust suction port which is arranged at the lower part of the vehicle body and abuts upon a road through a laterally-arranged connecting port of the swirler; the swirler takes the shape of a volute, wherein one side of the casing is connected with an air inlet pipe through an air inlet, and a hollow connecting shaft for connecting the exhaust blower and the combined filter cylinder is arranged in the center of the swirler; and a separating port communicated with the inner storage space of the trash box is arranged on the outer wall of the swirler.

Owner:SHANGHAI ZHONGHUAN TECH

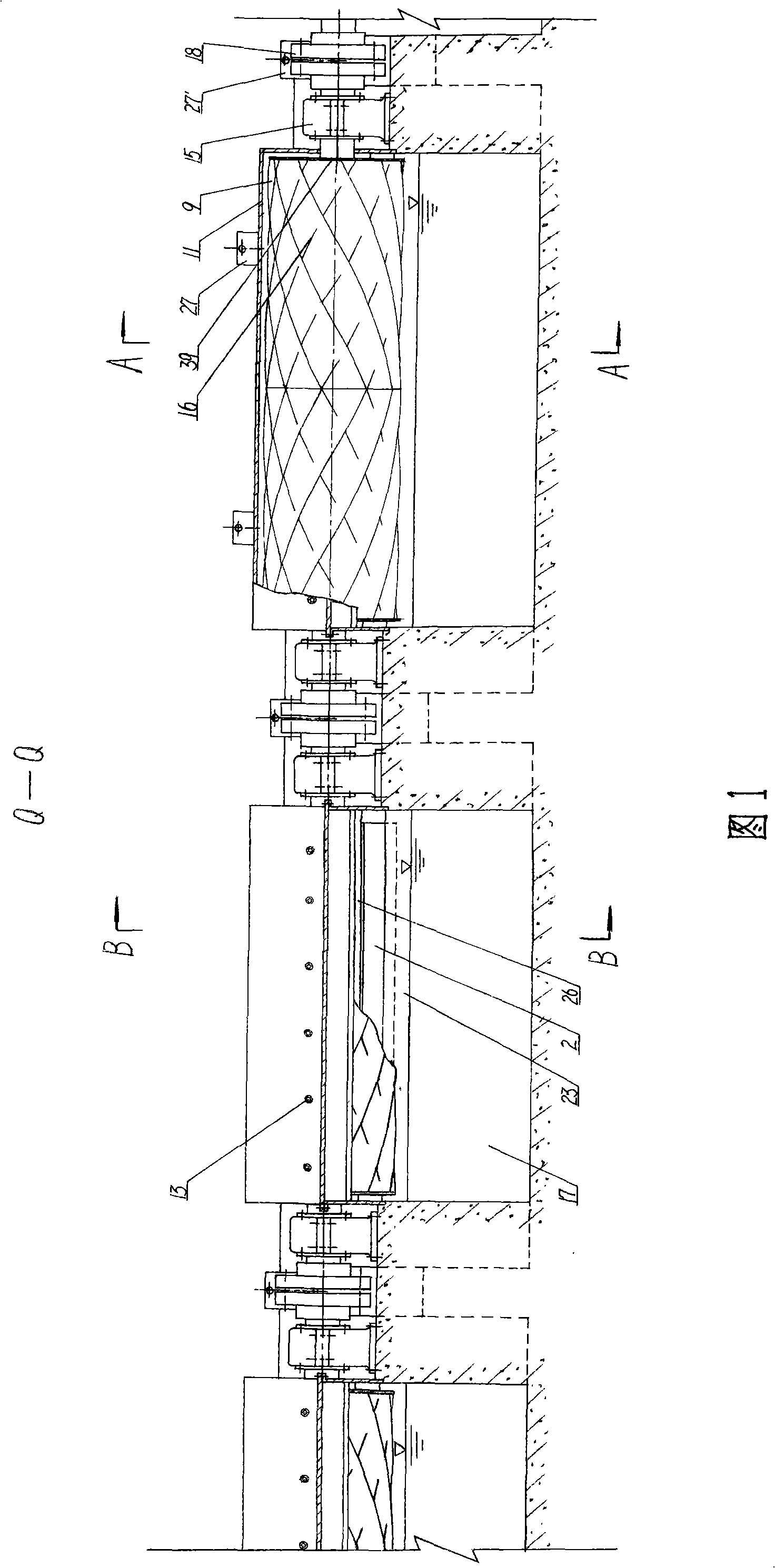

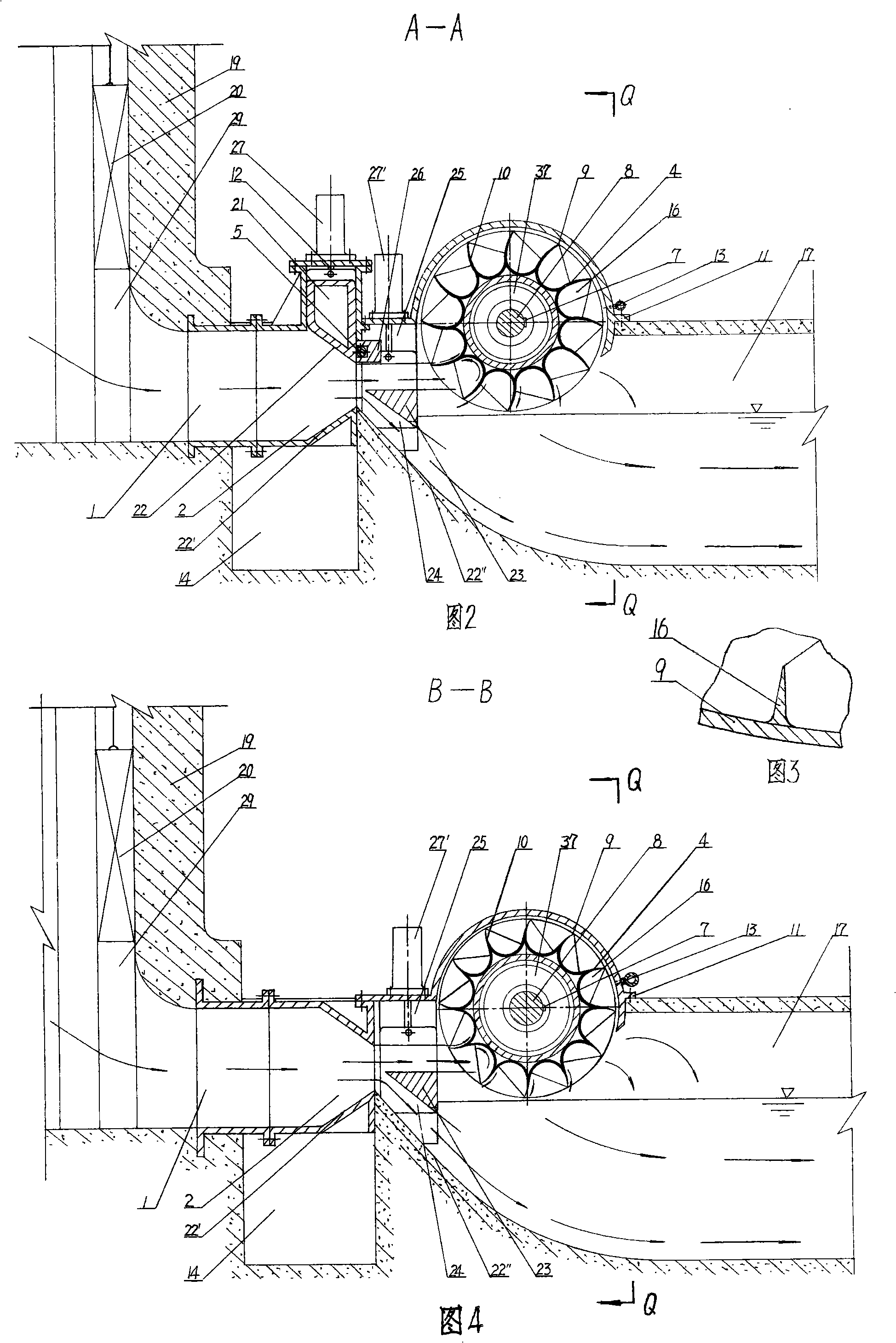

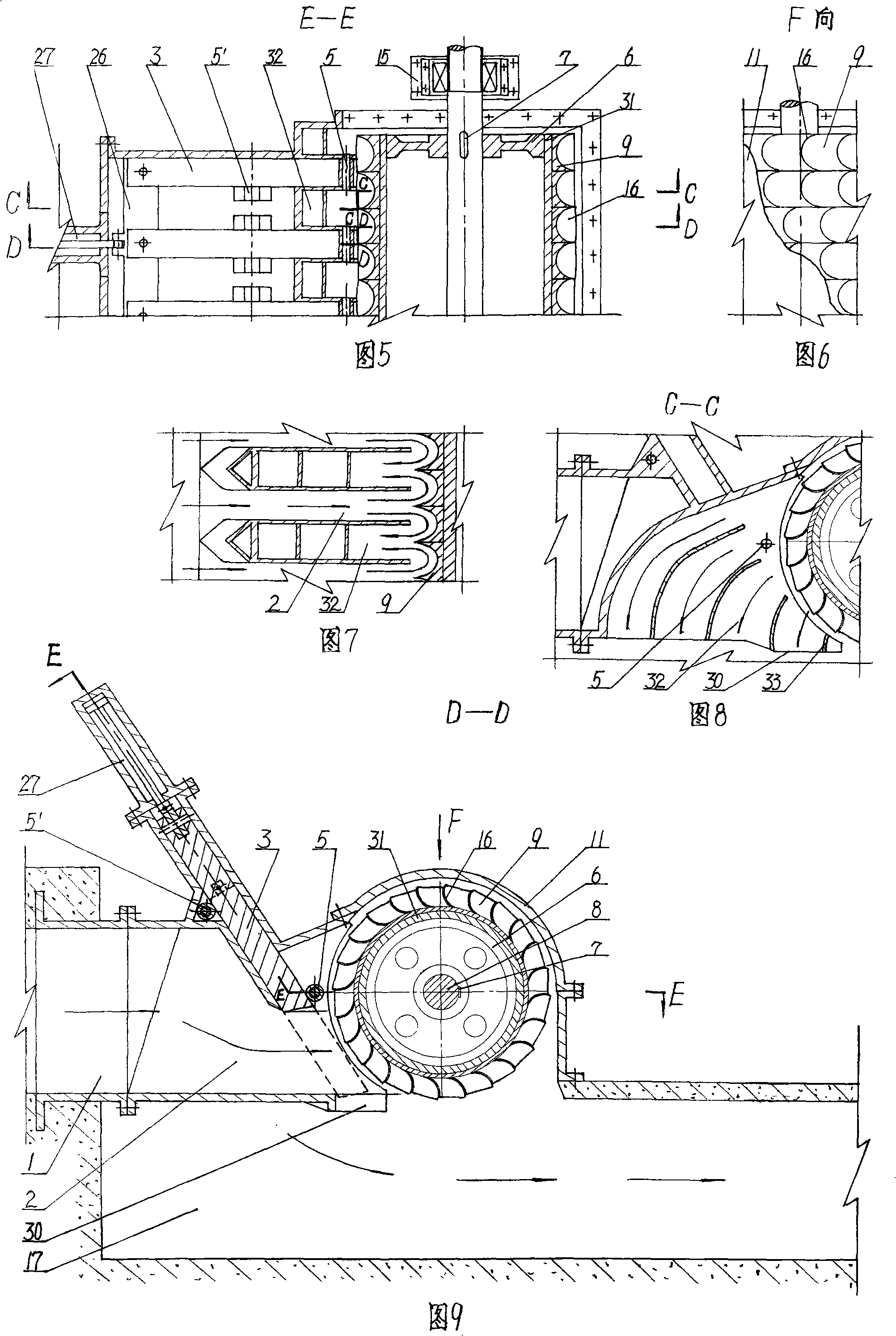

All-purpose hydroturbine

InactiveCN101354004ASmall lossSelf lossHydro energy generationEngine componentsHydro energyWater turbine

A universal water-turbine engine pertains to an impact water-turbine engine which converts pressure energy of current to kinetic energy and converts the kinetic energy to rotating mechanical energy in the hydraulic machinery; the water-turbine engine consists of a or a plurality of jet orifices, a device corresponding to the jet orifices, a or a plurality of turning wheels arranged on a main axis for the universal water-turbine engine, a tailrace arranged under the turning wheel, a speed governor, a driving device and other parts. The water-turbine engine can develop and exploit all waterpower resources and has high efficiency, large capacity, safe and reliable performance, simple and reasonable structure as well as low manufacturing cost; the application of the water-turbine engine significantly promotes the current development and exploitation of the waterpower resource, thus being capable of marking a new epoch of rapid development of the hydroelectric power industry.

Owner:黄国宏

Purchase-sales management system for store operation

InactiveCN105184485ARealize managementFacilitate decision-makingResourcesCommerceManagement unitInterface design

