Patents

Literature

90results about How to "Impact mitigation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

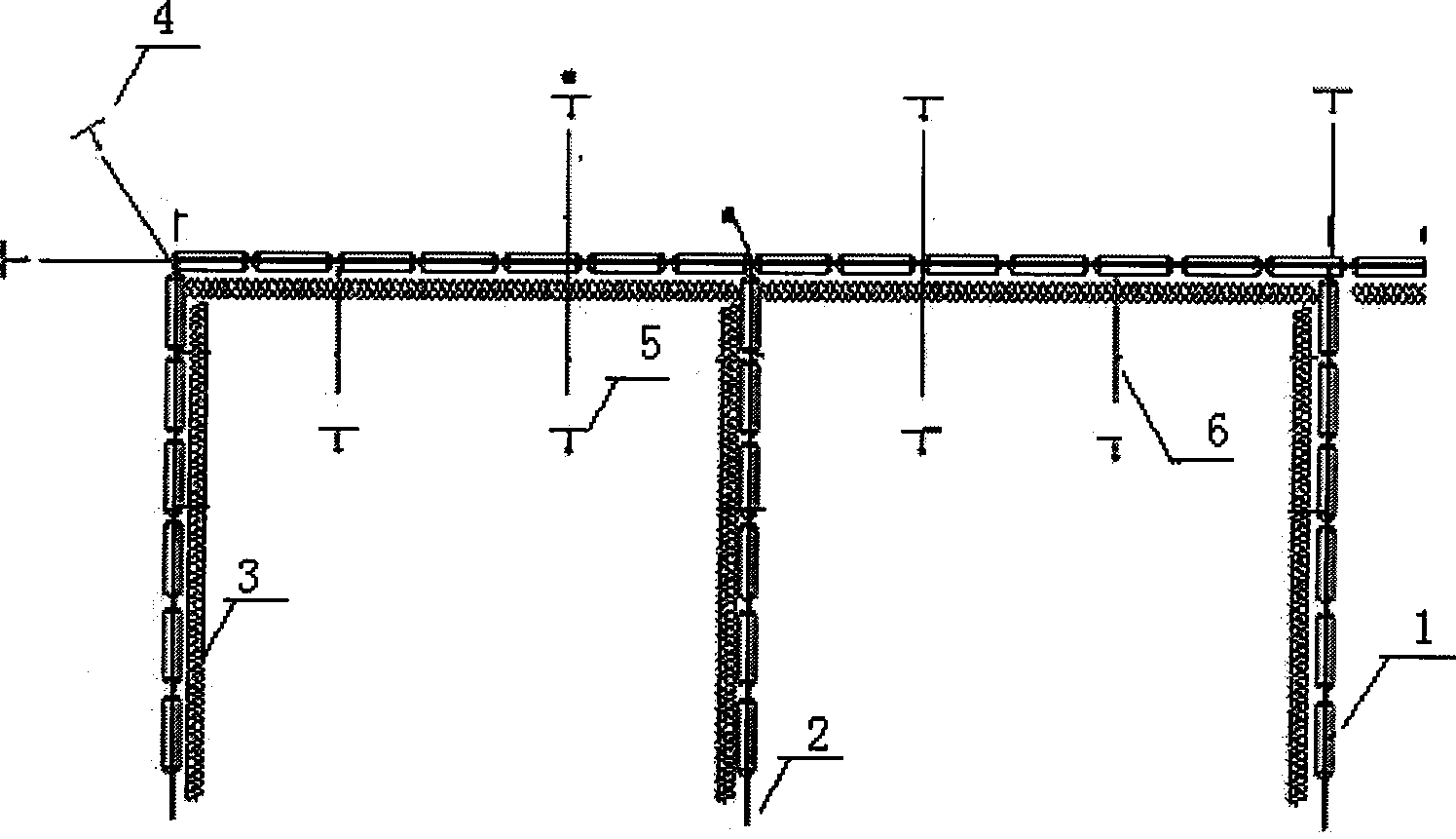

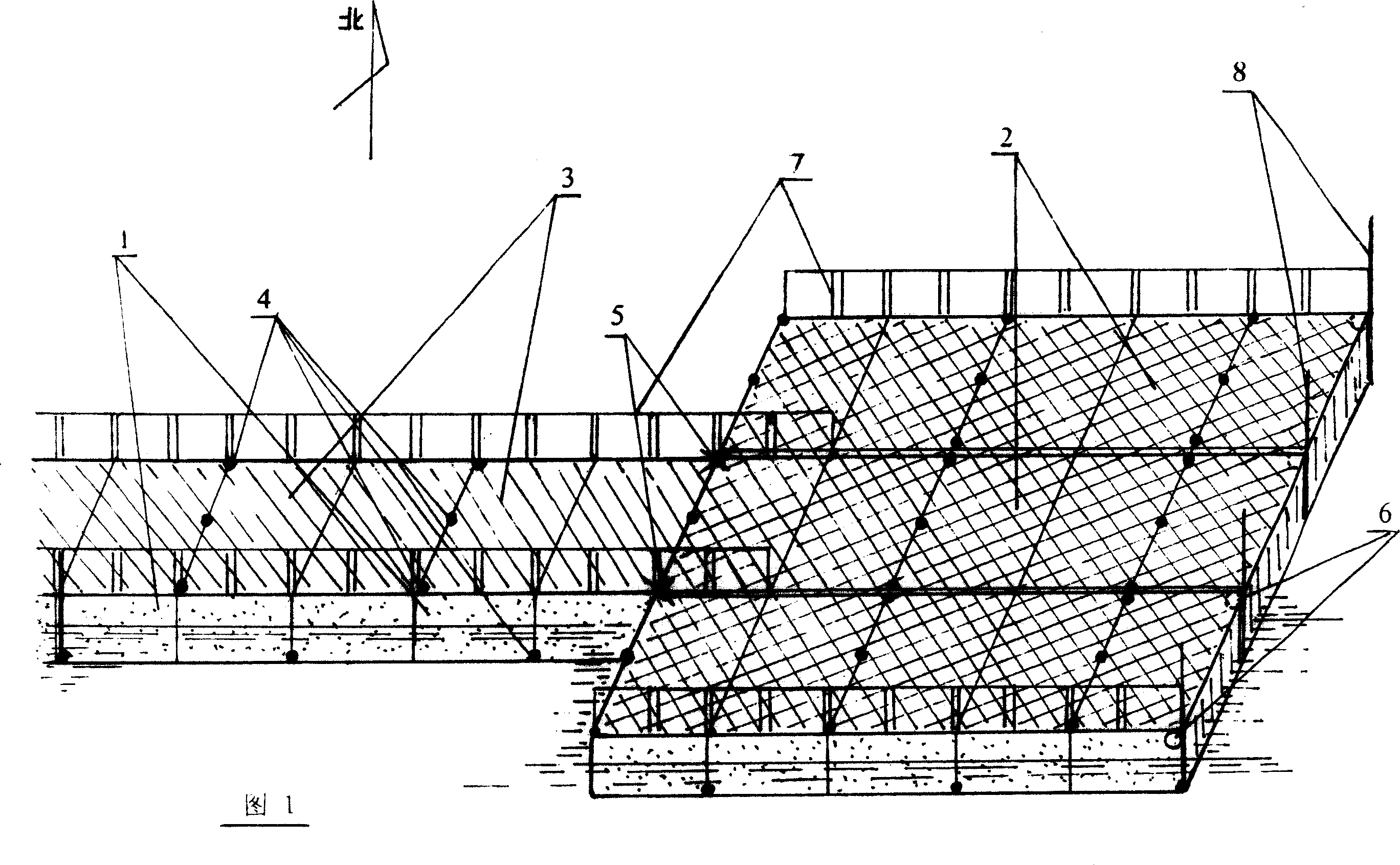

Method for plating water hyacinth with control in open water

InactiveCN101473742AReduce eutrophicationTreat and restore water qualityHarvestersReceptacle cultivationOpen waterUltrasound attenuation

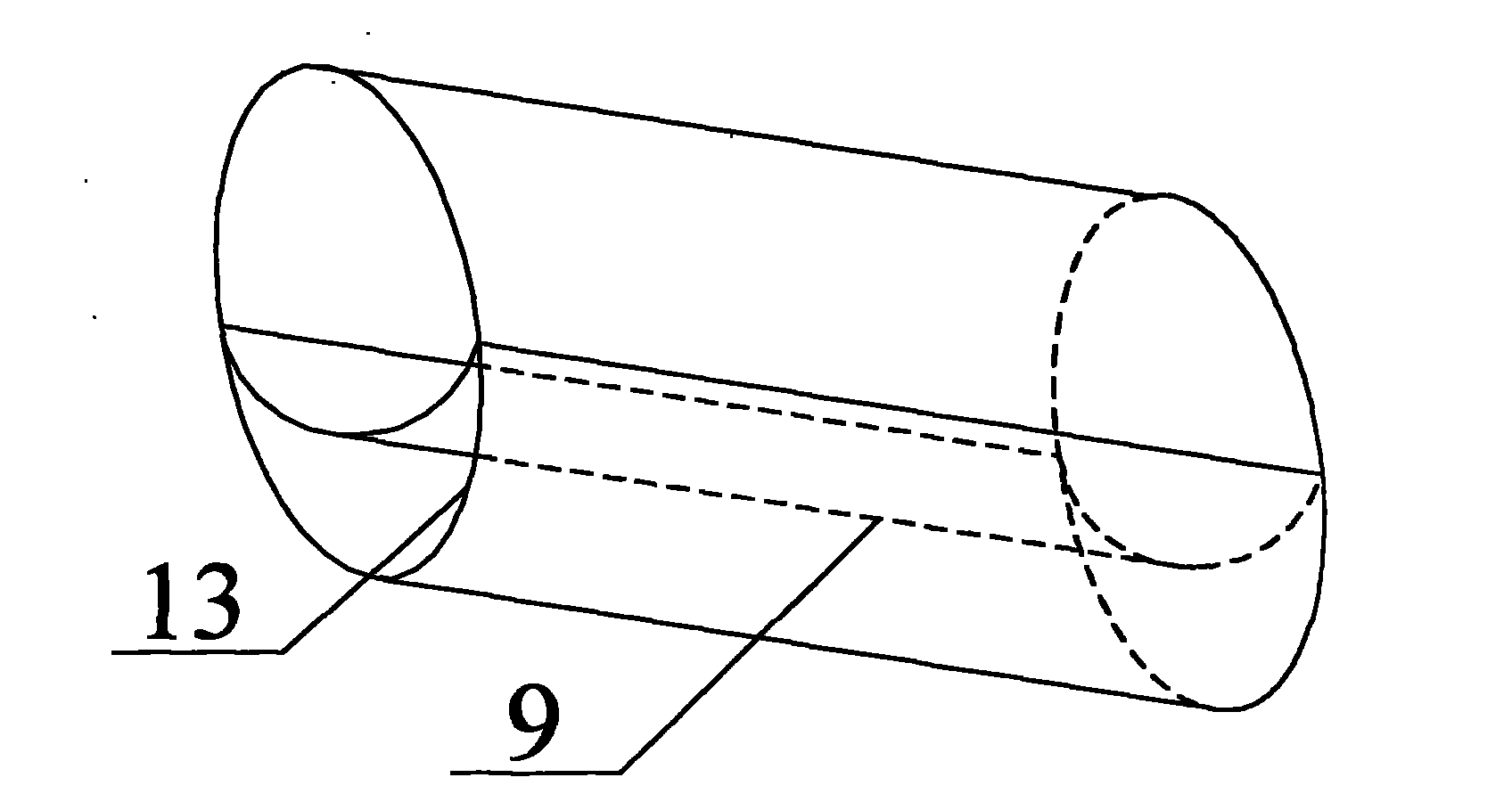

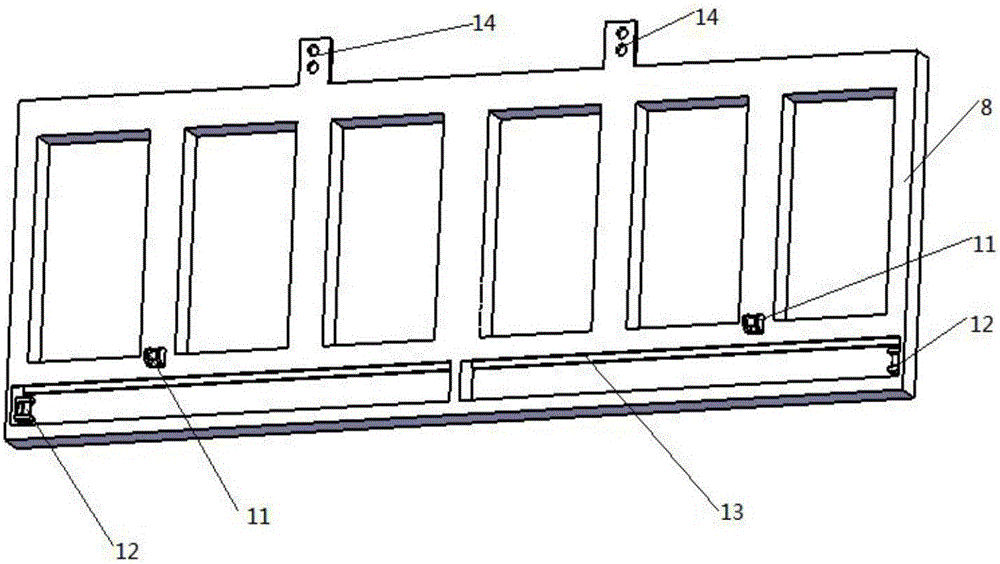

The invention discloses a method for controllably breeding water hyacinth in an open water body, belongs to the aquatic plant breeding technical field, and also belongs to the environmental protection technical field which utilizes aquatic plants to govern open water eutrophication. In the method, wave attenuation floating beds are employed to controllably breed the water hyacinth in the open water body, machinery is employed for salvage, the best stocking number is not less than 500kg per mou, the water body is kept a certain interchangeability after stocking, a firm floating movable fence (wave attenuation floating bed partition) is employed while stocking, the wave attenuation floating beds can automatically rise and fall with the water level, and are made of foam ball floats, steel tubes, meshes, iron anchors, sinkers and net ropes, the fence is formed with the wave attenuation floating beds according to specific situations of the lake surface, the fence area is controlled at 1 / 3 of the water surface area, the fence area of a wave attenuation floating bed is controlled at 100 mou, the breeding area of the water hyacinth is controlled at 1 / 4-1 / 3 of the area of the wave attenuation floating beds; and the water hyacinth is salvaged and utilized, and is made into an organic fertilizer by combining with sludge of sewage treatment plants.

Owner:沃邦(江苏)生态肥业有限公司

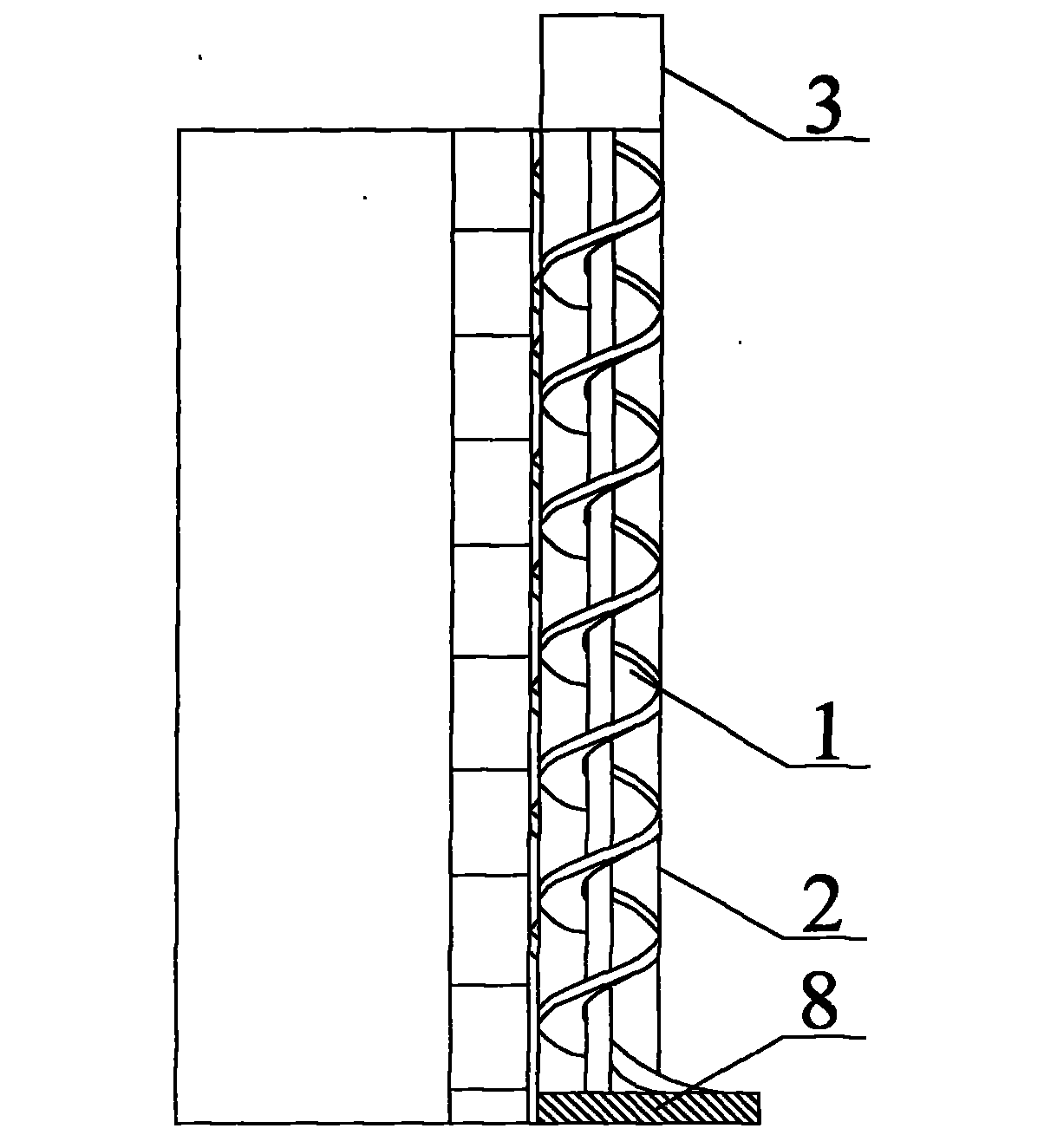

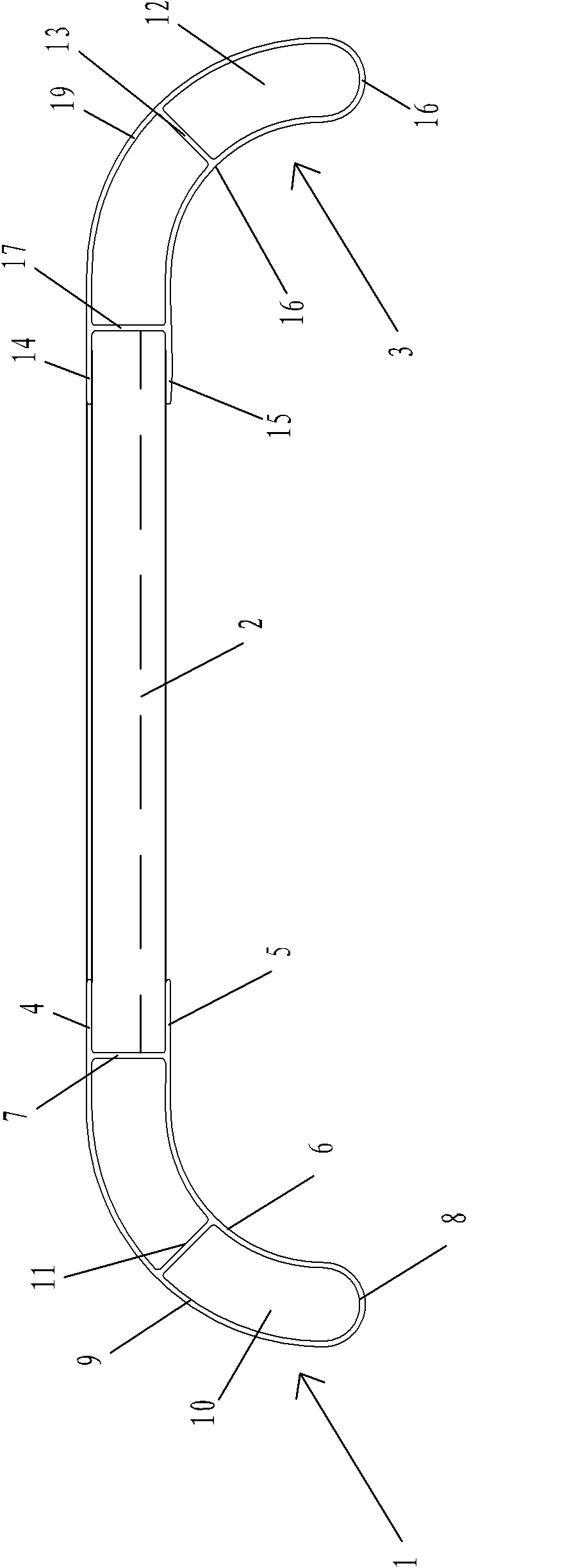

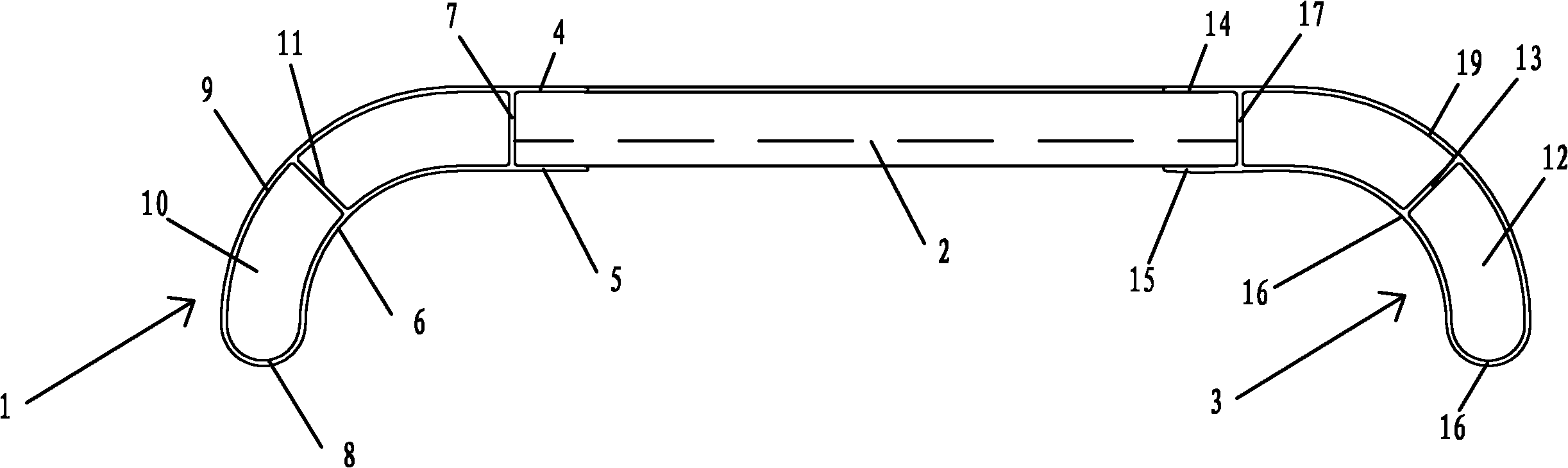

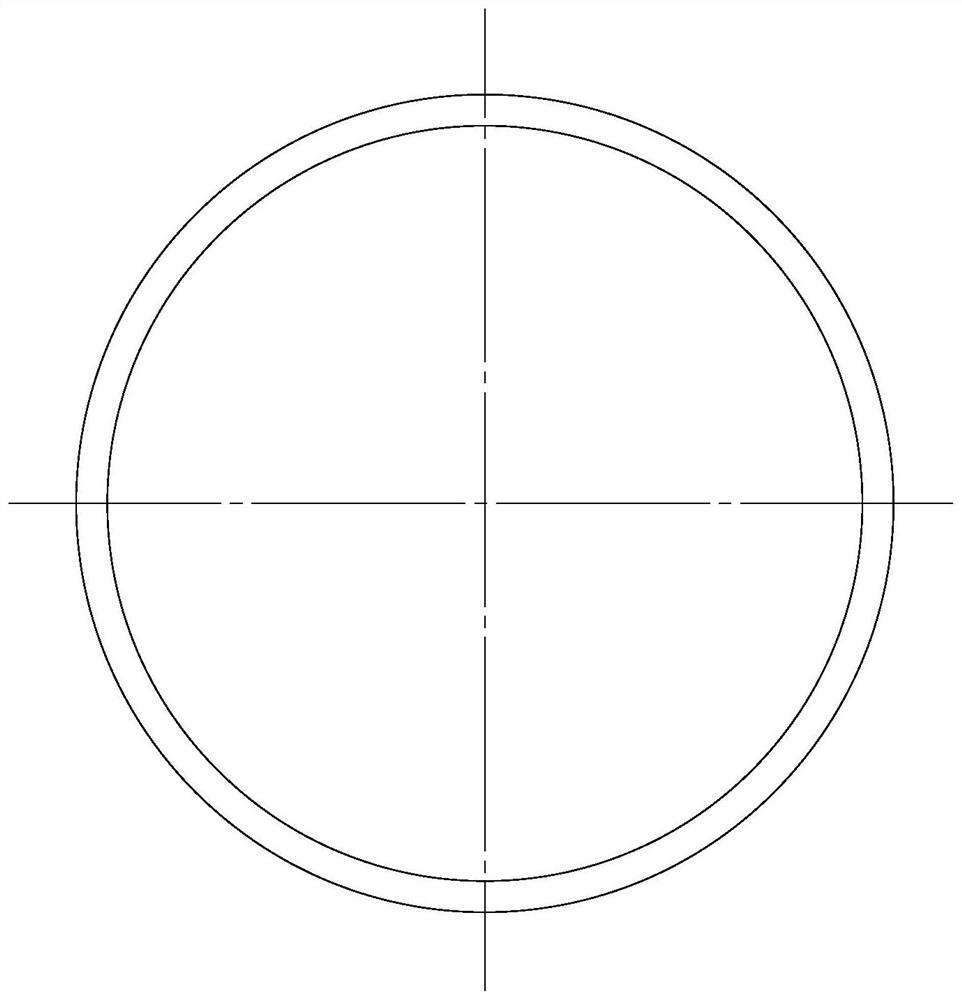

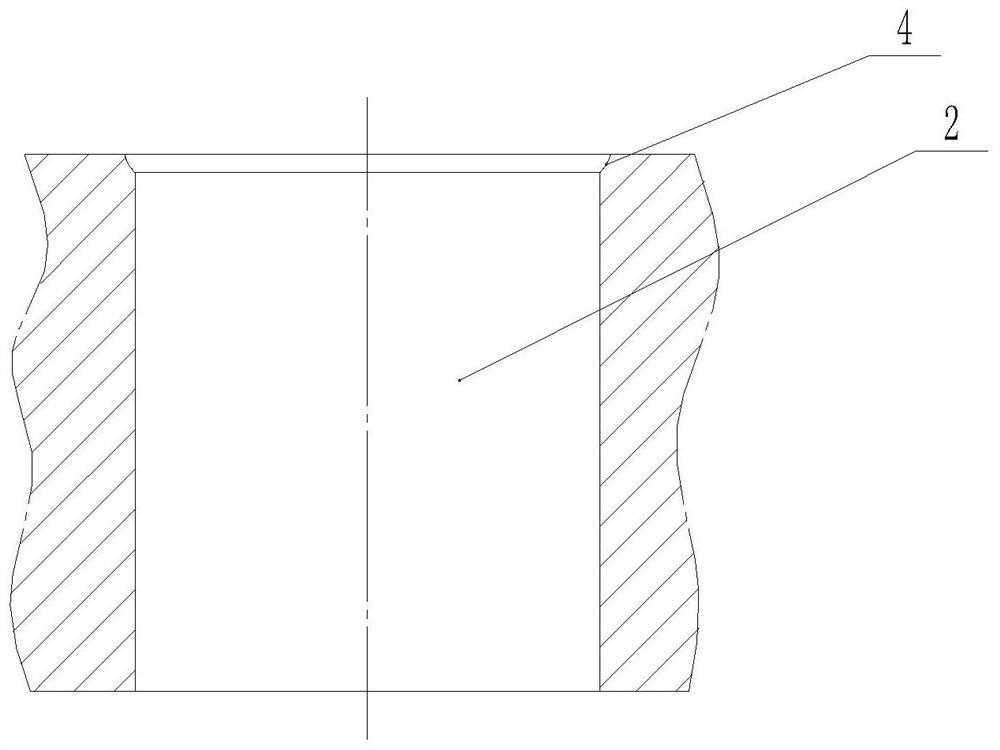

Telescopic type emergency escaping device for high-rise buildings

InactiveCN102120064AExtended service lifeWill not affect normal lifeBuilding rescueEngineeringHigh rise

