Patents

Literature

201results about How to "Improve the transformation effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for experimentally determining carbonate rock oil and gas reservoir acid fracturing fracture conductivity distribution

ActiveCN106522935AImprove the transformation effectThe distribution of diversion capacity is conducive to real evaluationConstructionsFluid removalAcid fracturingAcid etching

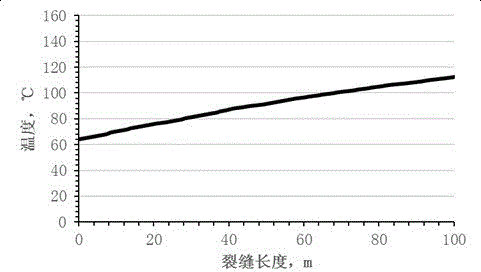

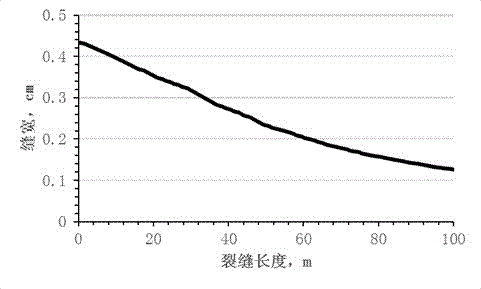

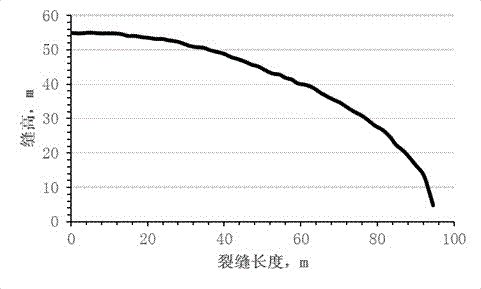

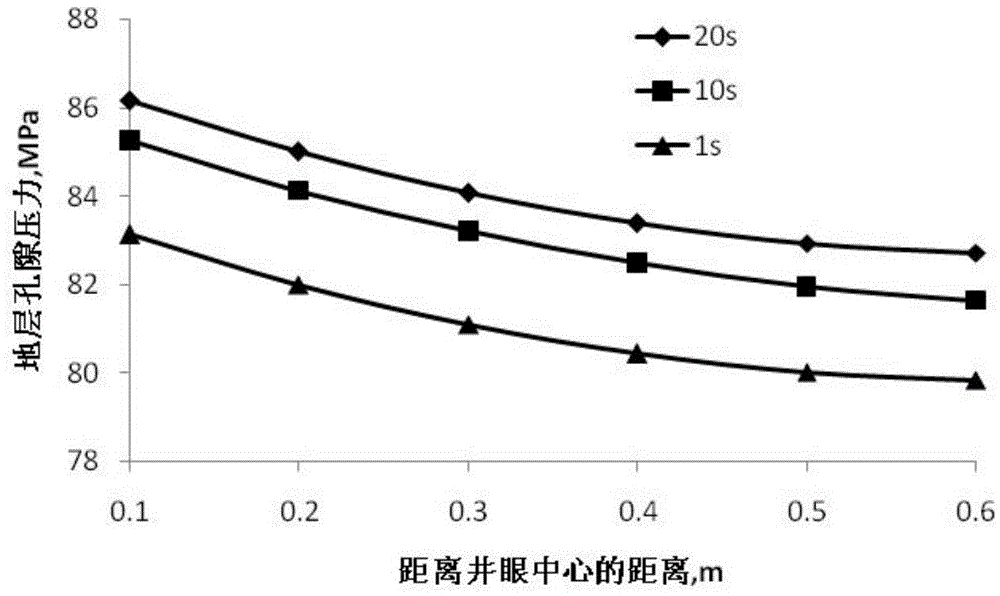

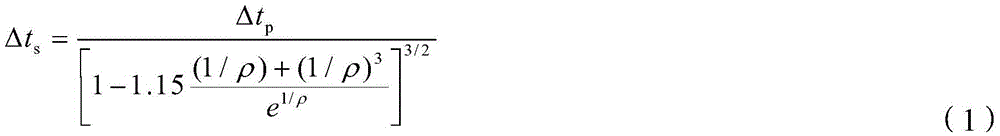

The invention discloses a method for experimentally determining carbonate rock oil and gas reservoir acid fracturing fracture conductivity distribution. The method comprises the steps that an acid fracturing simulator FracproPT is adopted for simulating the down-hole acid fracturing fracture extending and acid etching process during acid fracturing, and fracture width distribution, fracture height distribution, temperature distribution and acid liquor mass concentration distribution data in the hydraulic fracture length direction are obtained; in the hydraulic fracture length direction, fracture width, fracture height and temperature data of total 10 feature points with the acid liquor mass concentration being 100%, 90%, 80%, 70%, 60%, 50%, 40%, 30%, 20%, 10% of the initial mass concentration are selected; acid injection displacement of the oil field site scale is converted into acid injection displacement of the laboratory scale; according to the acid liquor mass concentration data of the 10 feature points, acid liquor used for an experiment is prepared; and the acid etching process is simulated, the conductivity under the condition of reservoir closed pressure is tested experimentally, and a distribution diagram of the acid etching fracture conductivity in the fracture length direction under the reservoir condition is drawn. The method is reliable in principle and simple and convenient to operate and has wide market prospects.

Owner:SOUTHWEST PETROLEUM UNIV

Video frame rate up-conversion system and method based on scene depth estimation

InactiveCN110351511AImprove system reliabilityVersatilityConversion by changing video signal frequencyConversion involving interpolation processesLabel freeSelf adaptive

