Patents

Literature

32 results about "Iron injection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Iron infusion vs. iron injection Iron infusions involve delivering a dose of iron through the vein with an IV drip. Iron injections involve injecting iron into a muscle with a needle.

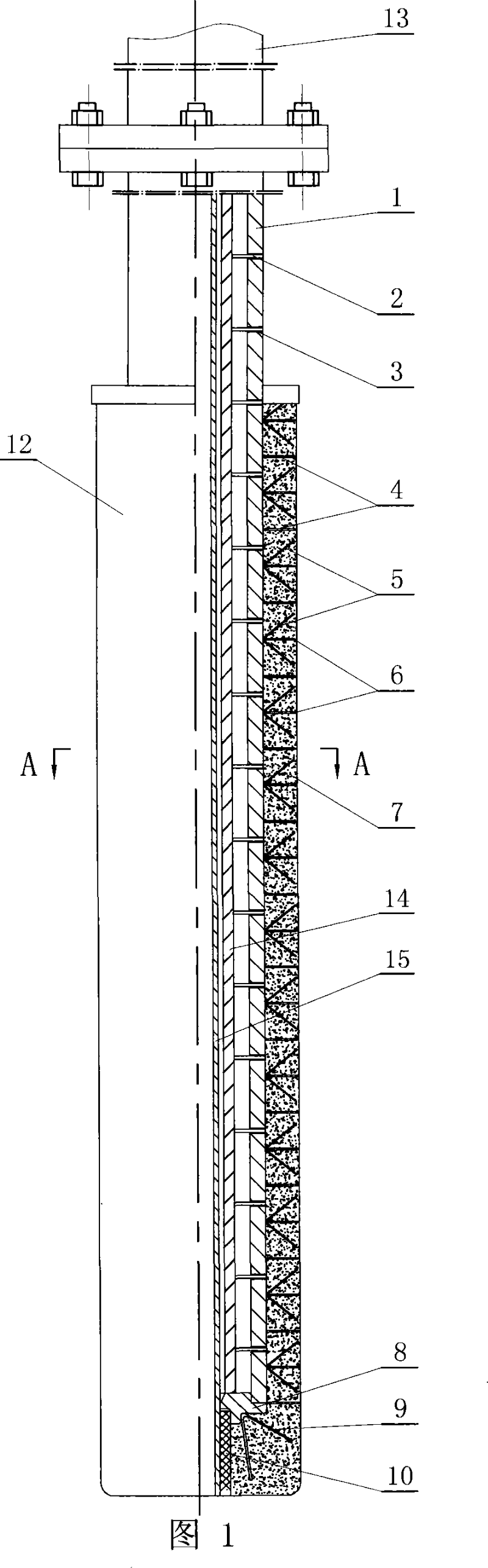

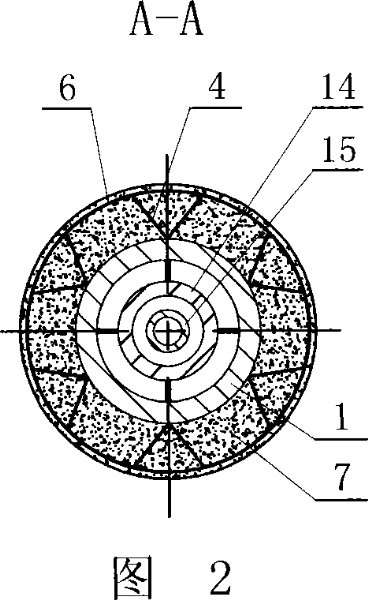

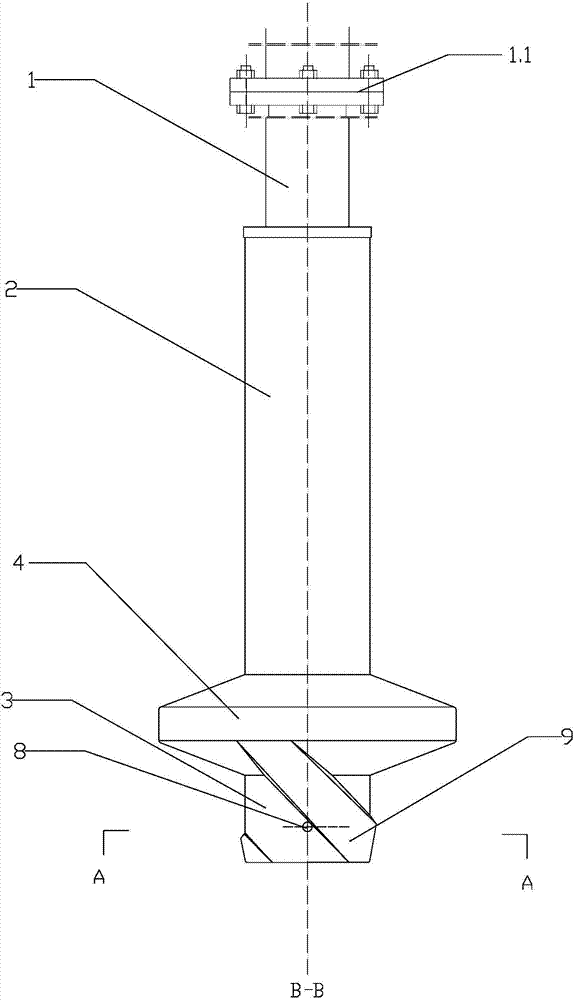

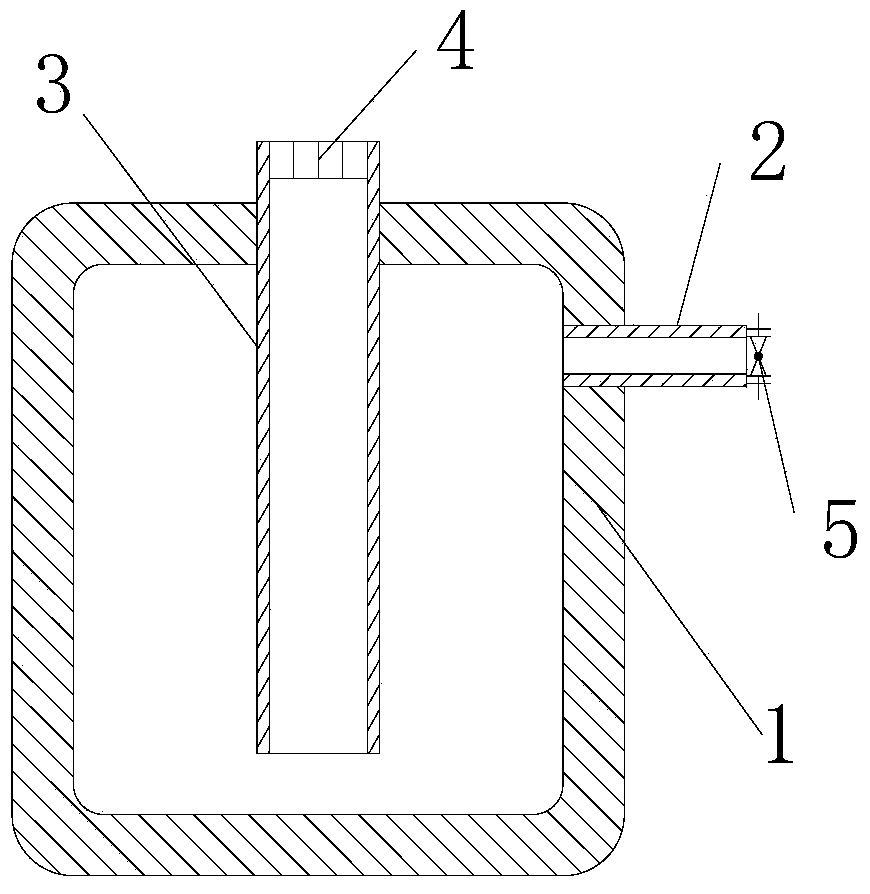

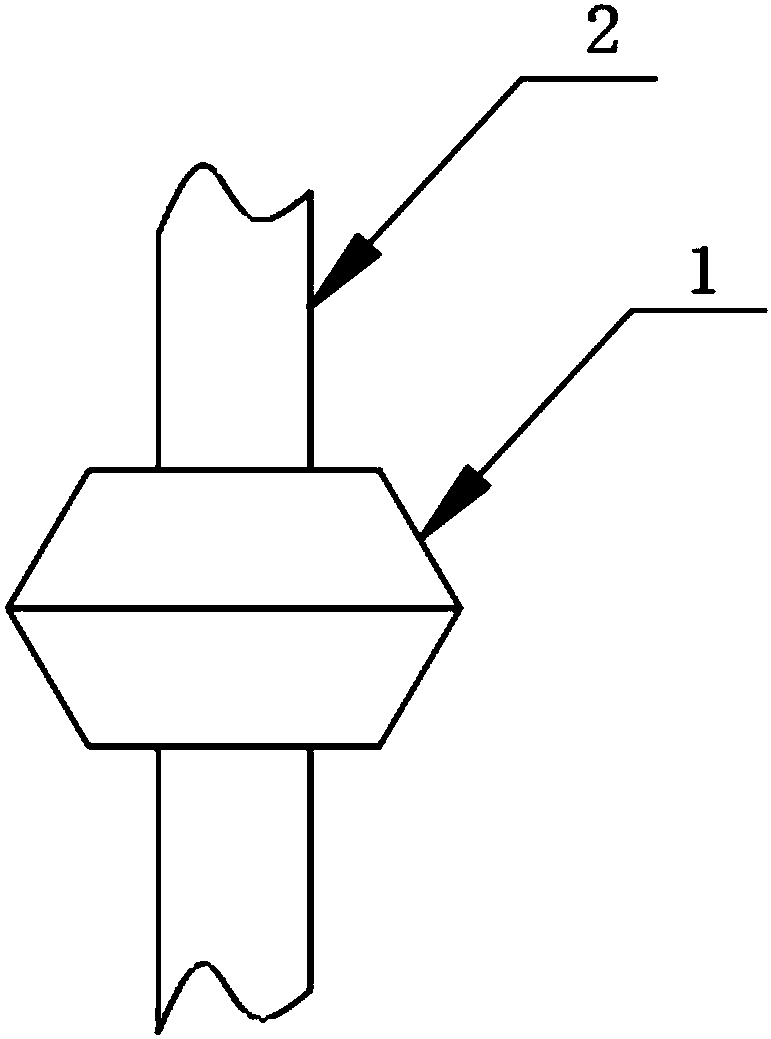

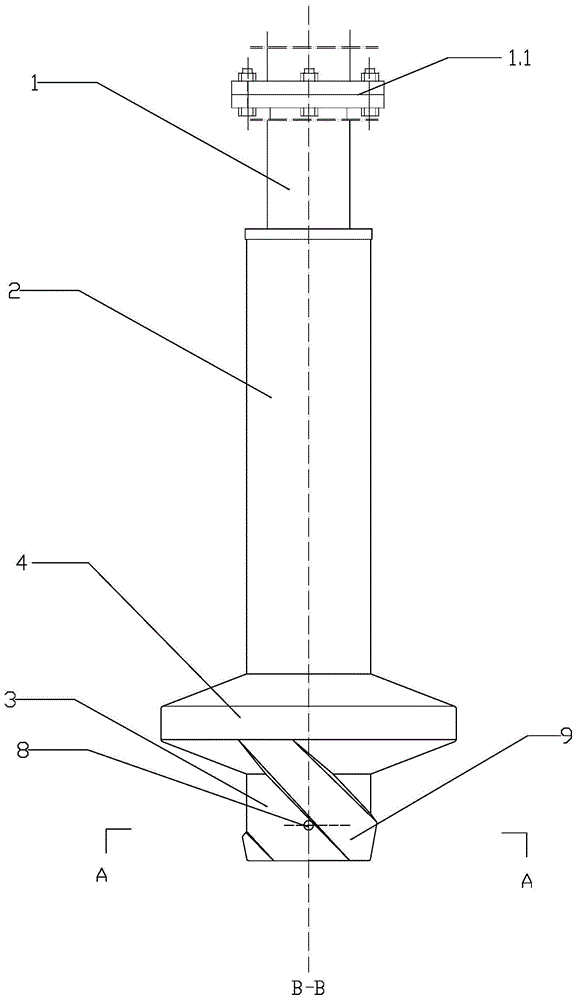

Molten iron spraying desulfurization spraying gun

InactiveCN101037717AAvoid distortionEnhance riveting forceManufacturing convertersRefractoryFireproofing

A desulfurization spray gun of molten iron injection, relates to a spray gun for the molten iron injection pretreatment of molten iron jar. The invention solves the problem that the core leading pipe of the spray gun in the existing art can be distorted in order that the injection tube can not be drawn out and changed when it is jammed, further not to repeatly reuse the the core of the spray gun. The invention comprises a gun body and a spray gun complex connecting with a flange of the spray gun. The said spray gun includes a intensifier tube, a main tube in the intensifier tube and an injection tube in the main tube, provided with a mounting base of graphite injection tube under the said intensifier tube and main tube, and a graphite injection tube outside of the injection tube bottom, fixed on the mounting base of graphite injection tube, there is a fireproofing gun lining outside of the intensifier tube, and a bridge weldment uniformly fixed between the intensifier tube and main tube along the circular and axial direction. The stucture can improve the rigidness and strength of the gun core, prevent the distort of the leading pipe caused by the repeat reusing of the spry gun, at the same time, the repairing and using number of the gun core is increased and the facturing cost of the spray gan is reduced.

