Patents

Literature

92results about How to "Satisfied with use" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

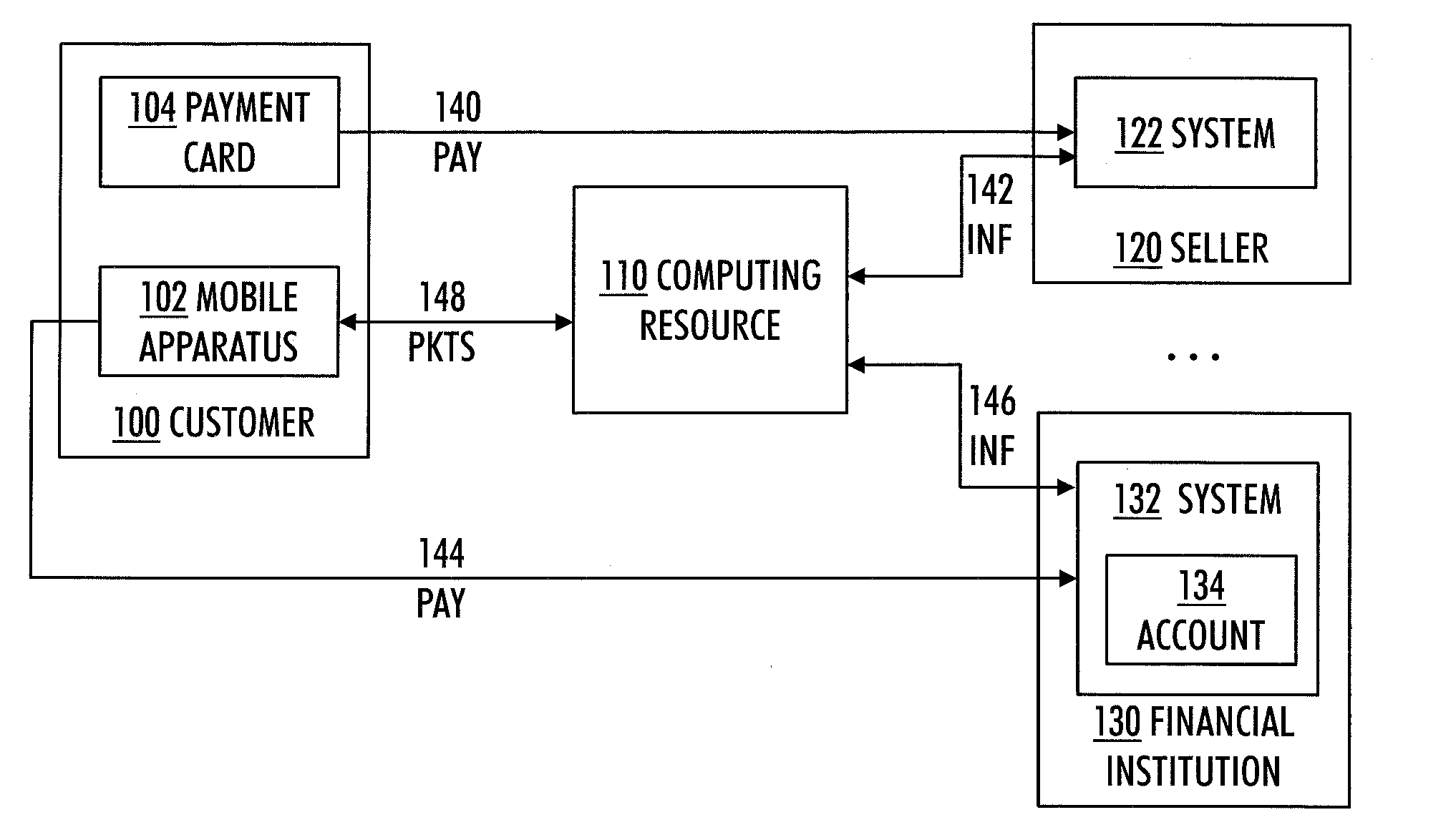

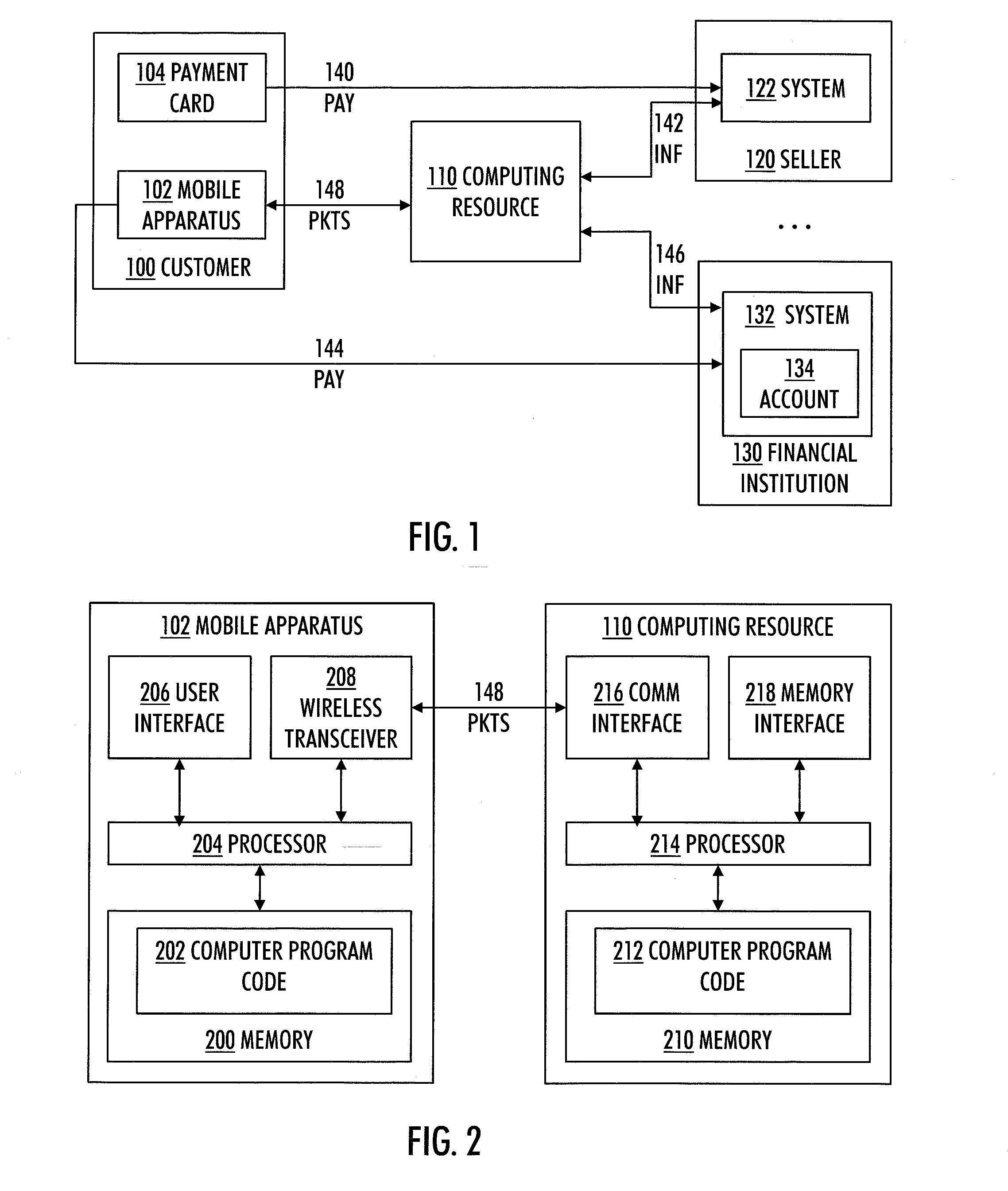

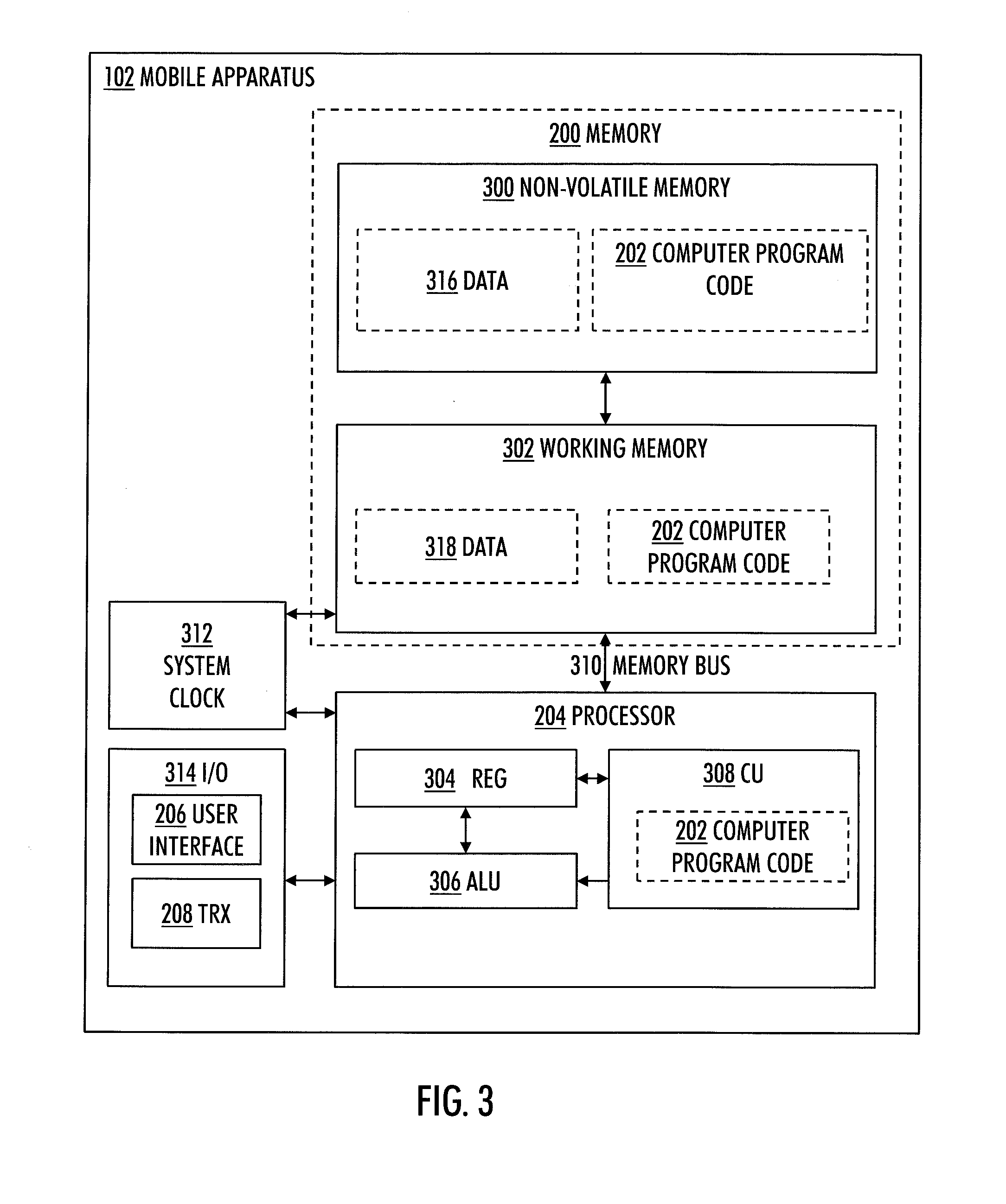

Mobile apparatus with transaction information

ActiveUS20140279442A1Easy to useLess timeFinancePayment architectureWireless transceiverMobile device

Mobile apparatus with transaction information is disclosed. The mobile apparatus receives, from an electronic service, with the wireless transceiver, a plurality of packets relating to transactions of an account linked with a payment card, transforms the received plurality of packets into transaction information, and displays, with the user interface, the transaction information such that transactions in relation to each other are represented by geometric objects.

Owner:OP PALVELUT

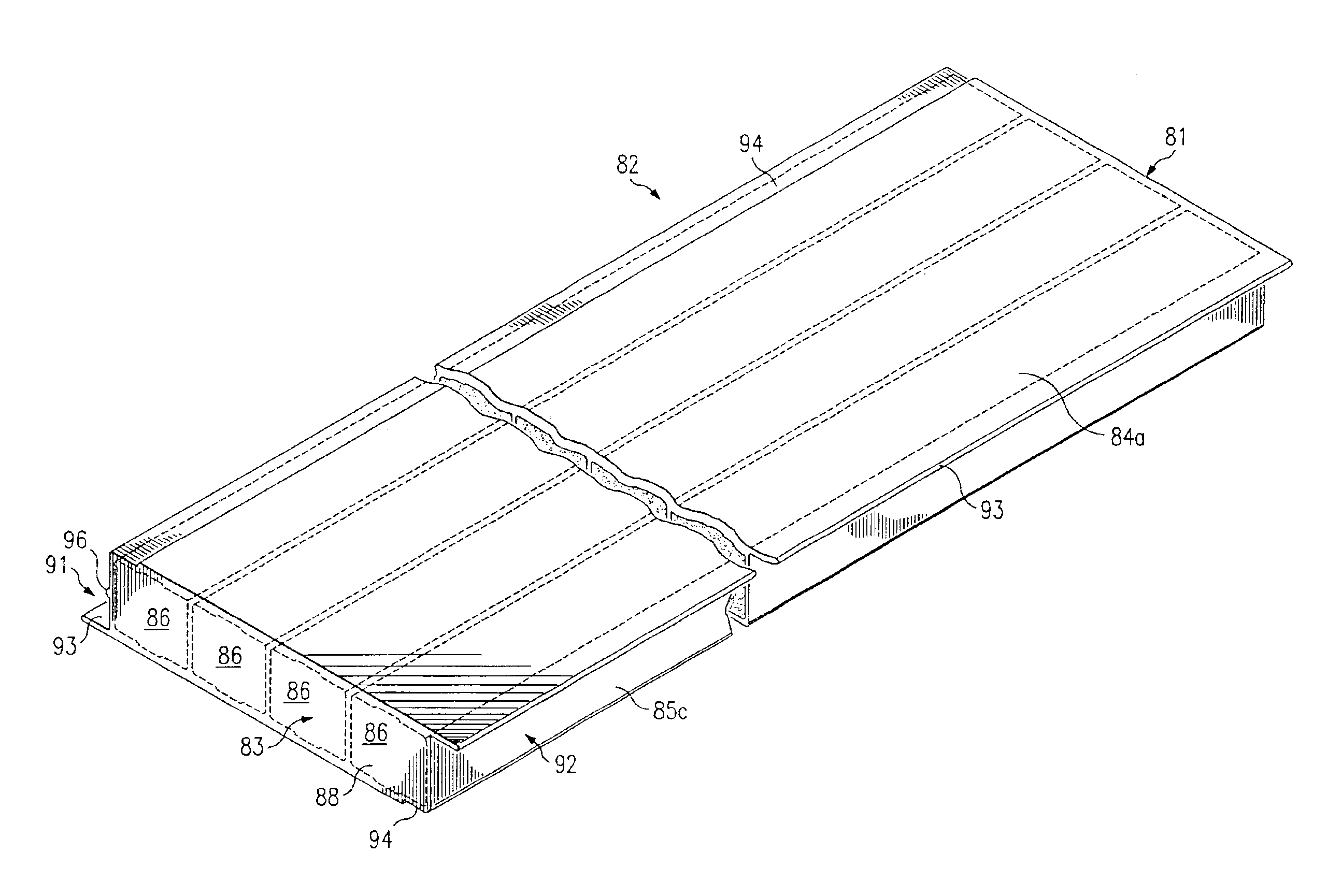

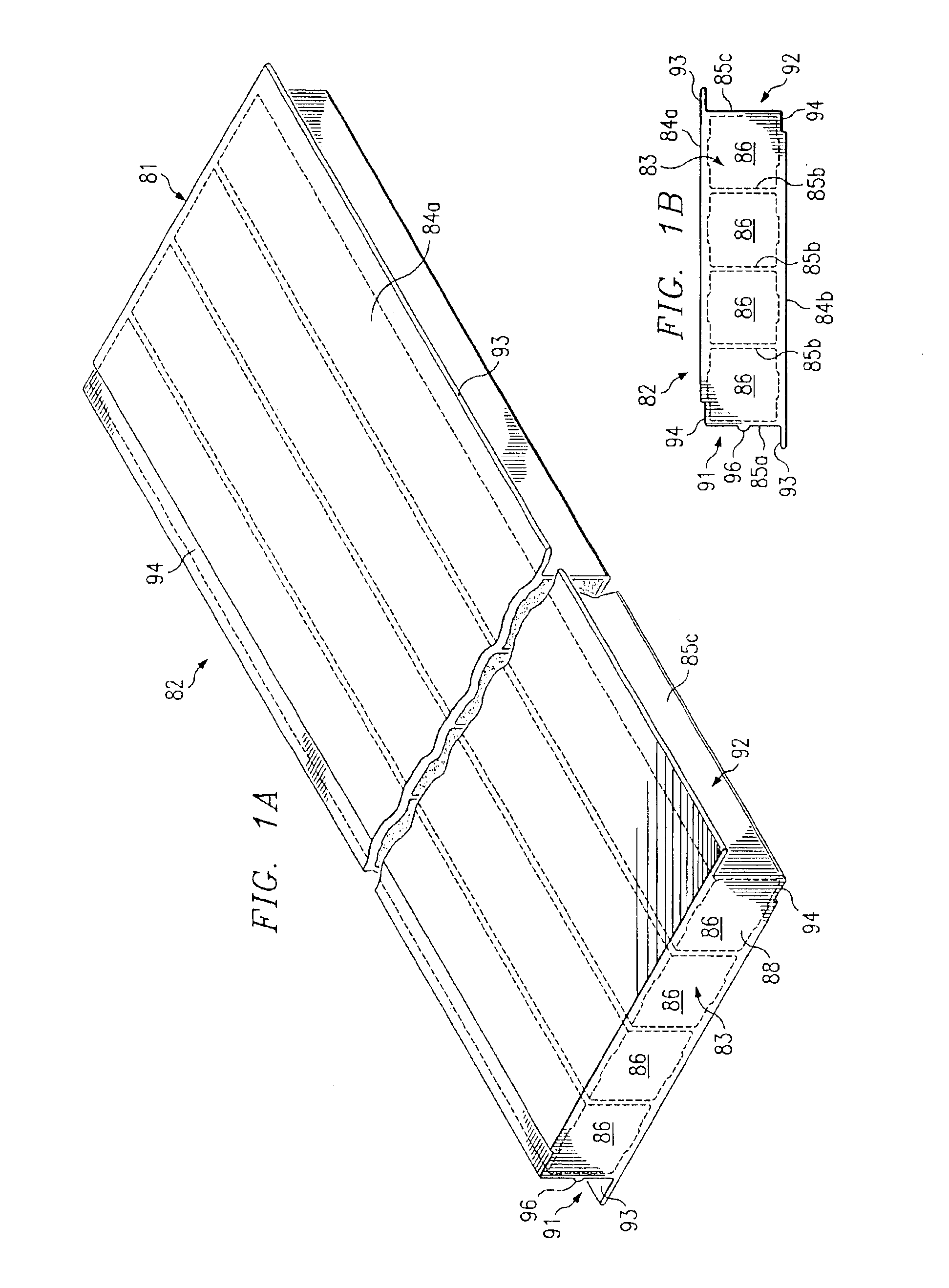

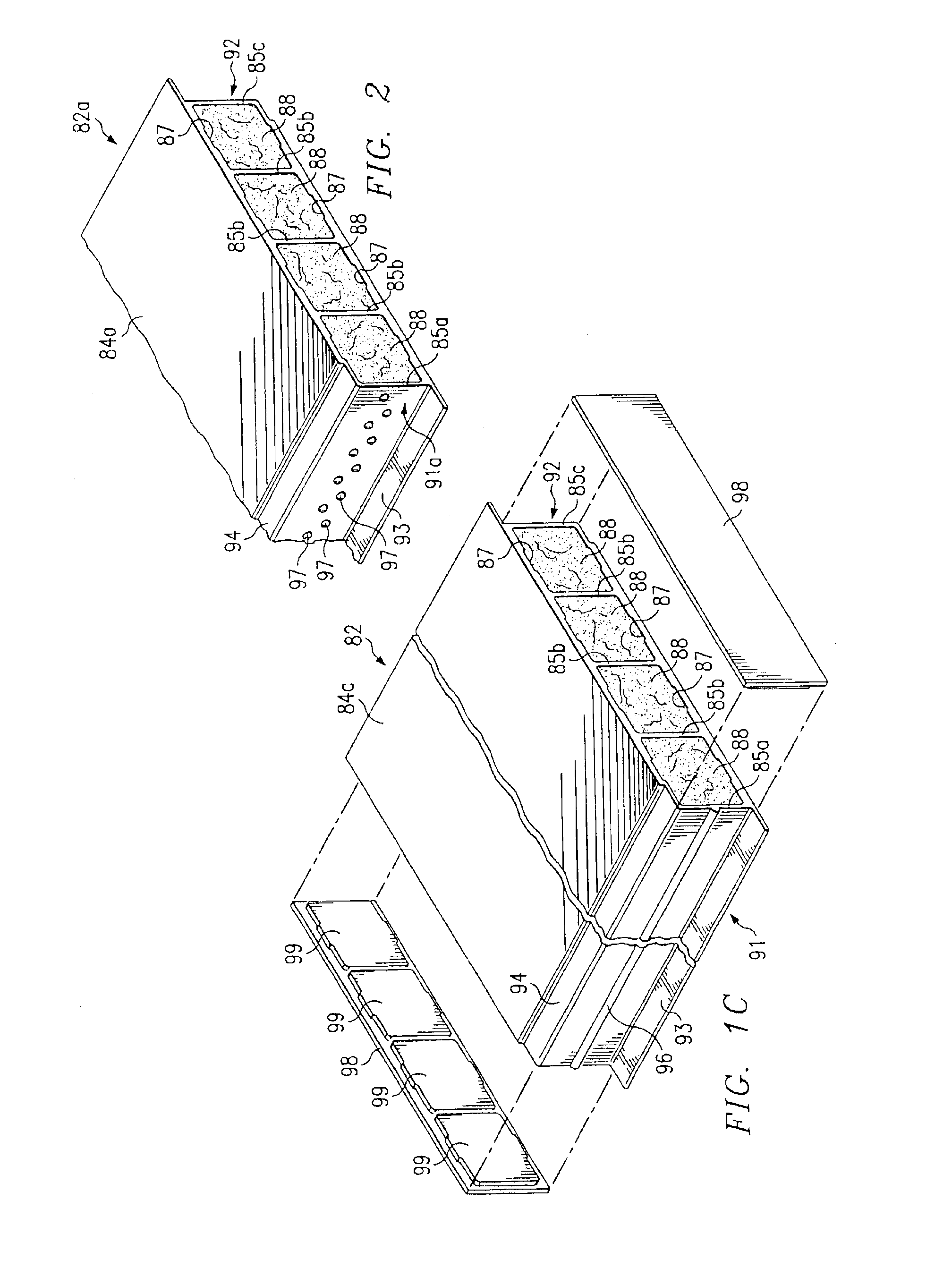

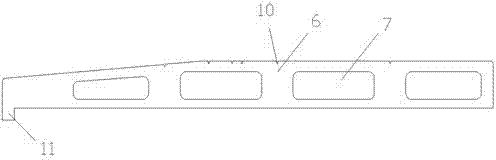

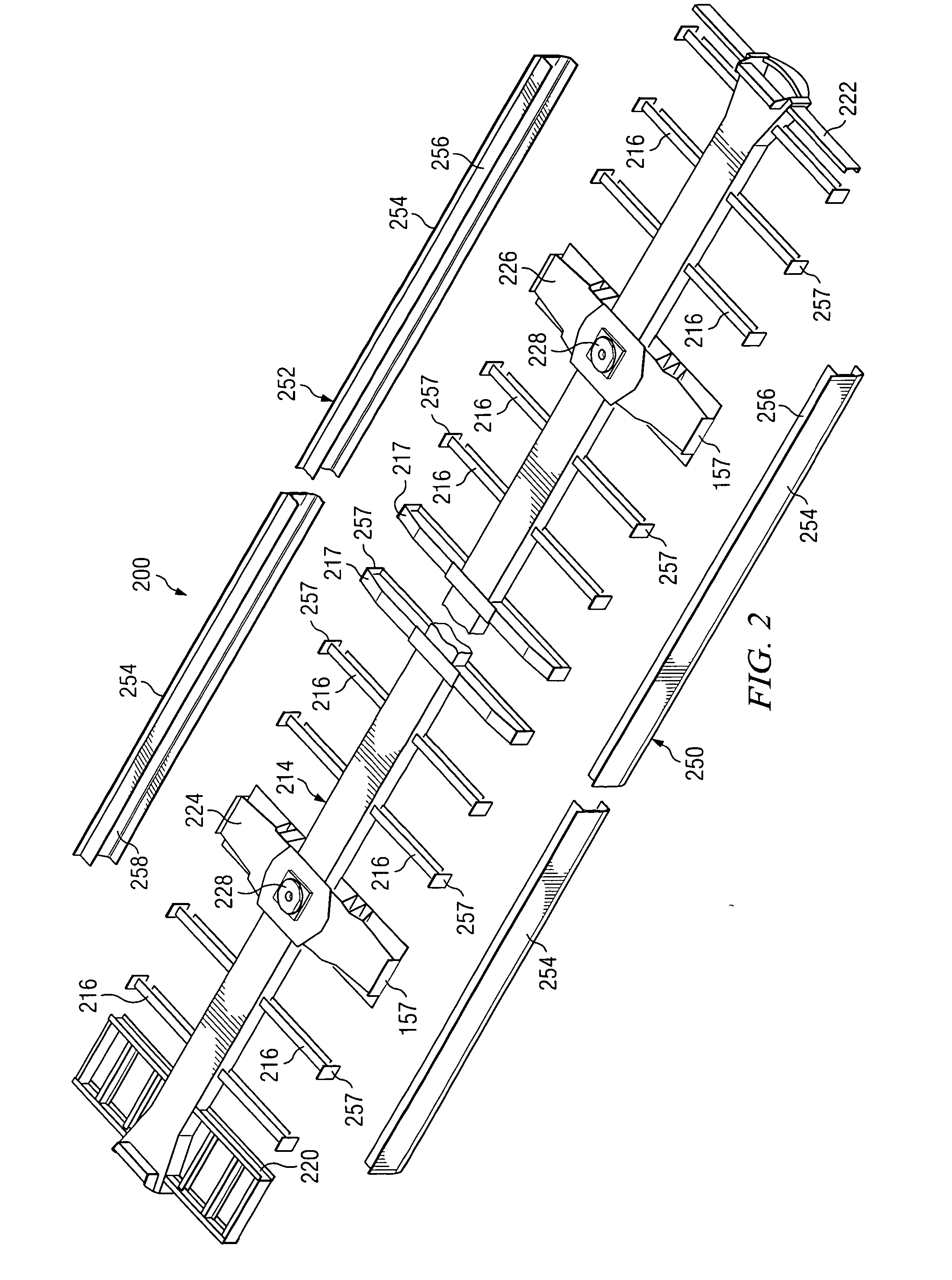

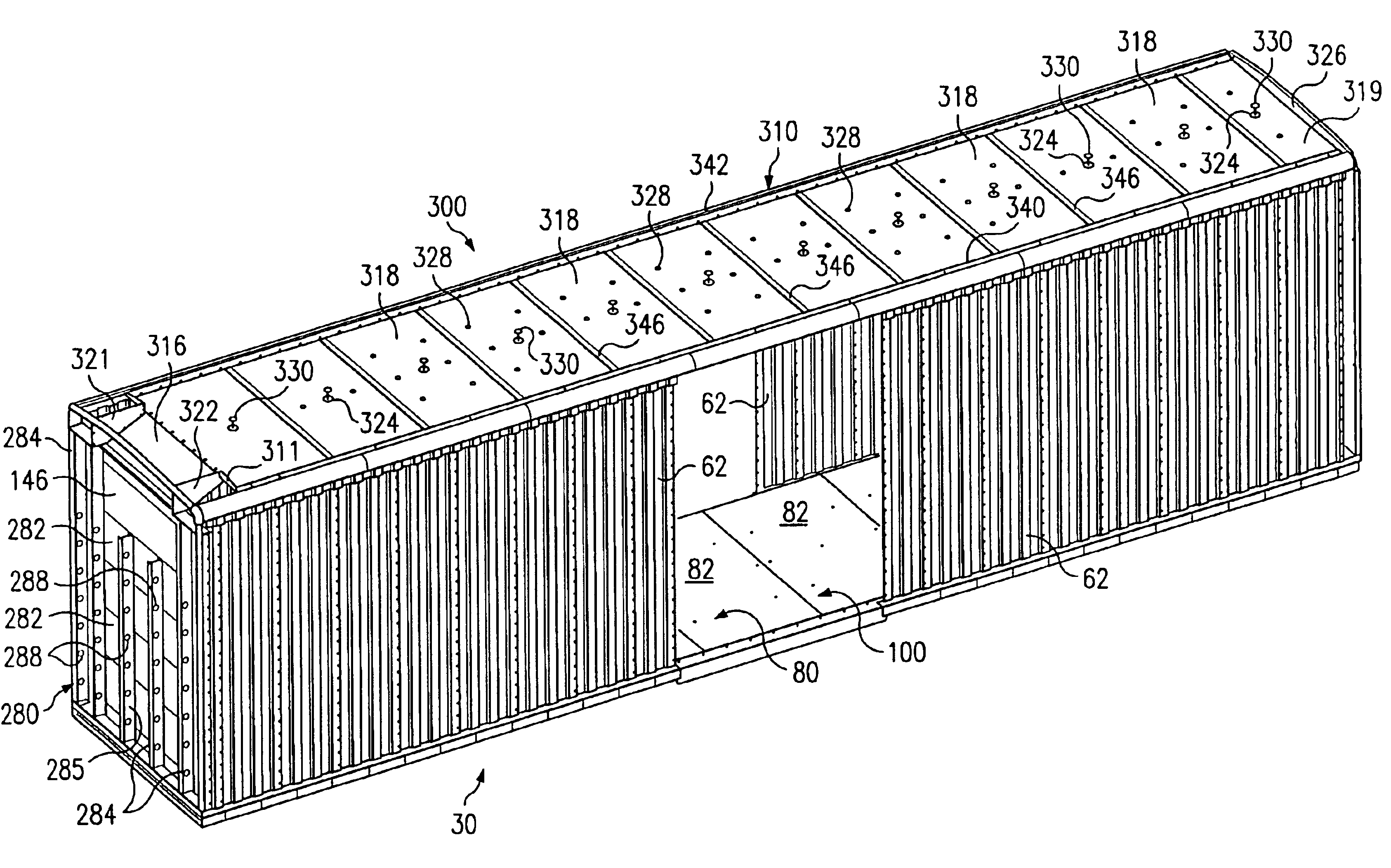

Pultruded panel

InactiveUS6871600B2Improve insulation performanceImprove carrying capacityRailway roofsRailway heating/coolingAdhesiveEngineering

Pultruded panels having a first longitudinal edge profile and a second longitudinal edge profile may be used to form a floor assembly mounted on a railway car underframe. The pultruded panels may also be used to form walkways, bridges, piers and other structures. A bead may be placed on at least one of the longitudinal edge profiles to form a gap between an adjacent pultruded panel. An adhesive may be placed within the gap to couple or bond adjacent pultruded panels with each other. Void spaces may be formed within the pultruded panel and filled with foam to provide improved resistance to heat transfer through the respective panel. Respective coverings may be placed on opposite ends of each panel to block access to the associated void spaces.