The invention belongs to the field of purchase-sales management systems, and particularly relates to a purchase-sales management system for store operation. The purchase-sales management system comprises an order management unit, a purchase management unit, an offline sales management unit, an inventory management unit, a commodity management unit, an after-sale management unit and a store diagnostic analysis unit. The purchase-sales management system for store operation introduces modern office software in store management, and achieves processing of supermarket commodity information, thereby facilitating decision making and management of managers and eliminating worries; the humanization and people-oriented spirit are represented in design; the interface is kind and friendly, simple and intuitive in design, and convenient to operate; and the core of the system is links among purchase, sales and inventory, the modification of each list involves other lists, and the modification of corresponding information is completed automatically by the system when the purchase, sales and commodity return operations are completed.

Owner:TIANJIN KEMEI INT TRADE CO LTD

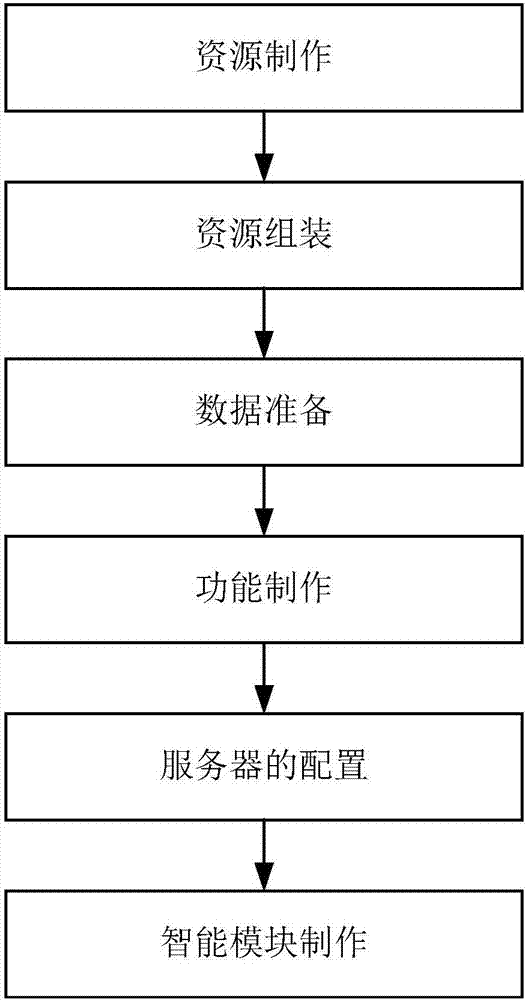

UE4-based interactive virtual reality implementation method and system thereof

The invention discloses a UE4-based interactive virtual reality implementation method comprising the steps of resource making, resource assembly, data preparation, function making, server configuration and intelligent module making. The system comprises a resource making module for performing model making, material making and special effect making; a resource assembly module for performing scene importing, terrain making and scene optimization; a data preparation module for implementing control of all data, control and exporting of Excel tables, and saving of .sav files in a UE4; a function making module for performing navigation special-purpose minimap making, a DIY function for enhancing reality, and virtual and reality interaction; a server configuration module for implementing furniture data and shopping mall synchronization, popular furniture ranking pushing, and database update; and an intelligent making module for implementing intelligent adsorption, intelligent home simulation, and artificial intelligence. Image quality is ensured, and VR+AR experience is improved.

