Anti-blocking self-vibrating ring for sprayed concrete pumping pipe

A shotcrete and pumping pipe technology, which is applied in the direction of pipe components, pipes/pipe joints/pipes, mechanical equipment, etc. The effect of mitigating the impact of impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

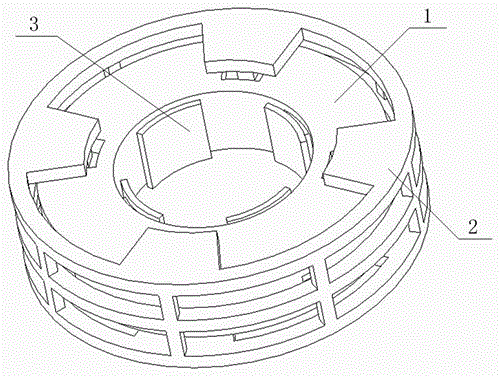

[0033] A shotcrete pumping pipe anti-blocking self-vibration ring, such as figure 1 As shown, it includes a vibrating ring 1, an annular support 2 sleeved outside the vibrating ring 1, and a pressure detection device 3 embedded in the vibrating ring 1;

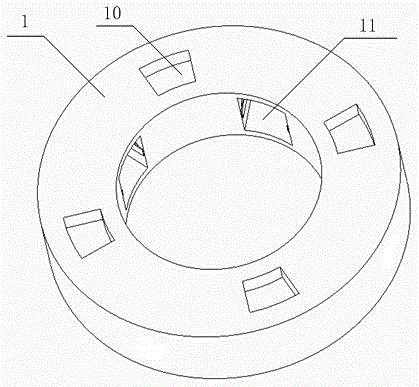

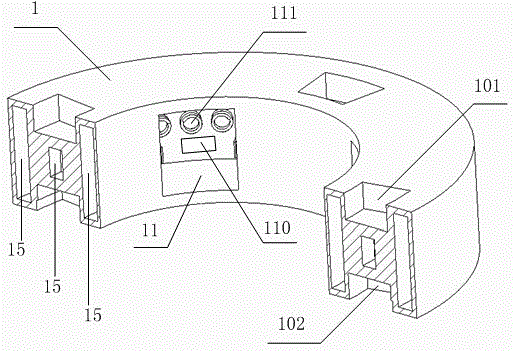

[0034] Among them, such as figure 2 with image 3 As shown, the upper surface and the lower surface of the vibrating ring 1 are respectively provided with corresponding grooves 10, the grooves 10 include a group of upper grooves 101 uniformly arranged on the upper surface, and the positions corresponding to the upper grooves 101 in the lower surface A group of lower grooves 102 with the same specifications as the upper grooves 101 are set;

[0035] In the middle of the upper groove 101 and the lower groove 102, as well as on the radially front surface and the rear surface, and the vibrating ring 1 that is located in the corresponding position, a magnetic levitation electromagnet 15 is arranged inside; the upper groove 101 a...

Embodiment 2

[0045] On the basis of embodiment 1, the distribution of the magnetic levitation electromagnet 15 around the upper groove 101 and the lower groove 102 can also be as follows Figure 4 Shown: the middle of the upper groove 101 and the lower groove 102, and the radial front surface and the rear surface and are located in the vibrating ring 1 in the corresponding position. A magnetic levitation electromagnet 15 is arranged inside; the upper groove 101 and the lower groove 102 Insulation baffles 104 are connected to the sidewalls on both sides of the interior along the circumferential direction through buffer springs 103 .

Embodiment 3

[0047] On the basis of embodiment 1, the corresponding two pressure sensors 16 in the vibration automatic adjustment circuit in the magnetic levitation and vibration automatic adjustment circuit II can also be connected to a microcontroller 13 at the same time, and this microcontroller 13 is connected with the The two pressure sensors 16 correspond to the vibrator 14 .

[0048] Working principle of the present invention: the present invention is controlled by two sets of circuits including power on and off and pressure applying circuit I and magnetic levitation and vibration automatic adjustment circuit II, which can realize automatic control of its vibration and stillness, pressure and relaxation, and can automatically control according to the pressure. The vibration frequency and amplitude can be adjusted, and magnetic levitation can be realized in the pipe diameter and along the pipe length, so that the impact of the vibration ring 2 on the outer pipe can be minimized, so th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com