Owner:TRINITY IND INC

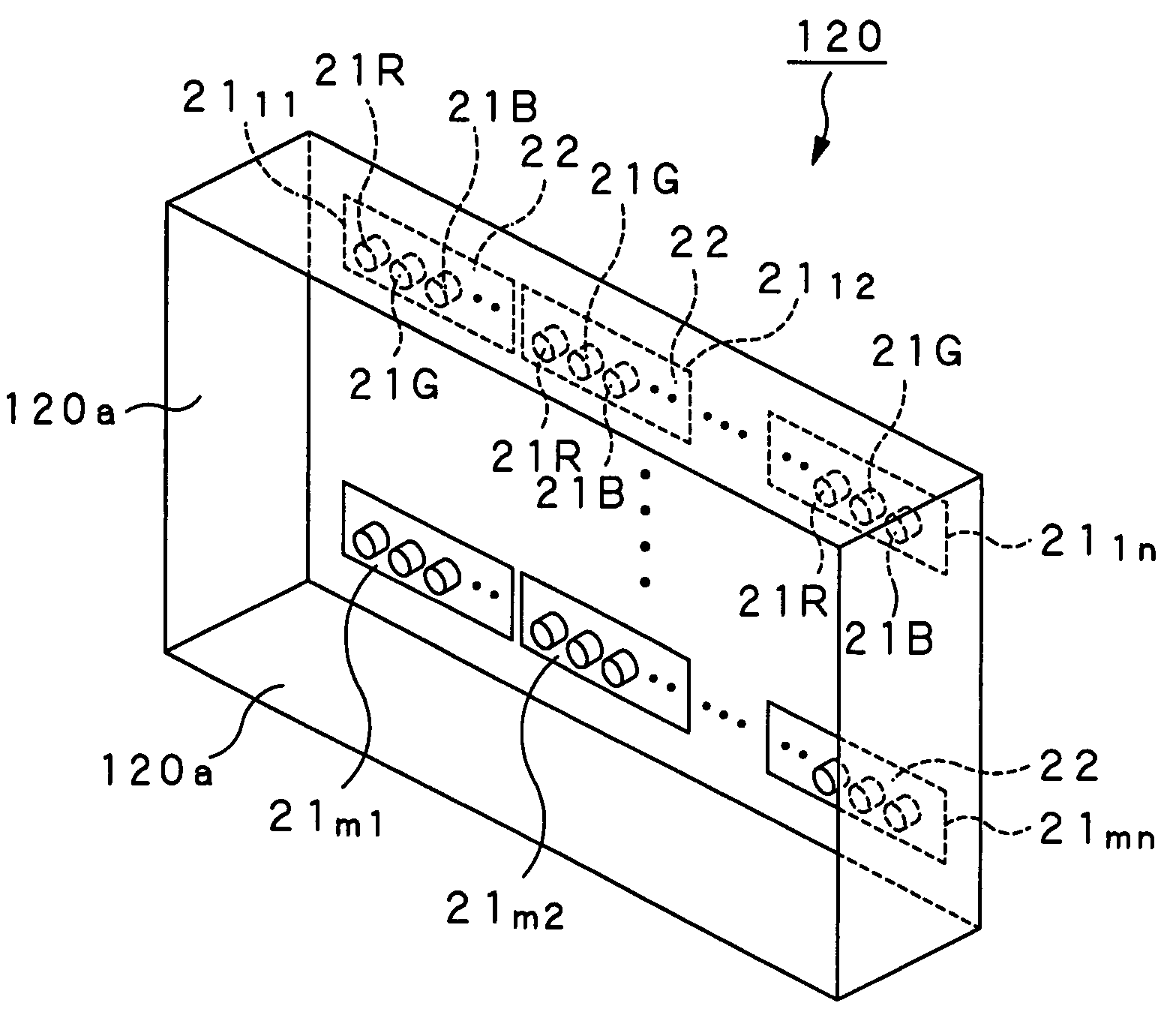

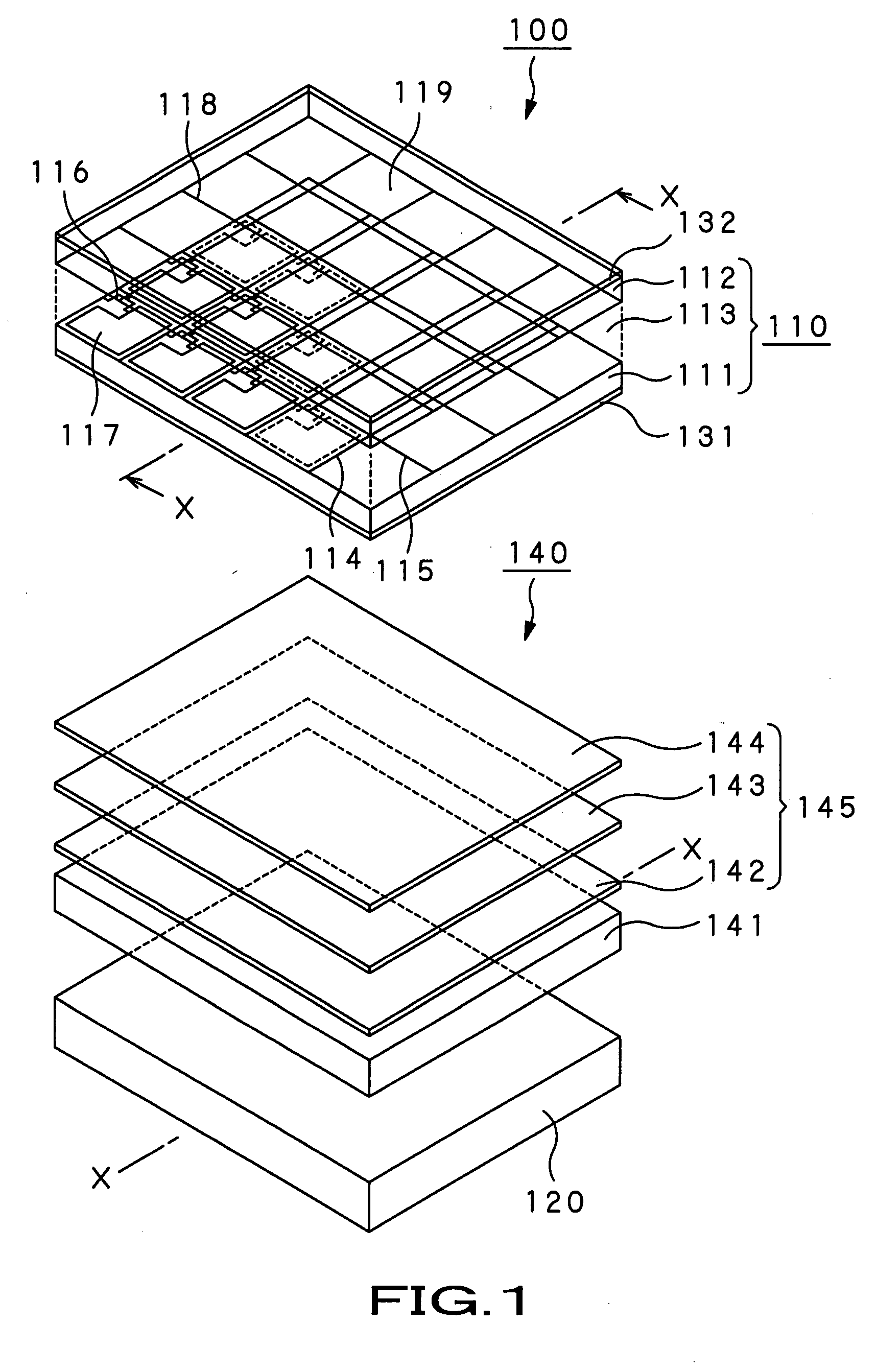

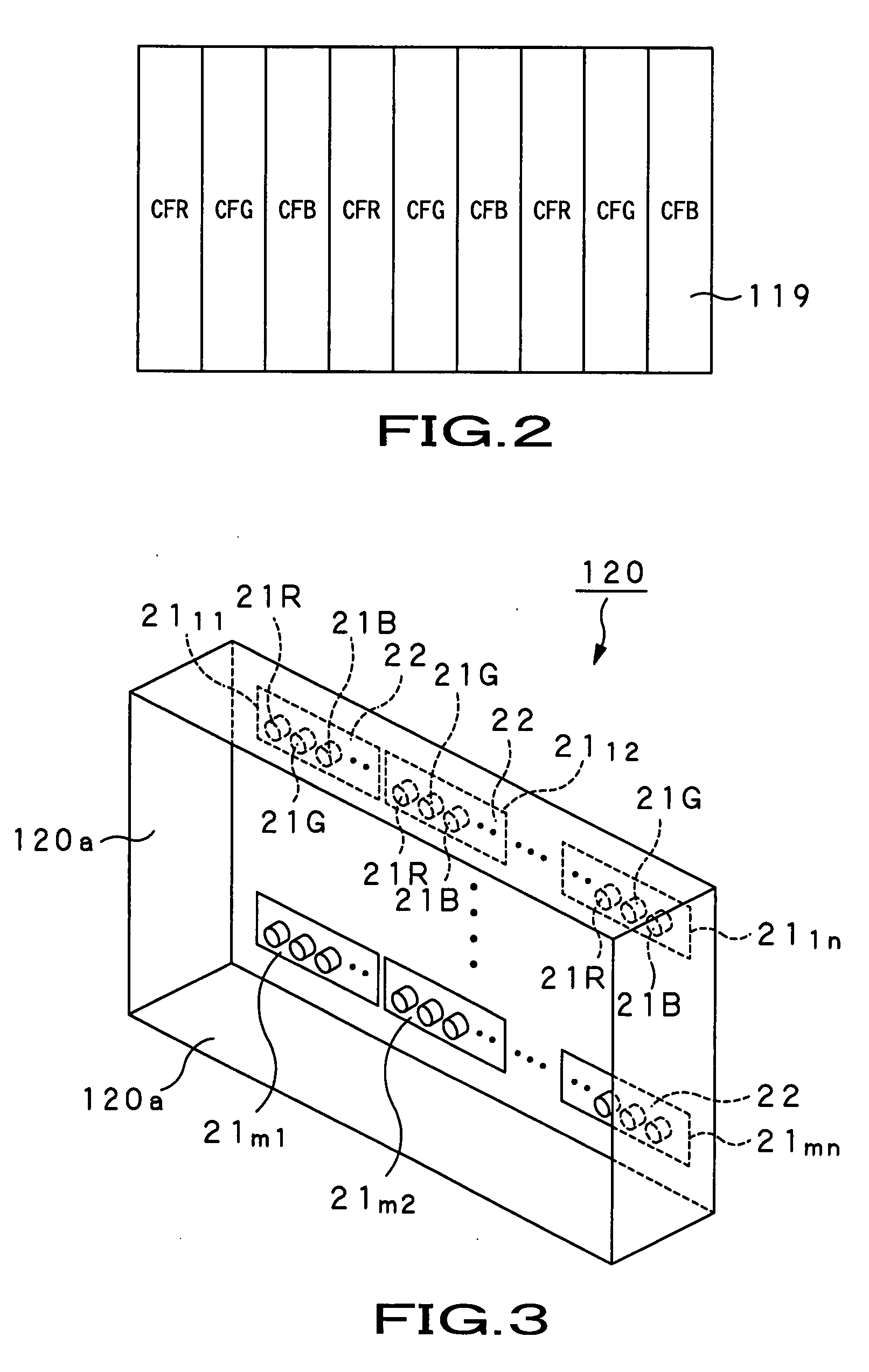

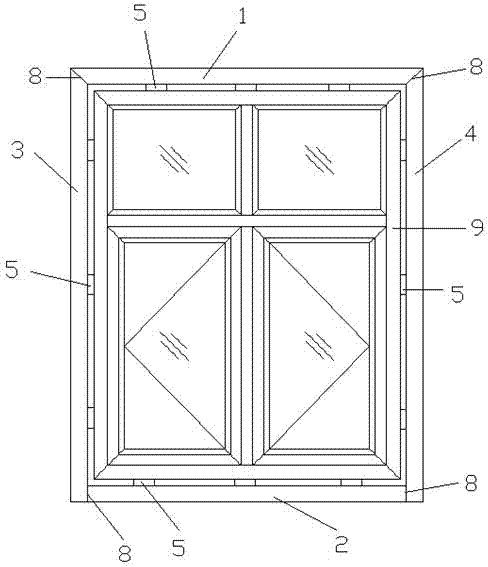

Backlight Device

InactiveUS20080285268A1Avoid wastingSatisfied with useIlluminated signsSpectral modifiersLiquid-crystal displayLight-emitting diode

Disclosed is a backlight device for illuminating a transmissive color liquid crystal display panel from its backside with white light. The backlight device includes, as a light source, a plural number of principal light emitting diode units 21mn, and a plural number of subsidiary light emitting diode units 21mn, where m and n are natural numbers. Each principal light emitting diode unit is made up by a plural number of light emitting diodes (21) arrayed in a string and emits white light of preset chromaticity. Each subsidiary light emitting diode unit is made up by a plural number of light emitting diodes (21) arrayed in a string and emits white light of chromaticity in the vicinity of the preset chromaticity. The number of the subsidiary light emitting diode units is smaller than that of the principal light emitting diode units. When the principal light emitting diode units and the subsidiary light emitting diode units are arrayed in a two-dimensional matrix, the subsidiary light emitting diode units 21mn are arrayed without being juxtaposed on the same row, and the subsidiary light emitting diode units 21mn, arrayed in a center column of the two-dimensional matrix, are arrayed towards the center of a color liquid crystal display panel (110).

Owner:SONY CORP

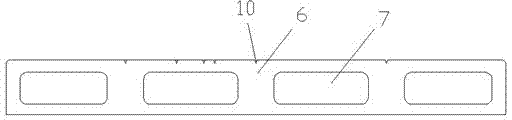

Energy-saving door and window attached frame and door and window installation method

ActiveCN102777103AAvoid installationSolve the connection waterproof problemFrame fasteningWindow/door framesBuilding energyConstruction engineering