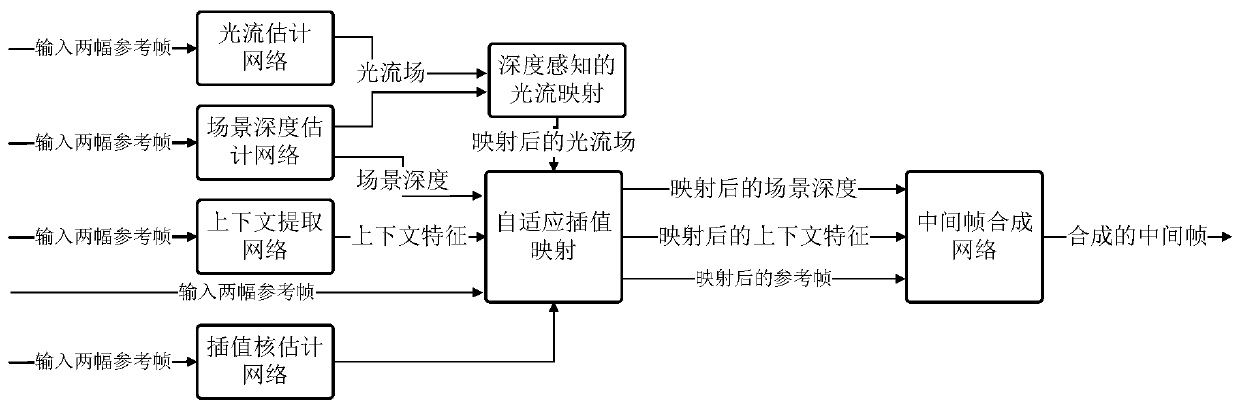

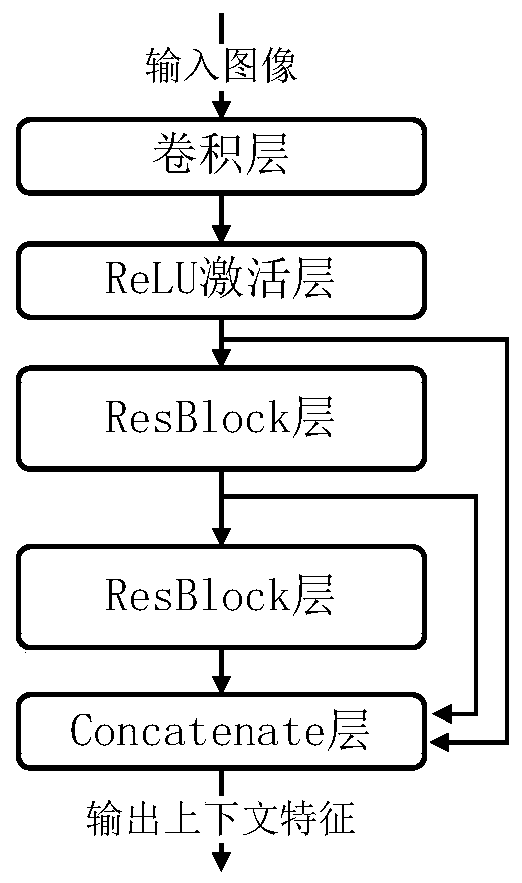

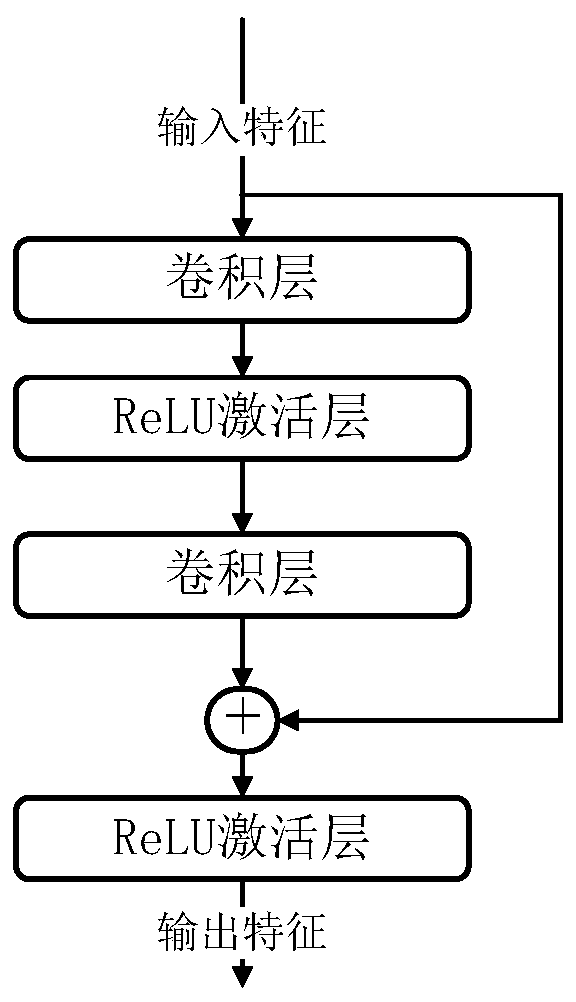

The invention provides a video frame rate up-conversion system and method based on scene depth estimation. The system comprises a module 1: an optical flow estimation network; a module 2: a scene depth estimation network; a module 3: a context extraction network; a module 4: an nterpolating kernel estimation network; a module 5: an optical flow field mapping of depth perception; a module 6: a self-adaptive interpolation mapping; a module 7: an intermediate frame generation network. According to the method, scene depth estimation is utilized, and a solution for the exposure shielding problem in video frame rate up-conversion is provided; a neural network system capable of being trained end to end by utilizing a deep learning technology, so that the system can be trained and optimized on alarge amount of label-free video data.

Owner:SHANGHAI JIAO TONG UNIV

Production method and application of sandy land conditioner made from bentonite

ActiveCN102656971AWell mixedPromote production and incomeClimate change adaptationOrganic fertilisersAlkali soilEngineering

The invention discloses a production method and application of sandy land conditioner made from bentonite. The production method and application include the steps of firstly, purifying and modifying bentonite, and adding special additive to produce sandy land conditioner; secondly, manually or mechanically evenly scattering the sandy land conditioner to sandy soil surface of leveled sandy land, dry farmland or arid farmland; thirdly, using a rotary tiller to perform rotary tillage so as to evenly mix the sandy land conditioner and the sand soil inside topsoil; and fourthly, fully irrigating with water to enable the sandy land conditioner to absorb water and turn adhesive so that the sandy land conditioner is well combined with the sand soil to form soil aggregates, thereby achieving water saving, water holding, fertilizer holding, wind proofing and sand stabilization and increasing yield of planted crops. The sandy soil conditioner is mainly used for modifying sand soil, dry farmlands and arid farmlands, and can also be used for modification of saline-alkali soil, impoverished soil, yellow mud soil and easily caking soil, desertification control and various sand stabilizing projects. The sandy land conditioner is more effective in application to rice planting.

Owner:郝国成

Slippery water fracturing fluid with ultra-low interfacial tension with crude oil after degradation

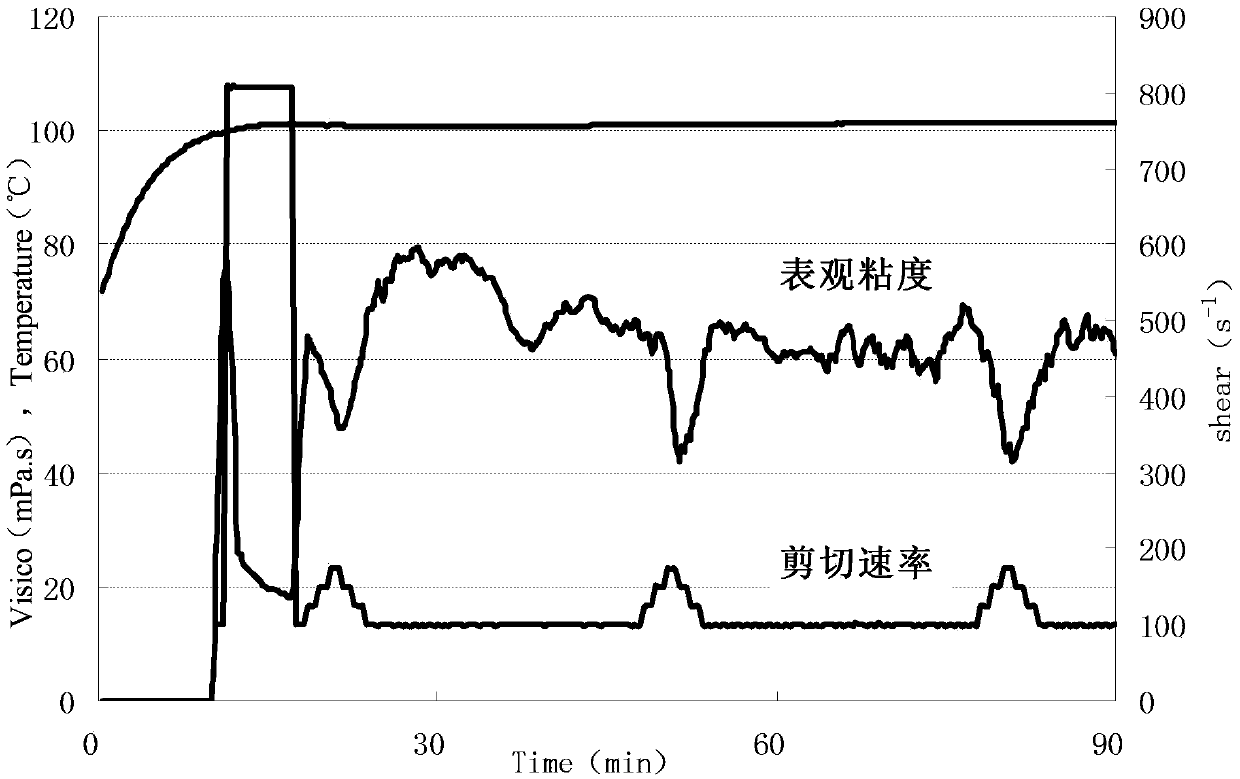

The invention discloses a slippery water fracturing fluid with ultra-low interfacial tension with crude oil after degradation. The slippery water fracturing fluid is prepared from an ultra-low interfacial tension drag reducer, a demulsify-cleanup additive, a clay stabilizer and a degrading agent. A preparation method of the slippery water fracturing fluid comprises steps as follows: 0.02%-0.10% in percentage by mass of the ultra-low interfacial tension drag reducer, 0.1%-0.2% in percentage by mass of the demulsify-cleanup additive and 0.3% in percentage by mass of the clay stabilizer are added to every ton of water, the agents are mixed to form a homogeneous solution, and 0.08% of the degradation agent is added from a mixing tank of blending equipment during construction. Additives of the slippery water fracturing fluid are all liquid phase, and the slippery water fracturing fluid can be quickly dispersed in water, have good salt tolerance, are not easily affected by the content of bacteria in a fluid preparation solution and have a stable drag reduction effect under the construction displacement of 6-20 m<3> / min; when applied to improvement of low-permeability oil and gas reservoirs, the slippery water fracturing fluid can reduce the interfacial tension between a gel breaking liquid and crude oil and reduce string and construction friction, helps production of the crude oil, increases of the yield of the crude oil and can be prepared repeatedly from backflow fracturing fluids.

