Combined buffering guardrail

A compound guardrail technology, applied to roads, road safety devices, roads, etc., can solve the problems of metal guardrails such as hardness, loss, and large injuries to vehicles and people, so as to increase impact resistance, strengthen toughness and elasticity, and avoid The effect of being seriously injured

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

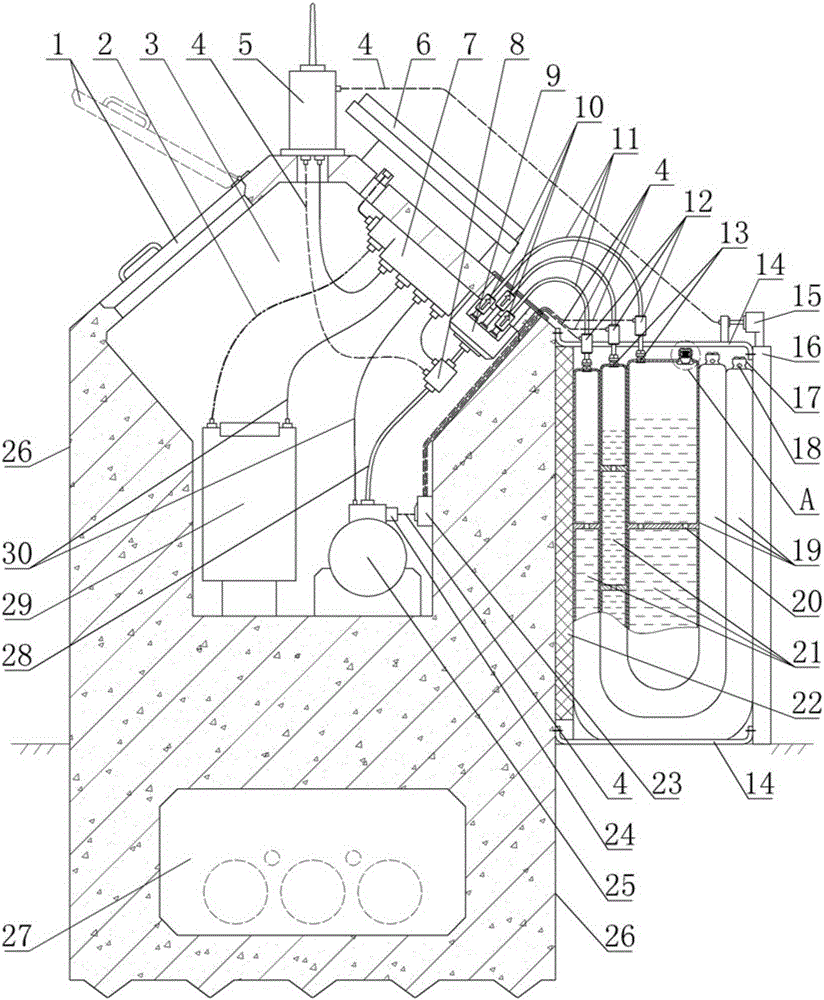

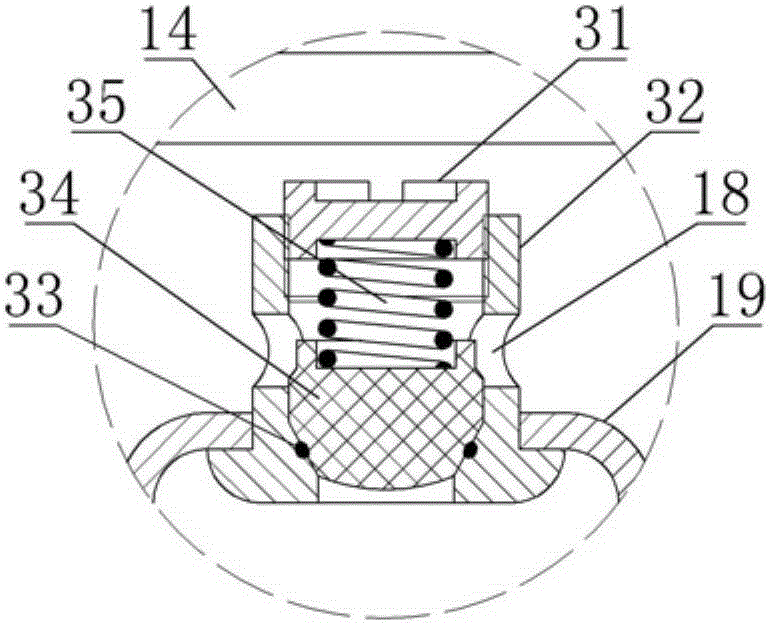

[0018] The composite buffer guardrail has a base body 26, and a buffer device is installed on one side of the base body. The buffer device has a nylon inner plate 22, a nylon outer plate 16 and a water bag 19, and the water bag is provided with a water inlet 13 and a pressure valve 17. The two sides of the water bag are respectively movable and crimped with the nylon inner plate and the nylon outer plate, the other side of the nylon inner plate is fixedly connected with the substrate, and the nylon outer plate is articulated with the substrate through the connecting belt 14 . The base body is a reinforced concrete prefabricated body. The length of the base body in the straight section is more than 5 meters. The base body in the turning section should be prefabricated to increase the overall weight and strength and resist the impact force; the nylon inner plate is fixed with the base body through embedded bolts. , the thickness of the nylon inner plate is 5-20 millimeters; the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com