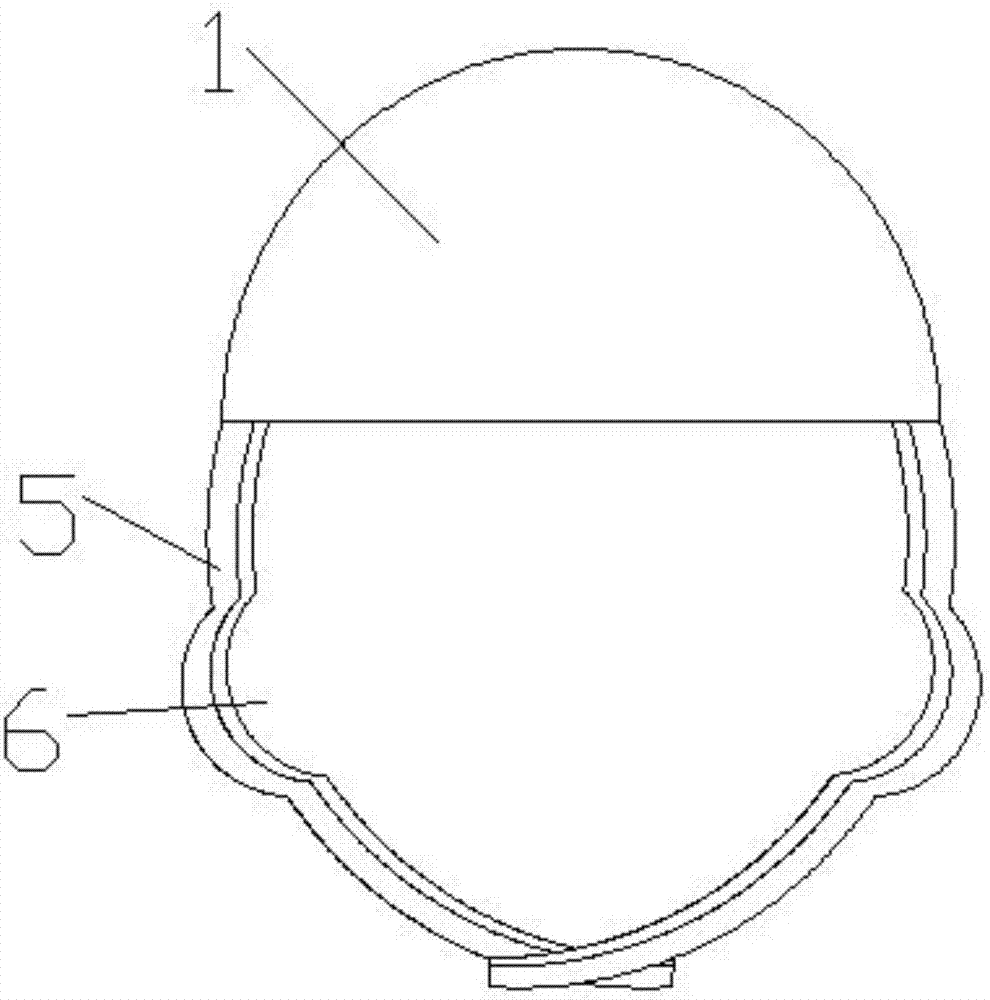

The invention discloses a telescopic type emergency escaping device for high-rise buildings, which comprises a safety screen (2) and a slide rail (1) arranged in the safety screen (2), wherein a hanging bracket (3) and a control device arranged in the hanging bracket (3) are arranged at top broadside of the high-rise building. The safety screen (2) comprises inner and outer two layers which are sleeved mutually; the slide rail (1) is distributed between the inner and outer layers of the safety screen (2) in spiral manner from up to down; and the inner broadside of the slide rail (1) is connected to the inner layer of the safety screen (2) while the outer broadside is connected to the outer layer of the safety screen (2). The telescopic type emergency escaping device for high-rise buildings is characterized in that both the inner wall of the outer-layer safety screen (2) and the outer wall of the inner-layer safety screen (2) are provided with protection pads for protecting the safety of people. By using the telescopic type emergency escaping device for high-rise buildings, when accident disaster happens, people can conveniently escape by opening the arranged telescopic type slide rail. The telescopic type emergency escaping device for high-rise buildings is convenient, quick and reliable to use.

Owner:刘畅

Children's roller skating safety helmet

InactiveCN107495525AGood anti-aging performanceExtended service lifeHelmetsHelmet coversWear resistantEngineering

The invention relates to a children's roller skating safety helmet. The children's roller skating safety helmet is reasonable in design and simple in structure; a cushion is arranged in a traditional helmet, buffer balls are arranged in the cushion, and the phenomenon that the head is impacted when the dangerous situation occurs is effectively relieved; besides, a sponge mat is arranged, the helmet can be more comfortable to wear, and the sponge mat has a certain buffer effect. The made helmet body is tougher and more wear resistant, the anti-ageing effect is better, when the helmet is used in summer and winter, the helmet is more resistant to high temperature and low temperature, the helmet is not likely to be damaged in the area having the temperature difference, and the service life is longer.

Owner:阜南县邰氏宇崴运动器材有限公司

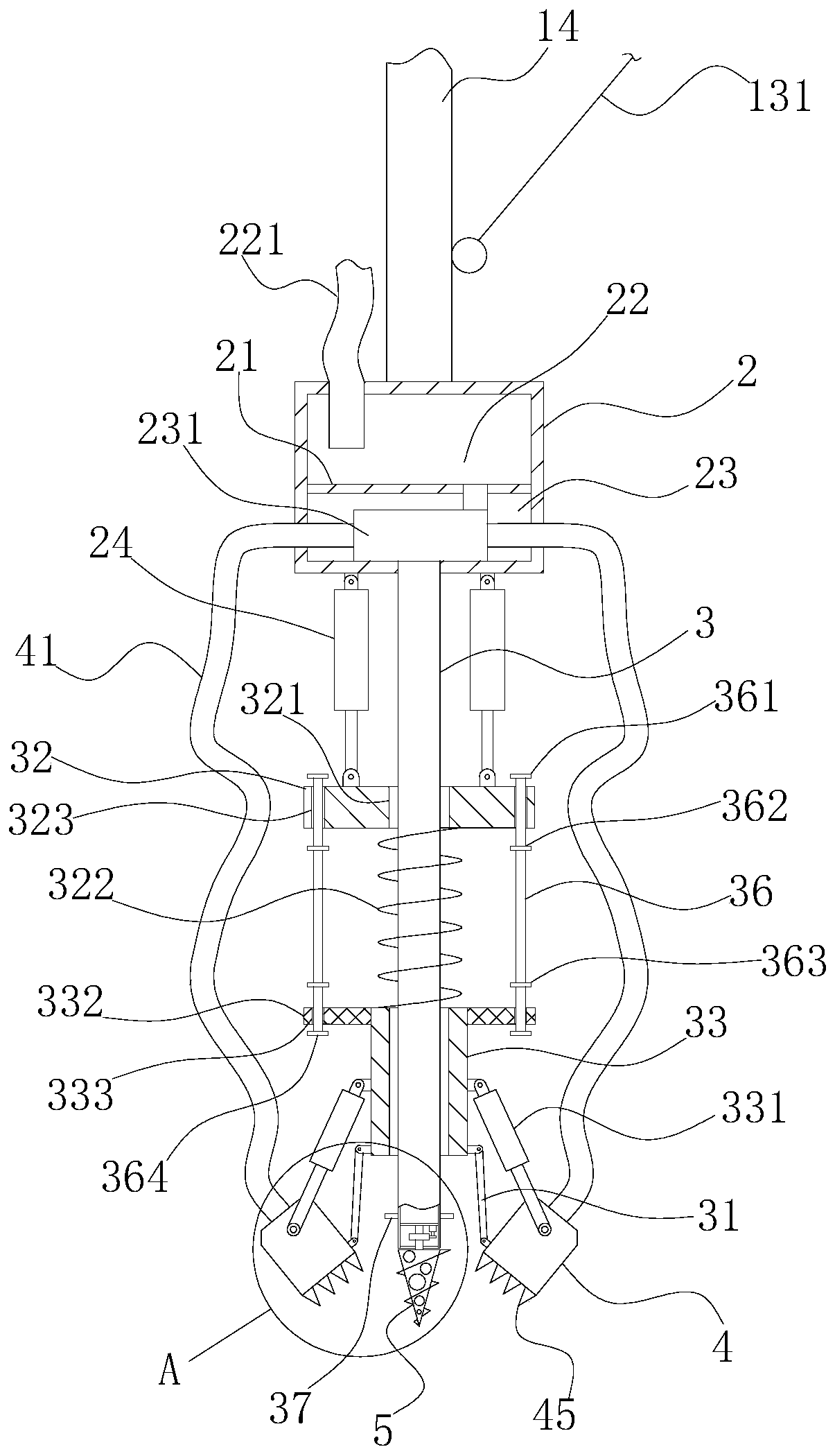

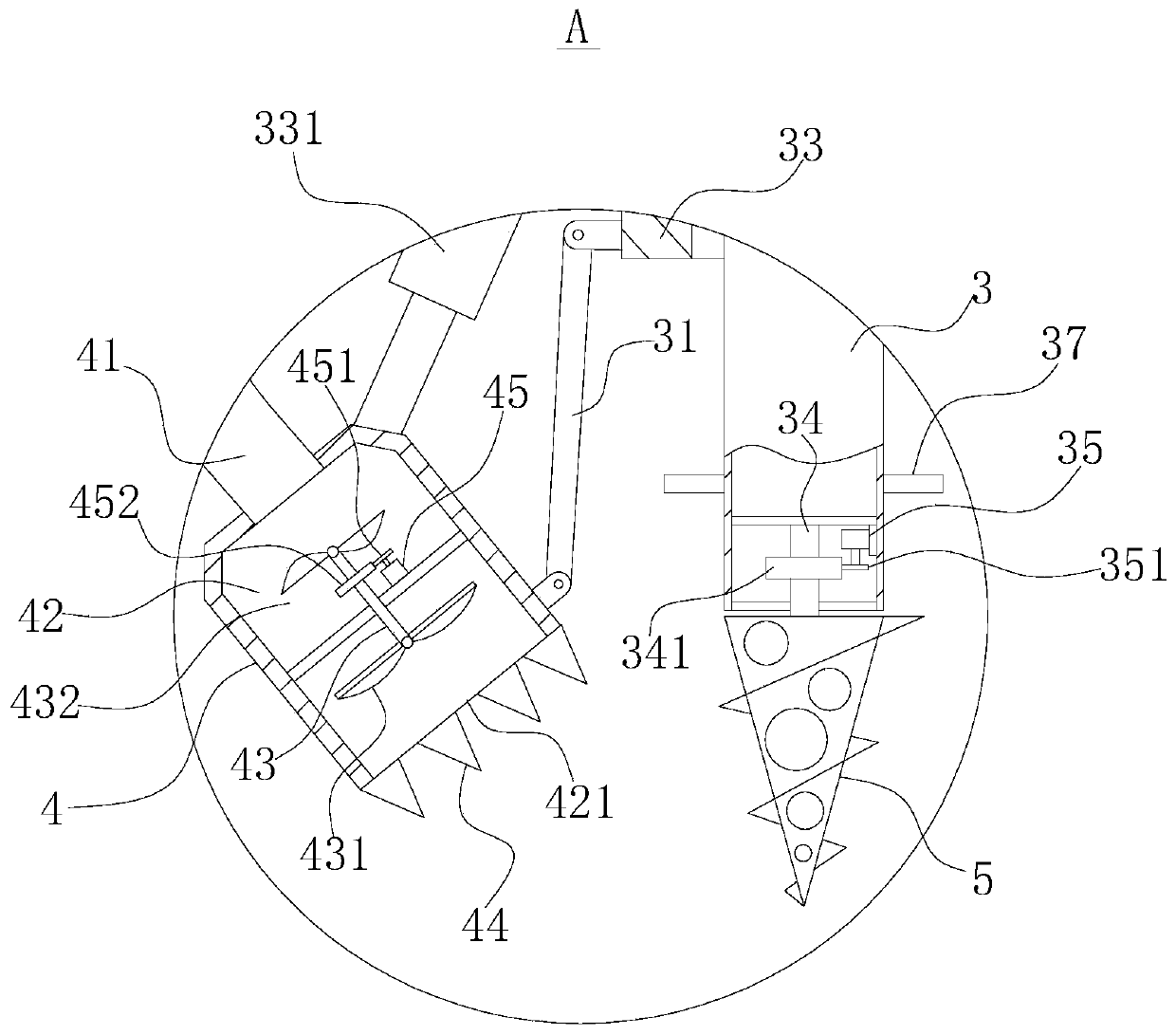

Cutter suction dredger with improved structure

PendingCN110042878AImprove suction efficiencyImprove work efficiencyMechanical machines/dredgersReamerEngineering

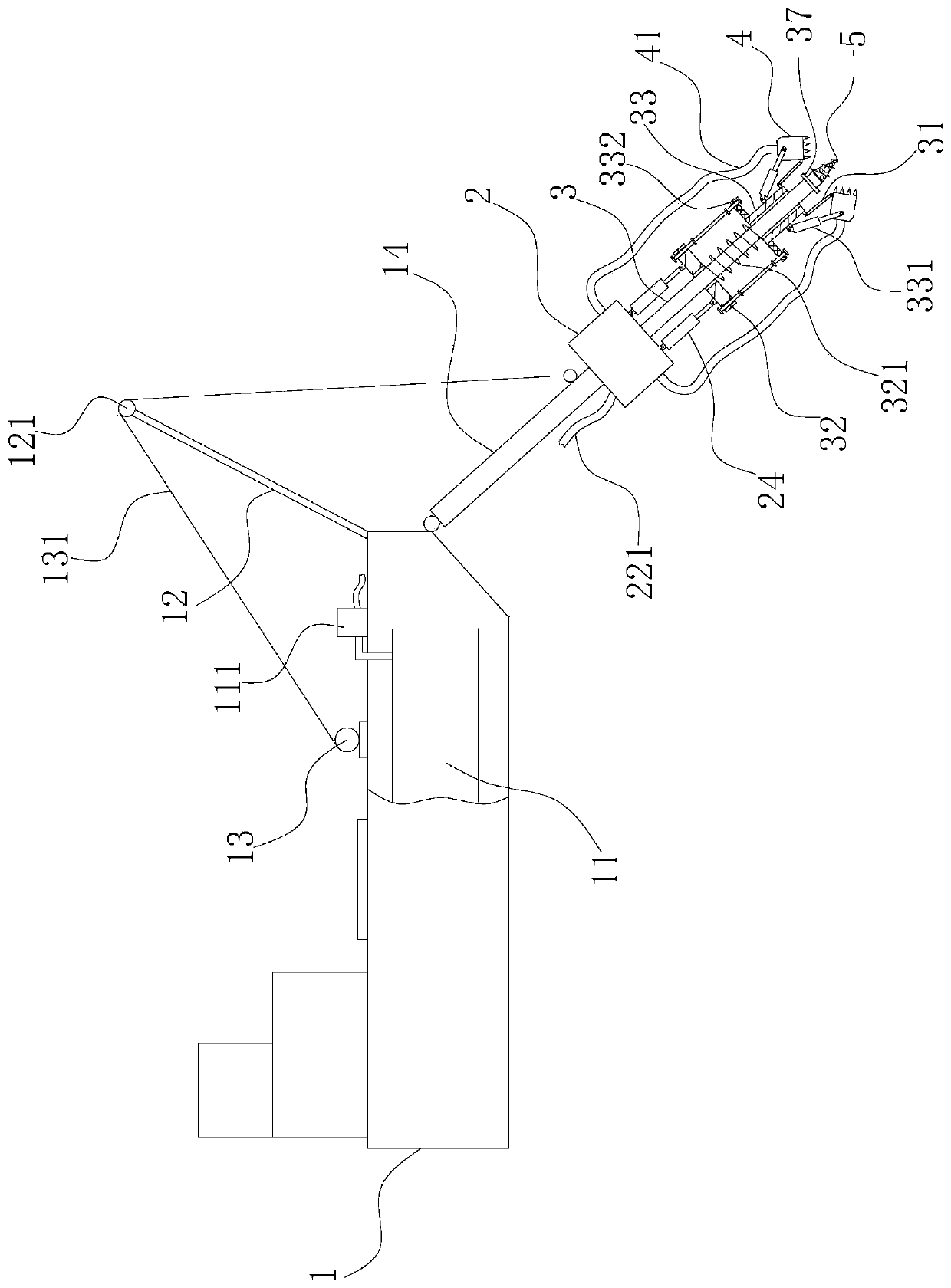

The invention provides a cutter suction dredger with an improved structure, and belongs to the technical field of dredgers. The cutter suction dredger with the improved structure comprises a hull structure, a rotary rod, an installation box and a mud conveying pipe, wherein a mud storage cabin is arranged in the hull structure; a first mud suction pump is arranged on the hull structure and communicates with the mud storage cabin through a pipe; one end of the rotary rod is hinged to the head part of the hull structure; one side of the installation box is fixedly connected with the rotary rod;the installation box comprises a clapboard; the clapboard divides the interior of the installation box into a storage chamber and an equipment chamber; the storage chamber is connected with an inlet of the first mud suction pump through a mud suction header pipe; a second mud suction pump is arranged in the equipment chamber; an outlet of the second mud suction pump is connected with the storage chamber through a pipe; the mud conveying pipe is fixedly connected with the installation box and is connected with an inlet of the second mud suction pump through a flexible pipe; a reamer is arrangedat the lower end of the mud conveying pipe; a sleeve pipe is arranged on the outer side of the mud conveying pipe in a sleeving way; and multiple auxiliary mud suction mechanisms capable of sucking silt are arranged on the sleeve pipe. According to the cutter suction dredger with the improved structure provided by the invention, the reamer can be assisted to quickly suck the silt, so that the working efficiency is improved.

Owner:ZHEJIANG INT MARITIME COLLEGE

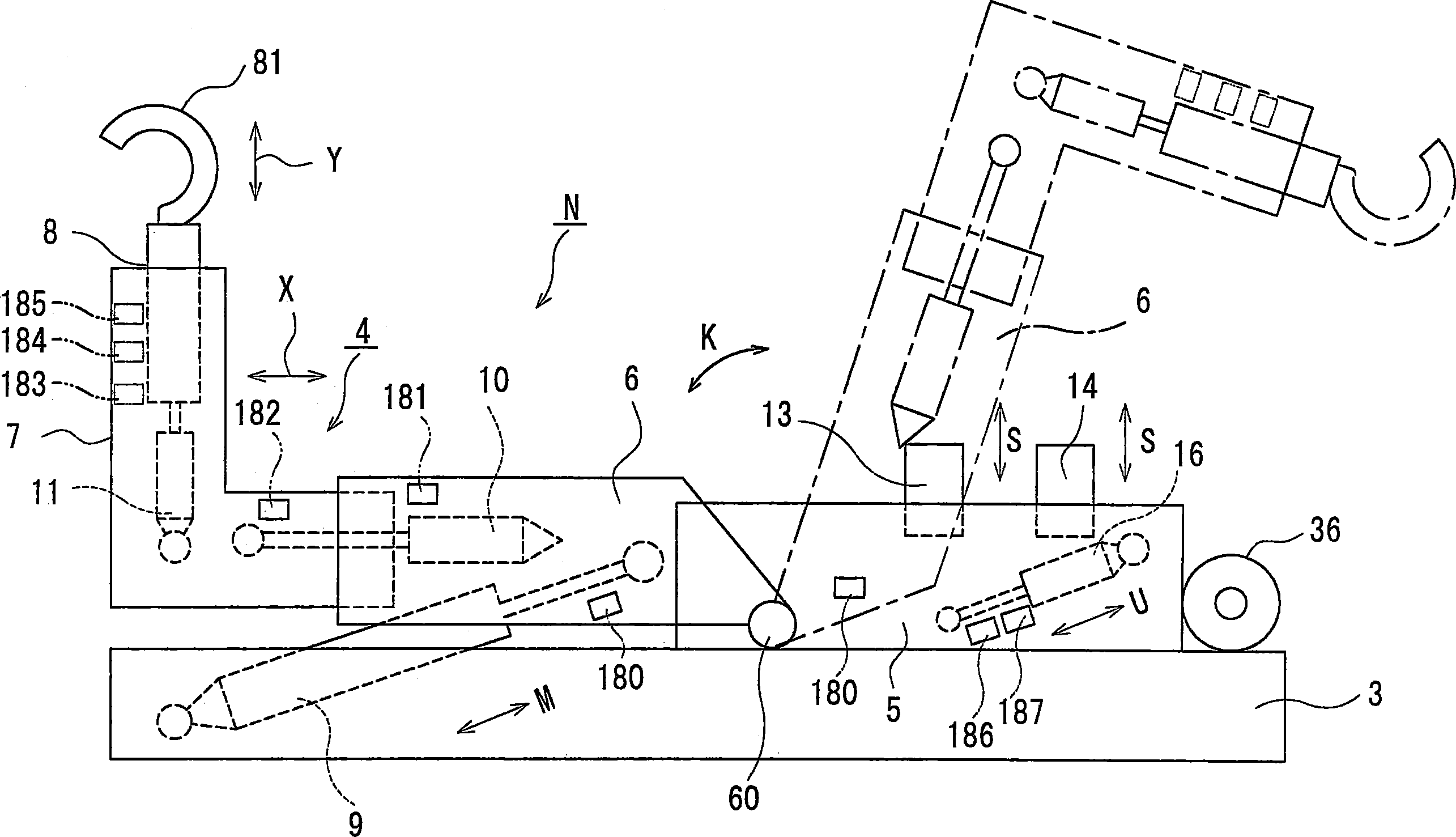

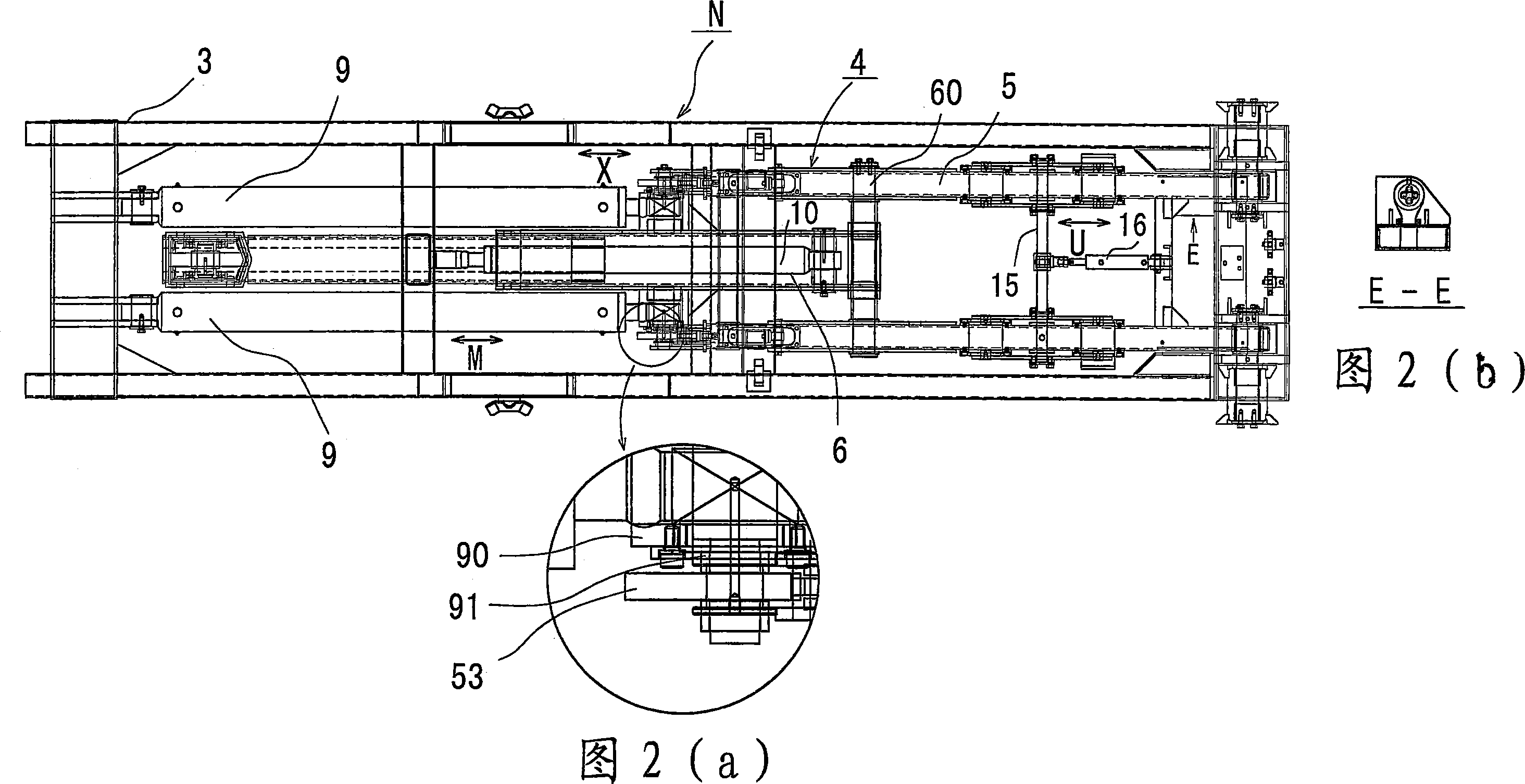

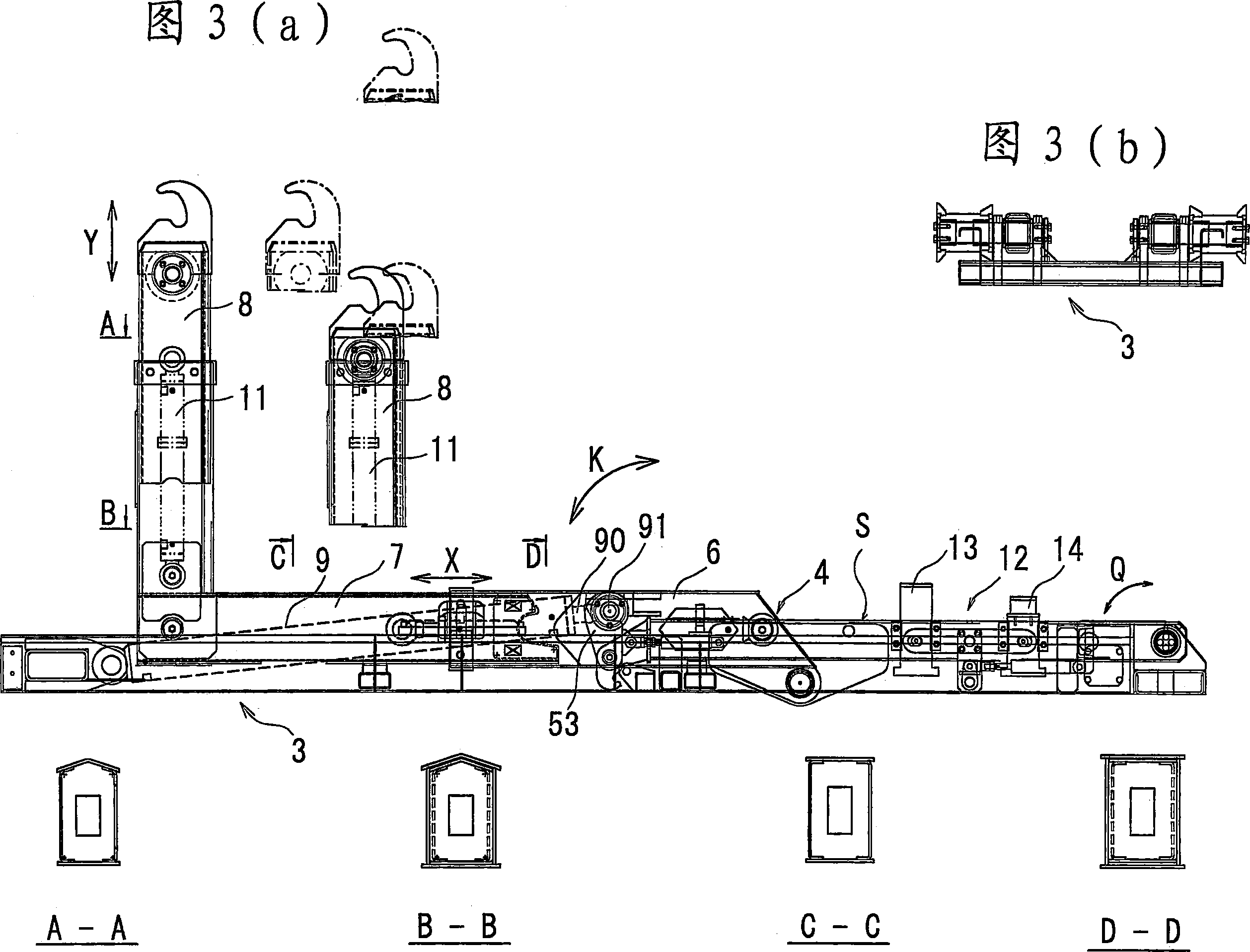

Container loading and unloading vehicle and container loading and unloading method