Owner:PETROCHINA CO LTD

Method and device for evaluating fracturing fluid flowback capacity of shale staged fracturing horizontal well

PendingCN106596380AImprove the transformation effectIncreased production from shale gas wellsPermeability/surface area analysisShale gasEnvironmental geology

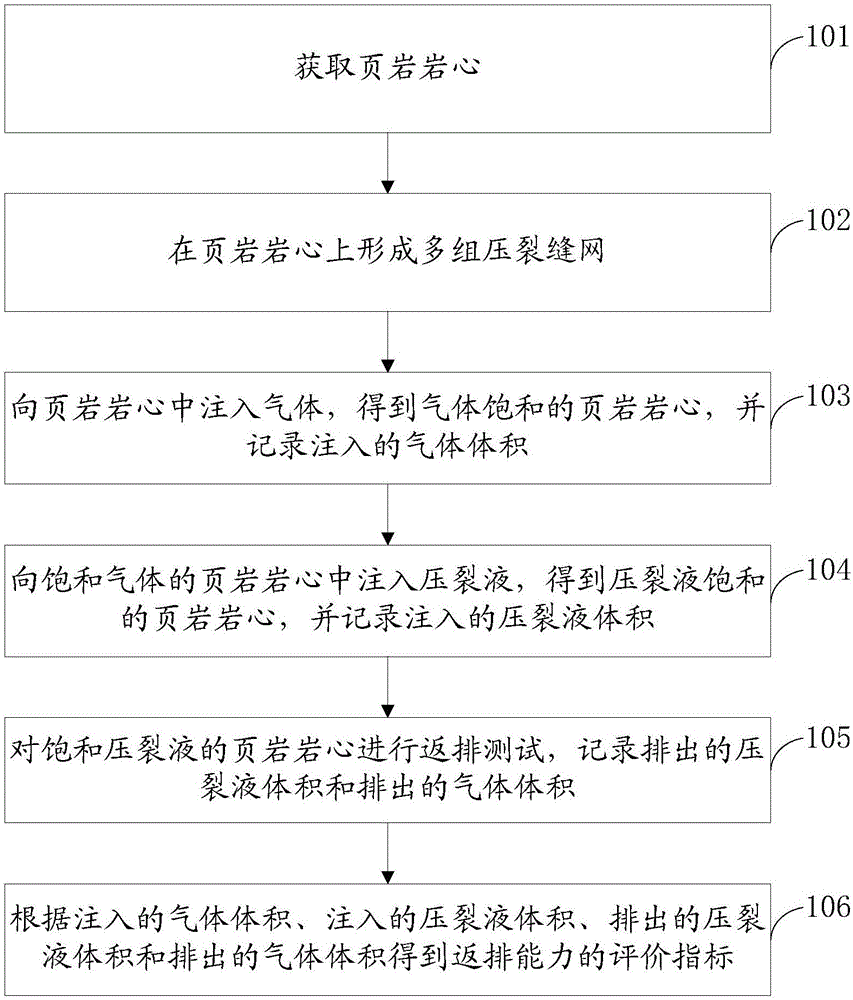

The invention discloses a method and device for evaluating the fracturing fluid flowback capacity of a shale staged fracturing horizontal well and belongs to the field of shale gas development. The method includes the steps of obtaining a shale core, forming multiple groups of fracturing seam nets on the shale core, injecting gas in the shale core to obtain the gas-saturated shale core, recording the volume of the injected gas, injecting fracturing fluid in the gas-saturated shale core to obtain the fracturing fluid saturated shale core, recording the volume of the fracturing fluid, conducting flowback test on the fracturing fluid saturated shale core, recording the volume of the discharged fracturing fluid and the volume of the discharged gas, and calculating a flowback capacity evaluation index. The method can be used for the study of the fracturing fluid flowback capacity of the shale staged fracturing horizontal well through an indoor similar physical simulation method and can provide a scientific basis for improving shale reservoir fracturing and rebuilding effects and improving shale gas-well production, and formulation of a reasonable shale staged fracturing horizontal well discharge and mining system is easily achieved.

Owner:PETROCHINA CO LTD

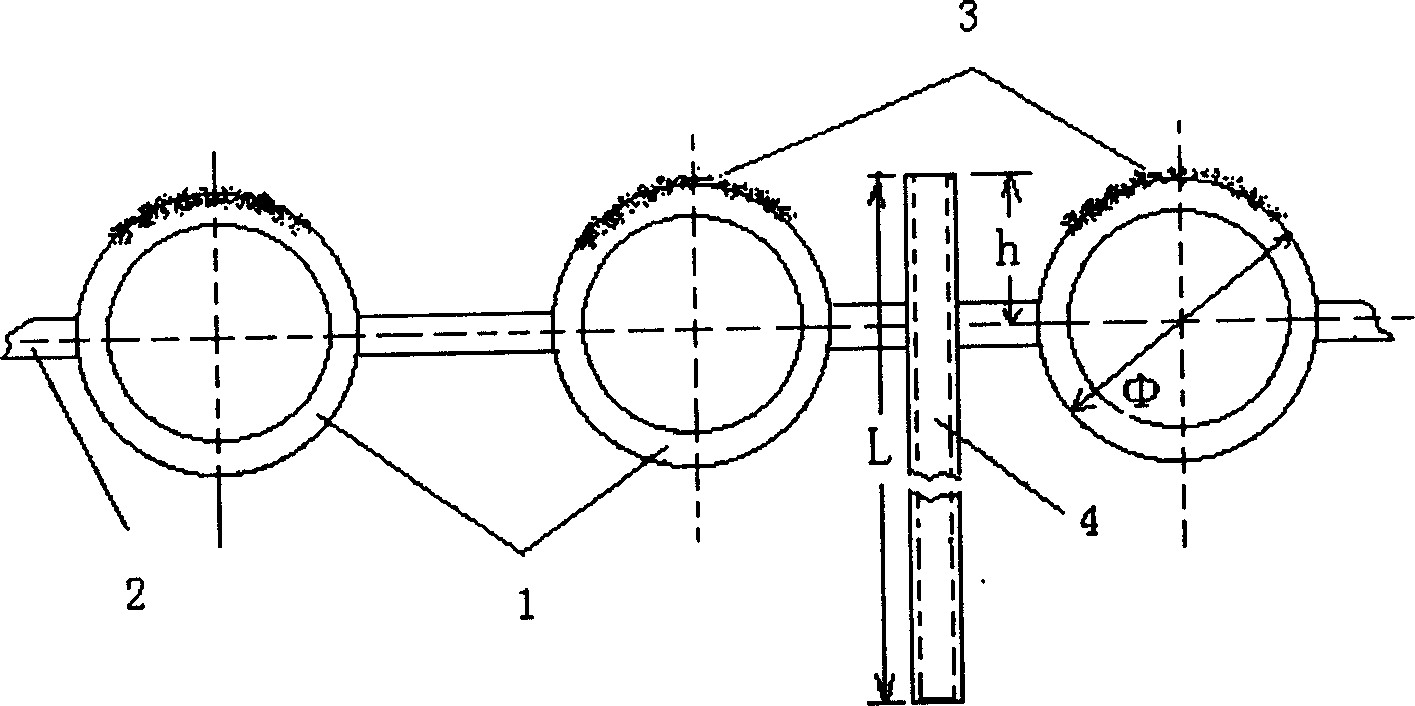

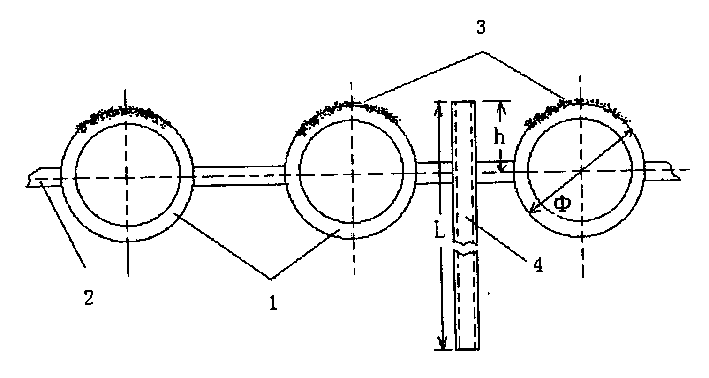

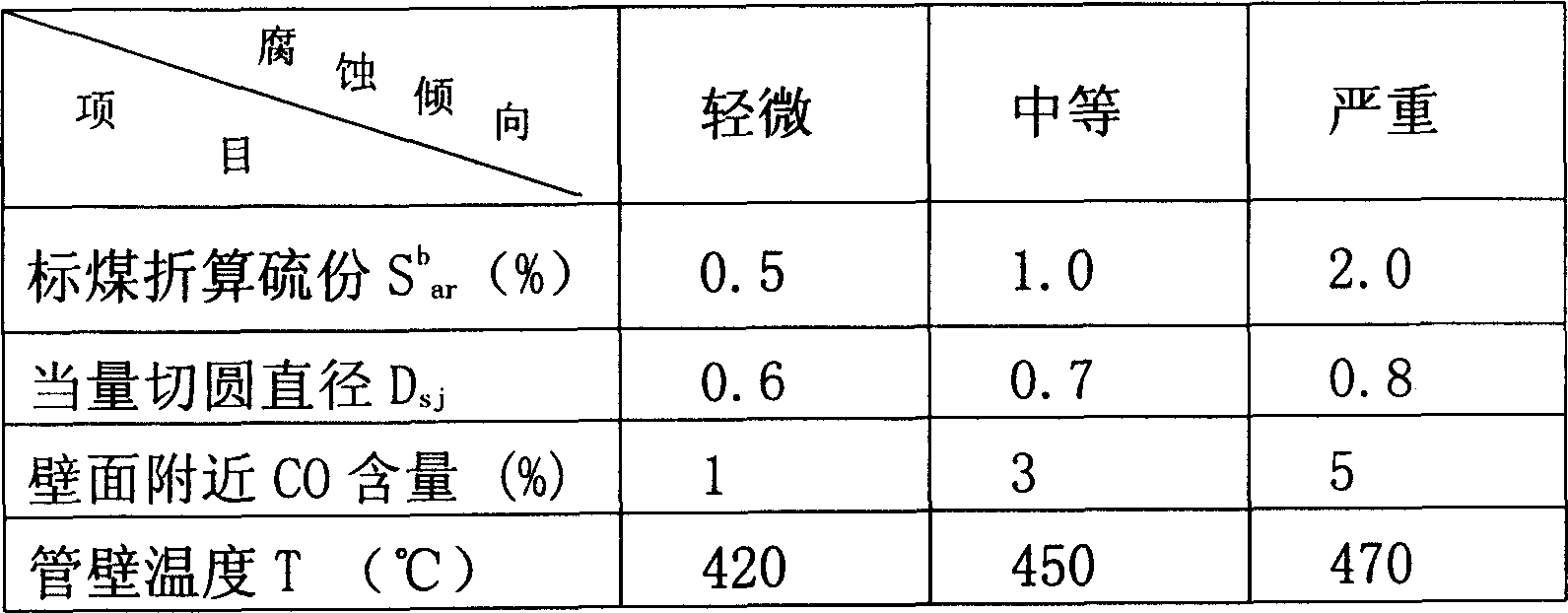

Judgment method for high temperature corrosion degree of boiler water cooling wall in large power station