Owner:WUHAN IRON & STEEL (GROUP) CORP

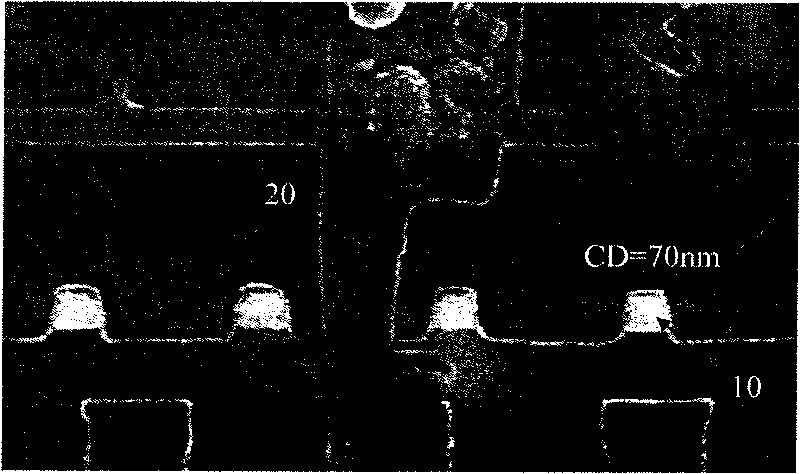

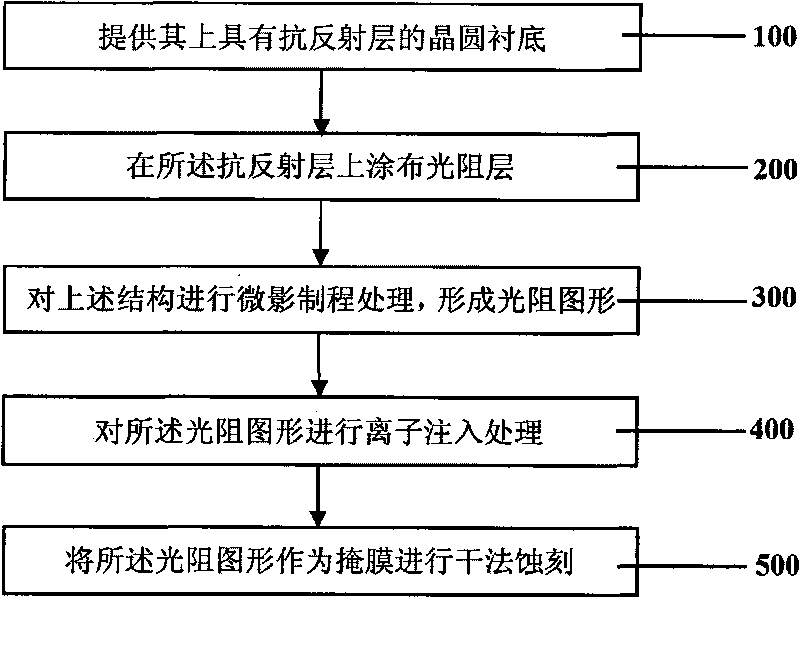

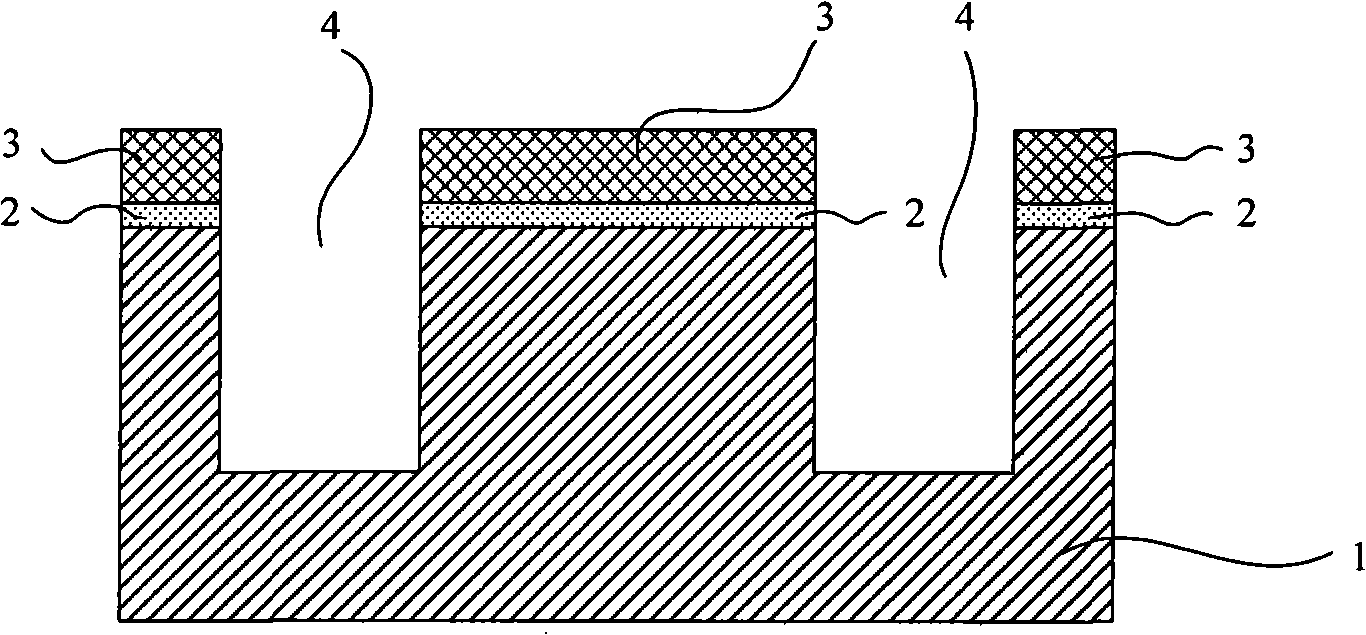

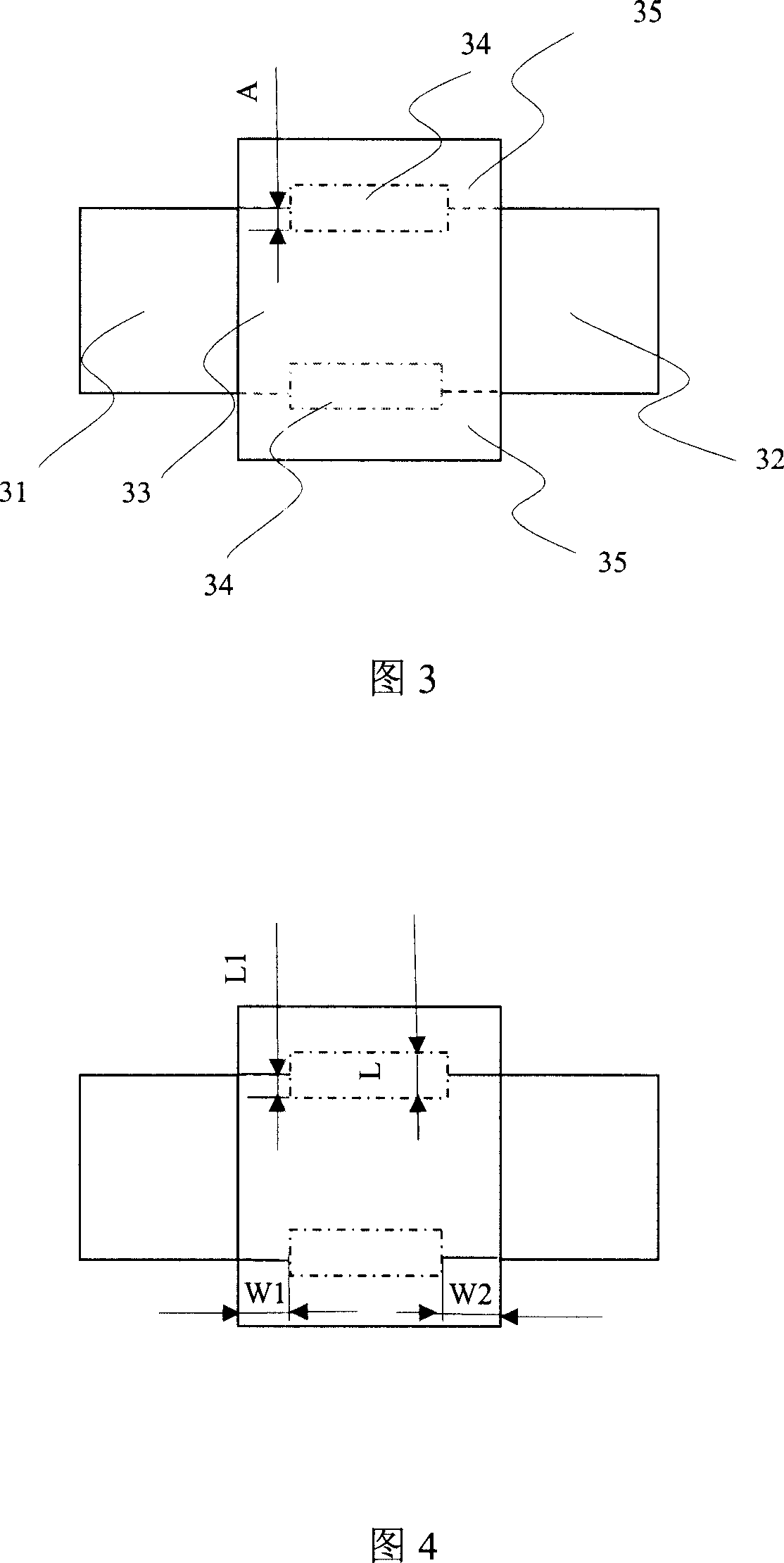

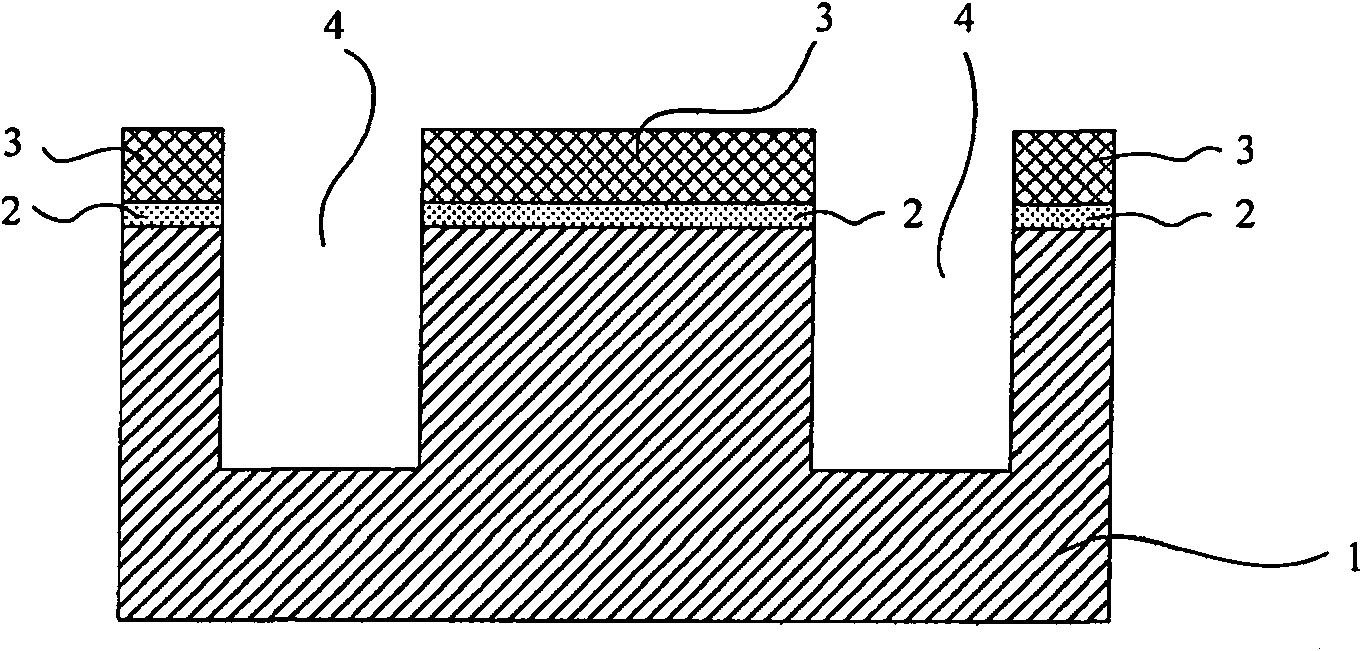

Method for shrinking line-shaped pattern character size

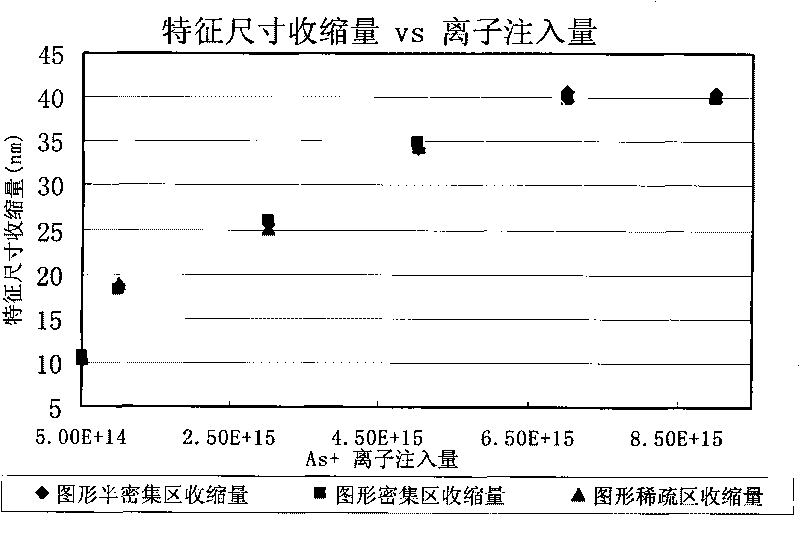

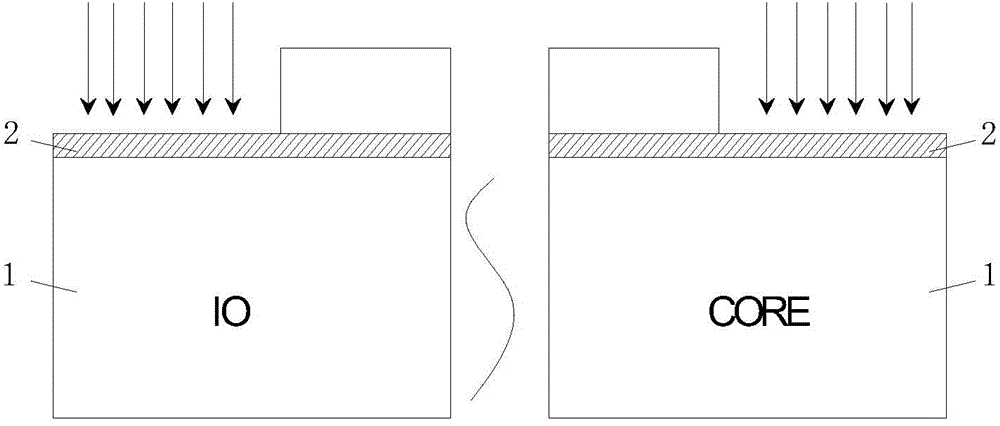

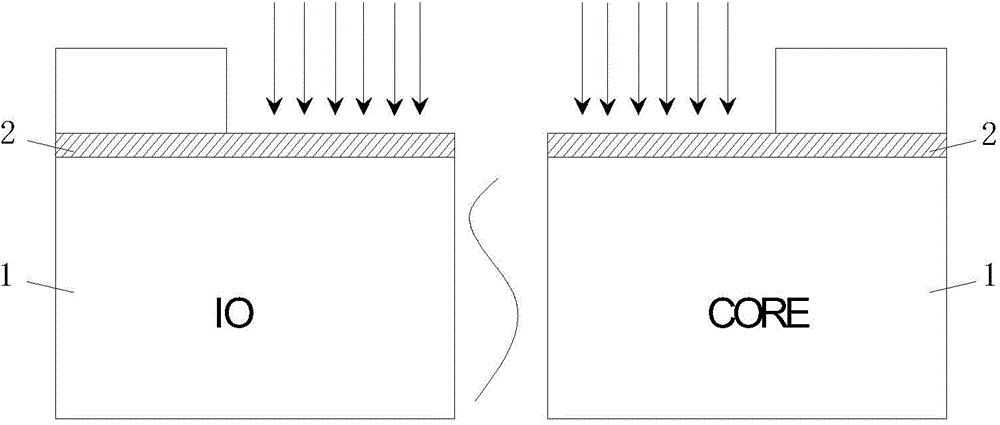

The present invention provides a method for shrinking line-shaped pattern character sizes, which comprises the following step: irons are injected to a photoresistive pattern as a mask to enable the character size of the photoresistive pattern to shrink. The method for shrinking line-shaped pattern character sizes can effectively shrink the character size of the photoresistive pattern to enable the roughness concentration of a photoresistive linear boundary to become smoother and ensure the uniformity of the character size of the whole wafer. After the processing of iron injection, the anti-etching ability of photoresistance in a subsequent etching process is largely strengthened, and the difference (that is micro load effect) of an intensive pattern and a thin pattern on the reduction of the character size is effectively reduced.

Owner:SEMICON MFG INT (SHANGHAI) CORP

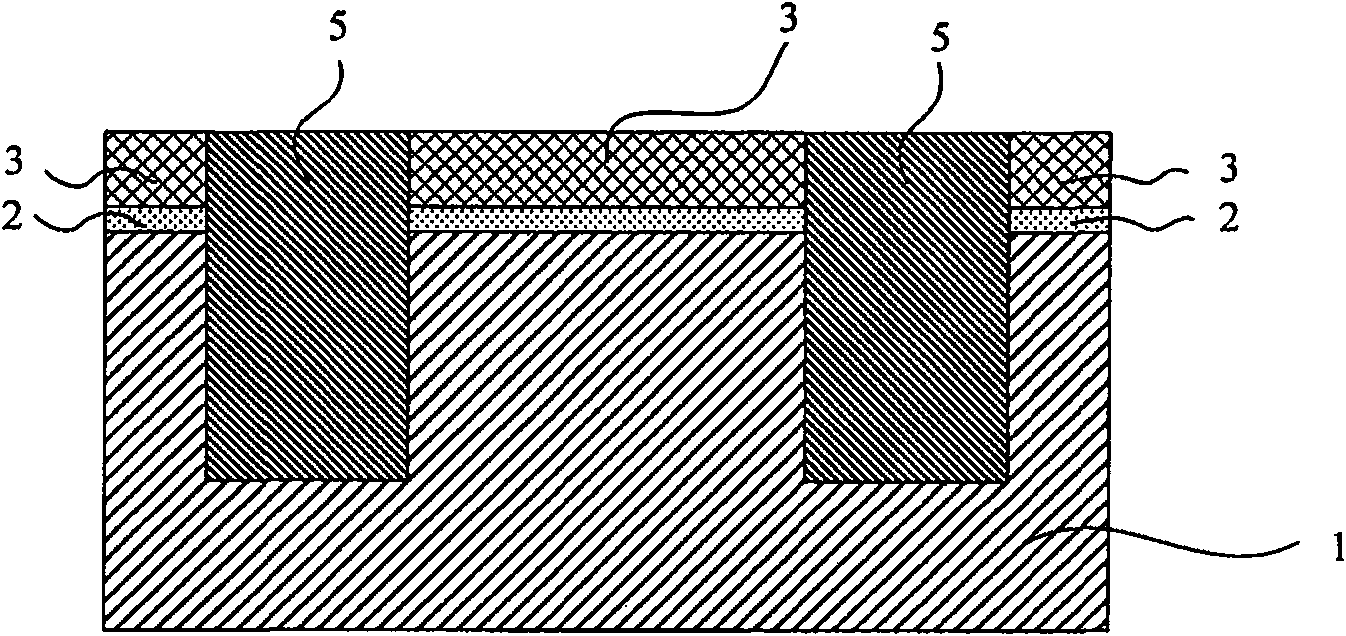

FinFET and preparation method thereof

ActiveCN105448984APrevent proliferationImprove mobilitySemiconductor/solid-state device manufacturingSemiconductor devicesIsolation effectHigh doses

The invention provides an FinFET and a preparation method thereof. Trenches among adjacent fin-shaped structures form shallow trench isolation structures (STI), and oxide layers and insulation material layers are arranged among shallow trenches, the fin-shaped structures and a substrate, so that isolation effect can be achieved well, and diffusion of doping-ions in the fin-shaped structures and the substrate can be avoided; iron injection of high dose C-co or high dose F-co in the conventional FinFET preparation process can be avoided, so that the damage to the substrate and the fin-shaped structures due to the bombardment effect during iron injection can be reduced; and furthermore, the form of an SSRW also can be maintained well, the carrier mobility can be effectively improved, and the performance of the device can be greatly improved.

Owner:SEMICON MFG INT (SHANGHAI) CORP

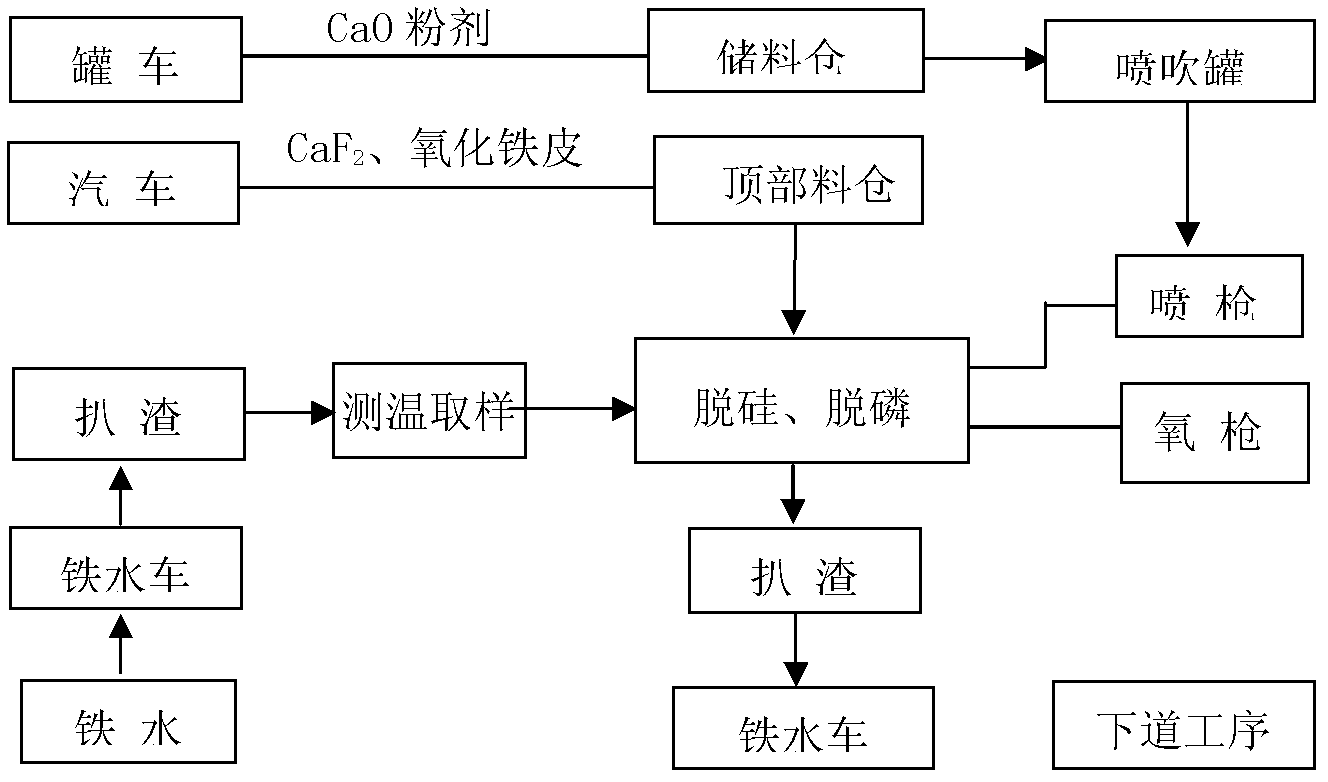

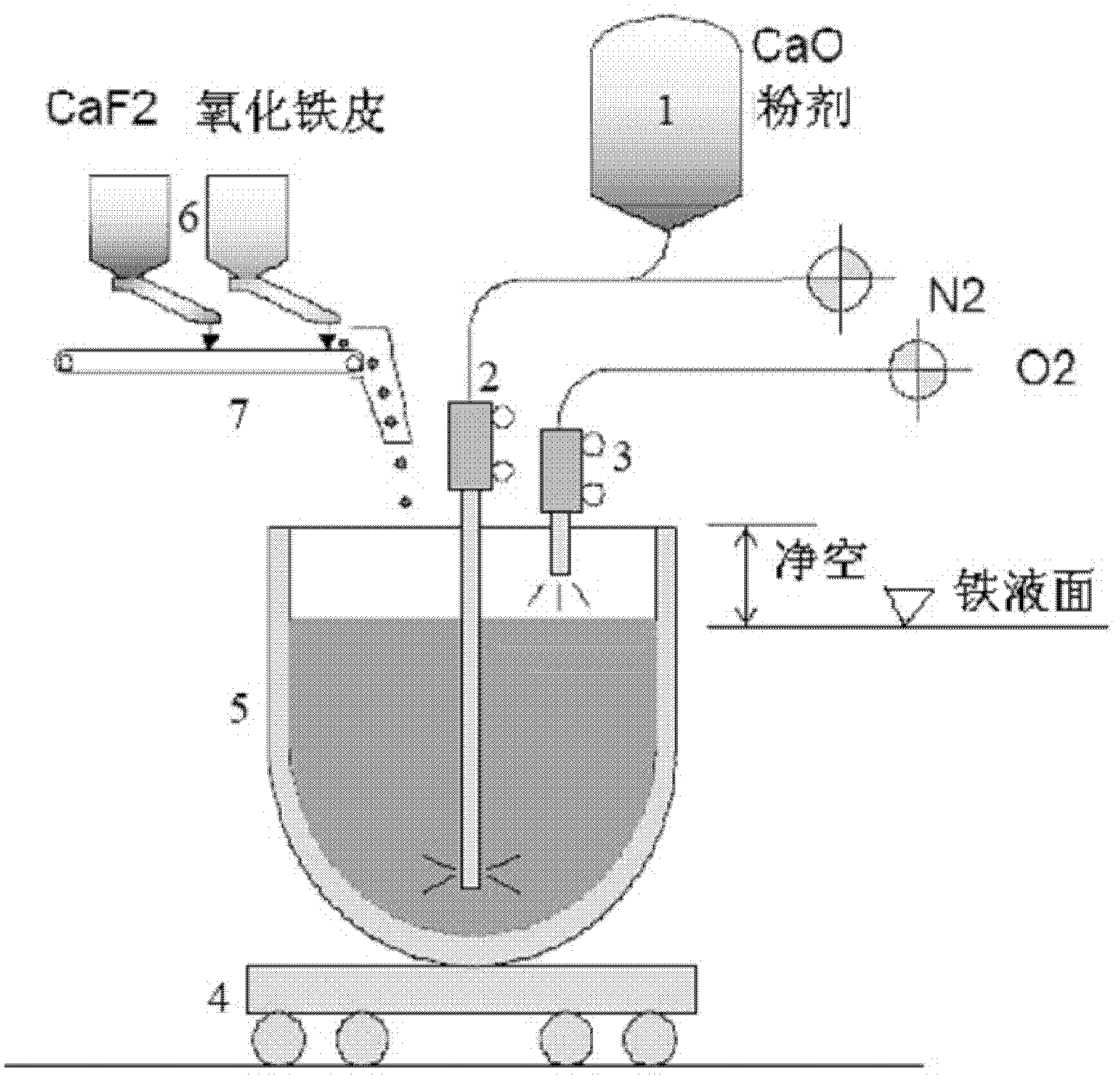

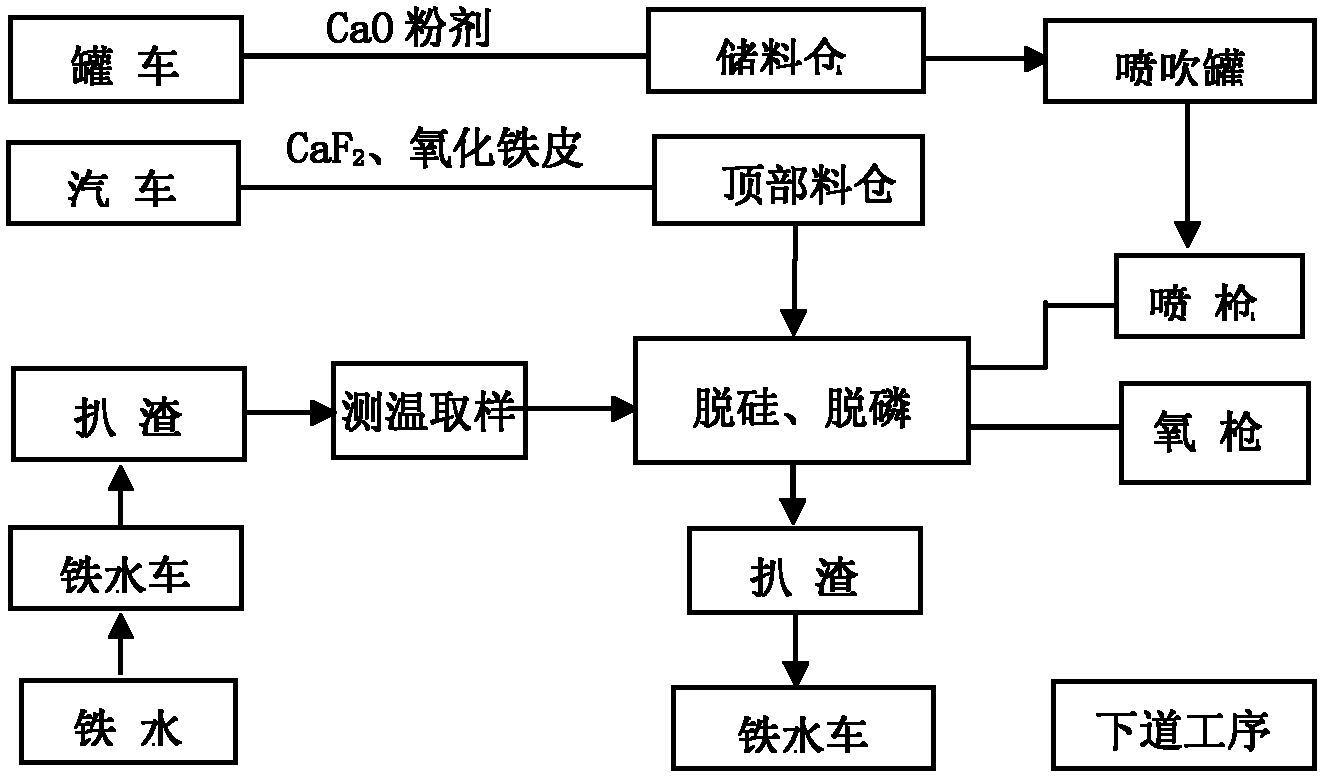

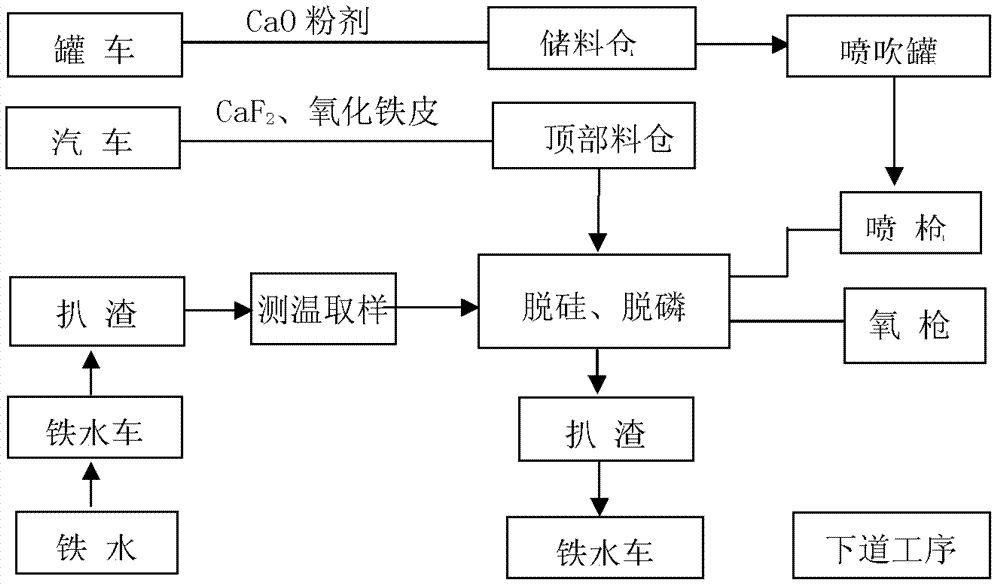

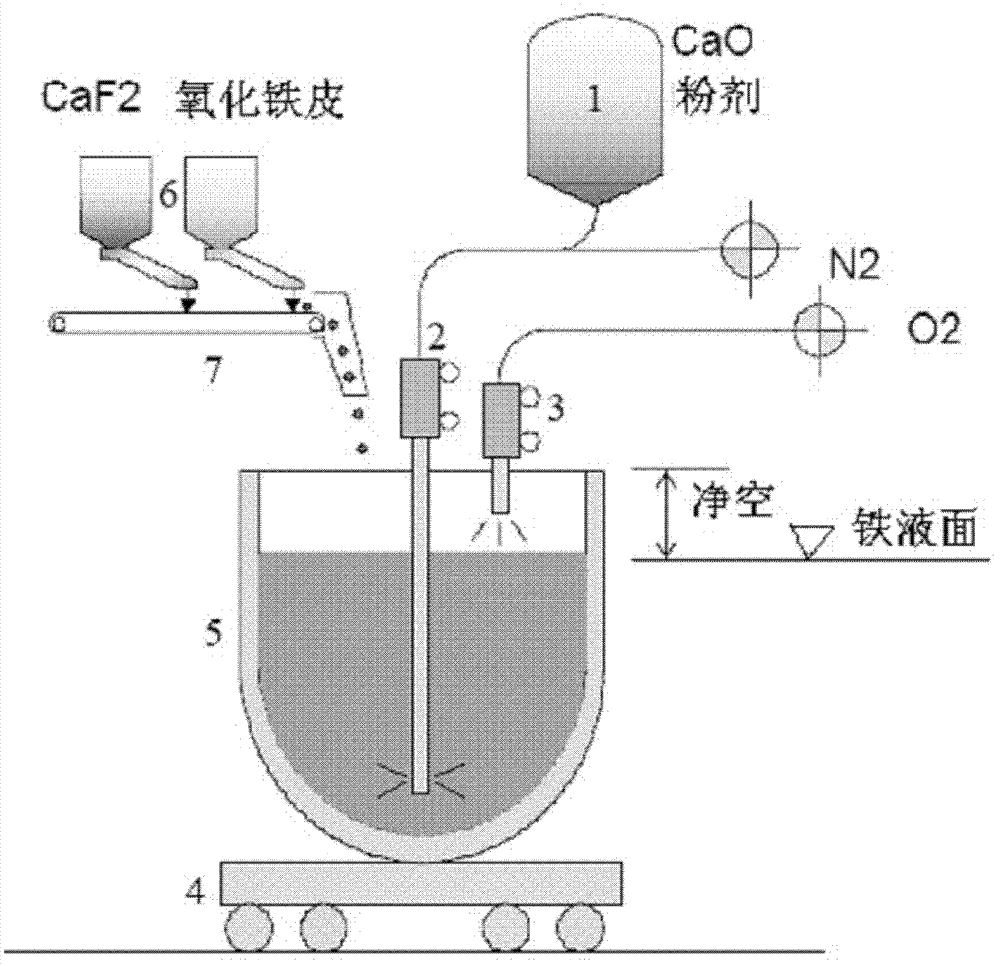

Low-temperature molten iron injection dephosphorization pretreatment method

ActiveCN102559999AReduce temperature dropReduce the amount addedProcess efficiency improvementPretreatment methodManganese

A low-temperature molten iron injection dephosphorization pretreatment method belongs to the field of steel-making molten iron pretreatment. A foundry ladle for dephosphorization is used to hold molten iron and a molten iron roll-over transport vehicle is used to transport the molten iron to a position wherein the molten iron will be processed. With the adoption of a dense phase conveying mode for injection, molten iron temperature reduction caused by carrier gas is minimized. With the blowing of oxygen, the gas O is provided for a reaction, the purpose of heating is achieved, and the addition amount of oxide scale is reduced so as to minimize molten iron temperature reduction caused by the addition of oxide scale. Low oxygen blowing speed realizes soft blow of the molten iron. Decarburization and demanganization reaction times are reduced, thus achieving the purpose of preserving carbon and manganese and maintaining chemical heat to the maximum. Due to the above positive effects, molten iron temperature reduction is minimized and the molten iron is heated by the use of oxygen. Finally, the low-temperature molten iron undergoes injection dephosphorization and the dephosphorizationrate reaches more than 90%.