InactiveCN1872584ADeletion of vehicle inspection feeReduce labor costsVehicles with cranesEngineeringMechanical engineering

Owner:TECHNO MIZUHO

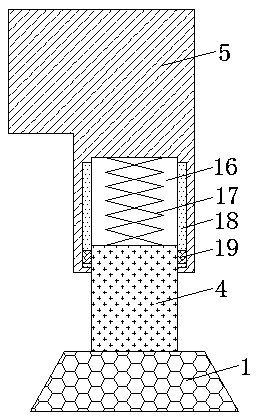

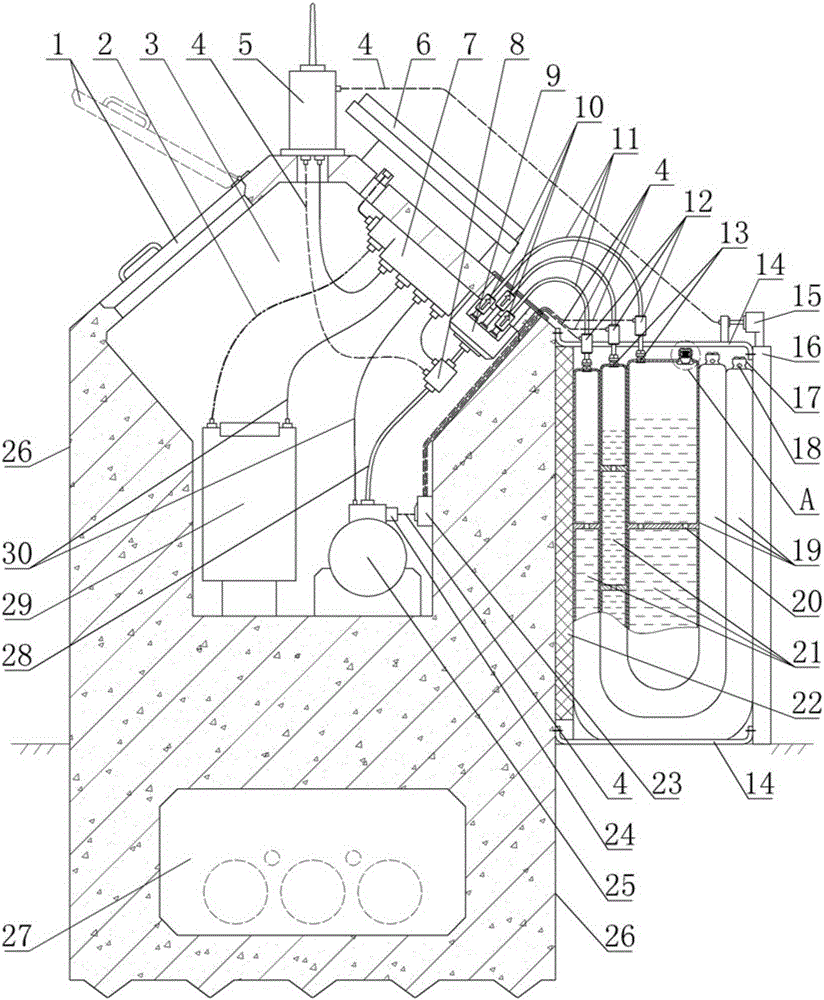

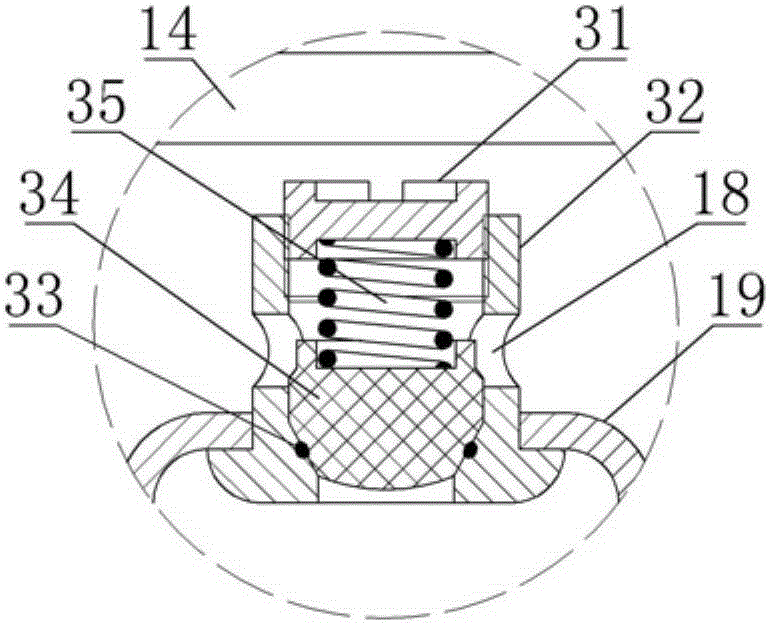

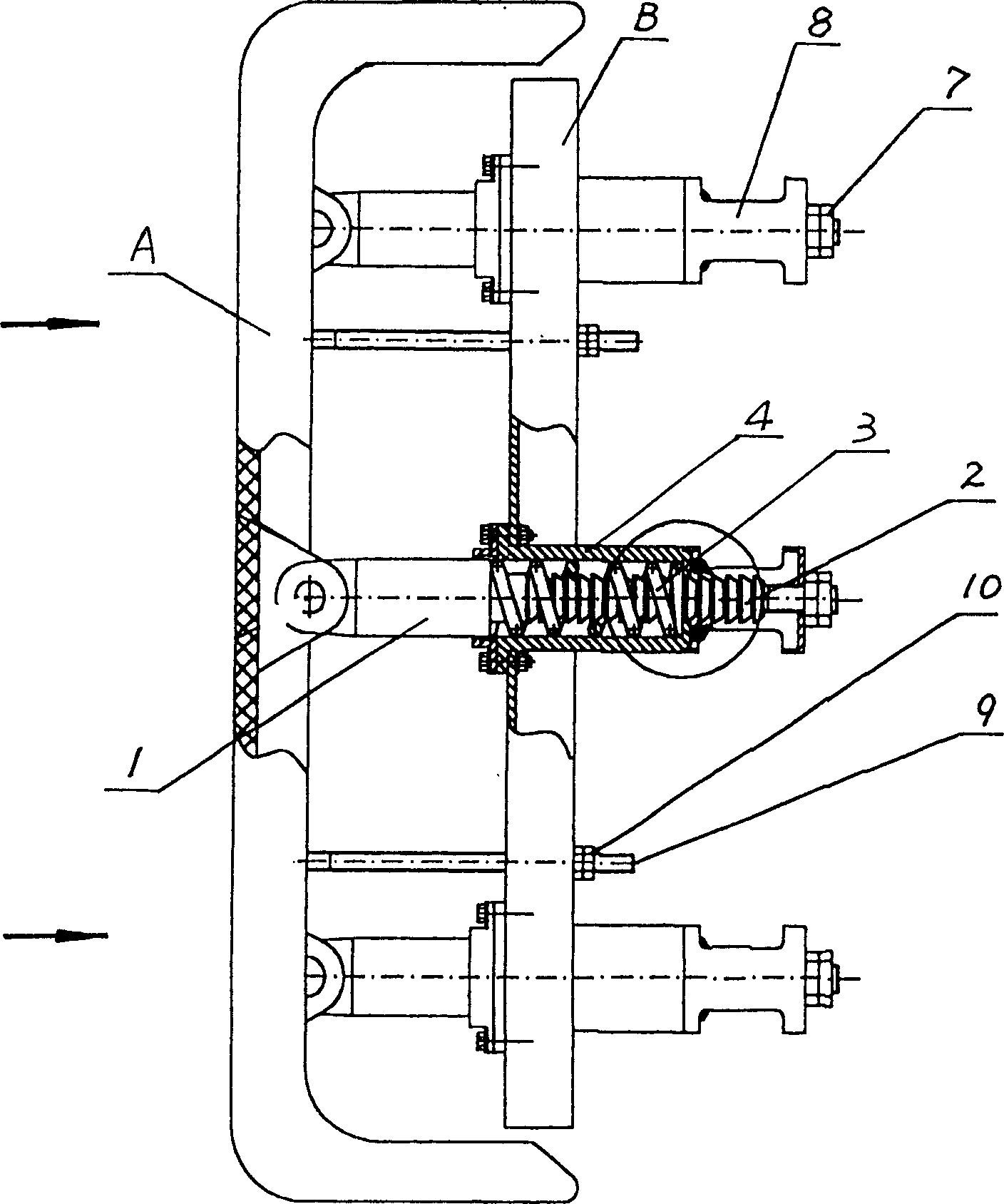

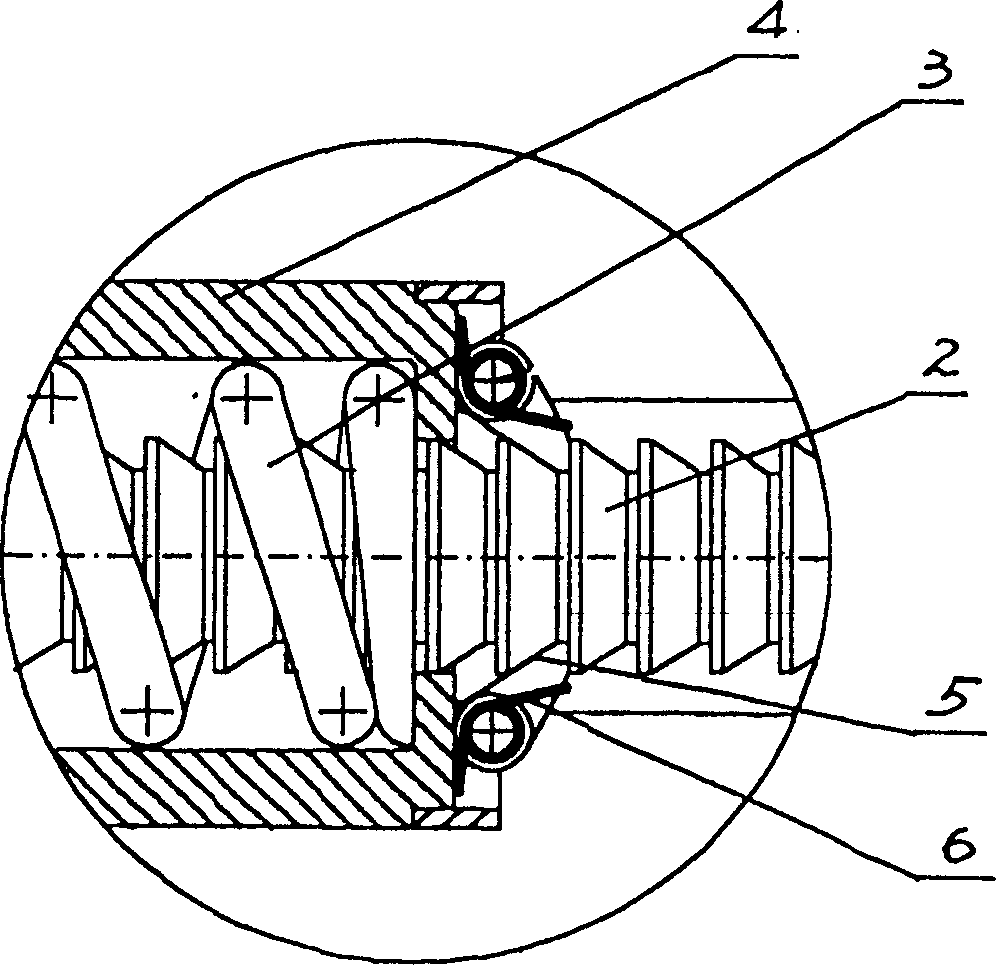

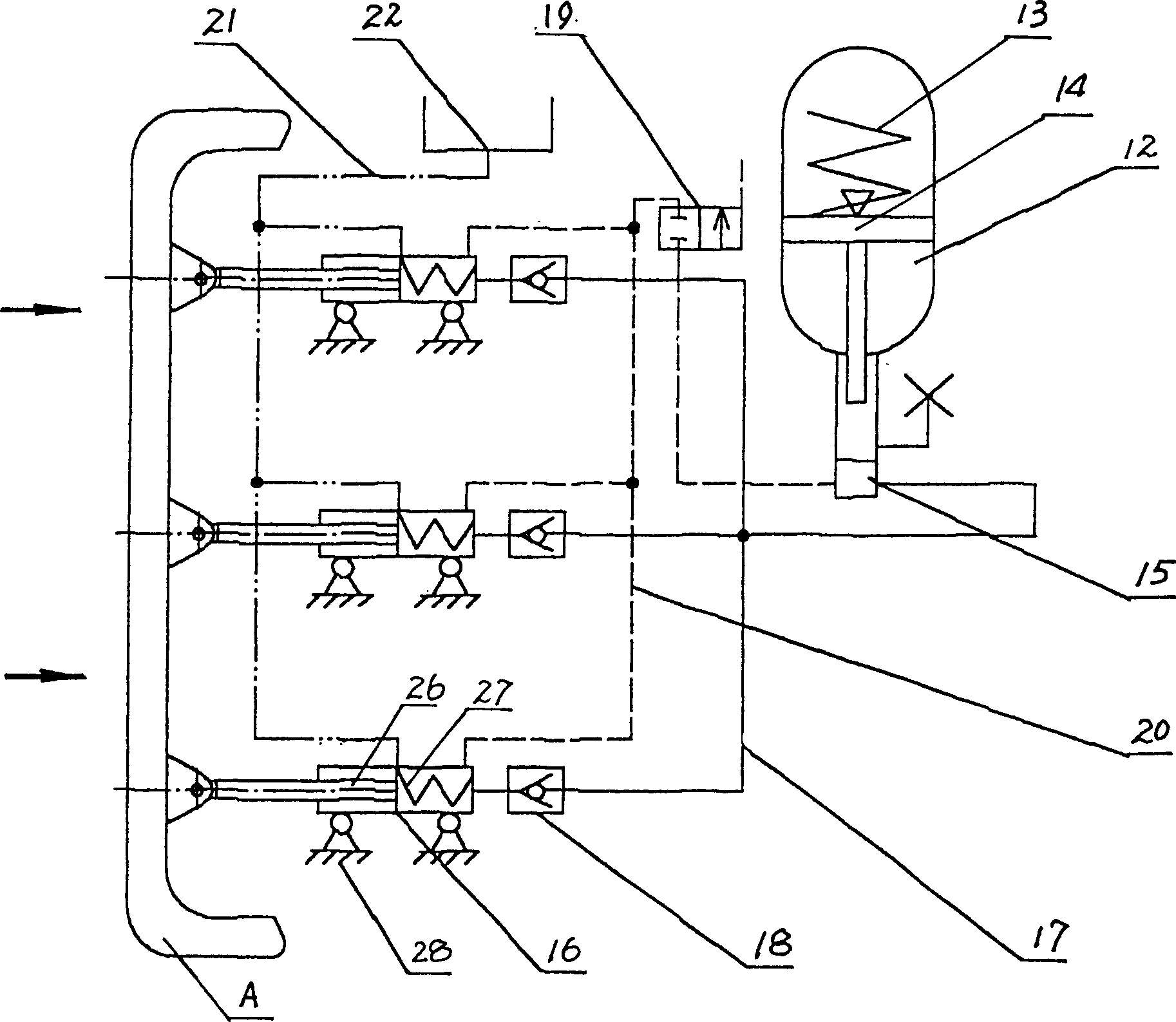

Longitudinal absorber for reducing perforation instantaneous shock vibration force

InactiveCN103174402AReduce vibration impactShock vibration force weakeningFluid removalVibration attenuationOperability

The invention relates to a longitudinal absorber for reducing perforation instantaneous shock vibration force. The longitudinal absorber comprises a pressure guide tube, an inner sleeve sleeved outside the pressure guide tube and an outer sleeve sleeved outside the inner sleeve; two ends of the pressure guide tube are respectively connected with an upper connector and a lower connector, a connection position between the pressure guide tube and the upper connector is fixed through threads, an internal cavity of the pressure guide tube is always communicated with that of the upper connector, and the pressure guide tube penetrates through an internal cavity of the lower connector to be communicated with the outside; a spring is further sleeved outside the inner sleeve, the spring and the outer sleeve are arranged in parallel, and an outer casing is sleeved outside the spring; and sealing pieces are arranged at the connecting position of the upper connector and the pressure guide tube and at the connecting position of the upper connector and the inner sleeve, and the sealing pieces are further arranged at the connecting position of the inner sleeve and the outer sleeve and at the connecting position of the lower connector and the pressure guide tube. The longitudinal absorber effectively solves the problem that a motive seal of a conventional perforation absorber is easy to damage, weakens the perforation instantaneous shock vibration force, changes the liquid compression vibration attenuation environment, improves safe reliability and is simple and reasonable in structural design and strong in operability.

Owner:CHINA PETROLEUM & CHEM CORP +1

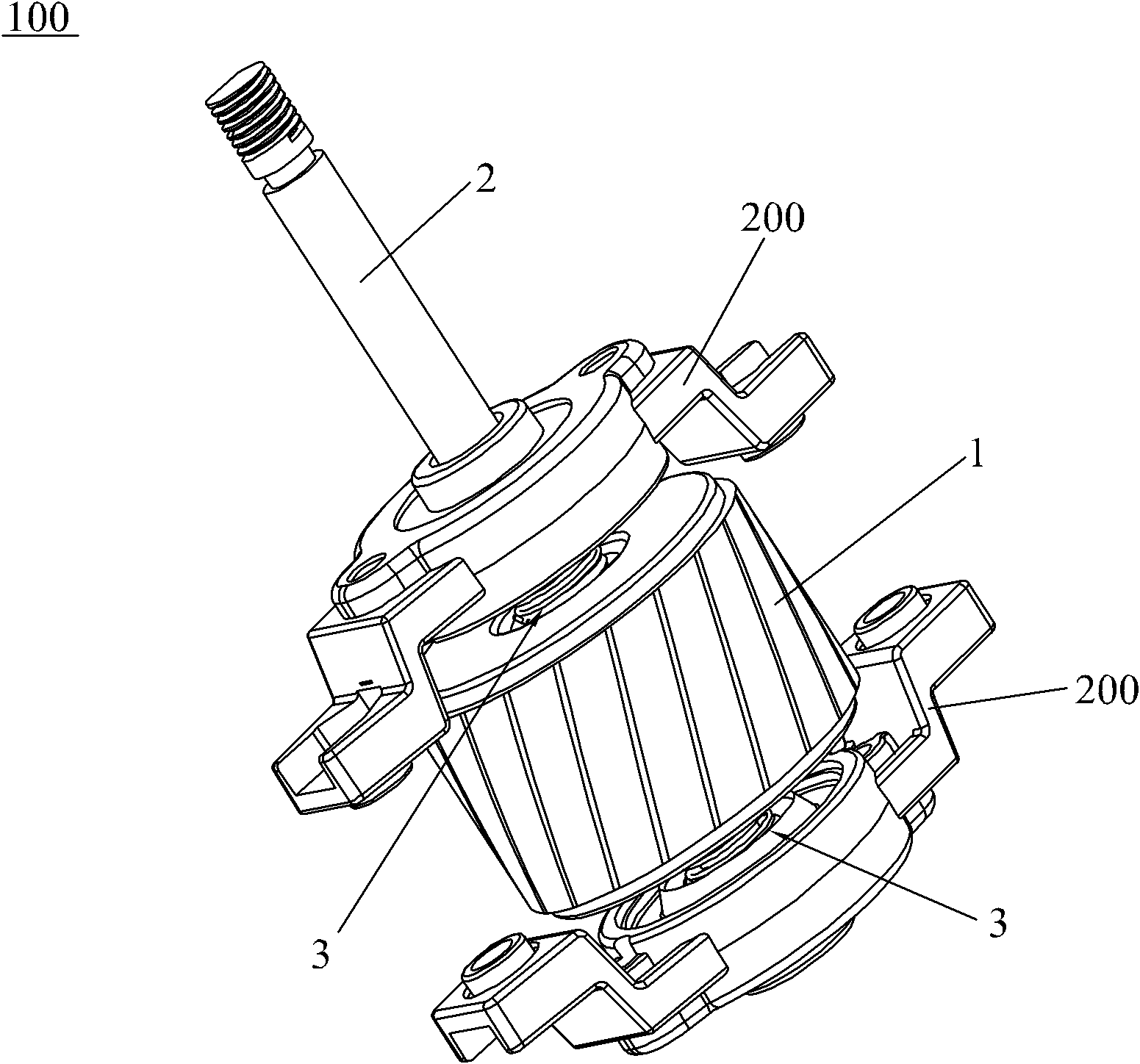

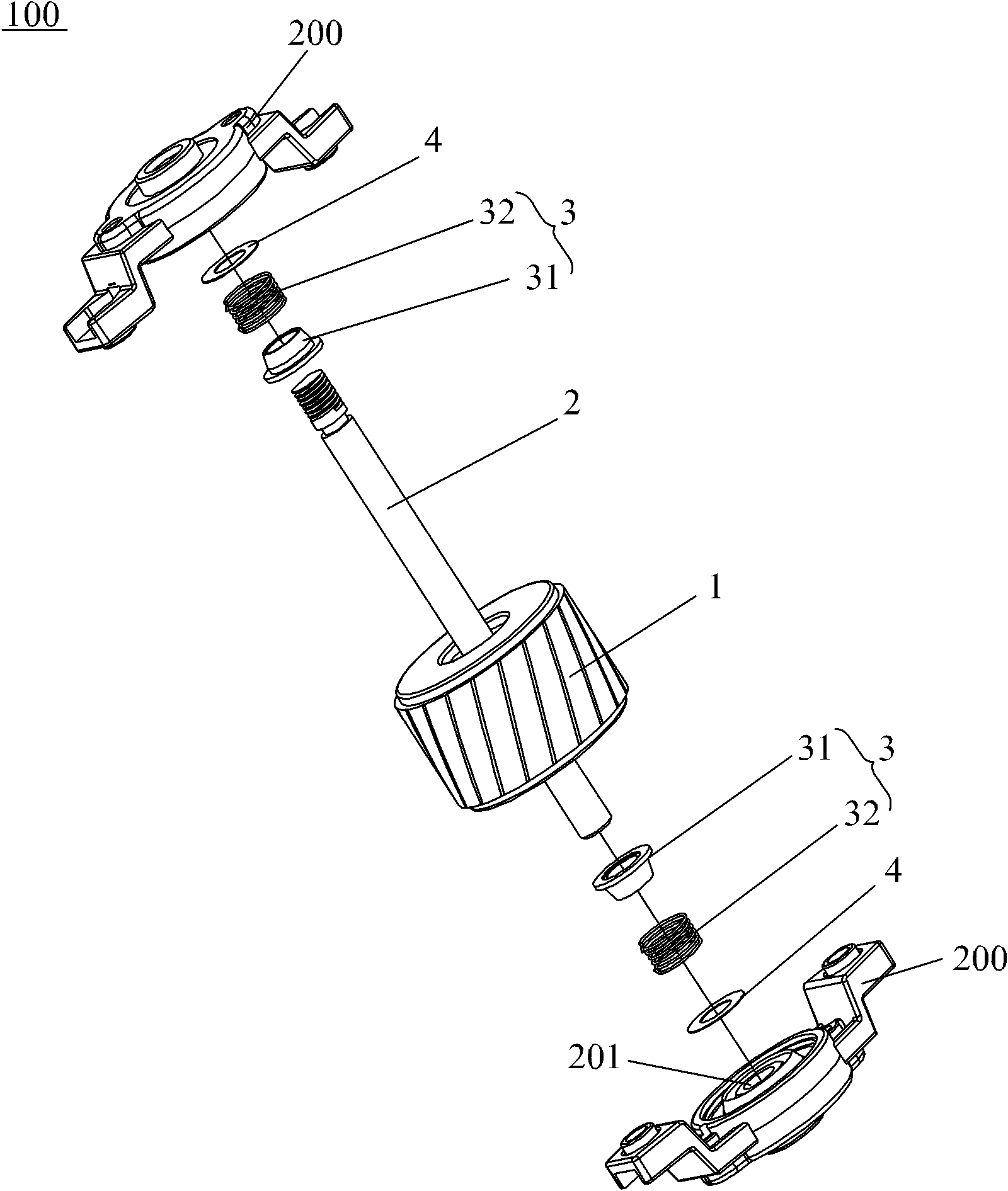

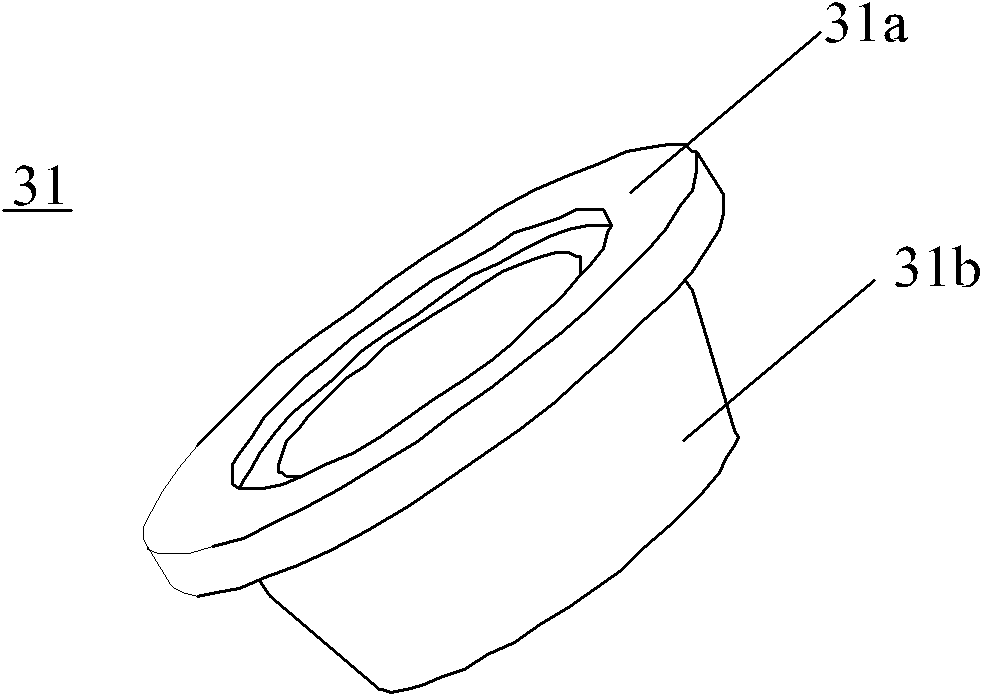

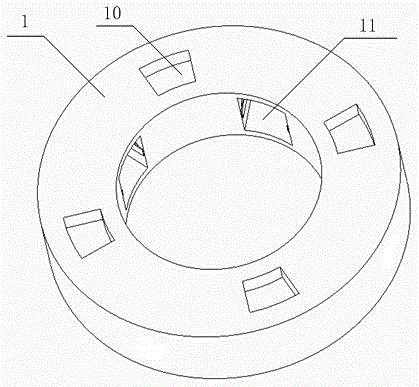

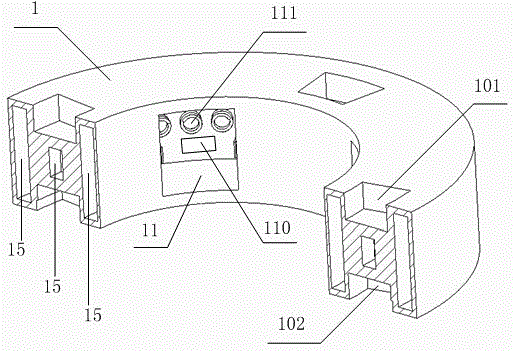

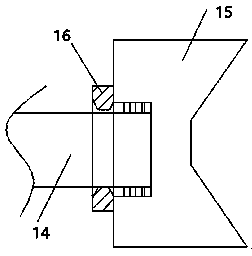

Vibration damping and noise reducing mechanism for motor rotor

The invention discloses a vibration damping and noise reducing mechanism for a motor rotor, which is suitable for small-power or micro-sensing motors. The mechanism comprises a rotor, a rotating shaft and vibration damping devices, wherein the rotor is fixed with the rotating shaft in a sleeve joint mode; the rotating shaft is pivoted on a bearing and one end of the rotating shaft passes through the bearing to form an output shaft; the vibration damping devices are respectively arranged between the rotor and the bearing symmetrically, and comprise a retainer ring and an elastic element; the retainer ring is sleeved on the rotating shaft; the elastic element is sleeved on the rotating shaft; one end of the elastic element is pressed against the retainer ring, and the other end of the elastic element is pressed against the end face of the bearing; and the retainer ring has stair-step structure and comprises a conflict part and a sleeve part, wherein the conflict part is resisted on the rotor, the sleeve part is sleeved on the elastic element. The vibration damping and noise reducing mechanism for the motor rotor can realize vibration damping in the radial direction, and can reduce noise generated by vibration.