Owner:JIANGSU HONGSHA DOOR & WINDOW +1

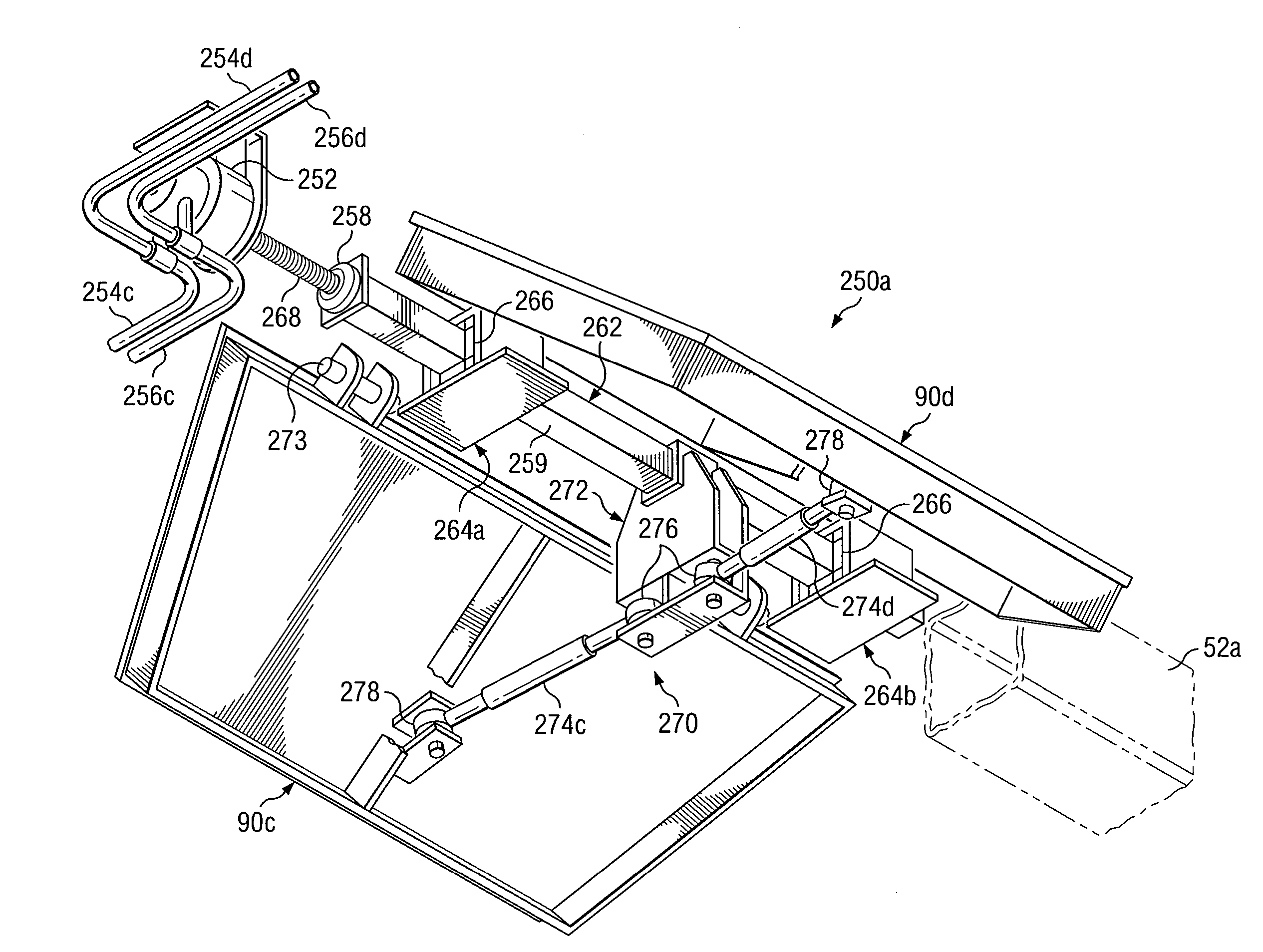

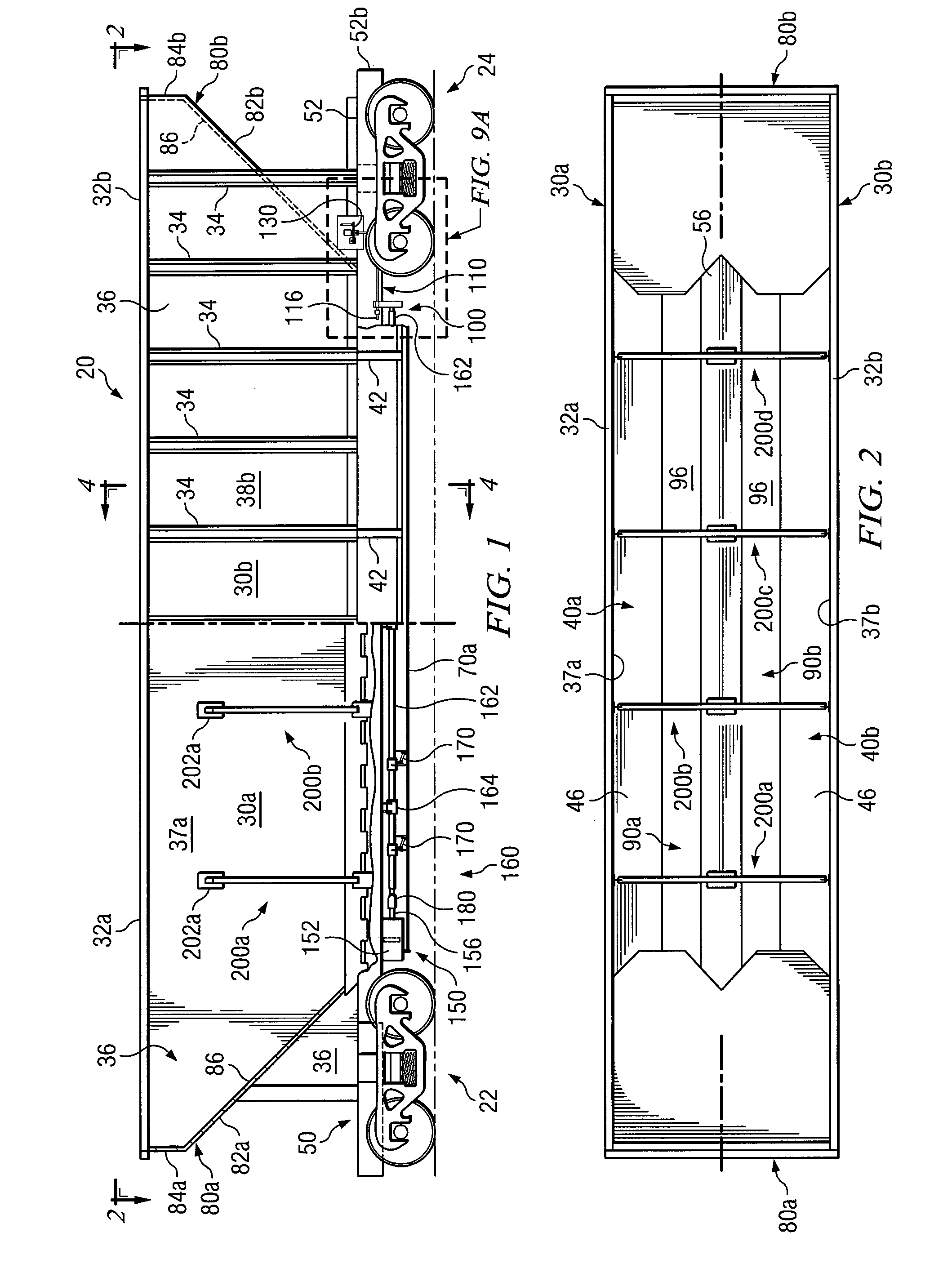

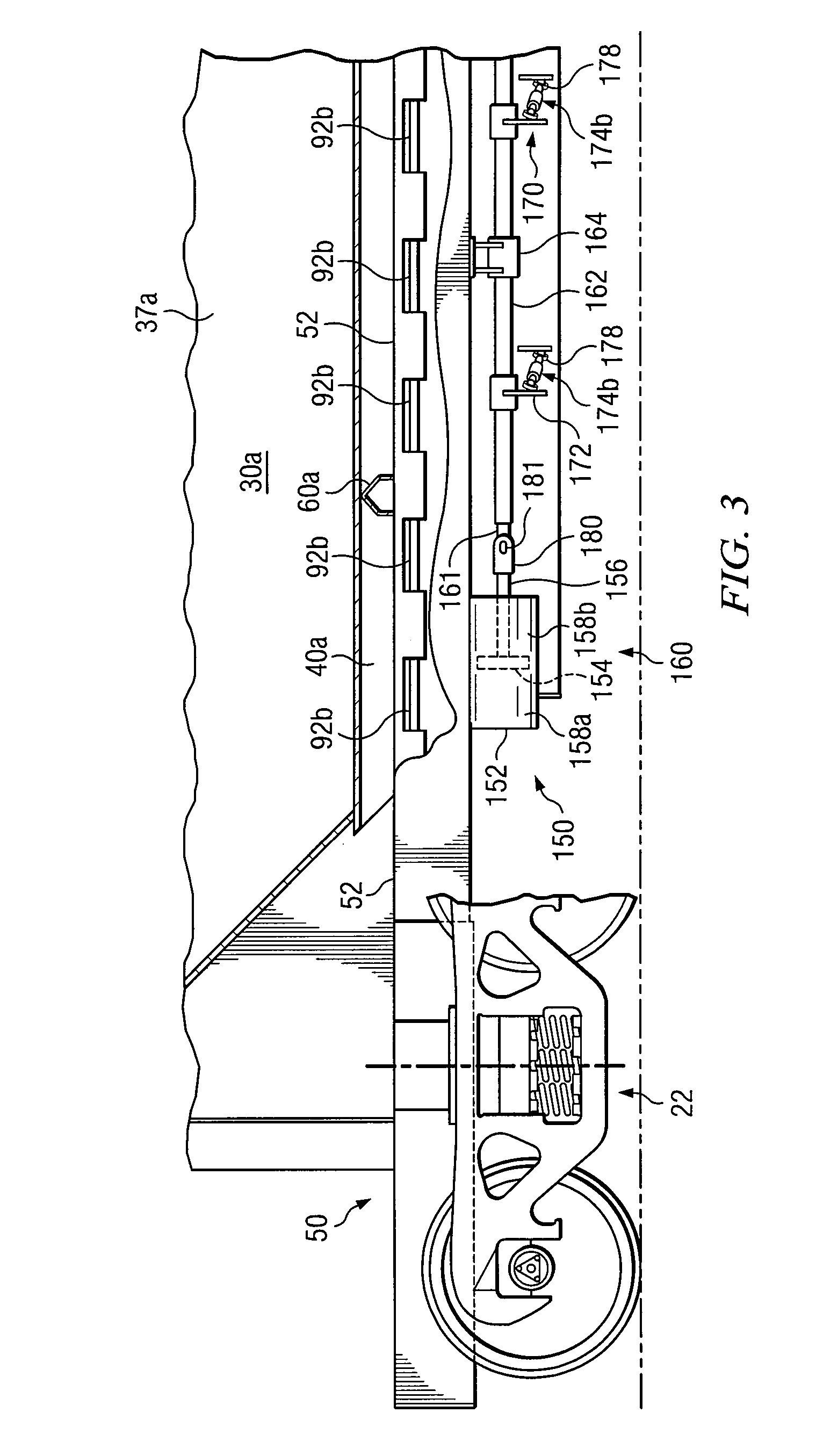

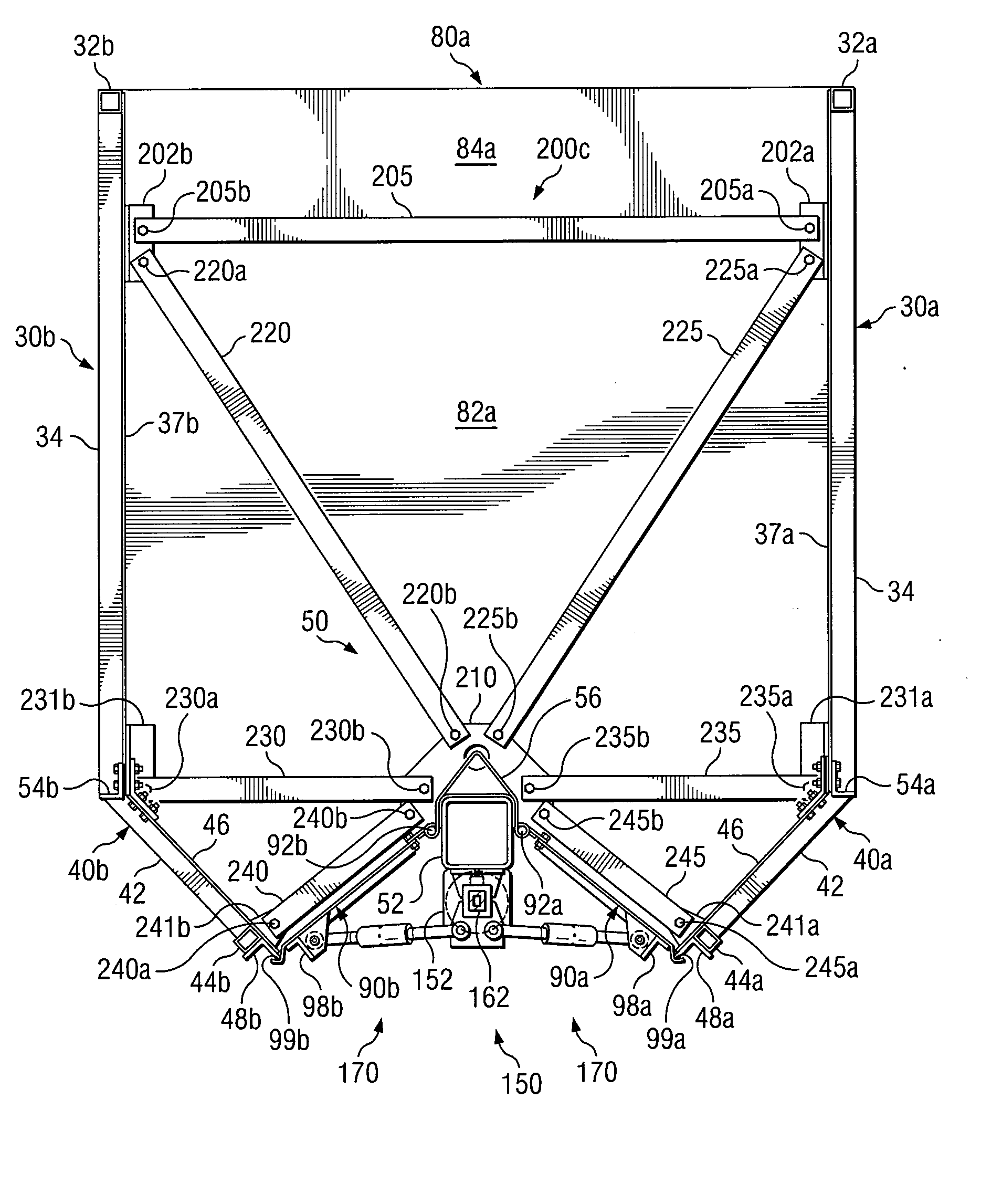

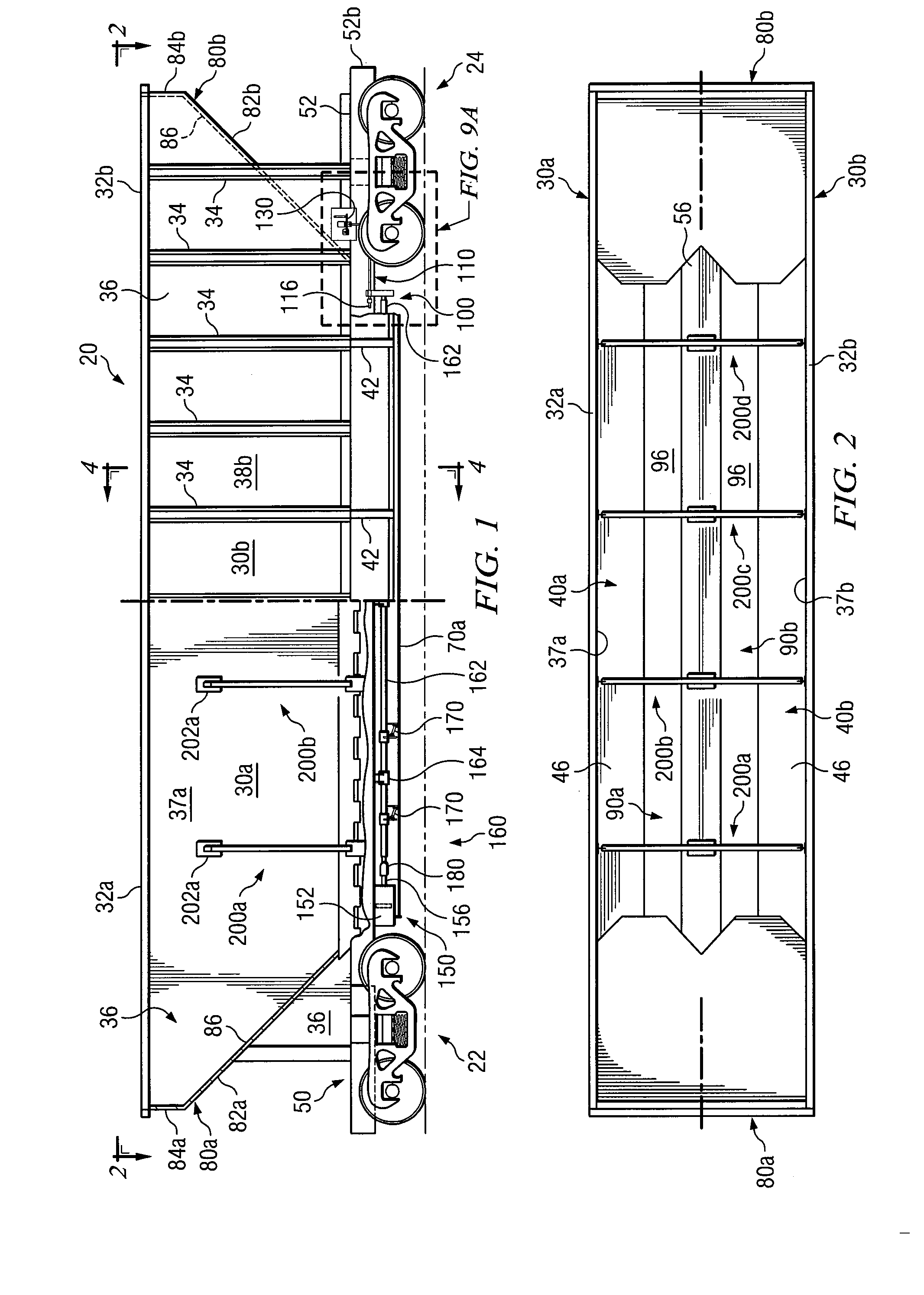

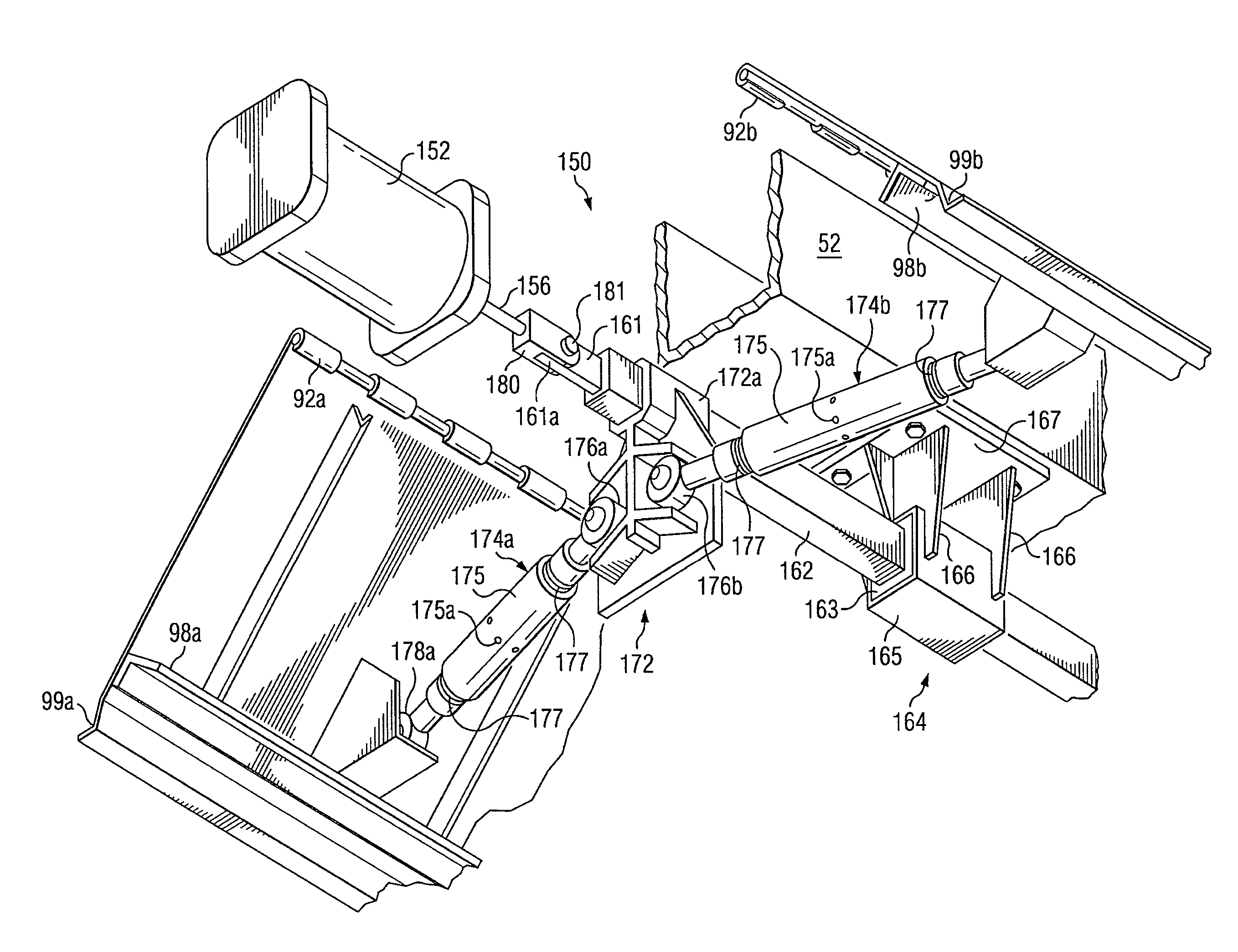

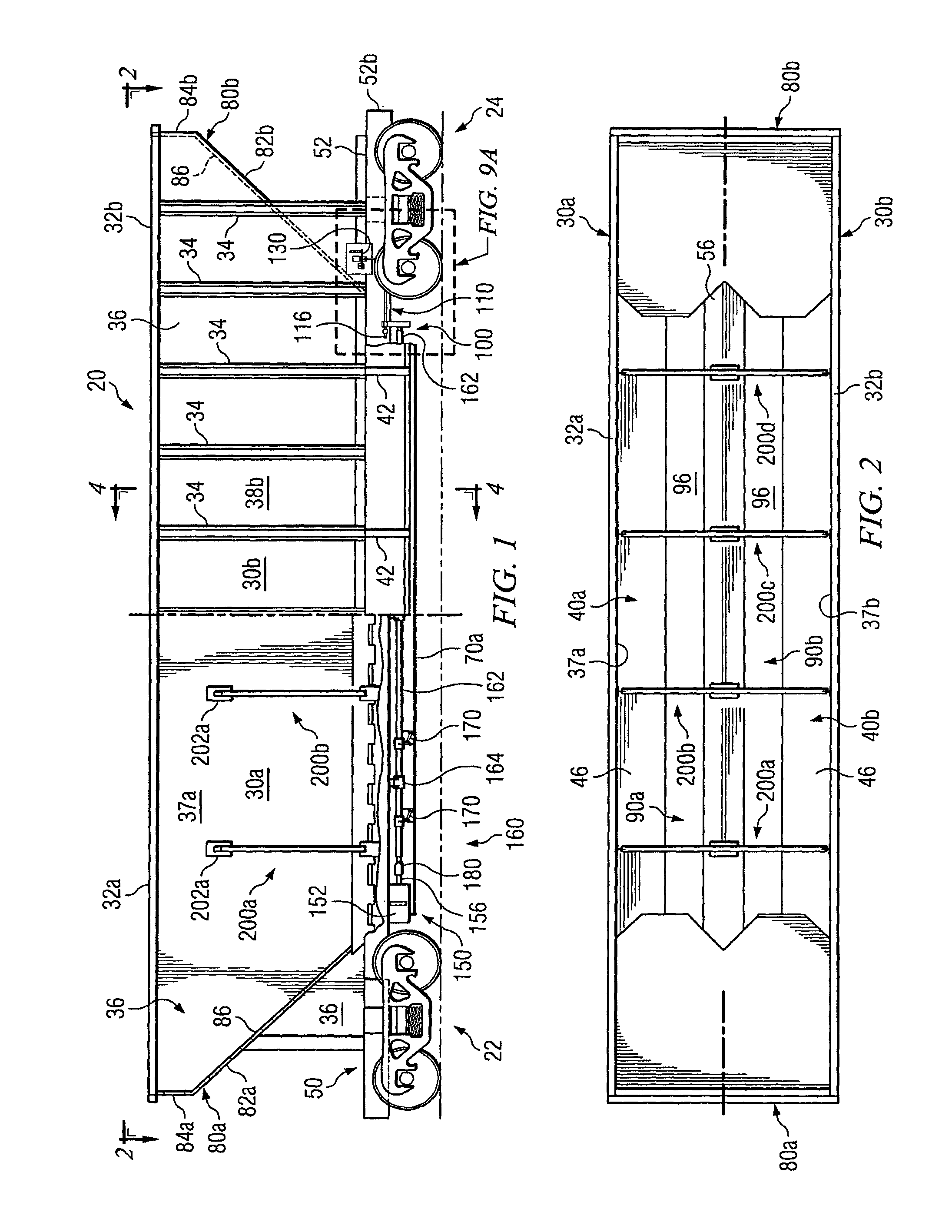

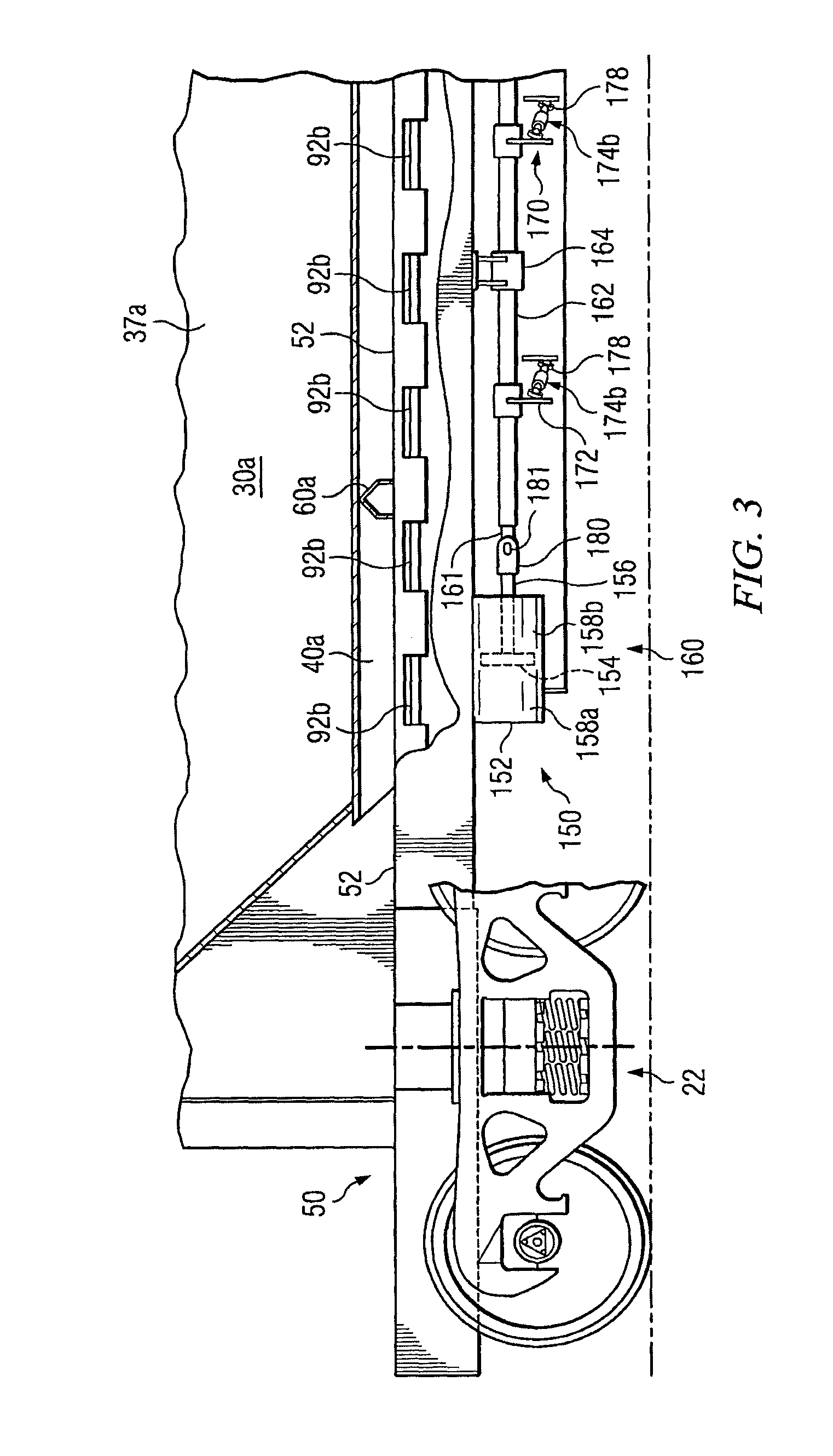

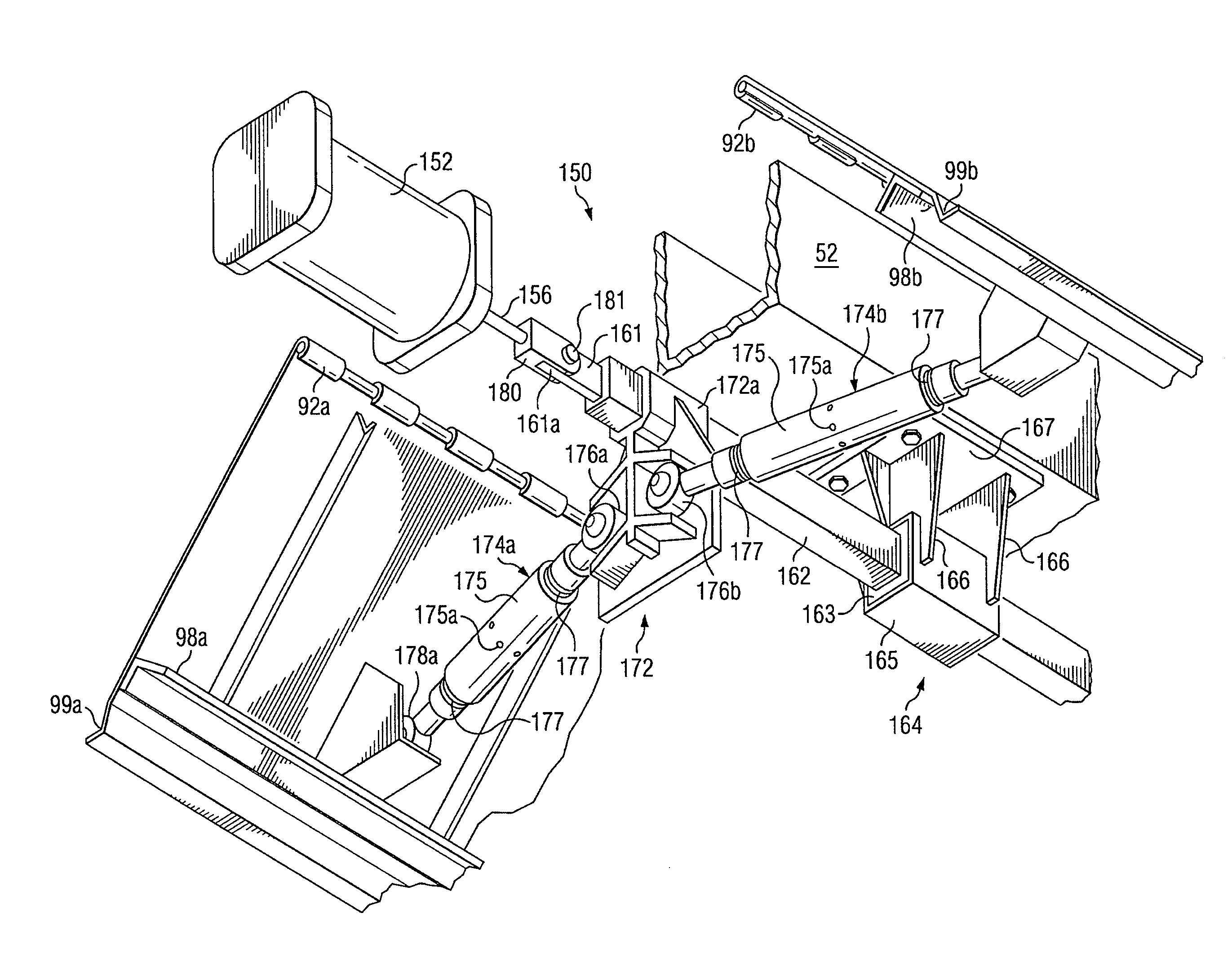

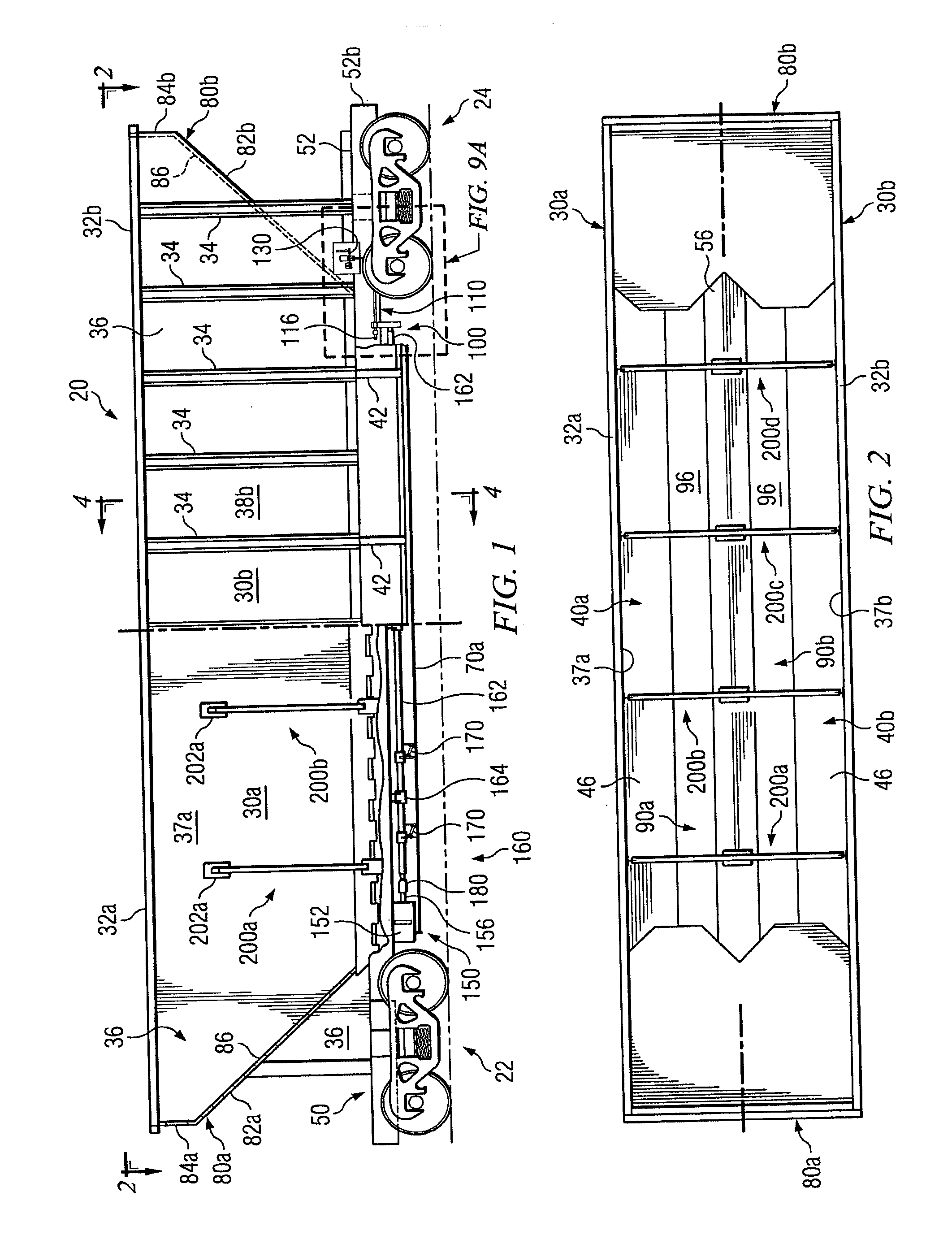

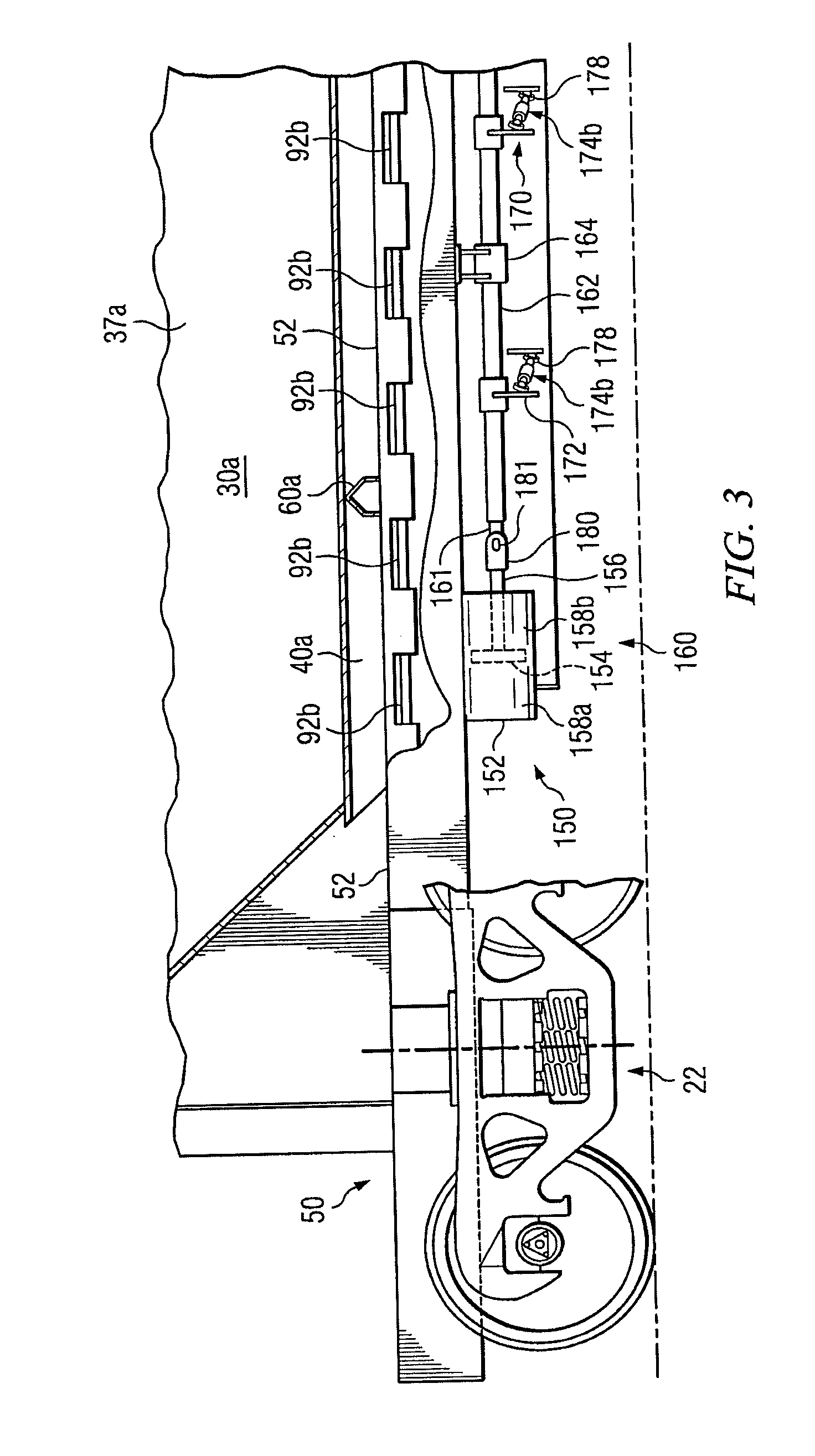

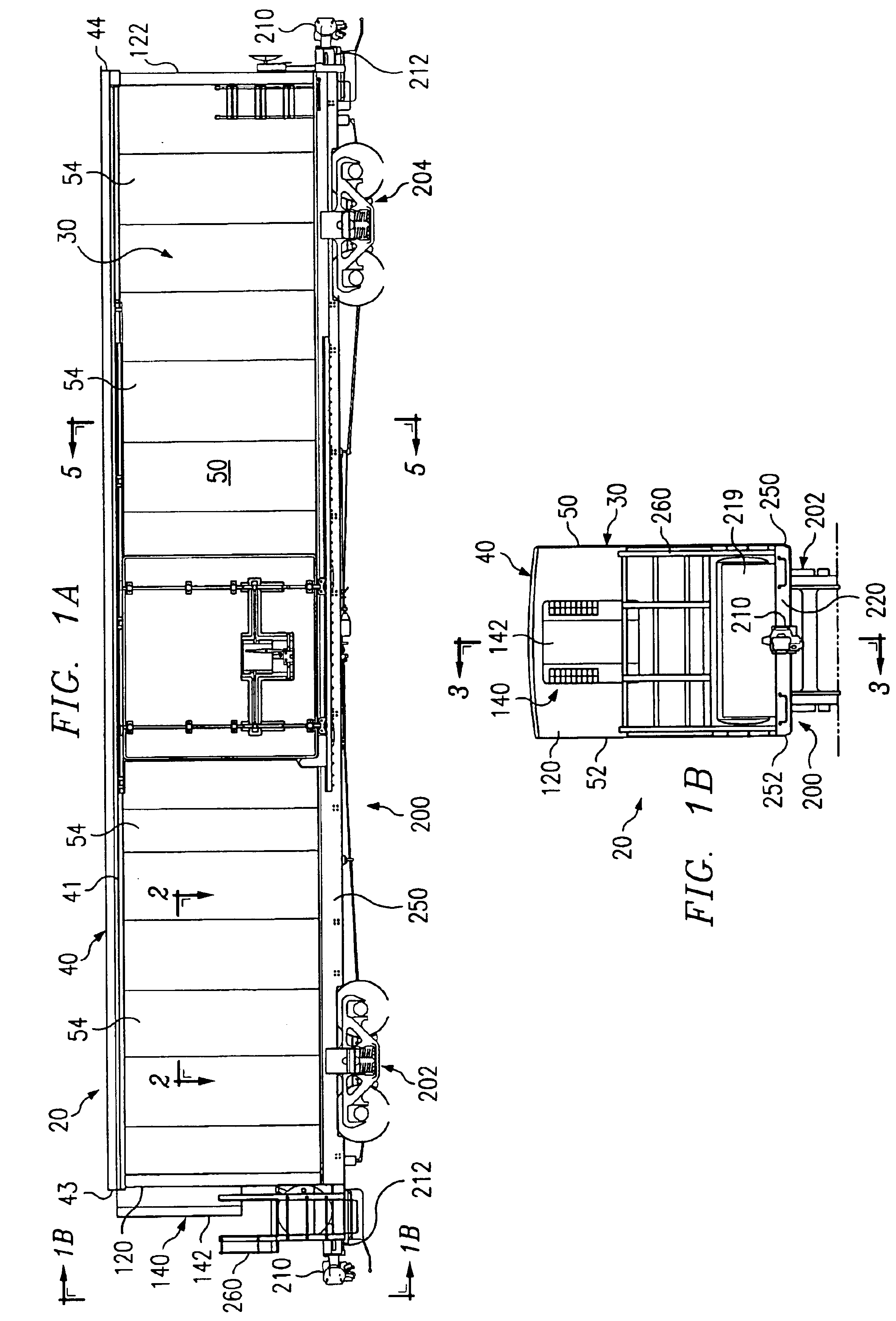

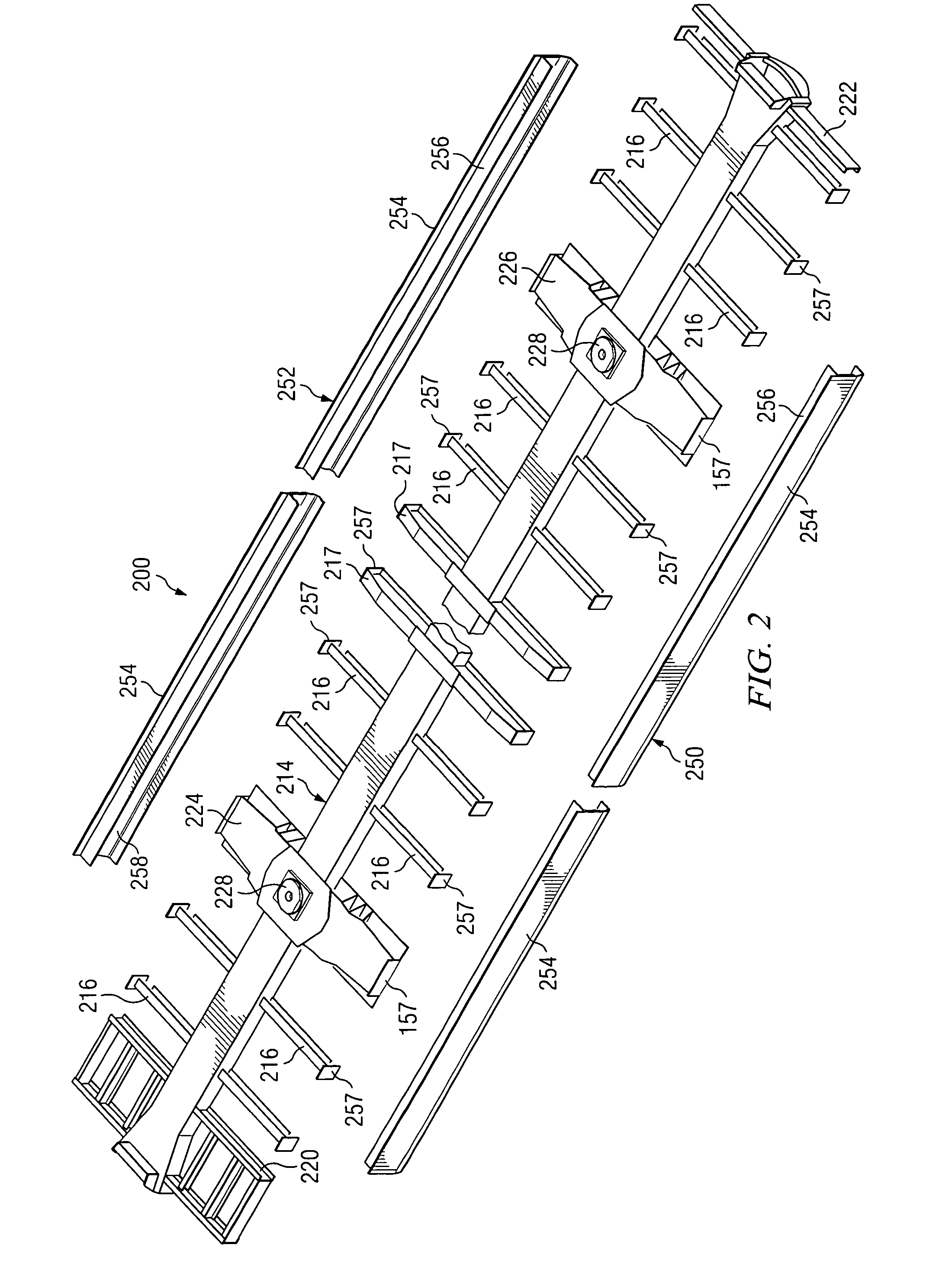

Hopper cars with one or more discharge control systems

ActiveUS7735426B2Enhanced advantageIntuitive adjustmentHopper carsWagons/vansHydraulic cylinderControl system

Hopper cars both open and covered and discharge control systems are disclosed. Each hopper car may include at least one hopper and a center sill which defines in part a longitudinal axis of the hopper car. At least one discharge opening may be formed proximate a lower portion of each hopper. A respective door assembly may be pivotally mounted adjacent to each discharge opening to control the flow of lading from the respective discharge opening. Each discharge control system may include a common linkage and associated secondary linkages operable to move associated door assemblies between a first position and a second position. A power source including a motor, an air cylinder or a hydraulic cylinder may be disposed on the railway car to move the common linkage. For other hopper cars a wayside drive system may be releasably engaged with a capstan operable coupled to the common linkage.

Owner:TRINITY IND INC

Hopper Cars With One Or More Discharge Control Systems

ActiveUS20070084378A1Enhanced advantageIntuitive adjustmentHopper carsWagons/vansHydraulic cylinderControl system

Hopper cars both open and covered and discharge control systems are disclosed. Each hopper car may include at least one hopper and a center sill which defines in part a longitudinal axis of the hopper car. At least one discharge opening may be formed proximate a lower portion of each hopper. A respective door assembly may be pivotally mounted adjacent to each discharge opening to control the flow of lading from the respective discharge opening. Each discharge control system may include a common linkage and associated secondary linkages operable to move associated door assemblies between a first position and a second position. A power source including a motor, an air cylinder or a hydraulic cylinder may be disposed on the railway car to move the common linkage. For other hopper cars a wayside drive system may be releasably engaged with a capstan operable coupled to the common linkage.

Owner:TRINITY IND INC

Soy milk compositions and methods of preparation

InactiveUS6322846B1Eliminate wasteSame tasteOther dairy technologyFood ingredientsParticulatesChemical composition

Soy milk and beverage compositions together with methods for preparation, such compositions utilizing soy particulates of consistent micron dimension, either alone or in conjunction with high process pressures, to provide texture and taste characteristics.

Owner:JENEIL BIOTECH INC

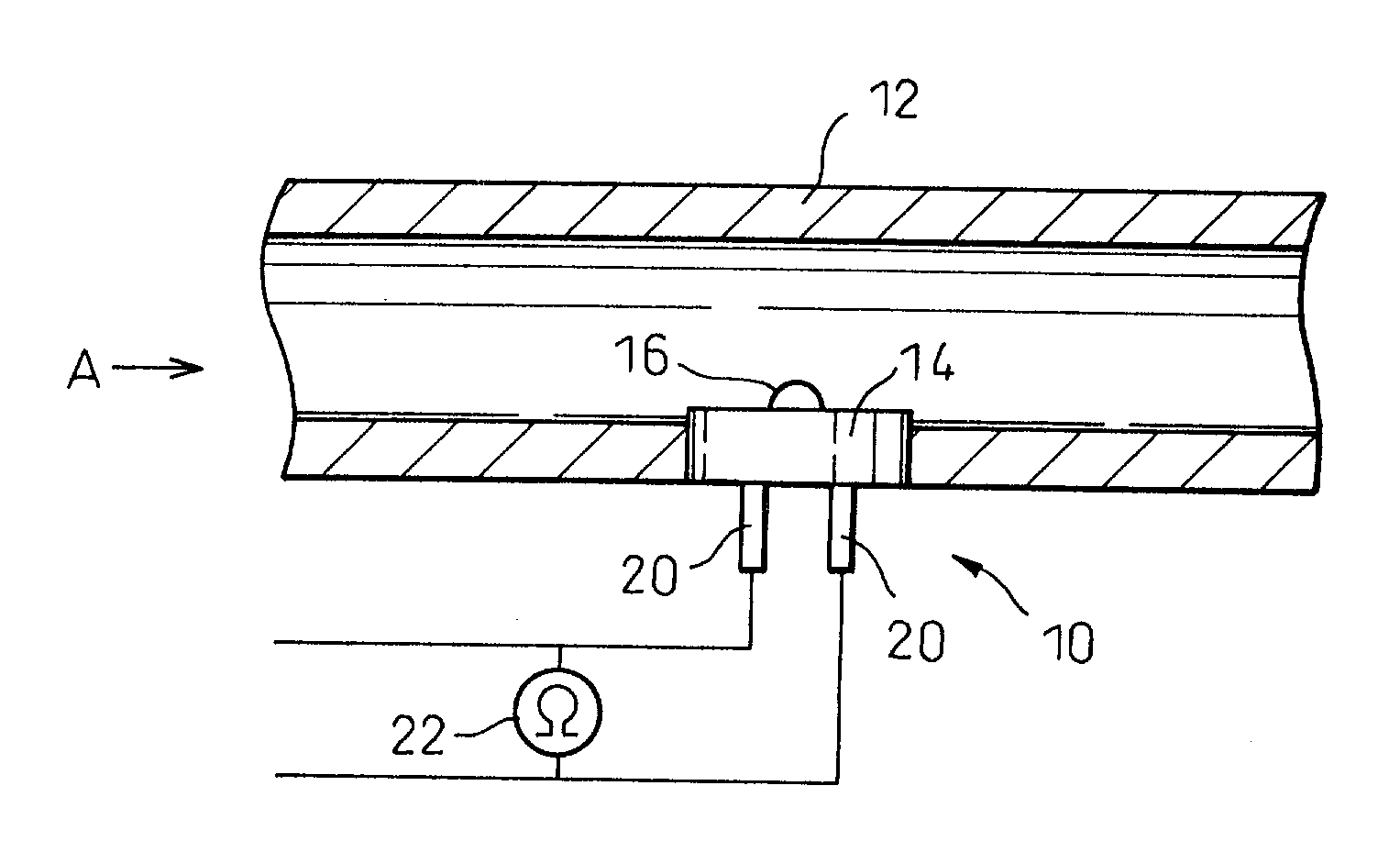

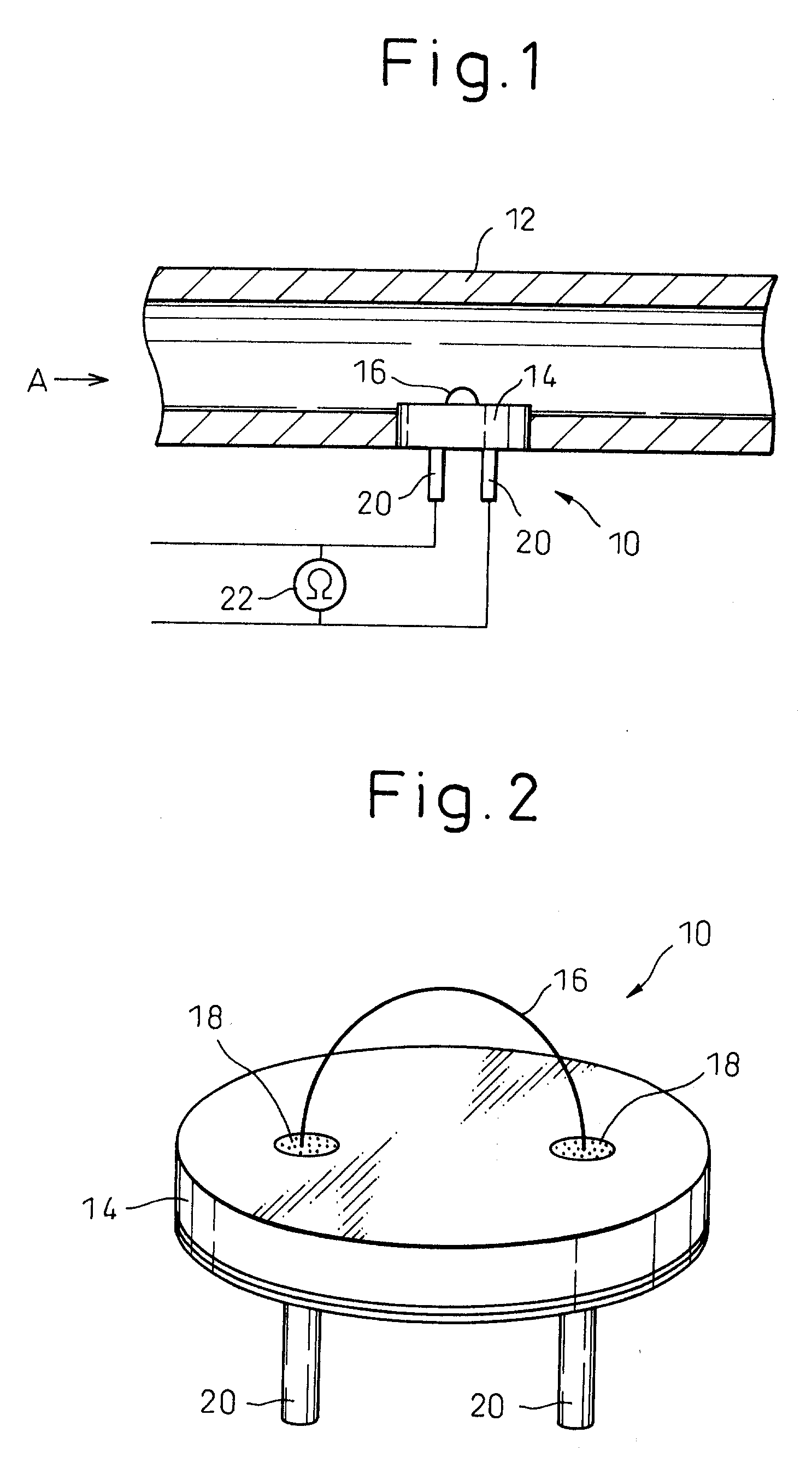

Sulfur component sensor and sulfur component detector

InactiveUS20040063215A1Increased electrical resistance valueEasy to scatterComponent separationBiological testingElectrical resistance and conductancePhase change

Abstract of the Disclosure A sulfur-detecting sensor for detecting an integrated amount of hydrogen sulfide present in a gas stream passed over the sensor, characterized in that the sensor comprises a member formed of a material which is stable to hydrogen sulfide, and having a contacting side which is brought into contact with hydrogen sulfide, and a measuring member located on the contacting side of the former member, the measuring member being formed of a material which reacts with hydrogen sulfide to yield a reaction product having an increased electrical resistance value and / or making a phase change into a phase easily scattered by the gas stream at a temperature of the vicinity of the contacting side, and allowing an integrated amount of hydrogen sulfide passed over the sensor to be measured by measuring its electrical resistance value. A sulfur-detecting device using the detecting sensor is also disclosed.

Owner:SHINKO ELECTRIC IND CO LTD

Lead-free solder alloys

InactiveUS6503338B1High bonding strengthAvoid heat damageWelding/cutting media/materialsSoldering mediaMelting temperatureLiquidus

A lead-free solder alloy which has a relatively low melting temperature and which is suitable for soldering electronic devices consists essentially of from 5 to 9 mass % of Zn, from 2 to 15 mass % of Bi, optionally from 0.001 to 1 mass % of P or from 0.001 to 0.1 mass % of Ge, and a balance of Sn. The solder alloy has a liquidus temperature of at most 220° C.