InactiveCN1506616AOvercome limitationsUniqueness guaranteedCasings/liningsChamber safety arrangementPower stationEngineering

The present invention relates to coal burning boiler in thermal power plant, and is especially judgment method for high temperature corrosion degree of boiler water cooling wall in large power station. The present invention features that the judgment includes first determining the main factors of affecting the high temperature corrosion of water cooling wall; then determining measuring conditions and relevant measuring parameters; and final rating to high temperature corrosion trend of water cooling wall via grey clustering procedure. The present invention makes it possible to grasp high temperature corrosion degree of boiler at all time for taking measures timely and to select apparatus reforming scheme with optimal performance / cost ratio.

Owner:湖南省电力试验研究所

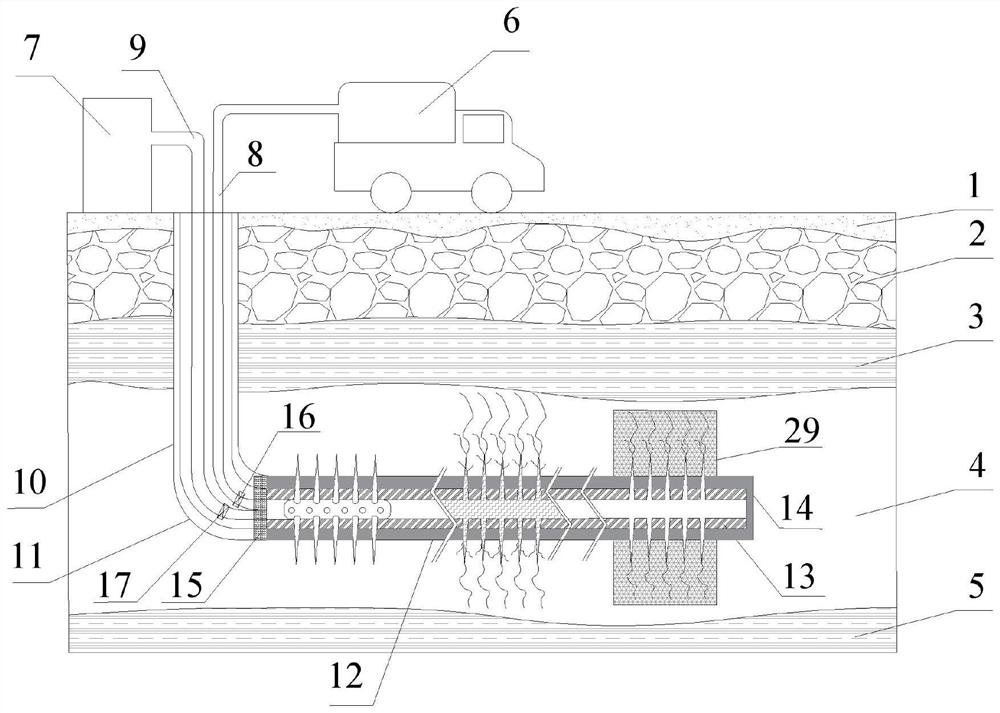

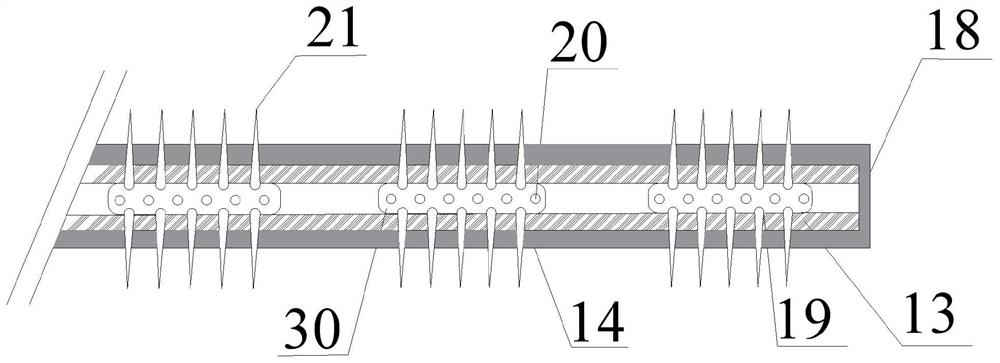

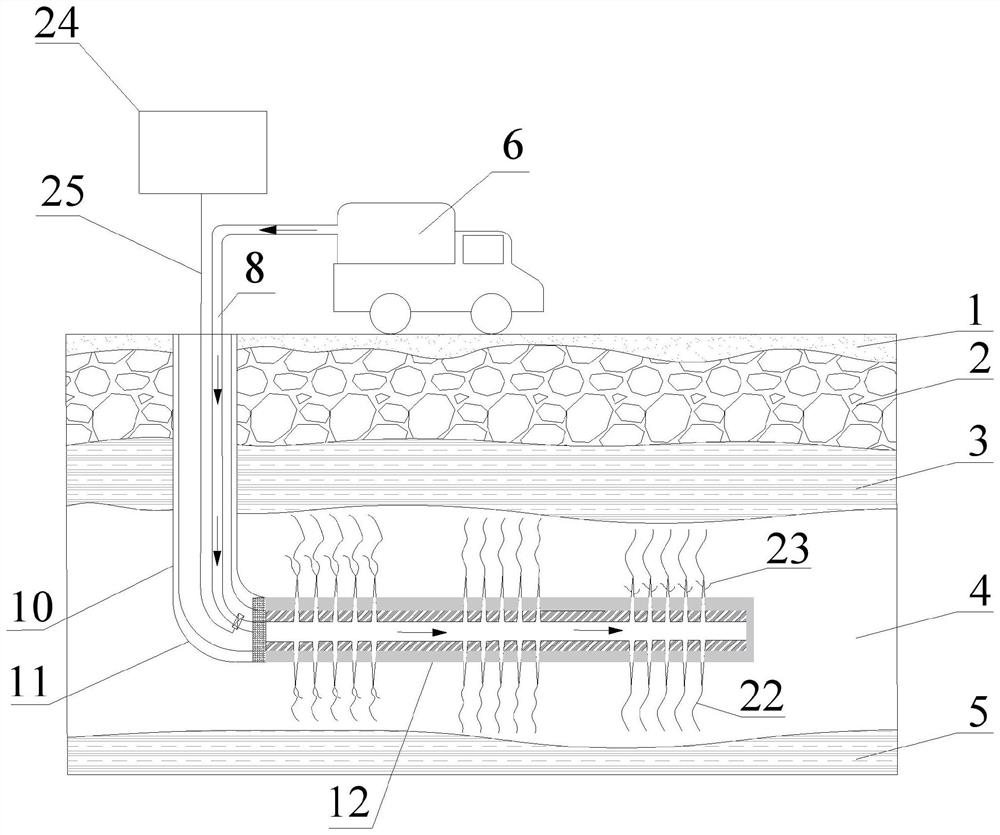

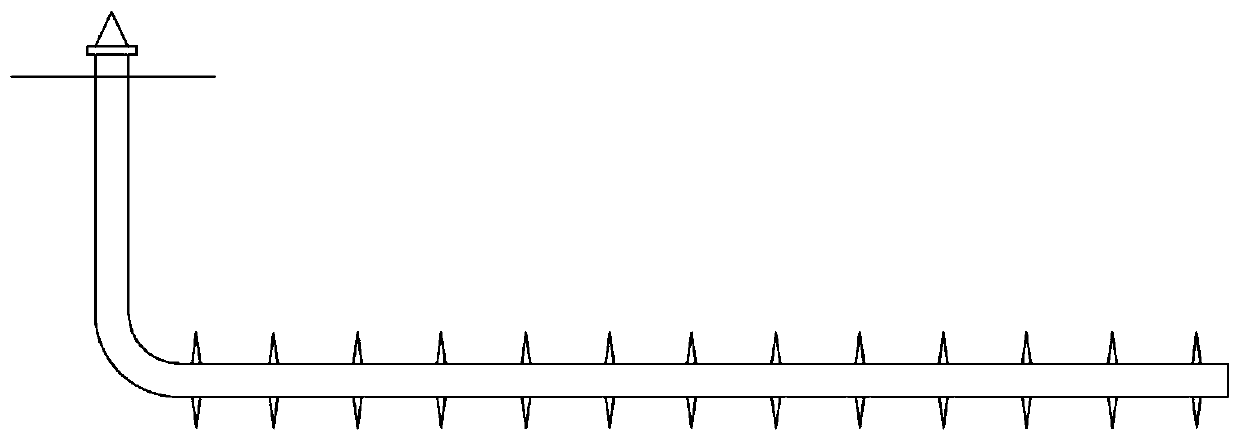

Hydraulic fracturing and methane in-situ blasting cooperative fracturing permeability-increasing method