Owner:DONGGUAN GUOLIANG MOTOR

Commercial vehicle active control anti-collision mechanism for protecting passengers and vehicles on multiple angles

ActiveCN106828400ARealize multi-angle anti-collision functionIncrease stiffnessPedestrian/occupant safety arrangementBumpersElectric controlControl theory

The invention relates to a commercial vehicle tail anti-collision device, and discloses a commercial vehicle active control anti-collision mechanism for protecting passengers and vehicles on multiple angles. The mechanism has multiple anti-collision functions, and can actively control the mechanism parameter to reduce the collision harm to vehicles and passengers. The impact energy of the vehicle in rear-end collision is absorbed by mating reaction of a spring and a damper, the collisions at different positions are actively controlled, thereby reducing the damage of vehicles and passengers by the vehicle rear-end collision accident; meanwhile, a camera and a radar mounted on the mechanism can actively control the spring damper through an electric control mechanism, and lighten the harm caused by collision greatly through actively adjusting the parameters of the spring and the damper; moreover, multiple driving modes can be used for realizing the mated work of the radar and the camera, thereby protecting passengers, in particular to children, buildings, and vehicles, and realizing the safe driving.

Owner:JILIN UNIV

Intelligent trash can with good stability performance

The invention discloses an intelligent dustbin with good stability, which comprises a base, two symmetrical outriggers are fixedly connected to the outer surface of the base, and a cavity is opened at the bottom of each outrigger, and each cavity The first damping spring is fixedly connected to the inner top wall of each cavity, and two symmetrical snap-in grooves are opened on the inner wall of each cavity. The smart trash can with good stability can effectively buffer the actual pressure of the trash can body. The trash can body can move up and down and left and right, and can effectively slow down the external collision force, effectively avoiding The tipping and bumping of the smart trash can effectively avoid the fall of family members, and the safety performance is good, ensuring the effective contact between the rubber suction cup and the placement surface, and has a certain anti-skid performance, which effectively avoids the large size of the smart trash can. The amplitude movement effectively enhances the friction between the smart trash can and the placement surface, and has good stability.

Owner:郑州永静智能科技有限公司

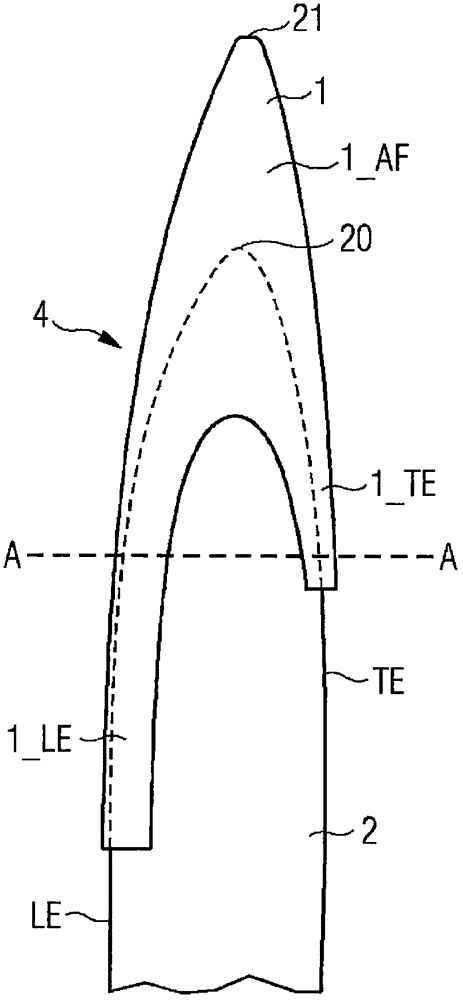

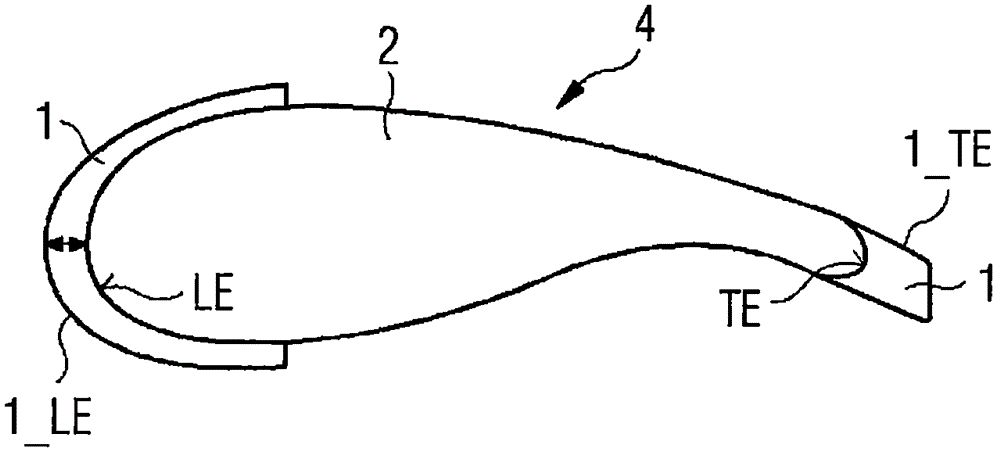

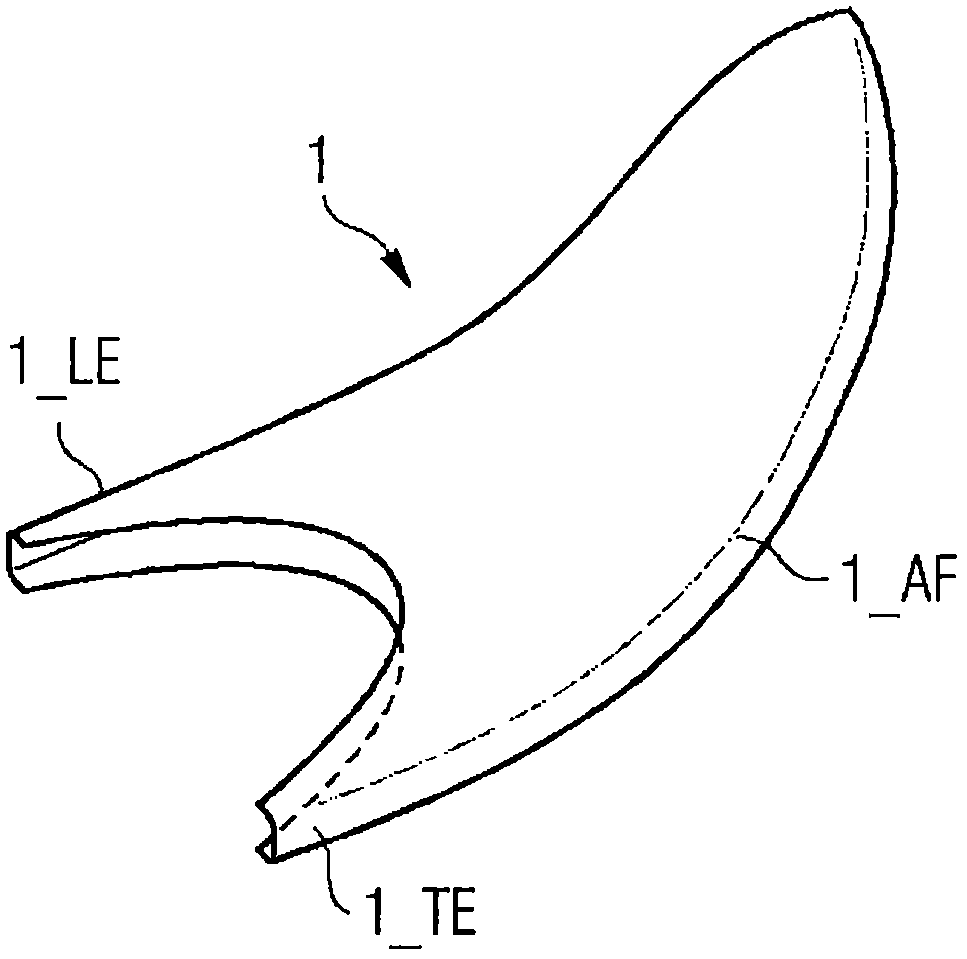

Rotor Blade Extension Part

InactiveCN105756865AImpact mitigationEngine manufactureFinal product manufactureLeading edgeTrailing edge

The invention describes a rotor blade extension part (1) realized for mounting over a tip (20) of a wind turbine (3) rotor blade (2), comprising an airfoil extension portion (1_AF) realized to extend the length (L 2 ) of the rotor blade (2); a leading edge portion (1_LE) realized to cover a profile of the leading edge (LE) of the rotor blade (2); and a trailing edge portion (1_TE) realized to cover a profile of the trailing edge (TE) of the rotor blade (2). The invention further describes a wind turbine (3) comprising a number of rotor blades (2) and a rotor blade extension part (1) according to the invention mounted to each rotor blade (2).

Owner:SIEMENS AG

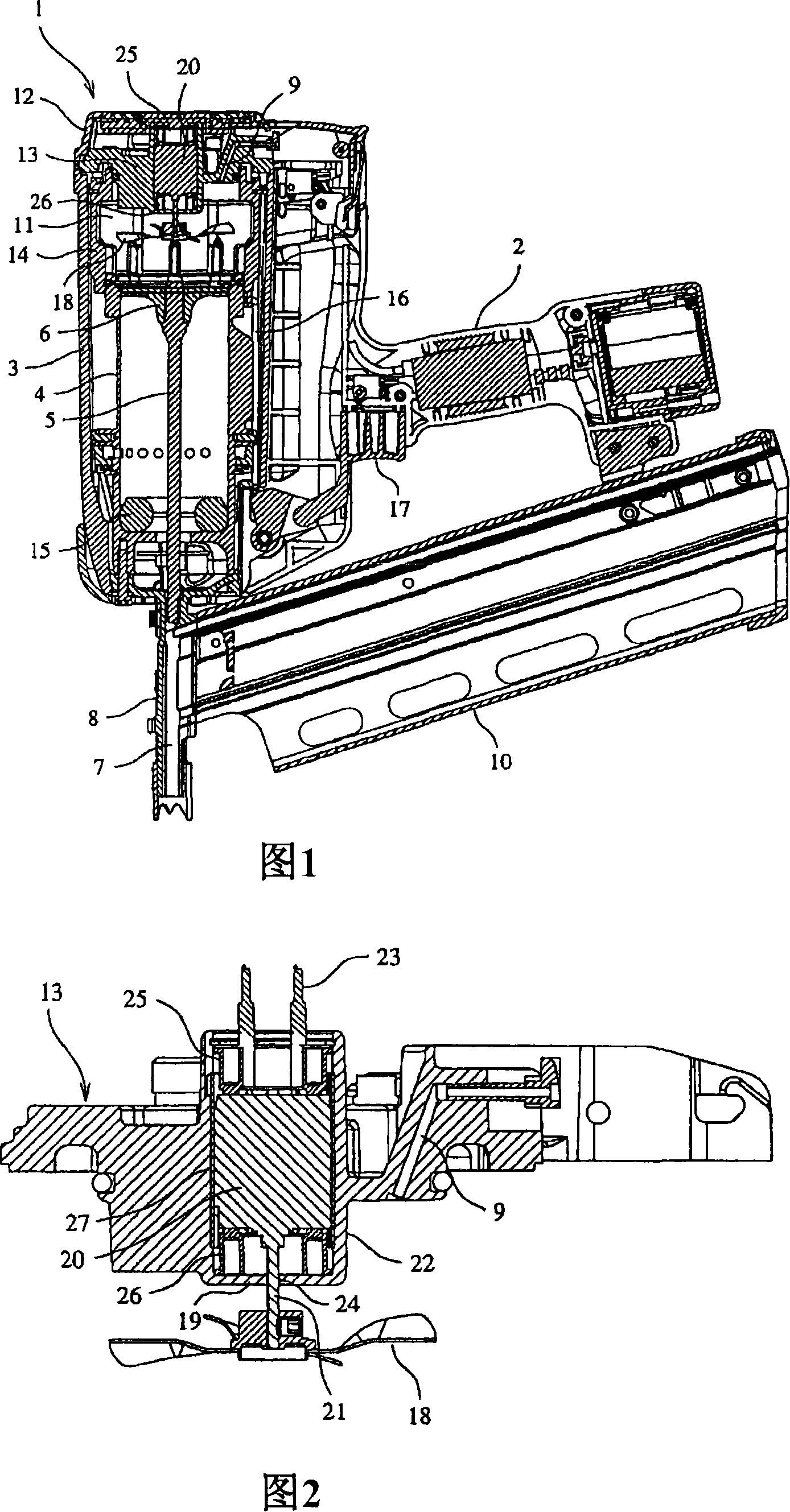

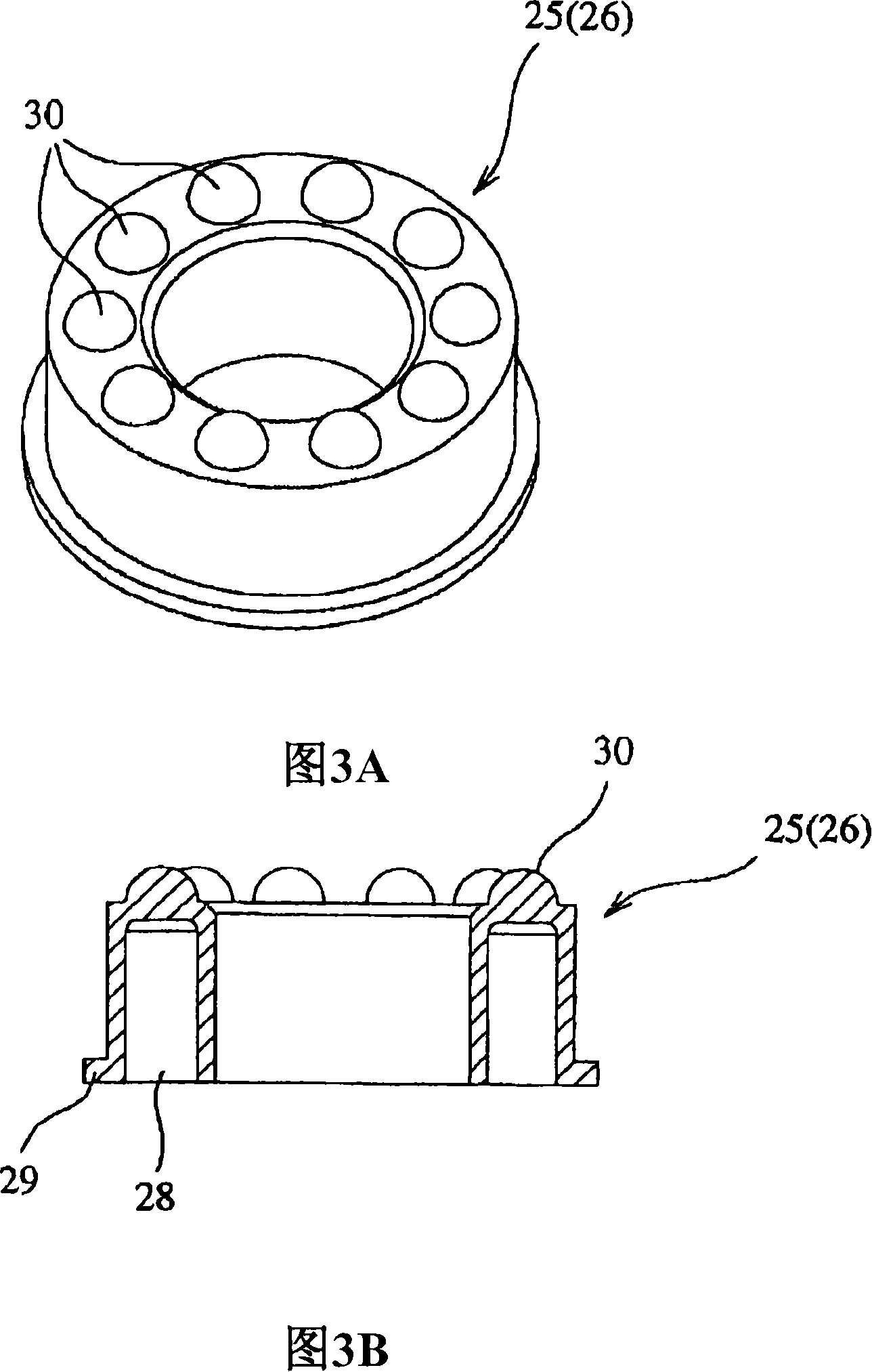

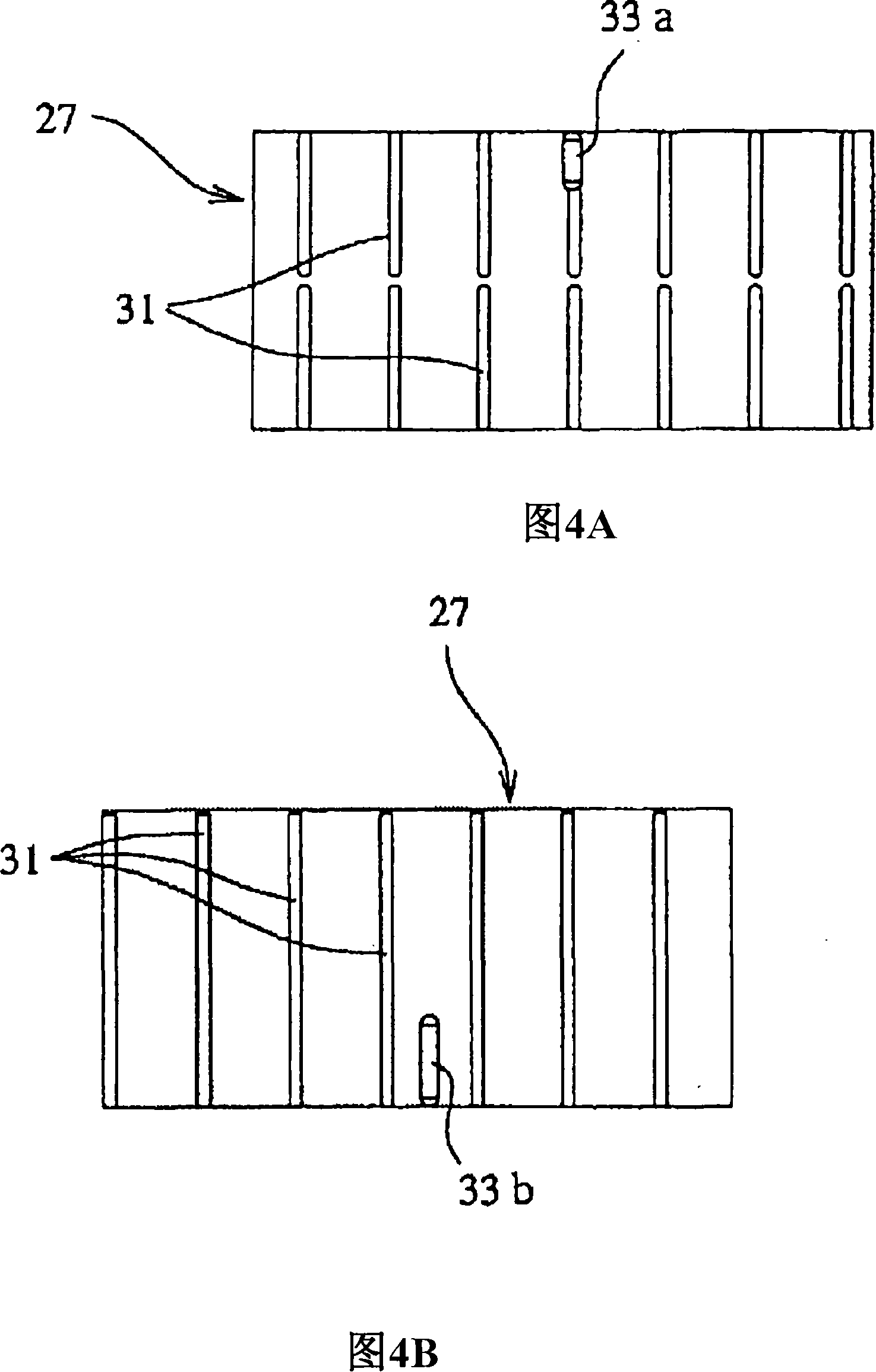

Gas combustion type hammering tool

InactiveCN101155668AImpact mitigationAvoid contactSpringsPortable power-driven toolsCombustion chamberEngineering

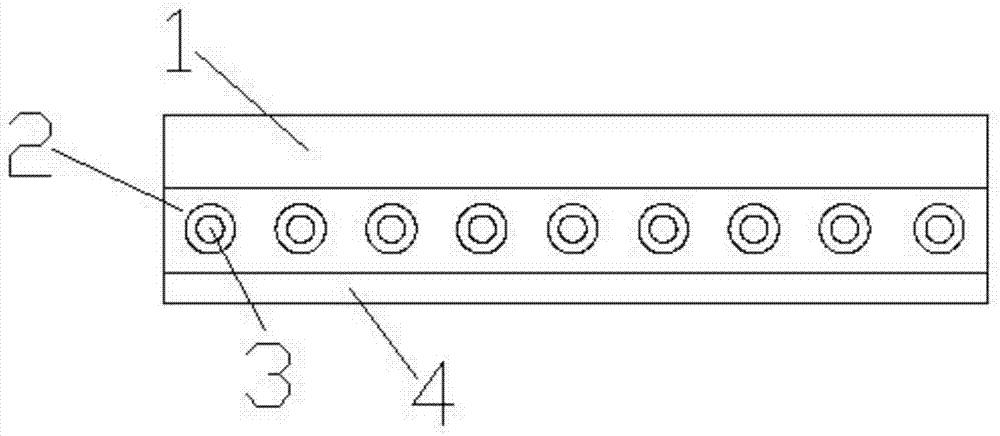

A gas combustion type hammering tool, wherein a motor storage part (22) is formed in the upper wall of a combustion chamber (11). The shaft (21) of a motor (20) is coupled to a rotating fan (18) facing the combustion chamber (11) through the bottom part of the storage part (22). A mixed gas obtained by mixing gases by the rotating fan (18) is ignited and burned in the combustion chamber (11). A fastener is hammered by the pressure of combustion gas produced by the combustion. The motor (20) is stored in the storage part (22) through short cylindrical elastic damping bodies (25) and (26) installed on the upper and lower parts thereof. A plurality of groove holes (28) longer in the vertical direction are formed in the damping bodies (25) and (26) at prescribed intervals along the circumferential direction.