Owner:SENJU METAL IND CO LTD

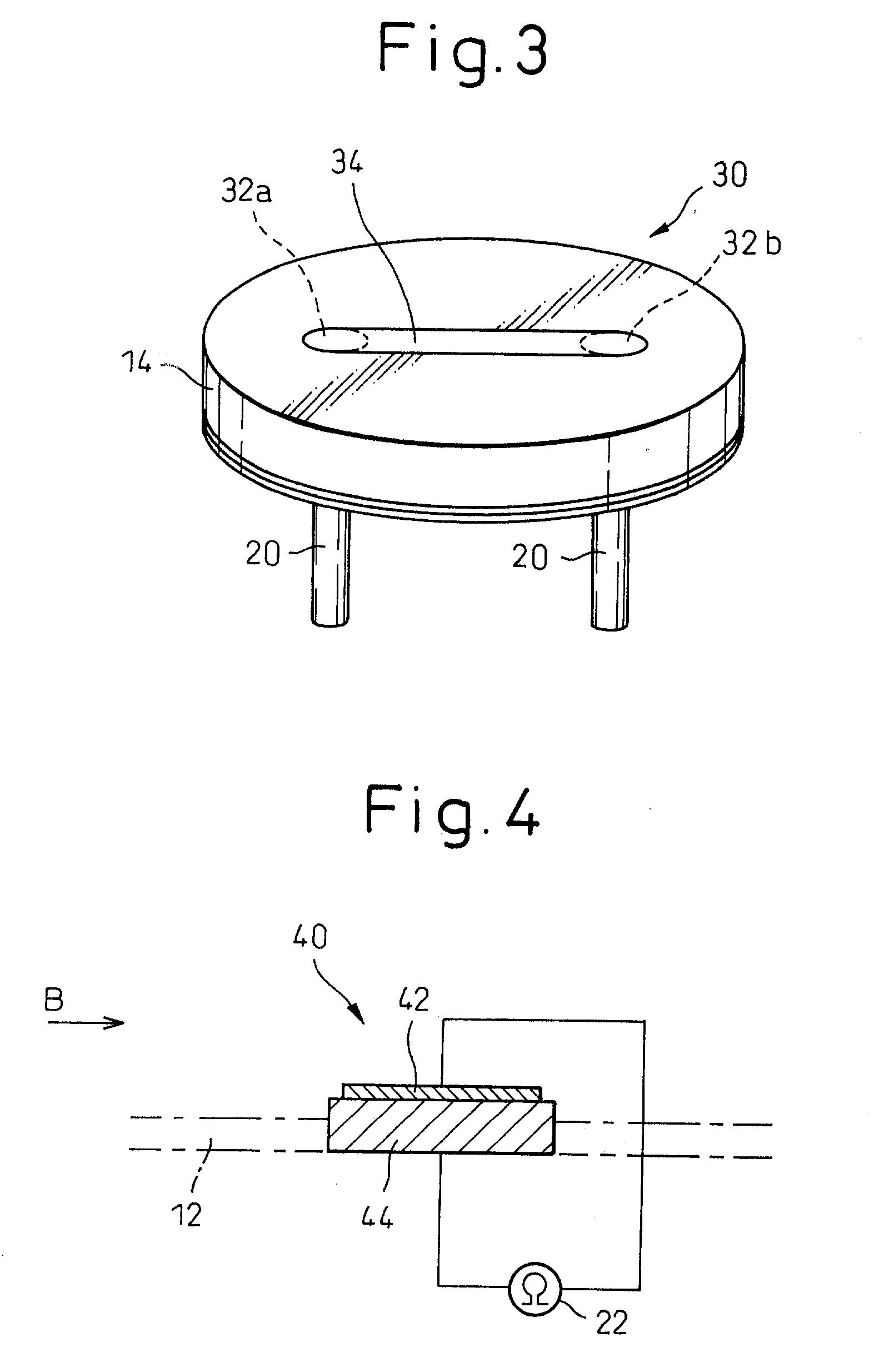

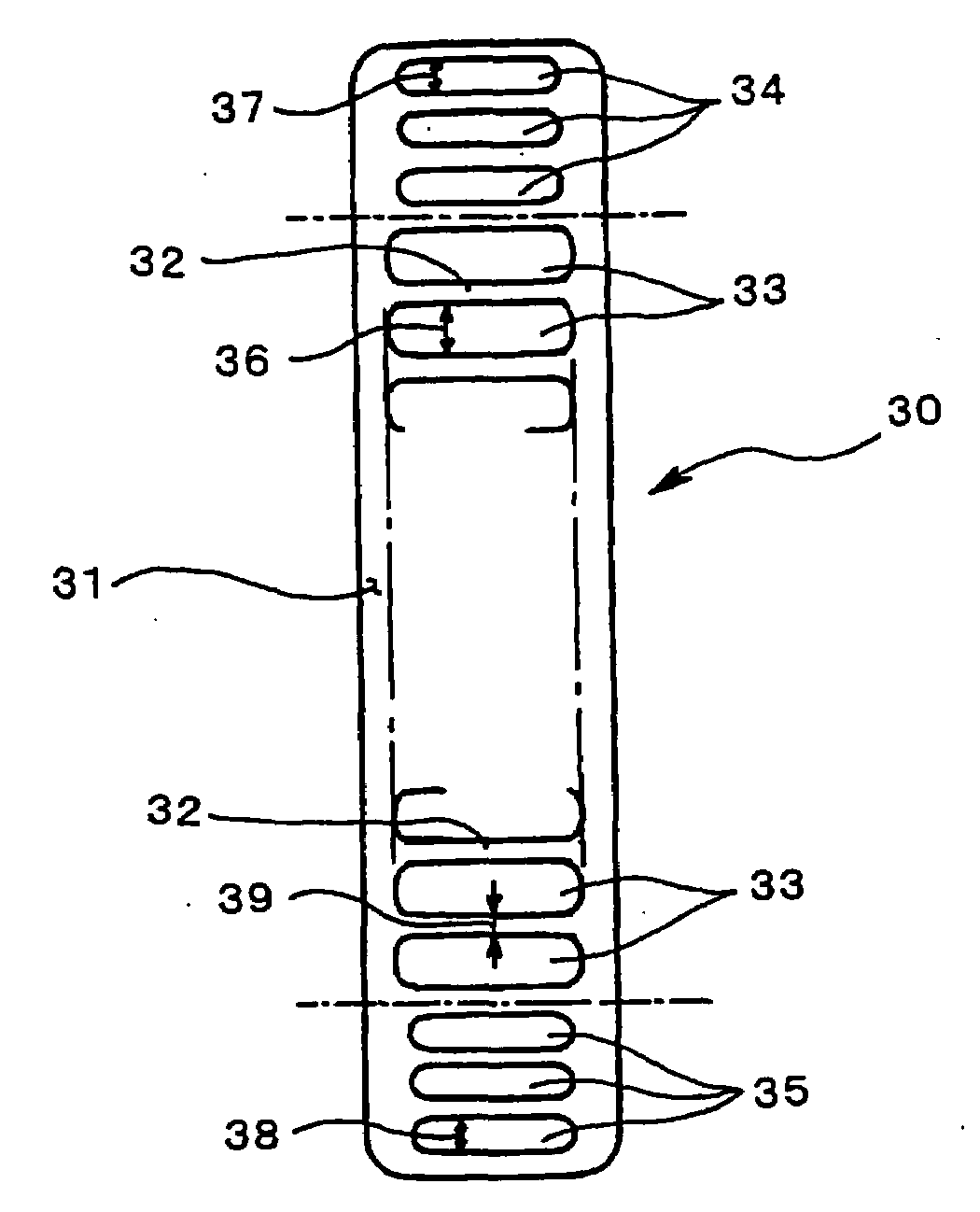

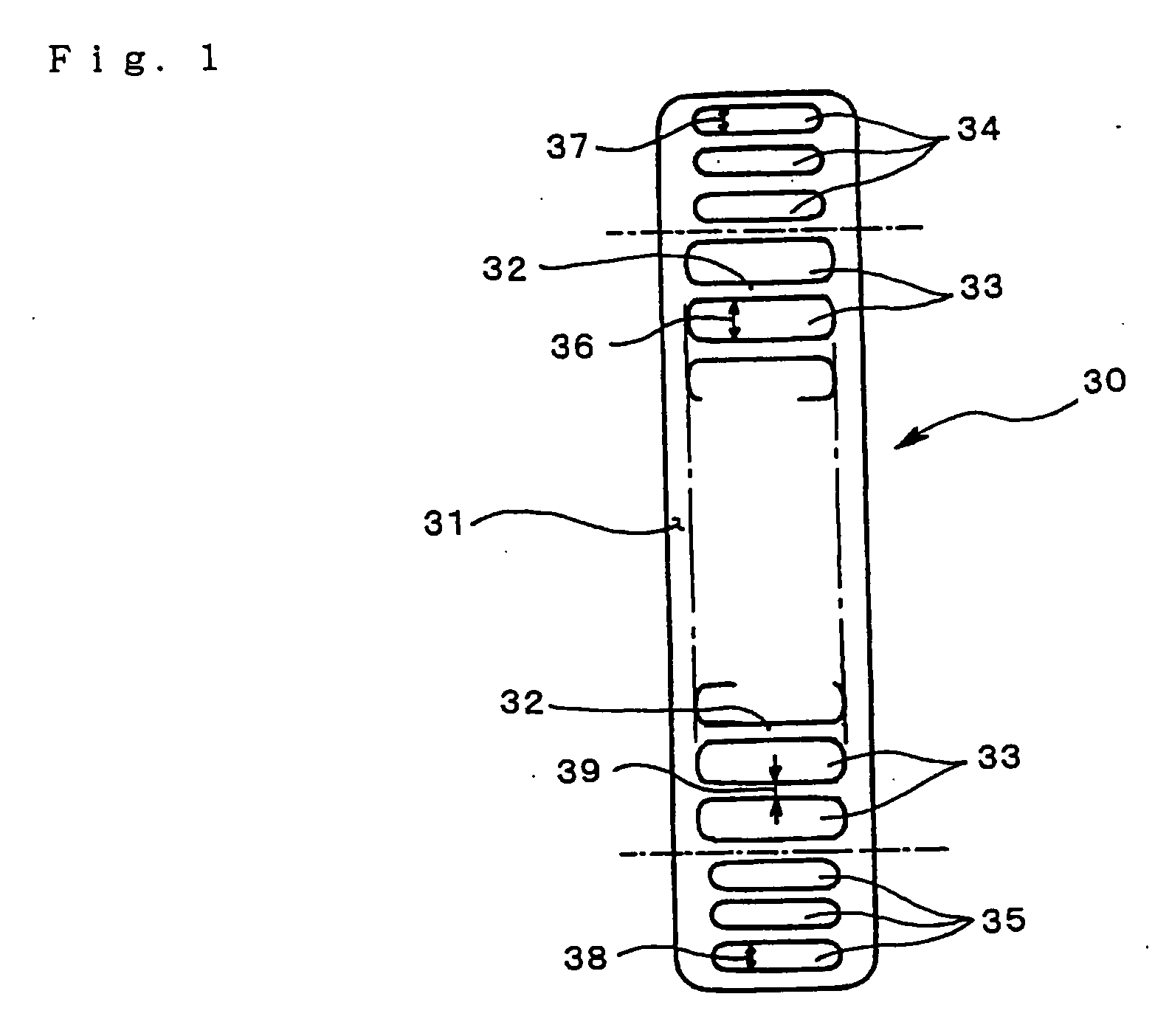

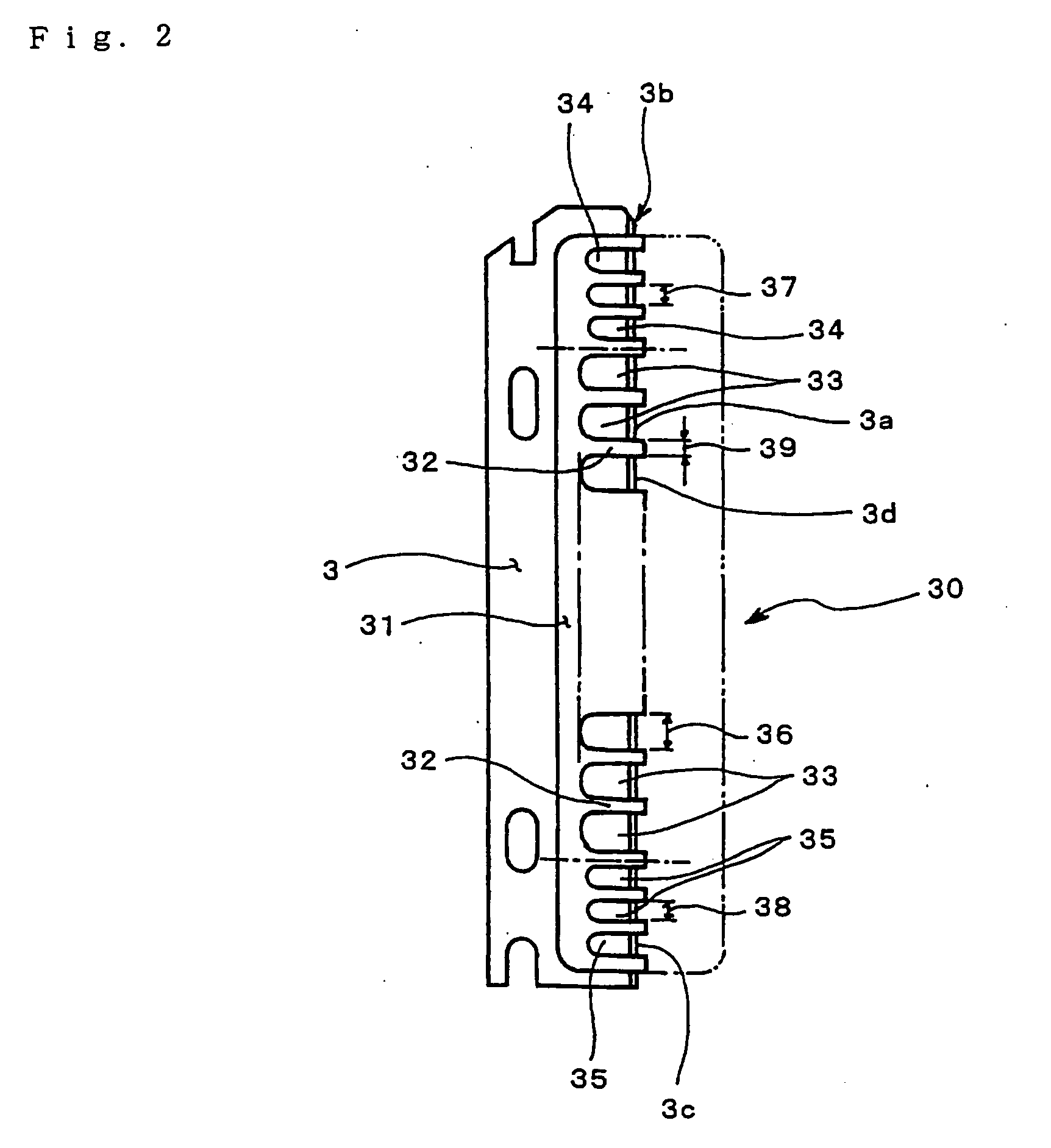

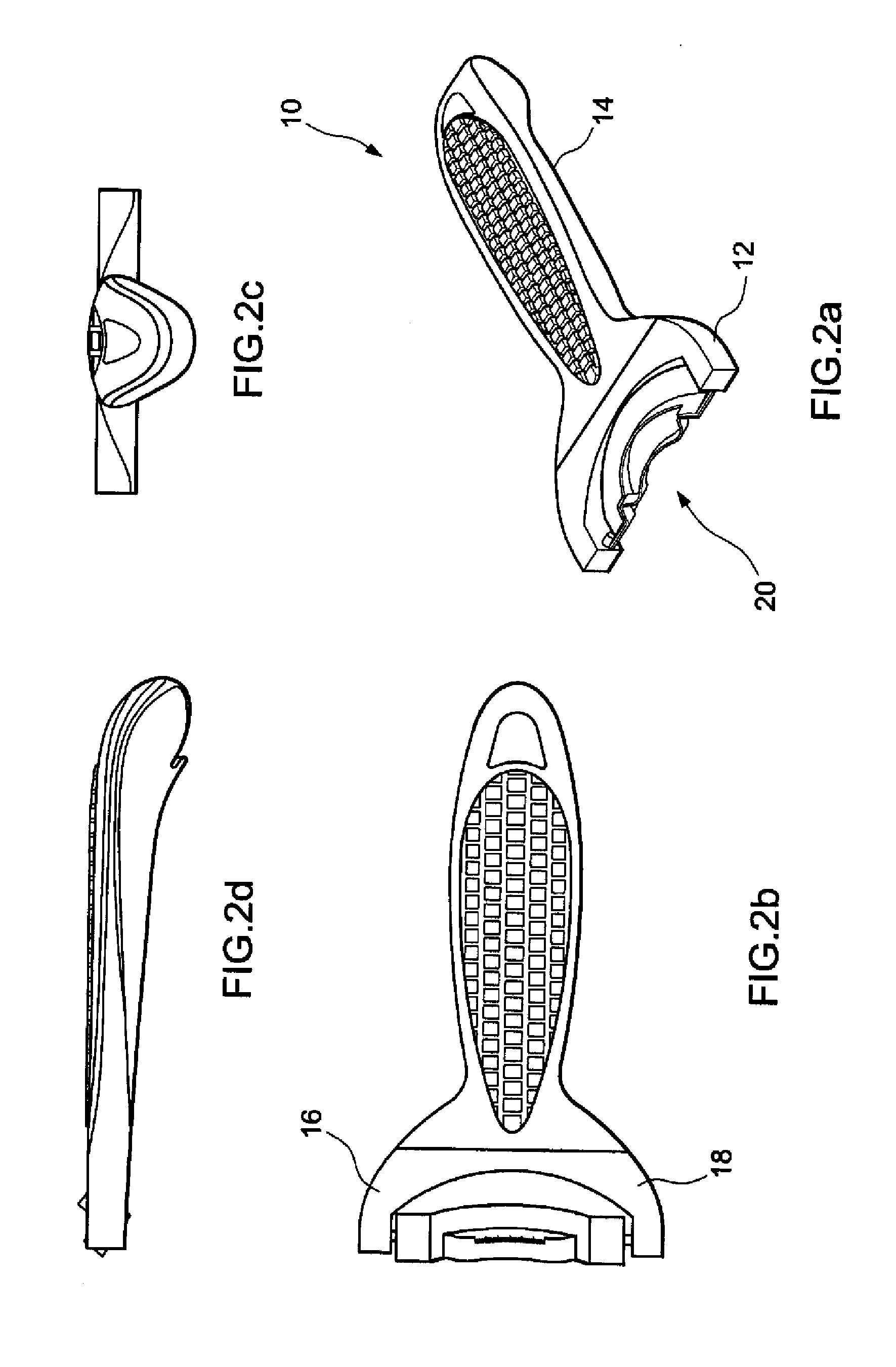

Razor Implement

InactiveUS20090007442A1Improve shaving efficiencySufficient feeling of satisfactionMetal working apparatusEngineeringElectrical and Electronics engineering

The present invention provides a razor implement which can be satisfactorily used by those who are accustomed to using razor implements, and exhibits an extremely high safety during shaving. The razor implement of the first present invention is a razor implement in which a safety guard 30 having slits exposing the blade edge of a blade by specified intervals and bridges covering the blade edge at a plurality of positions is mounted on the blade fitted at the tip part of a handle, and the slits of the safety guard 30 are constituted by providing the first slits 33 formed at the central part of the blade edge, the second slits 34 formed with smaller widths than the widths of the first slits on the tip side of the blade edge, and the third slits 35 formed with smaller widths than the widths of the first slits on the proximal end part side of the blade edge. In addition, the razor implement of the second present invention is a razor implement wherein a safety guard having slits exposing the blade edge of a blade by specified intervals and bridges covering the blade edge at a plurality of positions is mounted on the blade fitted on the tip part of a handle, and in the razor implement mounted with the safety guard equipped with the bridges covering the blade edge at a plurality of positions, the slits of the safety guard are constituted by providing a first sub-slit 134 formed by the tip part of the blade edge, a second sub-slit 135 adjoining the first sub-slit and formed with a smaller width than the width of the first sub-slit, a third sub-slit 136 adjoining the second sub-slit and formed with a smaller width than the width of the second sub-slit, and a plurality of main slits 137 formed by adjoining the third sub-slit.

Owner:KURIHAA INDS

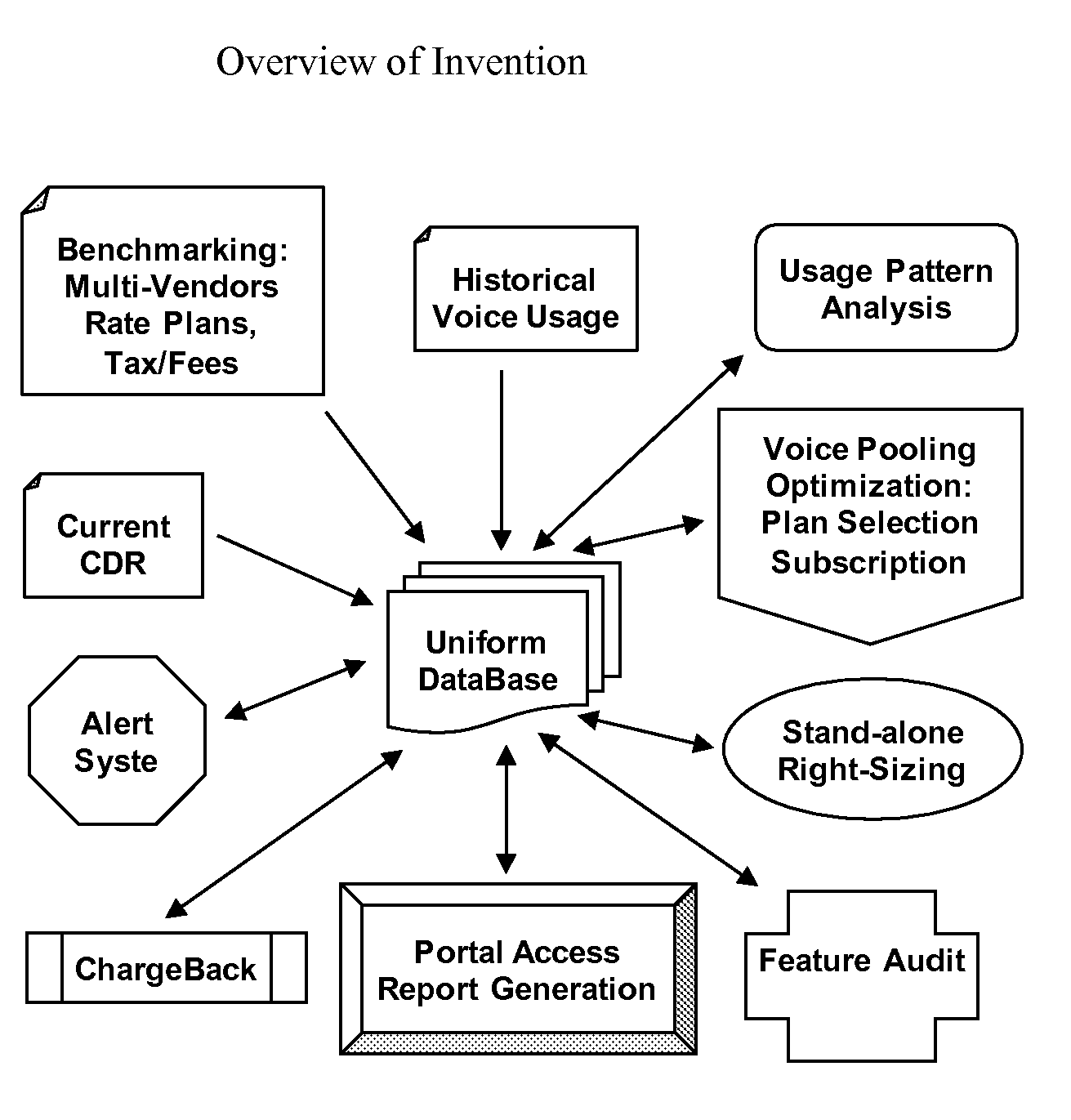

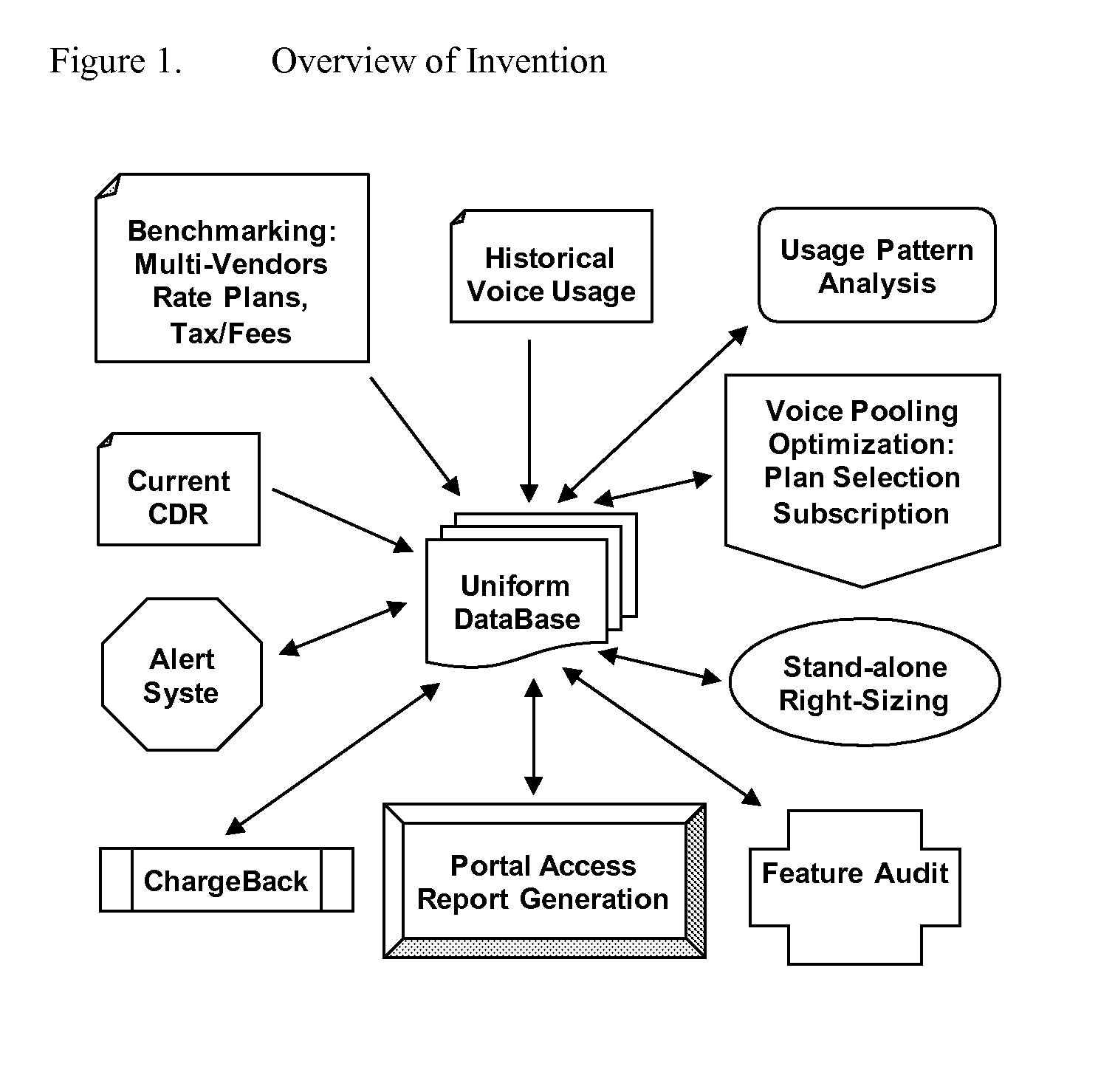

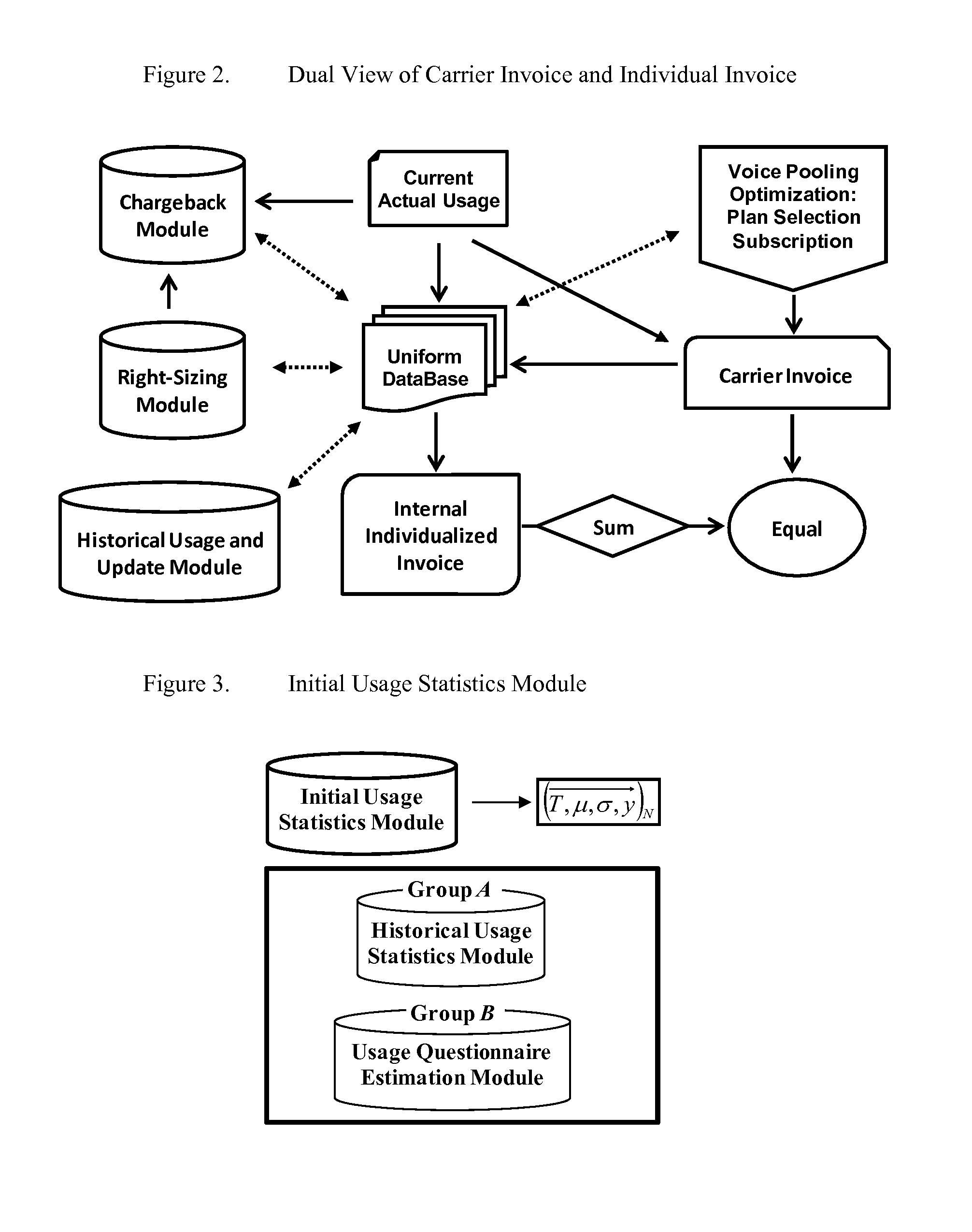

System and Method for Corporate Mobile Subscription Management

ActiveUS20140087688A1Minimize cost of usingSatisfied with useAccounting/billing servicesTelephonic communicationDual modeData access

This invention relates generally to a system and method to provide mobile subscription service management for medium and large corporations, allowing continuing backend total cost optimization. It determines a minutes pool collectively shared by a group of users, with an equitable cost allocation scheme which assures individual cost saving relative to the least cost stand-alone plan. The system provides real-time active mobile devices usage alert management, expense monitoring, report generation, individual internal cost center based billing and hierarchical data access through a web-based portal. The system is built on a Uniform Database, pulling information from Monthly Statements, Call Detail Records (CDRs), invoices, plan features and data usage summaries across diverse vendor platforms. The system covers all mobile communication devices, including but not limited to all smart phones (Blackberries, Androids, Windows and i-Phones herein), encompassing various protocols (CDMA, GSM or dual mode) and transmission media (WiFi and cellular network).

Owner:ONCEPT

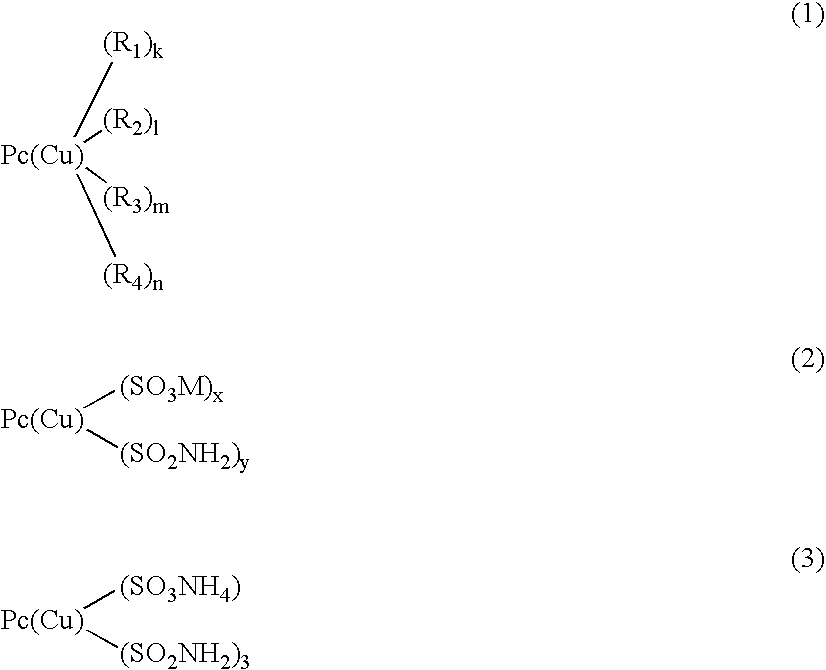

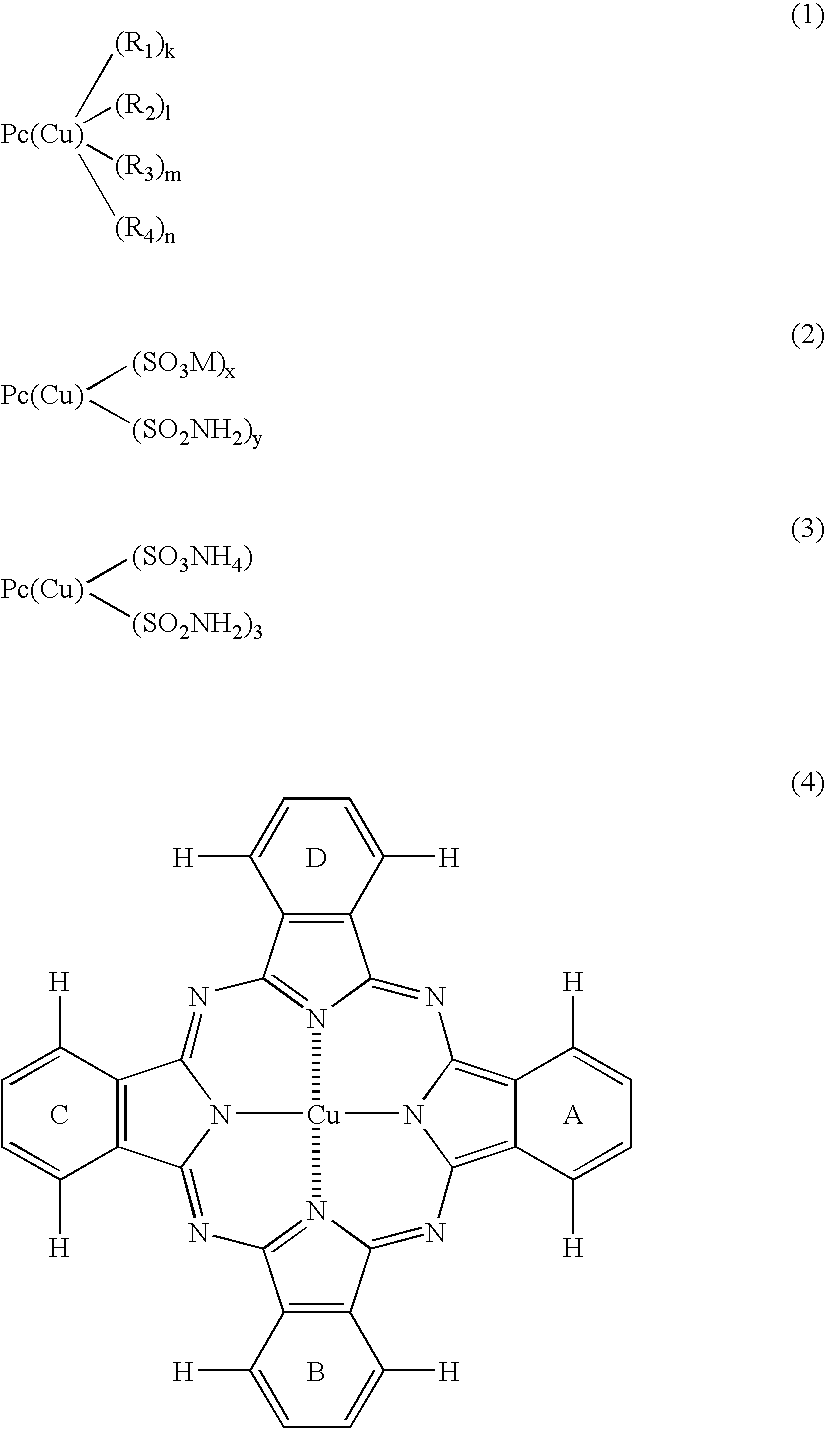

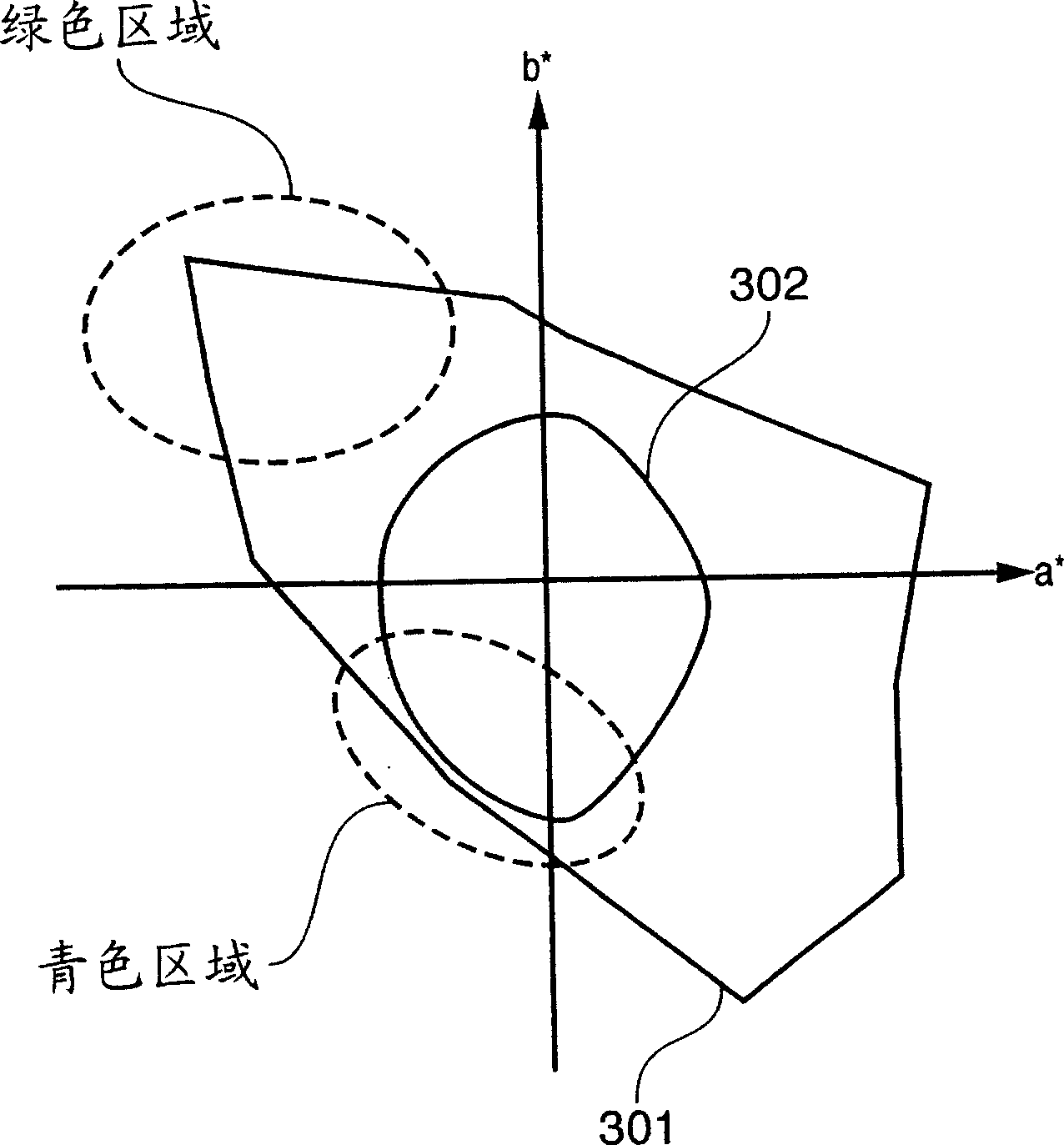

Cyan ink for ink-jet recording

A cyan ink for ink-jet recording contains a coloring agent, water and a water soluble organic solvent. Different types of dyes are employed as the coloring agent. In particular, a dye represented by the general formula (1) is used together with at least one dye selected from the group consisting of a dye represented by the general formula (2), a dye represented by the general formula (3) and C. I. Direct Blue 86. In the formulas, Pc(Cu) is a copper phthalocyanine nucleus.