Owner:BEIJING SHOUGANG INT ENG TECH

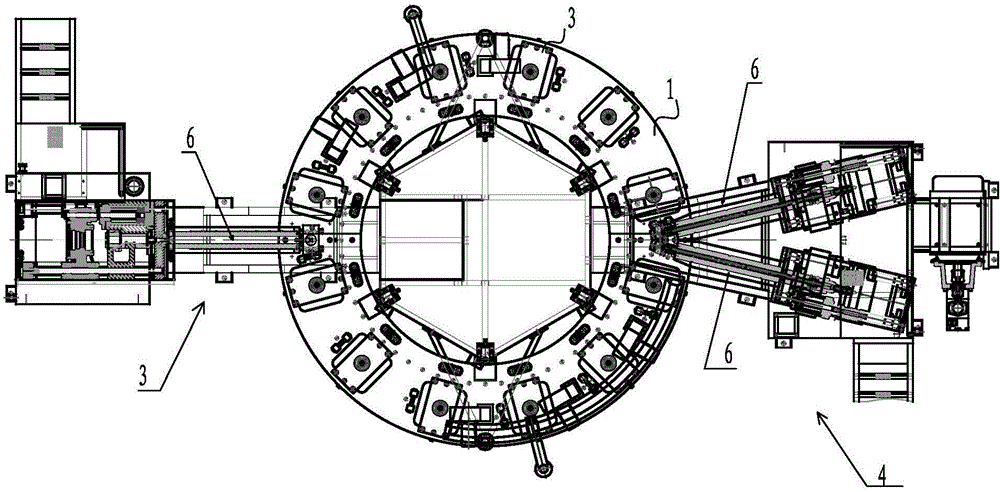

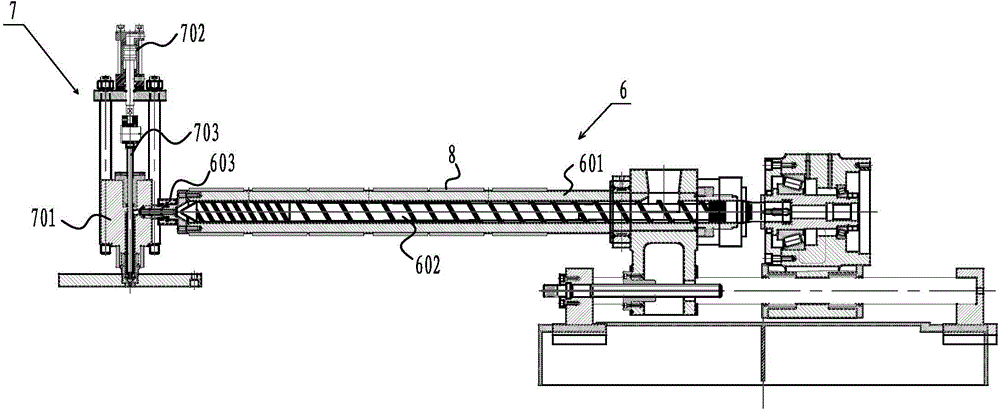

Three-color plastic sole molding machine

InactiveCN103978623AImprove heating efficiencyHeating up fastDomestic articlesControl systemMolding machine

The invention relates to a three-color plastic sole molding machine, comprising a clamping mechanism, a rotary mechanism, plasticizing and injection mechanisms, a hydraulic system and a control system. A primary injection device and an auxiliary injection device are provided, wherein the auxiliary injection device is provided with two groups of plasticizing and injection mechanisms, so that only two stations require workers to finish the injection molding of a three-color color product, thereby reducing operating workers; at the same time, the heating device consists of an electromagnetic spiral coil winding on a coil frame, high frequency alternating current power supply is applied on the spiral coil to induce eddy current on an iron injection screw for heating, and the raw materials are directly heated from the inside of a material canister, so as to achieve rapid heating and higher heating efficiency.

Owner:WENZHOU BENLONG MACHINERY

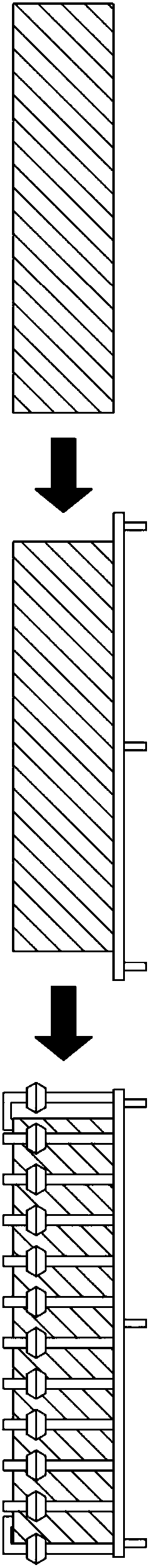

High silicon ball iron injection molding machine template casting preparing method

InactiveCN107513658AImprove mechanical propertiesSolve the shrinkage cavityProcess efficiency improvementSlagMolding machine

Disclosed is a high silicon ball iron injection molding machine template casting preparing method. The method comprises the steps that raw materials comprises, by weight, 40-50% of pig iron, 20-30% of scrap steel, 20-30% of foundry returns, 1-1.4% of silicon iron and 0.004-0.005% of Sb, and are configured; melting is conducted, sampling analysis and blending composition are conducted; firstly, a rare earth magnesium nodularizer and Sb are correspondingly placed on the two sides of a bottom transverse blocking of a nodulizing bag, scrap steel sheets covers the surface of the rare earth magnesium nodularizer, and molten iron is poured into the nodulizing bag with Sb on one side, after the nodulizing reaction begins, a ladle-to-ladle inoculant is added into the nodulizing bag for inoculation, meanwhile, the molten iron is stirred, and melting of the ladle-to-ladle inoculant is promoted; and slag removal and pouring are conducted. The high silicon ball iron injection molding machine template casting preparing method has the advantages that the defects such as shrinkage and shrinkage cavity of a casting can be effectively solved, and the brittleness of the casting can be reduced, thus the scrap rate of during high silicon ball iron injection molding machine template casting manufacturing can be greatly reduced.

Owner:RIYUE HEAVY IND

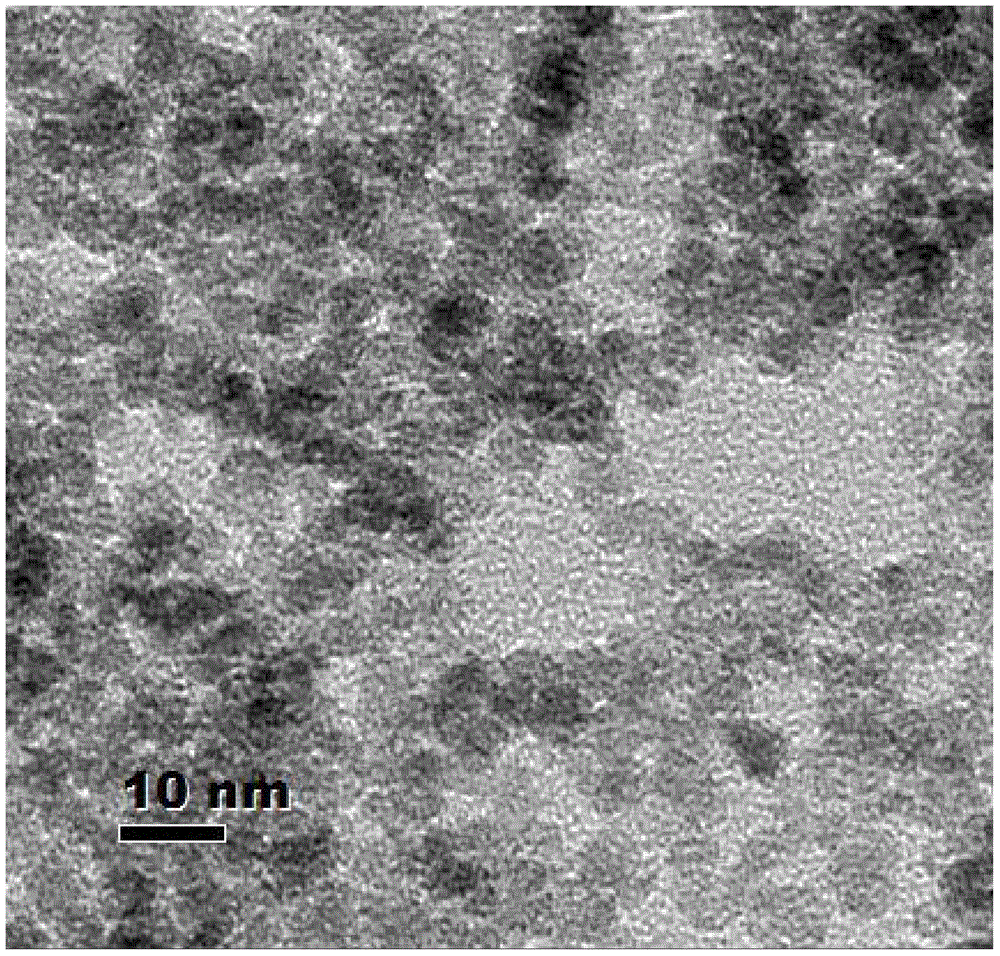

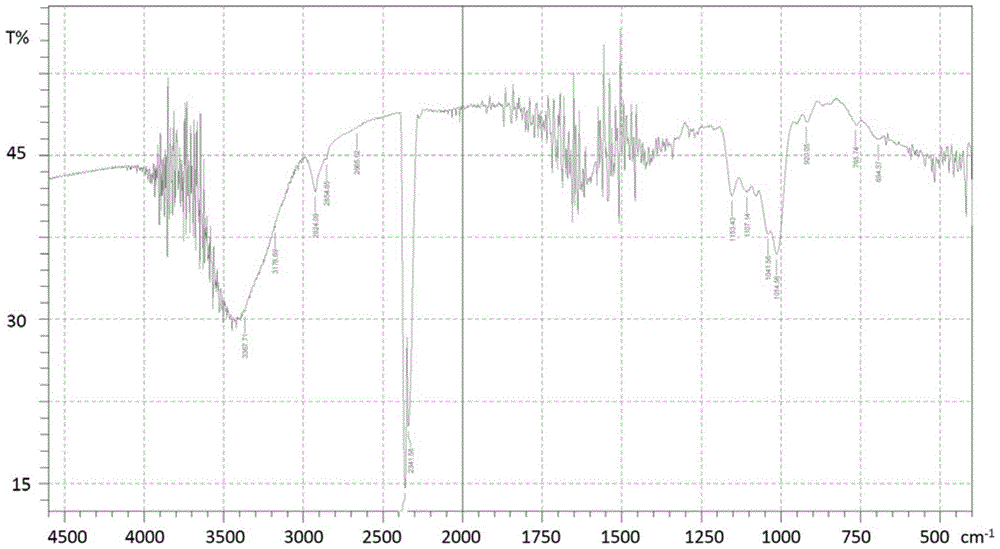

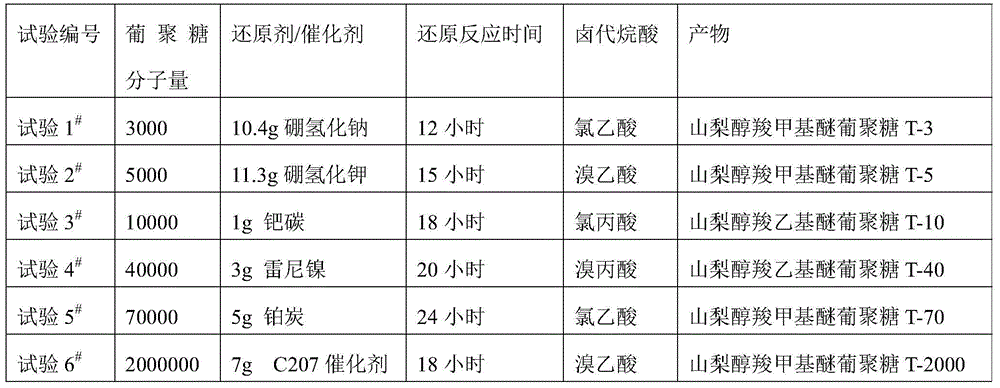

Reduced carboxy alkyl dextriferron injection and preparation method thereof

InactiveCN105708792AHigh biosecurityReduce concentrationOrganic active ingredientsMetabolism disorderForeign matterBULK ACTIVE INGREDIENT

The present application provides a reduced carboxyalkyl dextran iron injection, which comprises reduced carboxyalkyl dextran iron as an active ingredient, an optional acid-base regulator and water for injection. The present application also provides a preparation method of reduced carboxyalkyl dextran iron injection. The injection provided by the present application has a lower detection rate of visible foreign matter than the iron injection obtained in the prior art, and has good properties such as good physical stability and / or good chemical stability.

Owner:SHANXI PUDE PHARMA CO LTD

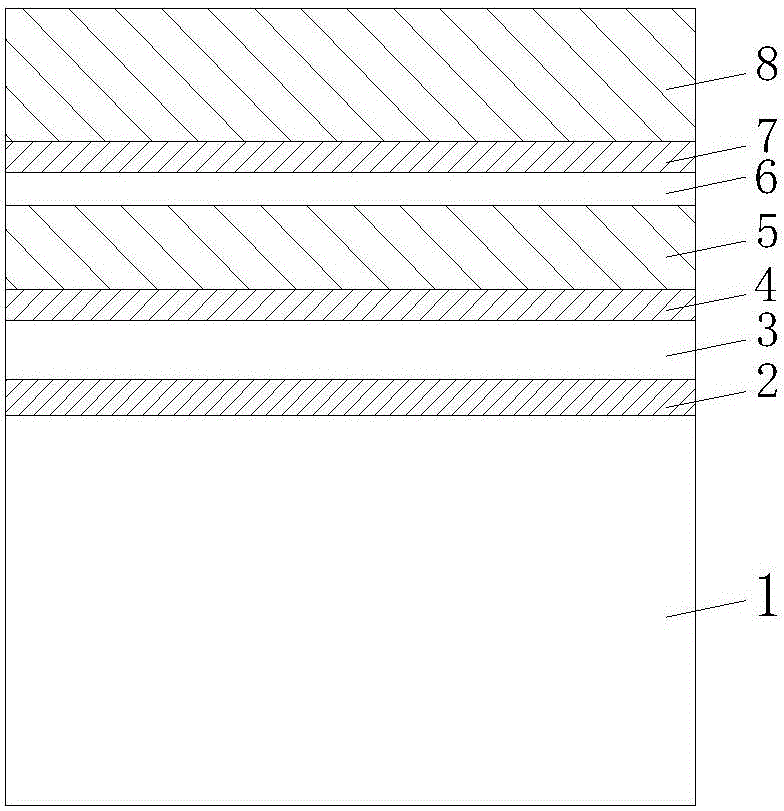

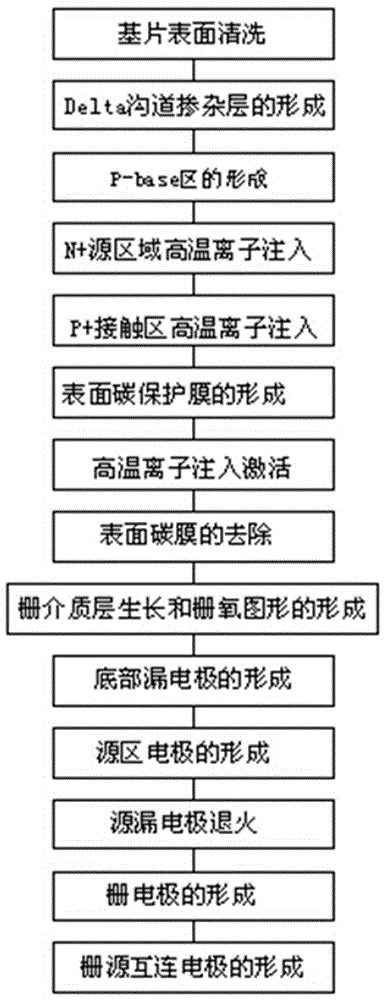

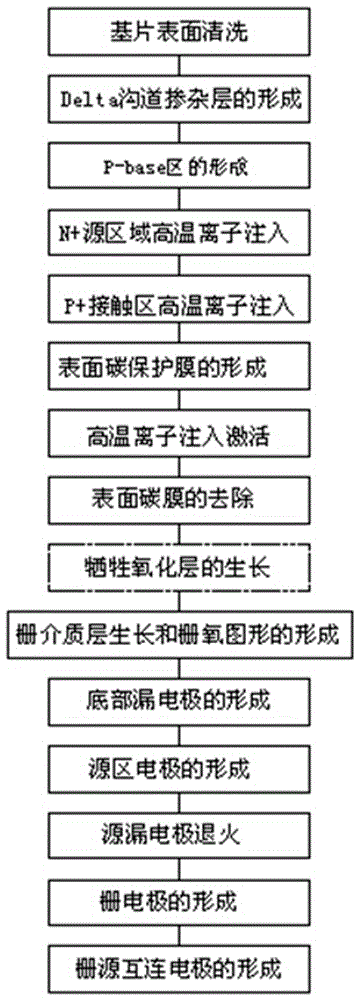

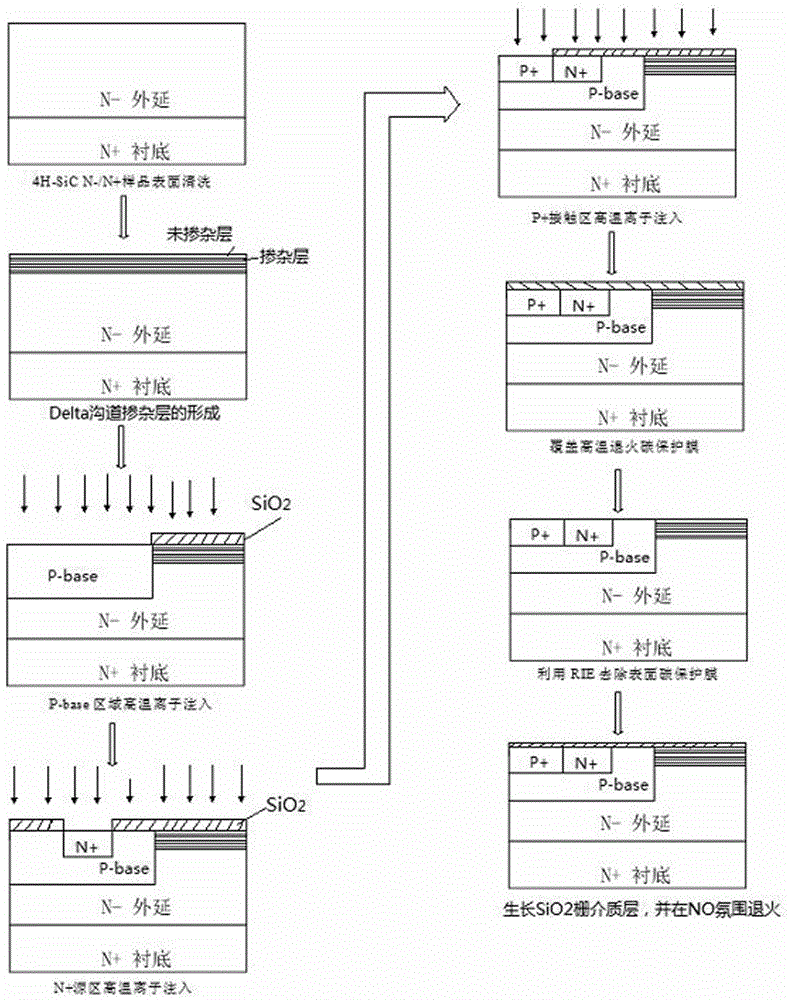

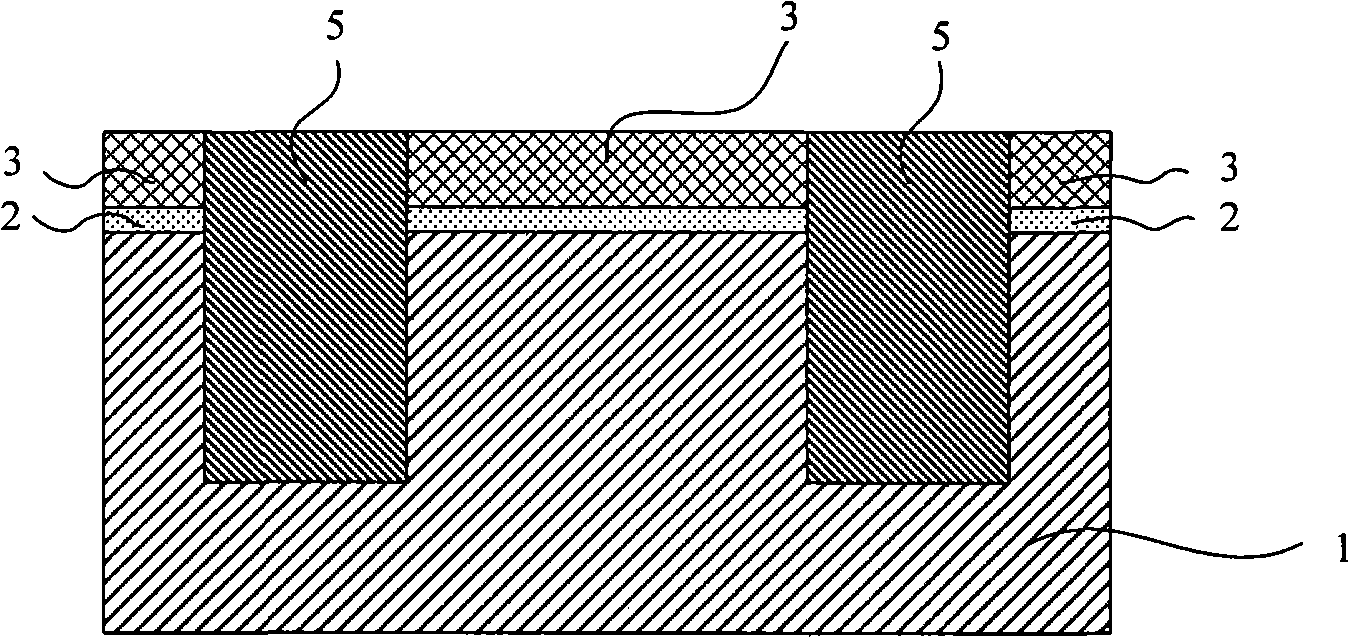

Delta channel doping SiC vertical power MOS device manufacturing method

ActiveCN105470288AImprove channel mobilityImprove conduction characteristicsSemiconductor devicesCarbon filmIron injection

The invention provides a Delta channel doping SiC vertical power MOS device manufacturing method. The method comprises the steps of: cleaning the surface of an N- / N+ type SiC epitaxial wafer; carrying out layered doping in a CVD furnace; etching out a P-base region and injecting high temperature Al irons; etching out an N+ doping source region and injecting high temperature N irons; etching out a P+ contact region and injecting high temperature Al irons; forming a carbon protection film on the surface of the N- / N+ type SiC epitaxial wafer; annealing high temperature iron injection; removing the surface carbon film; carrying out acid cleaning; growing a SiO2 insulating layer; growing a bottom drain electrode; smearing stripping glue and a photoresist, etching out a source contact hole, carrying out source metal deposition, and stripping the source metal to form a source pattern; annealing source and drain electrodes; forming a grid electrode; and forming a grid and source interconnection electrode. According to the invention, the channel effective migration rate of the vertical power MOS device is effectively improved, the threshold voltage of the device is reduced, and the conduction characteristic of the vertical power device is improved.

Owner:XIDIAN NINGBO INFORMATION TECH INST

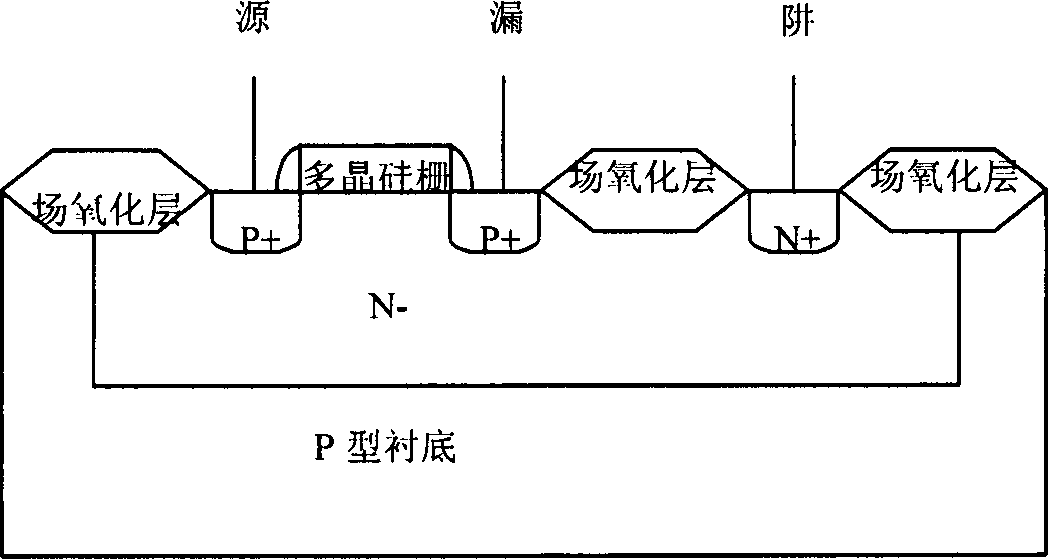

Method for preparing SON type metal oxide semiconductor field effect pipe device

ActiveCN101299411ASimple processLow costSemiconductor/solid-state device manufacturingMOSFETIron injection

The invention discloses a preparation method of the SON type metal-oxide semiconductor field transistor, including the steps of low temperature injecting the neon ion with secondary different energy in the large beam current, forming the void layer at the lower part of the active region after high temperature anneal; removing the silicon nitride side wall on the shallow trough insulation, preparing the MOSFET through the routine CMOS technology. The preparation method providing the SON type metal-oxide semiconductor field transistor can generate the air bubble with higher density due to the low dose Ne iron injection, adopts the low temperature with different energy to form two layers of air bubble belts, which combines to be the high relative density monolayer inanition after high temperature anneal, thereby forming the ultra-shallow junction SON structure with the heat emission channel with simple technology and low cost. Most steps are completed by the routine CMOS technology, which is convenient for the large scale integrated circuit industrial production and reduced in the production cost.