Owner:MAX CO LTD

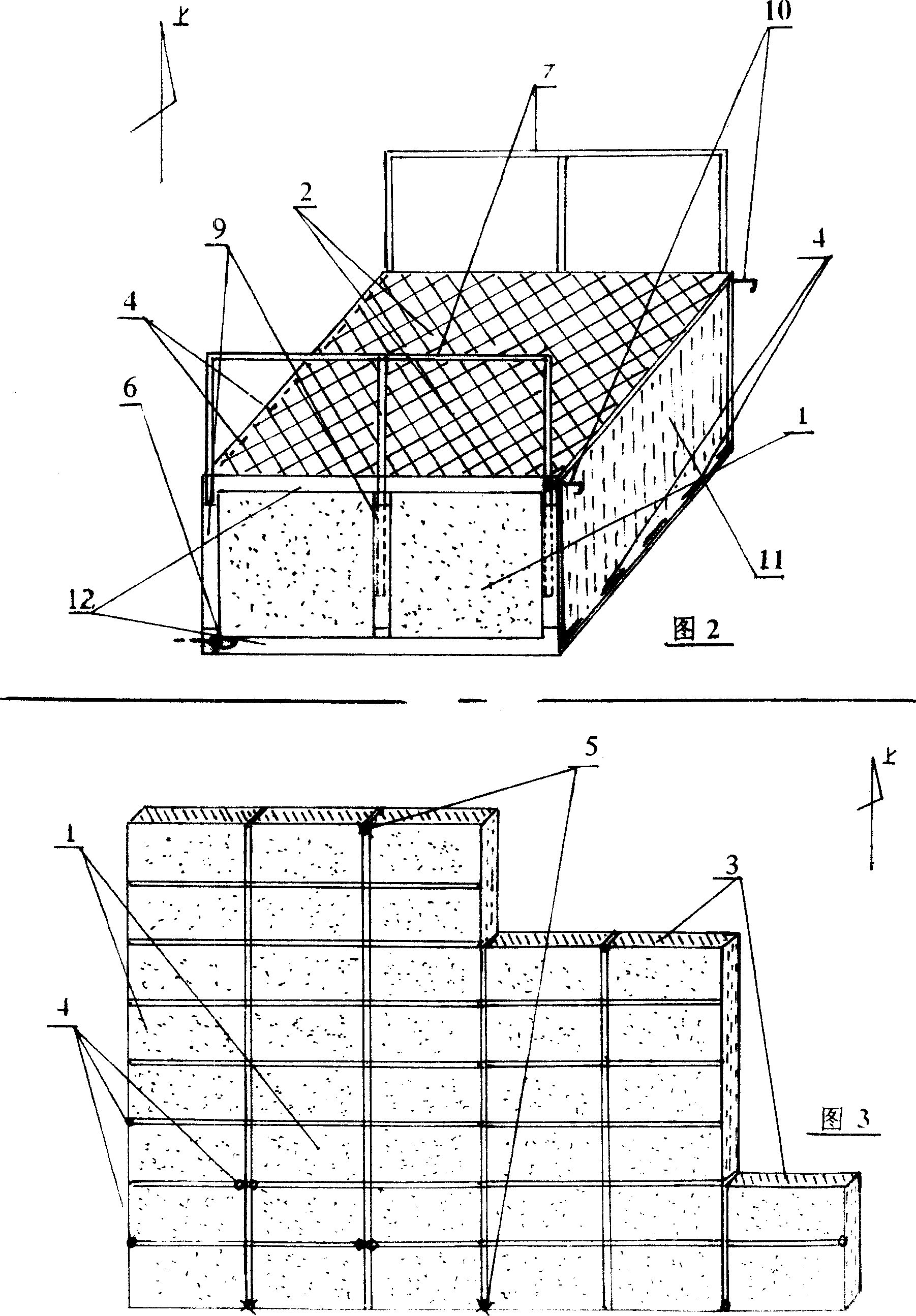

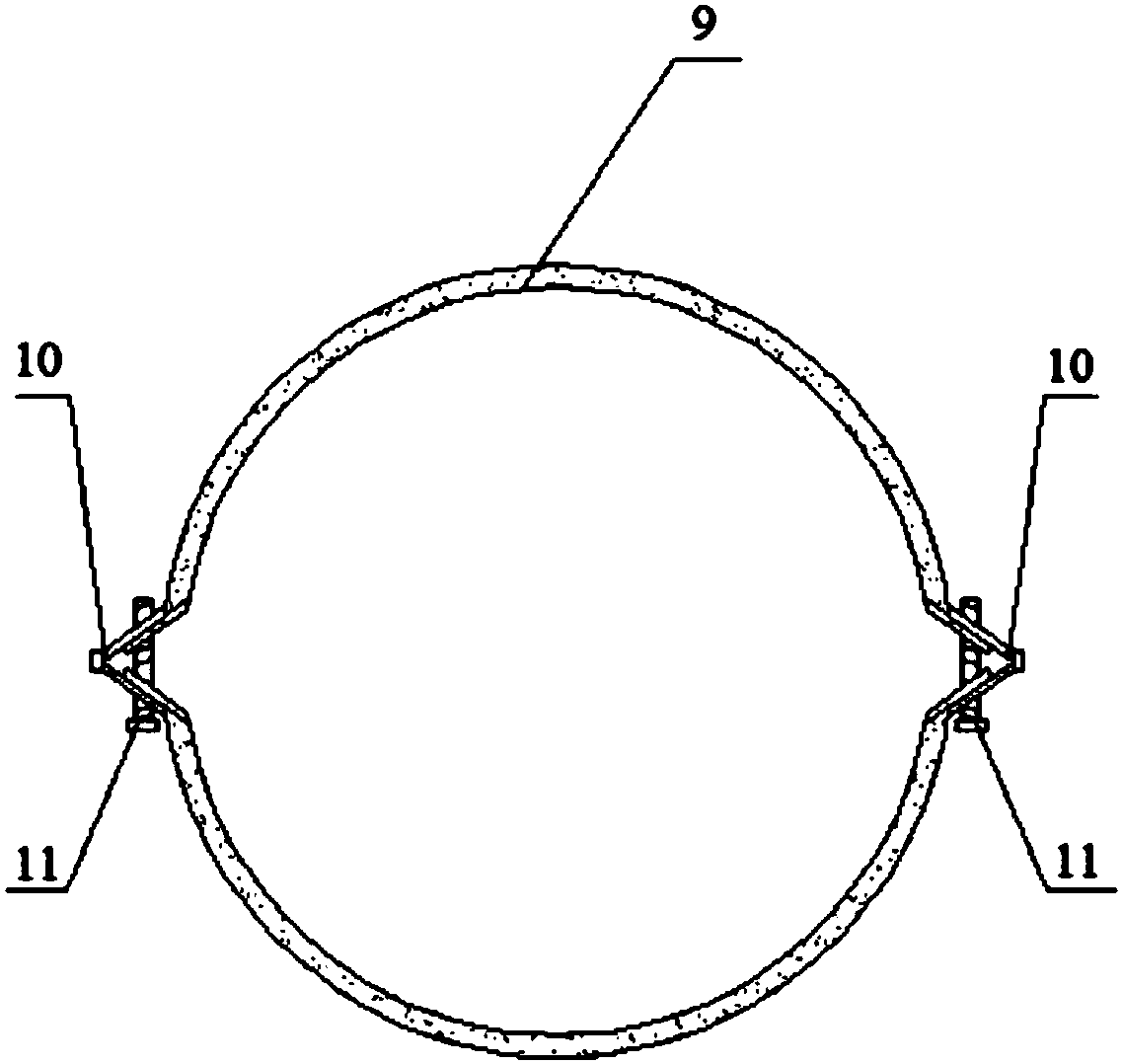

Offing temporary floating platform convenient for assembling and storing

InactiveCN101016079AEasy to storeEasy to expandWaterborne vesselsFloating bridgesFloating platformBuilding construction

A sea temporary floating table is mainly formed by a sea floating channel formed by light rectangle floating block units with strong stress frames, a floating platform connected with the channel and a storage drawing device. The invention is characterized in that the floating blocks are combined via leaf, hook and cable, to form the floating channel and platform quickly. The invention can be used in sea construction and rescue with low cost.

Owner:孙正维

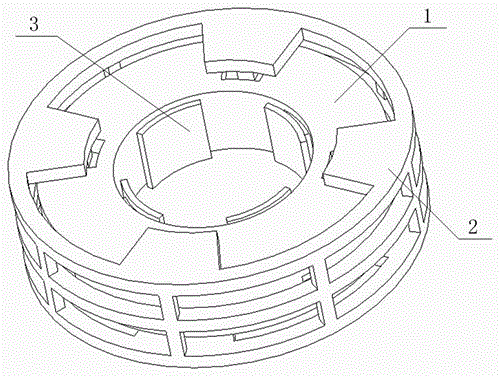

Anti-blocking self-vibrating ring for sprayed concrete pumping pipe

ActiveCN105546274ASolve the problem of pipe blockageHigh vibration frequencyPipe elementsShotcreteEngineering

The invention discloses an anti-blocking self-vibrating ring for a sprayed concrete pumping pipe. A groove is formed in the vibrating ring; a vibrator is mounted on the inner part of the vibrating ring; a pressure slot is arranged on the inner wall of the vibrating ring; a magnetic suspension electromagnet is mounted at the periphery of the groove; a fan-shaped frame is arranged on a ring-shaped bracket; a bulge is arranged on the fan-shaped frame; the magnetic suspension electromagnet is mounted at the periphery of the bulge; the bulge is embedded into the groove; and a pressure detecting device is mounted in the pressure slot. The anti-blocking self-vibrating ring has the function of automatically switching on and switching off, can complete switching among three working states of vibrating, strengthened vibrating, and stopping vibrating according to the blocking pressure of the pipe wall of the sprayed concrete pumping pipe, and also can automatically strength the vibrating frequency and the vibrating amplitude of the vibrating ring along with the increase of pressure, so that the pipe blocking problem of the sprayed concrete pumping pipe is solved, an interior electromagnet system can enable the vibrating ring to realize magnetic suspension in a pipe diameter direction and a pipeline direction, the impact effect of the vibrating ring to the pipeline outer pipe is greatly relieved, and the energy can be utilized to vibrate the sprayed concrete pumping pump to the greatest extent.

Owner:XIAN UNIV OF SCI & TECH

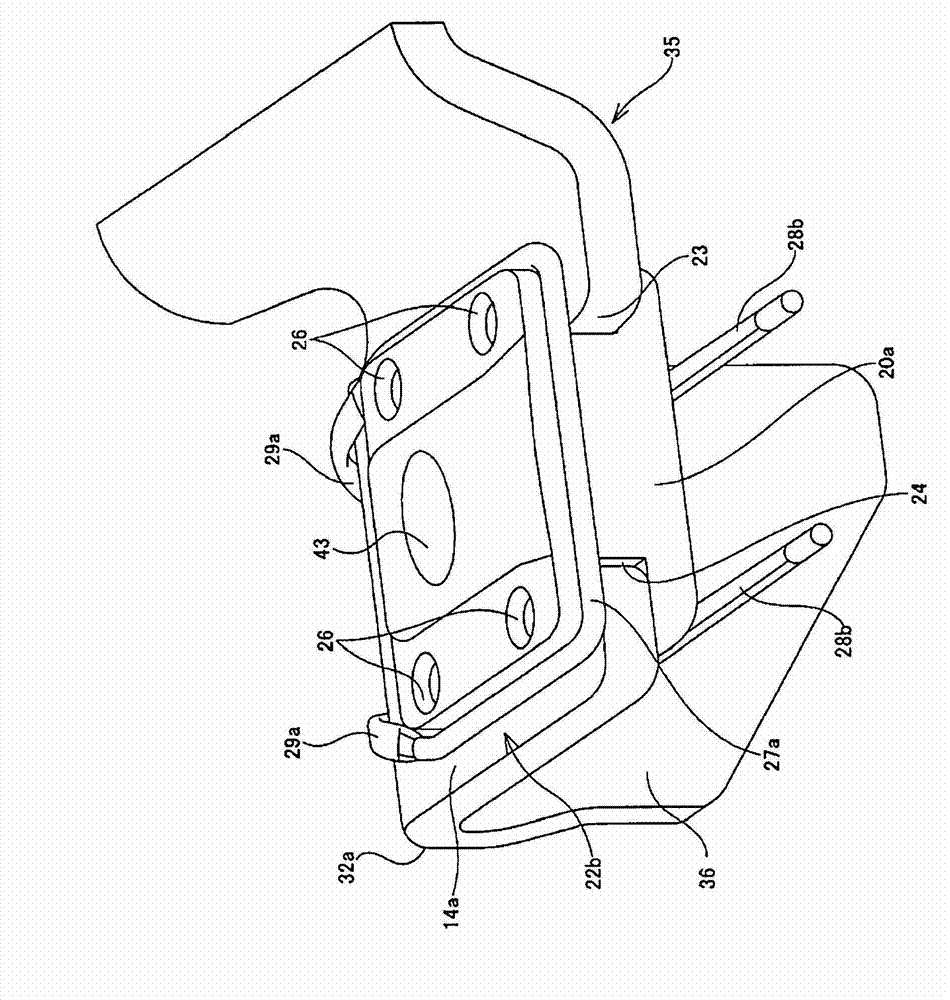

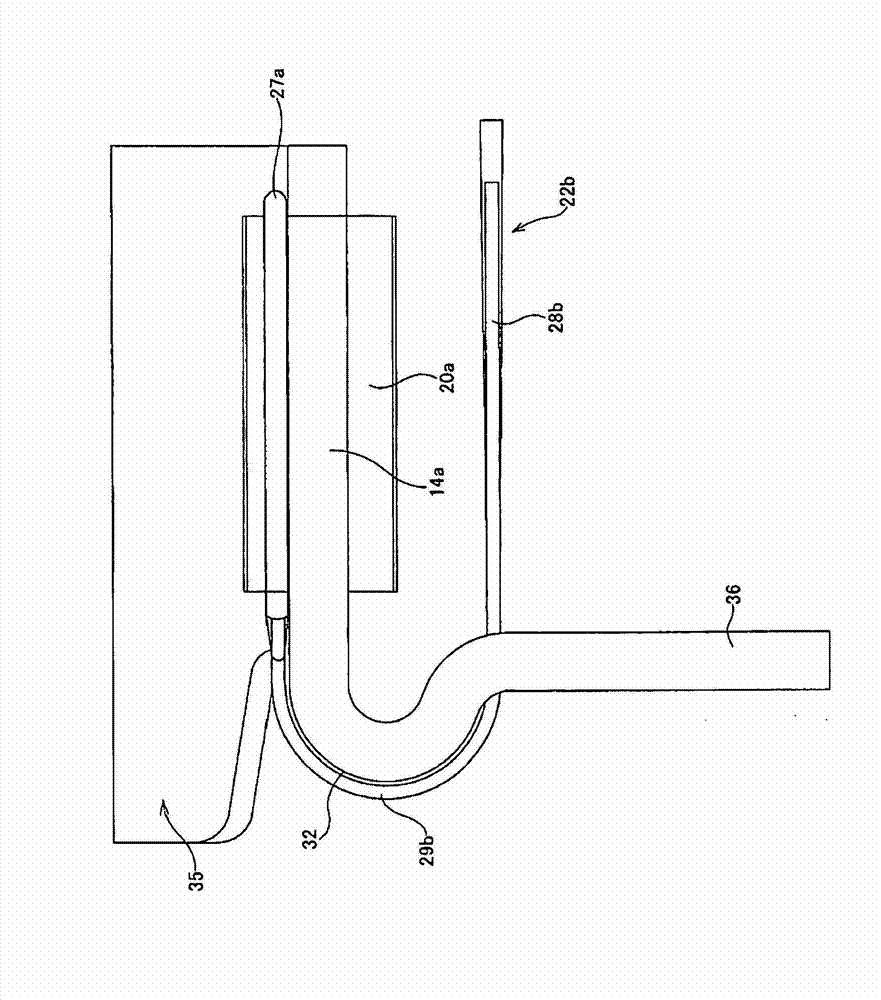

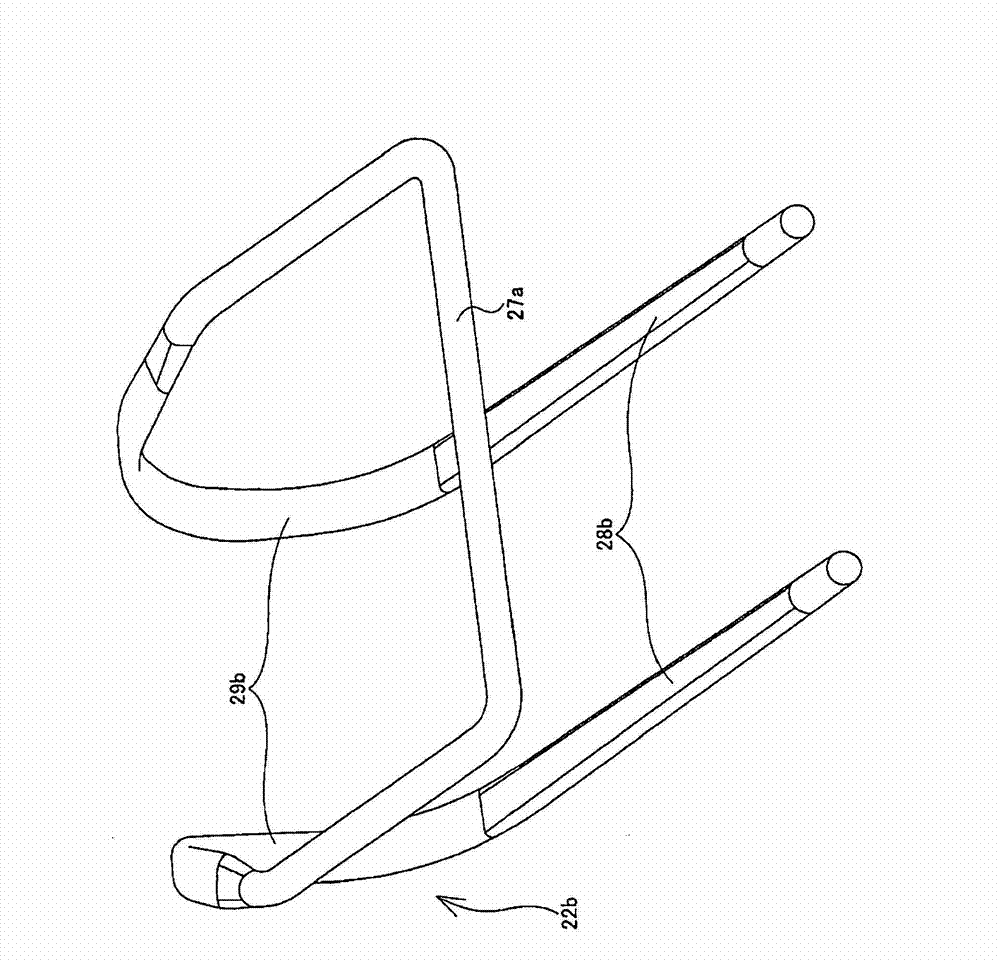

Energy absorption member and shock absorption steering device

ActiveCN103052556AReduce impact loadFully protectedPedestrian/occupant safety arrangementSteering columnsSteering wheelEnergy absorption

To further protect a driver in a secondary collision by gradually increasing the impact load absorbed by an energy absorption member (22b) to be equivalent to the frontward displacement of a steering wheel. The energy absorption member (22b) comprises: a base part (27a) disposed in a middle section; and a pair of impact absorption parts (28b) which extend forward from both ends of the base part (27a) and comprise a folded curved part (29b) that is folded in a U shape in the middle section. By crushing being carried out further toward the tip end side of the impact absorption parts (28b) than at least the folded curved part (29b), the height of the energy absorption member (22b) with respect to a handling part (32) gradually increases from the folded curved part (29b) toward the tip end side of the impact absorption parts (28b).

Owner:NSK LTD

Synthesis kettle with sufficient stirring function

ActiveCN108295796AStir fully and stablySame rotation rateChemical/physical/physico-chemical stationary reactorsReaction rateMechanical energy

The invention discloses a synthesis kettle with a sufficient stirring function. The synthesis kettle comprises a buffer outer tank, a heating interlayer, a synthesis inner kettle, a first motor, a first rotating shaft and a base. An electric control telescopic cylinder is arranged between the outer wall of the bottom of the heating interlayer and the inner wall of the bottom of the buffer outer tank; a fastening hoop surrounds the side wall of the heating interlayer, and a V-shaped plate is arranged on the side wall of the buffer outer tank; a mounting hole is formed in the V-shaped plate, andthe fastening hoop is fixedly connected with the V-shaped plate through a bolt penetrating through the mounting hole; the lower end of the first rotating shaft is connected with a first coupler, anda first stirring assembly is arranged at the lower end of the first coupler; the first stirring assembly comprises a main stirring rod, a first stirring blade set and a second stirring blade set. Thesynthesis kettle promotes sufficient and stable stirring of reaction materials in the synthesis kettle, electric energy and mechanical energy are saved, it is guaranteed that large turbulence is not generated in the kettle, and the reaction rate is increased.

Owner:NANJING FORESTRY UNIV

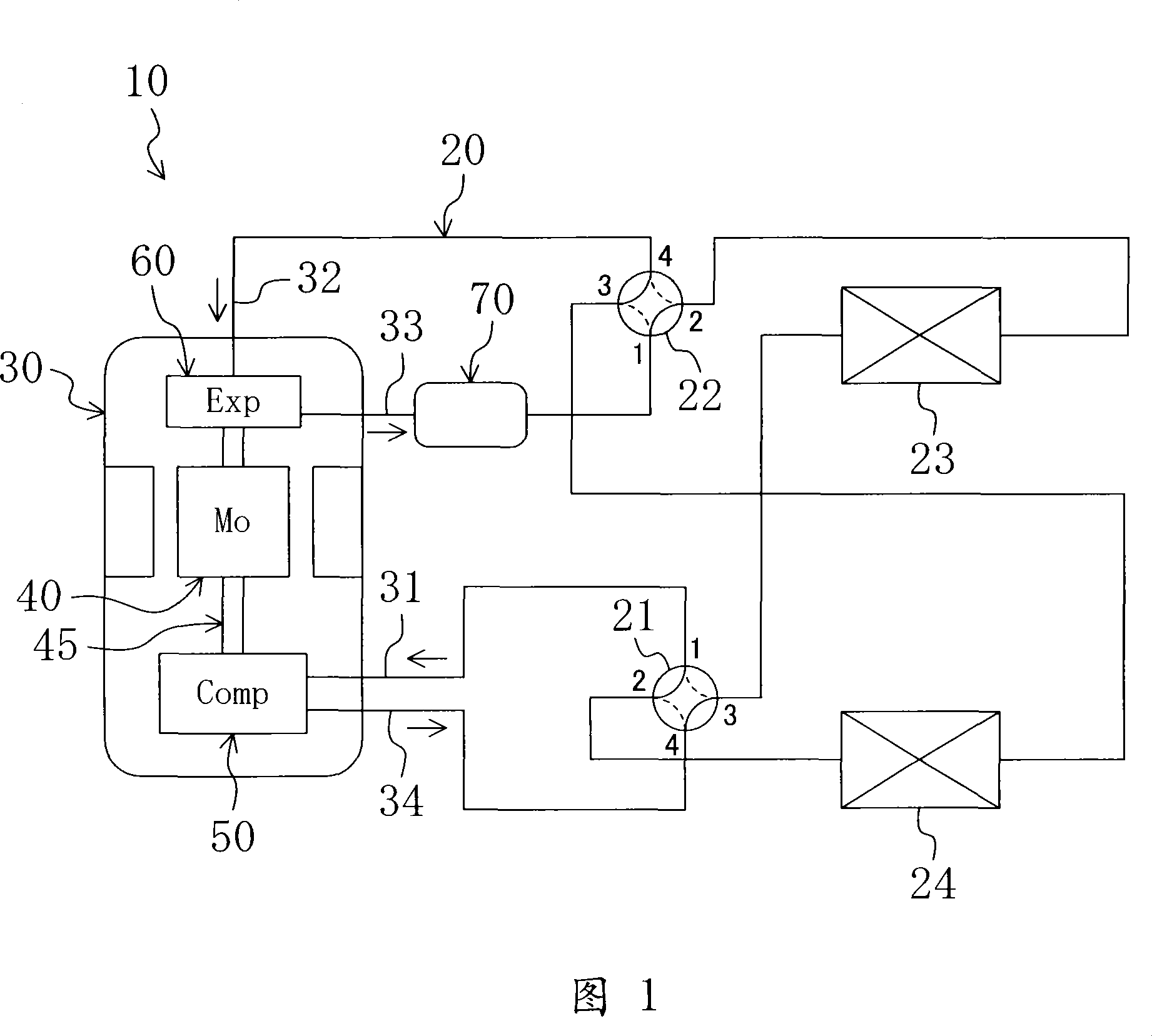

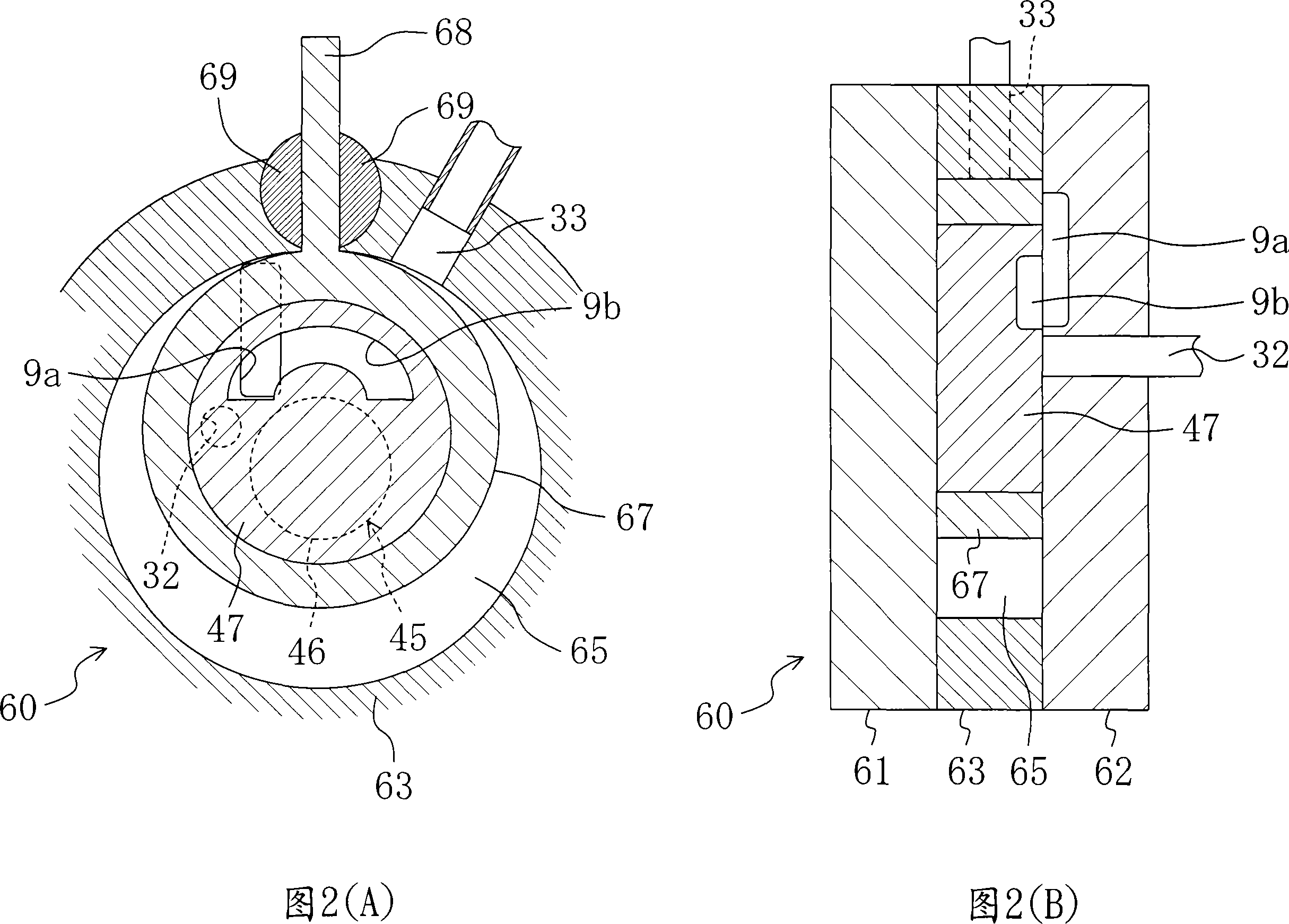

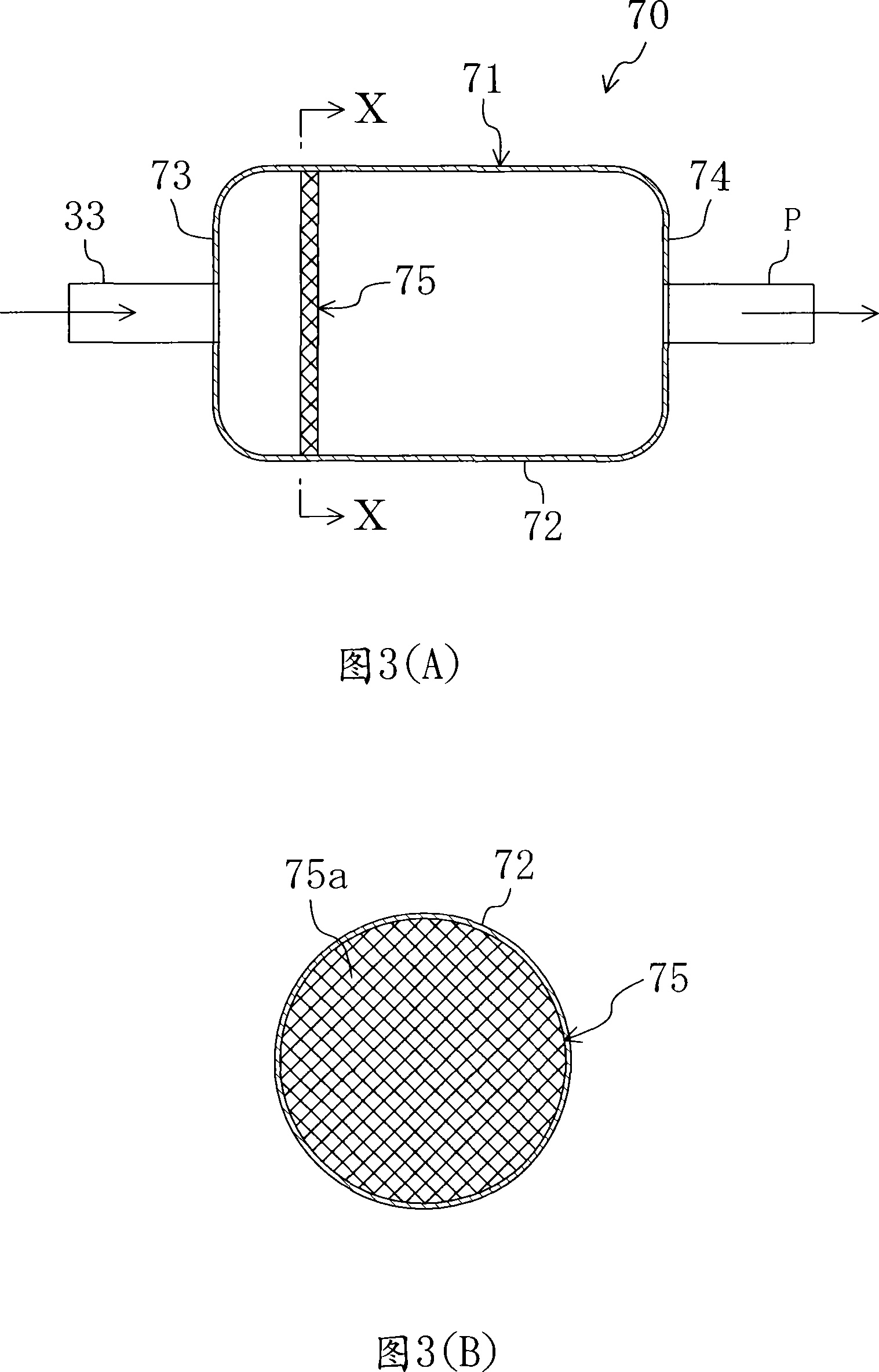

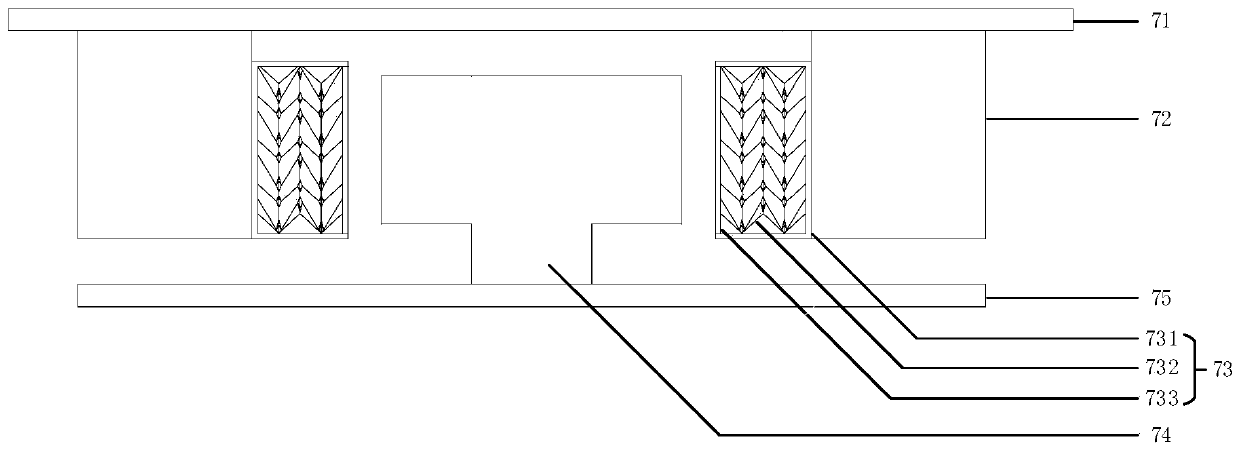

Refrigerating apparatus

InactiveCN101133291AReduce vibrationAvoid damageMechanical apparatusCompression machines with non-reversible cycleEngineeringRefrigerant

A buffer chamber (71) is connected to the outlet port (33) of an expansion mechanism (60). The buffer chamber (71) is formed in the shape of a cylinder extending in the direction of the flow of a cooling medium, and has a cross-sectional area greater than that of the outlet port (33). A rectifying plate (75) having a mesh section (75a) of a circular shape is provided inside the buffer chamber (71). The variation of pressure is relieved by the supply of pressure and the absorption of pressure by the buffer chamber (71), and also drops of the cooling medium are fined when they are passed through the plate (75).