Owner:BROTHER KOGYO KK

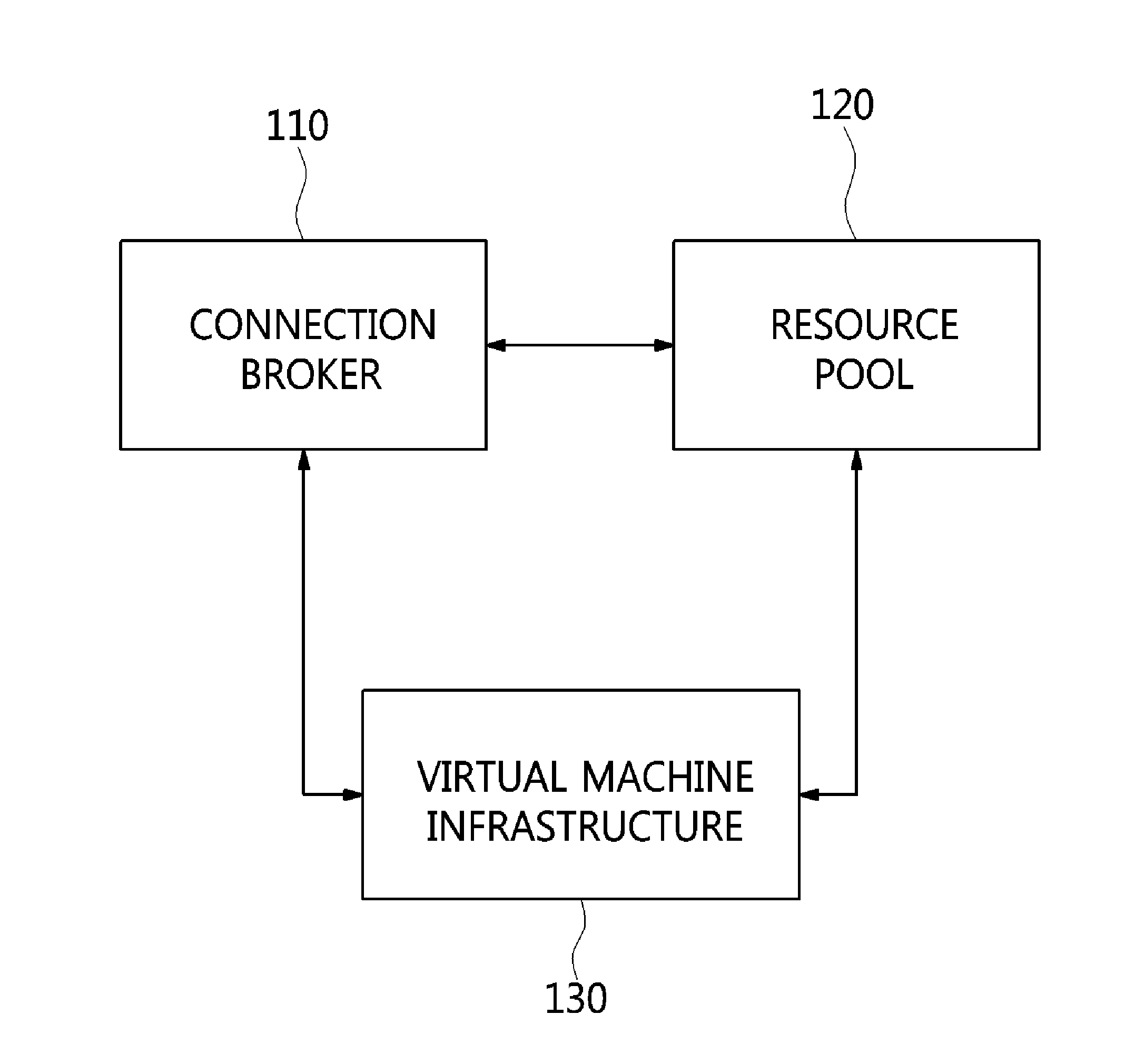

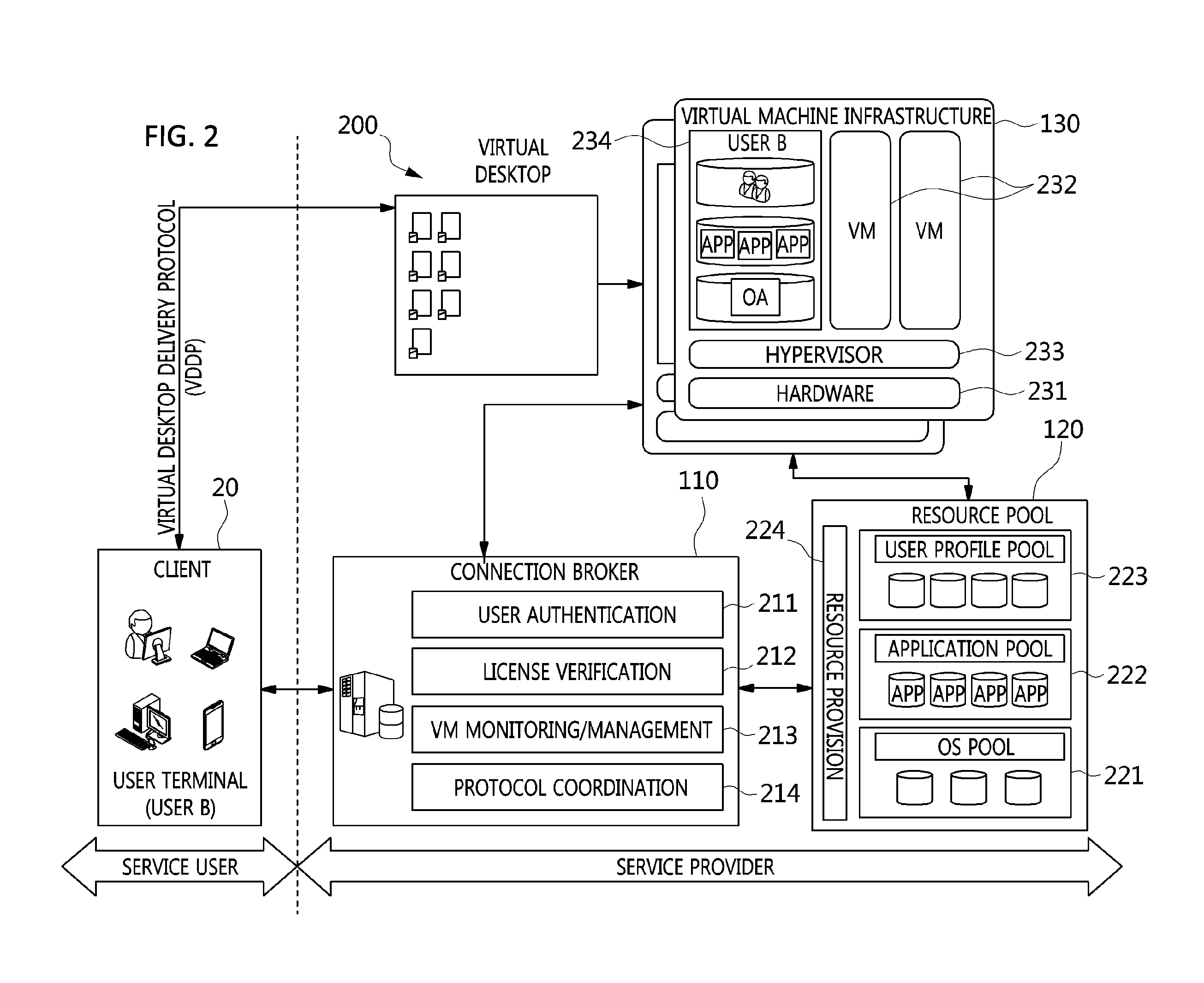

Apparatus and method for virtual desktop service

ActiveUS20160378534A1Efficiently provideEfficiently providedExecution for user interfacesSoftware simulation/interpretation/emulationResource poolOperational system

Disclosed herein are an apparatus and method for virtual desktop service. The apparatus for virtual desktop service includes a connection broker for performing a task for coordinating a delivery protocol that is used between at least one user terminal that uses virtual desktop service and multiple servers that provides the virtual desktop service, a resource pool for providing software resources including an Operating System (OS) for the virtual desktop service, and virtual machine infrastructure for supporting hardware resources.

Owner:ELECTRONICS & TELECOMM RES INST

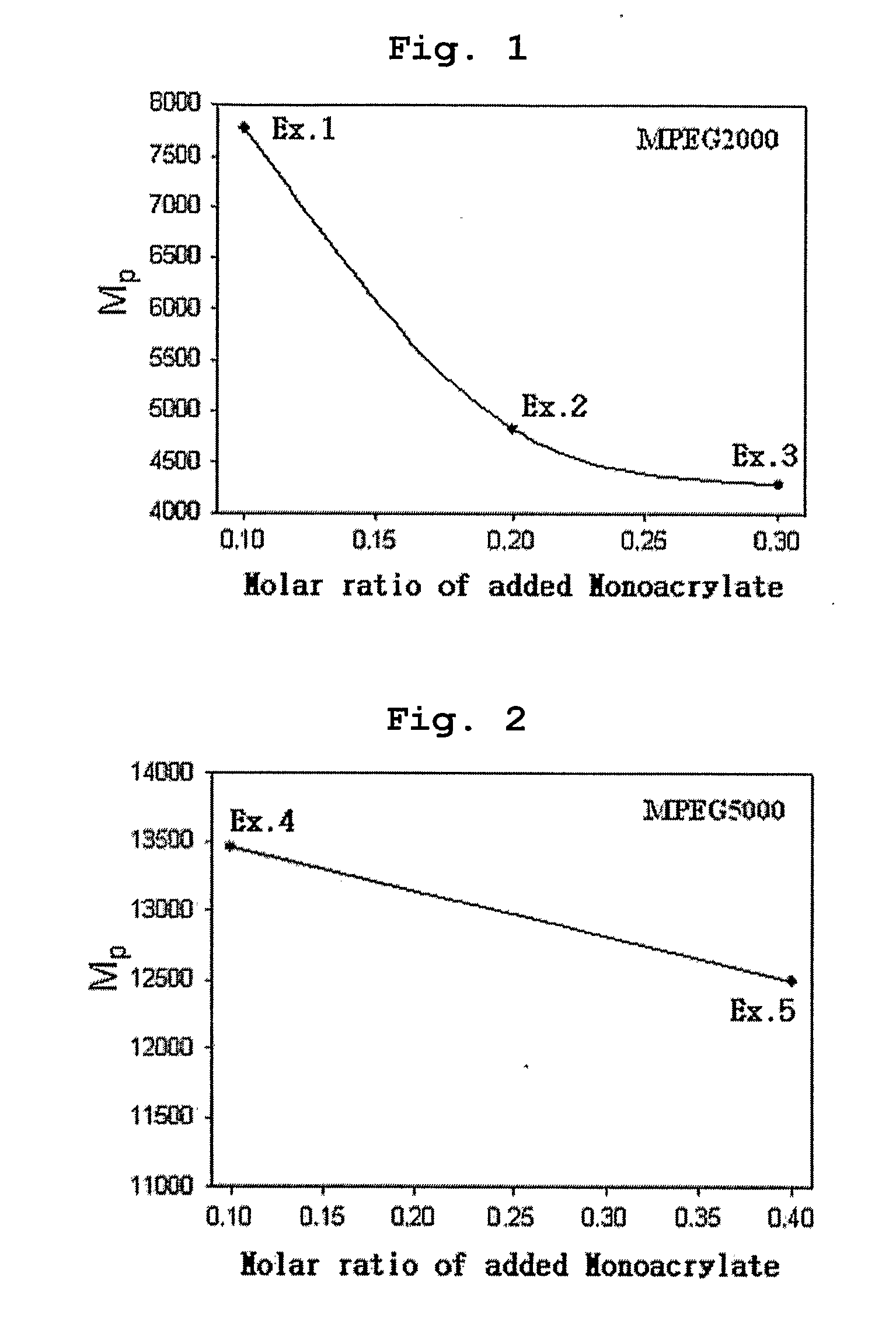

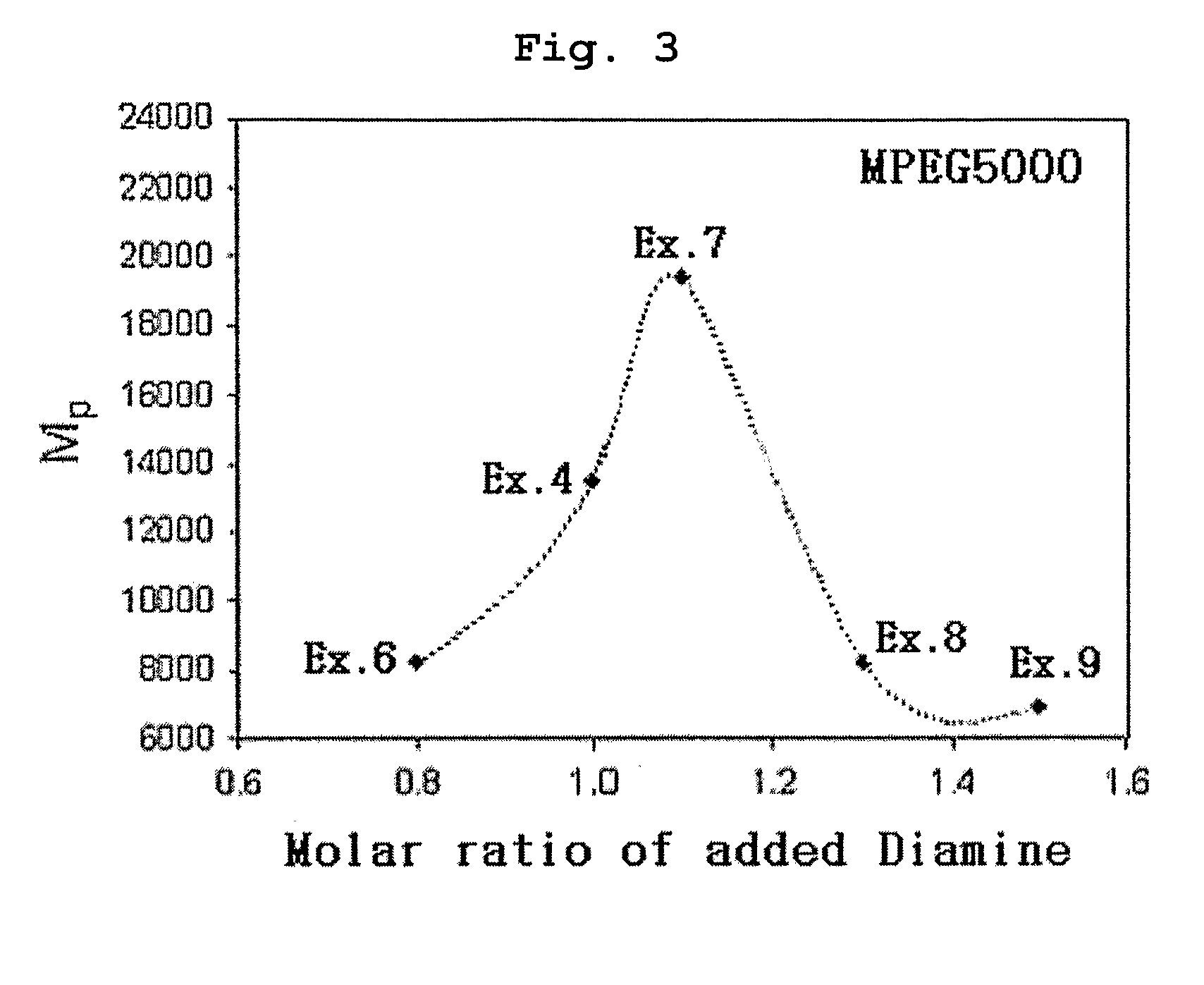

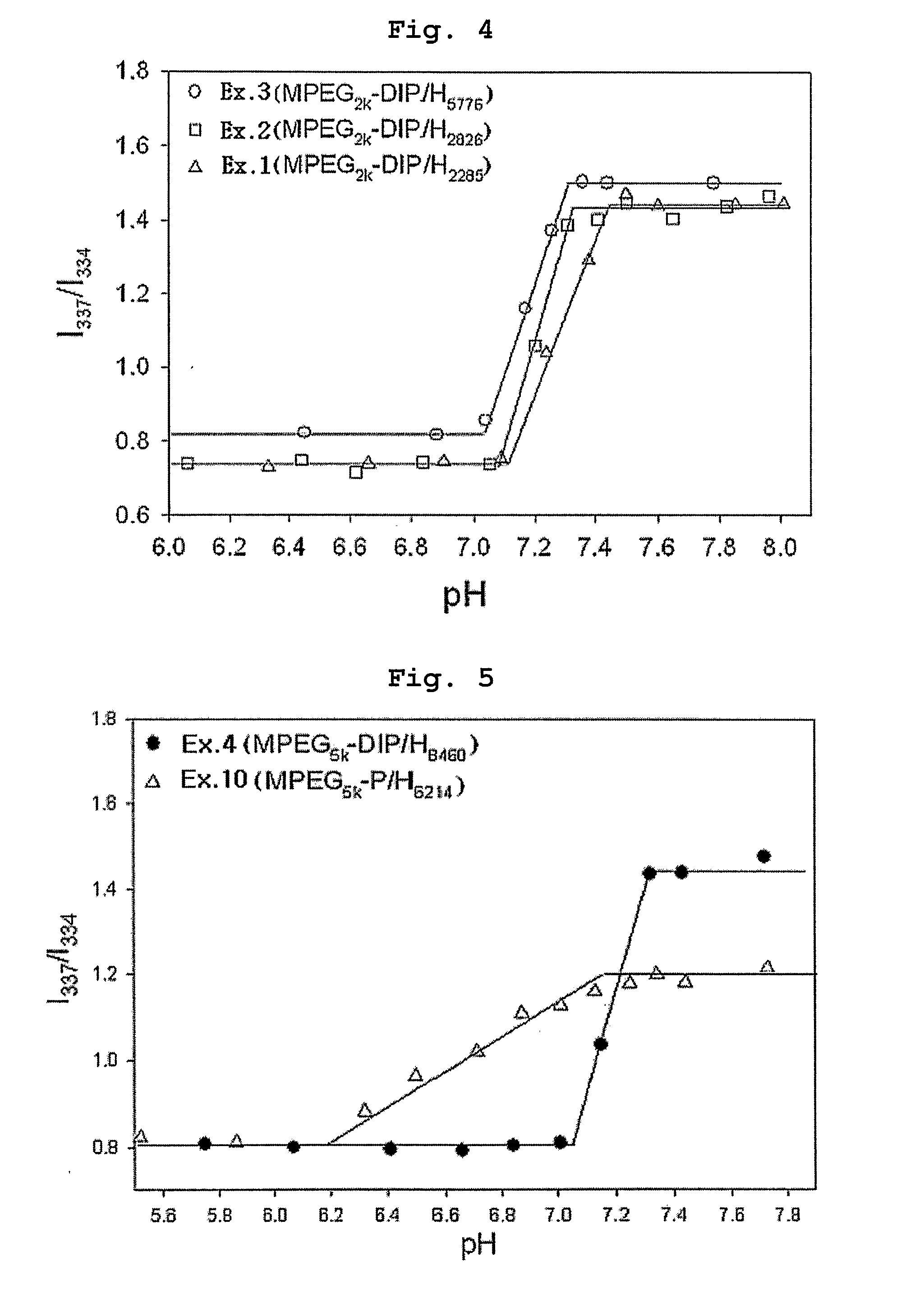

Ph Sensitive Block Copolymer and Polymeric Micelle Using the Same

ActiveUS20070218120A1Slow biodegradation rateAction is interruptedPowder deliveryPharmaceutical non-active ingredientsAmino estersDrug carrier

Disclosed is a pH-sensitive block copolymer obtained by copolymerization of: (a) a polyethylene glycol compound (A); and (b) at least one poly(amino acid) compound selected from the group consisting of a poly(β-amino ester) and poly(amido amine) or a copolymer thereof (B). A method for preparing the same block copolymer, and a polymer micelle type drug composition comprising the pH-sensitive block copolymer and a physiologically active substance that can be encapsulated with the block copolymer are also disclosed. The pH-sensitive block copolymer is obtained by polymerization of a hydrophilic polyethylene glycol compound with a pH-sensitive biodegradable poly(amino acid) compound. Therefore, the pH-sensitive block copolymer can form a micelle structure due to its amphiphilicity and ionization characteristics depending on pH variations, and thus can be used as drug carrier for target-directed drug delivery depending on pH variations in the body.

Owner:RES & BUSINESS FOUNDATION SUNGKYUNKWAN UNIV

Hopper cars with one or more discharge control systems

ActiveUS8915194B2Enhanced advantageIntuitive adjustmentHopper carsWagons/vansHydraulic cylinderControl system

Hopper cars both open and covered and discharge control systems are disclosed. Each hopper car may include at least one hopper and a center sill which defines in part a longitudinal axis of the hopper car. At least one discharge opening may be formed proximate a lower portion of each hopper. A respective door assembly may be pivotally mounted adjacent to each discharge opening to control the flow of lading from the respective discharge opening. Each discharge control system may include a common linkage and associated secondary linkages operable to move associated door assemblies between a first position and a second position. A power source including a motor, an air cylinder or a hydraulic cylinder may be disposed on the railway car to move the common linkage. For other hopper cars a wayside drive system may be releasably engaged with a capstan operable coupled to the common linkage.

Owner:TRINITY IND INC

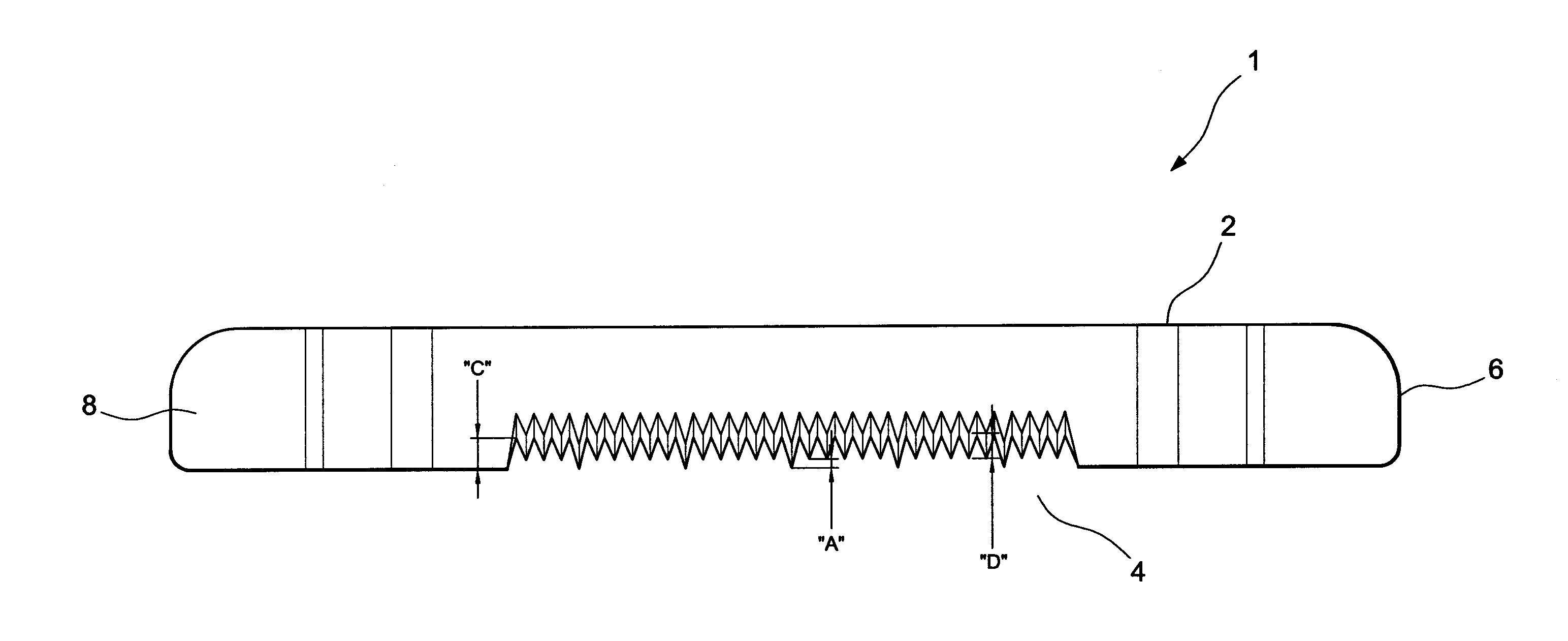

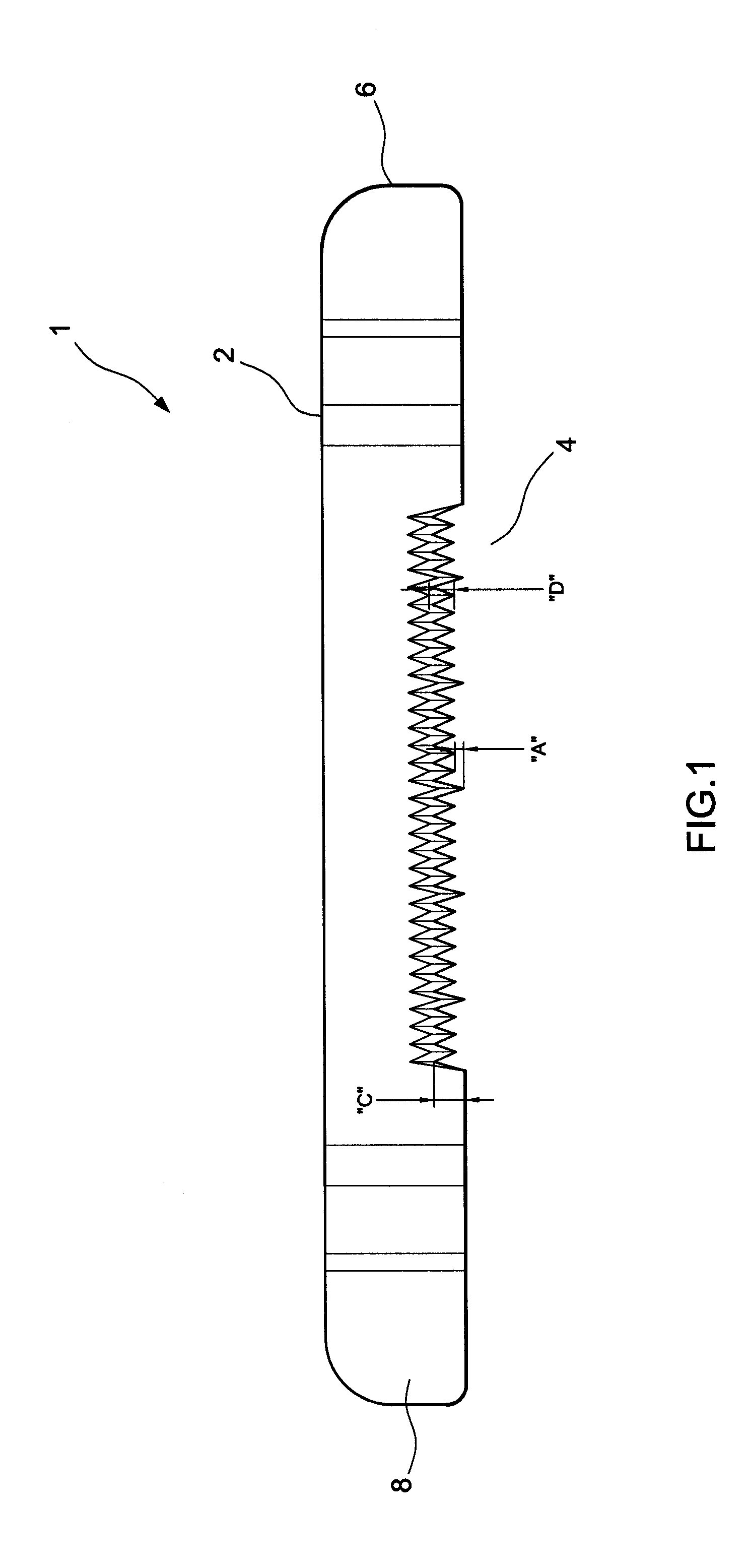

Separator

ActiveUS20100112432A1Improve heat resistanceImprove discharge characteristicsFinal product manufactureCell component detailsChemistryHeat resistant

Provided is a separator made of a laminated porous film in which a heat-resistant layer that comprises a heat-resistant resin and a shut-down layer that comprises a thermoplastic resin are laminated, wherein the heat-resistant layer further comprises two or more fillers, and the value of D2 / D1 is 0.15 or less where among values each obtained by measuring the average particle diameter of particles that constitute one of the two or more fillers, the largest value is let be Di and the second largest value is let be D2.

Owner:SUMITOMO CHEM CO LTD

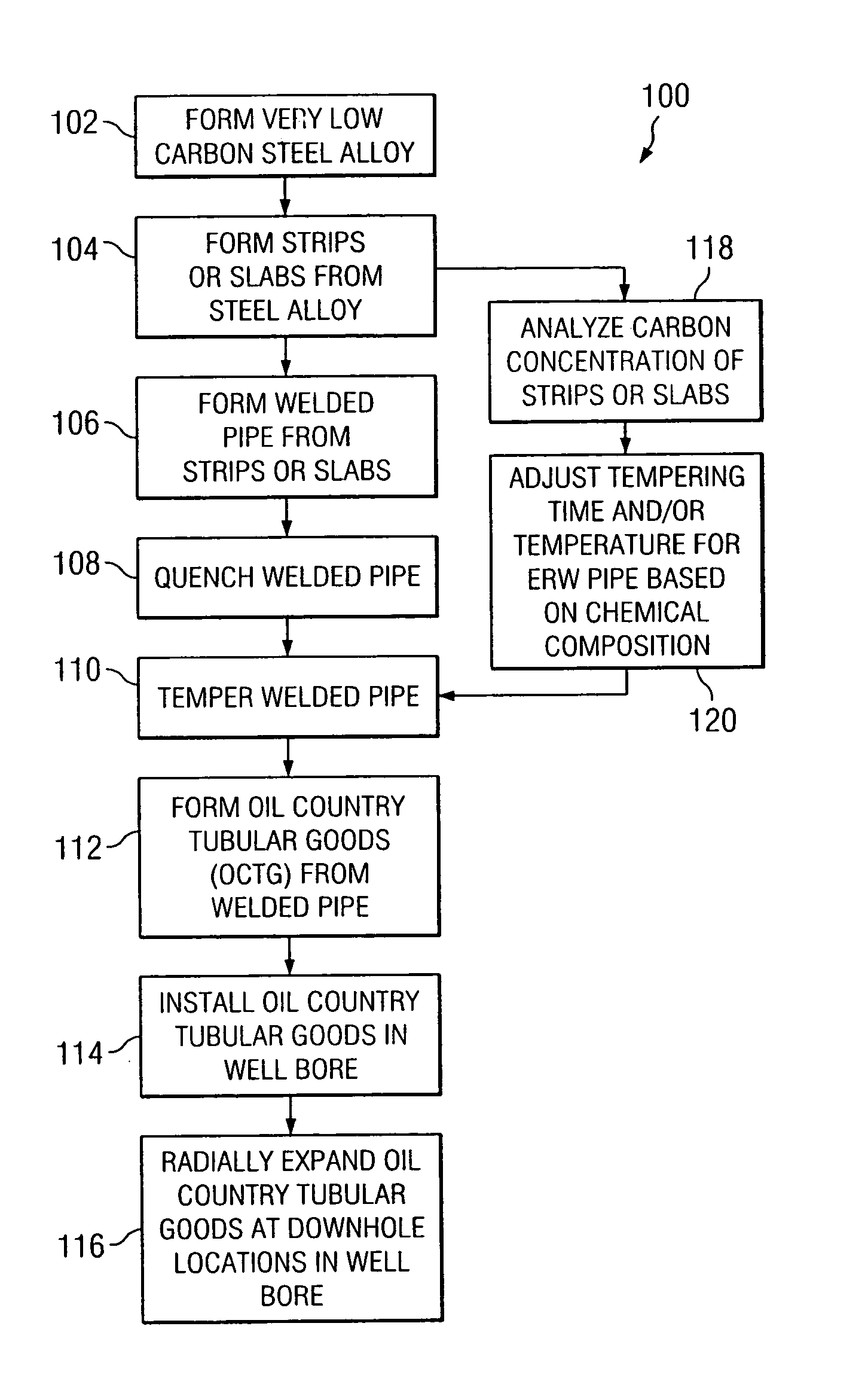

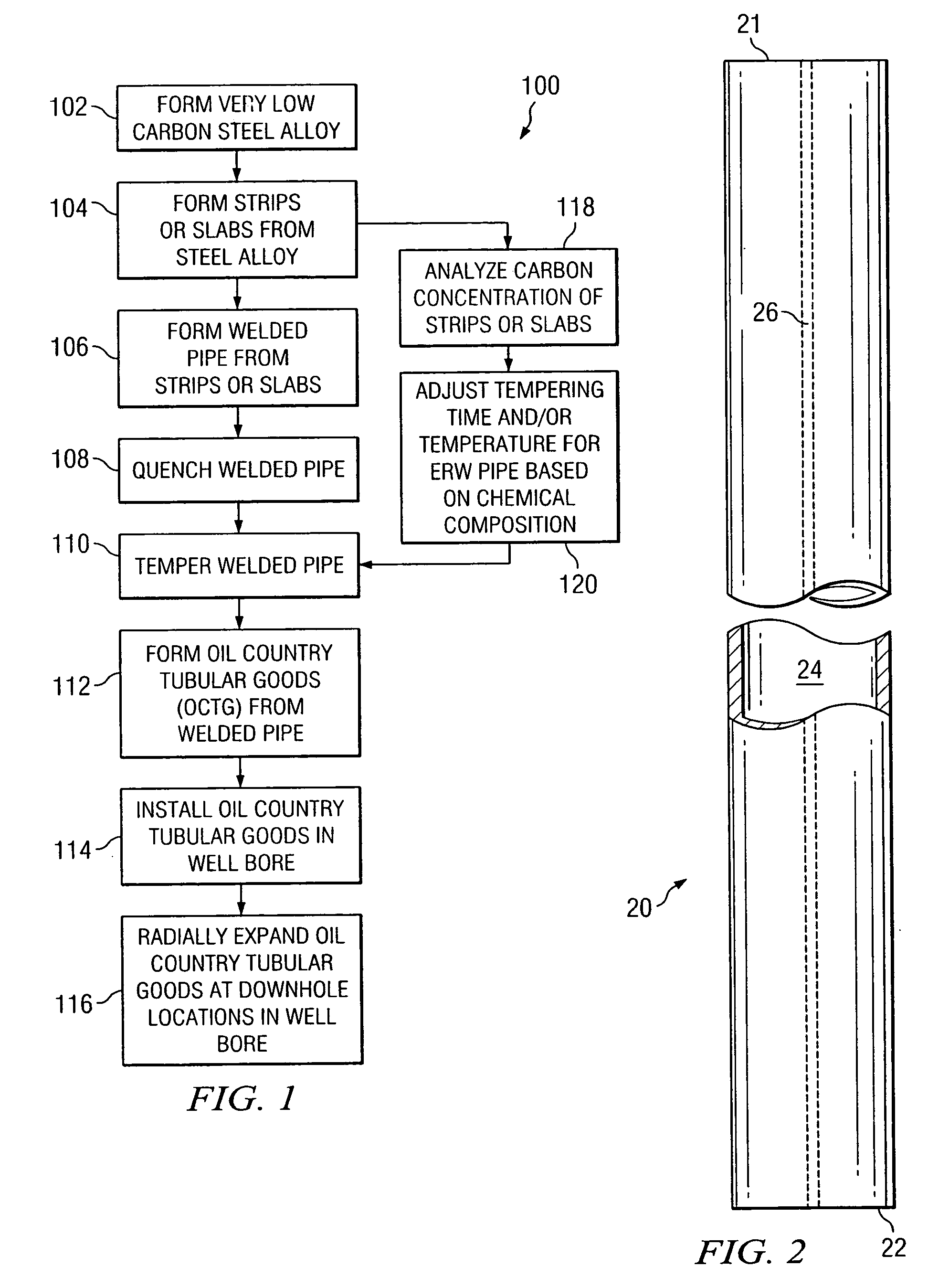

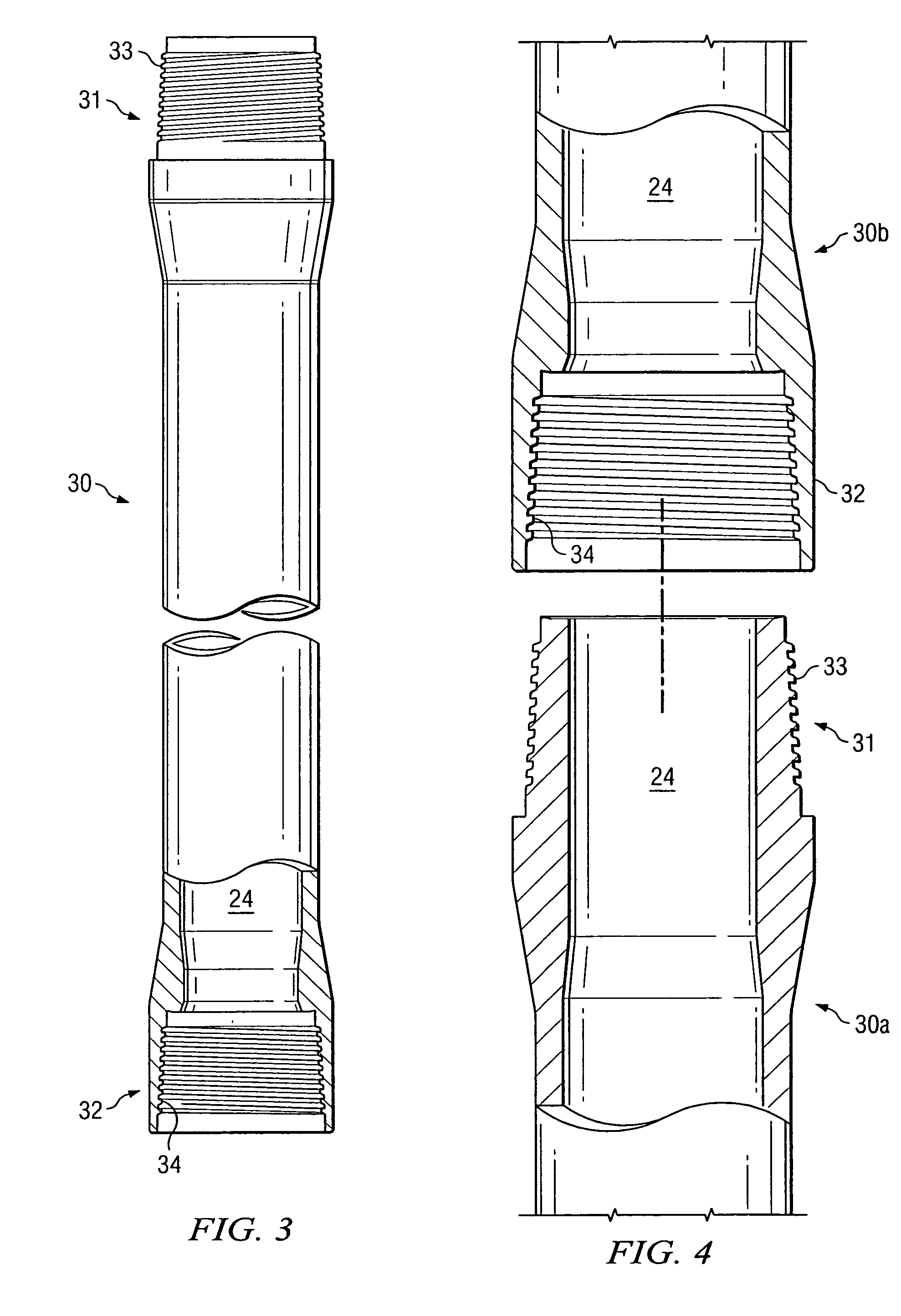

Solid expandable tubular members formed from very low carbon steel and method

ActiveUS7169239B2Reduce and eliminate requirementCost reductionDrilling rodsFurnace typesCarbon steelMaterials science

A very low carbon steel alloy is provided for use in manufacturing tubular members such as oil country tubular goods. The tubular members may be radially expanded from at least twenty percent to forty percent. Sections or joints of casing formed from the steel alloy may be installed within a wellbore and radially expanded during completion of the wellbore.