Owner:汉摩尼(江苏)光电科技有限公司

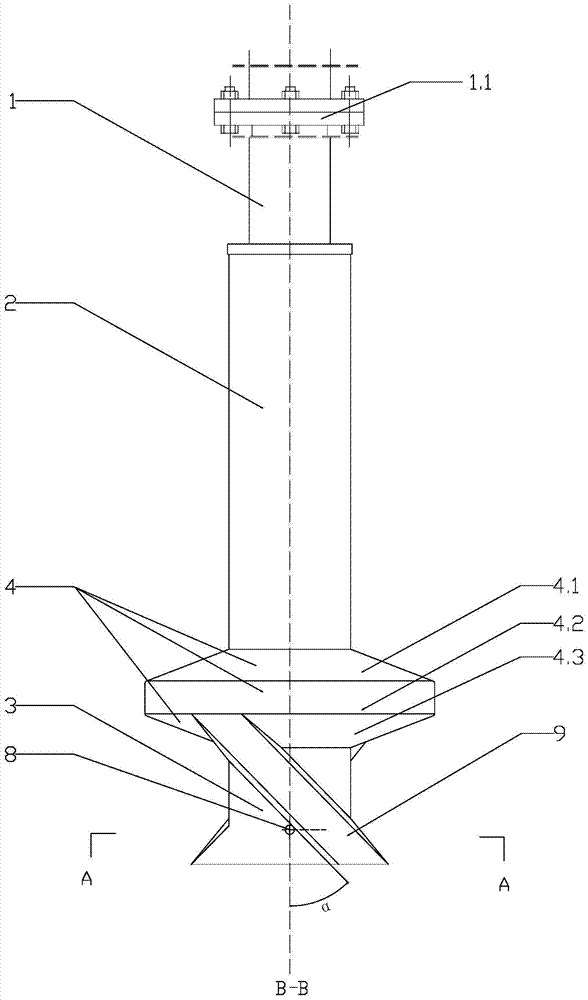

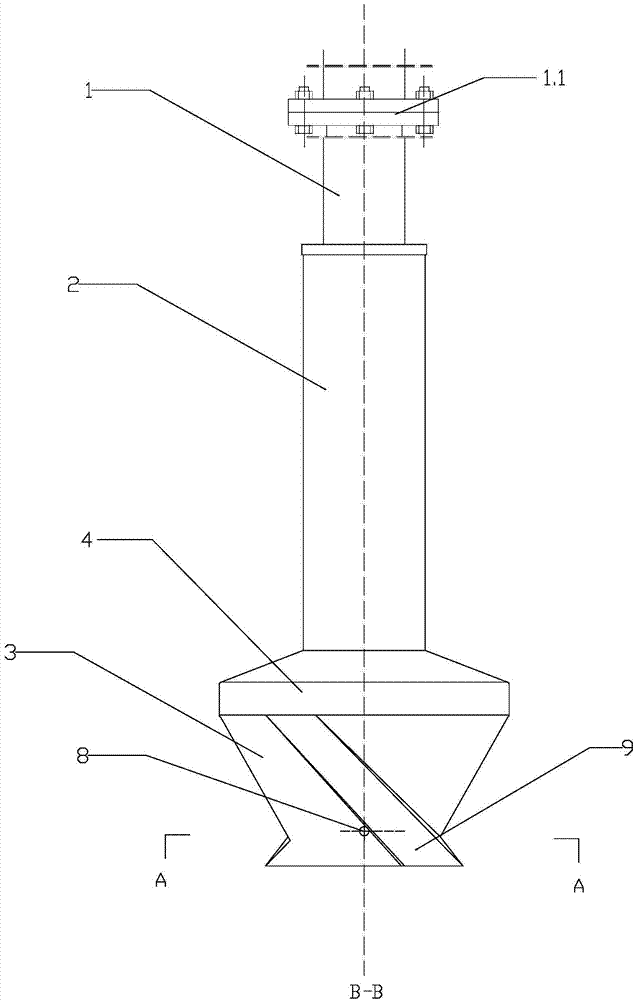

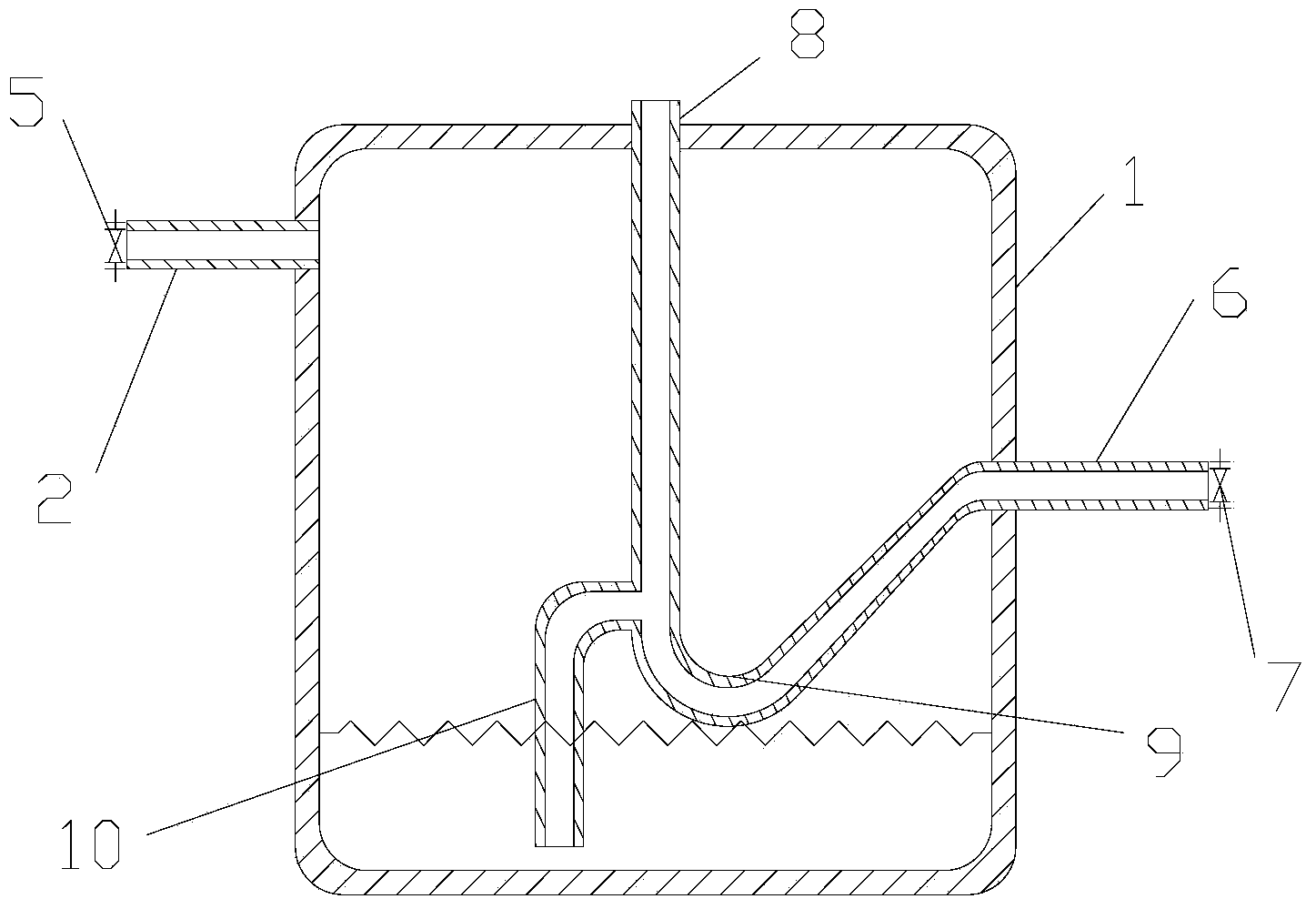

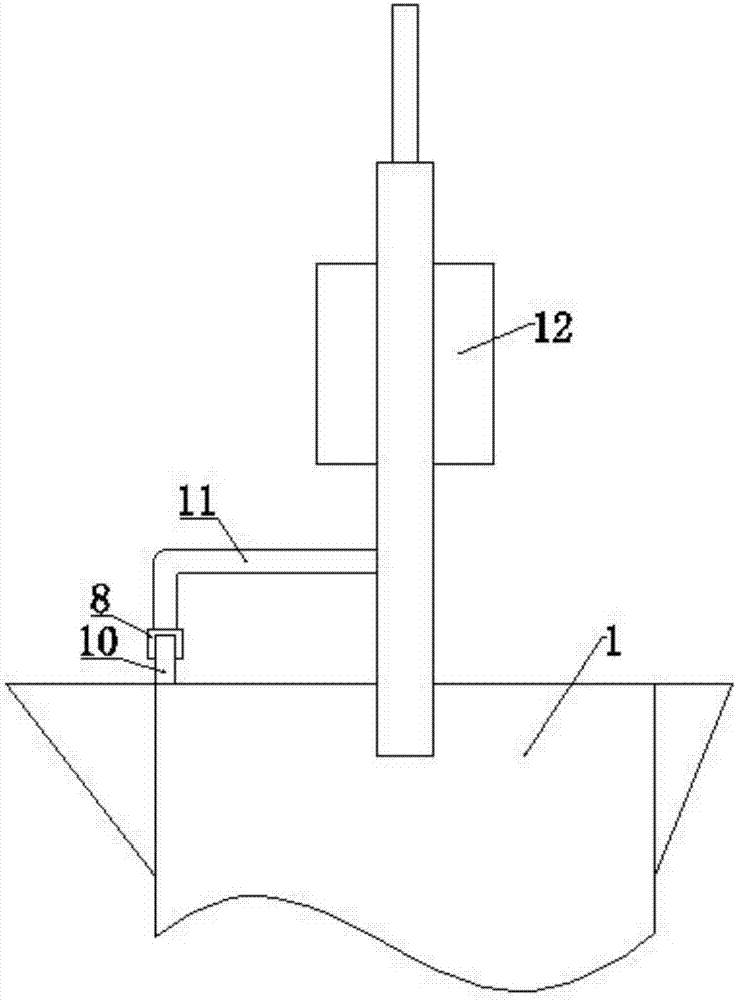

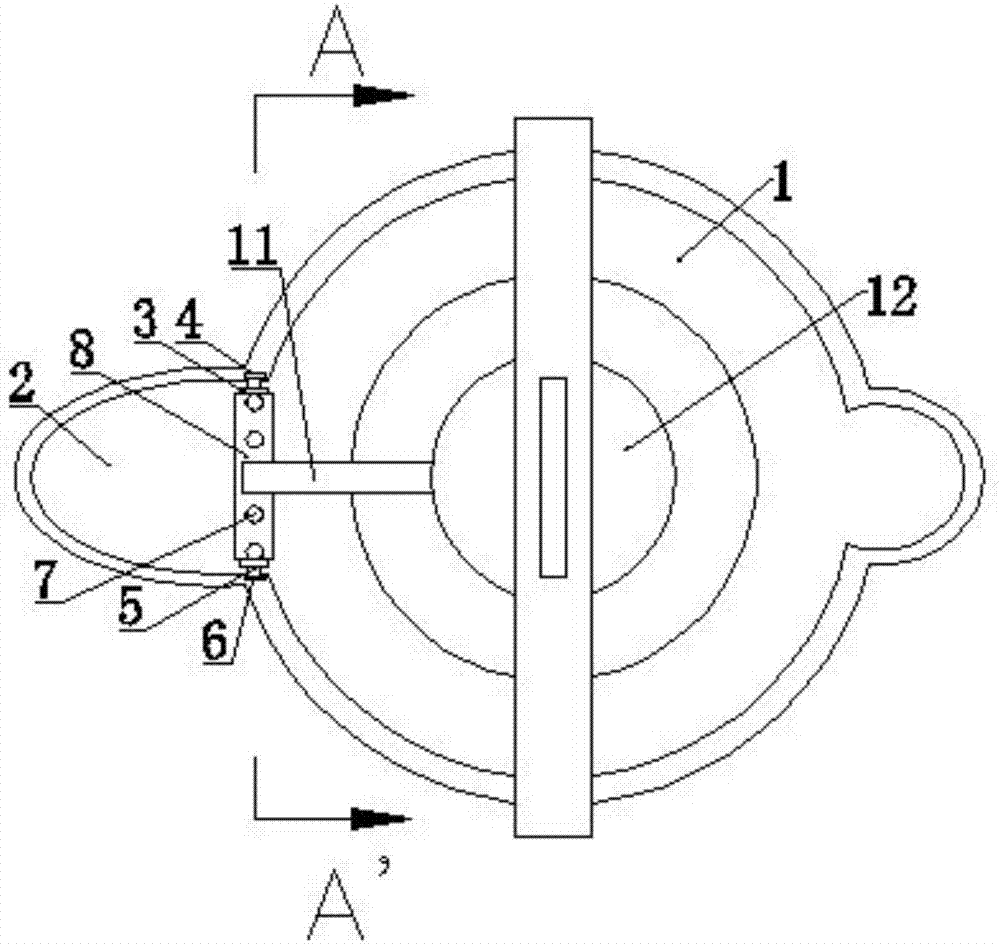

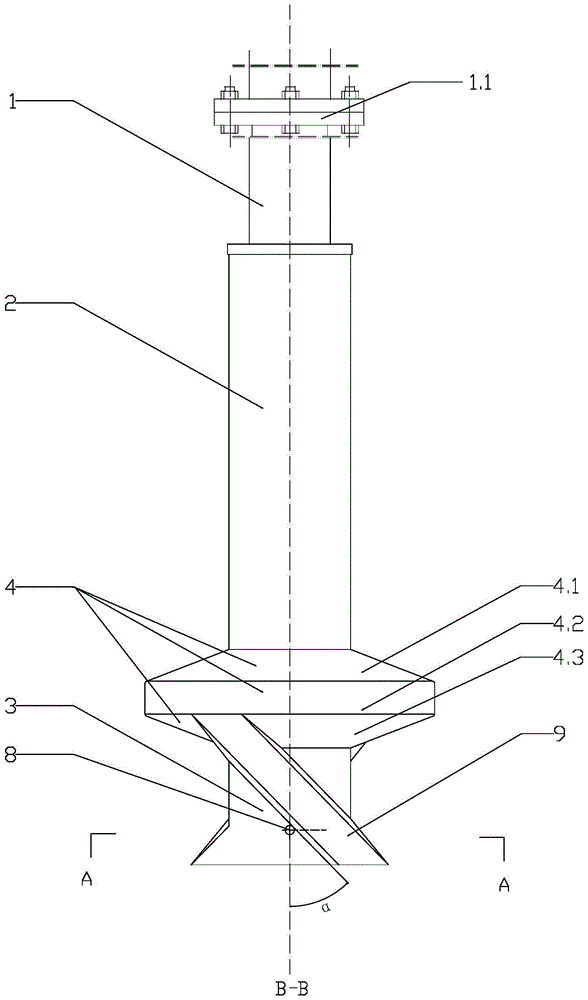

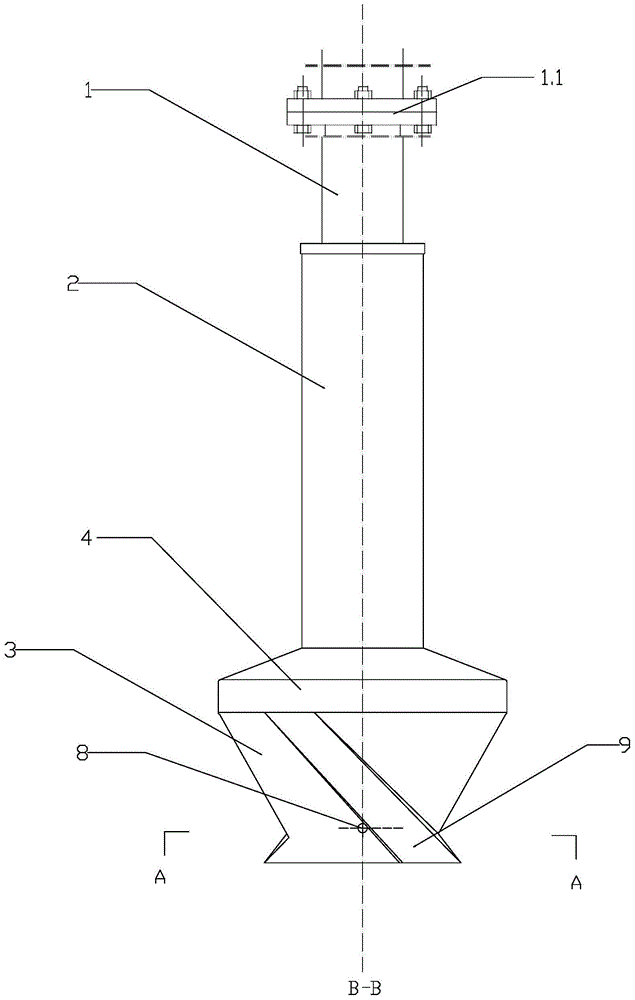

High-performance spray gun for molten iron injection pretreatment

The invention discloses a high-performance spray gun for molten iron injection pretreatment. The high-performance spray gun comprises a connection segment, a gun body segment and an injection segment, which are sequentially communicated, wherein a swirling diffuser is arranged between the gun body segment and the injection segment and comprises an upper cone, a cylinder and a lower reversed cone, which are sequentially communicated; 2-4 nozzles are uniformly formed between a main pipe of the spray gun and a seal head in the circumferential direction of the spray gun and positioned in the side wall of the injection segment; swirling pieces obliquely arranged on the outer wall from the top end of the lower reversed cone to the bottom end surface of the injection segment and positioned above the nozzles. By strengthening three key kinetic parameters of molten iron injection pretreatment, the spray gun significantly improves the kinetic conditions of molten iron injection pretreatment and achieves the comprehensive purposes of improving the sulfur removal efficiency of injection pretreatment and the utilization rate of desulfurizer reaction, shortening the injection time and increasing the production capacity of desulfurization equipment.

Owner:武汉钢铁有限公司

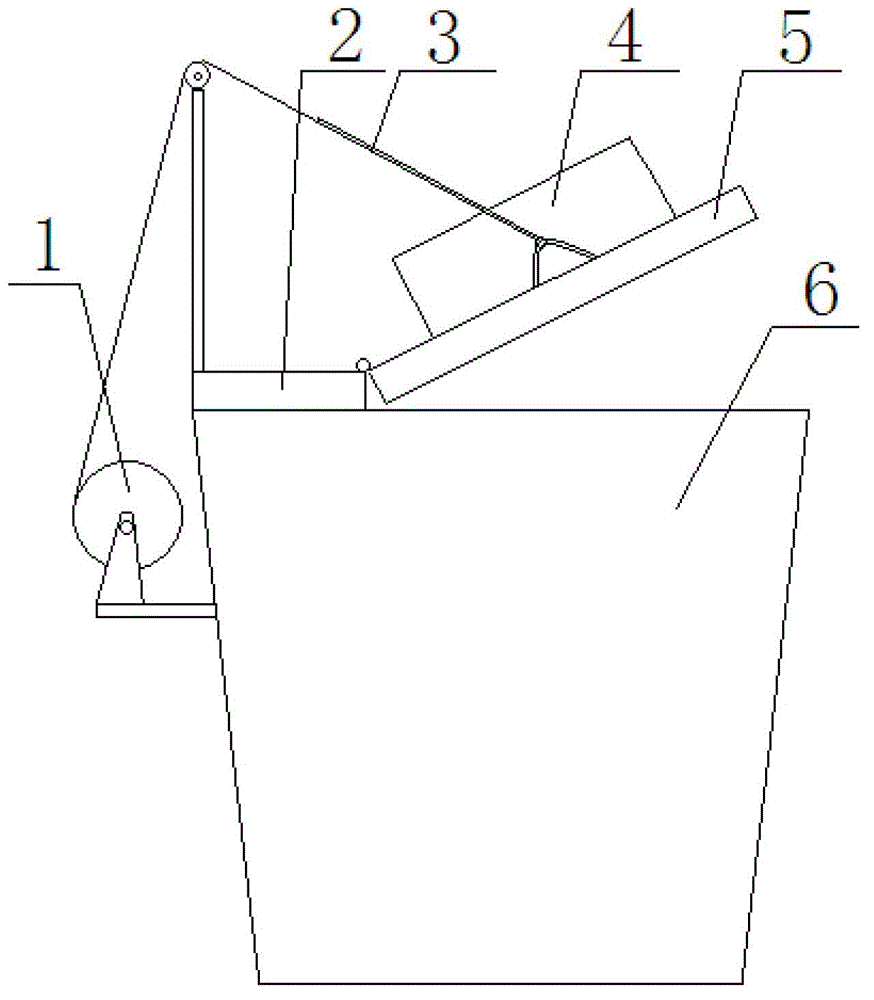

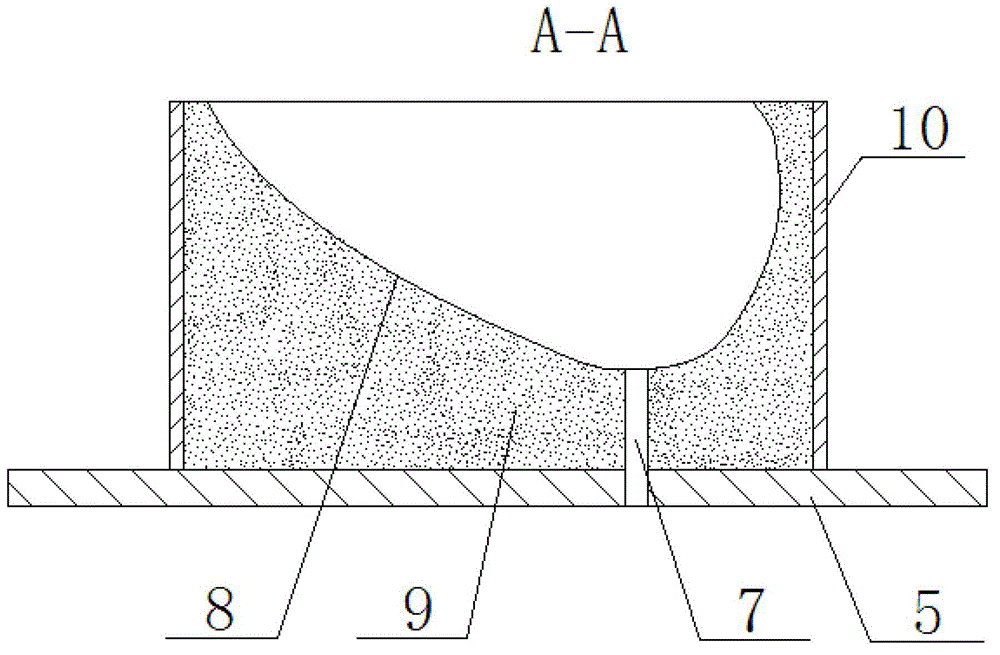

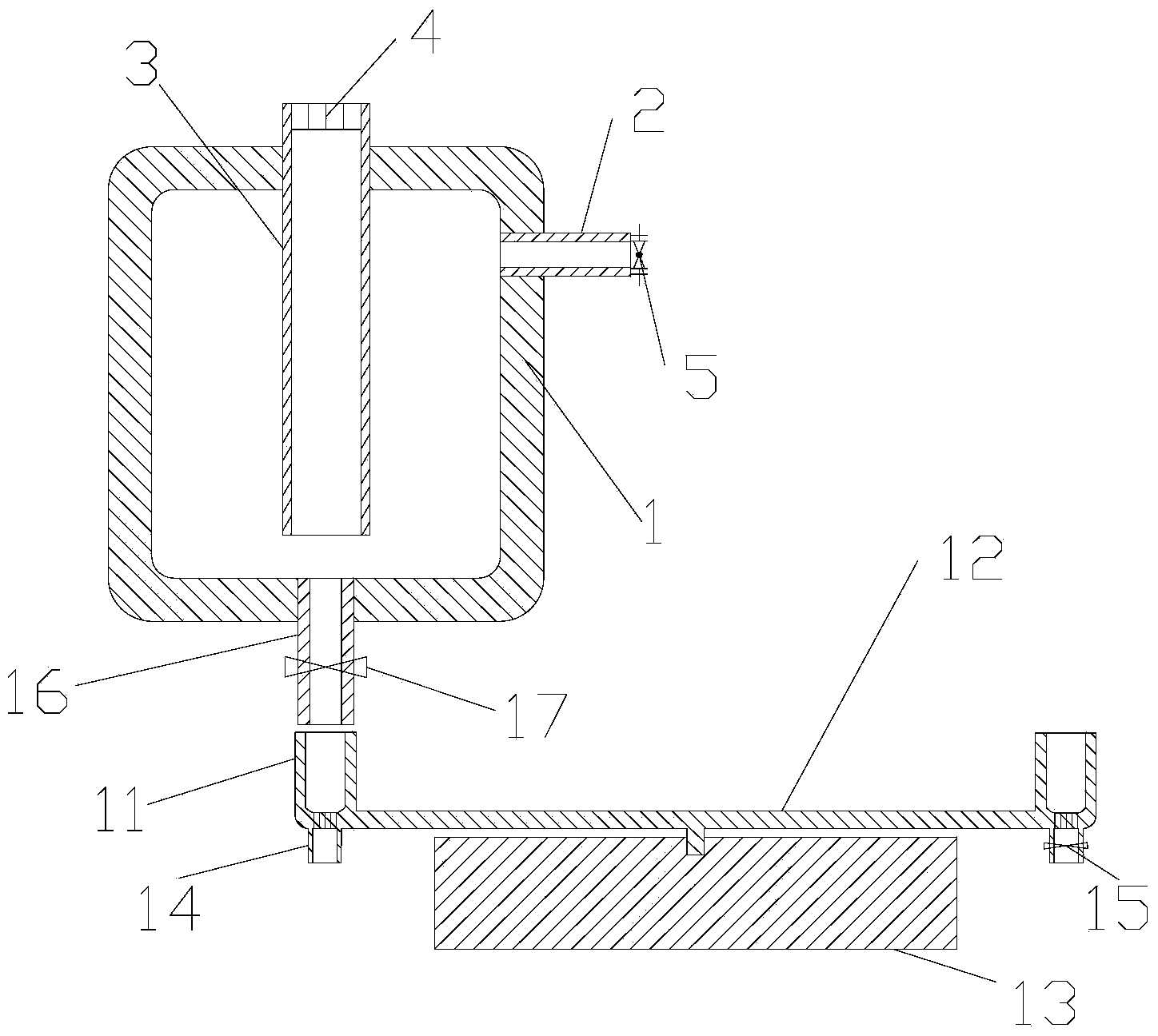

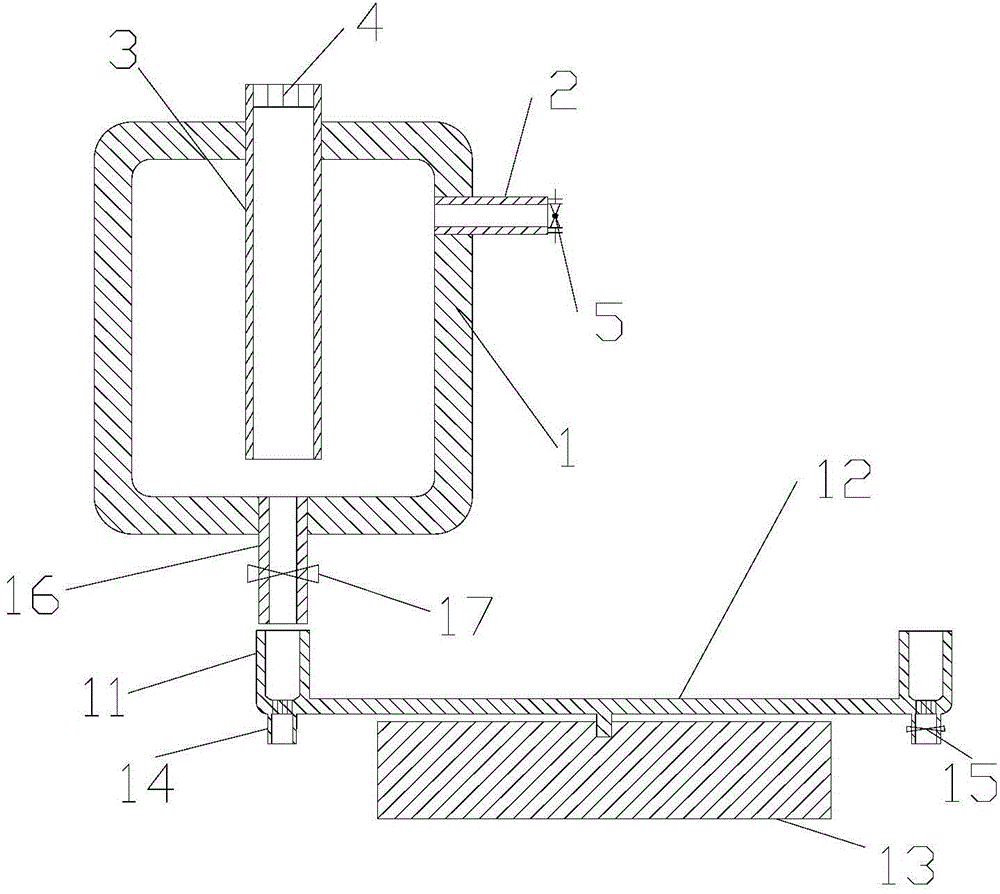

Turnover type balling ladle cover

The invention provides a turnover type balling ladle cover, and belongs to the technical field of casting. The turnover type balling ladle cover is mainly used for solving the problems that when integral movement is carried out on a large balling ladle cover in the prior art, time and labor are consumed, and popularization and application of the large balling ladle cover are influenced. The turnover type balling ladle cover comprises a ladle body and a turnover type ladle cover body, wherein the turnover type ladle cover body is composed of a fixed cover and a movable cover. The turnover type balling ladle cover is characterized in that the movable cover is hinged to the fixed cover, a lifting handle is arranged on the edge of the movable cover, the lifting handle is connected with a winch through a rope, the winch is arranged on the outer wall of the ladle body, a drainage device is arranged on the movable cover, the drainage device comprises an outer shell and a drainage device body which is made of hard fireproof materials, the drainage device body is provided with a circular-arc-shaped groove, a ramp is arranged on a center section structure of the circular-arc-shaped groove in the circular-arc direction, the two ends of the circular-arc-shaped groove are of a circular-arc shape, the transverse section of the drainage device is a parabola or a circular arc or an elliptic arc, an opening of the parabola or an opening of the circular arc or an opening of the elliptic arc is upward, and a melted iron injection opening is formed in the bottom of the ramp.