Owner:DAIKIN IND LTD

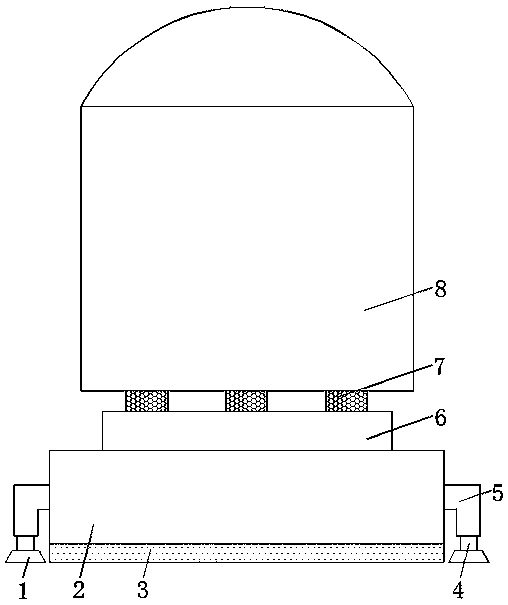

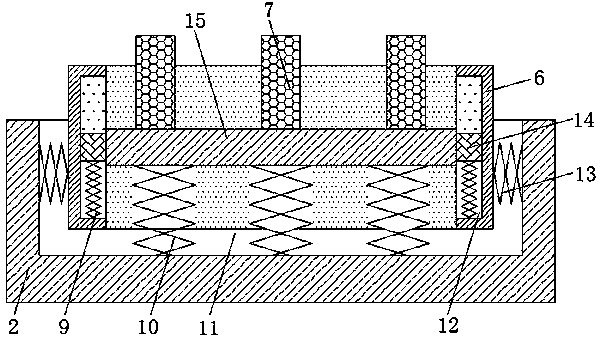

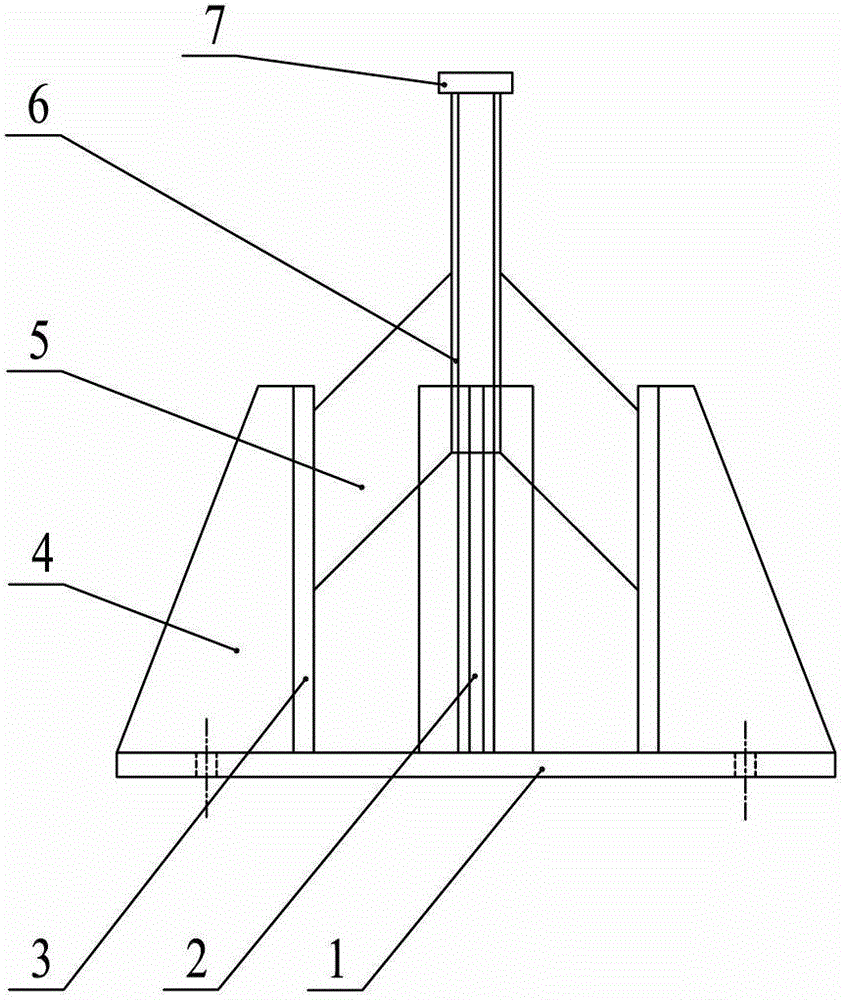

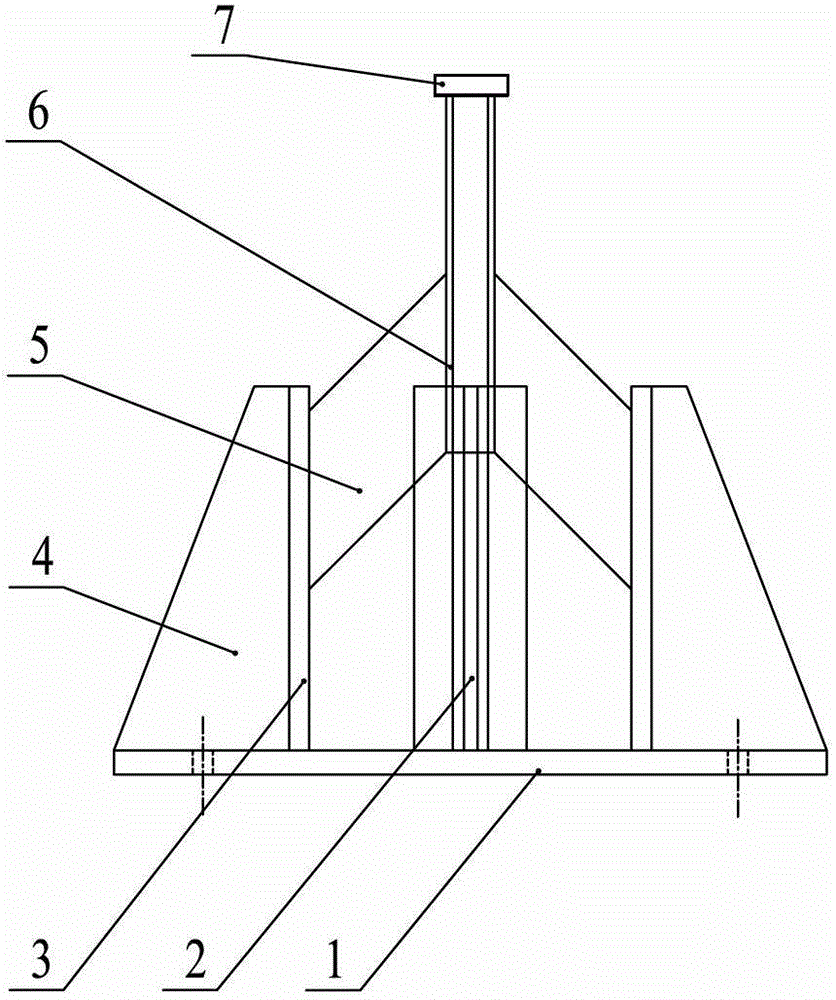

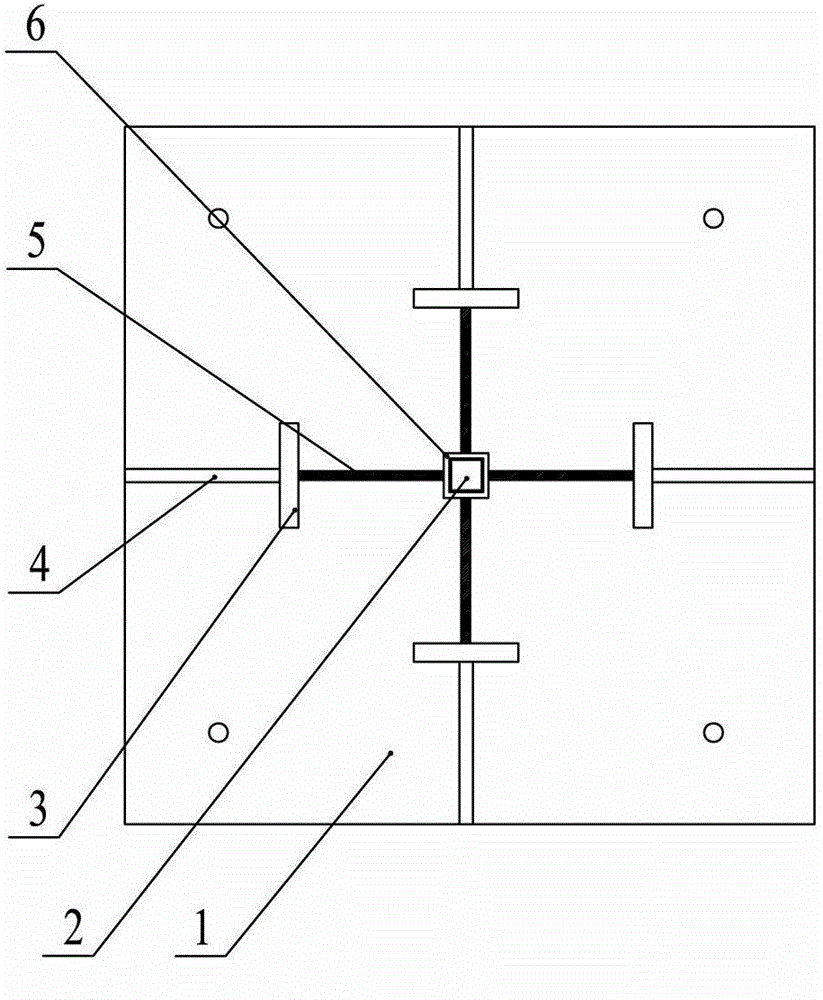

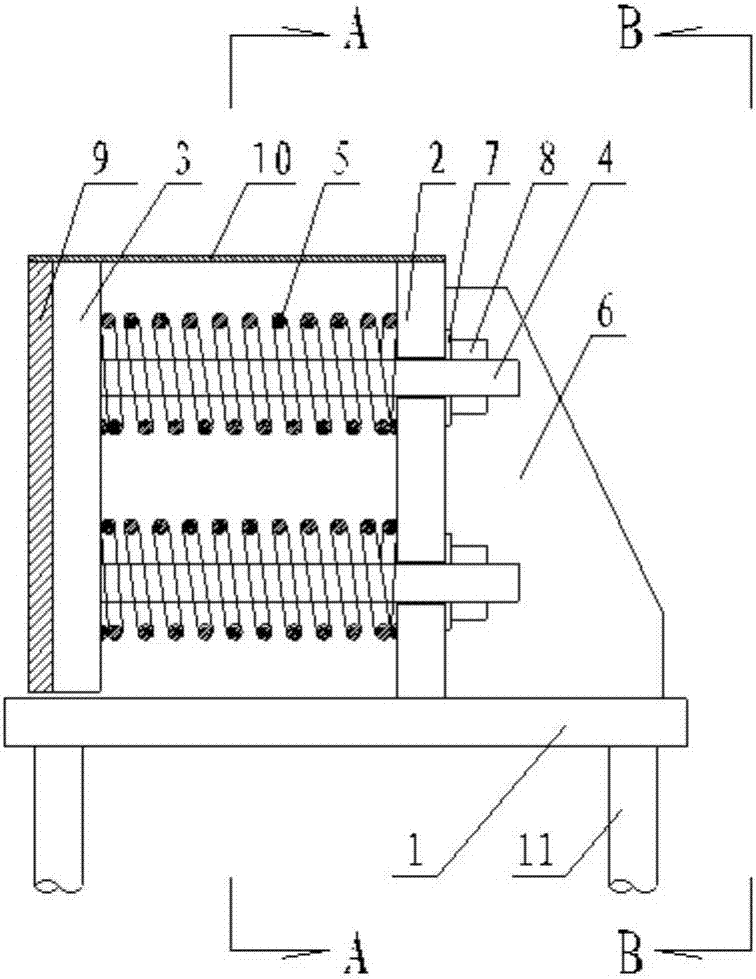

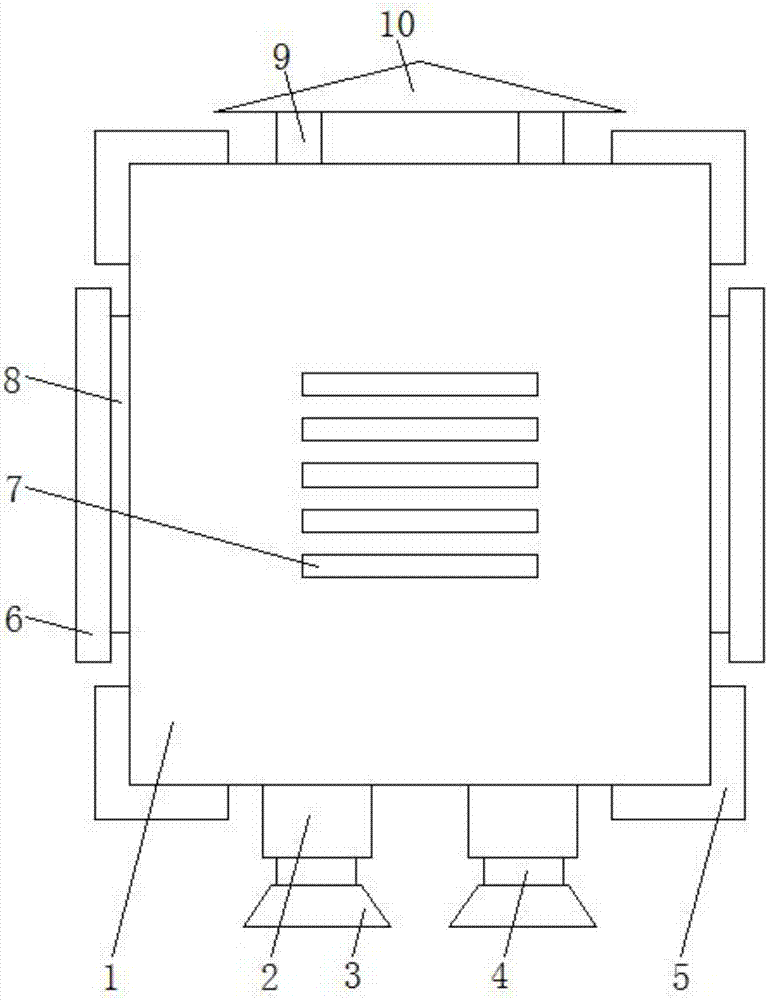

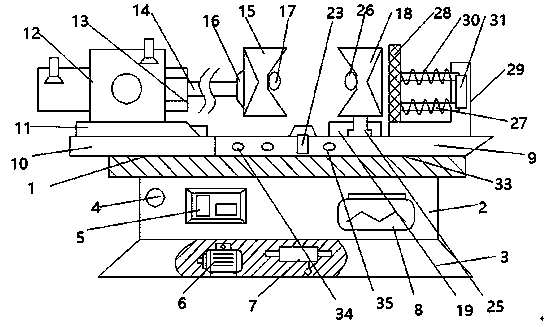

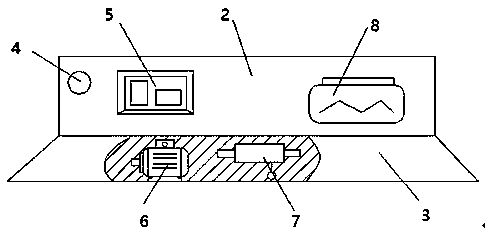

Mechanical energy-consumption-type buffer

The invention relates to a mechanical energy-consumption-type elevator buffer. The mechanical energy-consumption-type buffer is characterized by comprising a bottom plate, a guide rod, fixed plates, dead-soft steel energy-consumption dampers, a force guiding groove pipe and a top plate, wherein the guide rod is vertically fixed on the bottom plate; the force guiding groove pipe is movably sheathed on the guide rod; the at least three fixed plates are circumferentially and uniformly distributed at the periphery of the guide rod and are vertically fixed on the bottom plate; each fixed plate is correspondingly connected with one end of one dead-soft steel energy-consumption damper; the other end of each dead-soft steel energy-consumption damper is connected with the force guiding groove pipe; and a top plate for bearing the bottom of an elevator car is fixed at the top end of the force guiding groove pipe. The mechanical energy-consumption-type buffer has a simple, ingenious and reasonable structure; and the mechanical energy-consumption-type buffer is arranged under the lifting elevator car and is fixed on the ground by the bottom plate, the upper end of the mechanical energy-consumption-type buffer transfers impact force by virtue of the force guiding groove pipe, and collision energy is uniformly and stably absorbed by deformation of the dead-soft steel energy-consumption dampers, so that the impact to the elevator car and passengers is relieved, and thus the elevator car and the passengers are protected.

