Compound inoculant used for producing D-type graphite cast iron and preparation method thereof

A composite inoculant and graphite cast iron technology, applied in the field of inoculants, can solve problems such as a lot of research results, achieve the effects of reducing adverse effects, simple methods, and improving cutting performance

Inactive Publication Date: 2011-01-05

HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

View PDF0 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, there are many research results on which alloy elements have supercooling effect on cast iron, as well as the amount and method of addition, and some have developed intermediate alloys as inoculants, but there are not many reports on the products that have been put on the market to form products.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Login to View More

Abstract

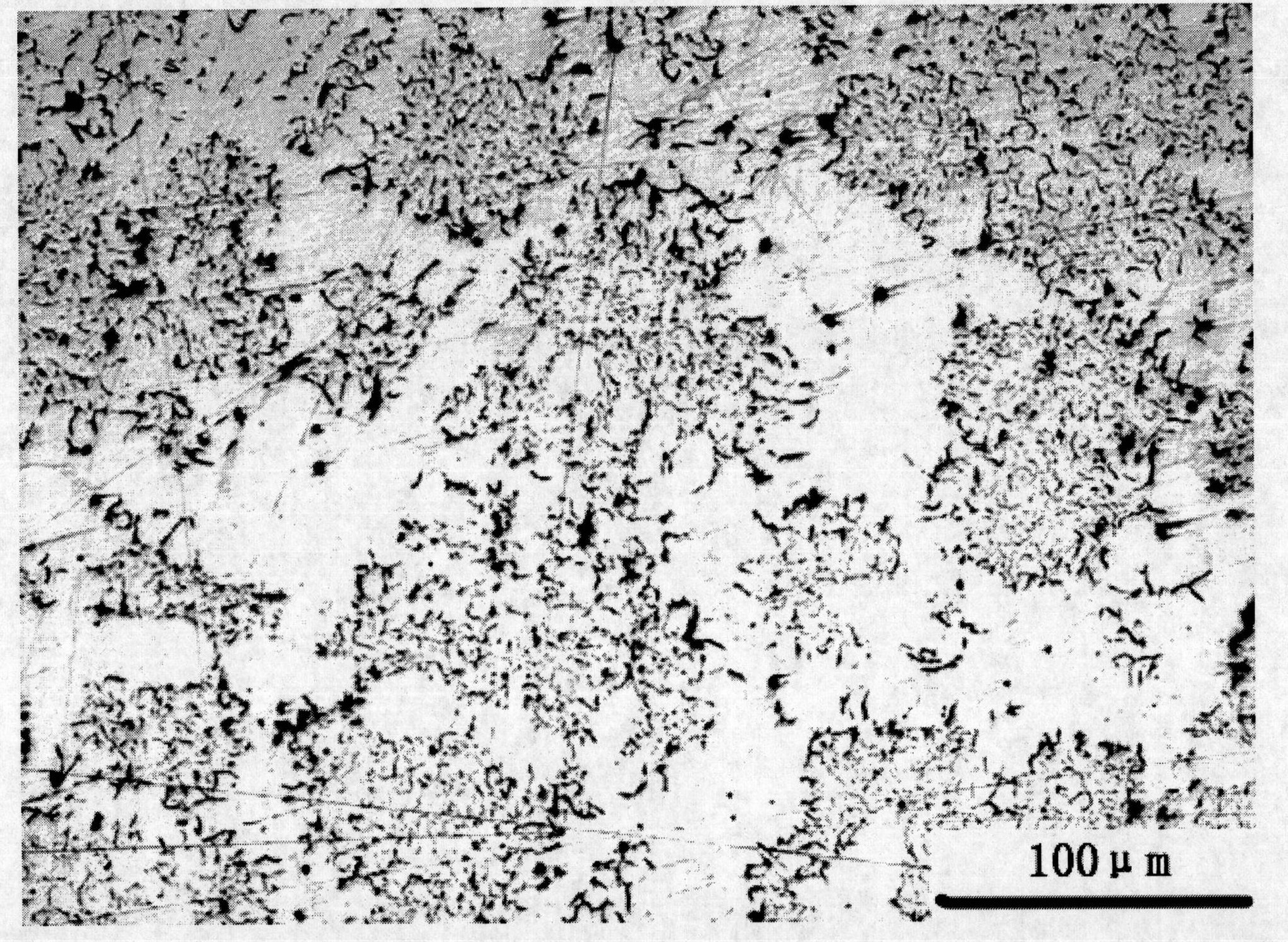

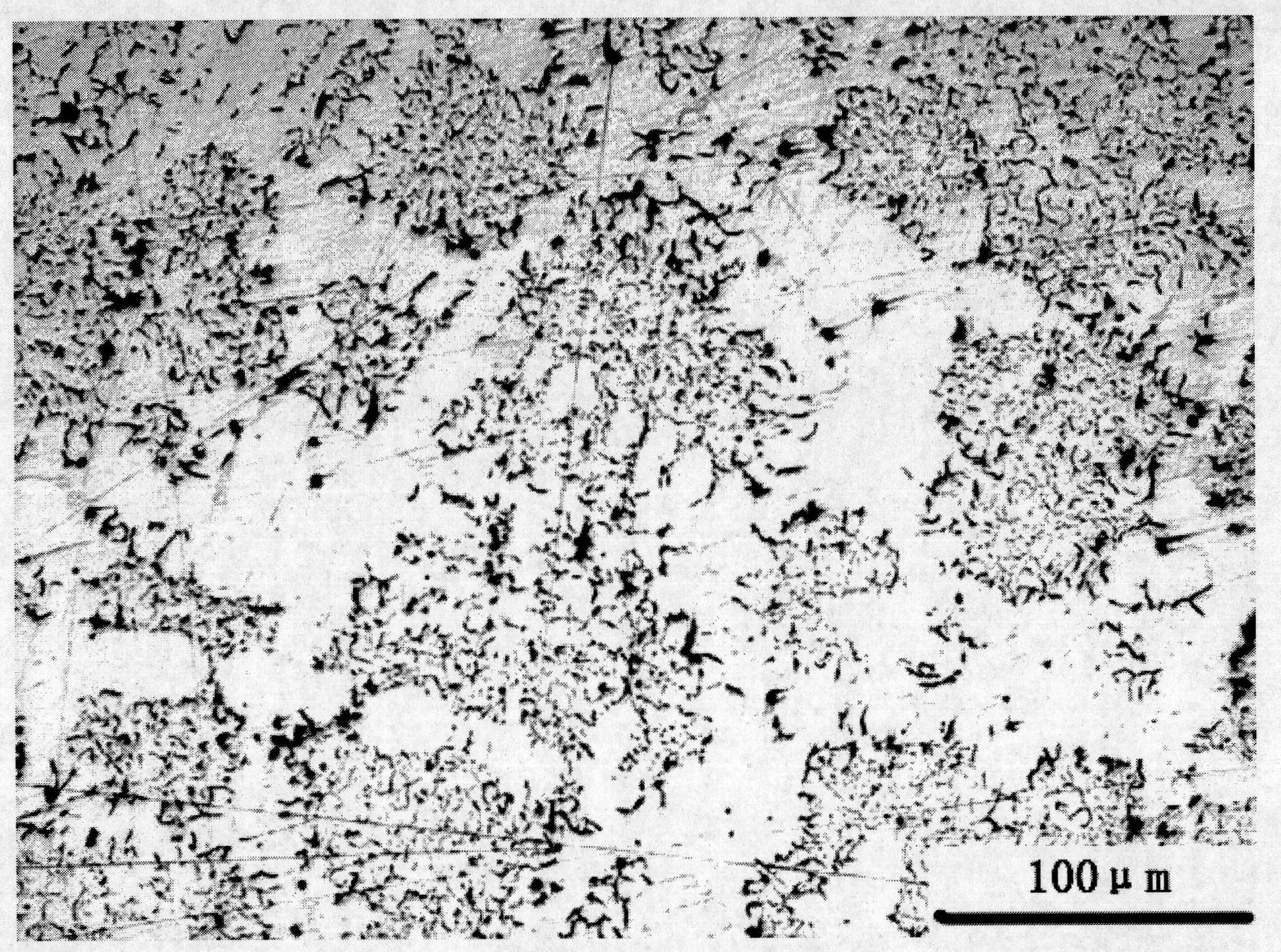

The invention discloses a compound inoculant used for producing D-type graphite cast iron, which is characterized in that the weight percents of the constituents are as follows: magnesium 1.0-4.0, rare earth 4.0-8.0, titanium 4.0-9.0, aluminum 1.5-3.0, stibium 0.5-2.0, calcium 2.0-5.0, barium 1.0-4.0, silicon 35-50 and the balance of iron. When the compound inoculant is employed to carry out inoculation on the melted iron with high carbon equivalent, the obtained graphite in the cast iron is the D-type graphite. The mechanical properties of castings are high, the tensile strength reaches over250MPa and the compactness is good. The melted iron has high carbon equivalent, thus greatly improving the casting properties of alloys, reducing the residual stress of the castings, contributing to good size stability and enhancing the machinability of the castings. The multiple compound inoculant adopts ladle bottom pouring process, namely, the compound inoculant is placed on the bottom of a ladle, then the melted iron is injected and the compound inoculant is continuously melted and absorbed in the process of melted iron injection, thereby reaching the satisfactory inoculation effect, therefore, the method is simple and the use is convenient.

Description

Composite inoculant for producing D-type graphite cast iron and preparation method thereof technical field The invention relates to an inoculant for cast iron, in particular to a composite inoculant for producing D-type graphite cast iron and a preparation method thereof. Background technique The carbon in ordinary gray cast iron generally exists in the form of flake graphite. According to its shape, flake graphite is divided into A, B, C, D, E, F and other types. The traditional point of view is that A-type graphite is evenly distributed, non-directional, and has less splitting effect on the matrix, so that cast iron has higher strength; D-type graphite is a point-like distribution between austenite dendrites without direction or small flakes of graphite, is a detrimental tissue that reduces the strength of cast iron. However, a large number of studies in recent years have shown that D-type graphite cast iron has higher strength, denser, better dimensional stability, be...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C22C33/10B22D1/00

Inventor 张忠诚王忠民刘瑞玲

Owner HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com