Owner:U S STEEL TUBULAR PROD

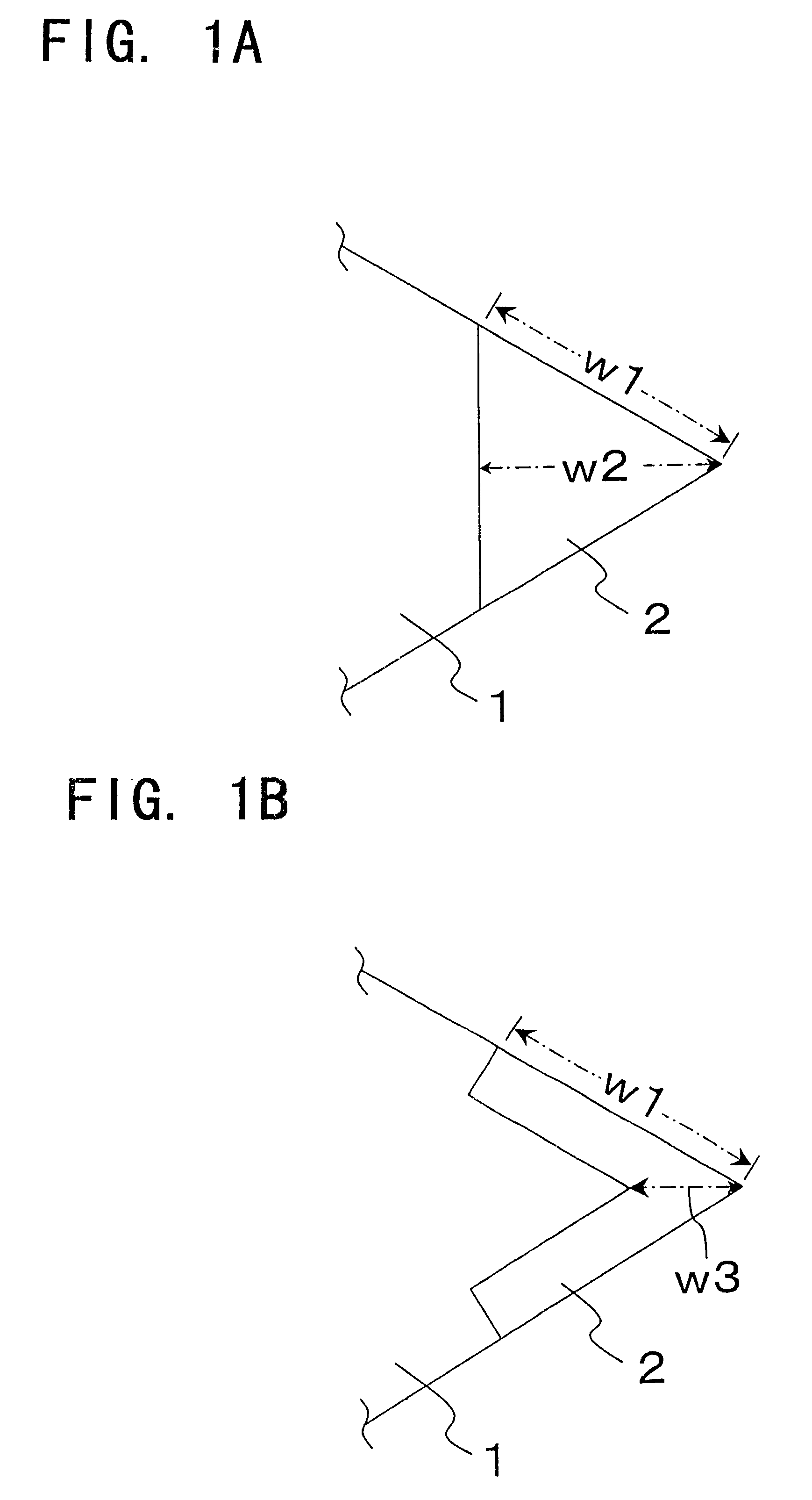

Cutting tool coated with diamond

InactiveUS6705806B2Short timeSatisfactory cuttingLayered productsMilling cuttersDiamond thin filmMaterials science

A cutting tool coated with diamond in which diamond is coated as a film on a substrate having a step 15 to 500 mum in height in the vicinity of a cutting edge on the rake surface and / or the flank surface. Only the diamond film in the vicinity of the cutting edge can be polished first, without polishing the film of the diamond formed centrally of the rake surface and / or the flank surface. This enables the maximum effect (sharpening of the cutting edge and prevention of welding formation at cutting edge) to be realized with the necessary minimum polishing (with a decreased polishing removal), without setting special conditions and which is suited as a finishing tool.

Owner:NGK SPARK PLUG CO LTD

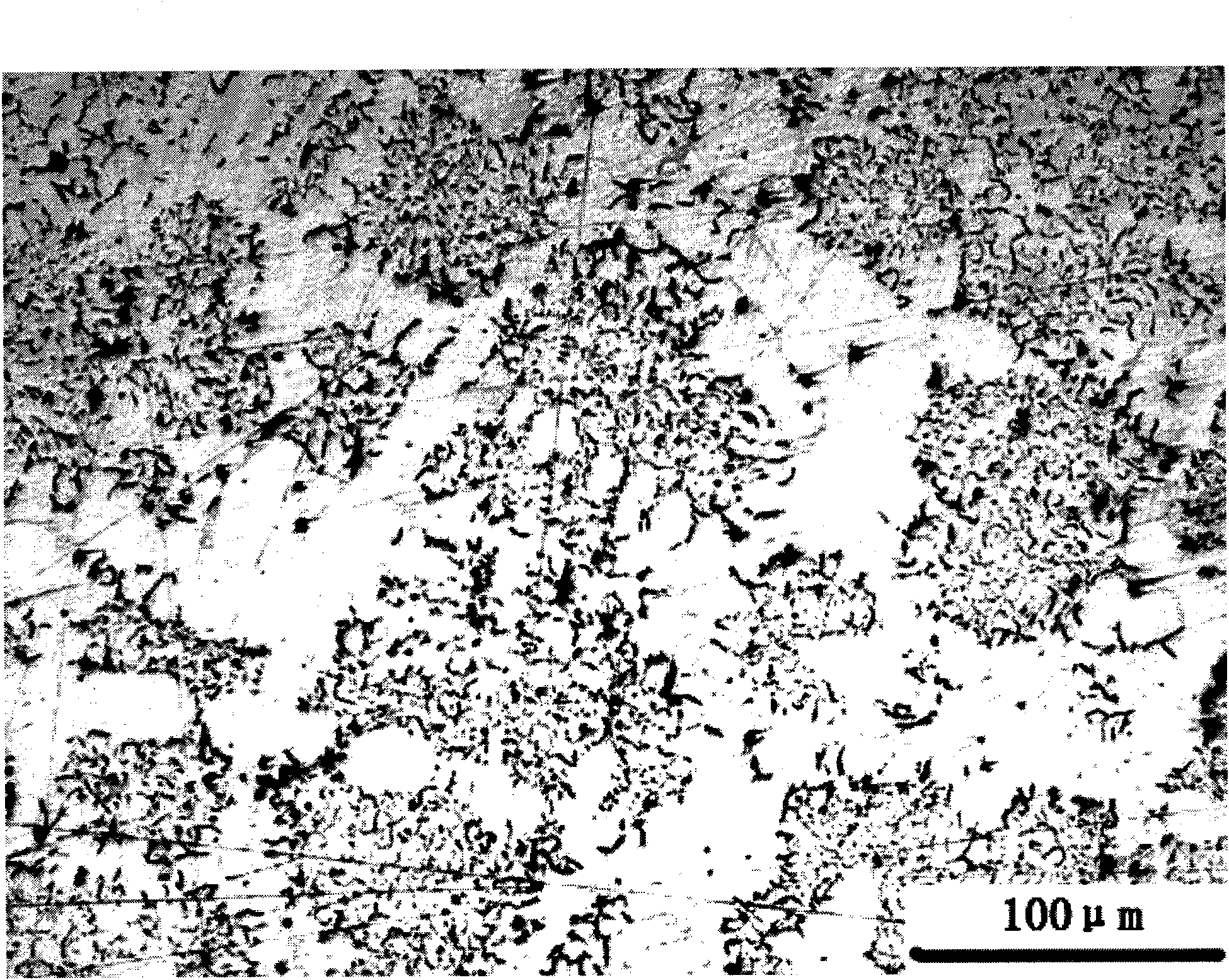

Compound inoculant used for producing D-type graphite cast iron and preparation method thereof

The invention discloses a compound inoculant used for producing D-type graphite cast iron, which is characterized in that the weight percents of the constituents are as follows: magnesium 1.0-4.0, rare earth 4.0-8.0, titanium 4.0-9.0, aluminum 1.5-3.0, stibium 0.5-2.0, calcium 2.0-5.0, barium 1.0-4.0, silicon 35-50 and the balance of iron. When the compound inoculant is employed to carry out inoculation on the melted iron with high carbon equivalent, the obtained graphite in the cast iron is the D-type graphite. The mechanical properties of castings are high, the tensile strength reaches over 250MPa and the compactness is good. The melted iron has high carbon equivalent, thus greatly improving the casting properties of alloys, reducing the residual stress of the castings, contributing to good size stability and enhancing the machinability of the castings. The multiple compound inoculant adopts ladle bottom pouring process, namely, the compound inoculant is placed on the bottom of a ladle, then the melted iron is injected and the compound inoculant is continuously melted and absorbed in the process of melted iron injection, thereby reaching the satisfactory inoculation effect, therefore, the method is simple and the use is convenient.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

Hopper cars with one or more discharge control systems

ActiveUS20100275811A1Enhanced advantageIntuitive adjustmentHopper carsWagons/vansHydraulic cylinderControl system

Hopper cars both open and covered and discharge control systems are disclosed. Each hopper car may include at least one hopper and a center sill which defines in part a longitudinal axis of the hopper car. At least one discharge opening may be formed proximate a lower portion of each hopper. A respective door assembly may be pivotally mounted adjacent to each discharge opening to control the flow of lading from the respective discharge opening. Each discharge control system may include a common linkage and associated secondary linkages operable to move associated door assemblies between a first position and a second position. A power source including a motor, an air cylinder or a hydraulic cylinder may be disposed on the railway car to move the common linkage. For other hopper cars a wayside drive system may be releasably engaged with a capstan operable coupled to the common linkage.

Owner:TRINITY IND INC

Culinary Utensil

InactiveUS20100263212A1Optimal cutting interactionMore predictable and reliable cuttingKitchen fruit stoningFruit coringEngineering

There is provided a culinary utensil comprising a blade provided with a cutting edge on at least one side thereof, said cutting edge is formed of at least one set of taller teeth and one set of shorter teeth, wherein at least two adjacent taller teeth are separated by three to eight shorter teeth on the cutting edge.

Owner:MAXPAT TRADING & MARKETING FAR EAST LTD

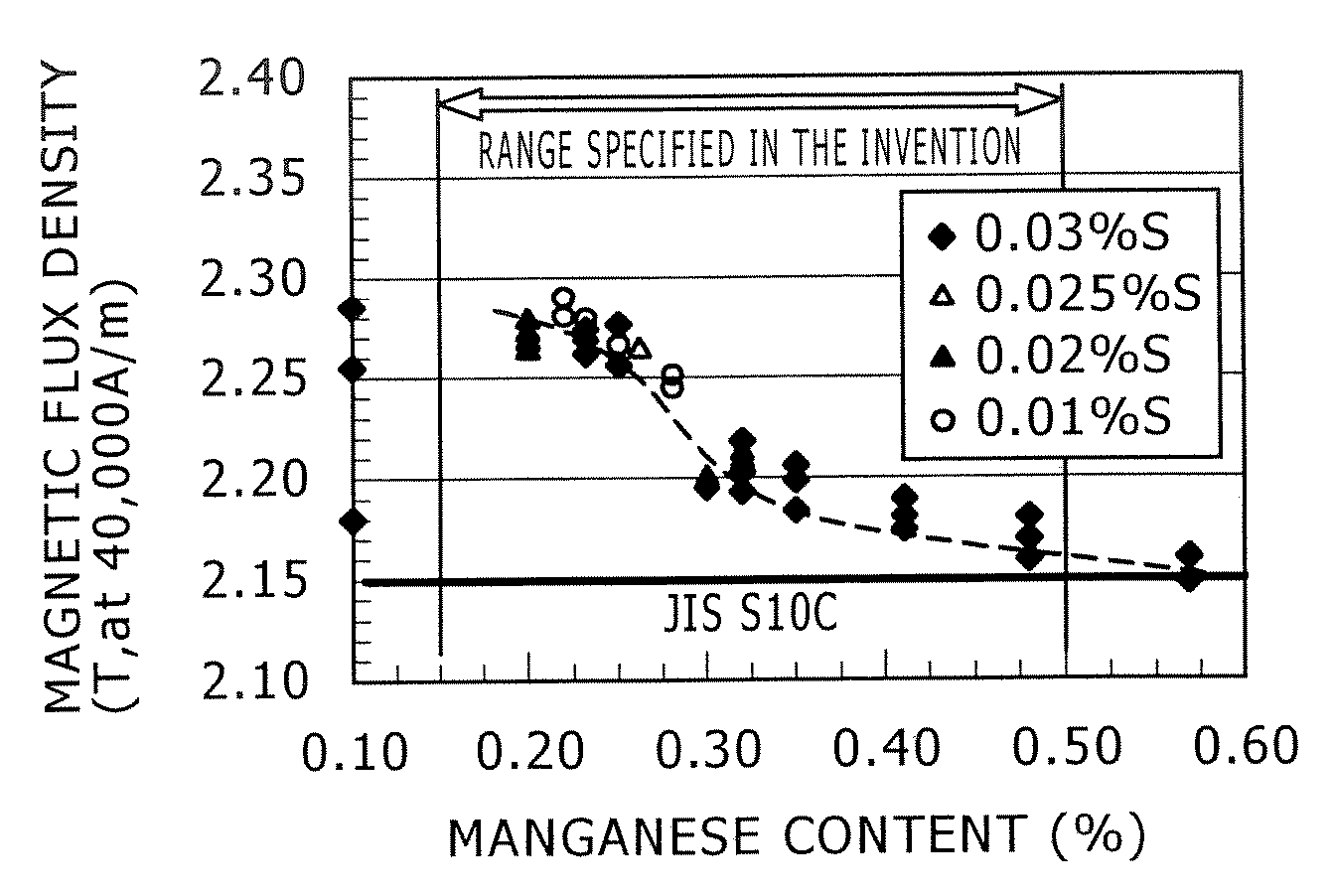

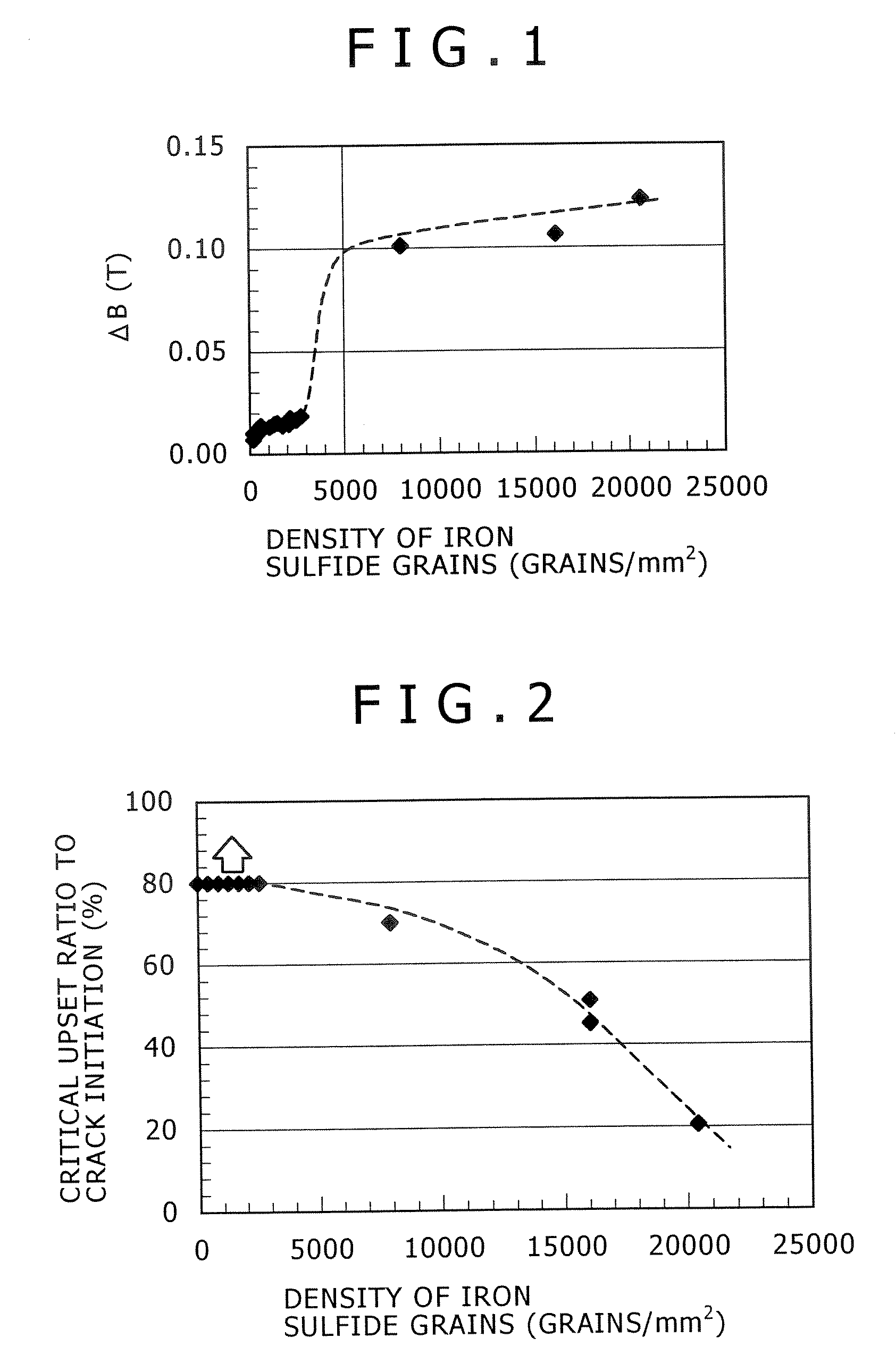

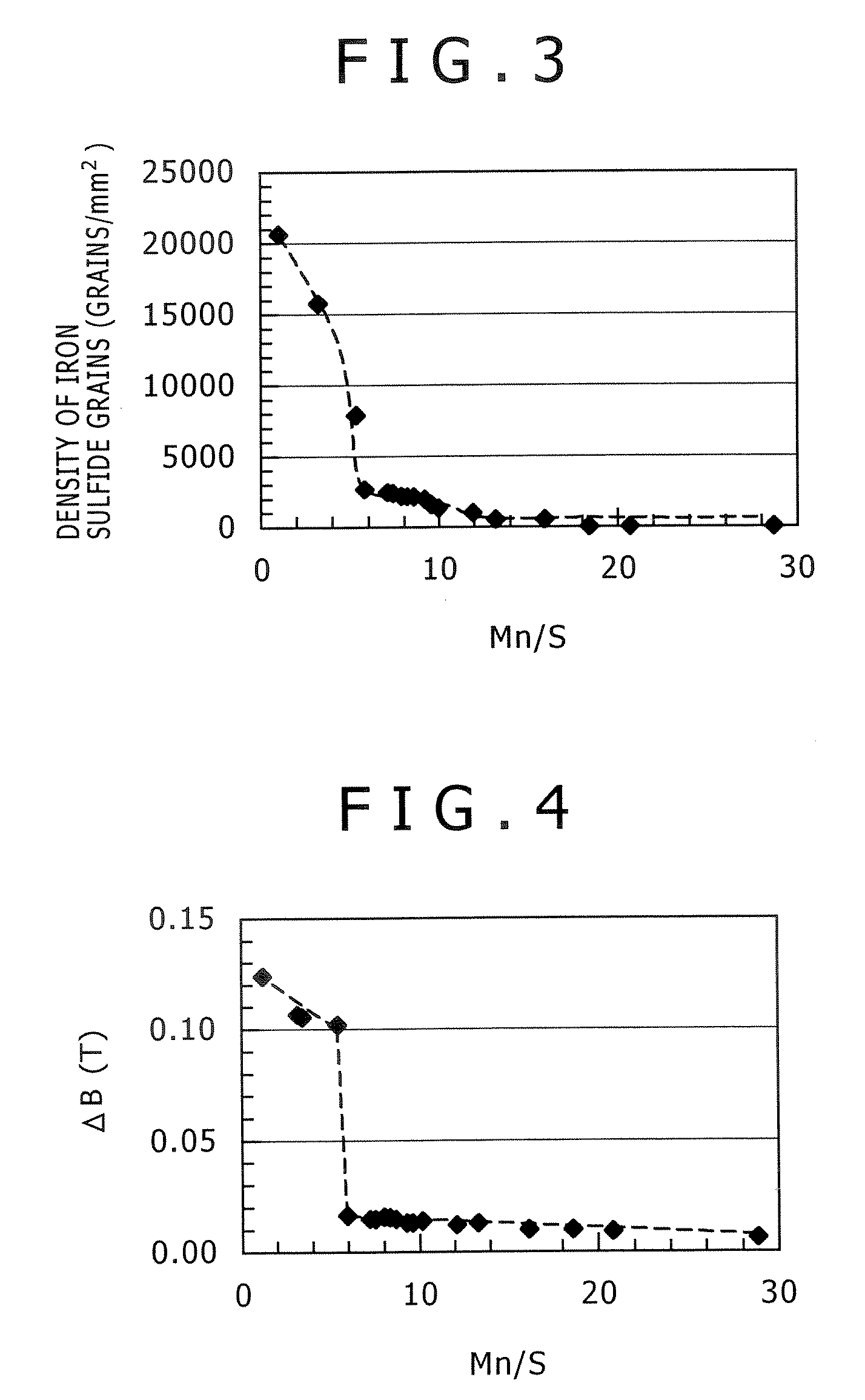

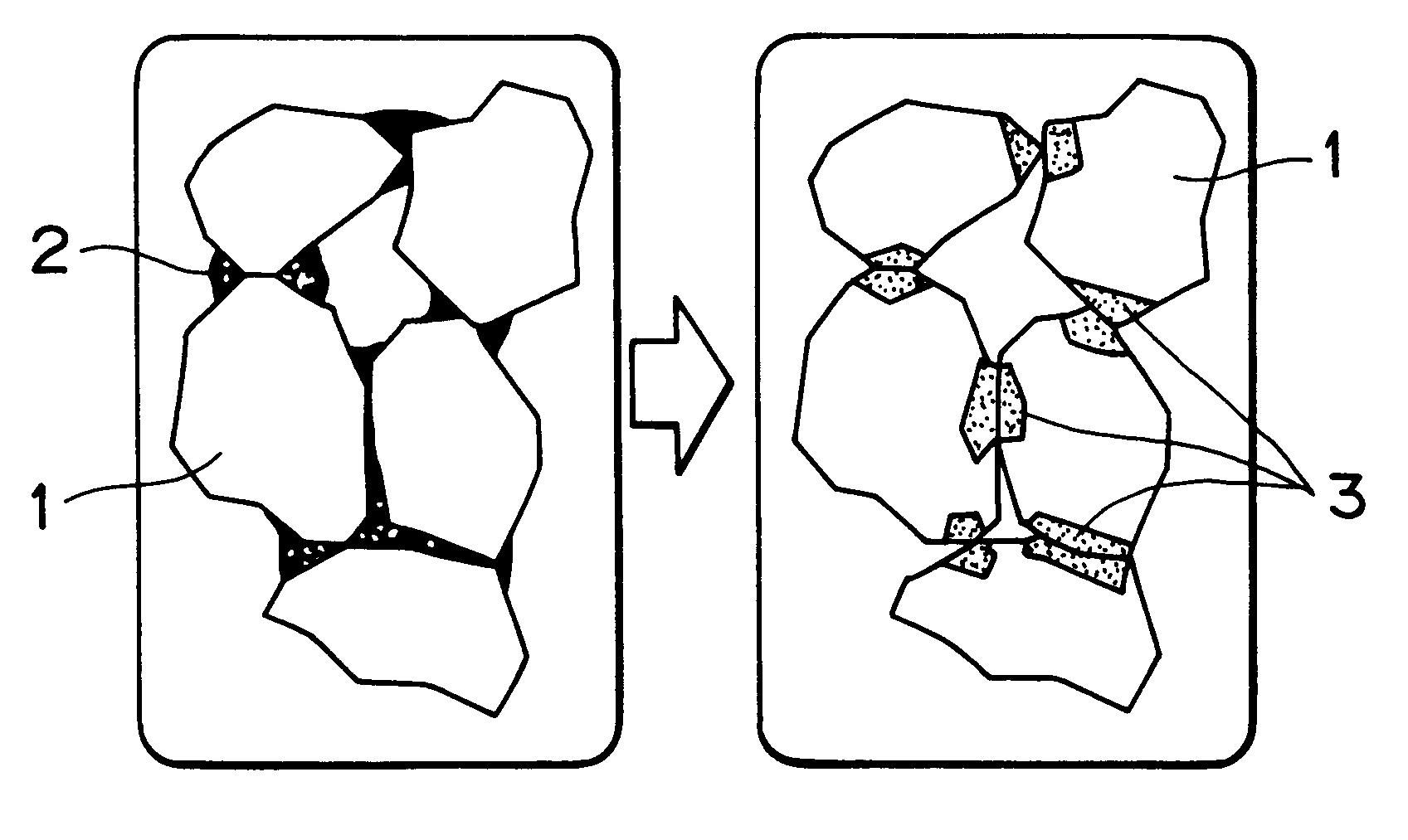

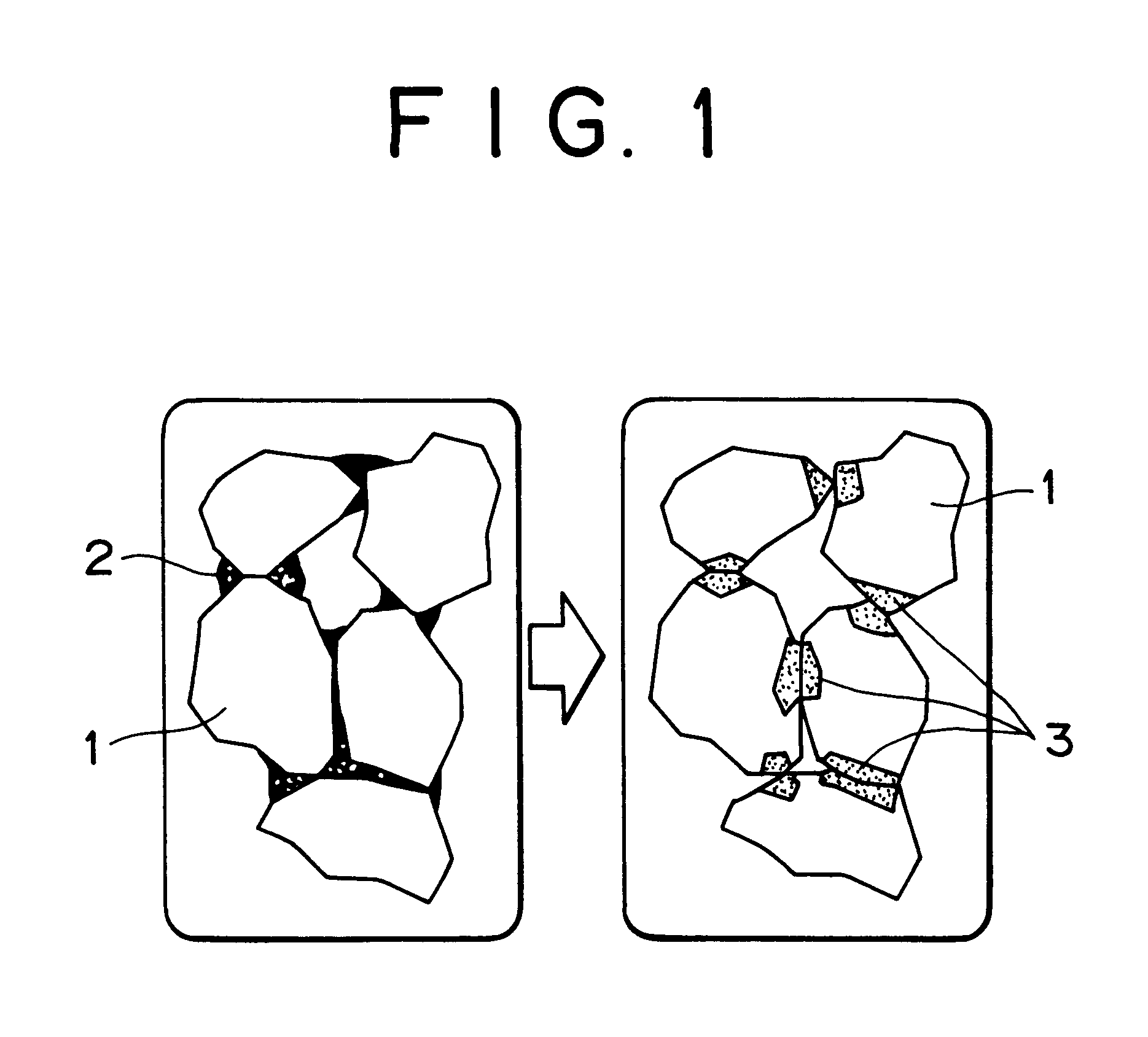

Soft magnetic steels excellent in cold forgeability, machinability and magnetic properties, and soft magnetic steel parts excellent in magnetic properties

A soft magnetic steel has, on the mass basis, a carbon content of 0.0015% to 0.02%, a manganese content of 0.15% to 0.5%, and a sulfur content of 0.015% to 0.1%, has a ratio Mn / S of 5.7 or more, and contains a single-phase ferrite microstructure as its metallographic structure, in which the density of precipitated FeS grains having a major axis of 0.1 pm or more is 5000 grains / mm2 or less. This steel ensures excellent magnetic properties with less variation after magnetic annealing, exhibits excellent machinability and cold forgeability during production processes, and can thereby yield a steel part even having a complicated shape and a large size in a high yield.