Owner:JIANGNAN UNIV

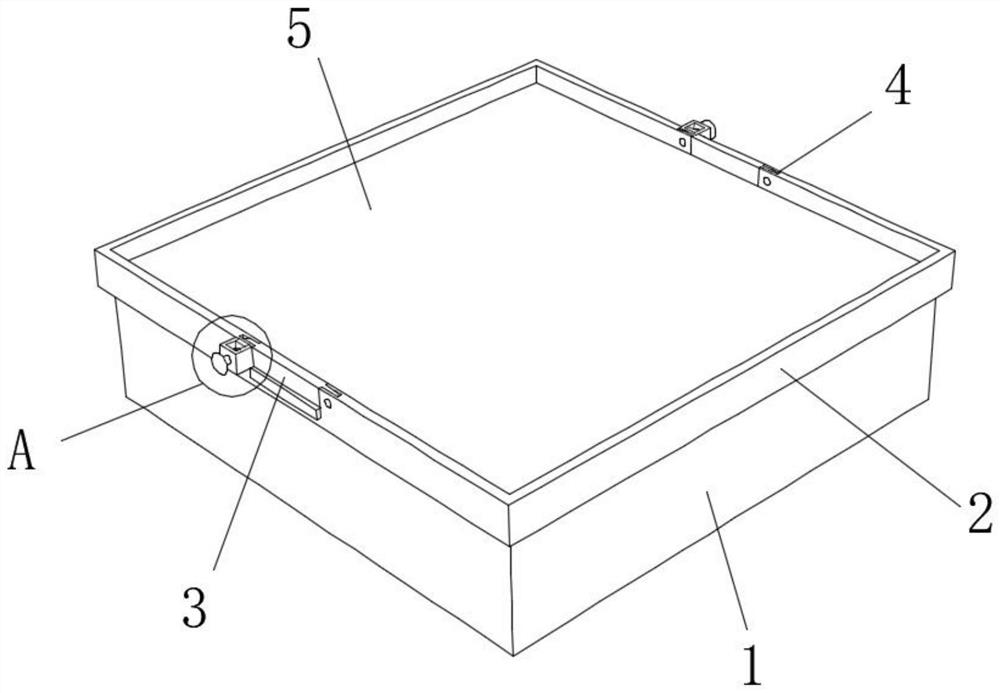

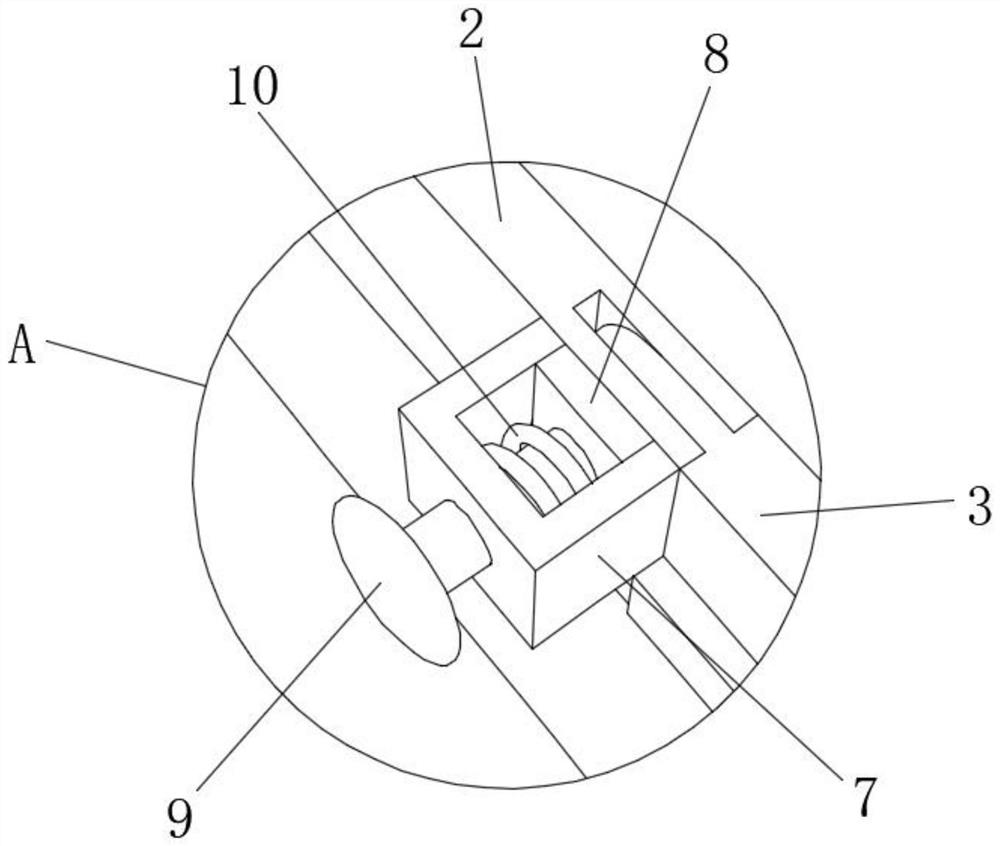

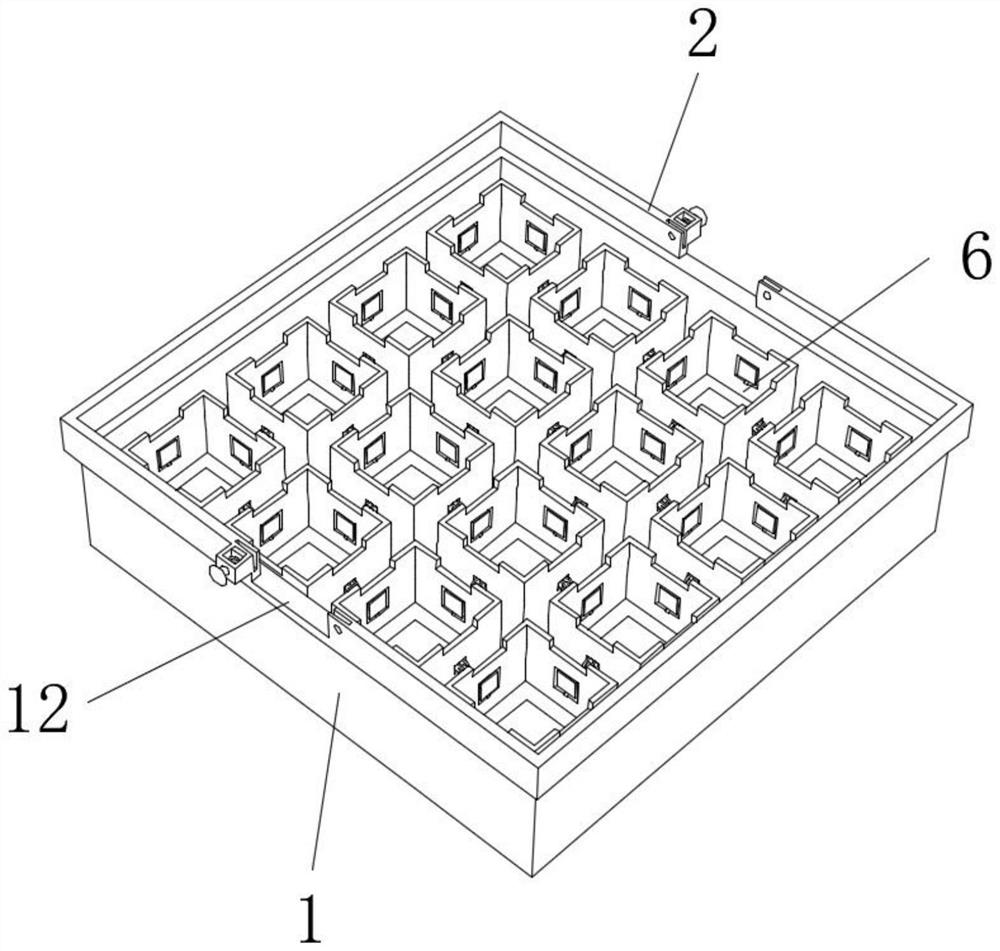

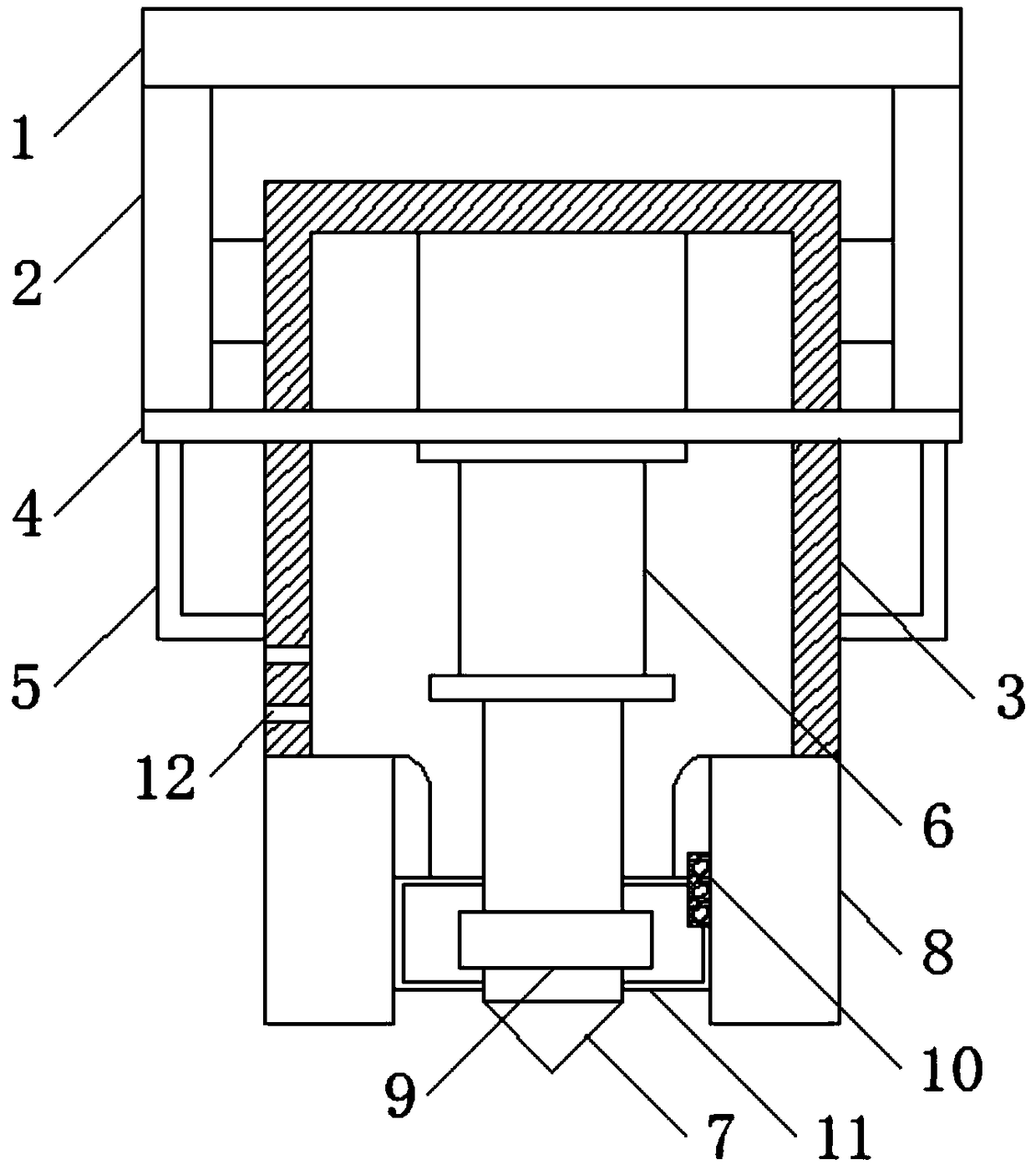

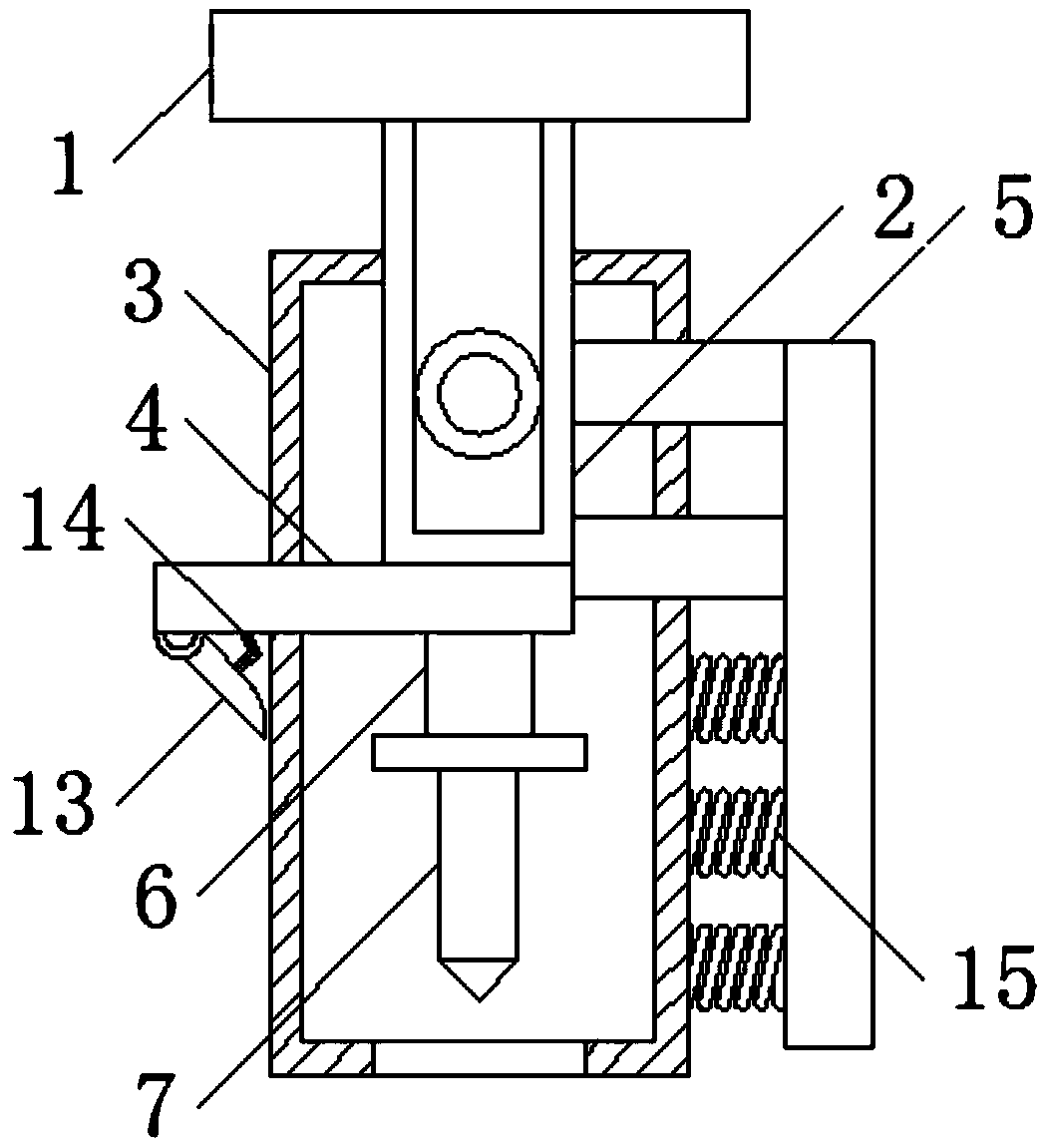

Packaging box for lithium battery production and transferring

InactiveCN111731644AAvoid direct contactShock mitigationContainers to prevent mechanical damageRigid containersLocking plateManufacturing engineering

The invention discloses a packaging box for lithium battery production and transferring, and relates to the technical field of lithium battery production. The box comprises a containing box body, a placing groove, a cover plate and a locking structure, wherein the locking structure and a locking plate lock the cover plate in the placing groove, a stabilizing mechanism is fixed on the inner bottomsurface of the containing box body, the stabilizing mechanism comprises a containing box, a lower pressing block, a cylinder and rotating shafts, a group of third fixing blocks are fixed to each of the four outer side faces of the containing box, arc-shaped rods are rotatably connected between the third fixing blocks in each group through the rotating shafts, one ends of the arc-shaped rods are rotatably connected with clamping plates through the fixing blocks, each arc-shaped rod is slidably connected with the lower pressing block, and a cylinder is fixed to the lower surface of the lower pressing block. According to the box, through the arrangement of the containing box body, the locking structure and the stabilizing mechanism, a lithium battery is clamped from six orientations, so thatthe lithium battery in the packaging box is in a stable state, and the problem of unstable placement of the lithium battery in the packaging box is solved.

Owner:合肥青鸾新能源科技有限公司

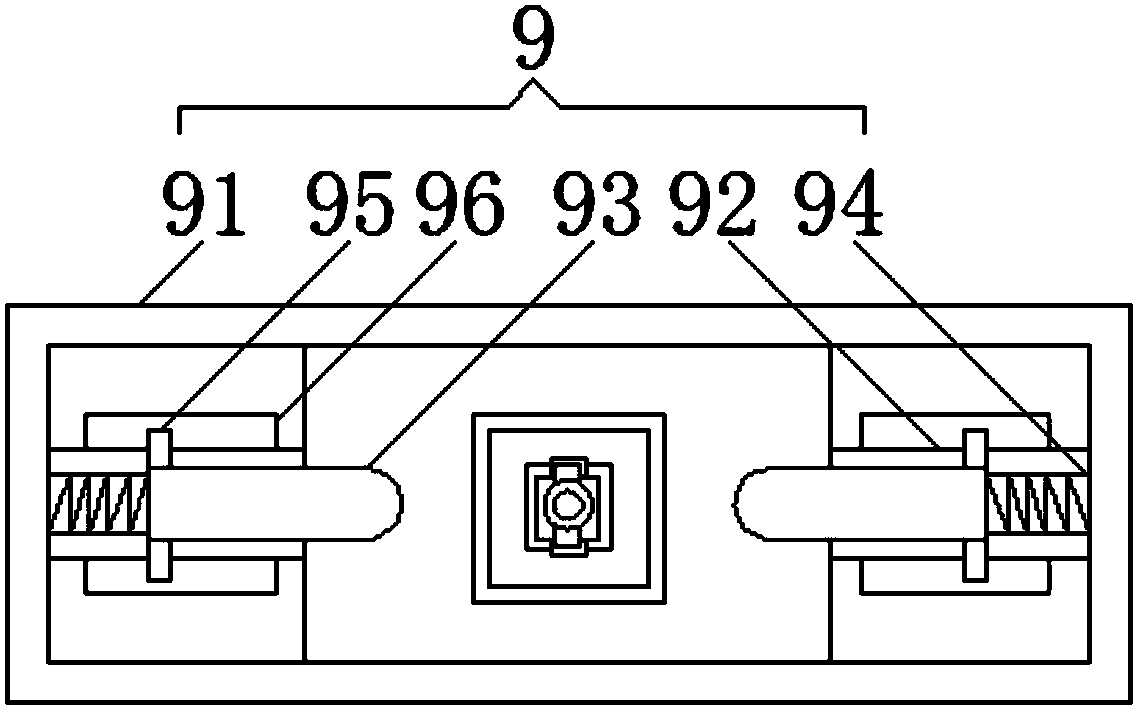

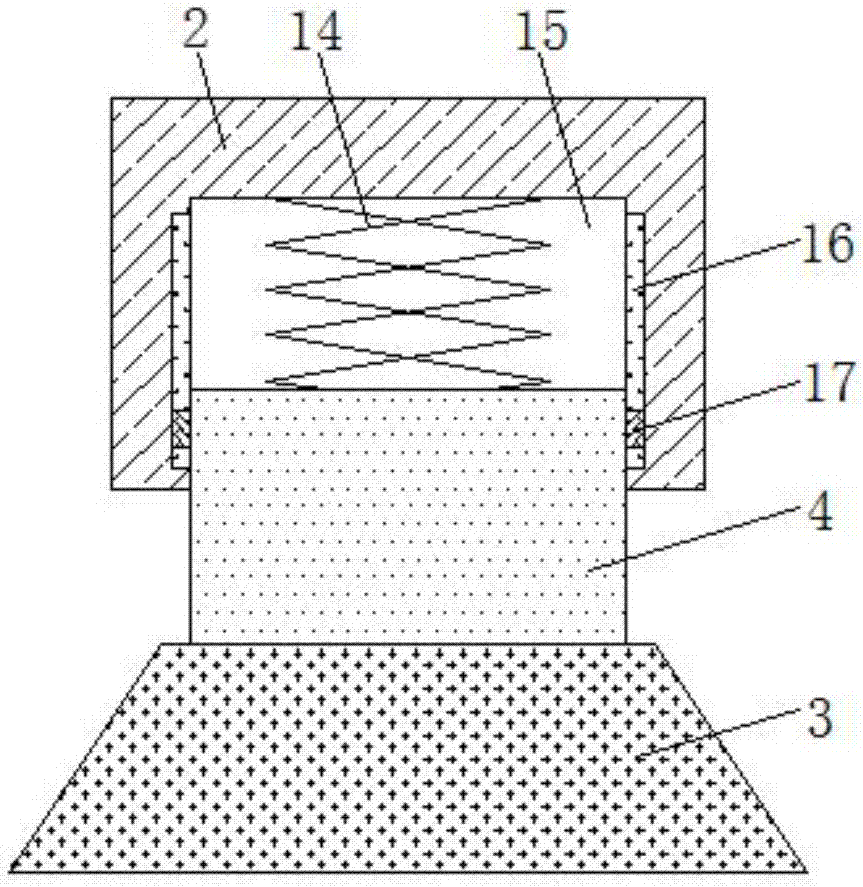

Anti-collision cutting head of laser cutting machine

InactiveCN108907481AImprove protectionImpact mitigationLaser beam welding apparatusLaser cuttingEngineering

The invention discloses an anti-collision cutting head of a laser cutting machine and belongs to the technical field of laser cutting machines. The anti-collision cutting head of the laser cutting machine comprises a fixing top plate; supporting frames are arranged on the left side and the right side of the bottom of the fixing top plate; an inner protective casing is movably arranged on the opposite end faces of the supporting frames through connection shafts; a front baffle is arranged at the bottoms of the two supporting frames; the rear end faces of the supporting frames are connected witha rear baffle; an electric telescopic rod is arranged on the top of an inner cavity of the inner protective casing; the bottom of the electric telescopic rod is connected with a cutting head througha fixing plate; fixing bases are arranged on the left side and the right side of the bottom of the inner protective casing; and the opposite end faces of the fixing bases are connected with a supporting plate. The front end of the supporting plate is provided with a limiting buffer device matched with the cutting head, so that the inner protective casing shakes front and back when bearing collision force so as to buffer the collision force, the cutting head in the inner protective casing can be bettered protected, the cutting head retracts back into the inner protective casing so as not to bedamaged, and the using performance of the laser cutting machine is improved.

Owner:江苏鸿鹄激光科技有限公司

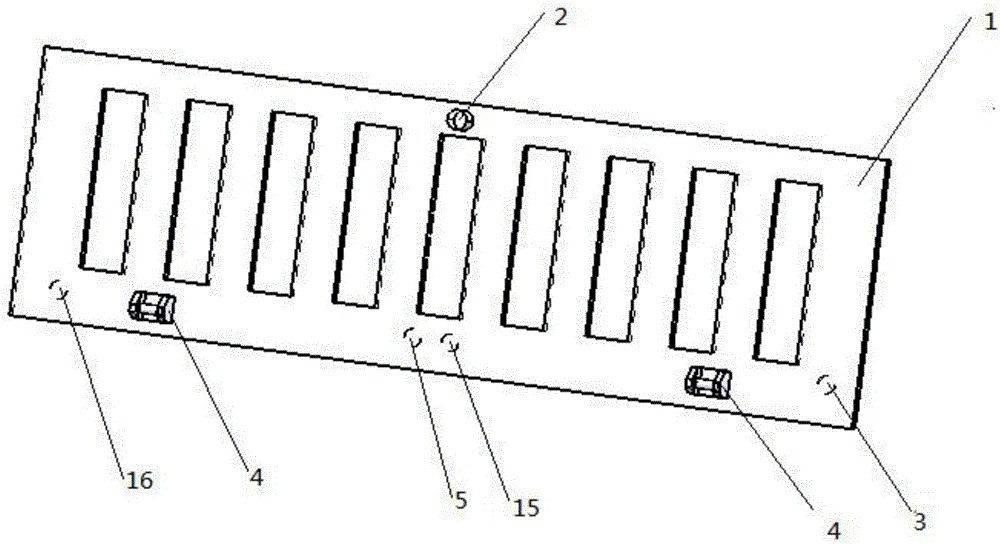

Aluminum alloy lateral protection fence for vehicle

Owner:SHANDONG CONGLIN FRUEHAUF AUTOMOBILE +1

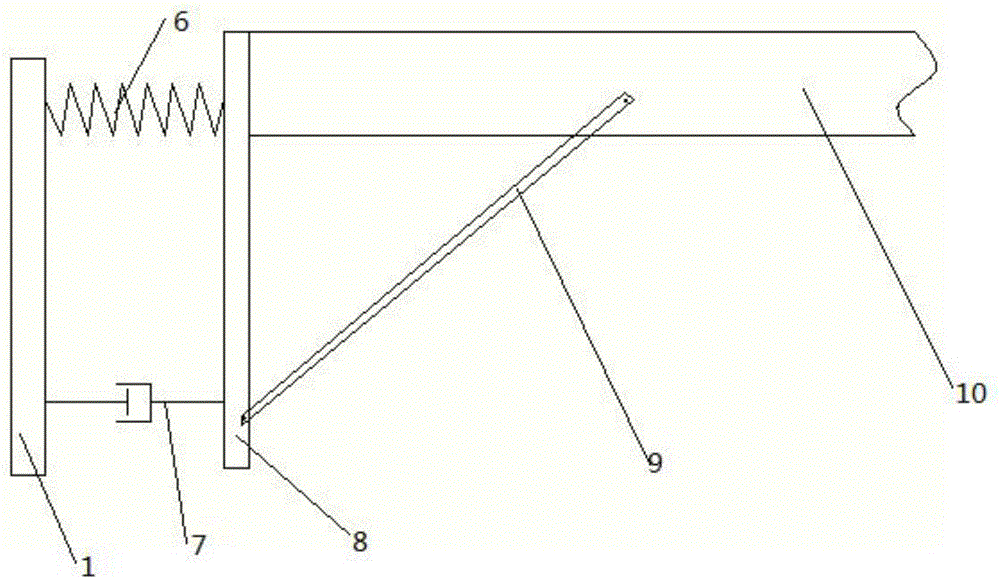

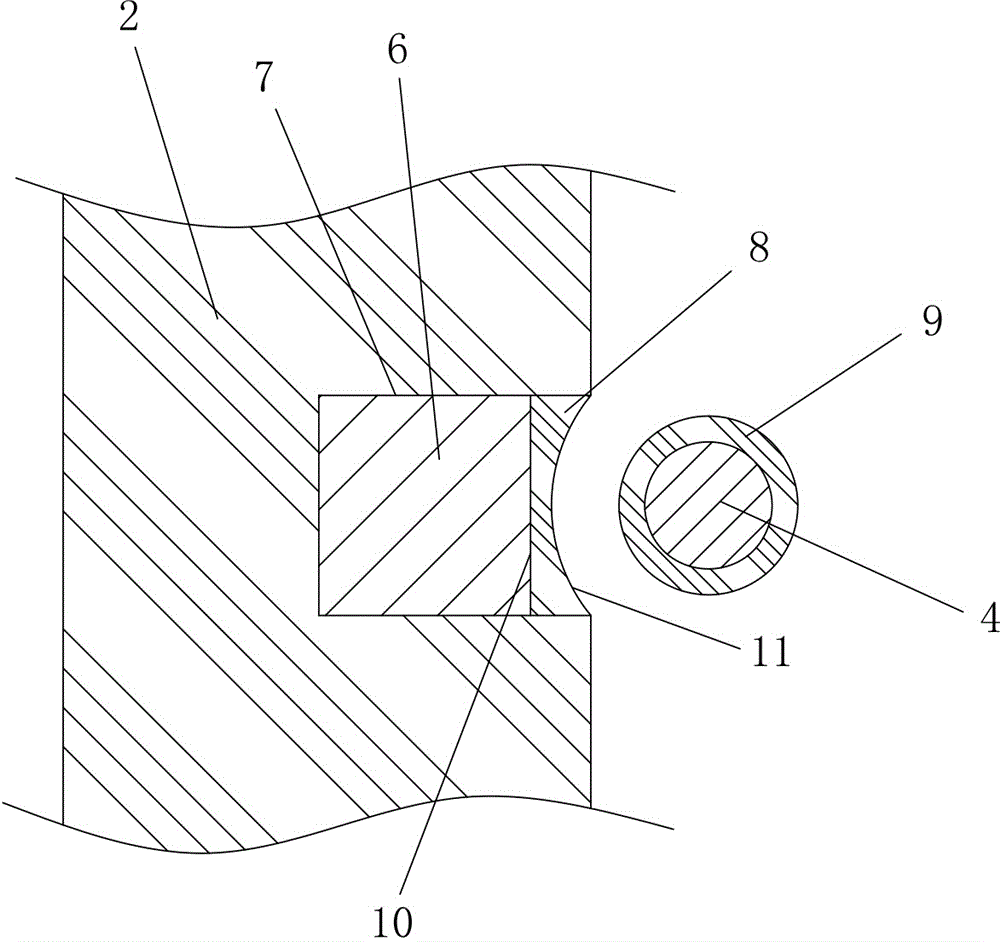

Resetting bridge baffle block

InactiveCN107268423AImpact mitigationIngenious ideaBridge structural detailsSheet steelArchitectural engineering

The invention discloses a resetting bridge baffle block. The resetting bridge baffle block includes a contact steel plate; the right side of the contact steel plate is welded to one ends of a plurality of guide rods; the other end of each guide rod passes through a corresponding hole formed in a fixing steel plate and is connected by a bolt; each guide rod between the contact steel plate and the fixing steel plate is sleeved with a spring; an outer side of the fixing steel plate is welded to a stiffening plate; the fixing steel plate is welded to a connection steel plate; the connection steel plate and the stiffening plate are welded; and the connection steel plate is anchored on a top surface of a lower structure or a bottom surface of an upper structure of a bridge through connection bolts. The resetting bridge baffle block is skillful in concept, is simple to manufacture, is clear in stress, can relieve impact of a horizontal action such as an earthquake on a main beam and a baffle block, and can reset the main beam after the horizontal action is finished.

Owner:CCCC HIGHWAY MAINTENANCE ENG TECH +1

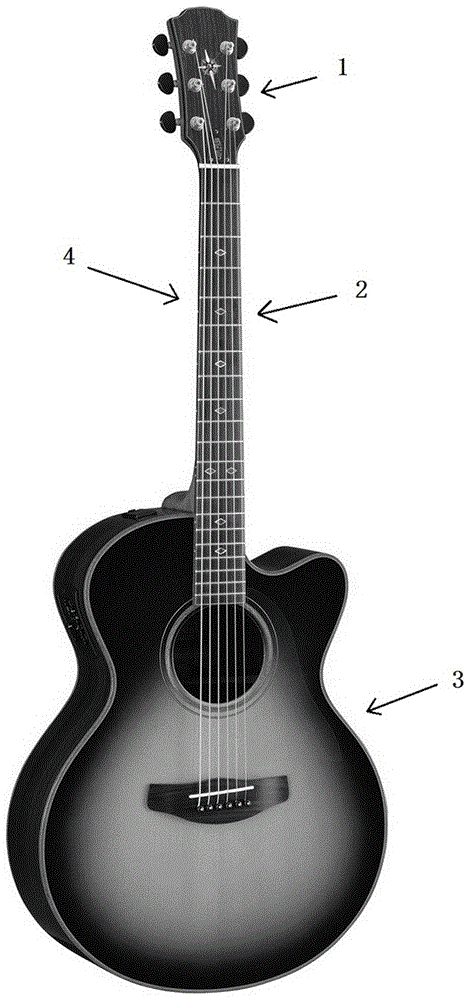

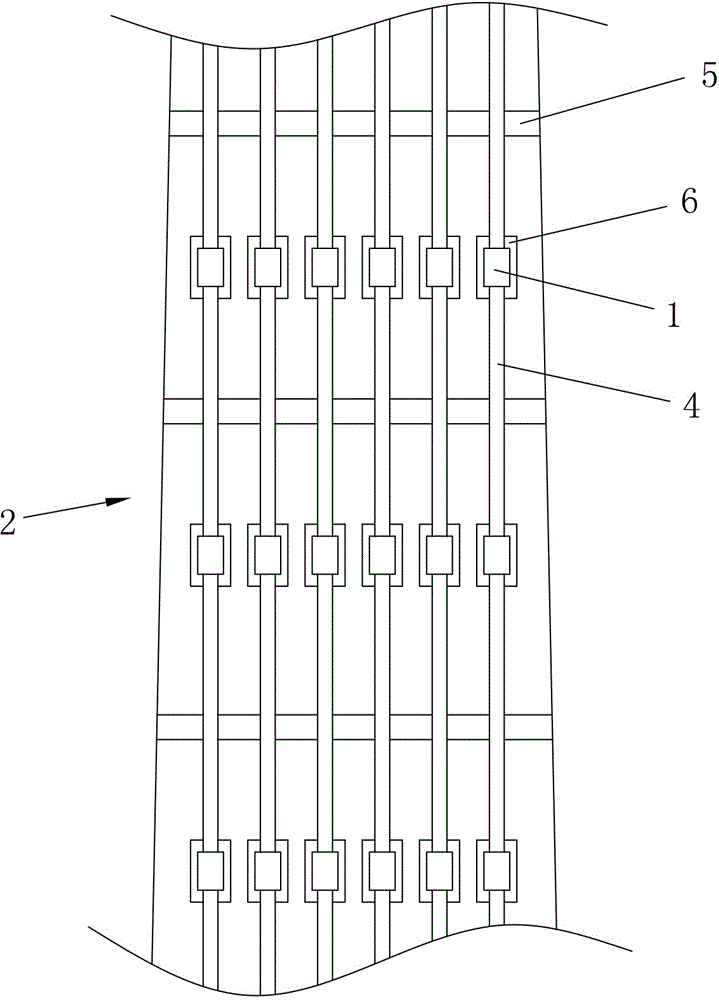

Easy-string-pressing guitar

InactiveCN105788570ASolve the problem of easily injured hands when playingExtended service lifeGuitarsGlovesResonanceEngineering

The invention discloses an easy-string-pressing guitar which comprises a guitar body and string pressing gloves. The guitar body comprises a guitar head, a finger plate, a resonance box and six strings. The finger plate is provided with a plurality of parallelly arranged fretwires. Six magnets are arranged between two random adjacent fretwires. The six magnets are arranged right below the six strings. The finger plate is provided with notches for placing the magnets. A thin sheet covers the surface of each magnet. A plurality of steel rings sleeve the strings. The steel rings are fixedly connected with the strings. The string right above each magnet is provided with a steel ring. The thin sheet is provided with a flat surface which abuts against the magnet, and an arc-shaped surface which abuts against the arc-shaped surface of the steel ring. The arc-shaped surface of the thin sheet is arranged on the surface of the magnet in a manner of facing the steel ring. The string pressing gloves comprise a left glove and a right glove. A soft cotton layer is fixed on the finger tip of the left glove. The cotton layer is connected with magnetic members. The magnetic members and the magnets attract each other. The finger nail of the right glove is provided with a guitar dialing piece which smoothly extends out. The invention provides the easy-string-pressing guitar.