ActiveCN113294134ARealize synergistic fracturing and anti-reflectionIncrease the volume of the transformationFluid removalWell/borehole valve arrangementsMining engineeringWell drilling

The invention relates to a hydraulic fracturing and methane in-situ blasting cooperative fracturing permeability-increasing method which is suitable for shale gas reservoir exploitation. The method comprises the steps that horizontal drilling construction is conducted on a to-be-constructed area, and then cracks are formed around the hole wall of a horizontal drill hole through energy-gathered perforation; the cracks around the horizontal drill hole continue to be expanded in a hydraulic fracturing mode, and methane extraction is conducted after fracturing fluid is discharged; after methane gas is reduced, in-situ blasting fracturing is conducted on methane participating in the horizontal drill hole; after blasting, the cracks in the horizontal drill hole continue to be expanded, so that the methane continues to seep, and then extraction continues to be conducted; and blasting fracturing and extraction operation are repeated, so that blasting cooperative fracturing permeability increasing is achieved, and the shale gas exploitation effect is greatly enhanced. The method is reasonable in design, high in construction operation feasibility and suitable for fracturing transformation of unconventional oil and gas reservoirs such as shale gas reservoirs, coal bed gas reservoirs and tight sandstone gas reservoirs.

Owner:CHINA UNIV OF MINING & TECH

Horizontal well segmented temporary blockage fracturing method

ActiveCN109763804AComplex seam structureRealize infinite continuous fracturingFluid removalFracturing fluidHydraulic fracturing

The invention relates to a horizontal well segmented temporary blockage fracturing method and belongs to the technical field of hydraulic fracturing of oil and gas field development. The method comprises the steps of: carrying out temporary blockage on a perforation of a horizontal well; forming a new crack around the temporary blocked perforation; and repeating the process above. The horizontal well segmented temporary blockage fracturing method achieves a segmented fracturing effect on a well section of a horizontal well and provides a more effective, rapider and more convenient mode for development of the horizontal well. Meanwhile, after a temporary blockage agent is degraded, a crack end port also can be supported so as to improve a fracturing success rate; the temporary blockage agent cannot be left in a shaft, meanwhile, has a very high degradation rate in fracturing fluid, and cannot generate pollution to the stratum, so that the transformation effect is greatly promoted.

Owner:PEKING UNIV

Shale gas bridge plug subsection completion method

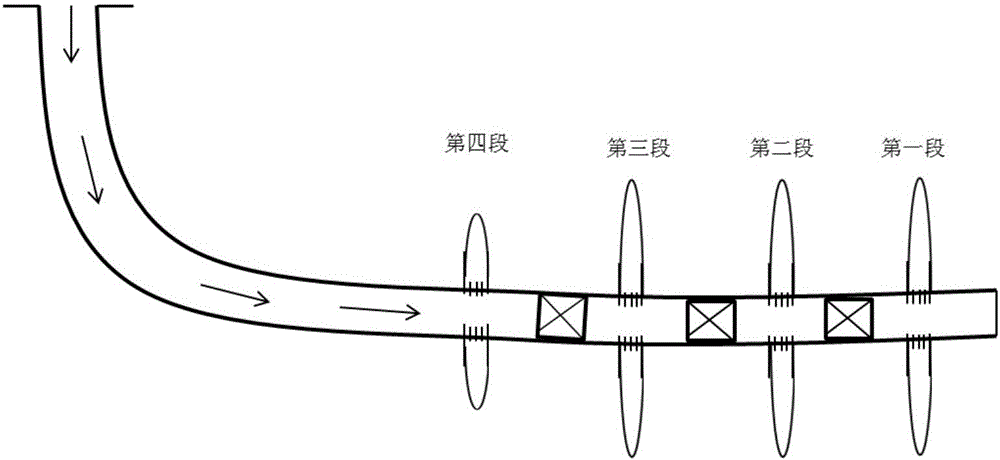

ActiveCN102777155AMeet the requirements of perforation completionSatisfy well completion requirementsFluid removalSealing/packingCoiled tubingHydraulic pump

The invention provides a shale gas bridge plug subsection completion method and belongs to the field of unconventional oil-gas reservoir well completion projects. The shale gas bridge plug subsection completion method comprises firstly using a hydraulic pump to transmit a widowmaker and a drilling removing type bridge plug to an objective layer section in a gas well through a hydraulic pump to conduct perforation, fracture and seat sealing interaction, then conducting the perforation, the fracture and the seat sealing interaction on a next objective layer section and achieving well completion of each objective layer section; and finally drilling a multistage bridge plug through a drilling and milling tool through a continuous oil tube, building production layer channels and conducting well completion operation. The shale gas bridge plug subsection completion method meets requirements for shale gas development well-case perforation completion, provides a solid well wall and a channel for communicating production layers for later stage construction, meets well completion requirements for multistage segmentation of a shale gas horizontal development well, can achieve sealing and separation of a lower bridge plug, perforation and fracture process seat interaction, simplifies well completion procedures, saves construction time, can drill the multistage bridge plug at one time in the drilling removing type bridge plug, and effectively shortens well completion periods.

Owner:CHINA PETROLEUM & CHEM CORP +1

Compound temporary blocking steering fracturing method capable of improving productivity of sandstone reservoir gas well

InactiveCN109458168AEffective blockingIncrease in sizeFluid removalDrilling compositionFiberDynamic data

The invention discloses a compound temporary blocking steering fracturing method capable of improving the productivity of a sandstone reservoir gas well. The method comprises the following steps that1, according to the reservoir stress data, micro-crack development conditions and reservoir brittleness data of the sandstone reservoir gas well, a transformed sandstone reservoir gas well and a transformed sandstone reservoir both of which can be subjected to temporary blocking steering fracturing are selected; 2, according to geological data of the sandstone reservoir gas well and production dynamic data of an adjacent well, in combination with fracturing analysis software for simulation calculation, fracturing construction parameters are determined; 3, the dosage of a composite temporary blocking agent is calculated, wherein the composite temporary blocking agent is composed of a foam temporary blocking agent and a fiber temporary blocking agent, and the dosage of the fiber temporary blocking agent is 3%o of the mass fraction of the foam temporary blocking agent; 4, pump injection construction steps are set, and a fracturing construction pump sequence is designed; 5, a foam temporary blocking agent work liquid is prepared; 6, main fracturing construction is carried out, the composite temporary blocking agent is used for blocking original cracks of the sandstone reservoir gas well, the cracks are subjected to steering, and then construction at a steering fracturing stage is carried out.

Owner:PETROCHINA CO LTD

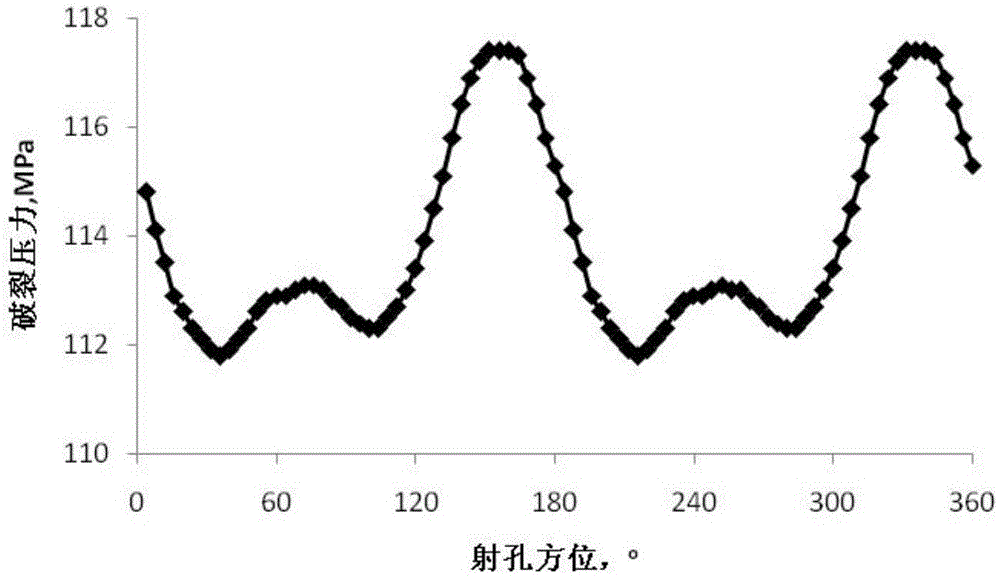

Method for selecting fracturing perforation orientation for inclined shaft

ActiveCN105484710AThe solution to poor fracking performanceImprove the transformation effectFluid removalStress distributionTectonic stress