Owner:深圳前海小橙网科技有限公司

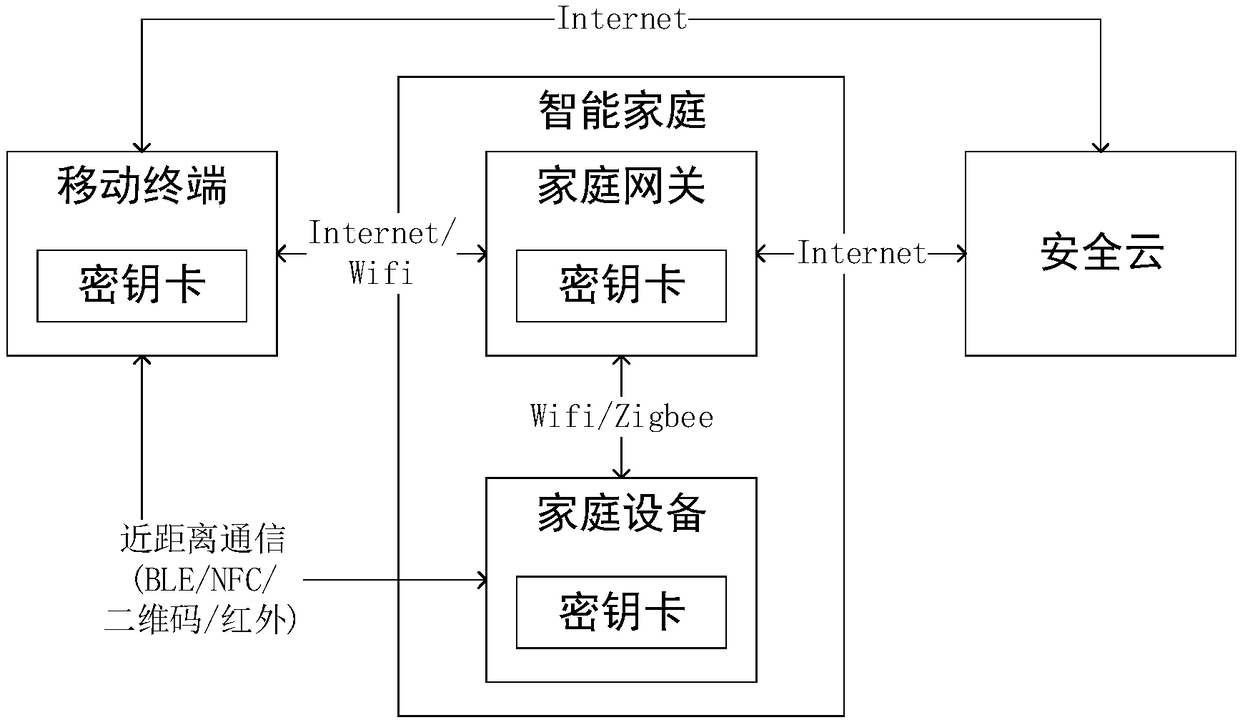

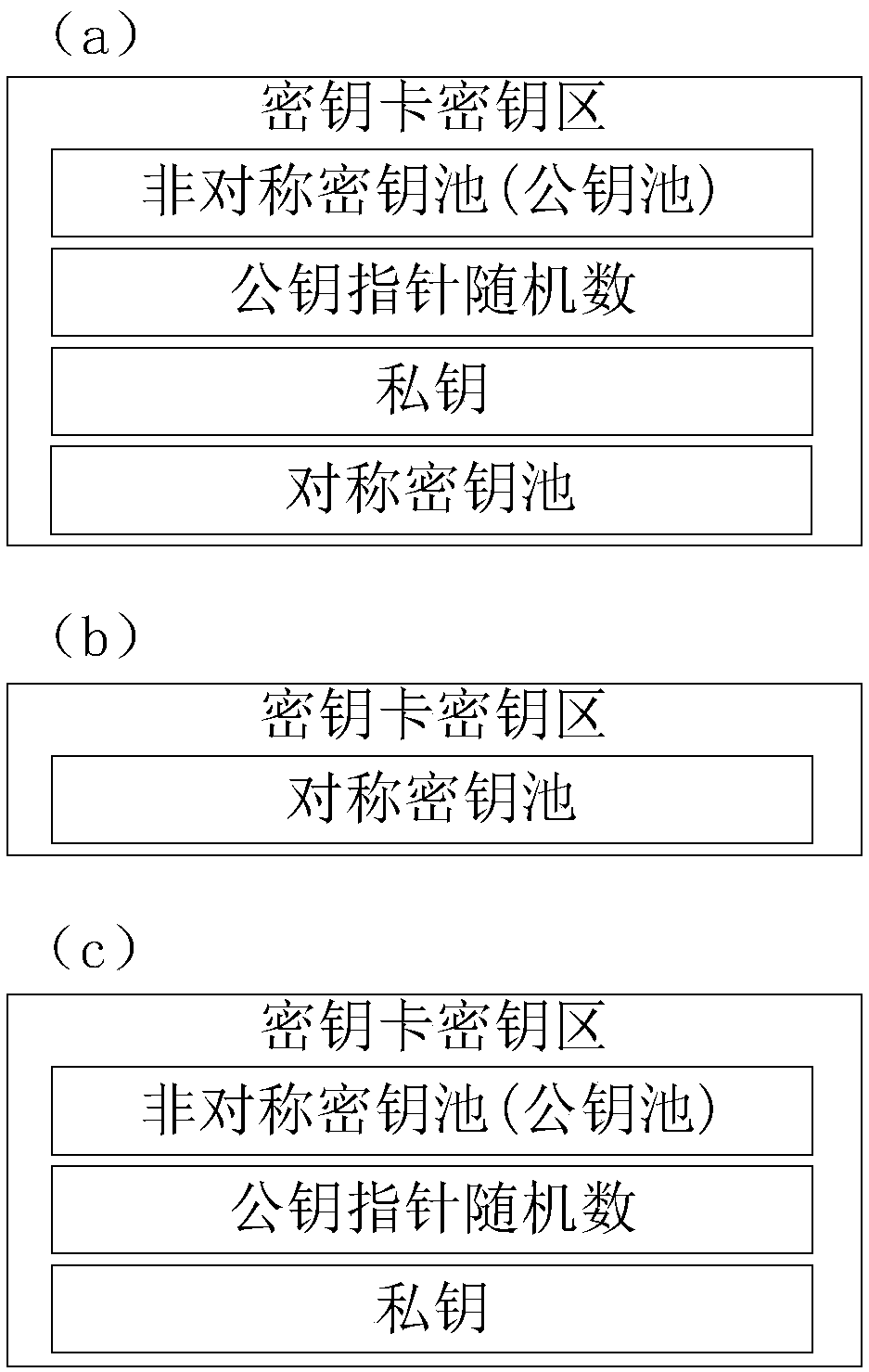

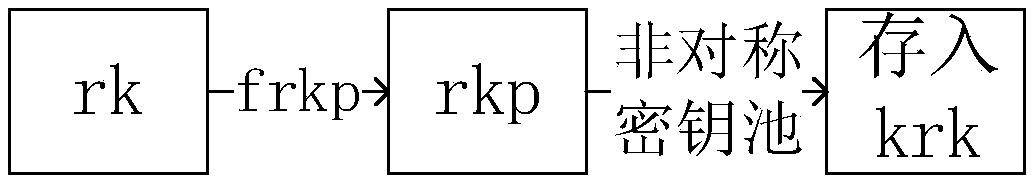

Anti-quantum computing smart home cloud storage method and system based on key card