Owner:QUWO COUNTY CIVIL AFFAIRS & WELFARE ENTERPRISES

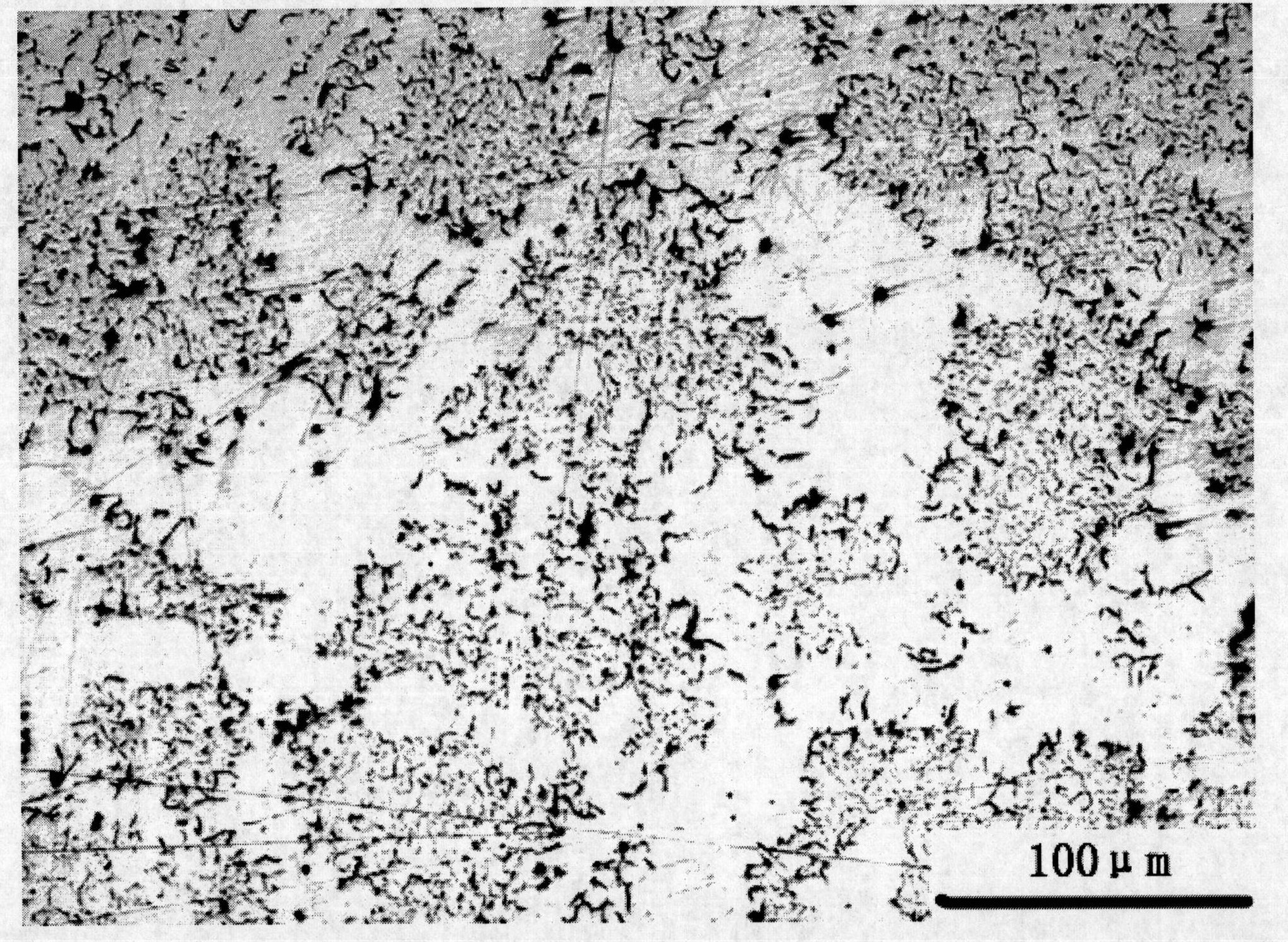

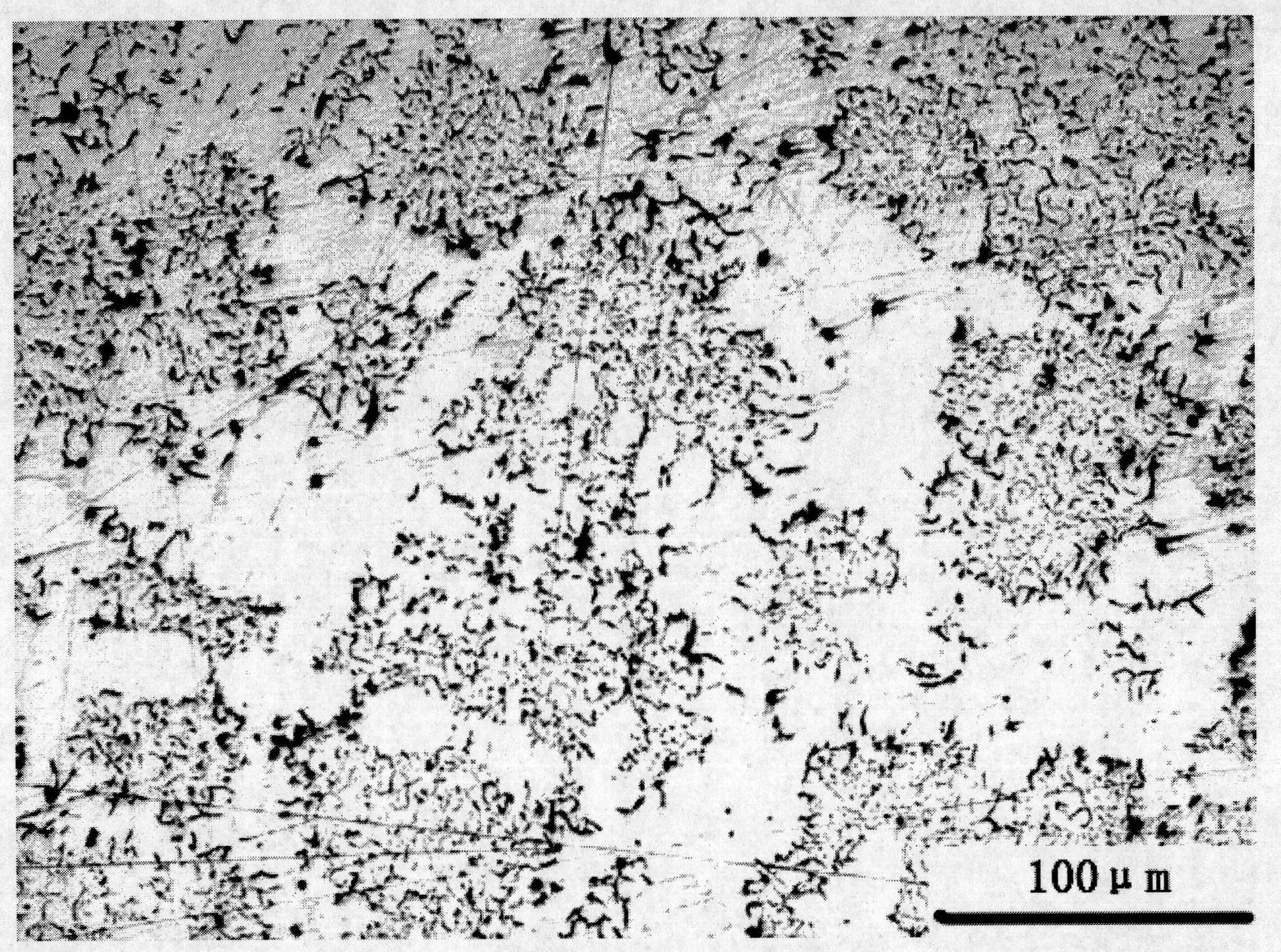

Compound inoculant used for producing D-type graphite cast iron and preparation method thereof

The invention discloses a compound inoculant used for producing D-type graphite cast iron, which is characterized in that the weight percents of the constituents are as follows: magnesium 1.0-4.0, rare earth 4.0-8.0, titanium 4.0-9.0, aluminum 1.5-3.0, stibium 0.5-2.0, calcium 2.0-5.0, barium 1.0-4.0, silicon 35-50 and the balance of iron. When the compound inoculant is employed to carry out inoculation on the melted iron with high carbon equivalent, the obtained graphite in the cast iron is the D-type graphite. The mechanical properties of castings are high, the tensile strength reaches over250MPa and the compactness is good. The melted iron has high carbon equivalent, thus greatly improving the casting properties of alloys, reducing the residual stress of the castings, contributing to good size stability and enhancing the machinability of the castings. The multiple compound inoculant adopts ladle bottom pouring process, namely, the compound inoculant is placed on the bottom of a ladle, then the melted iron is injected and the compound inoculant is continuously melted and absorbed in the process of melted iron injection, thereby reaching the satisfactory inoculation effect, therefore, the method is simple and the use is convenient.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

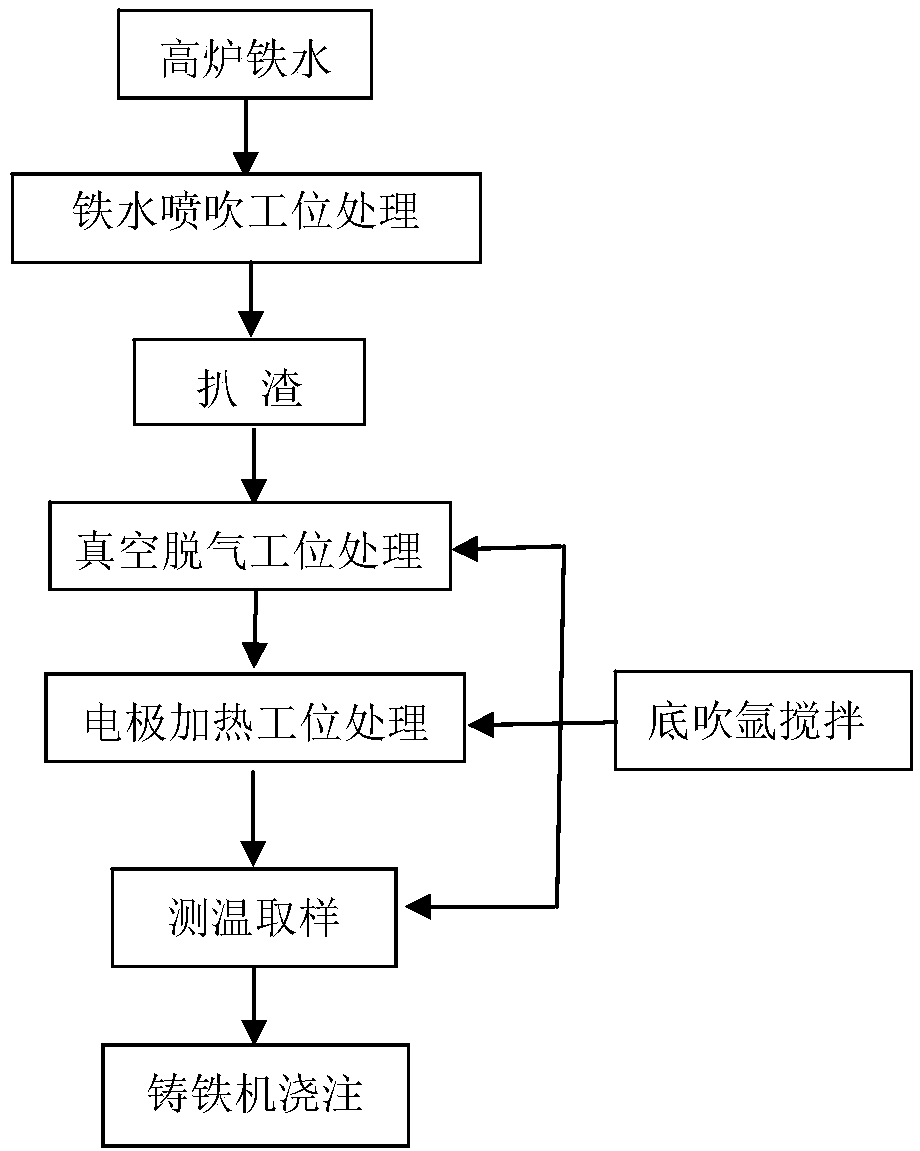

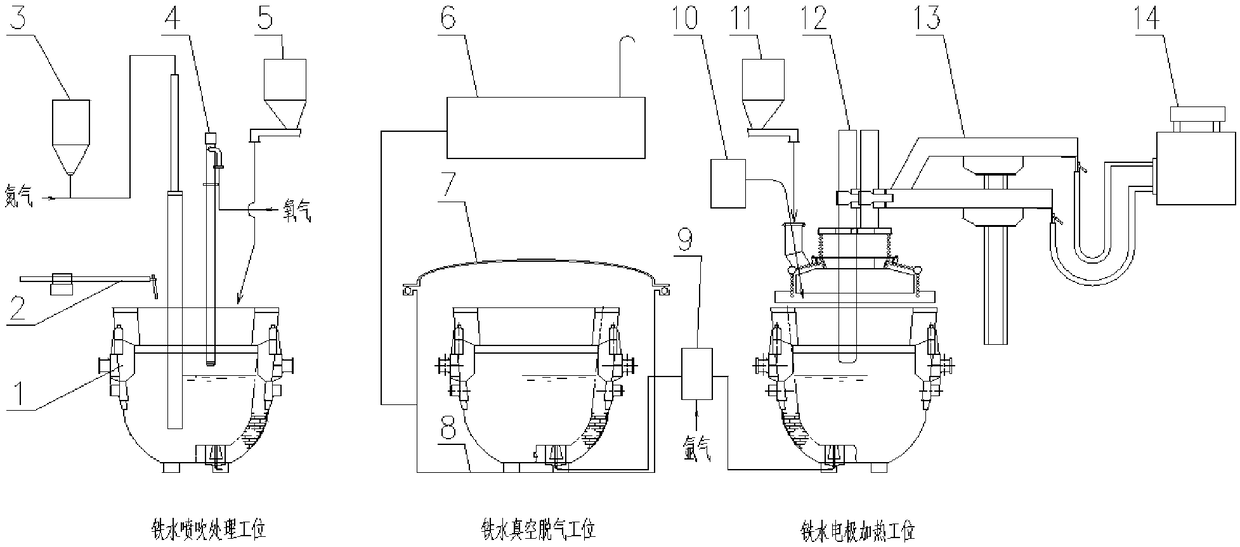

Process for producing high purity pig iron by molten iron injection, vacuum degassing and electrode heating

The invention relates to a process for producing high purity pig iron by molten iron injection, vacuum degassing and electrode heating, and belongs to the technical field of high purity pig iron casting. The purpose of desulfurization, dephosphorization, manganese removal and titanium removal of molten iron is achieved by injecting of a desulfurization and dephosphorization agent into the molten iron through an injection system, adding of an oxidizer and a manganese removal agent through a top feeding system, and oxygen blowing through a oxygen blower at an appropriate injection speed, feedingspeed, oxygen blowing quantity and oxygen blowing speed. Residual gas impurities and oxygen in the molten iron are removed by the vacuum degassing principle to ensure the compactness of a finished product; silicon, calcium and other deoxidizers are used to remove the residual oxygen in the molten iron to ensure the apparent quality of the finished product; and an electrode heating technology is used to increase the temperature after treatment of the molten iron, and higher than 1450 DEG C of pouring temperature of cast iron can be ensured. The advantages lie in further improving the purity ofthe molten iron and ensuring the internal quality of the finished product. The process has a good application prospect in the production of high purity pig iron for high-end casting.

Owner:BEIJING SHOUGANG INT ENG TECH

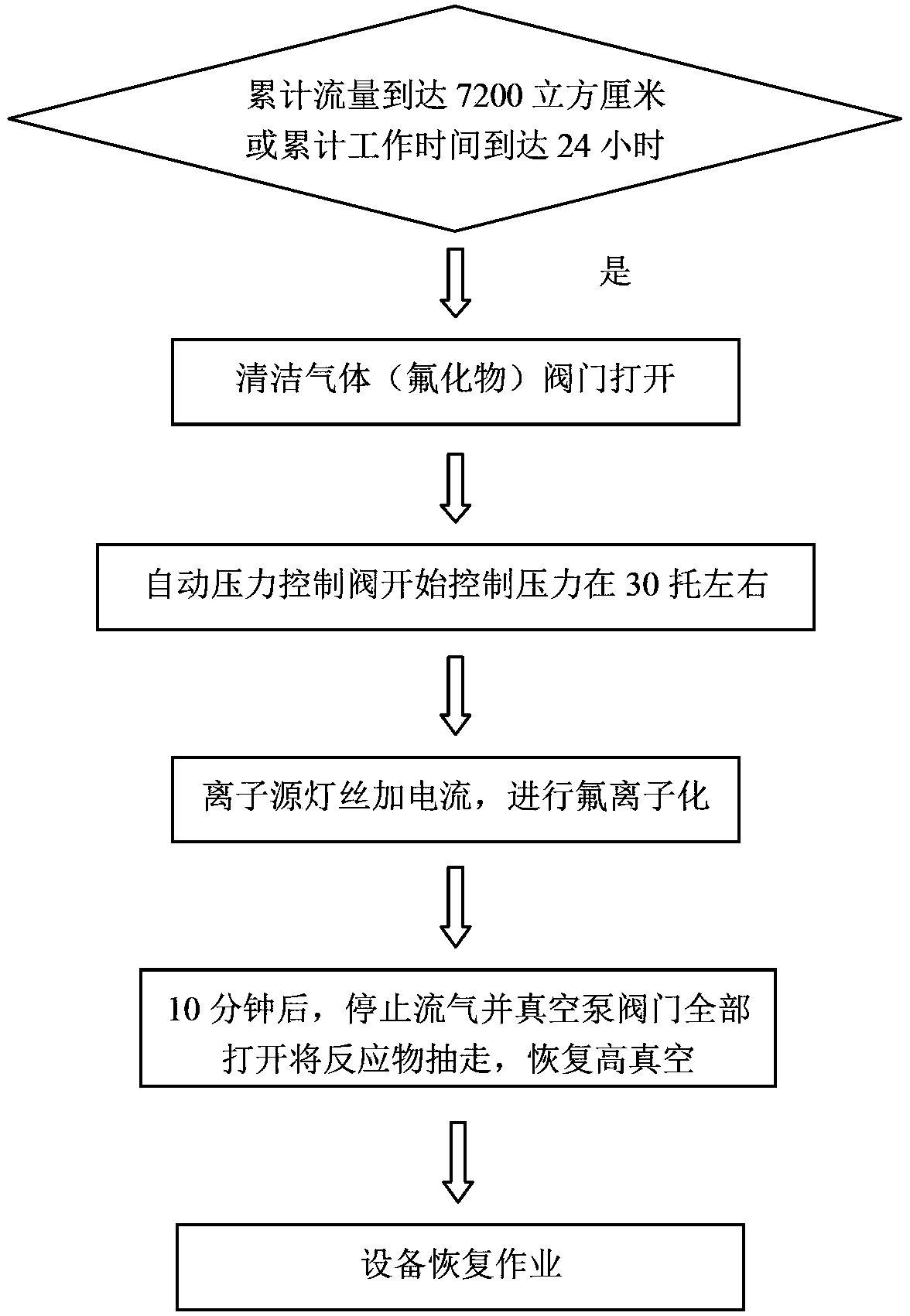

Method for improving service life of parts through ion chamber automatic cleaning through ion injection device

InactiveCN103785647AExtended service lifeExtended working hoursCleaning processes and apparatusChemical reactionMachine utilization

The invention discloses a method for improving the service life of parts through ion chamber automatic cleaning through an ion injection device. The method comprises step 1, guiding the fluoride gas serving as the cleaning gas into an iron injection chamber; step 2, controlling the chamber pressure during reaction to maintain sufficient plasmas; step 3, performing heating and fluorine ionization through ion source lamp filaments and performing the chemical reaction on ion injection doped residual materials which are accumulated in fluorine ions and the ion injection chamber; step 4, removing the reactant gas after the reaction through a vacuum pump. According to the method for improving the service life of the parts through the ion chamber automatic cleaning through the ion injection device, the fluorine ions are guided in to be reacted with the residual materials to achieve the automatic cleaning effect and accordingly the machine utilization rate can be increased, the cost can be saved, and the machine granular level can be reduced.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

Iron openwork beating device

The invention relates to the field of mechanical equipment, in particular to an iron openwork beating device. The iron openwork beating device comprises a smelter, a first molten iron injection pipe and a first high-pressure air inlet pipe. Pig iron materials in the smelter is heated to be in a molten state through the smelter, and the first high-pressure air inlet pipe is communicated with the smelter so that high-pressure air can be provided to the interior of the smelter. The first molten iron injection pipe is communicated with molten iron in the smelter, a first control valve arranged on the first high-pressure air inlet pipe is opened, the molten iron is ejected upwards through the top end of the first molten iron injection pipe under the thrust of the high-pressure air, and splendid iron openwork is formed.

