Hydraulic fracturing and methane in-situ blasting cooperative fracturing permeability-increasing method

A hydraulic fracturing and methane technology, which is applied in the direction of earthwork drilling, production fluid, wellbore/well components, etc., can solve the problems of small scale of fracture expansion and poor safety of pyrotechnics, etc., to expand the volume of reservoir stimulation and improve Improve the effect of reconstruction and increase the density of fractures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Embodiments of the present invention will be further described below in conjunction with accompanying drawings:

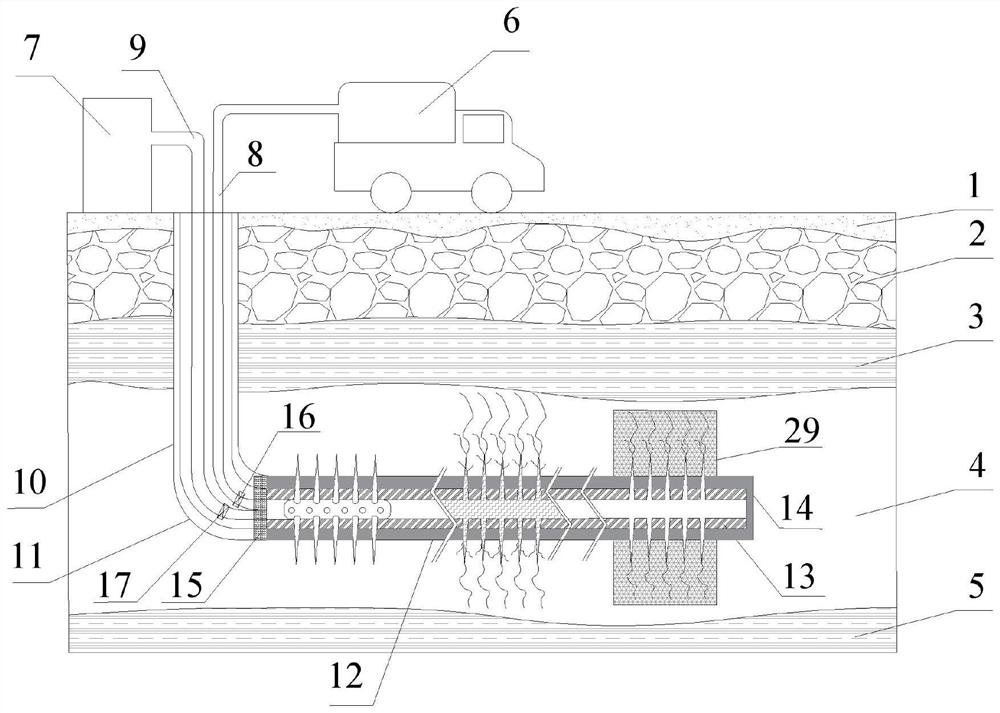

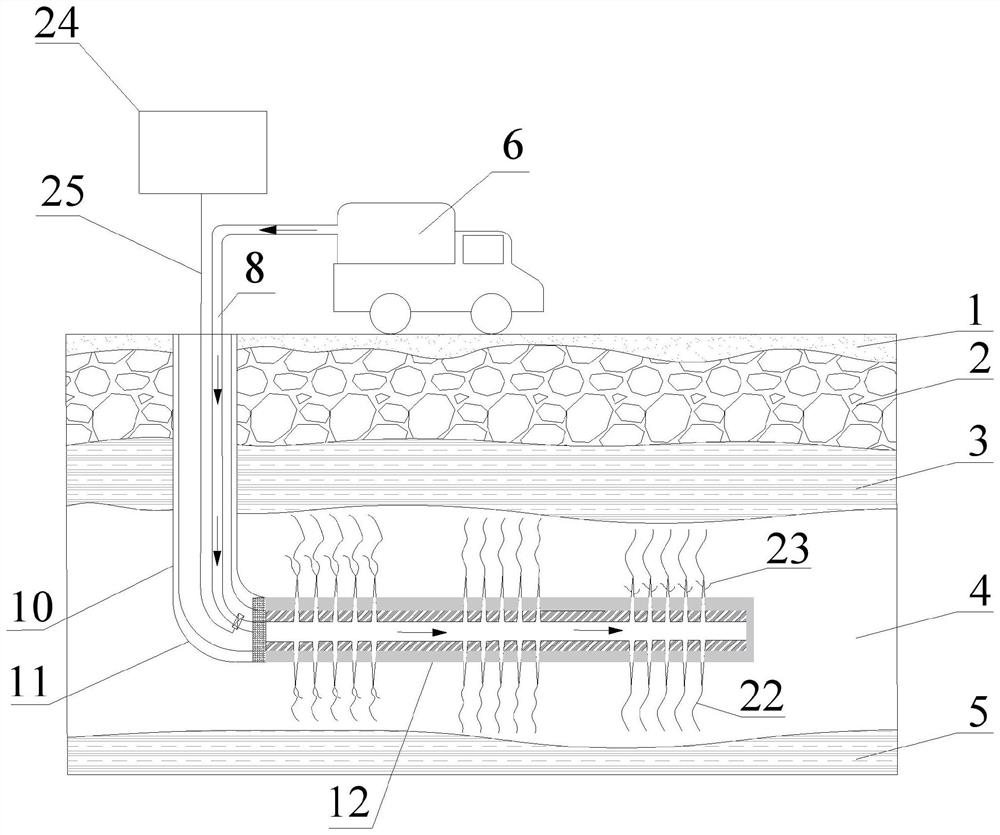

[0032] Such as figure 1 As shown, a hydraulic fracturing and methane in-situ detonation synergistic fracturing and anti-permeation method of the present invention comprises the following steps:

[0033] (1) Drilling preparations.

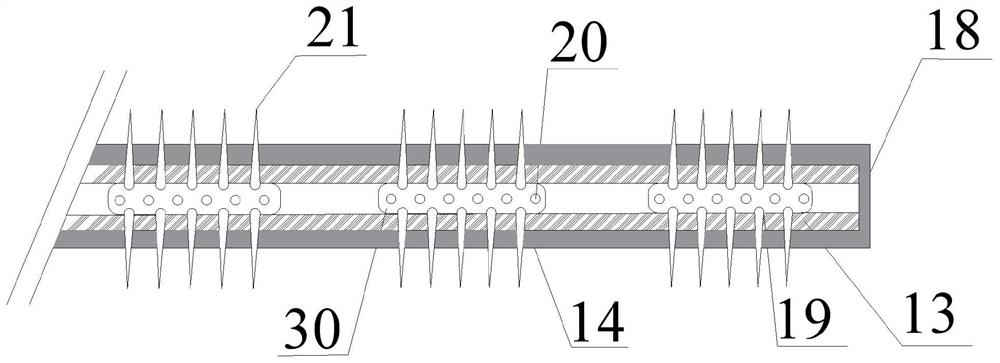

[0034] Through the previous geological exploration, the positions of the shale roof 3 and the shale floor 5 were ascertained, the fracturing section and location of the shale reservoir 4 were determined, and the pre-fracturing section of the shale reservoir 4 was opened on the ground 1. Drill a vertical shaft 10, pass through the overburden 2 and the shale roof 3 to enter the shale reservoir 4, and use the diverter 11 to drill the horizontal gas well 12 to reach the pre-fracturing position. Afterwards, the casing is lowered to the horizontal well section, and the two casings are sealed and connected to form a casing string 13, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com