Owner:KOBE STEEL LTD

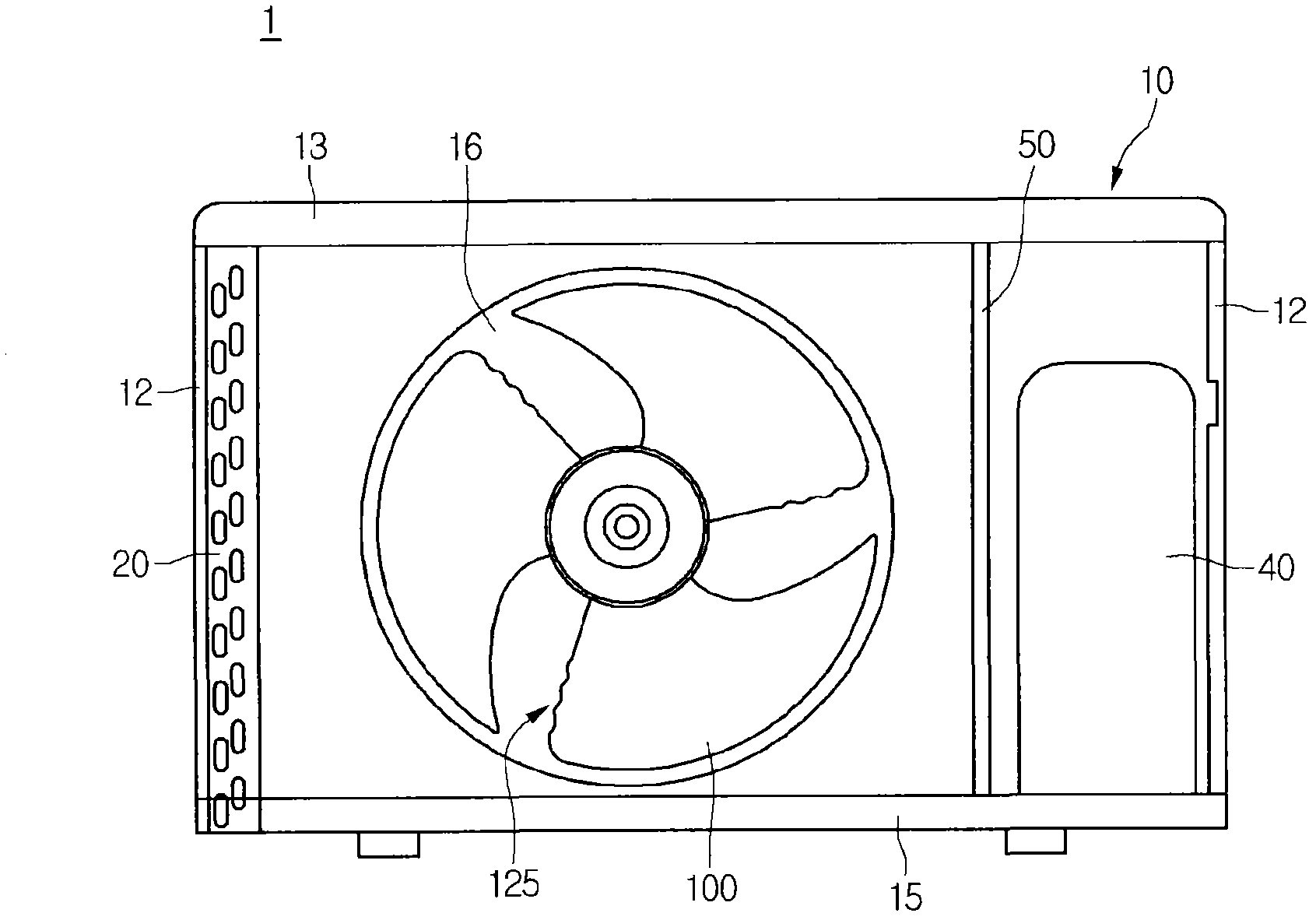

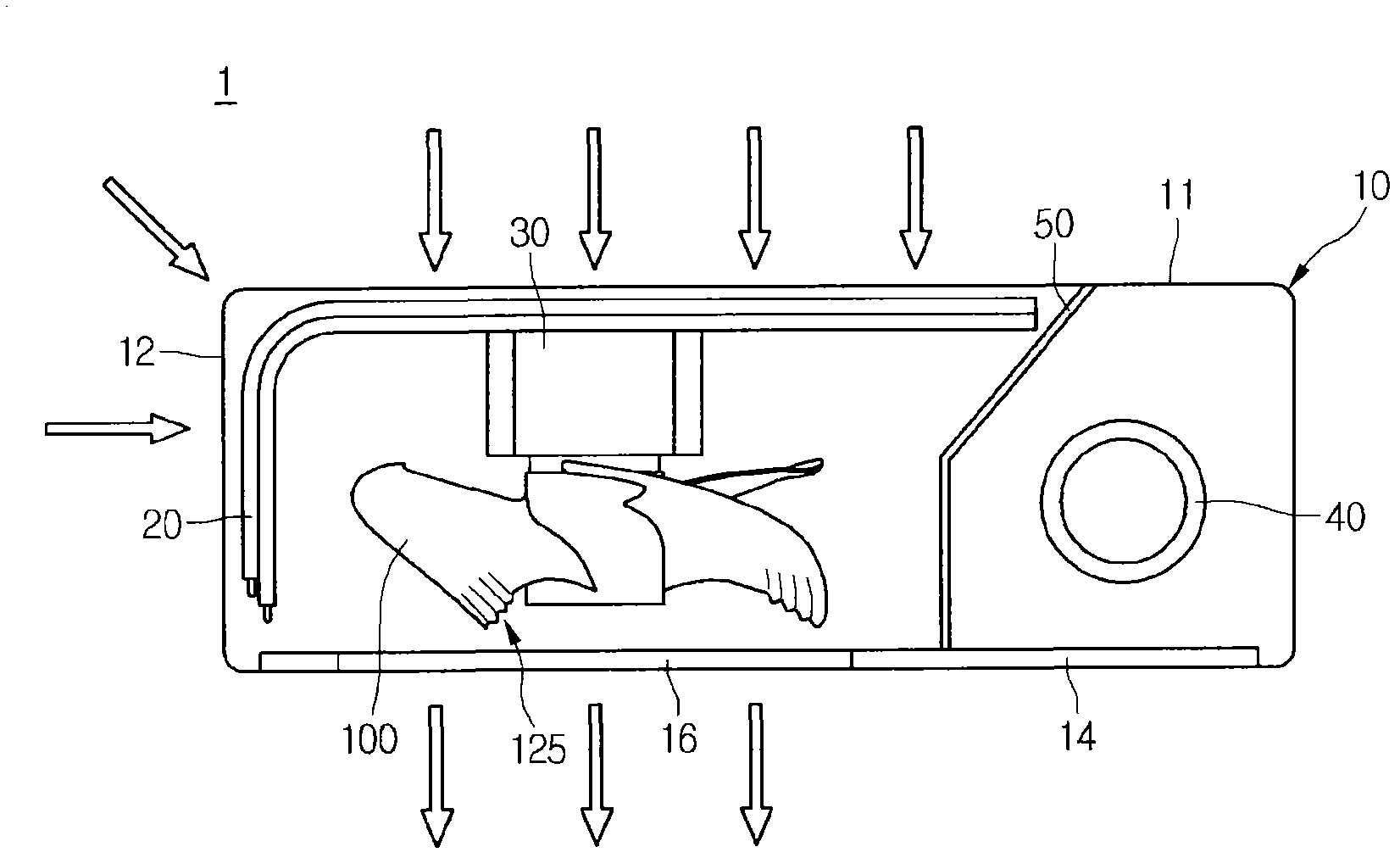

Axial flow fan and air conditioner

InactiveCN103047180ASatisfied with useIncrease flow ratePump componentsLighting and heating apparatusEngineeringMechanical engineering

Owner:LG ELECTRONICS INC

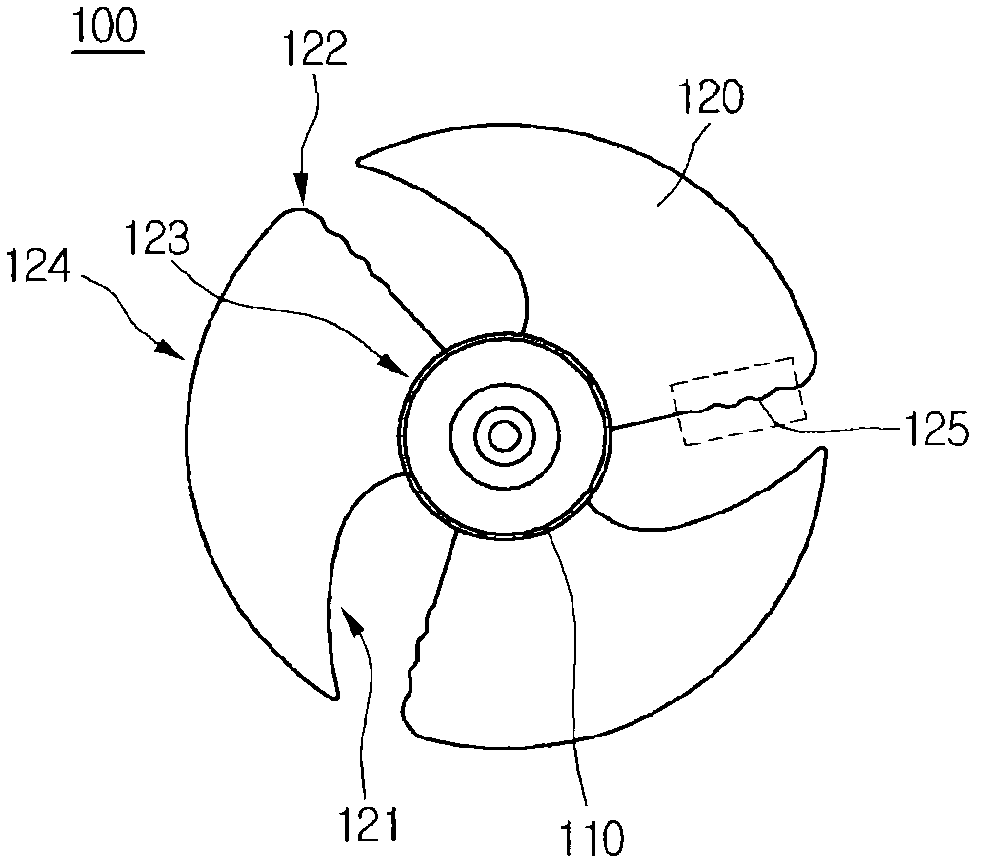

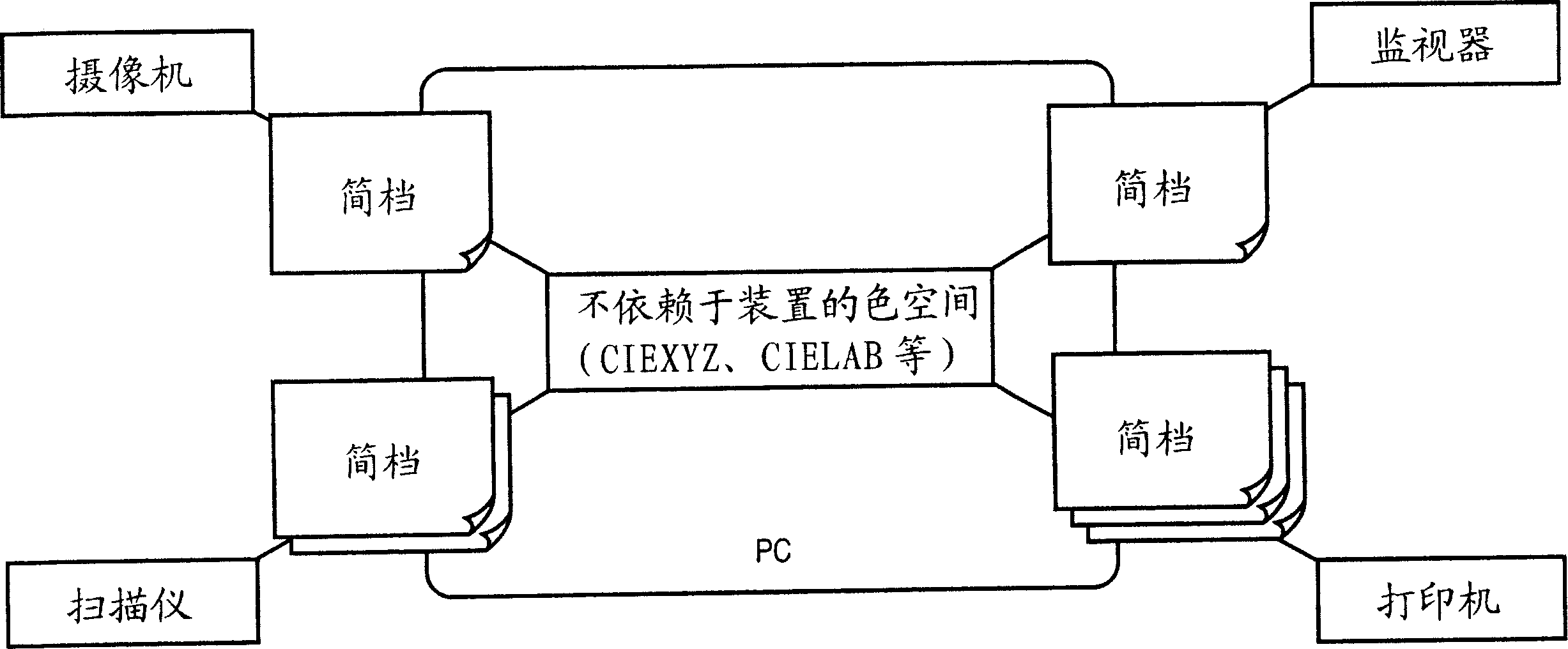

Color processing method and apparatus

Owner:CANON KK

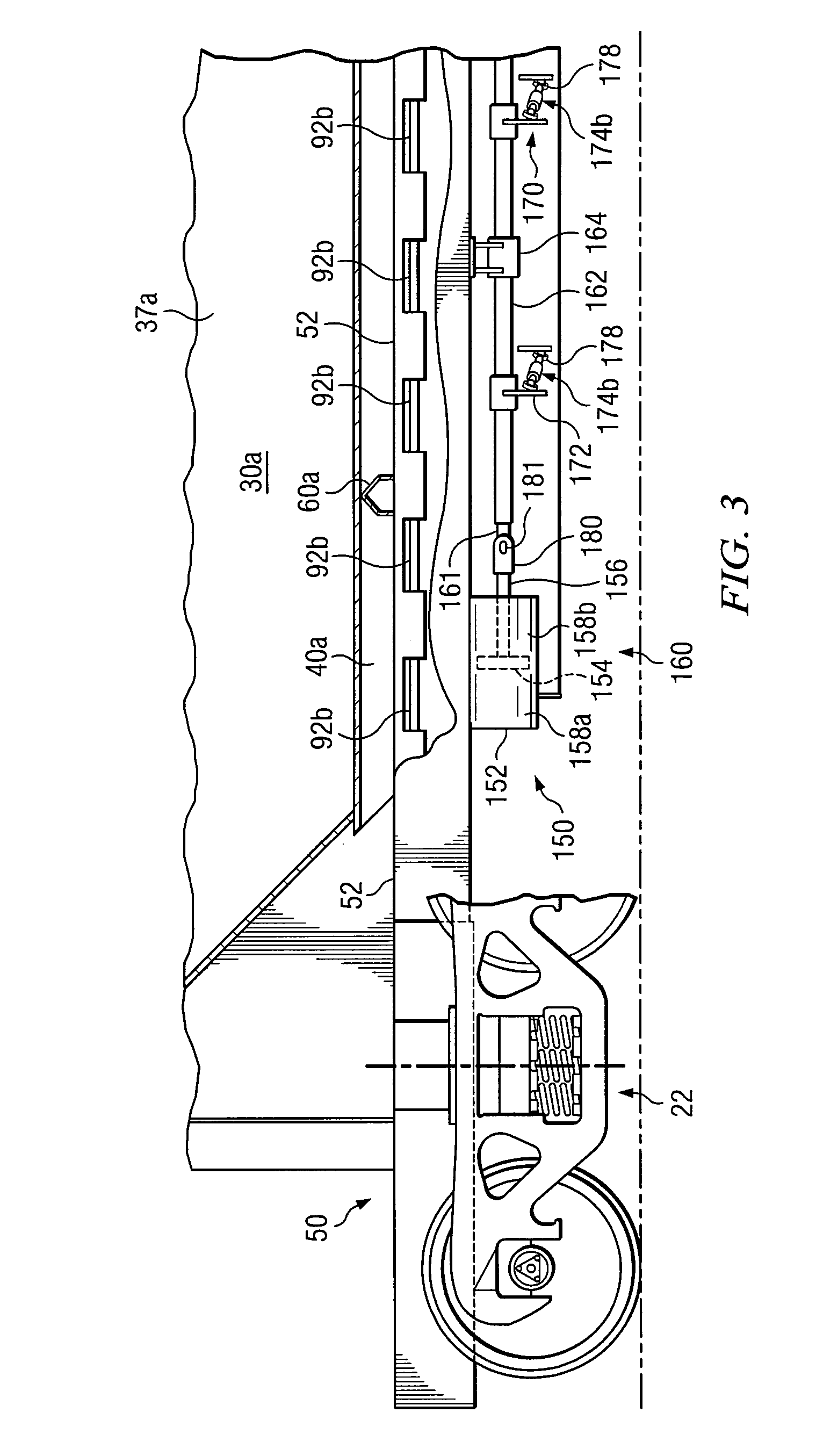

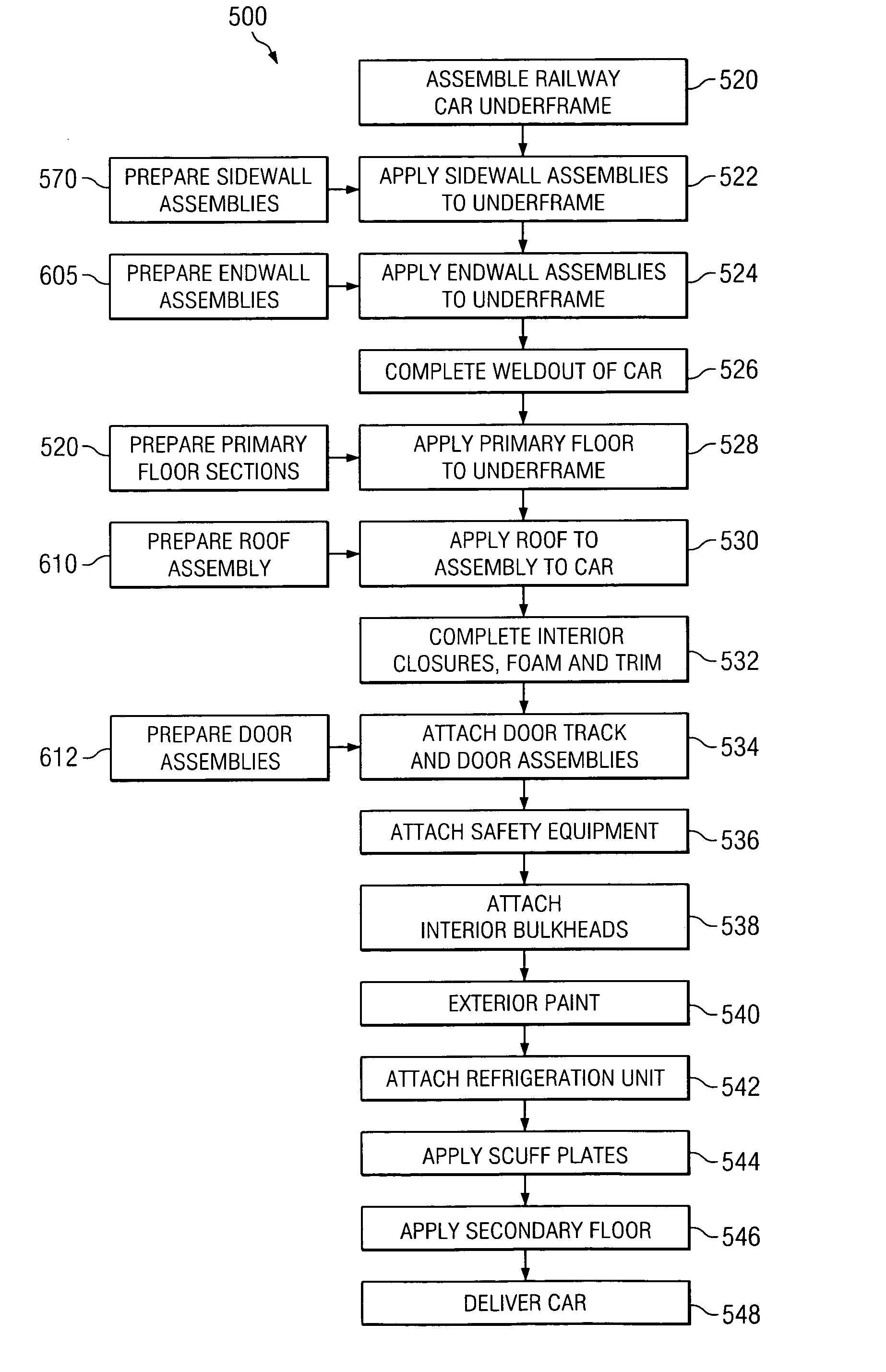

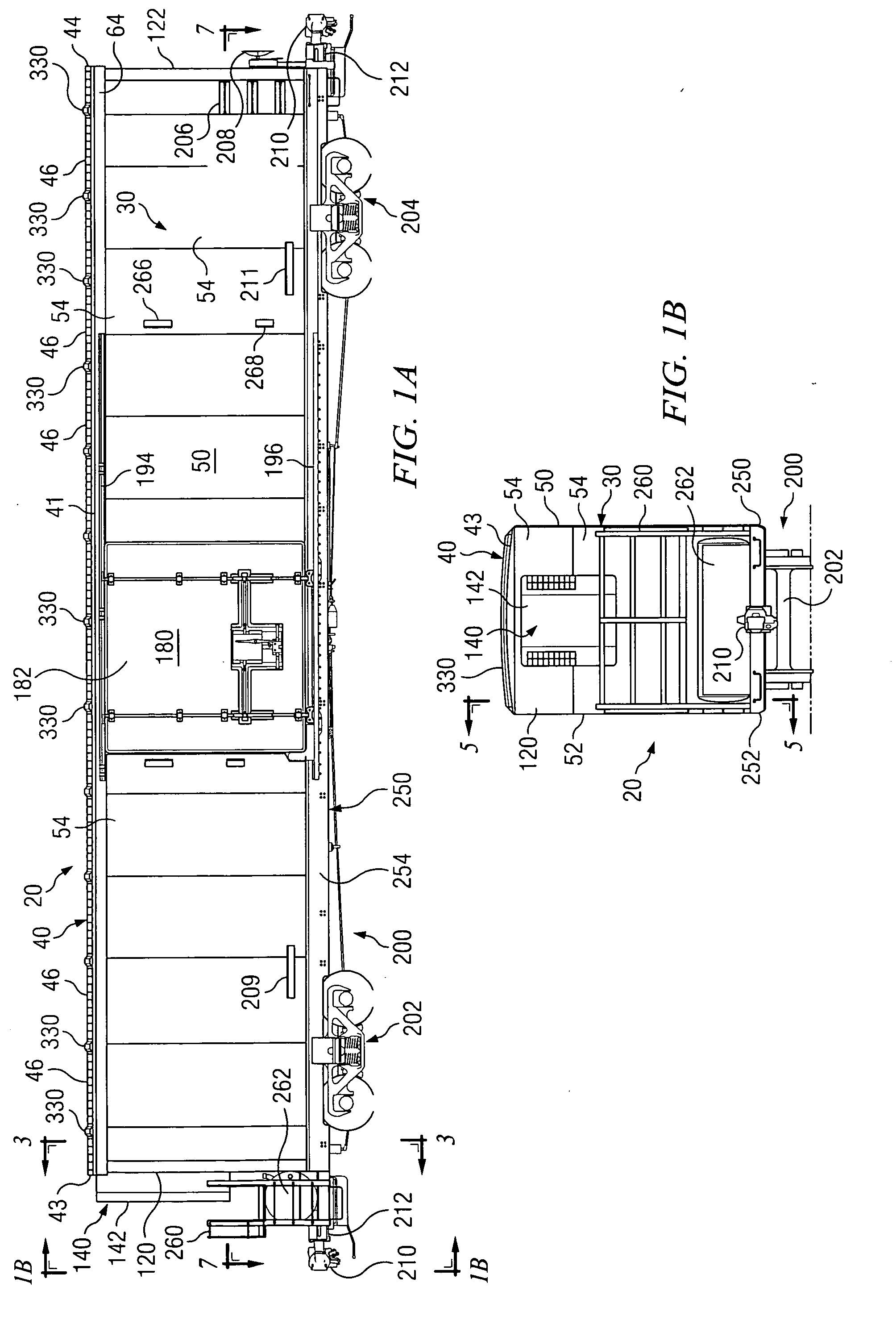

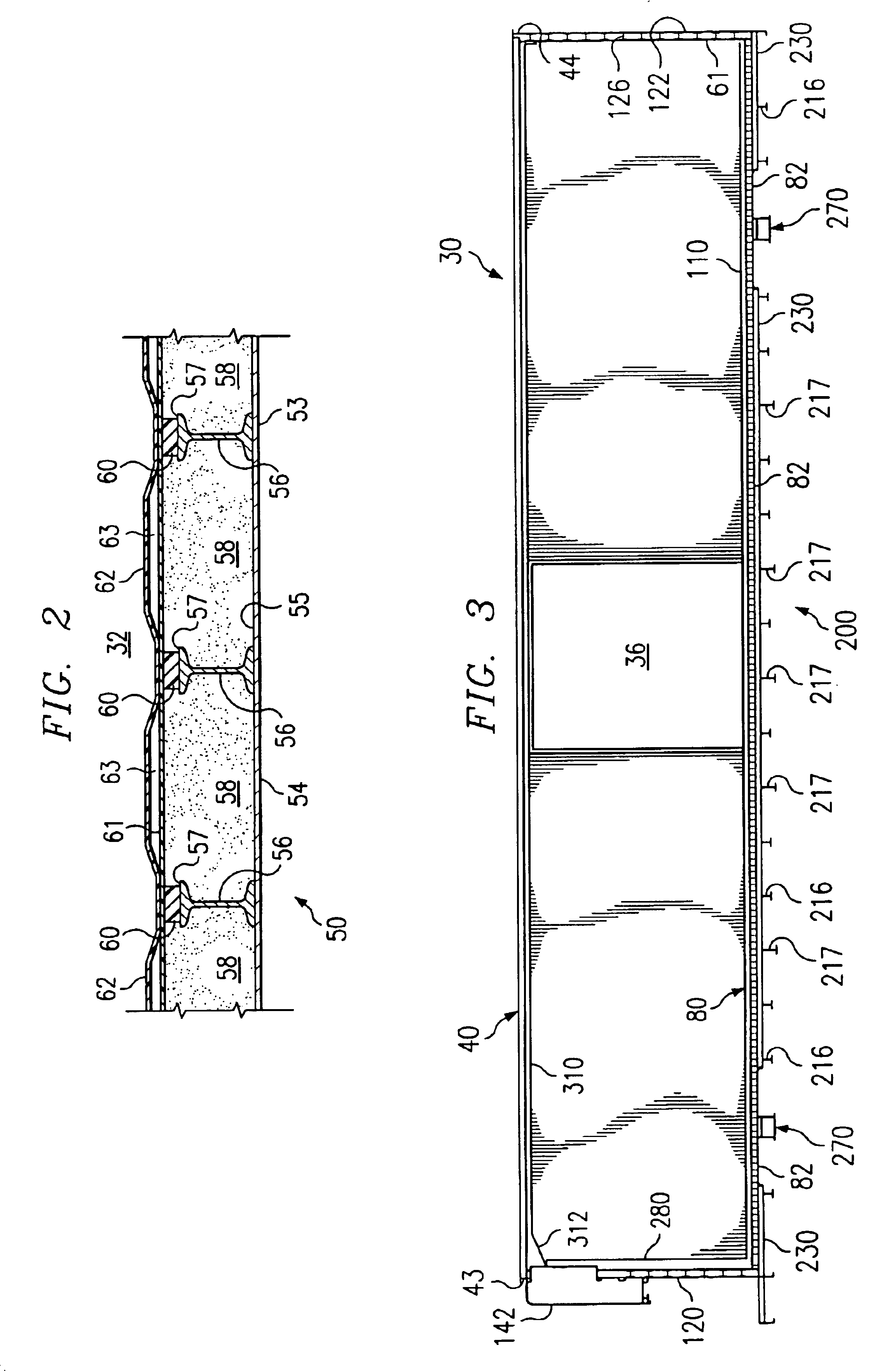

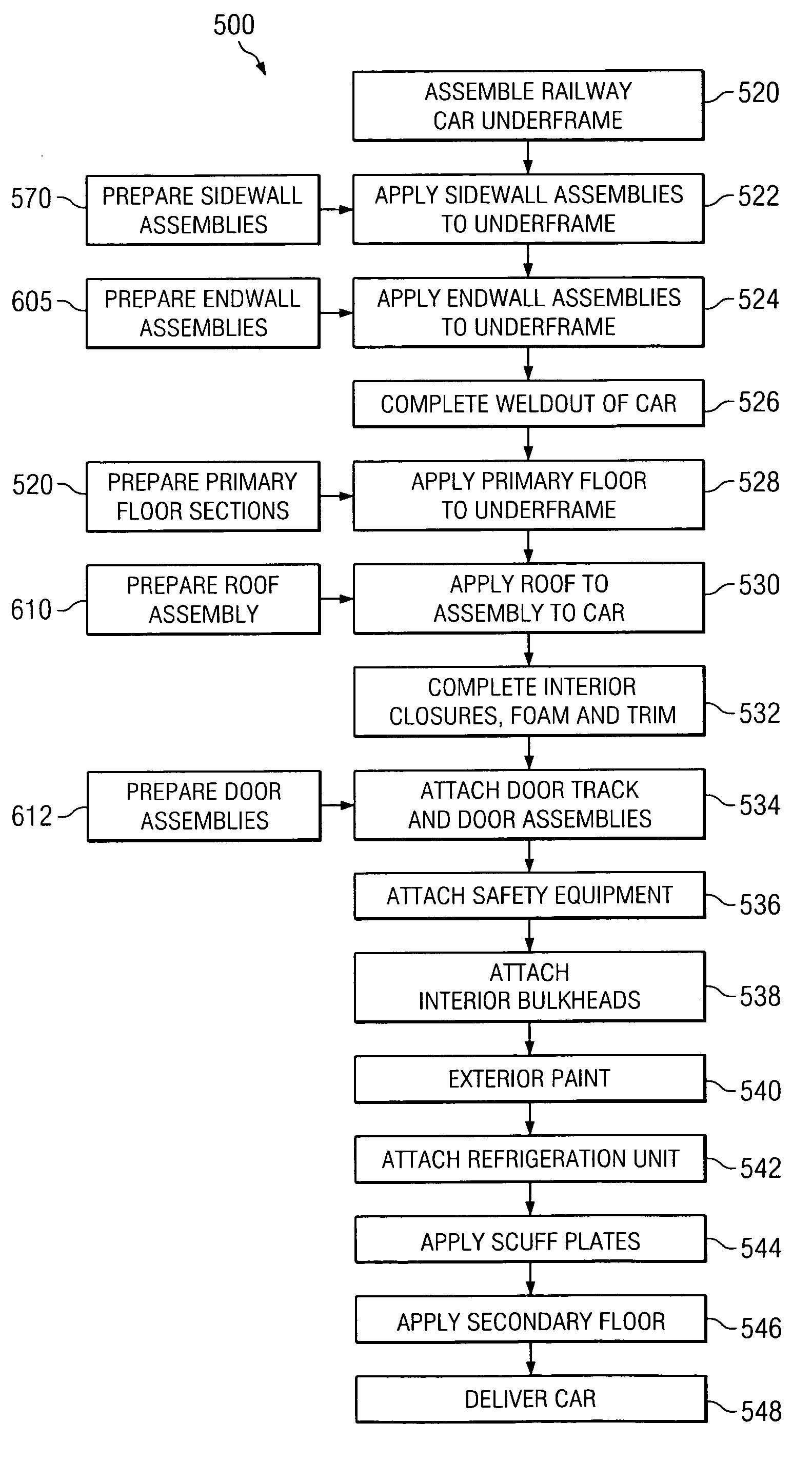

Manufacturing facility and method of assembling a temperature controlled railway car

InactiveUS20050204536A1Improve heat transfer characteristicsSatisfied with useAssembly machinesAxle-box lubricationFiberTemperature control

A manufacturing facility and method for assembling a railway car having a composite box structure mounted on a railway car underframe are provided. The composite box structure may be defined in part by exterior metal sheets, side stakes attached to the exterior metal sheets, insulating materials disposed between the side stakes and the exterior metal sheets and at least one layer of fiber reinforced material. The composite box structure preferably includes a pair of endwalls, a pair of sidewalls, a floor assembly and a roof assembly.

Owner:TRINITY IND INC

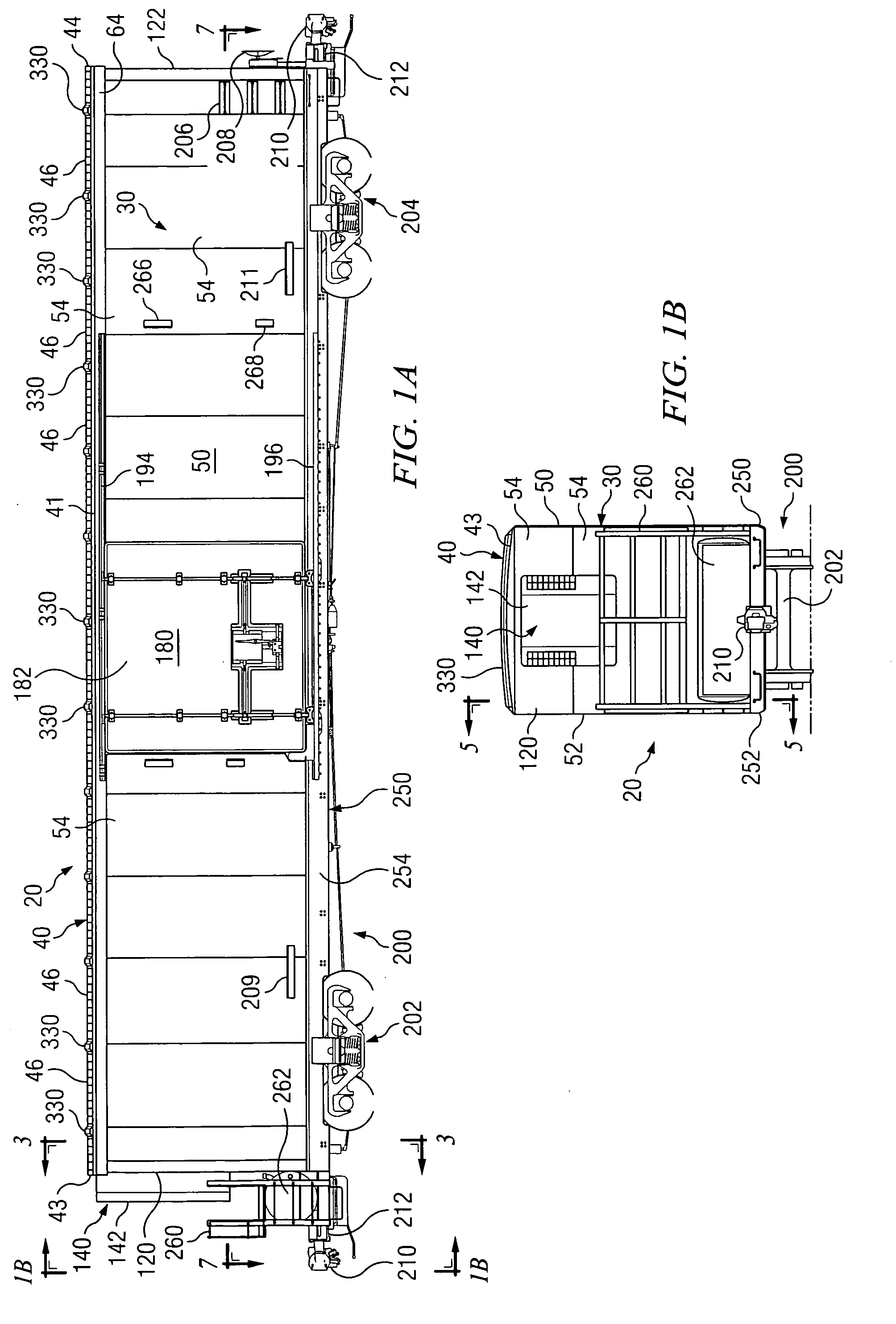

Roof assembly and airflow management system for a temperature controlled railway car

InactiveUS6904848B2Satisfied with useImprove insulation performanceRailway roofsRailway heating/coolingTemperature controlControl system

A roof assembly mounted on a composite box structure with an air plenum assembly attached to and extending from an interior surface of the roof assembly. The composite box structure includes a pair of end wall assemblies, a pair of side wall assemblies, a floor assembly and the roof assembly. An opening may be formed in one end of the end wall assemblies to allow installing a temperature control system. An airflow management system may be incorporated into the composite box structure. The composite box structure may be assembled on a railway car underframe to form a temperature controlled railway car or an insulated box car.