Owner:马季元 +1

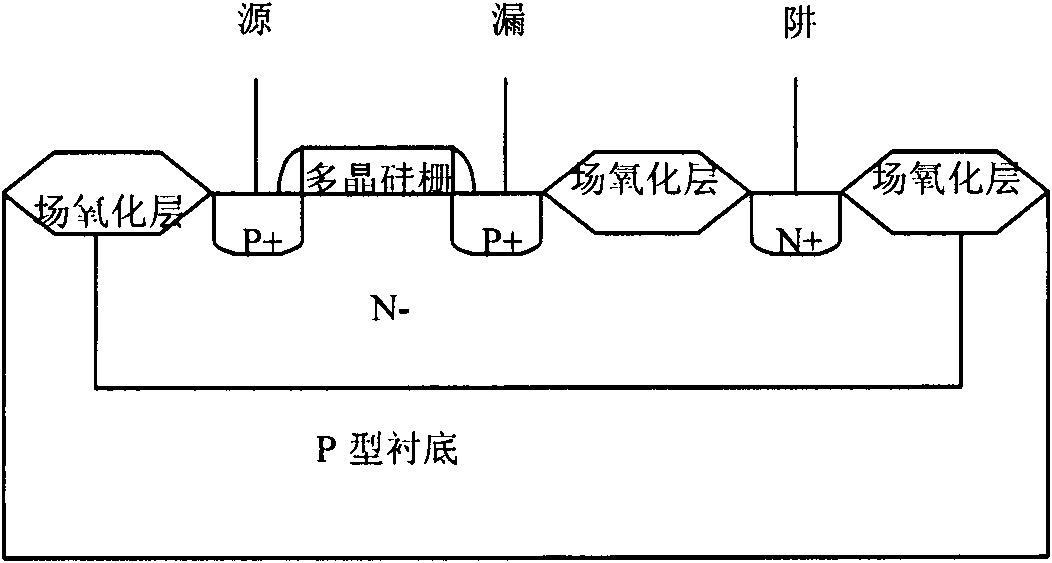

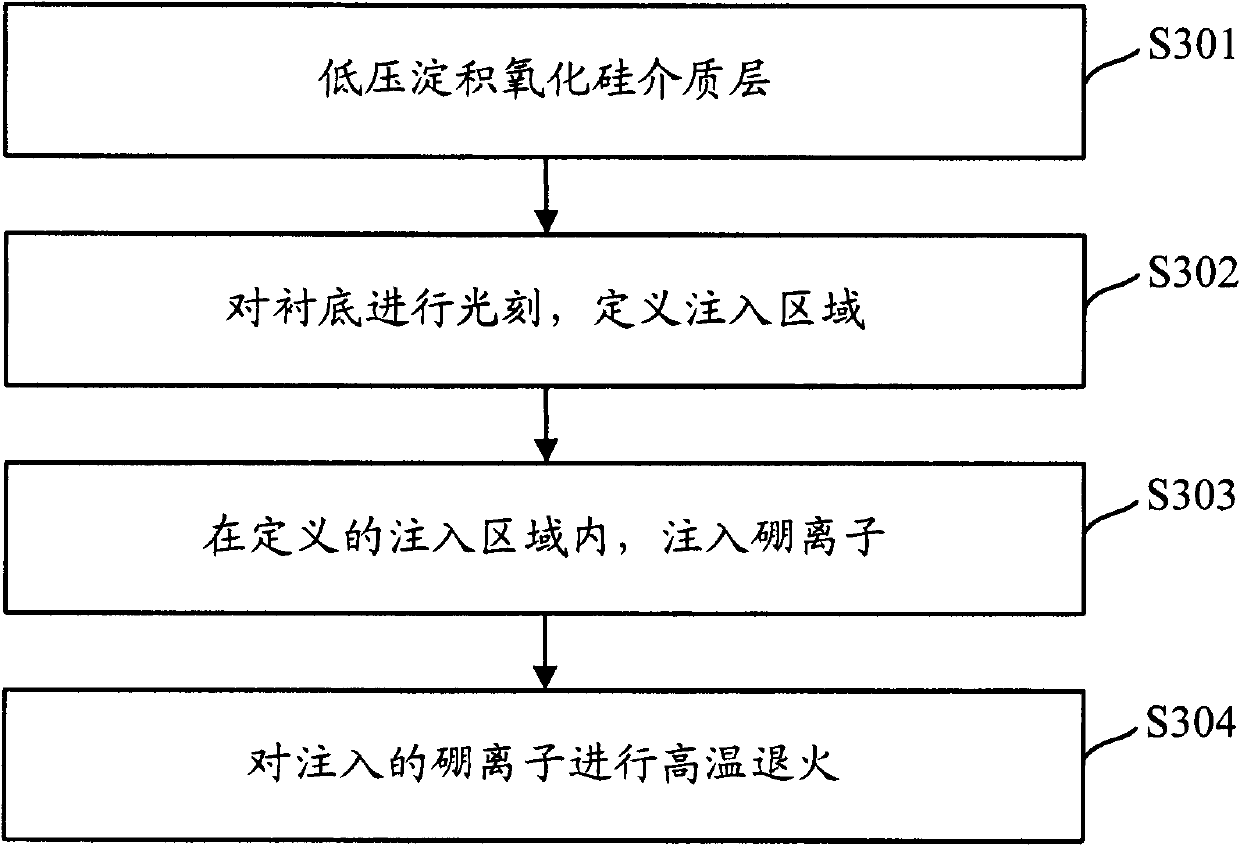

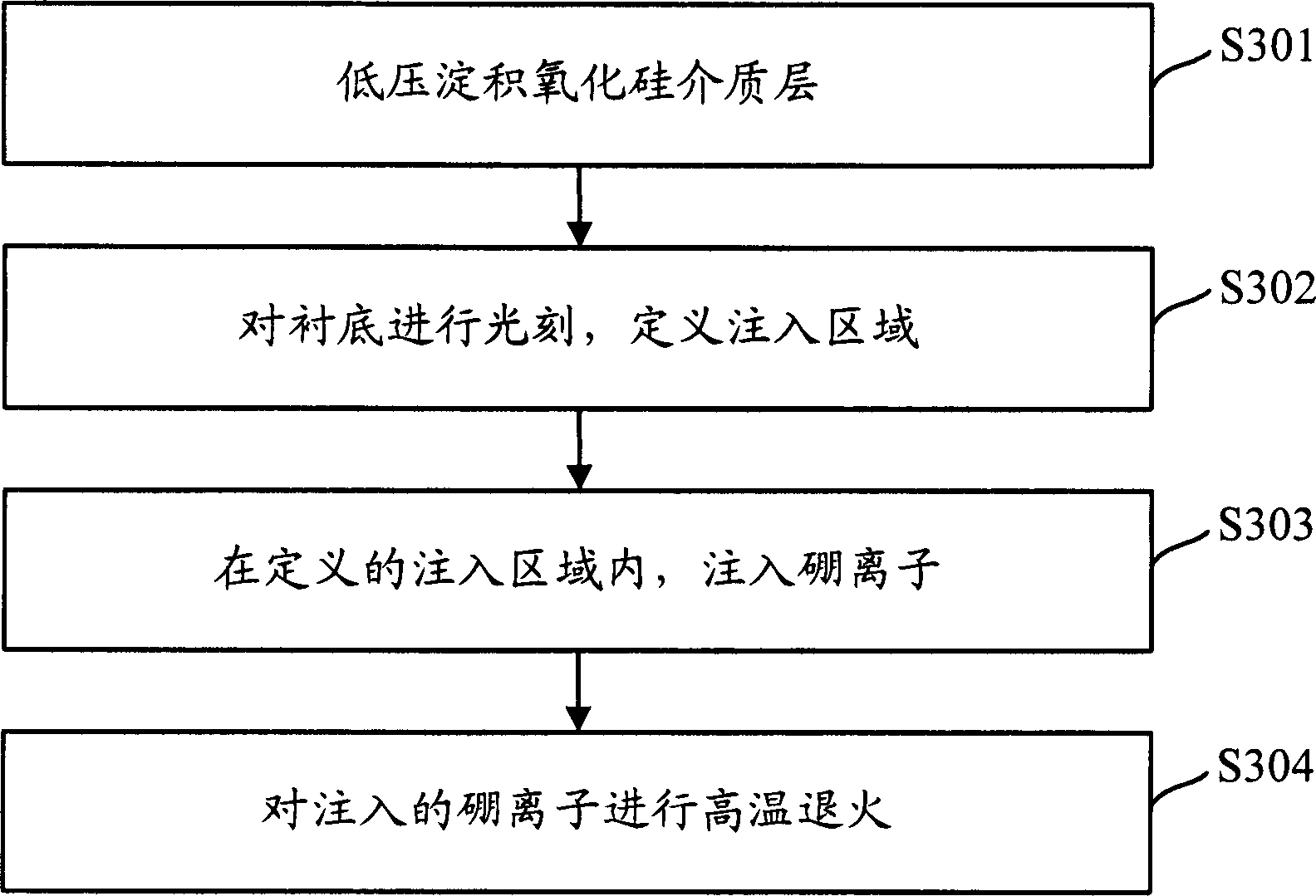

P-type high-concentration doped silicon and technology for preparing P-channel MOS (Metal Oxide Semiconductor) pipe of BCD (Bipolar, Complementary Metal-Oxide-Semiconductor and Double-Diffusion Metal-Oxide-Semiconductor) products

ActiveCN102569084AImpact mitigationReduce impactSemiconductor/solid-state device manufacturingHigh concentrationDouble diffusion

The invention discloses P-type high-concentration doped silicon and a technology for preparing a P-channel MOS (Metal Oxide Semiconductor) pipe of a BCD (Bipolar, Complementary Metal-Oxide-Semiconductor and Double-Diffusion Metal-Oxide-Semiconductor ) products, aiming at solving the problem of electricity leakage resulting from a lattice defect of the P-type high-concentration doped silicon manufactured with the prior art. A realization method of the technology of the P-type high-concentration doped silicon comprises the steps of conducting low-pressure deposition to form a silicon oxide dielectric layer, photoetching a substrate, defining an injection area, injecting boron ions in the defined injection area and conducting high-temperature annealing on the injected boron ions. According to the embodiment of the invention, before the P-type high-concentration doped silicon is prepared, the impact of the injection of the boron ions onto the surface of the silicon can be relieved by the low pressure deposition of the silicon oxide dielectric layer; the boron ions are injected when iron injection is conducted; as the molecular weight of the boron ions is smaller, the injected energy is smaller and the impact to the surface of the silicon is reduced; and in addition, as the injected impurities do not contain fluorine atoms, the defect problems caused by the fluorine atoms are avoided, and thus, the risk of generating the lattice defect is reduced and the probability of electricity leakage is lowered.

Owner:FOUNDER MICROELECTRONICS INT

Anti-corrosion treatment method for neodymium iron boron ferrite

InactiveCN106637122AImprove corrosion resistanceWon't fall offVacuum evaporation coatingSputtering coatingSurface cleaningIron injection

The invention relates to an anti-corrosion treatment method for neodymium iron boron ferrite. The anti-corrosion treatment method comprises the following steps: pretreatment: removing oil from the neodymium iron boron ferrite, and performing bright dipping, bleaching, activating, re-bleaching and the like in order to keep the outer surface of the neodymium iron boron ferrite clean and smooth; injecting tin and an anti-corrosion material into the surface of the neodymium iron boron ferrite by an iron injection way; forming a metal oxide layer or a clad layer or an anti-corrosion layer on the surface of the neodymium iron boron ferrite.

Owner:薛亚红

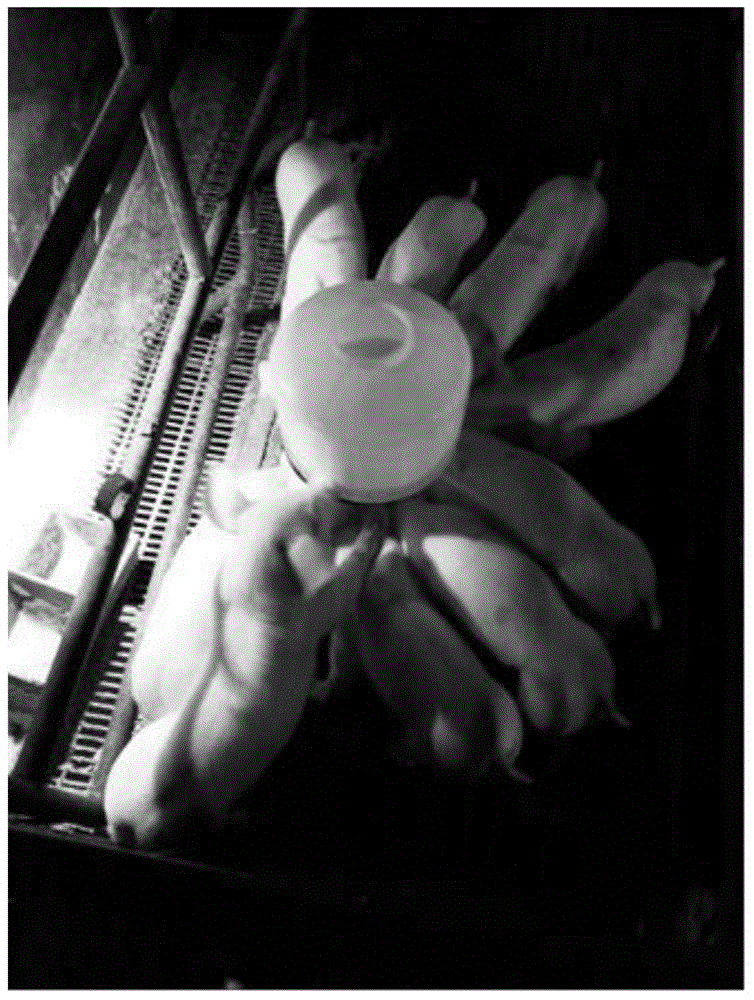

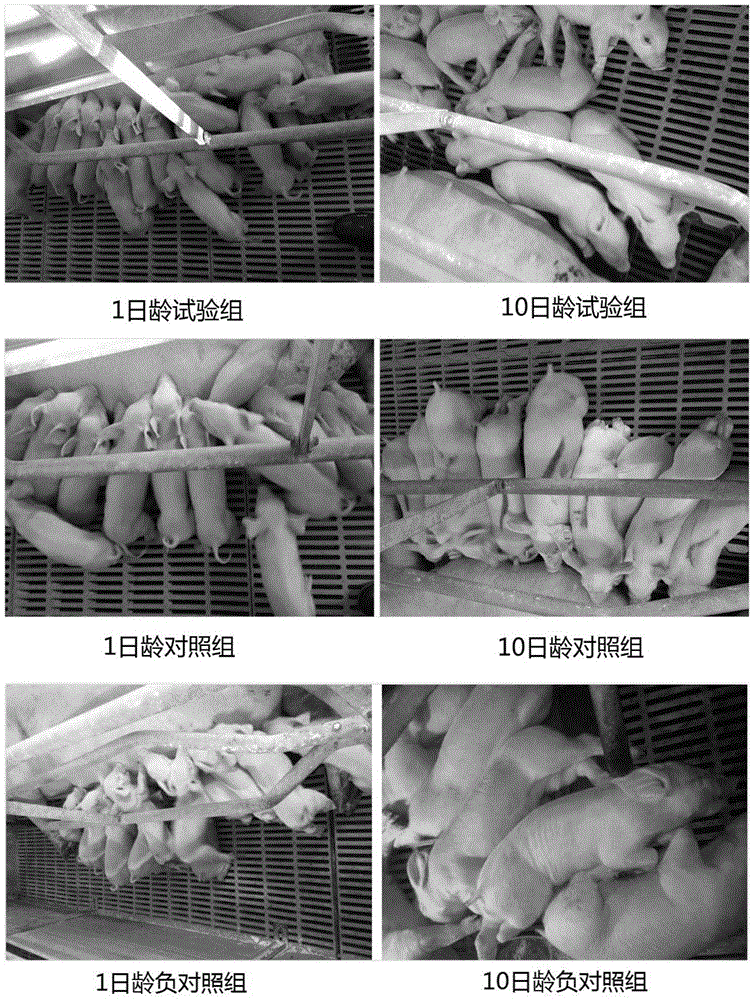

Iron supplementing method for piglets

The invention discloses an iron supplementing method for piglets. The iron supplementing method for the piglets comprises the steps that 1, 320-480 g / ton of iron supplementing compositions are added into basic ration of sows during one month before parturition of the sows and two to four weeks after parturition of the sows; 2, two-time water feeding and iron supplementation are conducted on the piglets when the piglets are 8-21 days old, the iron supplementing compositions are solved in water according to the proportion of 3.2-4.8 g / L, and the dissolved solution is fed to the piglets according to the 150-300 mL amount for each piglet, wherein the iron supplementing compositions consist of porphyrin iron and flavones. According to the iron supplementing method for the piglets, direct and indirect iron supplementing modes are combined, so that newly born piglets subjected to iron supplementation have no stress, labors are decreased, and cross infection is not caused. For the piglets fed by means of the iron supplementing method, the proportion of living born piglets, mean weight of the newly born piglets, the living piglet proportion of weaned piglets, the hemoglobin concentration of the newly born piglets and the hemoglobin concentration of the weaned piglets are all higher than those of a control group taking iron injections.

Owner:广东驱动力生物科技集团股份有限公司

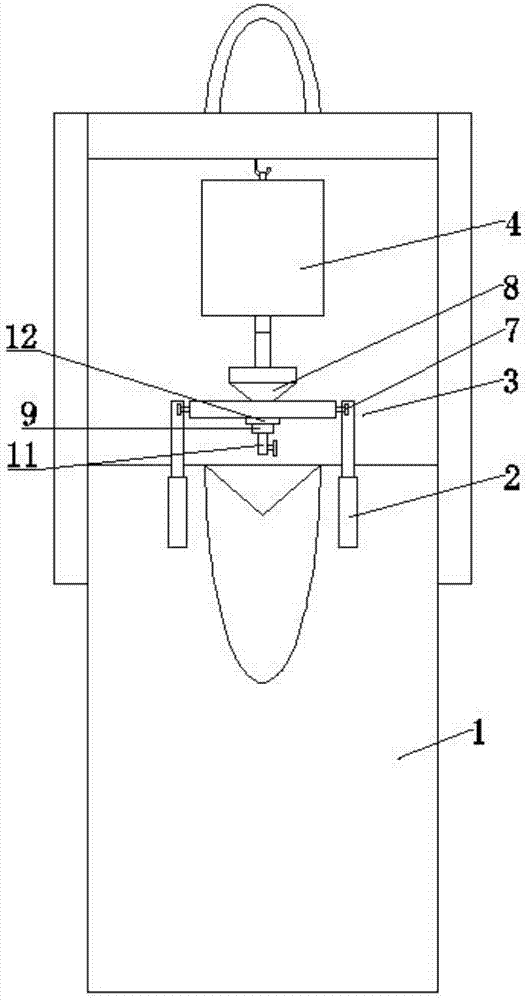

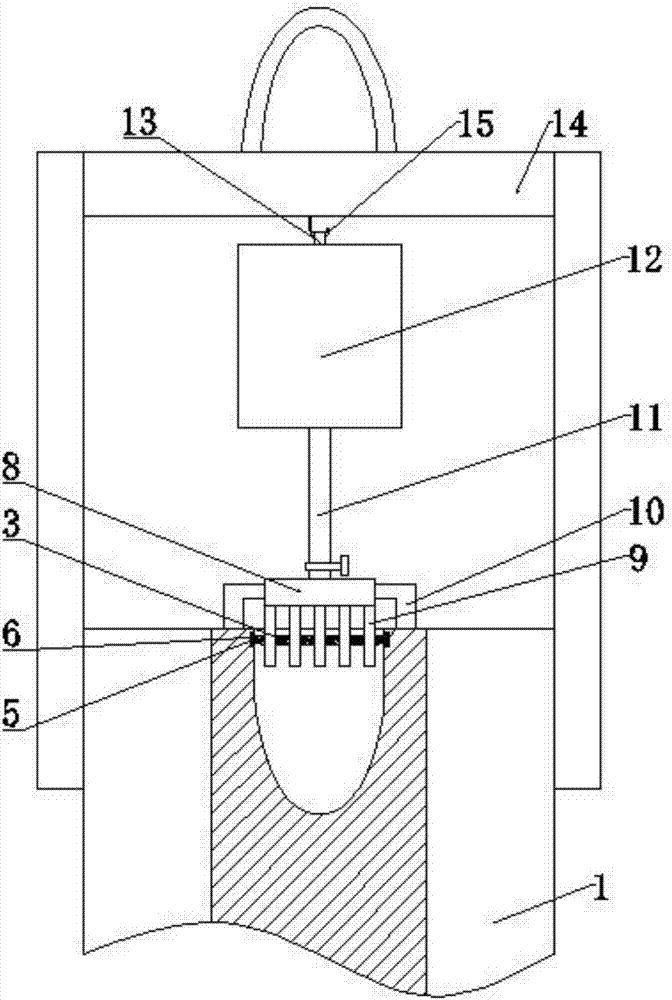

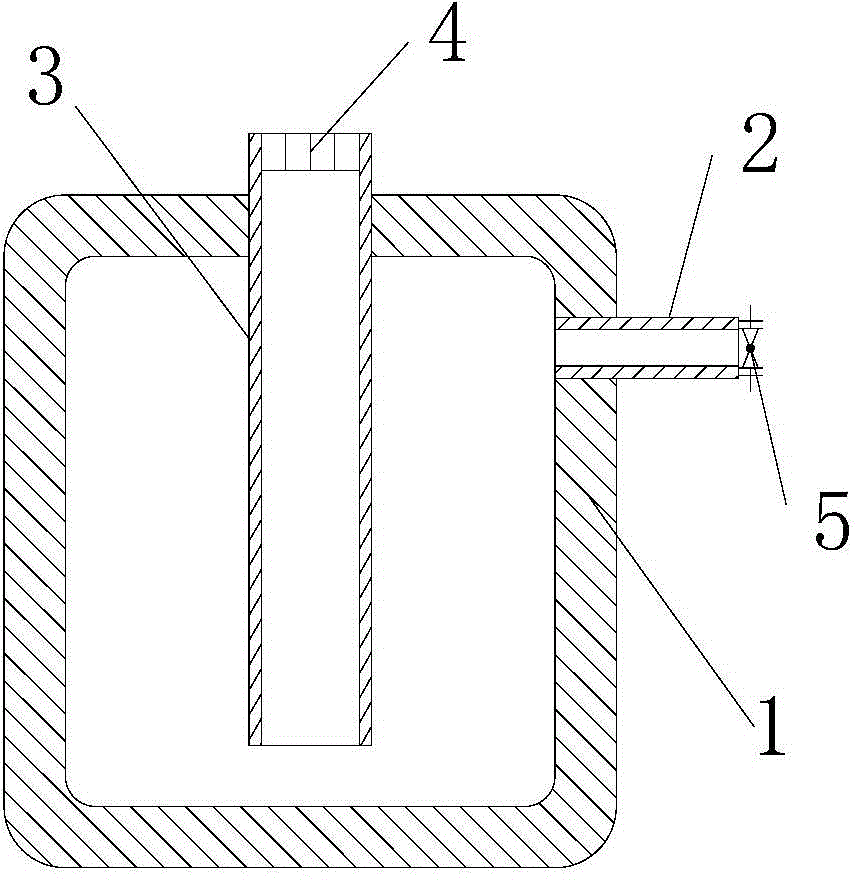

High-end casting following nucleating agent injection device

InactiveCN107498007AImprove the breeding effectEasy to assemble and disassembleMelt-holding vesselsIron injectionInjection device

The invention relates to the technical field of high-end castings, and provides a high-end casting following nucleating agent injection device. The high-end casting following nucleating agent injection device comprises a casting ladle, fixing casing pipes are arranged on the two sides of a molten iron injection nozzle of the casing ladle, and a nucleating agent injection device body is arranged above the fixing casing pipes and comprises an inserting support and a nucleating agent storage tank; the inserting support comprises inserting rods and a transverse plate, and the inserting rods are inserted in the fixing casing pipes; the two ends of the transverse plate are connected with cylinder fixing bodies through connecting shafts; the upper ends of the opposite inner surfaces of the inserting rods are provided with rotation grooves matched with the cylinder fixing bodies, and bearings are arranged at the connecting positions of the connecting shafts and the inserting rods; an installing hole is formed in the center position of the transverse plate and internally provided with a material injection funnel, and a material outlet pipe at the lower end of the material injection funnel penetrates out of the installing hole; and a discharging pipe is arranged on the bottom face of the nucleating agent storage tank, and the other end of the discharging pipe is inserted in the material injection funnel. By means of the high-end casting following nucleating agent injection device, uniform nucleating agent injection is achieved, the flow speed is controllable, dismounting and mounting are convenient, and usage is convenient.

Owner:NINGGUO SOUTHERN WEAR RESISTANT MATERIALS

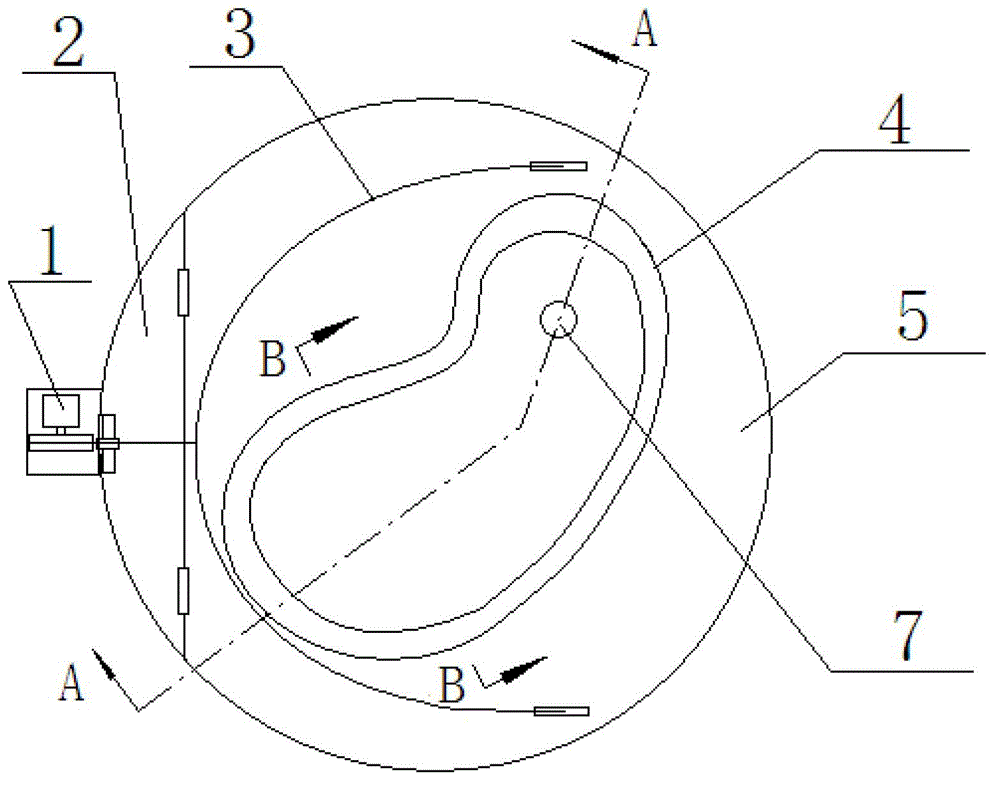

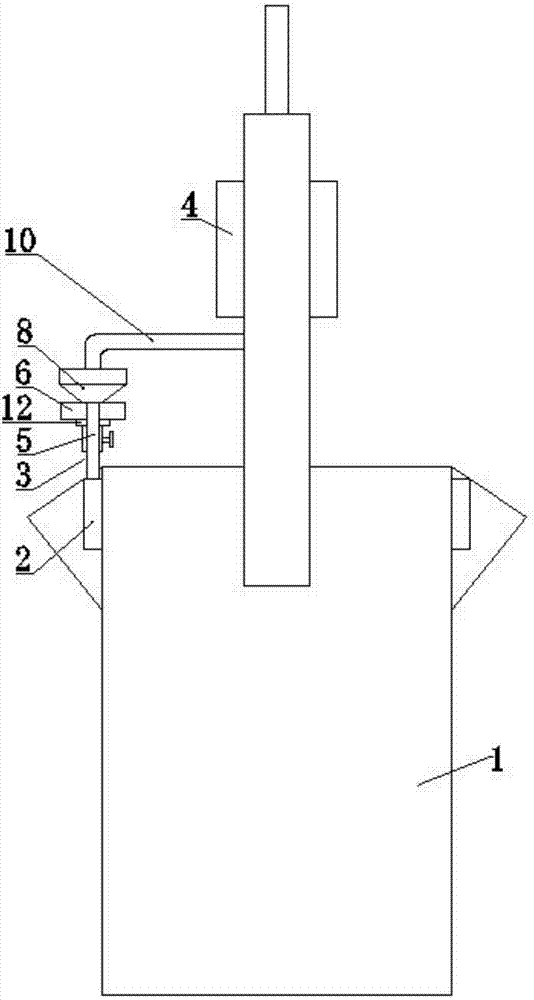

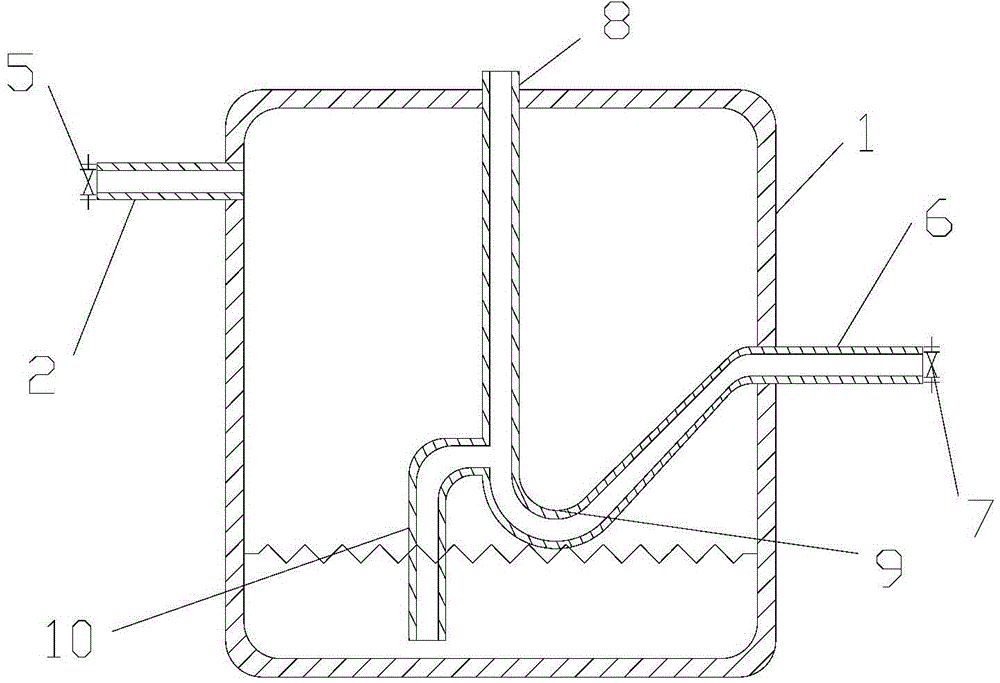

High-end casting uniform injection nucleating agent device

The invention relates to the technical field of high-end castings, and provides a high-end casting uniform injection nucleating agent device. The high-end casting uniform injection nucleating agent device comprises a molten iron ladle, a shunting plate is arranged at a molten iron injection inlet of the molten iron ladle, and T-shaped grooves are formed in the side wall of the molten iron injection inlet; the two ends of the shunting plate are connected with a circular clamping plate through connecting shafts, and shunting holes are formed in the shunting plate at equal intervals; a shunting box is arranged above the shunting plate, shunting pipes are arranged on the bottom surface of the shunting box, and the shunting pipes are inserted into the shunting holes; the two ends of the shunting box are fixedly connected with the upper end surface of the molten iron injection inlet through L-shaped connecting rods, and the top surface of the shunting box is communicated with the bottom part of a nucleating agent cylinder through a lower injection pipe; and a hanging ring is arranged on the top surface of the nucleating agent cylinder, and a hook is arranged on the lower surface of a lifting cross rod of the molten iron ladle. According to the high-end casting uniform injection nucleating agent device, the nucleating agent can be uniformly injected into a molten iron flow, so that quality of the castings is greatly improved, structure is reasonable, and operation is convenient.