ActiveCN109495251AImplement storage securityAchieve safe useKey distribution for secure communicationPublic key for secure communicationComputer hardwareData cloud

The invention relates to an anti-quantum computing smart home cloud storage method and system based on a key card. The smart home system comprises smart home components and security cloud. Each smarthome component is provided with a key card. An anti-quantum computing public key is combined with an asymmetric key pool in a key card to extract the public key of each smart home component. A real random number encrypted file in the own key card and a true random number are encrypted and uploaded to the security cloud. Each smart home component is equipped with a key card in order to ensure the security in key storage and use of all components. At the same time, only files encrypted by quantum random numbers and encrypted keys are stored in the security cloud, thereby solving the problem thata user worries about the data cloud. Each smart home component extracts the public keys of required smart home components by combining an anti-quantum computing public key with the asymmetric key pool, thereby effectively lowering the risk that a quantum computer acquires a corresponding public key rapidly through a public key.

Owner:RUBAN QUANTUM TECH CO LTD

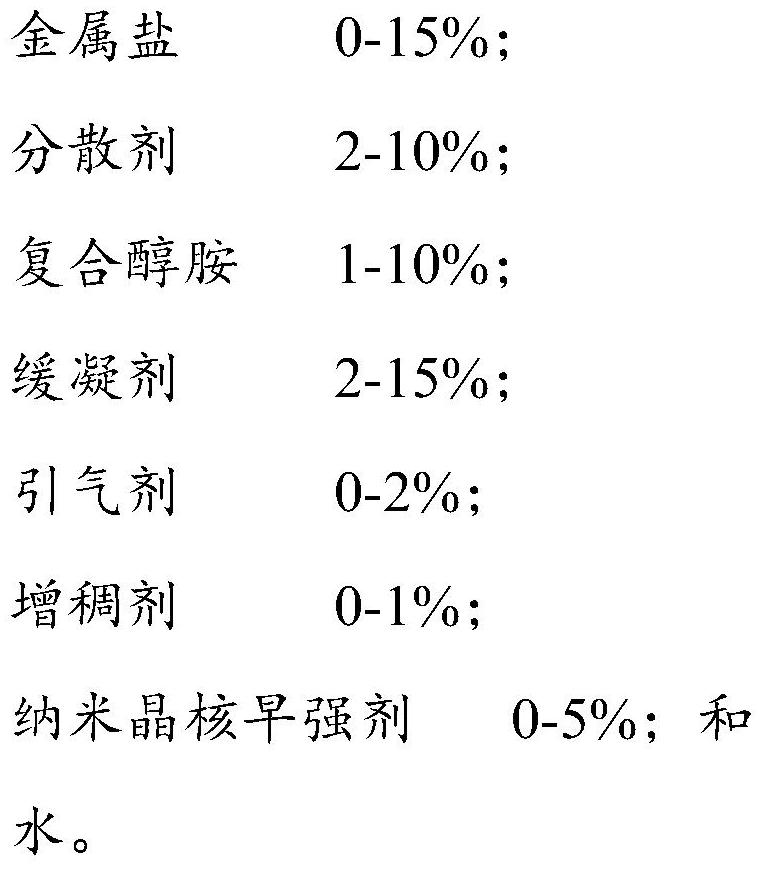

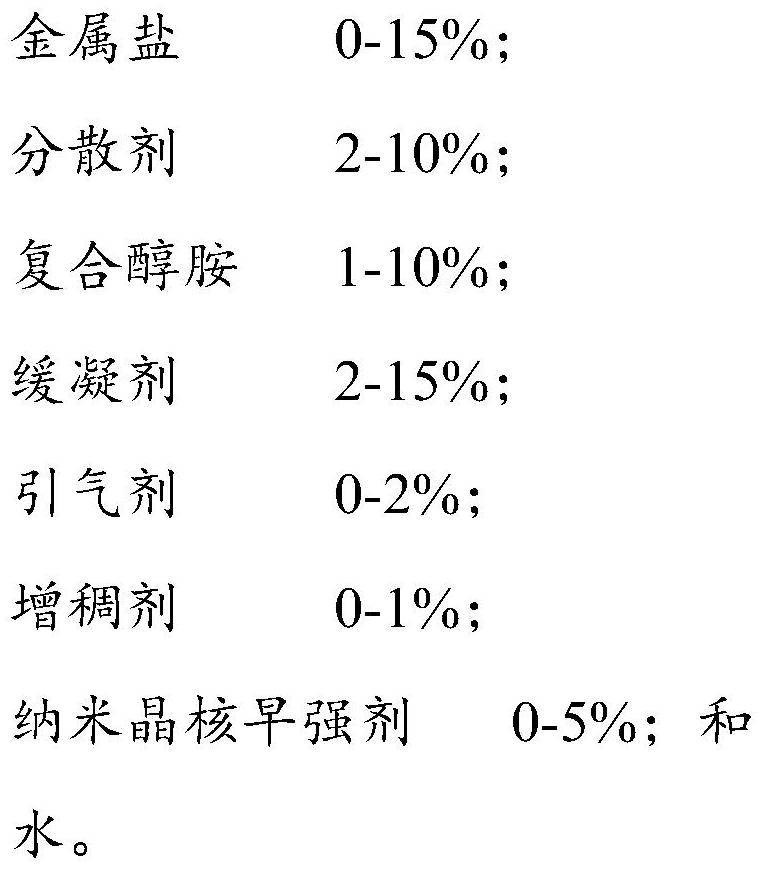

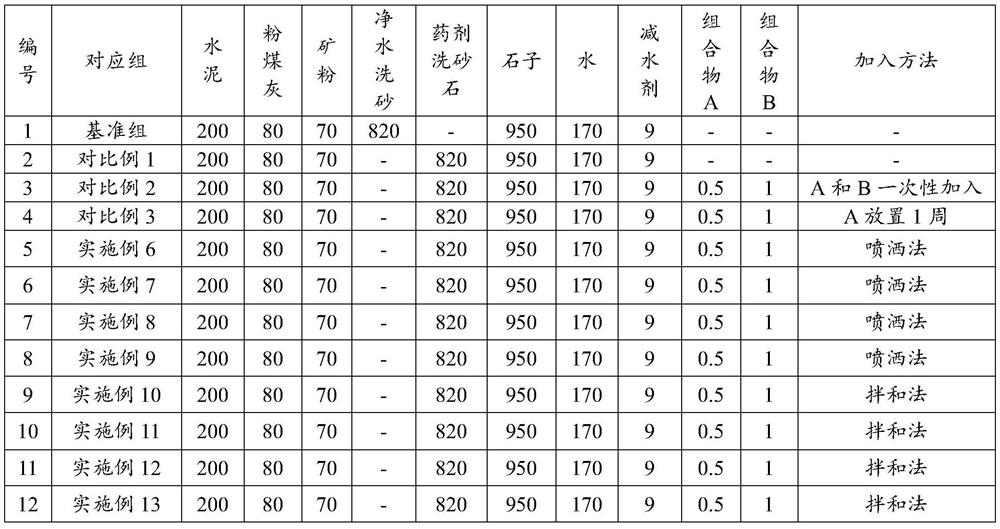

Water-washed sandstone treating agent and method for preparing concrete

The invention provides a composition A, a composition B and a water-washed sandstone treating agent. The composition A comprises the following components by weight percentage: 0.1-20% of inorganic salt, 0.1-10% of polyethylene glycol represented by a formula (I): HO(CH2CH2O)nH (I), and 0-10% of a polyol represented by a formula (II): HO-R1-Y-R2-OH (II), wherein n is an integer of 3 or more. The composition B comprises the following components in percentage by weight: 0-15% of metal salt, 2-10% of dispersing agent, 1-10% of composite alcohol amine, 2-15% of retarder, 0-2% of air entraining agent, 0-1% of thickening agent, 0-5% of nanocrystalline core early strength agent, and water. The water-washed sandstone treating agent comprises the composition A or comprises the composition A and thecomposition B. According to the prepared treating agent, the finished product is low in toxicity and pollution, the slump and compressive strength of the water-washed sandstone concrete can be remarkably improved through matching of the composition A and the composition B, and the negative performance influence of 70-100% water-washed sandstone concrete can be remarkably reduced.

