High-end casting uniform injection nucleating agent device

An inoculant and casting technology, applied in the field of high-end castings, can solve the problems of low casting quality and uneven inoculant injection, and achieve the effects of improving casting quality, reducing labor costs, and improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

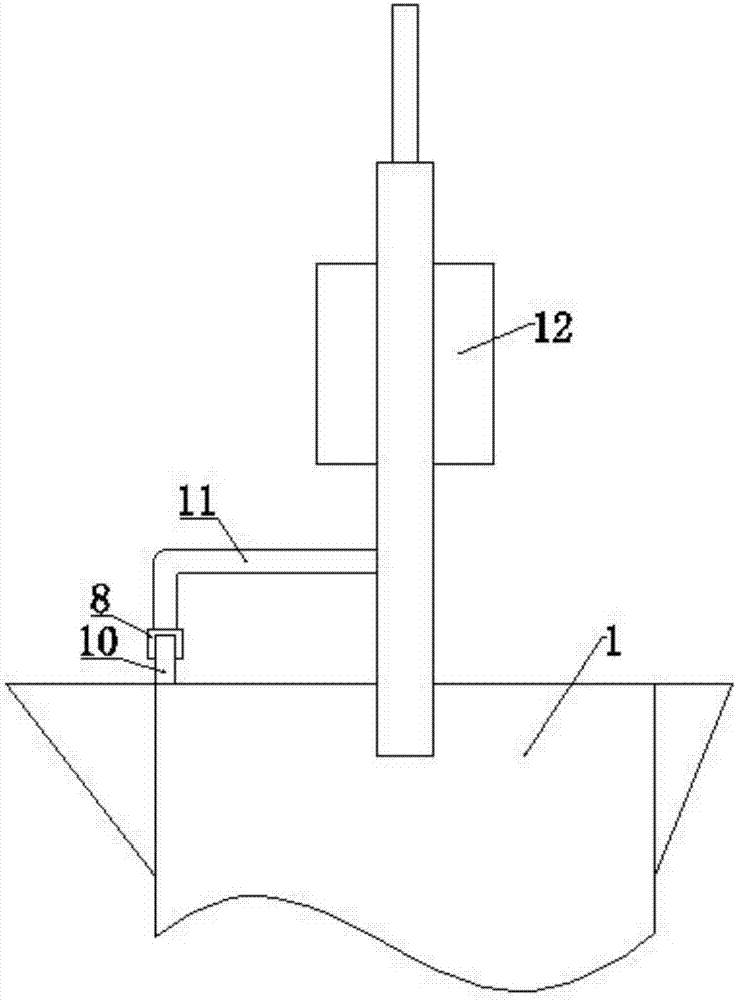

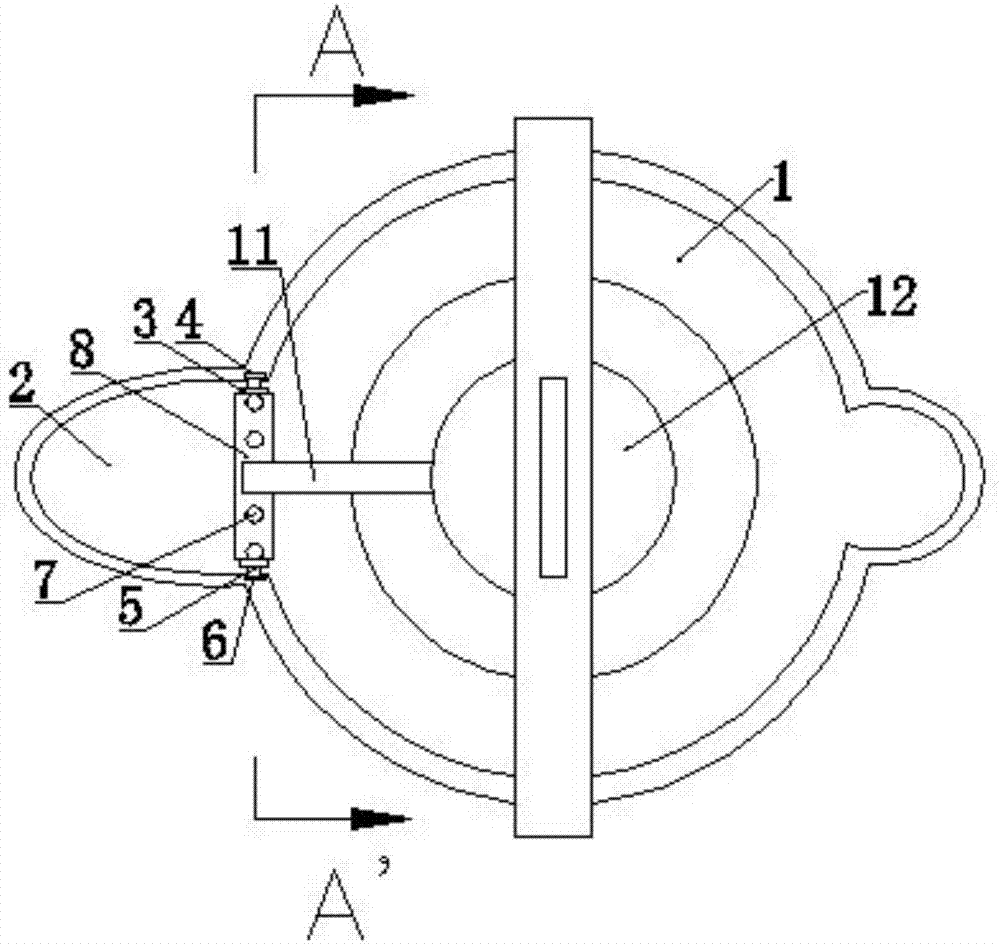

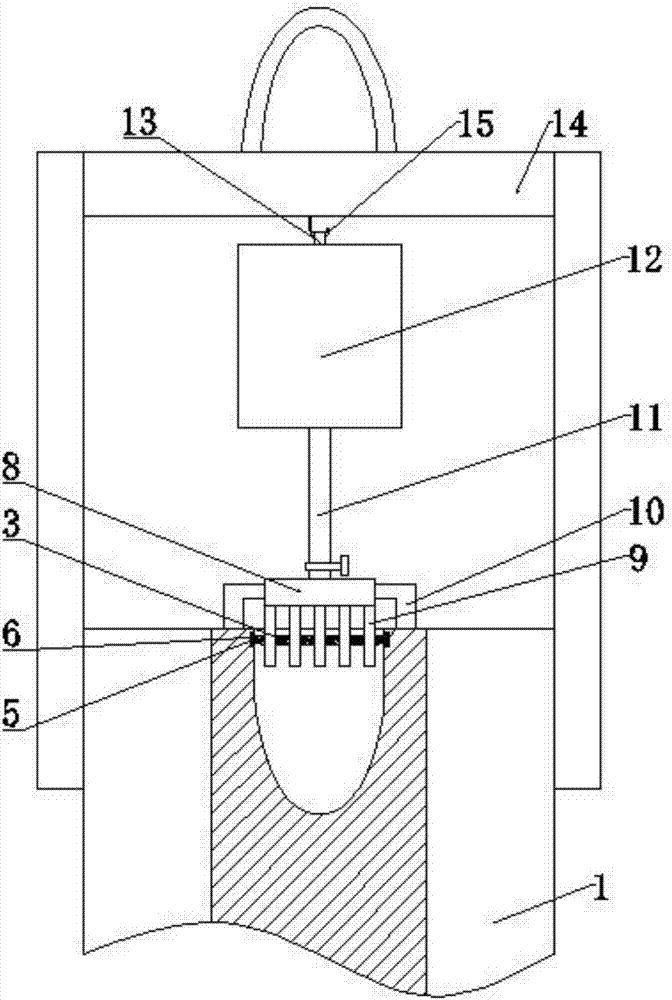

[0025] A high-end casting uniform injection inoculant device of this embodiment includes a ladle 1, a diverter plate 3 is provided at the molten iron injection port 2 of the ladle 1, and a T-shaped groove 4 is provided on the side wall of the molten iron injection port 2; both ends of the diverter plate 3 The circular clamping plate 6 is connected through the connecting shaft 5, and the distribution holes 7 are arranged at equal intervals on the distribution plate 3; the distribution box 8 is arranged above the distribution plate 3, and the distribution tube 9 is installed on the bottom of the distribution box 8, and the distribution tube 9 is inserted in the distribution hole 7 The two ends of the distribution box 8 are fixedly connected to the upper surface of the molten iron injection port 2 through the L-shaped connecting rod 10, and the top surface of the distribution box 8 is connected to the bottom of the inoculant cylinder 12 through the injection pipe 11; the top surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com