Owner:NINGGUO SOUTHERN WEAR RESISTANT MATERIALS

Method for three-box casting of large movable beam and movable column planer type milling machine lathe bed

InactiveCN108555249AIncrease injection speedIncrease productivityFoundry mouldsFoundry coresEngineeringMachine design

The invention discloses a method for three-box casting of a large movable beam and movable column planer type milling machine lathe bed. The method comprises the following manufacturing methods including milling machine design, milling machine die production, multi-point flow dividing straight-into pipeline pavement, pouring and forming. According to the casting structure features, technique requirements and production types, a casting scheme is determined, and a corresponding milling machine die design drawing is manufactured; according to the designed milling machine die drawing paper, a milling machine die is produced, and an injection molding pipeline is fixedly arranged on the periphery of the top of the milling machine die; and a plastic inlet pipe is arranged on the top of the injection molding pipeline, and the output end of the plastic inlet pipe is connected with the input end of the injection molding pipeline. Through the arrangement of a flow dividing straight-into pipeline, molten iron can be better synchronously injected into the milling machine die in a multi-point manner; and compared with single pipeline molten iron injection, the injection speed of the molten ironcan be increased by at least four or more times, the time spent on pouring is greatly shortened, and accordingly the production efficiency is improved.

Owner:芜湖久弘重工股份有限公司

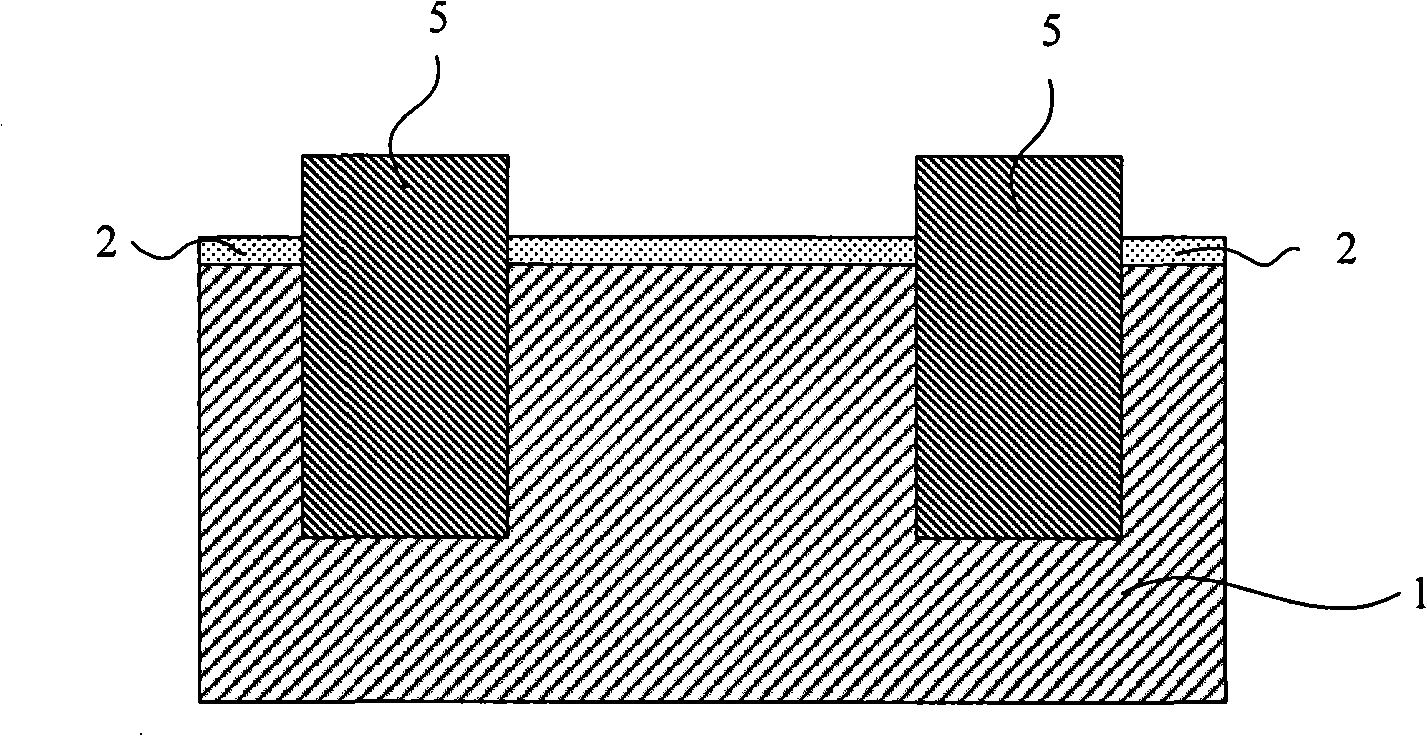

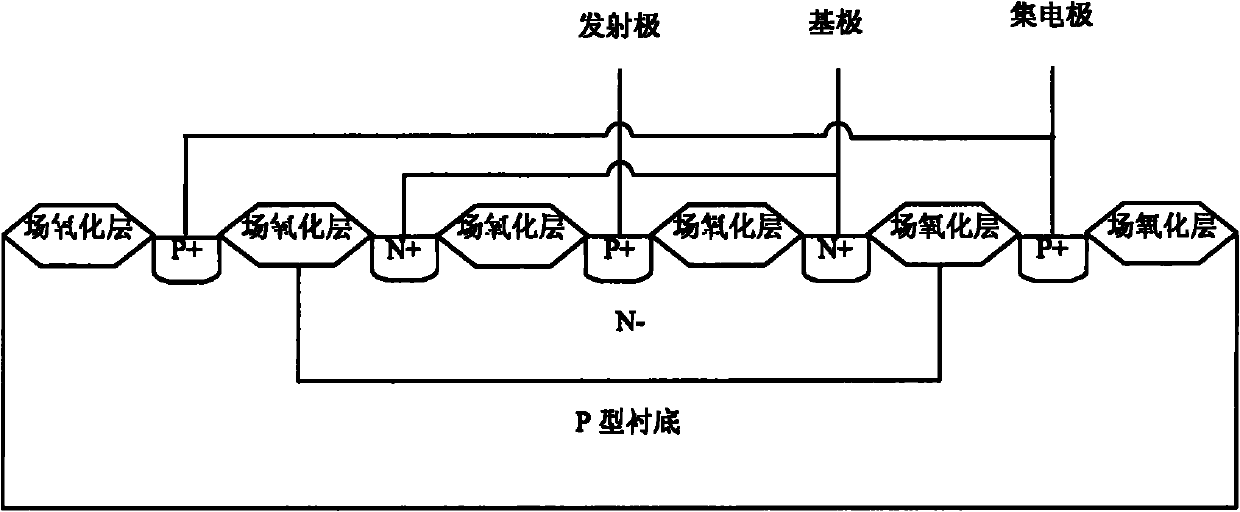

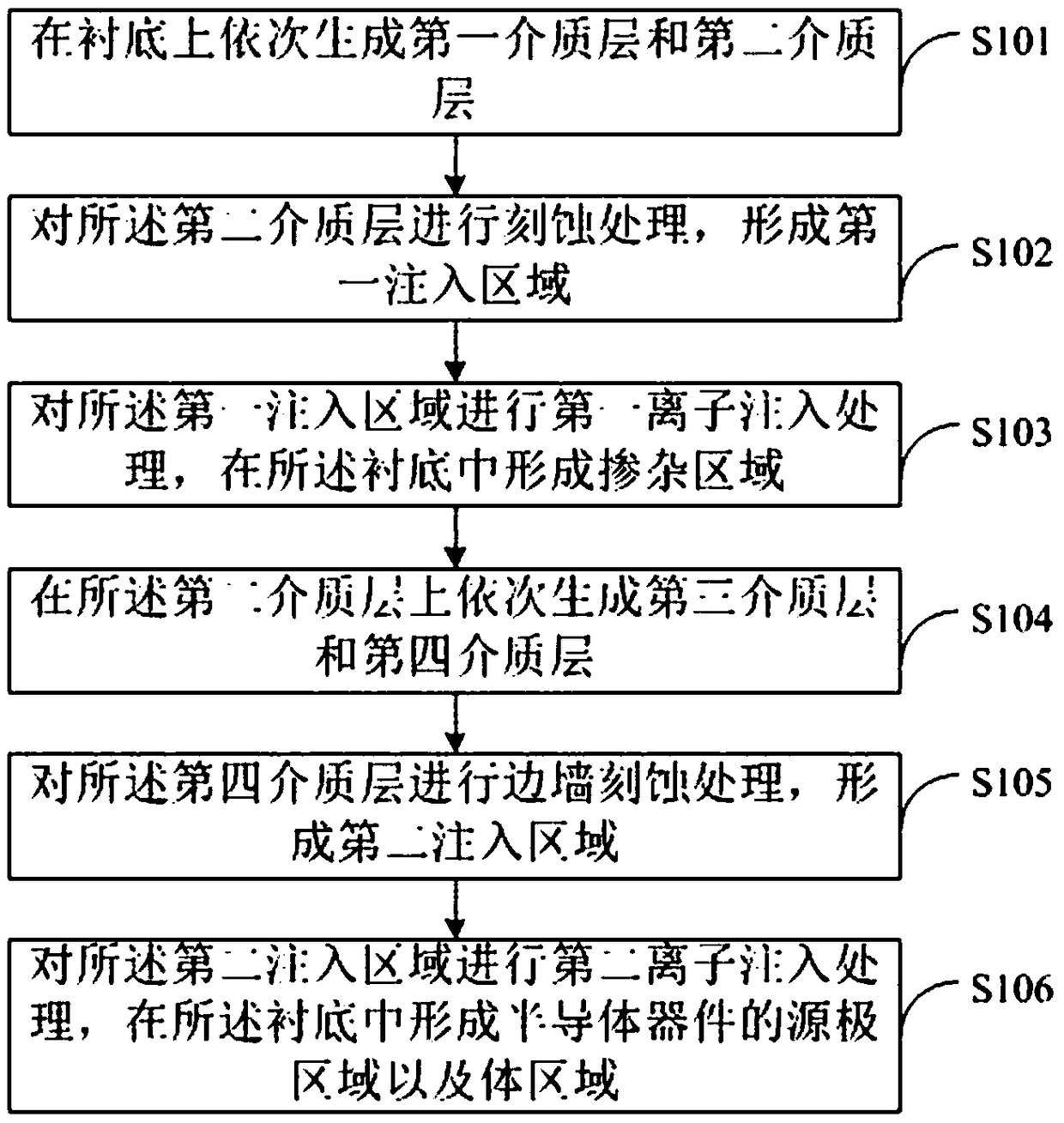

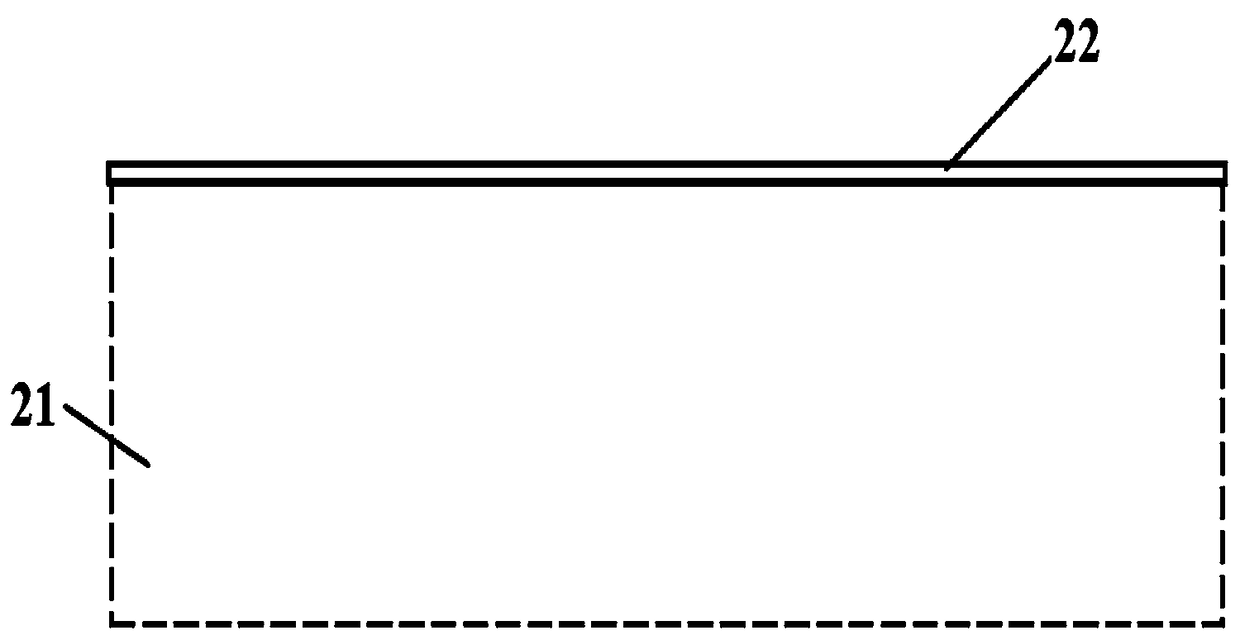

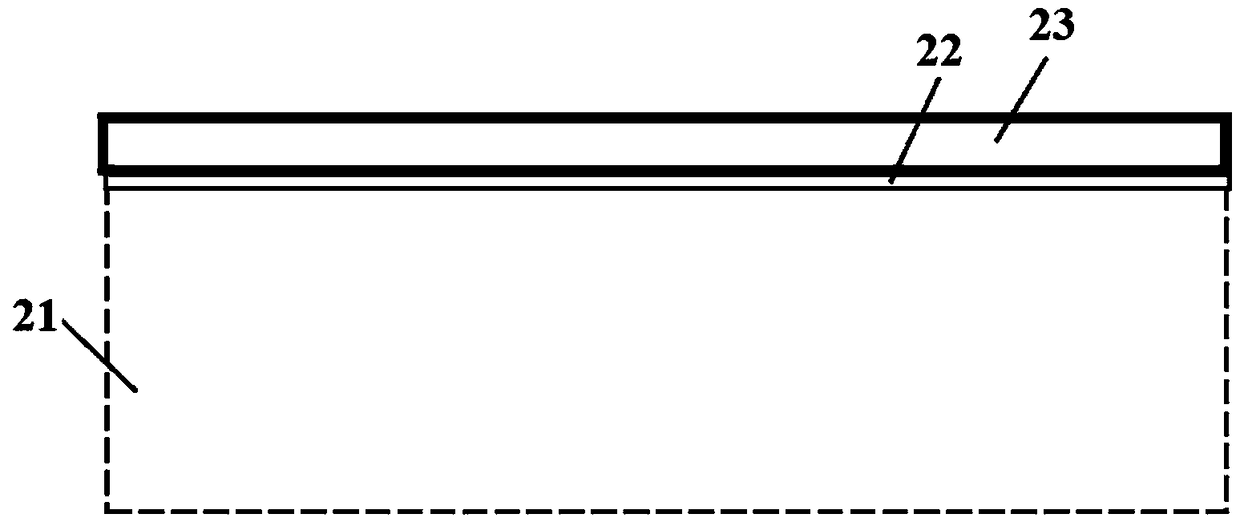

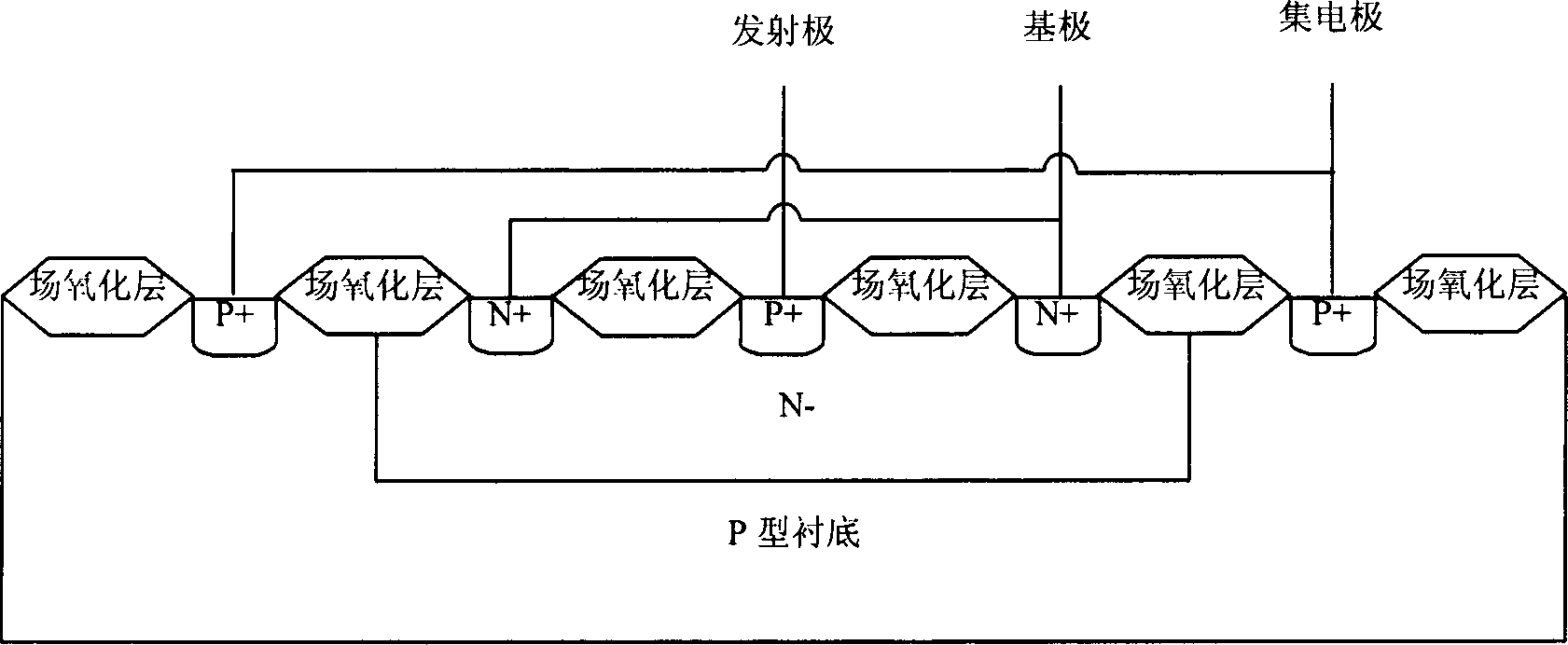

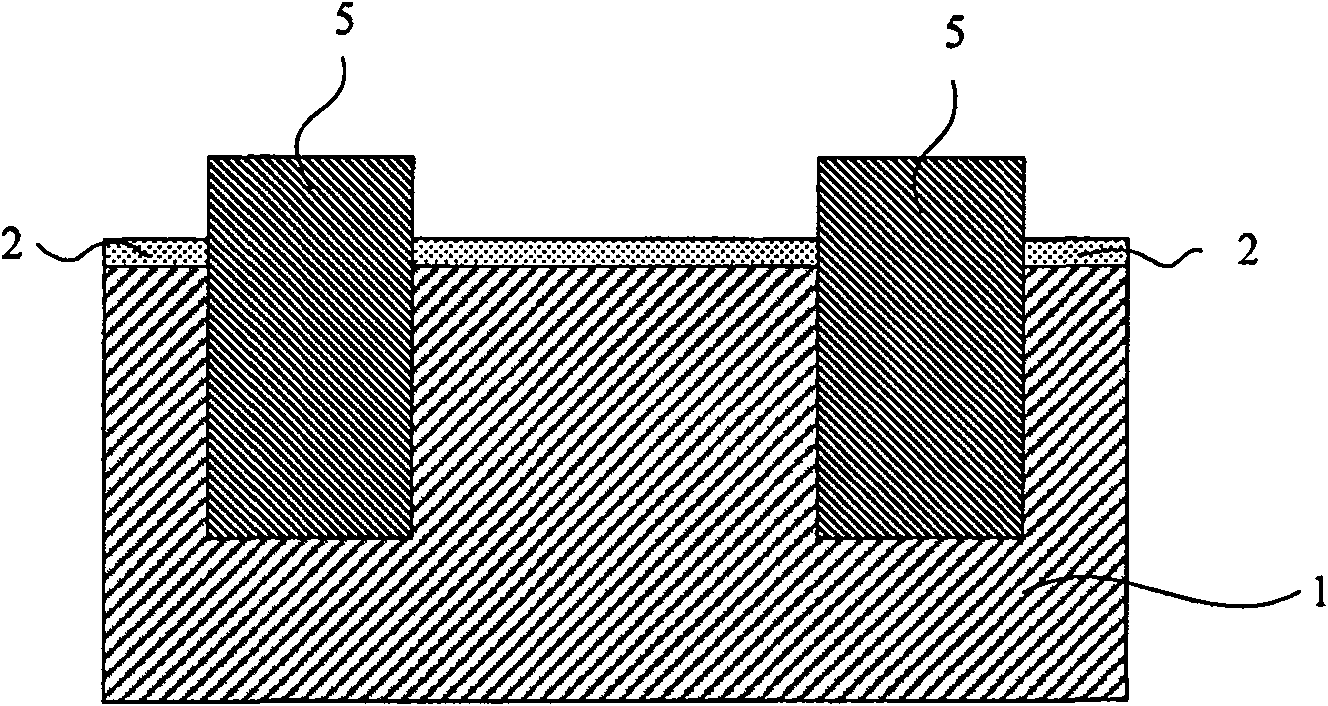

Semiconductor device structure and method of forming the same

ActiveCN108417639BAccurate control of channel lengthImprove performanceSemiconductor/solid-state device manufacturingSemiconductor devicesBody areaSource area

Owner:INVENTCHIP TECH CO LTD

Low-temperature molten iron injection dephosphorization pretreatment method

ActiveCN102559999BReduce temperature dropReduce the amount addedProcess efficiency improvementPretreatment methodManganese

A low-temperature molten iron injection dephosphorization pretreatment method belongs to the field of steel-making molten iron pretreatment. A foundry ladle for dephosphorization is used to hold molten iron and a molten iron roll-over transport vehicle is used to transport the molten iron to a position wherein the molten iron will be processed. With the adoption of a dense phase conveying mode for injection, molten iron temperature reduction caused by carrier gas is minimized. With the blowing of oxygen, the gas O is provided for a reaction, the purpose of heating is achieved, and the addition amount of oxide scale is reduced so as to minimize molten iron temperature reduction caused by the addition of oxide scale. Low oxygen blowing speed realizes soft blow of the molten iron. Decarburization and demanganization reaction times are reduced, thus achieving the purpose of preserving carbon and manganese and maintaining chemical heat to the maximum. Due to the above positive effects, molten iron temperature reduction is minimized and the molten iron is heated by the use of oxygen. Finally, the low-temperature molten iron undergoes injection dephosphorization and the dephosphorizationrate reaches more than 90%.