Owner:江苏超力建材科技有限公司 +1

Wet type treatment process for stainless steel slag

InactiveCN102836778ASolve your worriesTake advantage ofProcess efficiency improvementWet separationSlagSewage

The invention relates to a wet type treatment process for stainless steel slag, which belongs to the field of peripheral recycling of stainless steel and achieves the purposes of resource recycling of turning harm into a benefit and waste into wealth on the basis of taking full advantage of a slag resource. The wet type treatment process for the stainless steel slag adopts advanced and reliable slag and steel separation equipment, recovers metal and steel slag resources in the stainless steel slag to the greatest extent, takes full advantage of the slag, and turns the harm into the benefit and the waste into the wealth. With the adoption of a centralized treatment mode for stainless steel slag, the subsequent trouble in steel manufacturing is overcome fundamentally, and the social problem of environmental pollution arising from the steel slag discharge due to nonstandard treatment modes of the steel slag, such as selling, is solved. The treatment process for the stainless steel slag comprises the steps that the stainless steel converter slag and electric furnace / refining slag are crushed, sieved, recrushed, reselected and magnetically separated, and subjected to sewage concentration, slag slurry dehydration and detoxification of circulation process water. In consideration of the particularity of the converter slag and for the convenience of comprehensive utilization of tailings, the treatment process is divided into a converter slag production treatment line and an electric furnace / refining slag production treatment line.

Owner:庞兵

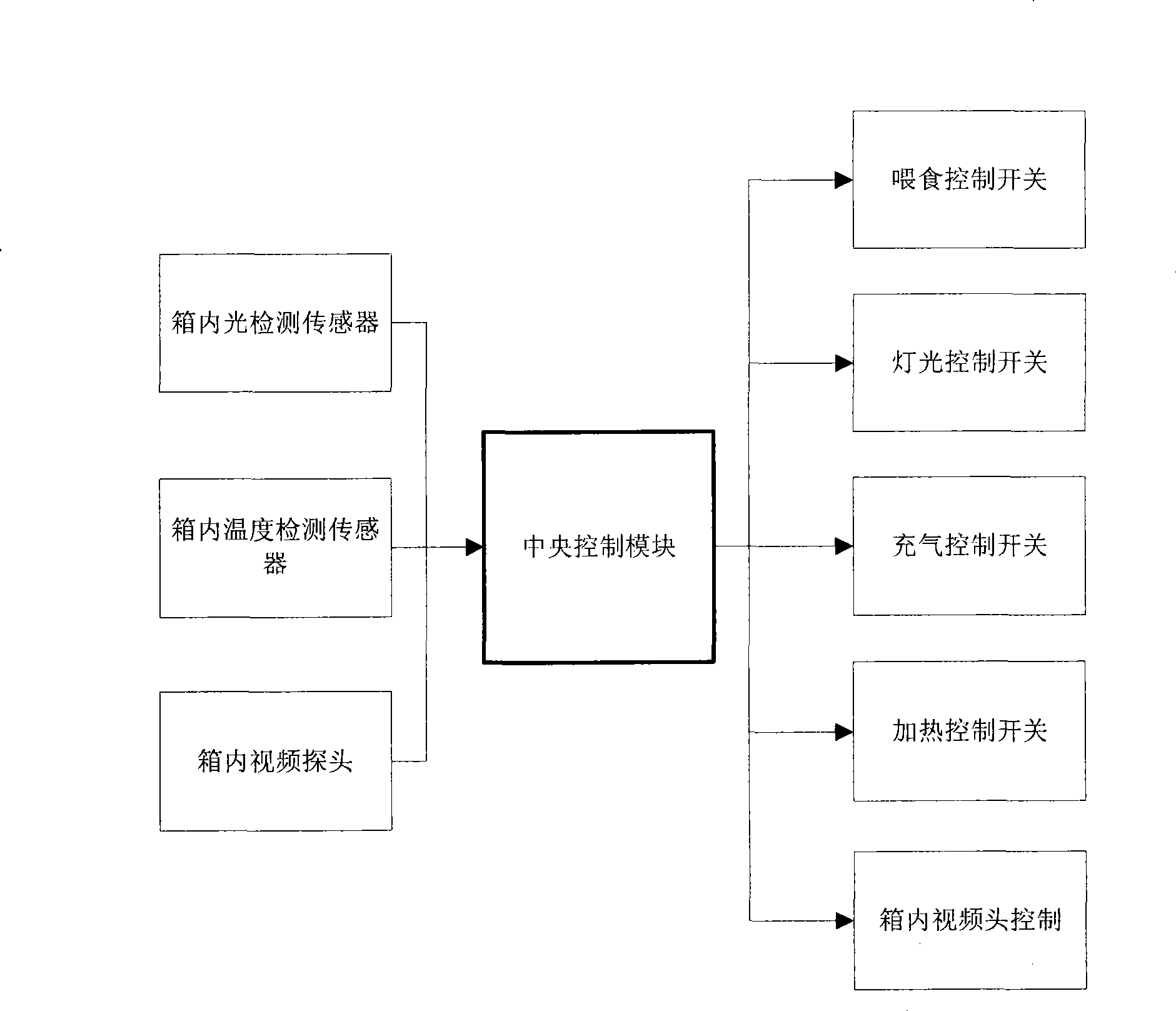

Mobile phone operated intelligent aquarium

The invention aims at providing an intelligent fish tank controlled by a mobile phone, comprising a central control module, wherein the central control module can carry out wireless communication with the mobile phone of a user by the 3G network, and is respectively connected with a controllable video probe, a temperature detection sensor and a photo detection sensor which are arranged in a box, so as to detect the intensity of light and temperature in the fish tank; and the central control module is also connected with a feeding control switch, a light control switch, an air inflation control switch and a heating control switch, and a user can remotely control the entire system of the fish tank by the control switches. The intelligent fish tank causes fish-farming residents to easily and conveniently control the feeding or the air-entrapping, and other functions during a longtime business tour or a long tourist tour, thereby overcoming the disadvantage of the prior art that the existing fish tank can only control the definite time feeding or air-entrapping, which is not beneficial to the raising of delicate fishes.