The invention discloses a method for selecting the fracturing perforation orientation for an inclined shaft. The method comprises the following steps: 1, collecting data, including the hole drift angles, the azimuthal angles and the reservoir permeability, of a fracturing well section of the inclined shaft, calculating the main terrestrial stresses of original fields of three far fields of the inclined shaft through inclined shaft logging and adjoining well fracturing tectonic stress coefficient data, and collecting the fracturing fluid viscosity parameter and the construction displacement parameter; 2, transferring the terrestrial stresses of the original fields of the three far fields into an inclined shaft rectangular coordinate system, so that six corresponding stress components are obtained; 3, calculating a shaft peripheral stress distribution model of an inclined shaft perforation well section in the process of injecting fracturing fluid into the inclined shaft; 4, calculating the fracture pressure of inclined shaft fracturing at different perforation azimuthal angles, and selecting the orientation where the fracturing pressure is the minimum as the optimal perforation orientation of inclined shaft fracturing. By means of the technical scheme of the method, optimization of inclined shaft fracturing perforation orientation can be achieved rapidly, the problem that the inclined shaft fracturing effect is not good is effectively solved, thereby the basis is provided for optimization of inclined shaft fracturing perforation orientation, and the reservoir reconstruction effect is improved.

Owner:SOUTHWEST PETROLEUM UNIV

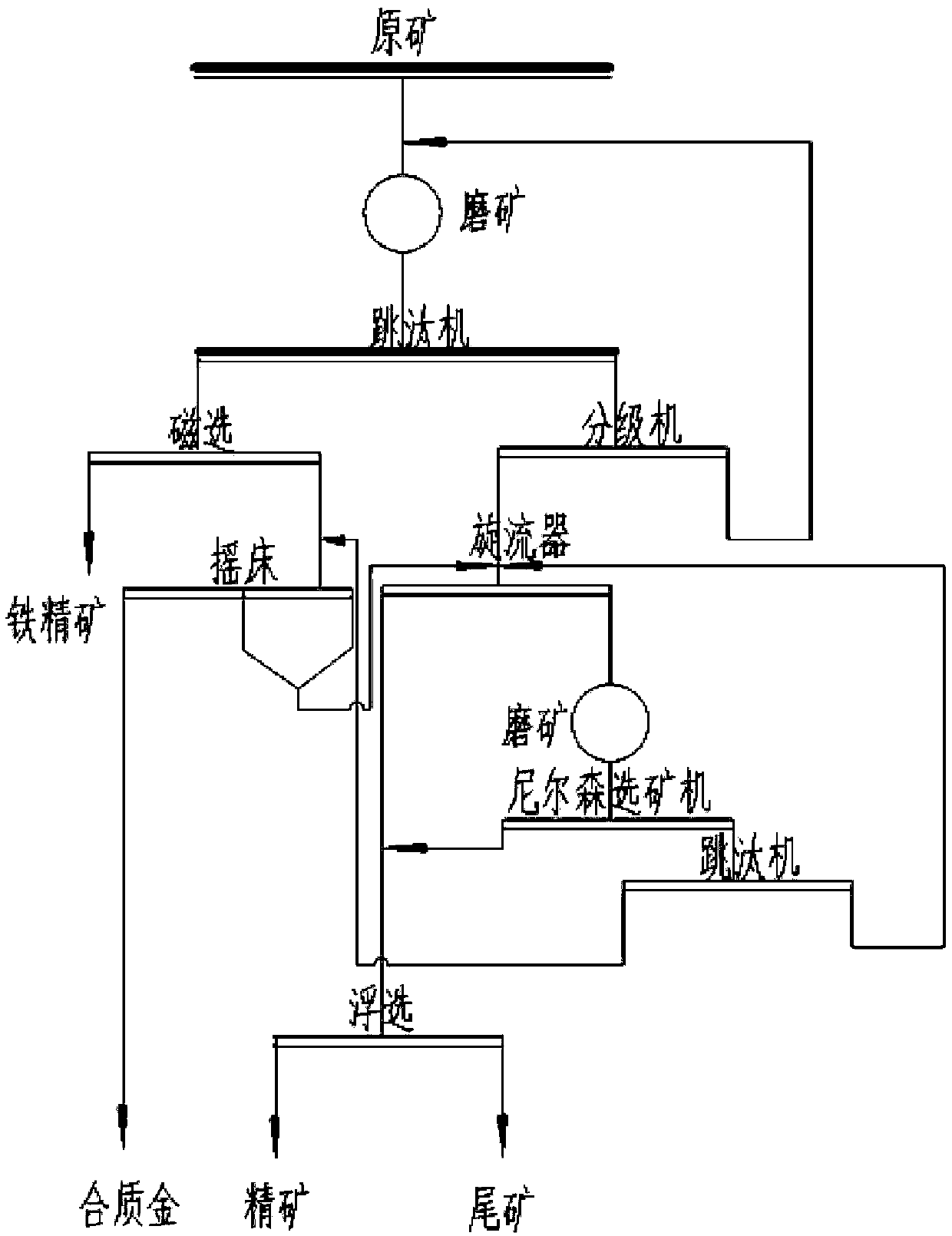

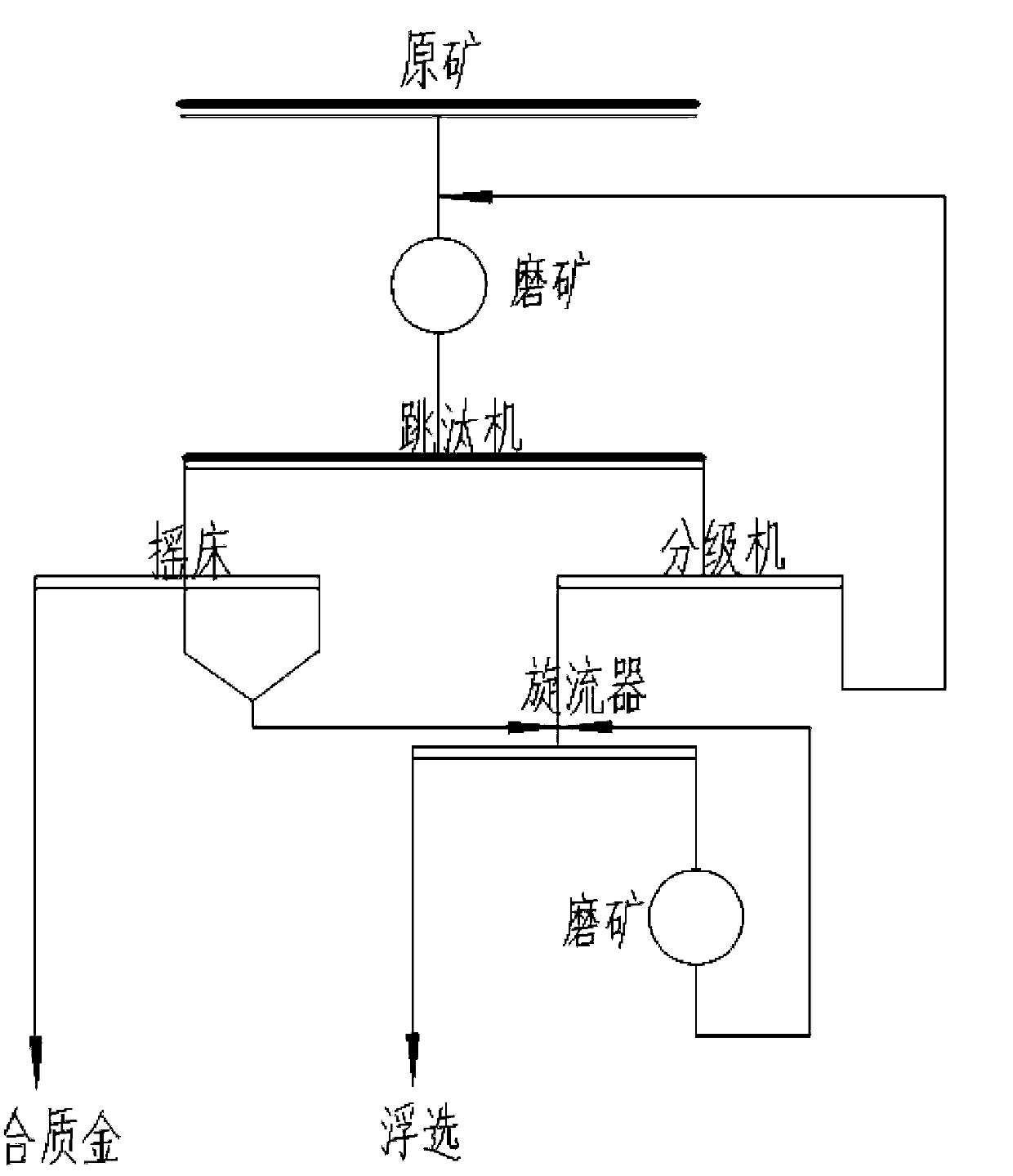

Reselection recovery method and device for gold

The invention discloses a reselection recovery method for gold. The method comprises the following steps that primary ore grinding is carried out on raw ore, ore pulp generated after ore grinding is sorted by a jigging machine, magnetic separation is carried out on jigged concentrates, and jigged tailings enter a classifier; the magnetic concentrates are selected finely to obtain iron ore concentrates, the magnetic tailings enter a table concentrator, and concentrates of the table concentrator are adopted as alloy gold; classification and machine overflowing are carried out on middlings and tailings of the table concentrator, the middlings and the tailings enter the cyclone, and coarse particles return to a first-stage ball grinder to be ground again; the cyclone carries out overflowing, the floatation operation is executed, secondary ore grinding is carried out on cinnabar, and materials obtained after ore grinding enter a Nelson concentrating machine; floatation is carried out on tailings of the Nelson concentrating machine, and concentrates begin to be jigged; the jigged concentrates enter the table concentrator, and jigged tailings return to the cyclone to be classified; the concentrates and the tailings are obtained through flotation. According to the reselection recovery method for the gold, the reselection recovery rate is improved by 22.11 percent, and the total recovery rate of ore dressing is improved by 2.69 percent.