Owner:TRINITY IND INC

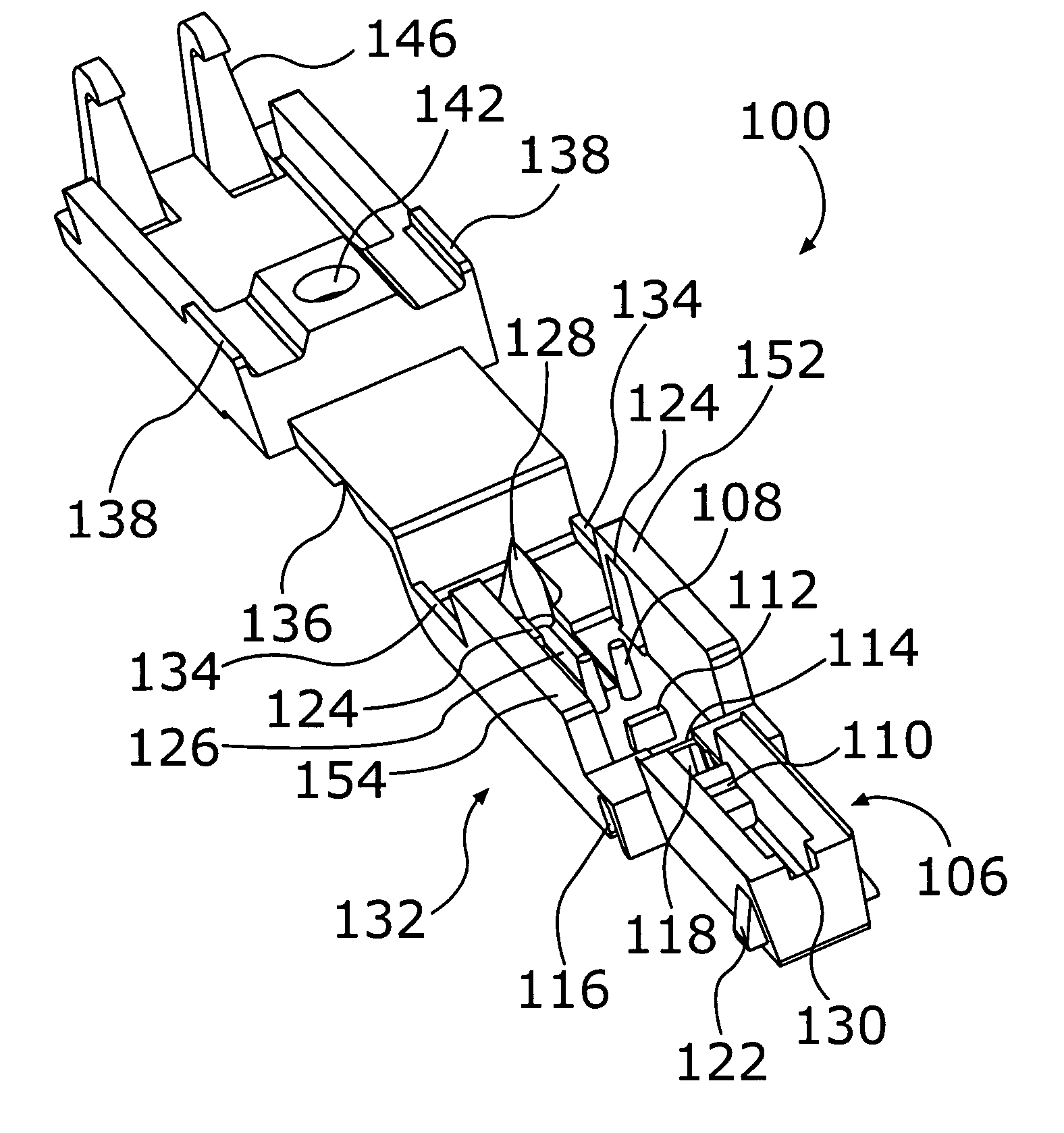

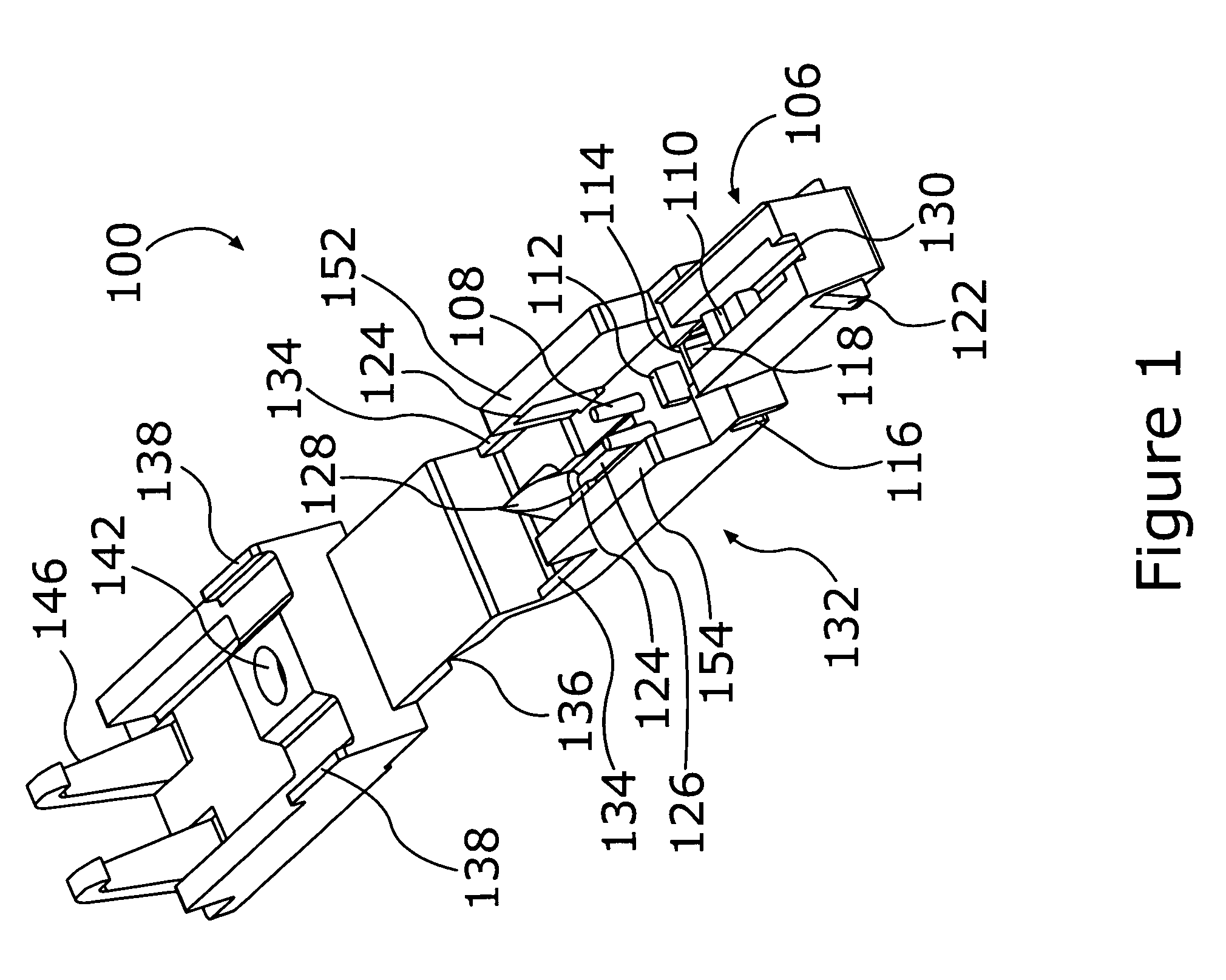

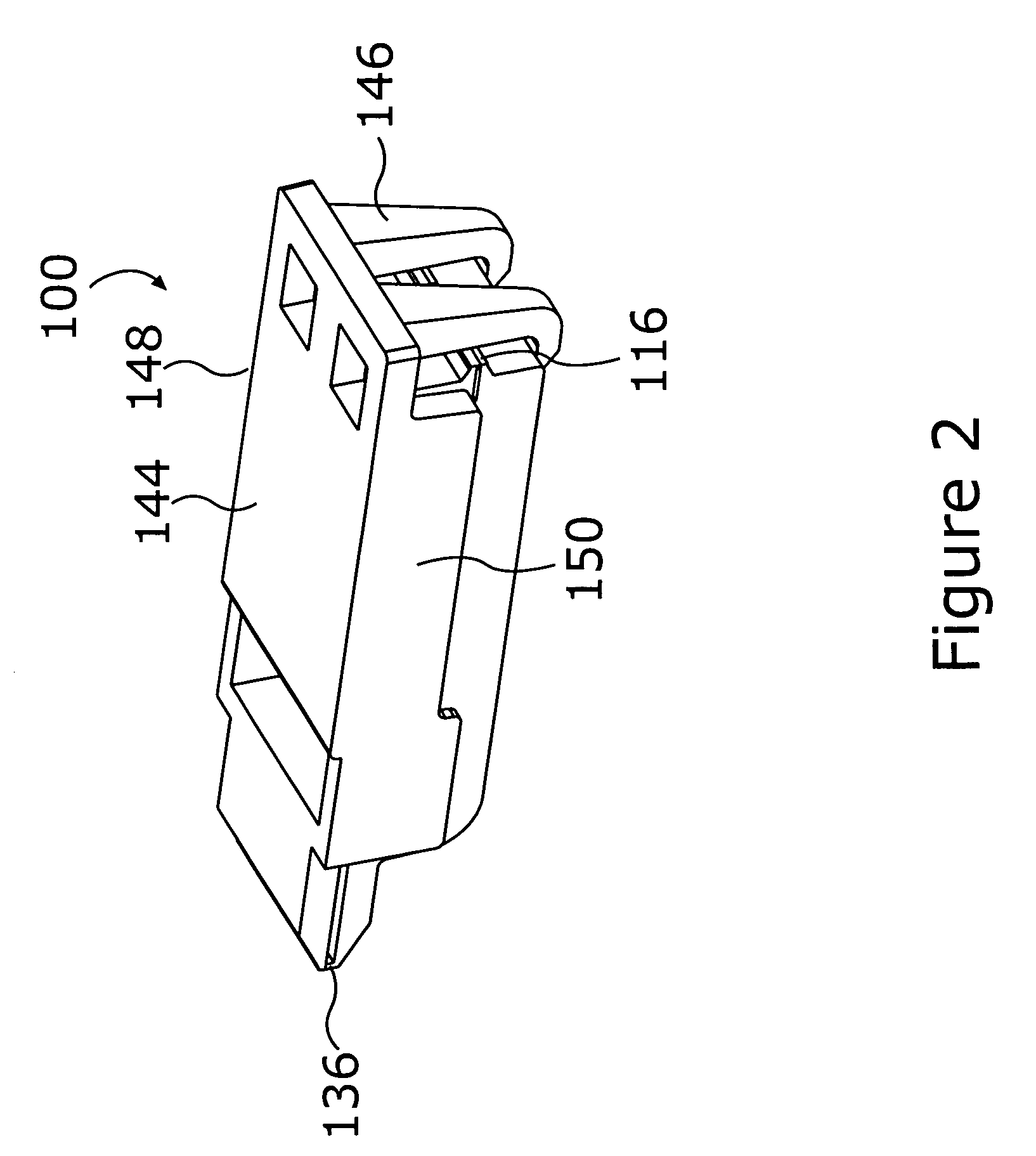

Clip-on device for coupling an electric match to a pyrotechnic fuse

InactiveUS6966260B1Rapid and accurate attachmentEliminate needBlasting cartridgesFuse ignition meansElectricityCoupling

There is provided a molded polymeric coupling device incorporating integral hinges, latches and strain-relief features adapted to receive an electric match having a protective chamber, and a quickmatch fuse of a pyrotechnic device. After the quickmatch fuse is suitably placed in the coupling device, it is latched in a closed position around the quickmatch fuse. A piercing structure such as a cone forms an opening in the outer layer of the quickmatch fuse so that, upon ignition of the electric match, flame therefrom is directed into and ignites the central blackmatch core of the quickmatch fuse. The coupling device allows rapid and accurate attachment of an electric match to a quickmatch fuse at the fireworks display site by persons of limited skill and / or experience. The electric matches are protected by the coupling device, preventing unexpected ignition from impact, friction, ESD, or other similar ignition sources.

Owner:MARTINEZ PHILLIP M

Method of assembling a temperature controlled railway car

InactiveUS7543367B2Satisfied with useMinimize heat transfer rateAssembly machinesAxle-box lubricationTemperature controlFiber

A manufacturing facility and method for assembling a railway car having a composite box structure mounted on a railway car underframe are provided. The composite box structure may be defined in part by exterior metal sheets, side stakes attached to the exterior metal sheets, insulating materials disposed between the side stakes and the exterior metal sheets and at least one layer of fiber reinforced material. The composite box structure preferably includes a pair of endwalls, a pair of sidewalls, a floor assembly and a roof assembly.

Owner:TRINITY IND INC

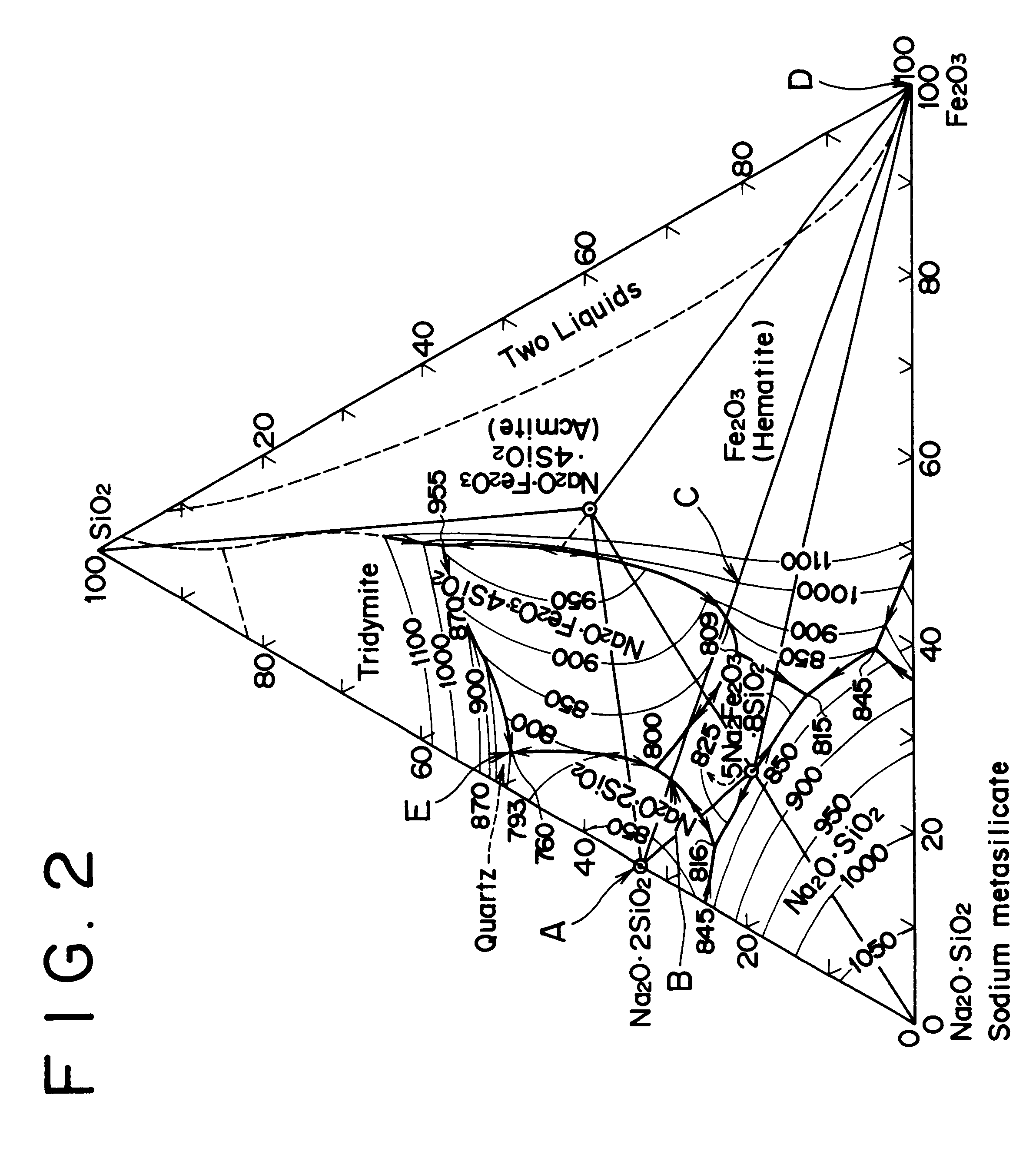

Production of iron ore pellets

InactiveUS6241808B1High strengthMaintain good propertiesBlast furnace componentsBlast furnace detailsIronstoneKiln

A process for producing fired pellets by granulating finely-ground iron ore and subjecting the resulting granules sequentially to drying, dehydration, preheating, and firing, wherein said process comprises adding an additive to said finely-ground iron ore at the time of granulation, said additive reacting with iron ore to form a compound which has a melting point lower than the preheating temperature. Owing to the additive (or sintering auxiliary) added in a small amount to iron ore powder, it is possible to produce preheated pellets by using the existing grate kiln without increasing the amount of preheating energy. The resulting preheated pellets have improved strength and produce no adverse effect on finished pellets.

Owner:KOBE STEEL LTD

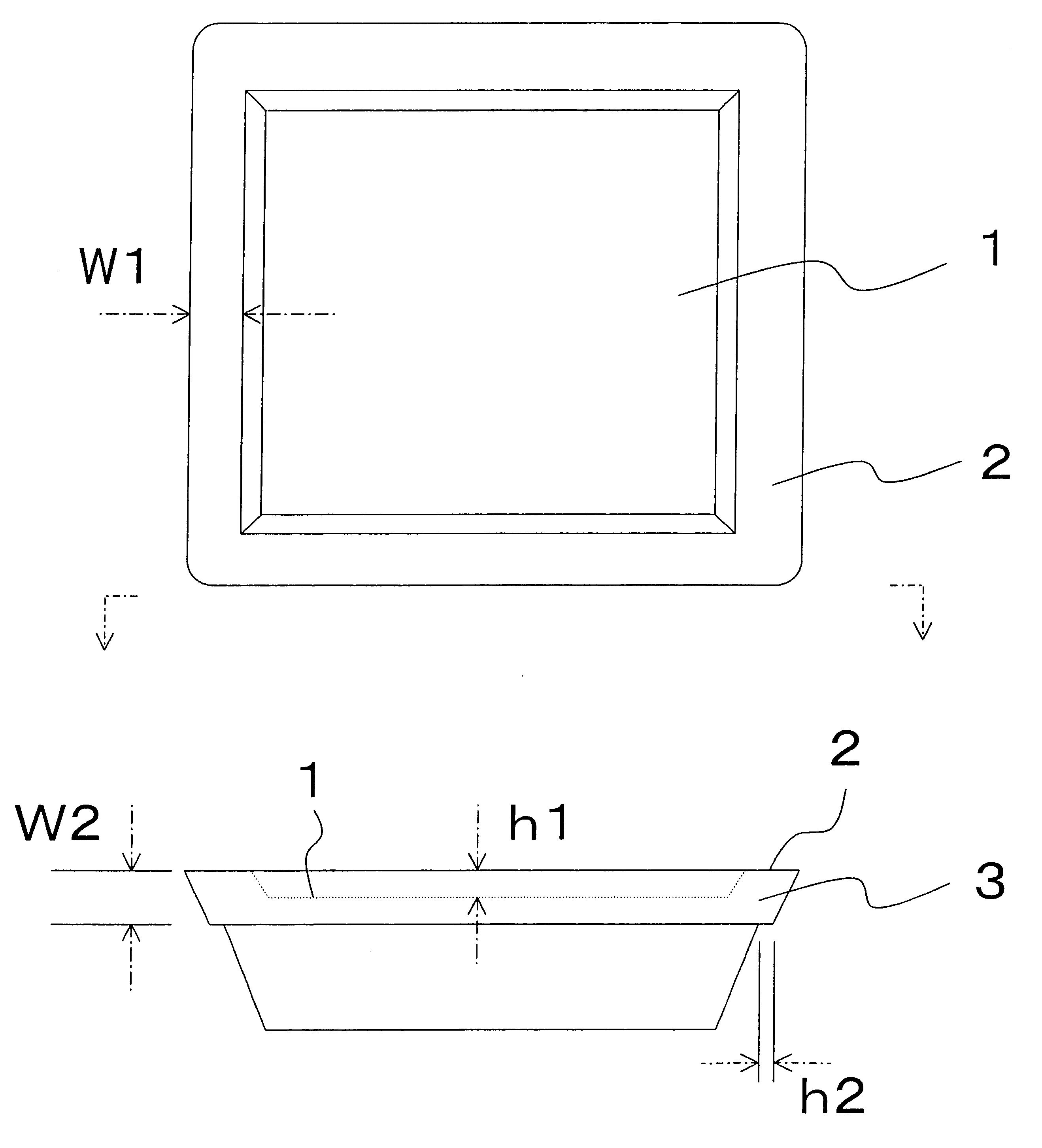

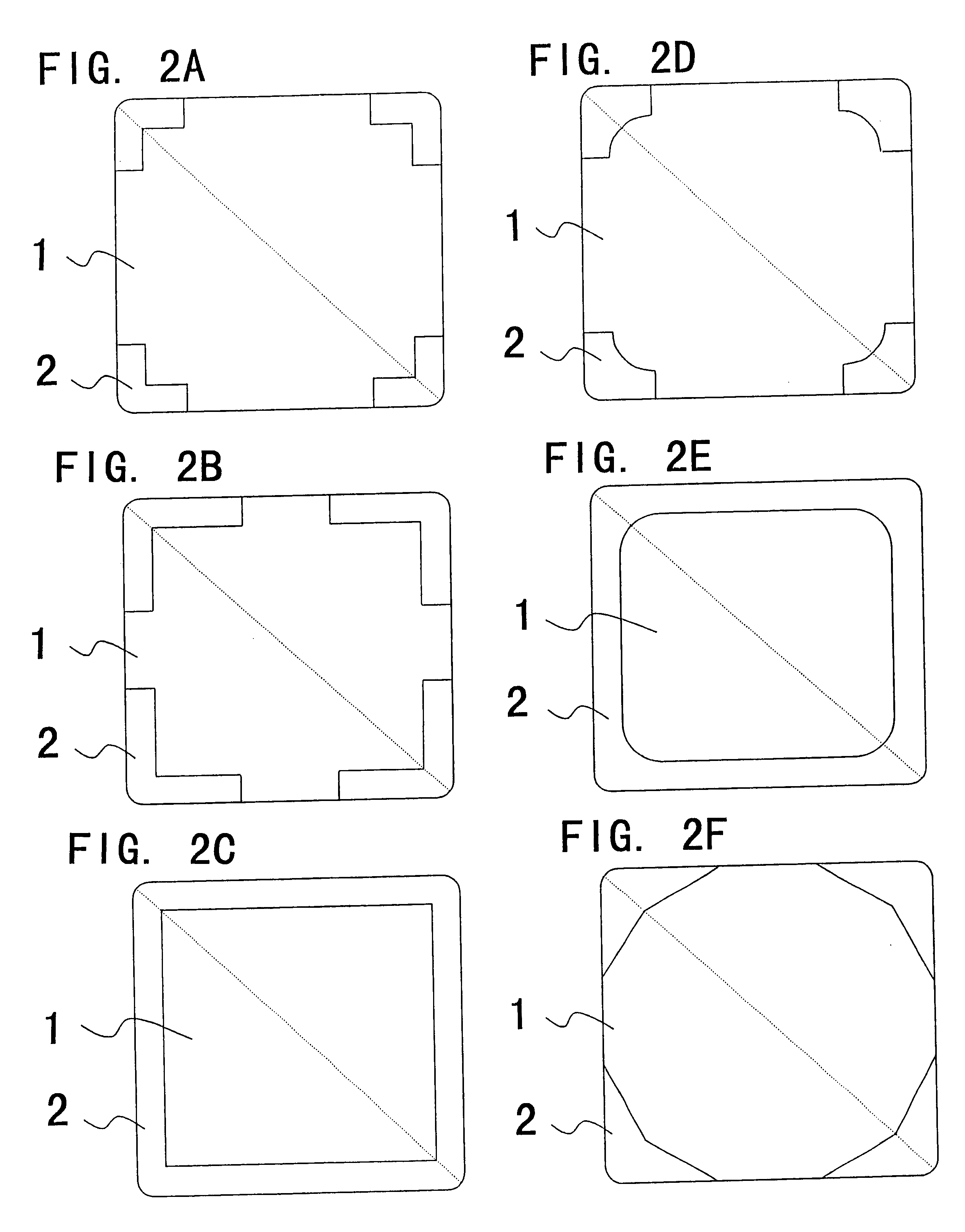

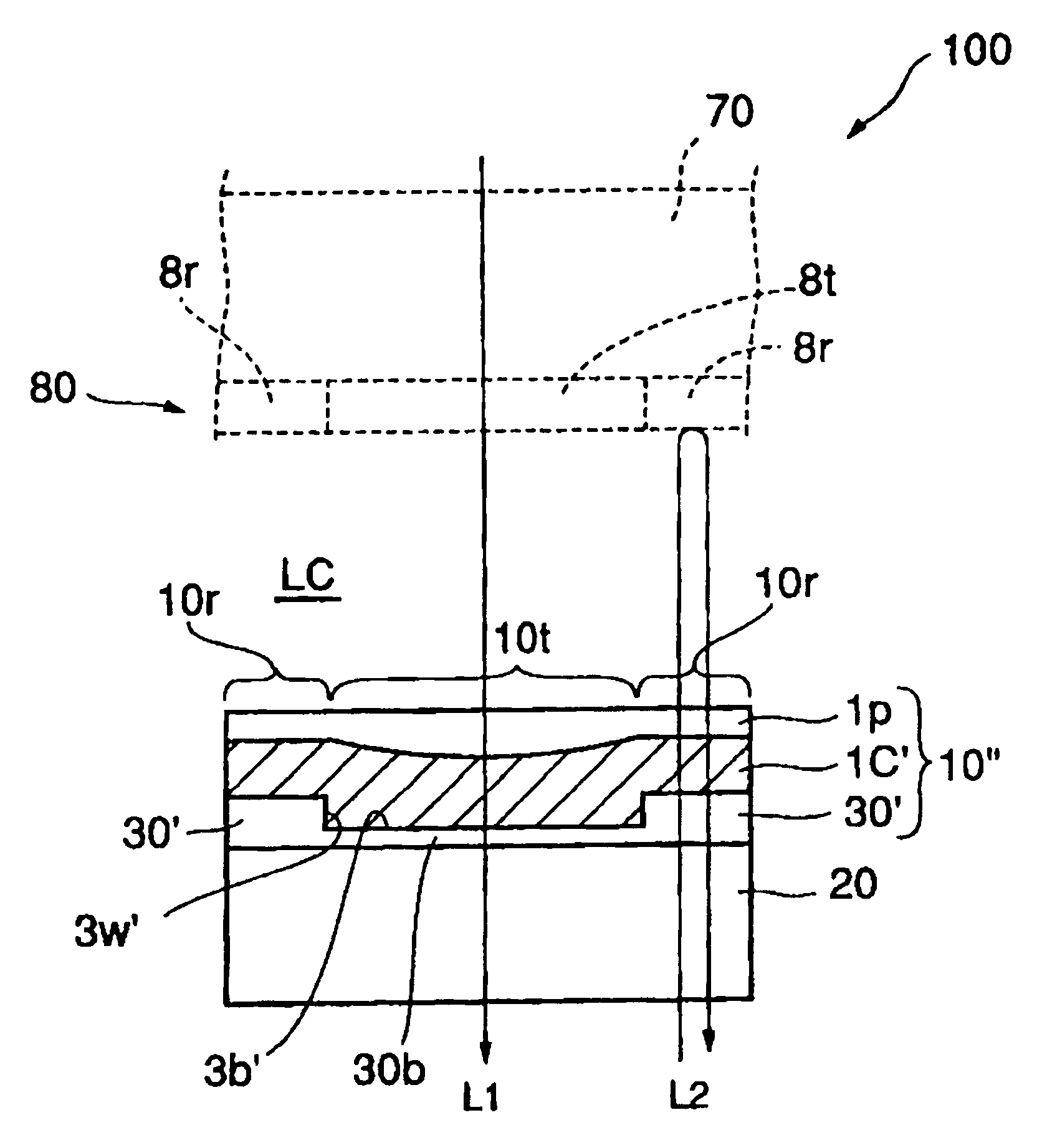

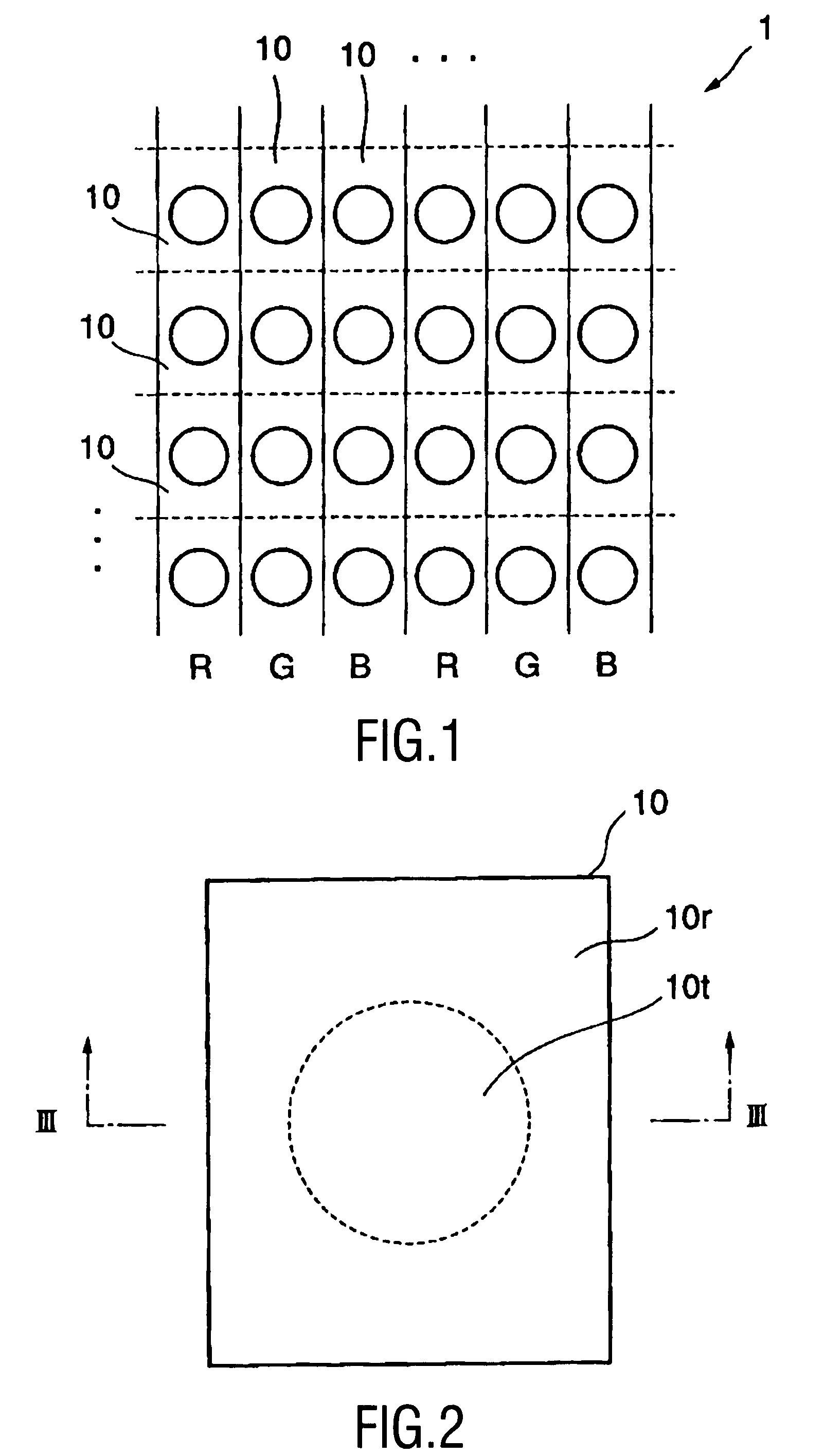

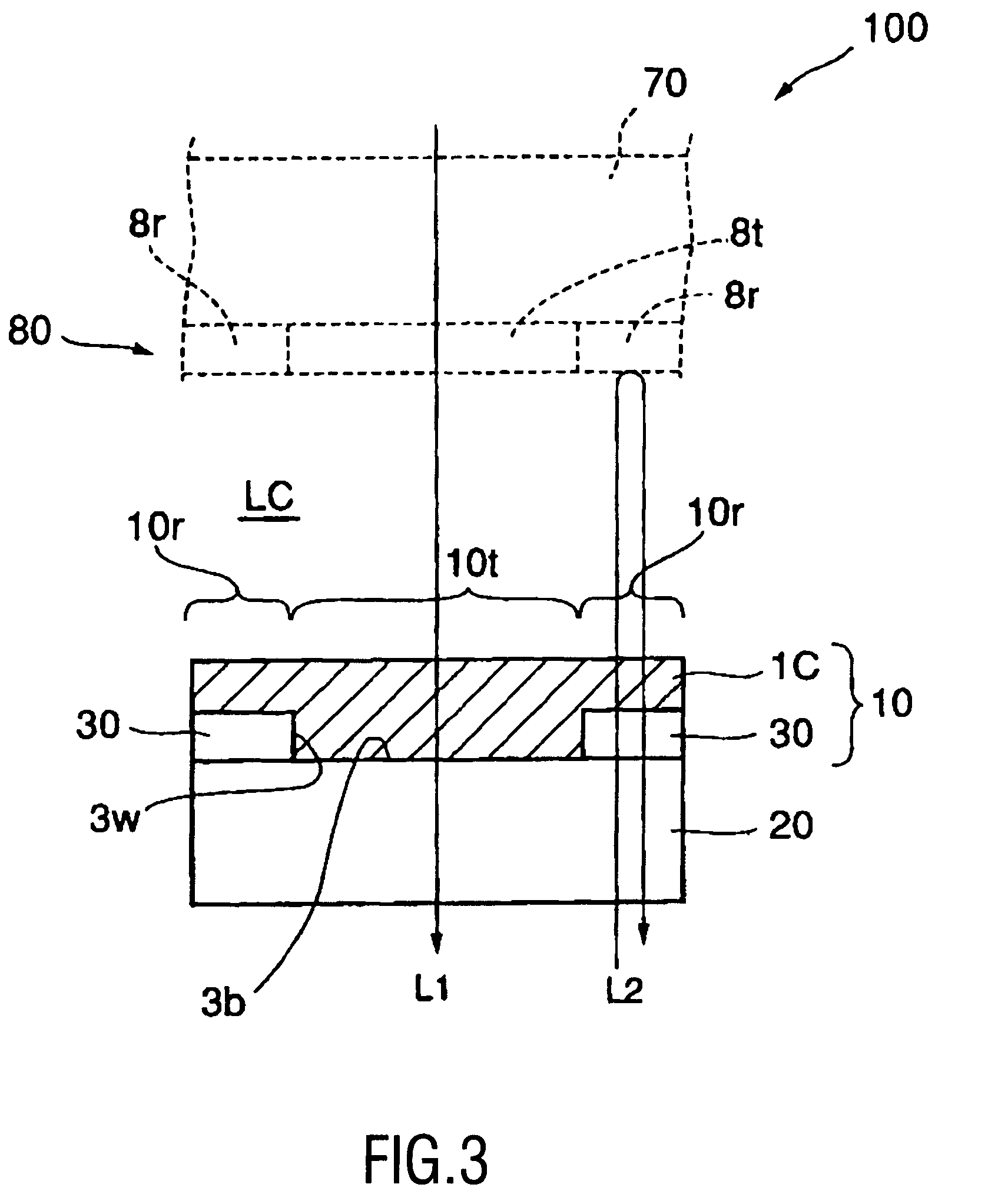

Color filter and liquid crystal display device using it, and manufacturing method thereof

InactiveUS6975373B2Reproduce chromaticitySatisfied with useMirrorsDiffusing elementsLiquid-crystal displayColor purity

An object of the invention is to provide a color filter and a liquid crystal display device using it, which can acquire uniform color purity within a pixel. A color filter for coloring the first light ray L1 having a unidirectional optical path and the second light ray L2 having a bidirectional optical path for each pixel. This filter comprises: a step-forming layer of optically transmissive material, which can be supported by a base layer 20, and which is patterned for a pixel to form at least one recess-shaped portion having a bottom face 3b of a predetermined shape corresponding to an area wherein the first light ray L1 is caused to be transmitted and a wall face 3w of a predetermined height; and a coloring layer 1C deposited on the step-forming layer 30 and the recess-shaped portion for coloring the first and second light rays.

Owner:TPO HONG KONG HLDG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com