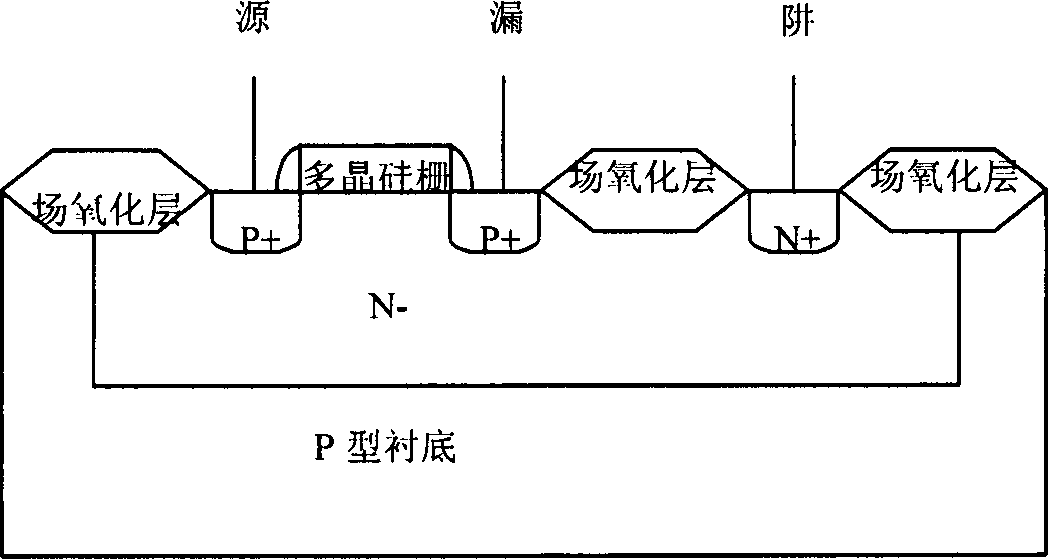

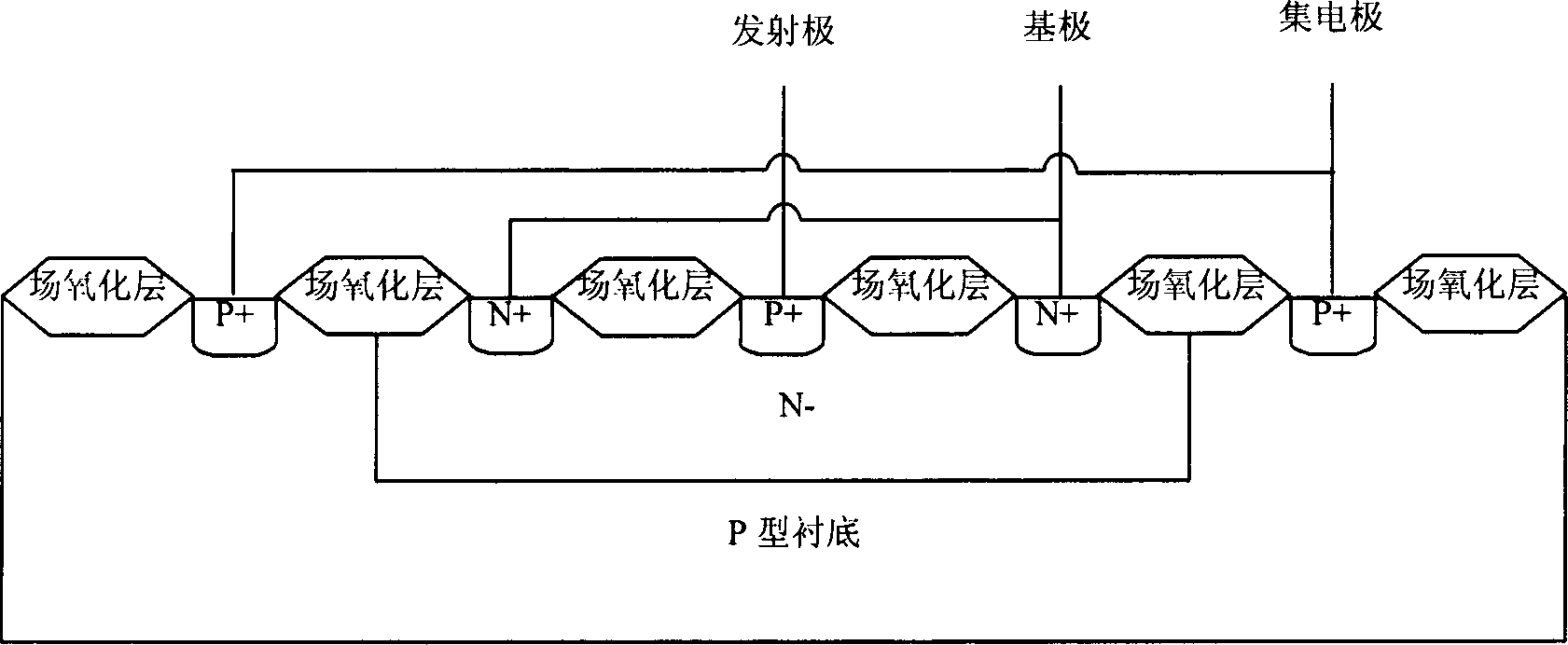

P-type high-concentration doped silicon and technology for preparing P-channel MOS (Metal Oxide Semiconductor) pipe of BCD products