Owner:HABAHE JINBA MINING

Fracturing and cavern integrated completion method for coal-bed gas reservoir

InactiveCN104213896AImprove permeabilityImprove the transformation effectFluid removalProduction rateLine tubing

The invention relates to a fracturing and cavern integrated completion method for a coal-bed gas reservoir. The method comprises the following steps: firstly, forming a crack connected with a shaft in a coal bed through hydraulic fracturing equipment, and then, performing cavern completion operation by utilizing fluid supercharging equipment, a supercharging pipeline, fluid depressurization equipment and a depressurization pipeline to form a wide-range permeability growth zone, therefore increasing the production rate of coal-bed gas. According to the fracturing and cavern integrated completion method for the coal-bed gas reservoir, provided by the invention, by comprehensively utilizing the advantages of hydraulic fracturing and cavern completion, the design problem of a fracturing and cavern construction is solved; the fracturing and cavern integrated completion method for the coal-bed gas reservoir is especially suitable for the development of the low-permeability coal-bed gas reservoir; the production rate of the coal-bed gas is greatly increased; the high-efficient mining of the coal-bed gas of the low-permeability reservoir is realized.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Method for determining real-time steering fracturing parameters based on composite temporary plugging system

ActiveCN110905472ASignificant complexityIncreased complexityFluid removalDesign optimisation/simulationShale oil and gasGeophysics

The invention discloses a method for determining real-time steering fracturing parameters based on a composite temporary plugging system, and relates to the technical field of unconventional shale oiland gas reservoir reconstruction. The method for determining the real-time steering fracturing parameters comprises the following steps that temporary plugging of perforating holes and fractures of different scales is achieved by using the composite temporary plugging system including a soluble temporary plugging ball and temporary plugging particles, meanwhile, integrating of the data analysis of geological parameters, construction pressure, and micro-seismic real-time monitoring is conducted to form the real-time optimization of the adding amount, adding timing and adding frequency of composite temporary plugging materials, the uniform transformation of the horizontal section is achieved, and the complexity of a fracture network is improved.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD +1

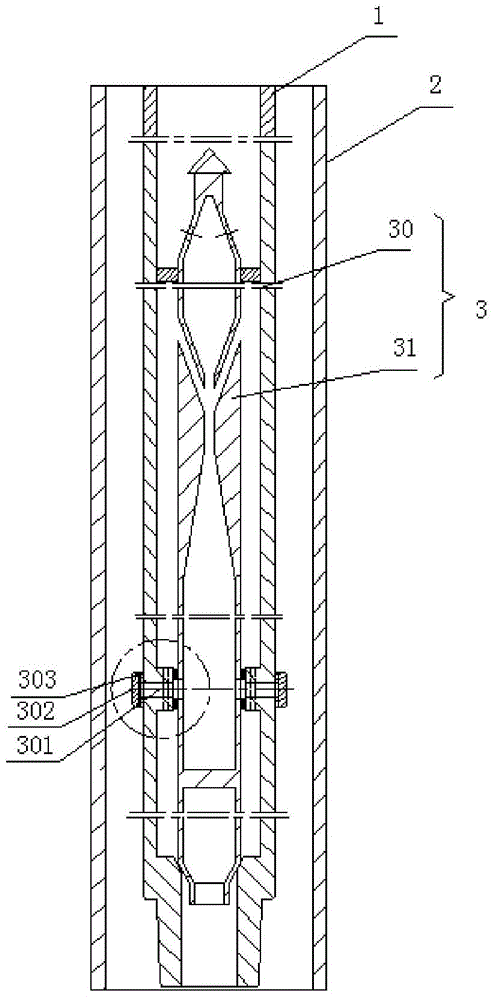

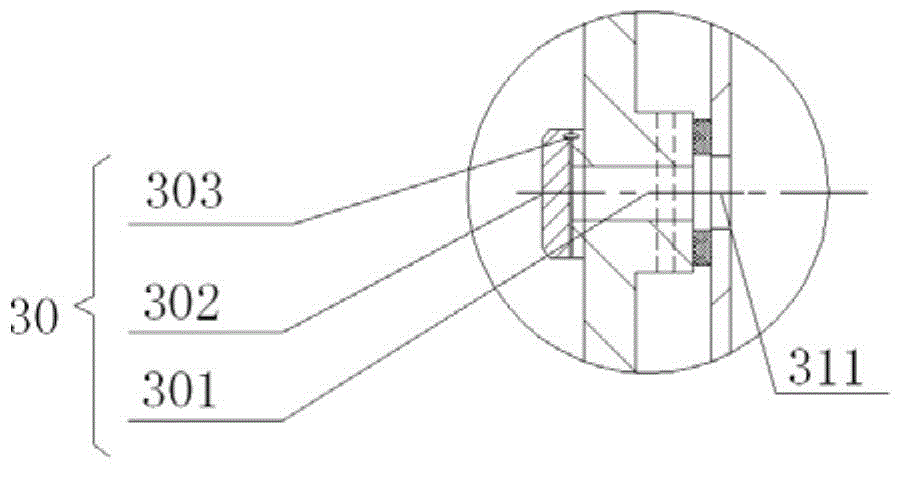

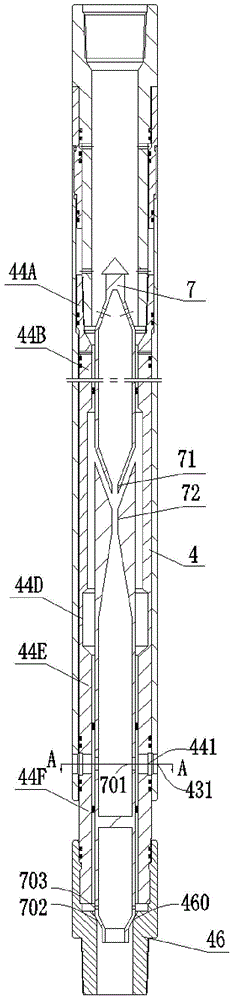

Jet pump and oil test technologies based on same

ActiveCN104454669AImprove the transformation effectImprove admission qualitySurveyJet pumpsHydraulic cylinderEngineering

The invention discloses a jet pump which comprises an upper connector provided with upper pressure transmitting holes and middle pressure transmitting holes, a first sleeve, a second sleeve, a third sleeve and a lower connector, wherein the first sleeve is arranged on the upper connector in a sleeving mode, and an upper hydraulic cylinder communicated with the upper pressure transmitting holes is arranged between the first sleeve and the upper connector; the second sleeve is fixedly arranged outside the first sleeve in a sleeving mode; the upper end of the third sleeve is fixedly arranged on the upper connector in a sleeving mode, a middle hydraulic cylinder communicated with the middle pressure transmitting holes is arranged between the upper end of the third sleeve and the lower end of the first sleeve, a lower hydraulic cylinder is arranged between the third sleeve and the second sleeve, the third sleeve is provided with lower pressure transmitting holes communicated with the lower hydraulic cylinder, provided with inner circulating holes and provided with suction holes in the axial direction, and the second sleeve is provided with outer circulating holes matched with the inner circulating holes; the lower connector is fixedly connected with the lower end of the third sleeve. By means of the jet pump, the oil test technologies such as perforation, test, pumping drainage, high-pressure pump injection and pump drainage combining five kinds of operation can be achieved under the condition that the sleeves are protected.