Owner:SHANGHAI SIMCOM LTD

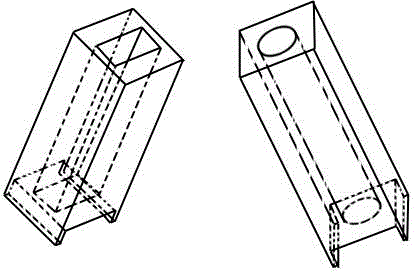

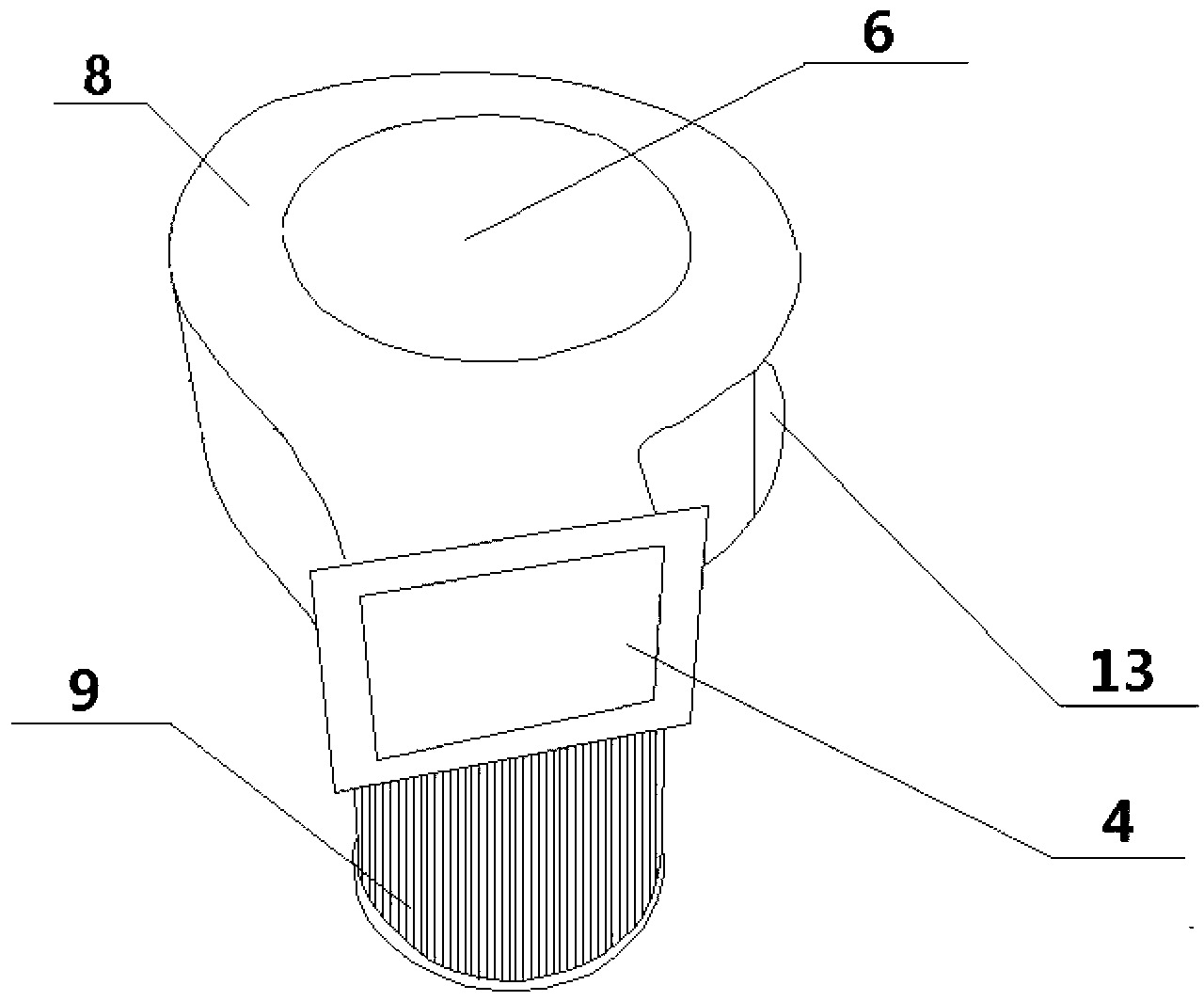

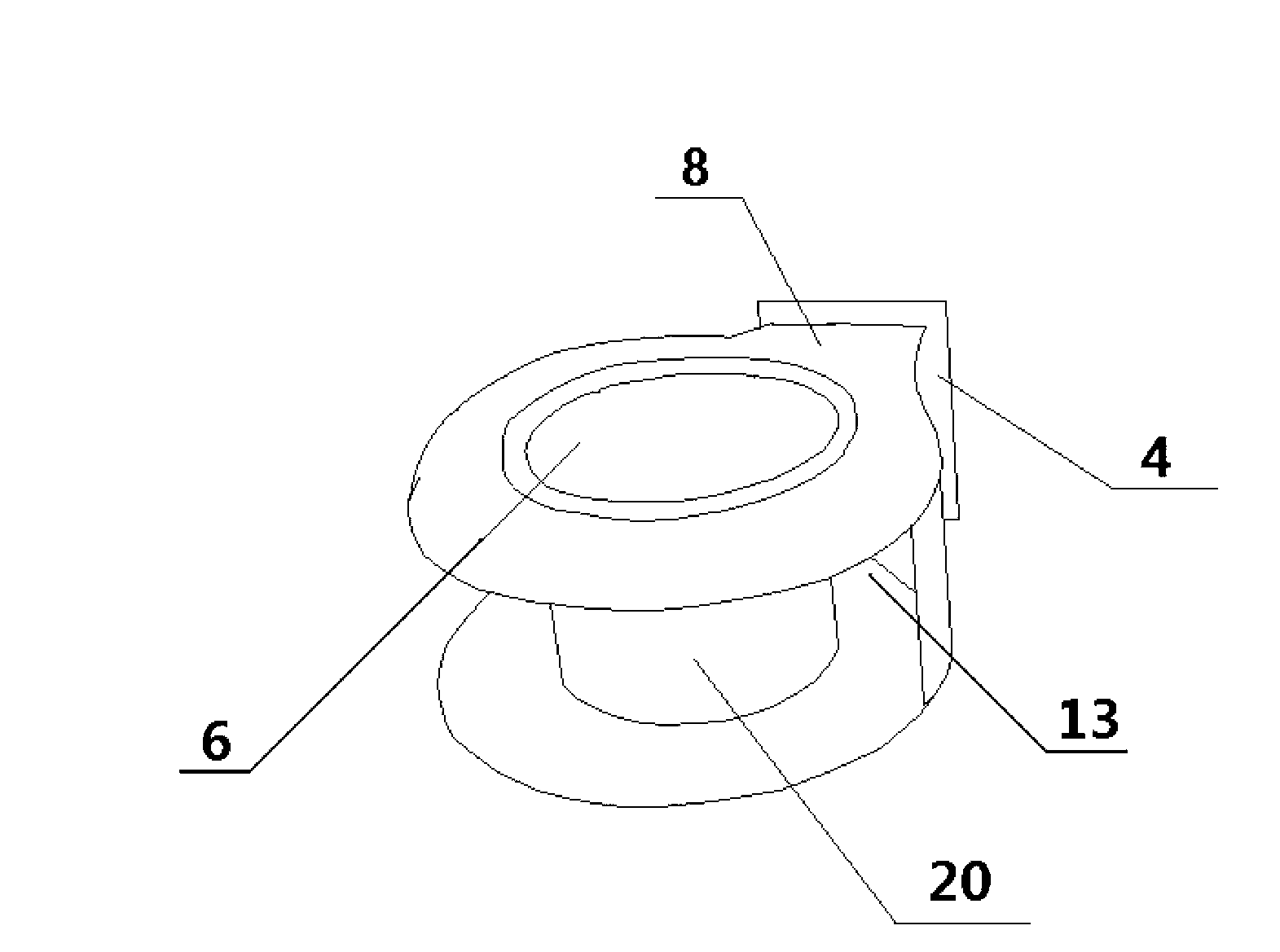

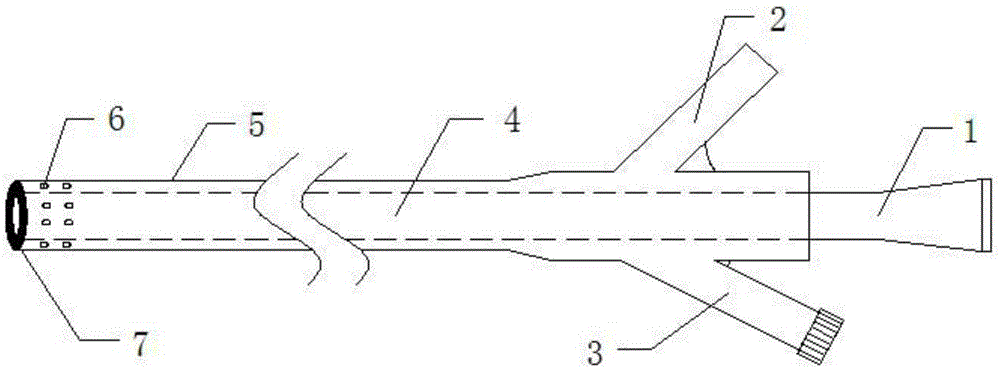

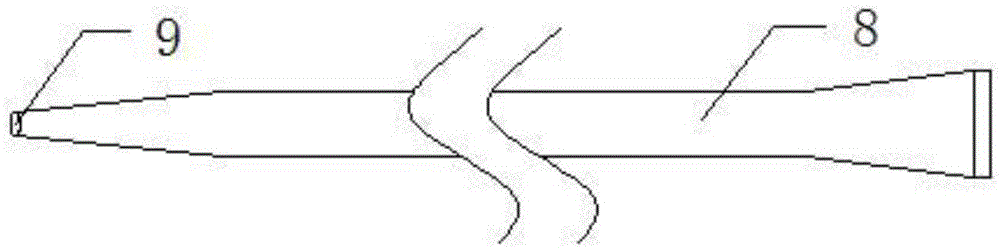

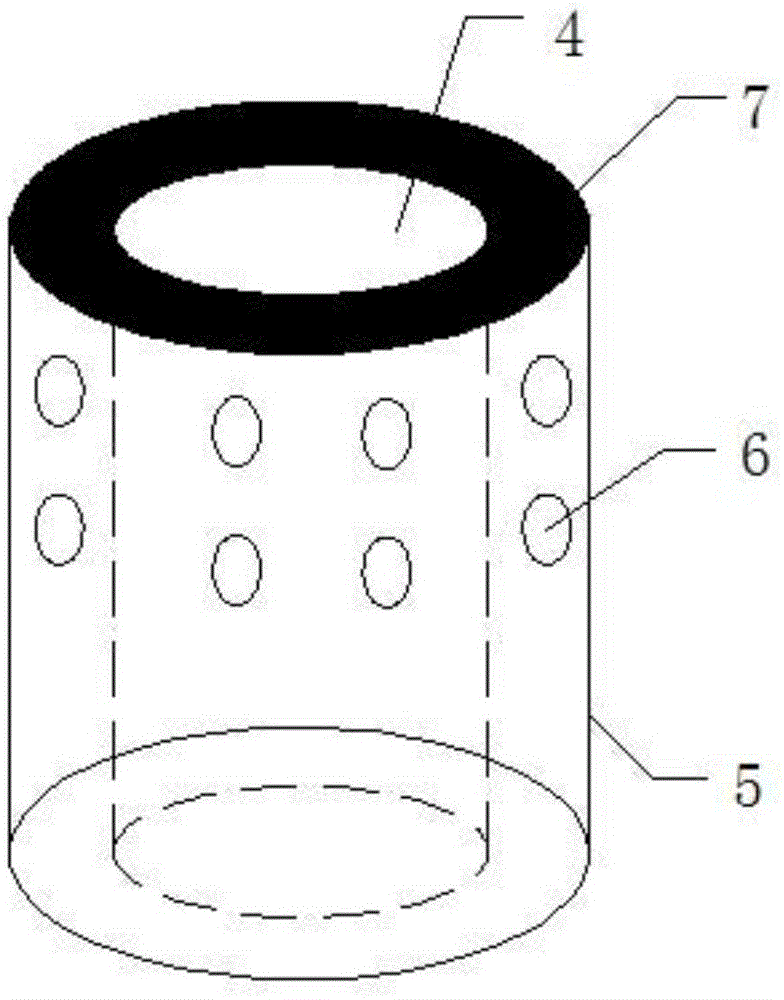

Coaxial sleeve tube type water circulation quick calculus removal device used after flexible ureteroscope lithotripsy

The invention discloses a coaxial sleeve tube type water circulation quick calculus removal device used after flexible ureteroscope lithotripsy. The device comprises a coaxial sleeve tube and a pushing rod (8) for pushing the coaxial sleeve tube to a ureteropelvic junction, wherein the coaxial sleeve tube comprises a water-filling catheter (5) and a drainage catheter (4) arranged in the water-filling catheter (5); a closed structure (7) is arranged at the joint of the water-filling catheter (5) and the front end of the drainage catheter (4); a plurality of water outlets (6) are formed in the side wall of the front end of the water-filling catheter (5); and a water-filling tube (2) and a decompressor (3) are connected to the side wall of the back end of the water-filling catheter (5). According to the device, the first-stage calculus removal efficiency is improved, the operative time is shortened, and the indications of the flexible ureteroscope holmium laser lithotripsy are expanded.