A MOS tube and manufacturing process technology, applied in the field of semiconductor chip manufacturing process, can solve problems such as lattice defects and leakage, and achieve the effect of reducing the possibility of leakage, slowing impact, and reducing impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

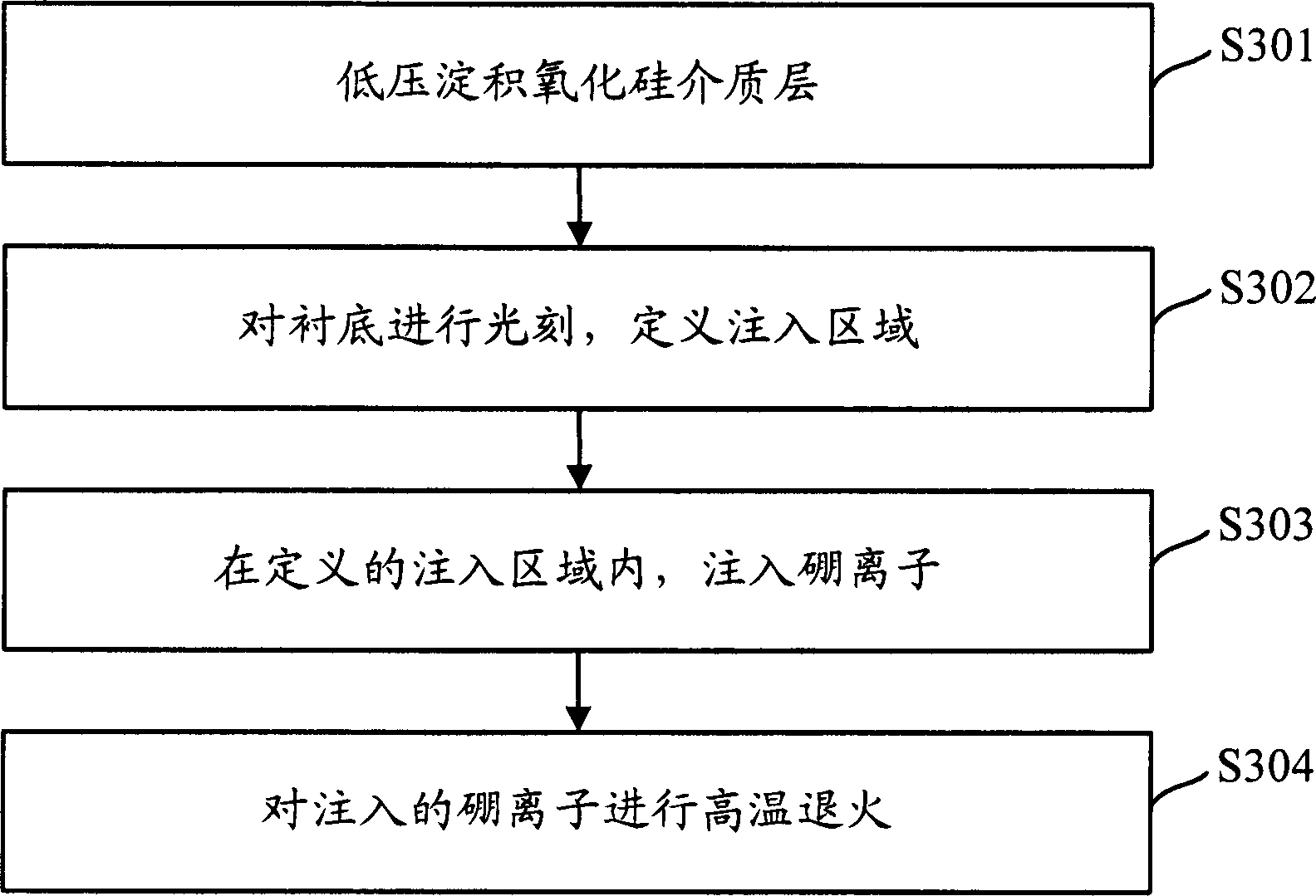

[0029] In order to effectively reduce the leakage problem in BCD products, the embodiment of the present invention provides a process realization method of P-type high-concentration doped silicon. In this step, an implantation region is defined, boron ions are implanted in the defined implantation region, and high-temperature annealing is performed on the implanted boron ions. Since the silicon oxide dielectric layer is deposited at a low pressure before the P-type high-concentration doped silicon is produced in the embodiment of the present invention, the impact of boron ion implantation on the silicon surface can be greatly reduced, and at the same time, the boron ion implantation energy can be controlled within achievable equipment and Within the range of process capability, on the other hand, during ion implantation, boron ions are implanted. Since the molecular weight of boron ions is relatively small, the implanted energy is relatively small, and the impact on the silicon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com