Pressurizing connector for short-distance material conveying

A short-distance, material technology, applied in conveyors, conveying bulk materials, transportation and packaging, etc., can solve the problems of reduced construction efficiency, large impact force, waste of energy of relay pump ships, etc., and achieve the effect of improving construction efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

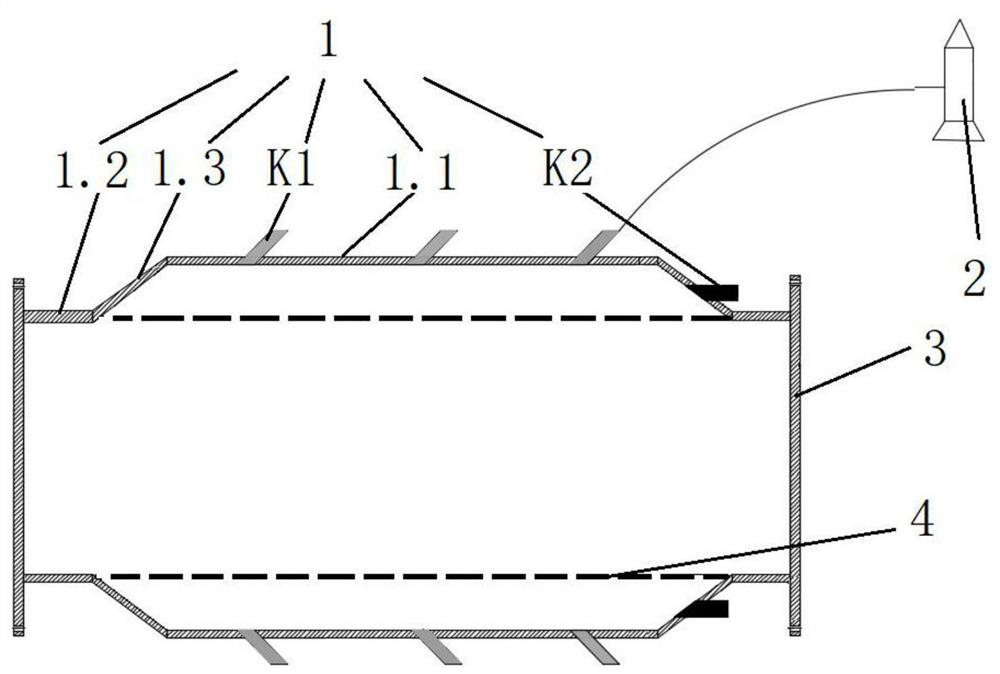

[0026] see figure 1 , a pressurized joint for short-distance material transportation, comprising a pressurized pipe 1, a pressurized device 2, and a connecting flange 3, both ends of the pressurized pipe 1 are provided with a connecting flange 3;

[0027] The pressurized pipe 1 includes a pressurized section 1.1 and a fixed section 1.2 arranged at both ends of the pressurized section 1.1, the free end of the fixed section 1.2 is connected to the connecting flange 3, and the connecting flange 3 is used for connecting The pressurization pipe 1 and the delivery pipeline; several pressurization holes K1 are arranged on the pipe wall of the pressurization section 1.1;

[0028] The pressurizing device 2 communicates with the pressurizing hole K1 to provide pressurized pressure for the pressurizing pipe 1; the included angle between the axis direction of the pressurizing hole K1 and the material conveying direction is 30°-60° (45° in this embodiment).

[0029] In this embodiment, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com