Owner:BEIJING SHOUGANG INT ENG TECH

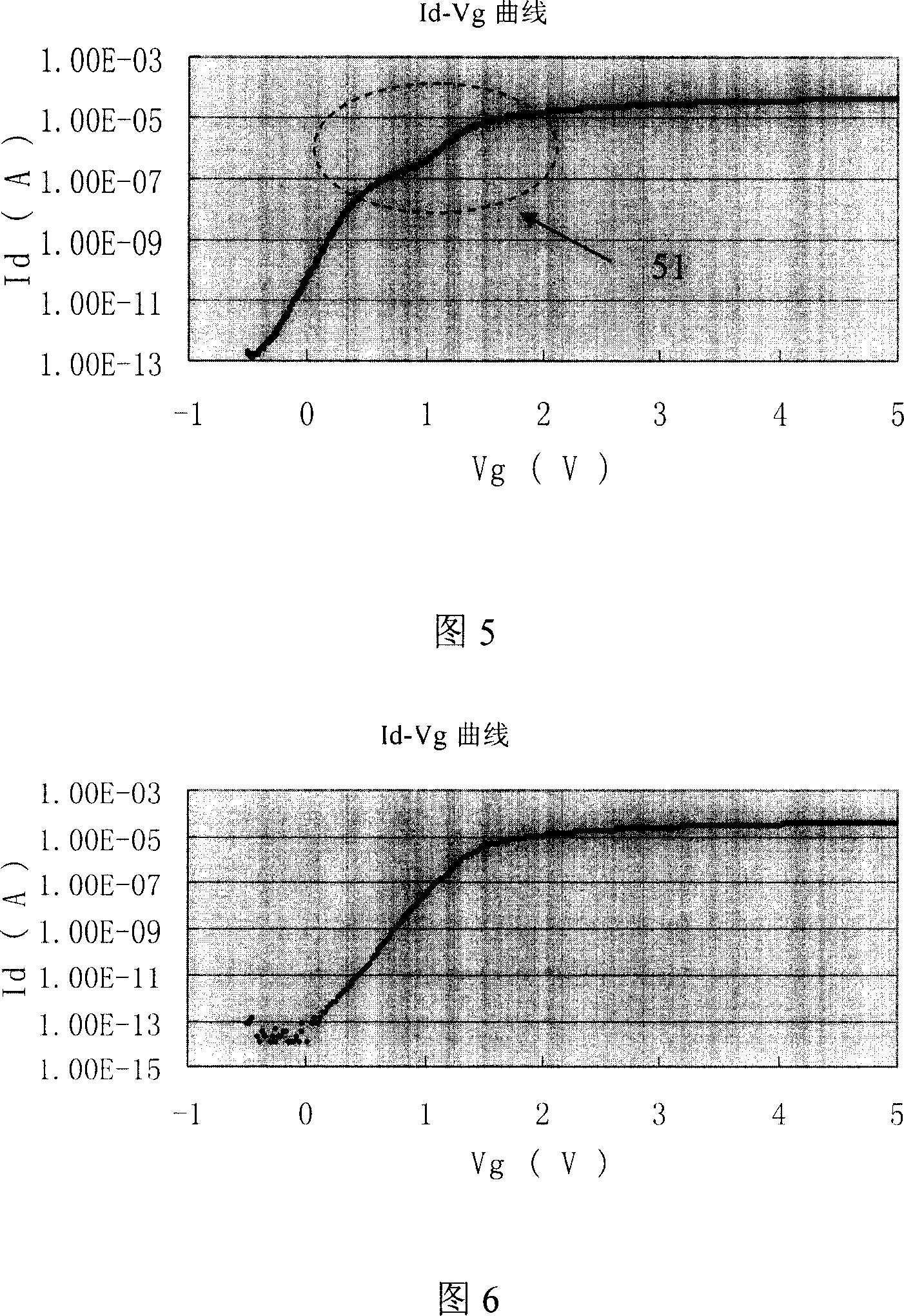

A compensation injection method for effectively reducing LDNMOS cut-off current and avoiding dual peak feature and its application

The invention discloses a compensation injection method able to effectively lower LDNMOS cut-off current and avoid double-hump characteristic. Besides ordinary photosensitive and ion injection techniques, the invention uses the photosensitive technique to generate a given area, which spans over the boundary of LDNMOS grid and shallow groove separation. The invention carries out iron injection contrary to the electric property of groove in the area, thus lowering the cut-off current and avoiding double-hump characteristic of LDNMOS appliances.

Owner:SEMICON MFG INT (SHANGHAI) CORP

A kind of iron flower device

The invention relates to the field of mechanical equipment, in particular to an iron openwork beating device. The iron openwork beating device comprises a smelter, a first molten iron injection pipe and a first high-pressure air inlet pipe. Pig iron materials in the smelter is heated to be in a molten state through the smelter, and the first high-pressure air inlet pipe is communicated with the smelter so that high-pressure air can be provided to the interior of the smelter. The first molten iron injection pipe is communicated with molten iron in the smelter, a first control valve arranged on the first high-pressure air inlet pipe is opened, the molten iron is ejected upwards through the top end of the first molten iron injection pipe under the thrust of the high-pressure air, and splendid iron openwork is formed.

Owner:马季元 +1

P-type high-concentration doped silicon and technology for preparing P-channel MOS (Metal Oxide Semiconductor) pipe of BCD products

ActiveCN102569084BImpact mitigationReduce impactSemiconductor/solid-state device manufacturingNon-linear opticsHigh concentrationDouble diffusion

The invention discloses P-type high-concentration doped silicon and a technology for preparing a P-channel MOS (Metal Oxide Semiconductor) pipe of a BCD (Bipolar, Complementary Metal-Oxide-Semiconductor and Double-Diffusion Metal-Oxide-Semiconductor ) products, aiming at solving the problem of electricity leakage resulting from a lattice defect of the P-type high-concentration doped silicon manufactured with the prior art. A realization method of the technology of the P-type high-concentration doped silicon comprises the steps of conducting low-pressure deposition to form a silicon oxide dielectric layer, photoetching a substrate, defining an injection area, injecting boron ions in the defined injection area and conducting high-temperature annealing on the injected boron ions. According to the embodiment of the invention, before the P-type high-concentration doped silicon is prepared, the impact of the injection of the boron ions onto the surface of the silicon can be relieved by the low pressure deposition of the silicon oxide dielectric layer; the boron ions are injected when iron injection is conducted; as the molecular weight of the boron ions is smaller, the injected energy is smaller and the impact to the surface of the silicon is reduced; and in addition, as the injected impurities do not contain fluorine atoms, the defect problems caused by the fluorine atoms are avoided, and thus, the risk of generating the lattice defect is reduced and the probability of electricity leakage is lowered.

Owner:FOUNDER MICROELECTRONICS INT

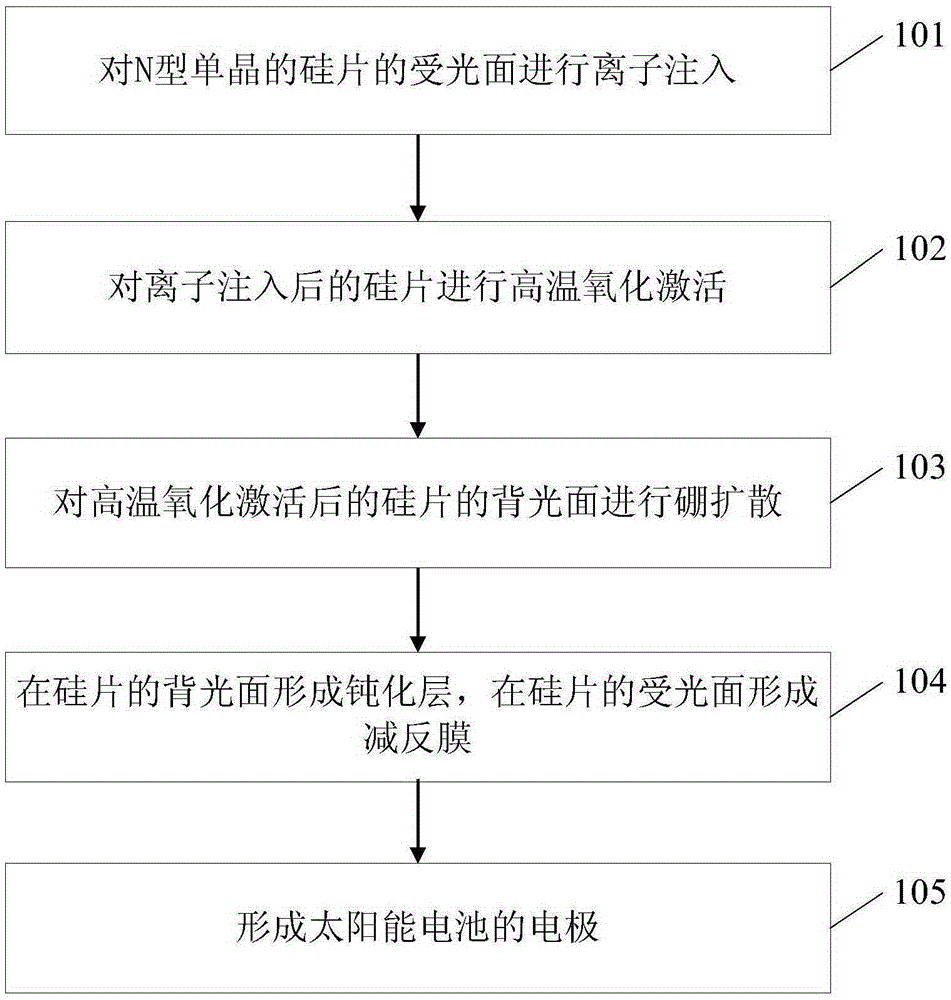

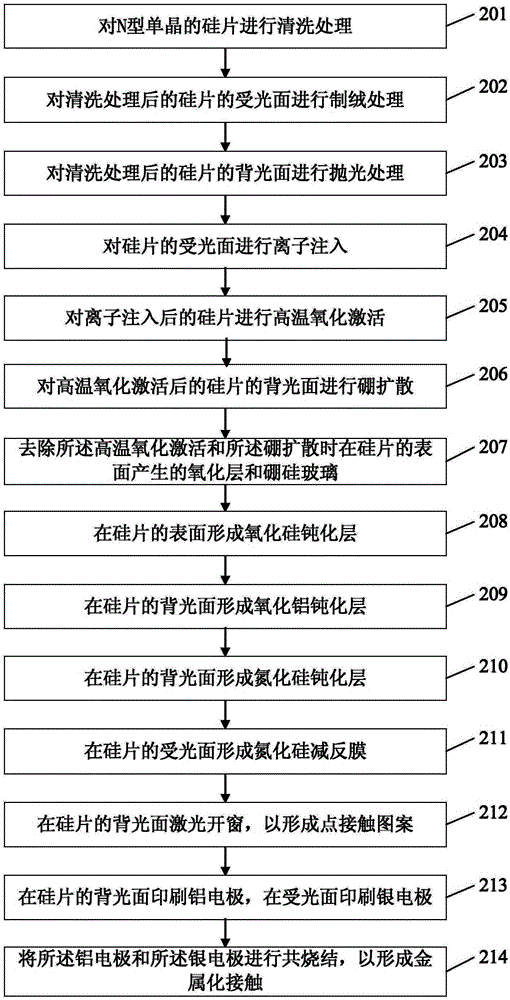

A kind of preparation method of n-type back junction solar cell

ActiveCN103681971BImprove photoelectric conversion efficiencyReduce manufacturing costFinal product manufactureSemiconductor/solid-state device manufacturingSingle crystalIron injection

The invention discloses a preparation method of an N type back knot solar cell. The preparation method comprises the steps of: performing iron injection on a light receiving face of an N type monocrystal silicon wafer, performing high-temperature oxidation activation on the silicon wafer after the ion injection, performing boron diffusion on the shady face of the silicon wafer after the high-temperature oxidation activation, forming a passivation layer on the shady face of the silicon wafer and forming an anti-reflection film on the light receiving face of the silicon wafer, and forming electrodes of the solar cell. The preparation method of the N type back knot solar cell can improve photoelectric conversion efficiency of the solar cell.

Owner:CSI CELLS CO LTD

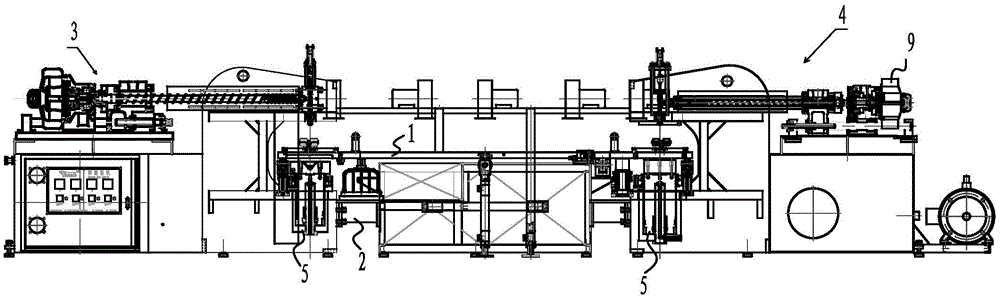

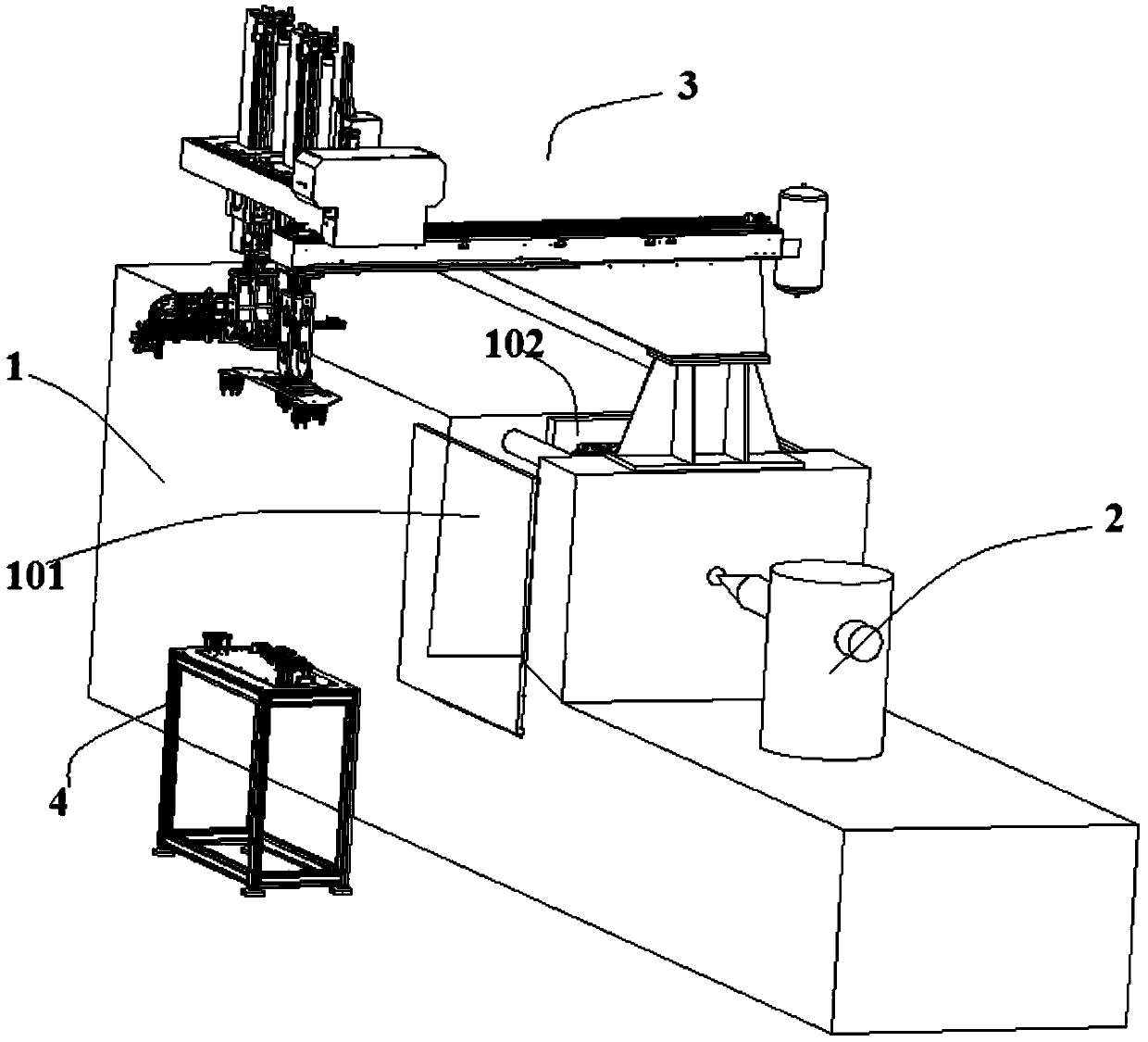

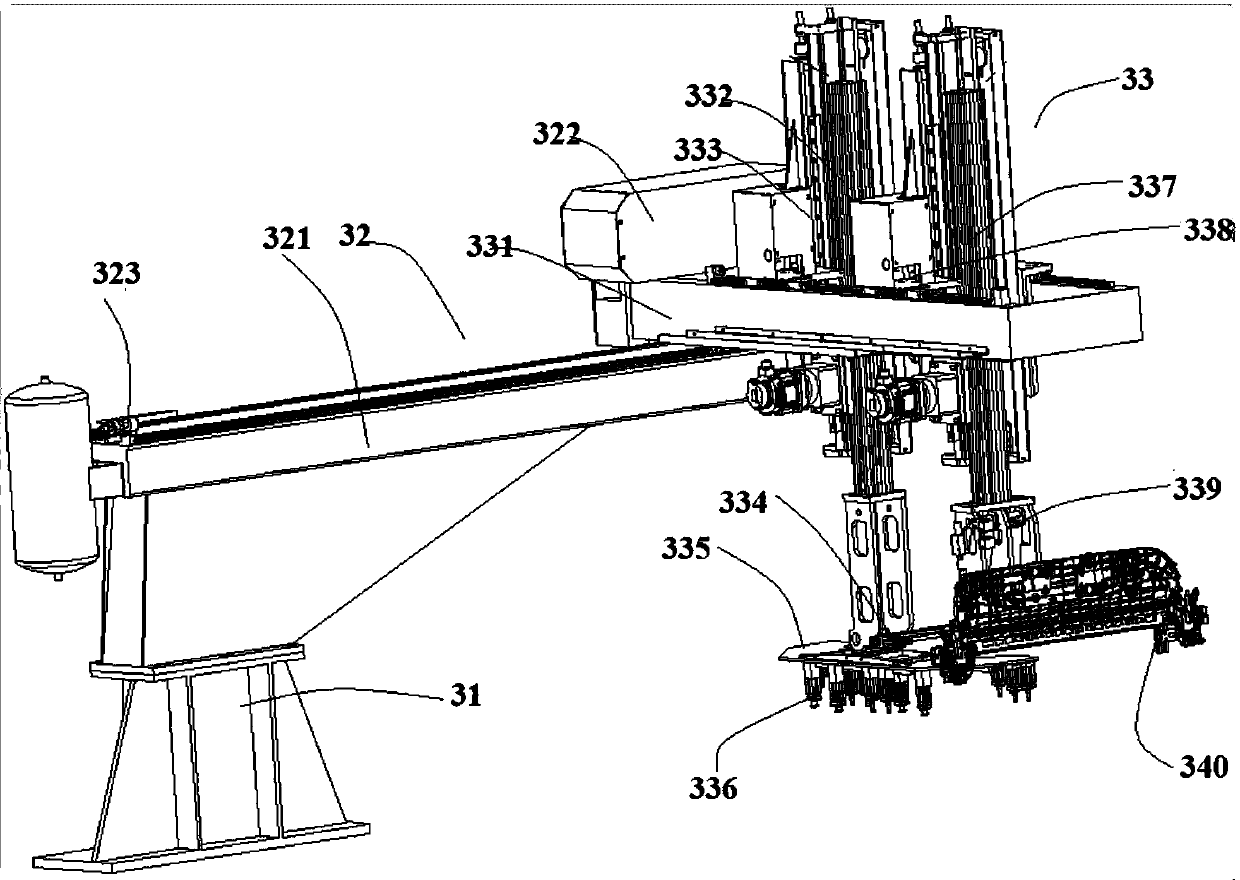

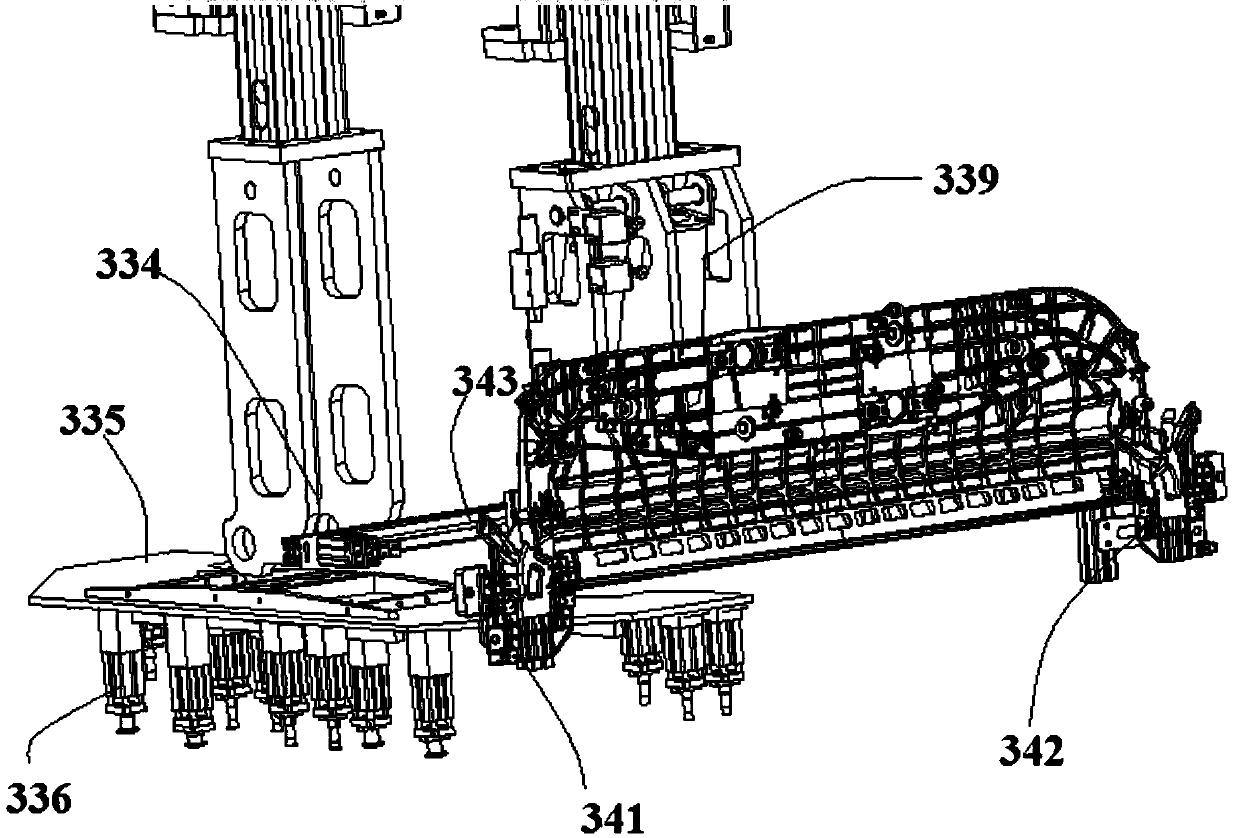

Automatically embedded iron parts injection molding equipment and injection molding method

ActiveCN105538597BHigh degree of automationImprove injection molding efficiencyProgramme-controlled manipulatorGripping headsRobotic armInjection molding machine

Owner:SUZHOU HENGYUANSHENG MOLDING CO LTD

Method for preparing SON type metal oxide semiconductor field effect pipe device

ActiveCN100587928CSimple processLow costSemiconductor/solid-state device manufacturingMOSFETIron injection

The invention discloses a preparation method of the SON type metal-oxide semiconductor field transistor, including the steps of low temperature injecting the neon ion with secondary different energy in the large beam current, forming the void layer at the lower part of the active region after high temperature anneal; removing the silicon nitride side wall on the shallow trough insulation, preparing the MOSFET through the routine CMOS technology. The preparation method providing the SON type metal-oxide semiconductor field transistor can generate the air bubble with higher density due to the low dose Ne iron injection, adopts the low temperature with different energy to form two layers of air bubble belts, which combines to be the high relative density monolayer inanition after high temperature anneal, thereby forming the ultra-shallow junction SON structure with the heat emission channel with simple technology and low cost. Most steps are completed by the routine CMOS technology, whichis convenient for the large scale integrated circuit industrial production and reduced in the production cost.

Owner:汉摩尼(江苏)光电科技有限公司

High-performance lances for hot metal injection pretreatment

The invention discloses a high-performance spray gun for molten iron injection pretreatment. The high-performance spray gun comprises a connection segment, a gun body segment and an injection segment, which are sequentially communicated, wherein a swirling diffuser is arranged between the gun body segment and the injection segment and comprises an upper cone, a cylinder and a lower reversed cone, which are sequentially communicated; 2-4 nozzles are uniformly formed between a main pipe of the spray gun and a seal head in the circumferential direction of the spray gun and positioned in the side wall of the injection segment; swirling pieces obliquely arranged on the outer wall from the top end of the lower reversed cone to the bottom end surface of the injection segment and positioned above the nozzles. By strengthening three key kinetic parameters of molten iron injection pretreatment, the spray gun significantly improves the kinetic conditions of molten iron injection pretreatment and achieves the comprehensive purposes of improving the sulfur removal efficiency of injection pretreatment and the utilization rate of desulfurizer reaction, shortening the injection time and increasing the production capacity of desulfurization equipment.

Owner:武汉钢铁有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com