Owner:吴娟

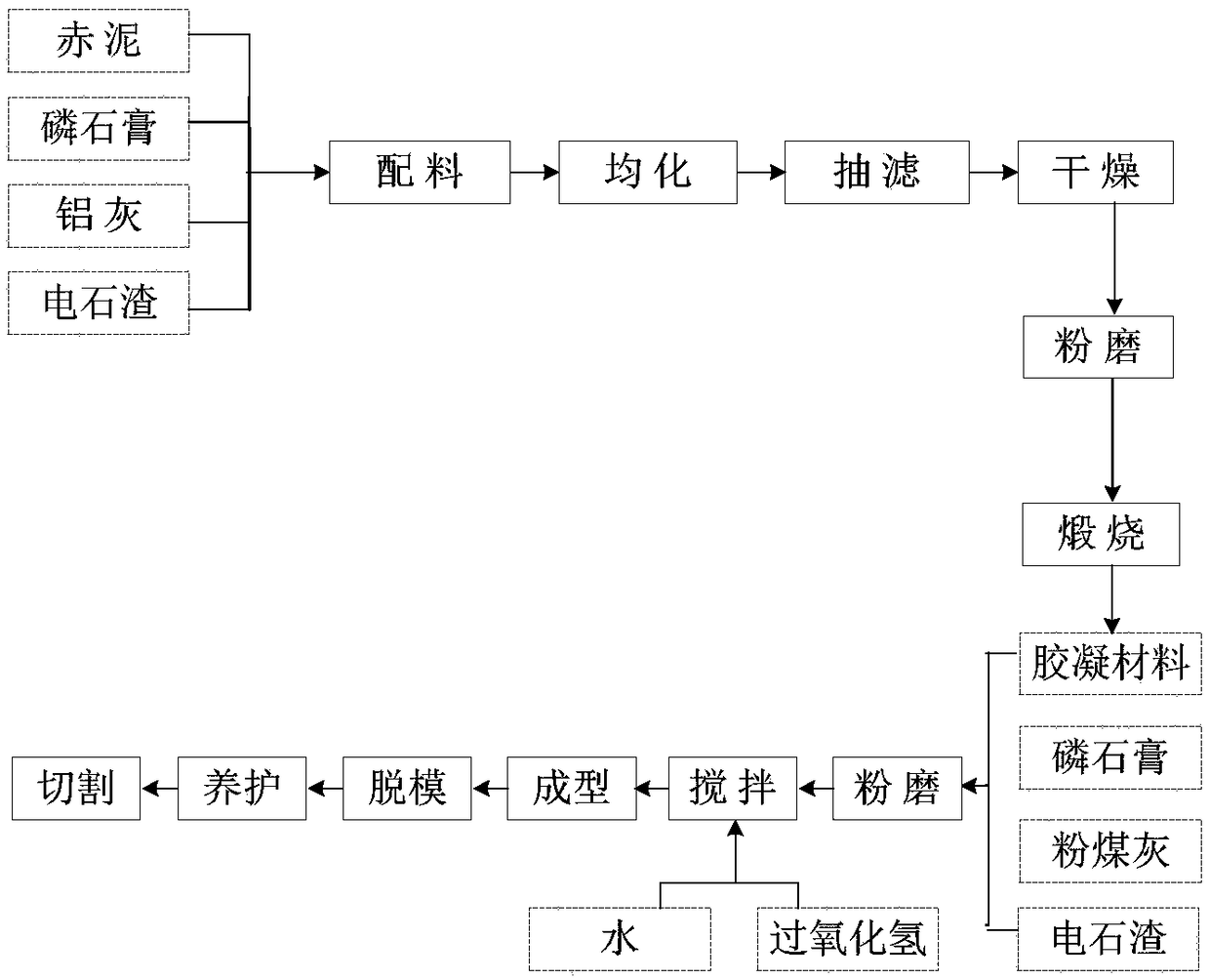

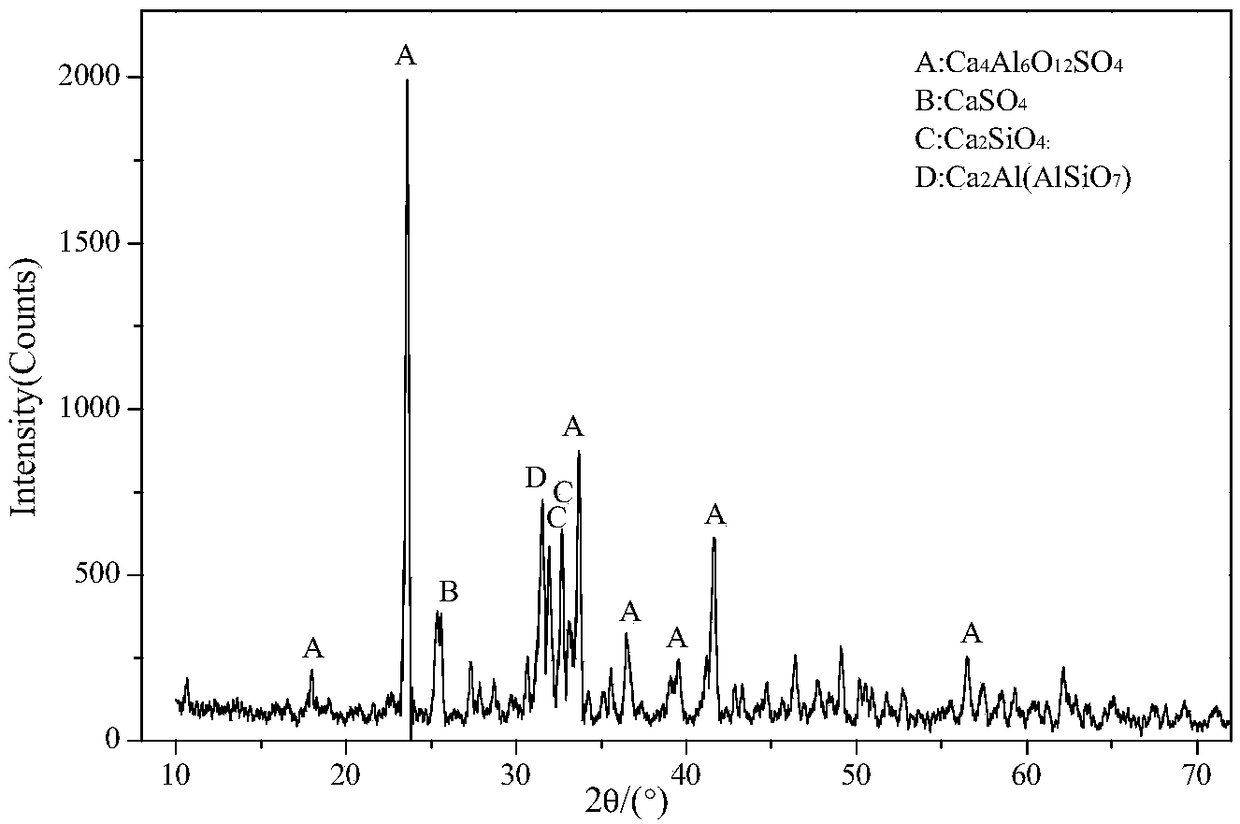

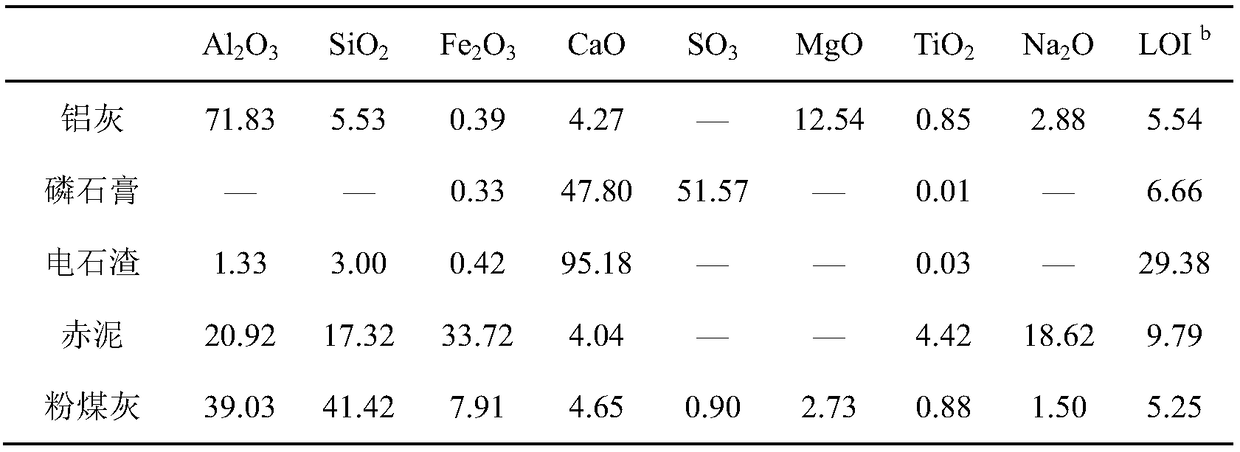

Full industrial solid waste high strength ready-to-use foamed concrete material and preparation method thereof

ActiveCN108821671AHigh compressive strengthImprove environmental adaptabilityCement productionCeramicwareSlagRed mud

The invention relates to a full industrial solid waste high strength ready-to-use foamed concrete material and a preparation method thereof, and belongs to the technical field of foamed concrete preparation. The method adopts a preparation idea of synergistic complementarity and two-stage transition of a plurality of kinds of industrial solid waste: first, the industrial solid waste is prepared into a high-activity cementitious material, the high-activity cementitious material is prepared into the high strength ready-to-use foamed concrete material, the high strength ready-to-use foamed concrete material is prepared by full industrial solid waste as the cementitious material and an admixture; The high strength ready-to-use foamed concrete material is prepared while large-scale resource utilization of the industrial solid waste such as aluminum ash, red mud, calcium carbide slag, phosphogypsum and pulverized coal without consumption of any natural mineral resources during preparation. In addition, the high strength ready-to-use foamed concrete material prepared by the method does not require autoclave curing or steam curing, only can be cured only under standard curing conditions, thereby greatly reducing the production cost and energy consumption of foamed concrete wall insulation materials, and realizing saving both in resources and energy.

Owner:SHANDONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com