Owner:邹桂平

Anti-collision device, with high protection capability, of power electric cabinet

InactiveCN107046242AImprove the protective effectEasy to useAnti-seismic devicesEngineeringDissemination

Owner:ZHAOQING SHENGSHANG INTPROP SERVICE CO LTD

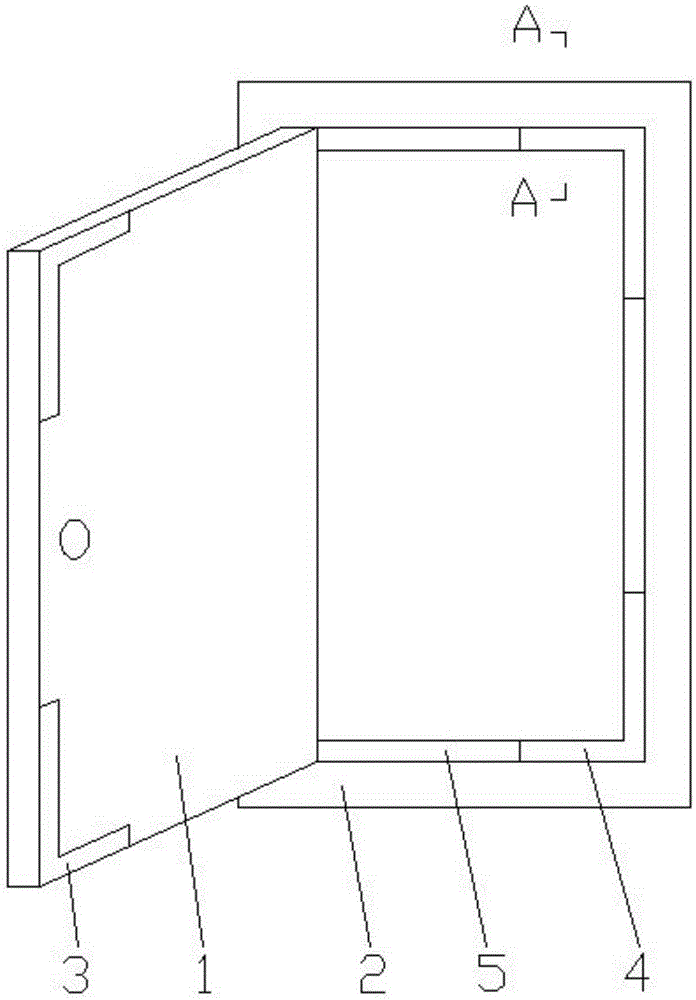

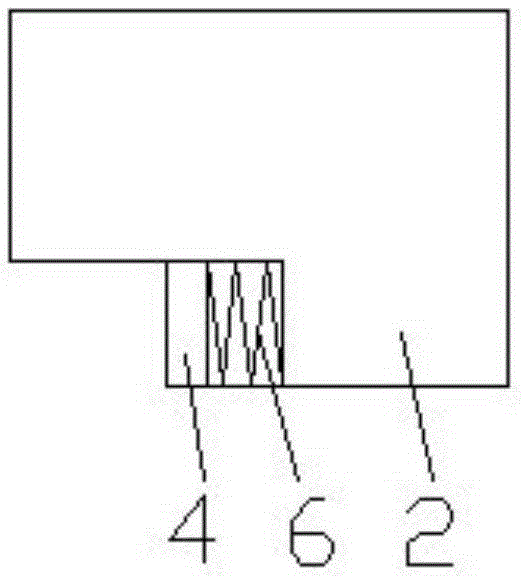

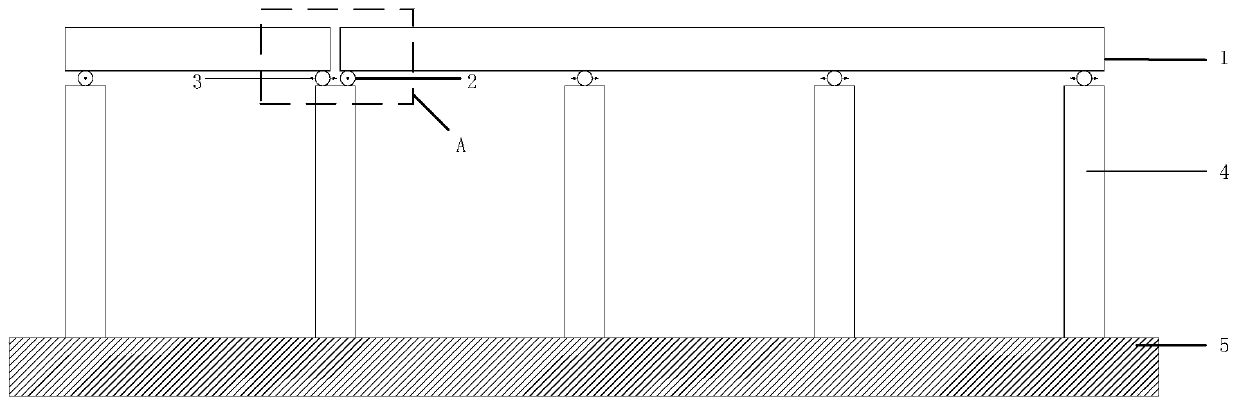

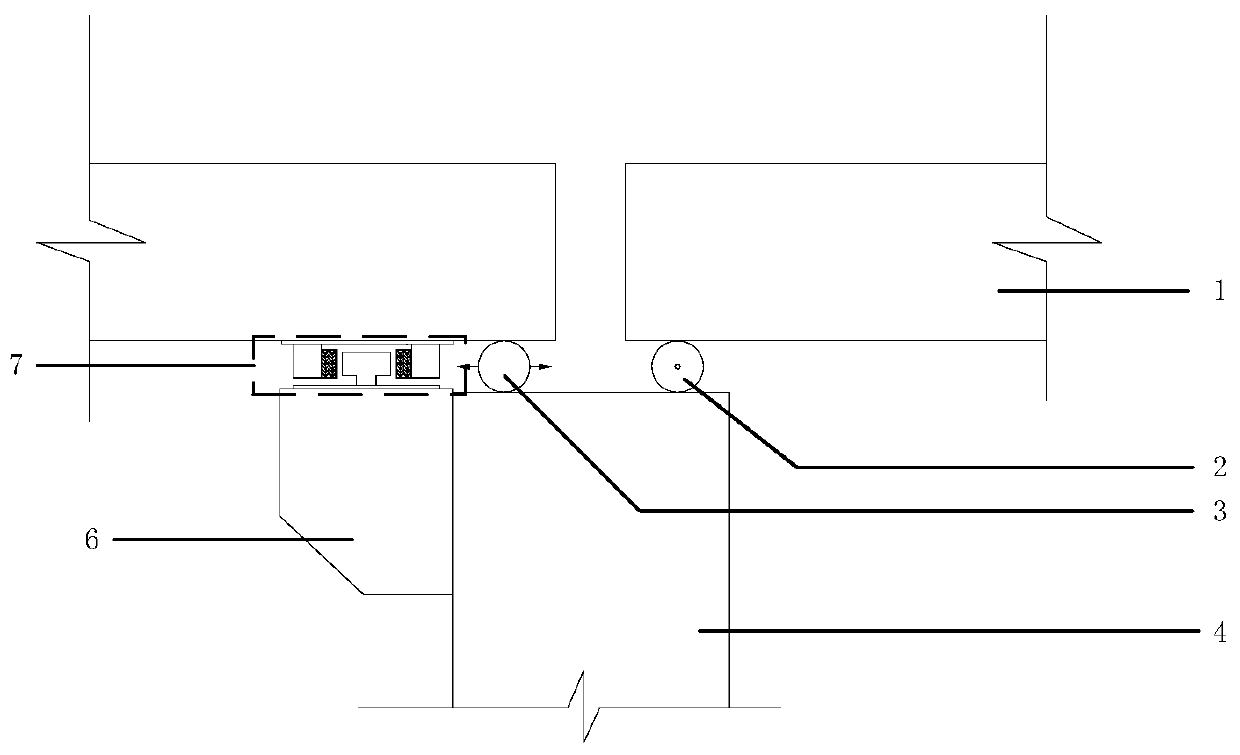

Sound-proof damping door

InactiveCN105350887AImpact mitigationExtended service lifeBuilding braking devicesNoise insulation doors/windowsEngineeringSquare Shape

The present invention discloses a sound-proof damping door. The door comprises a door frame and a door body, one side of the door body is hinged onto the door frame, a pair of right-angle iron sheets are fixed on the other side of the door body opposed to the hinged side and are at the right angle corners of the door body, the door frame is square-shaped, a lap of grooves limiting movements of the door body is disposed in an inner side of the door frame, right angle baffle plates are disposed at two right angle sides of the groove corresponding to the right angle iron sheets and are fixed on the groove through springs, positions of the groove except from the right angle baffle plates are provided with a rubber layer, and a layer of magnet is disposed on the right angle baffle plates. Through the above method, collision between the door body and the door frame can be reduced, the service life of the door is raised, and the sound-proof damping door has a good sound-proof effect.

Owner:SUZHOU XINYUANTONG DECORATION ENG CO LTD

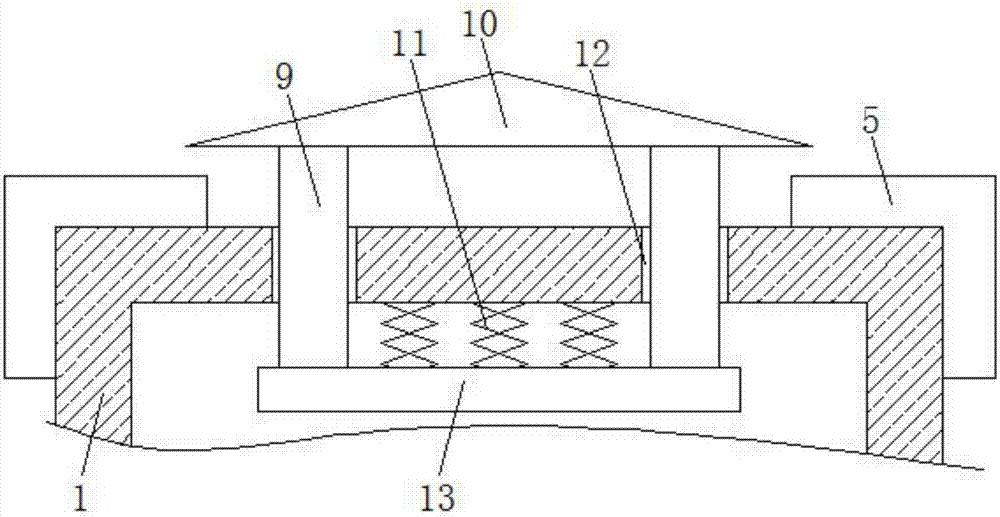

Anti-beam-falling device based on paper folding springback mechanism

ActiveCN111155417AIncrease elasticityImpact mitigationBridge structural detailsStructural engineeringCompressive deformation

The invention discloses an anti-beam-falling prevention device based on a paper folding springback mechanism. The anti-beam-falling prevention device comprises a steel check block upper bottom plate,a steel check block upper part, a steel check block lower part, a steel check block lower bottom plate and a paper folding springback mechanism arranged between the steel check block upper part and the steel check block lower part, wherein the steel stop block upper bottom plate is fixed with the lower bottom surface of a bridge, the steel stop block upper part is fixed with the steel stop block upper bottom plate, the steel stop block lower part is fixed with the steel stop block lower bottom plate, and the steel stop block lower bottom plate is fixed with the top surface of a steel corbel; the paper folding springback mechanism comprises a sleeve, a paper folding type structure and a composite material plate, the sleeve is fixed to the inner side of the steel check block upper part, andwhen the paper folding springback mechanism is extruded by the lower portion of the steel check block in the bridge following direction, compression deformation can be generated in the direction, andmeanwhile springback force is generated. Earthquake energy is absorbed through deformation of the paper folding springback mechanism so as to relieve the impact effect of the earthquake effect on thebeam and the check block, and the beam can be reset after the horizontal effect is finished.

Owner:ZHEJIANG UNIV

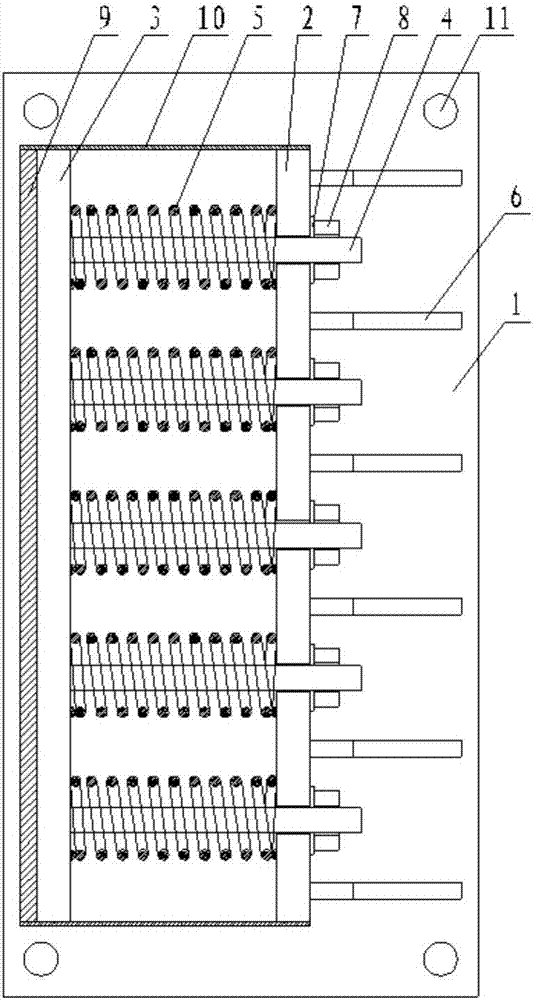

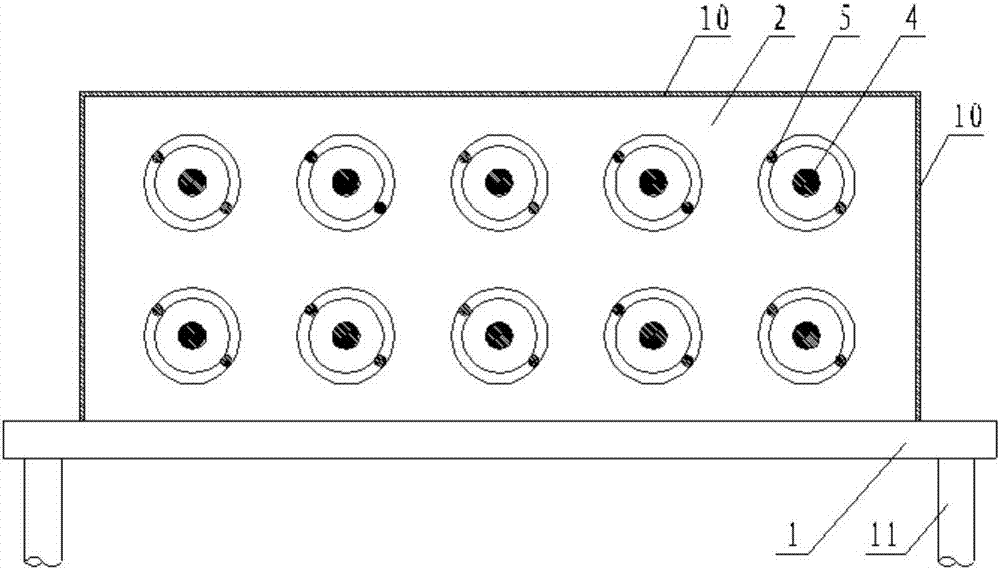

Automatic multi-point positioning and clamping die

InactiveCN108655784AAvoid damageAvoid destructionWork clamping meansMeasurement/indication equipmentsMicrocomputerMultiple sensor

The invention discloses an automatic multi-point positioning and clamping die. The automatic multi-point positioning and clamping die comprises a positioning die body of a space three-dimensional frame structure. An operation workbench is arranged above the positioning die body, a bottom support is arranged below the operation workbench, a warning lamp is arranged on the surface of one side of theoperation workbench, and a work display screen located on the surface of the operation workbench is arranged on one side of the warning lamp. A stretching guiding rod and a compression spring can effectively relieve impacts and collisions during positioning through spring compression, and the service life of the device is prolonged. A single-chip microcomputer is connected with multiple sensors so that automatic die recognizing and clamping can be achieved, efficient and automatic operation of clamping is achieved, digital and intelligent application is improved, the operation efficiency is improved, and manual labor is reduced; and positioning protruding points can conduct accurate multi-point positioning on a machined workpiece, the clamping positioning error is reduced, and the machining precision and stability are improved.

Owner:杨桂华

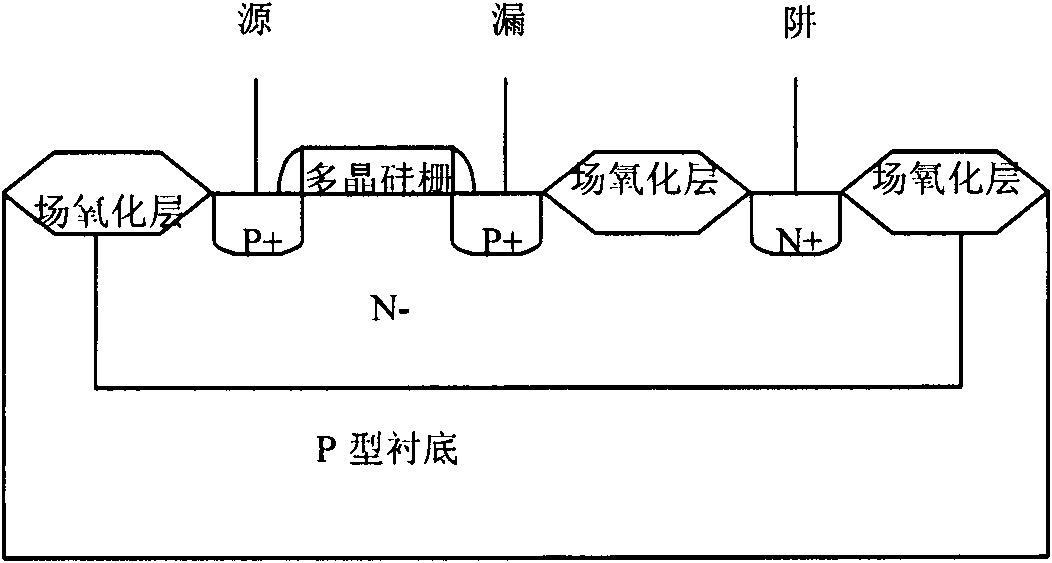

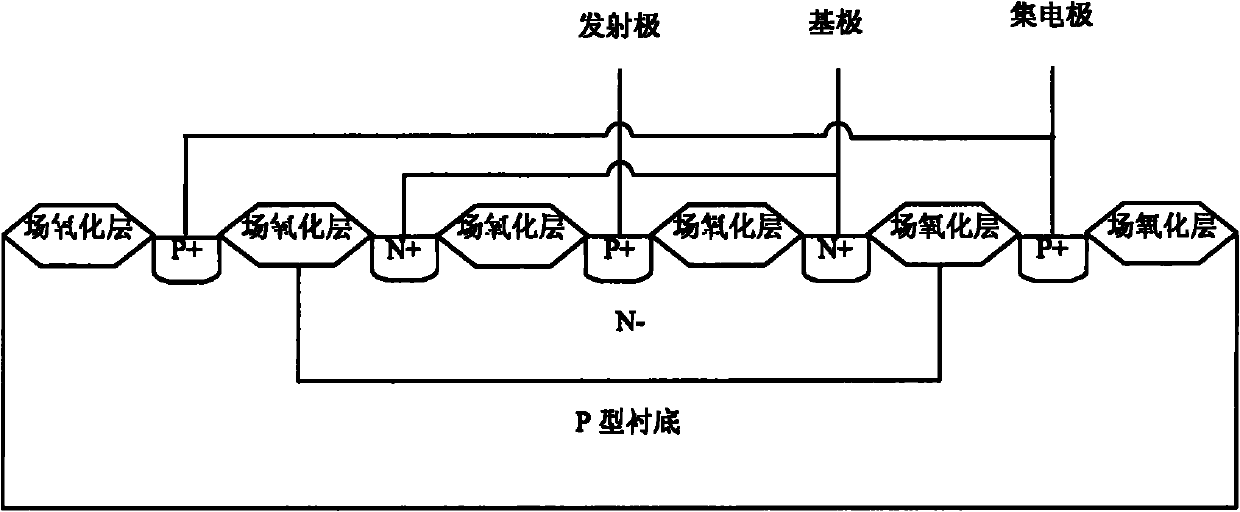

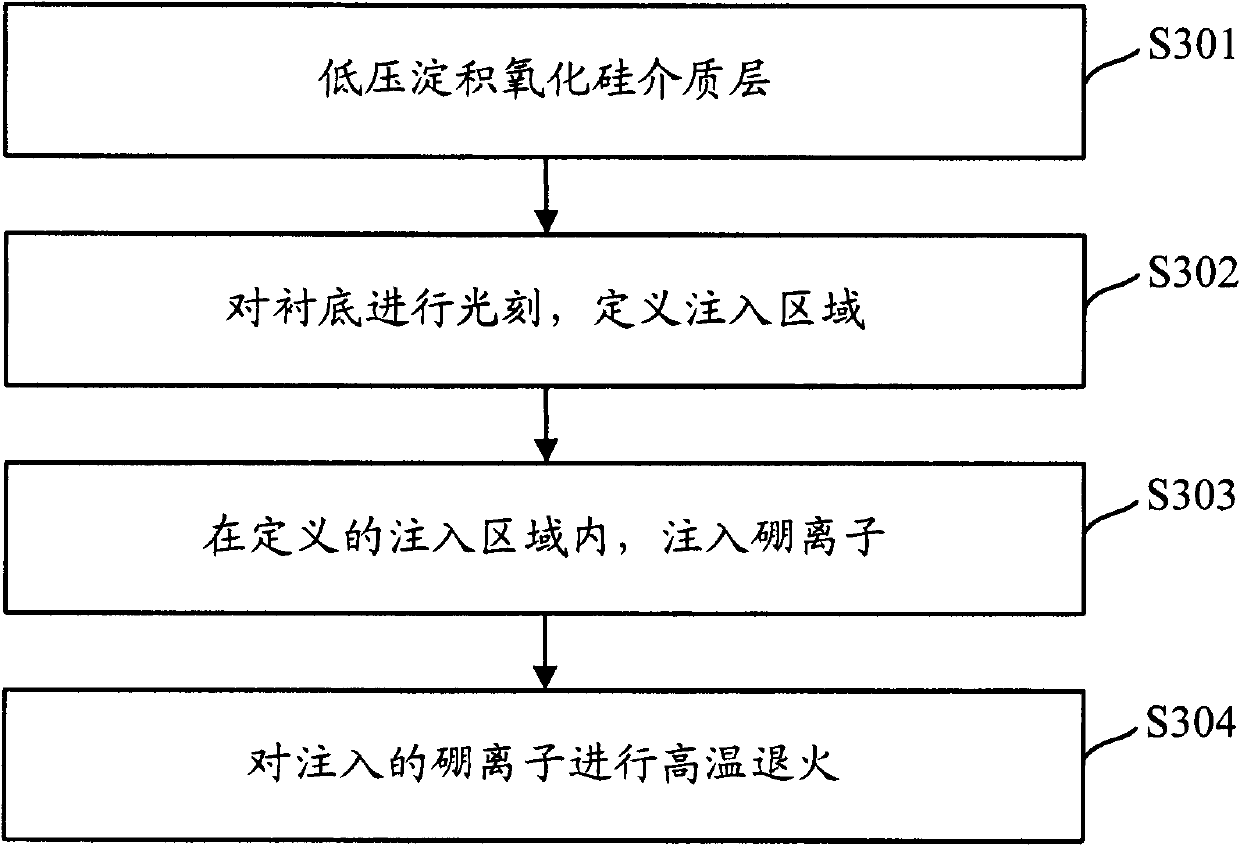

P-type high-concentration doped silicon and technology for preparing P-channel MOS (Metal Oxide Semiconductor) pipe of BCD (Bipolar, Complementary Metal-Oxide-Semiconductor and Double-Diffusion Metal-Oxide-Semiconductor) products

ActiveCN102569084AImpact mitigationReduce impactSemiconductor/solid-state device manufacturingHigh concentrationDouble diffusion

The invention discloses P-type high-concentration doped silicon and a technology for preparing a P-channel MOS (Metal Oxide Semiconductor) pipe of a BCD (Bipolar, Complementary Metal-Oxide-Semiconductor and Double-Diffusion Metal-Oxide-Semiconductor ) products, aiming at solving the problem of electricity leakage resulting from a lattice defect of the P-type high-concentration doped silicon manufactured with the prior art. A realization method of the technology of the P-type high-concentration doped silicon comprises the steps of conducting low-pressure deposition to form a silicon oxide dielectric layer, photoetching a substrate, defining an injection area, injecting boron ions in the defined injection area and conducting high-temperature annealing on the injected boron ions. According to the embodiment of the invention, before the P-type high-concentration doped silicon is prepared, the impact of the injection of the boron ions onto the surface of the silicon can be relieved by the low pressure deposition of the silicon oxide dielectric layer; the boron ions are injected when iron injection is conducted; as the molecular weight of the boron ions is smaller, the injected energy is smaller and the impact to the surface of the silicon is reduced; and in addition, as the injected impurities do not contain fluorine atoms, the defect problems caused by the fluorine atoms are avoided, and thus, the risk of generating the lattice defect is reduced and the probability of electricity leakage is lowered.

Owner:FOUNDER MICROELECTRONICS INT

Steering knuckle and bushing push-free process

ActiveCN111922631AReduce resistanceImprove integrityMetal working apparatusStructural engineeringMachine

The invention provides a steering knuckle and bushing push-free process. The process comprises the following steps that S1, a bushing is placed in a numerically controlled lathe, and an excircle guideangle at the bottom of the bushing is turned and formed; S2, a steering knuckle is fixed in a vertical machining center, and main pin holes of an upper lug and a lower lug of the steering knuckle arebored and formed through rough boring, chamfering and fine boring by adopting a fine machining process; S3, pretreatment before press-in is carried out, specifically, the bushing is placed in a liquid nitrogen environment to be treated for 2-3 hours; and S4, press fitting of the bushing is carried out, the bushing is pressed into the main pin holes in the two sides by adopting a press fitting machine. According to the process, the improvements in three aspects of processing technology, structure and mounting operation of the bushing and the steering knuckle are adopted, which are different from the prior art that an ironing rod needs to be used for ironing and pushing the interior of the bushing, so that the steering knuckle and bushing push-free process is realized, the bushing is smallin deformation, free of bulges, good in coaxiality and complete and attractive in inner hole surface of the bushing after pressing, and finally, the purpose of prolonging the service life of the steering knuckle, the bushing, a main pin and even the whole front axle is achieved.

Owner:HUBEI TRI RING FORGING

Combined buffering guardrail

ActiveCN105155442AIncreasing the thicknessImprove impact resistanceRoadway safety arrangementsReinforced concreteTraffic accident

A combined buffering guardrail is used for buffering impacting force of vehicles and reducing damage of traffic accidents. A buffering device is arranged on one side of a base body of the combined buffering guardrail and provided with a nylon inner plate, a nylon outer plate and a water bag. The water bag is provided with a water adding port and a pressure valve. The two sides of the water bag are movably connected with the nylon inner plate and the nylon outer plate respectively in a pressed manner. The other side of the nylon inner plate is fixedly connected with the base body. The nylon outer plate is connected with the base body in a hanging manner through a connecting band. A threading hole is formed in the lower portion of the base body. The base body is a reinforced concrete base body. An equipment bin is arranged in the base body and internally provided with a gas pump, a storage battery, a distributor and a gas flow dividing valve. The base body is provided with a solar power generating assembly and a wireless signal emitting device. The capacity of water of the water bag is 50-90% of the interior capacity of the water bag. A displacement sensor is arranged on the nylon outer plate. A signal emitting output port of the displacement sensor is connected with a signal input port of the wireless signal emitting device.

Owner:白峻光 +3

Force absorbing energy storage anti-colliding safety device

The invention relates to a force-adsorption energy-storage anti-impact safety device, which comprises: a spring gas energy storage device, a spring return plug cylinder, a hydraulic oil tube, a one-way valve and a control valve, wherein the invention is characterized in that: the plug cylinder via the hydraulic oil tube and one-way valve is connected to the gas inlet of spring gas energy storage device whose gas outlet via the bypass hydraulic oil tube forms the circuit with the control valve and the spring return plug cylinder. With said invention, when the vehicle is impacted, it will cutoff power and brake, to adsorb and store external force, and convert the external force into the force resistant to the impact, to avoid rebounding the bumper and release the impact, to confirm the safety; and it will return after impact, to be used again. The invention can be mounted on the front and back bumpers, with simple structure.

Owner:梁文华 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com