Owner:PETROCHINA CO LTD

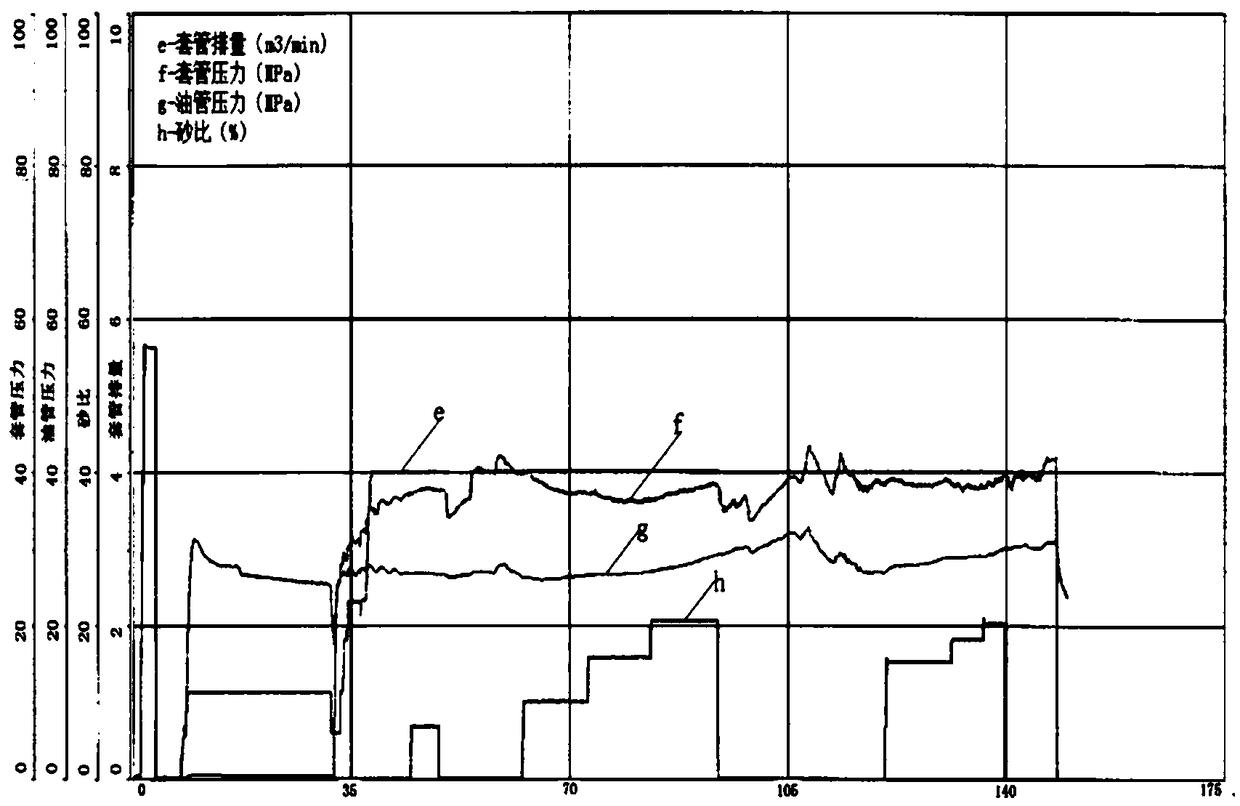

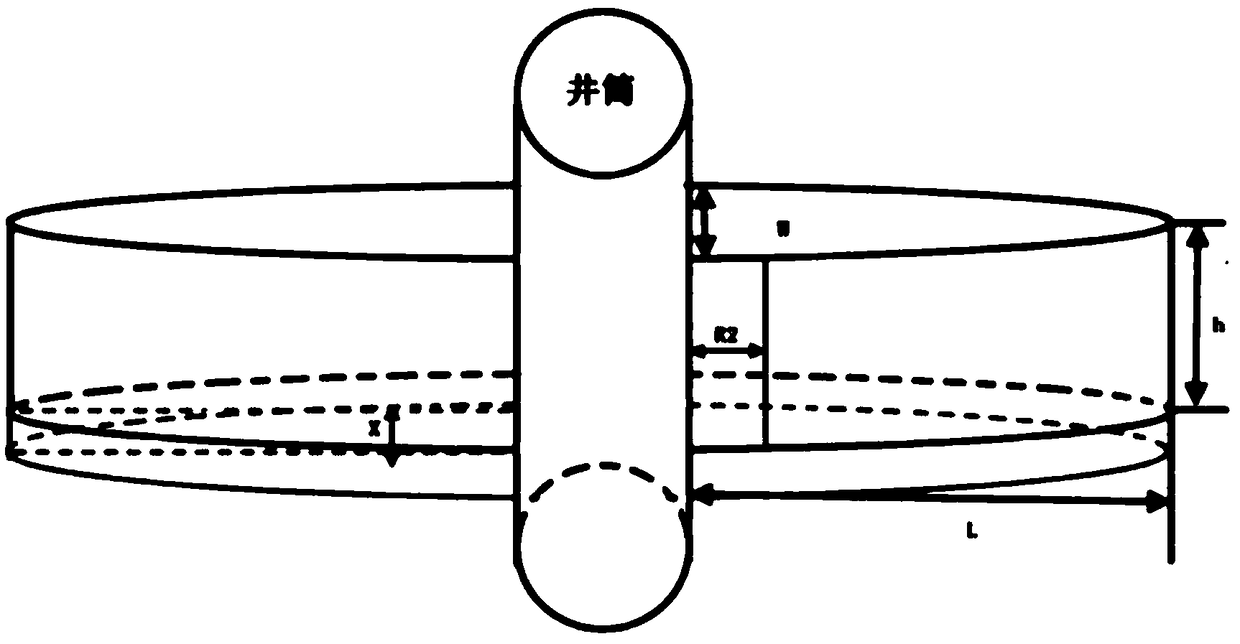

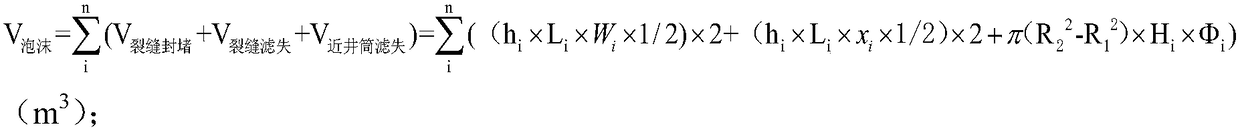

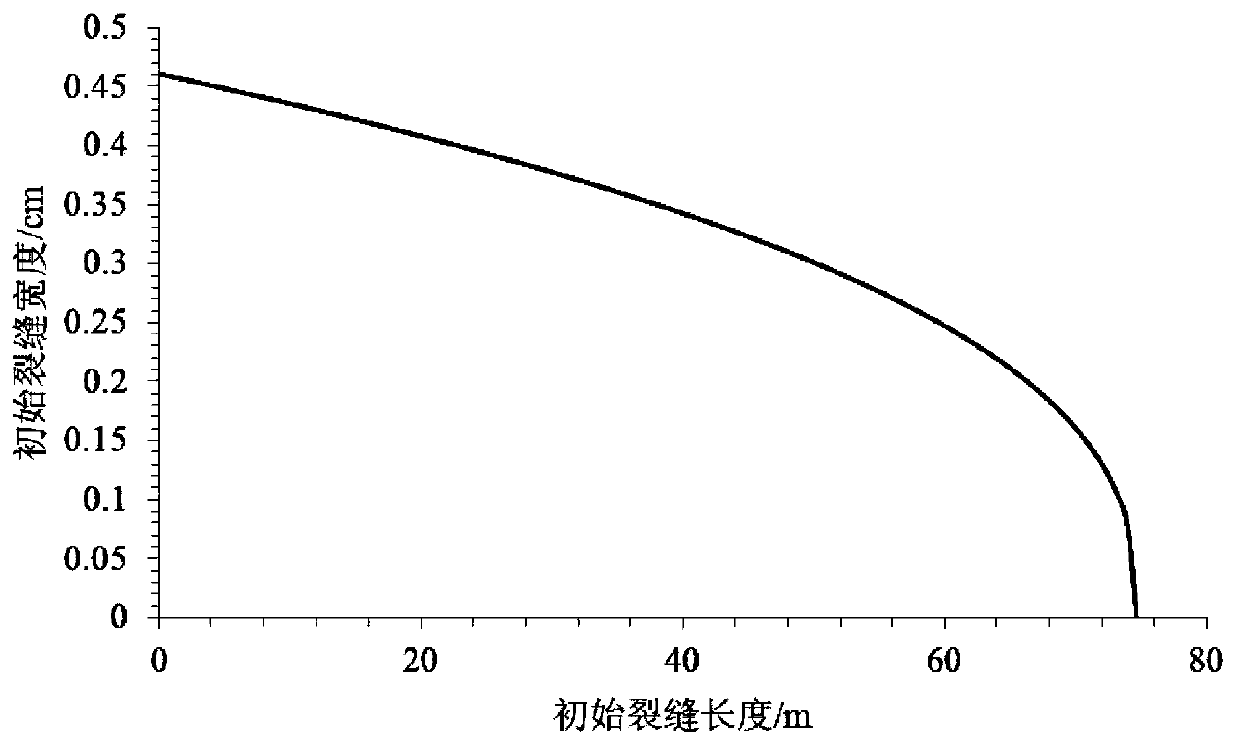

Method for predicting pad-acid-fracturing crack flow conductivity distribution of carbonate rock

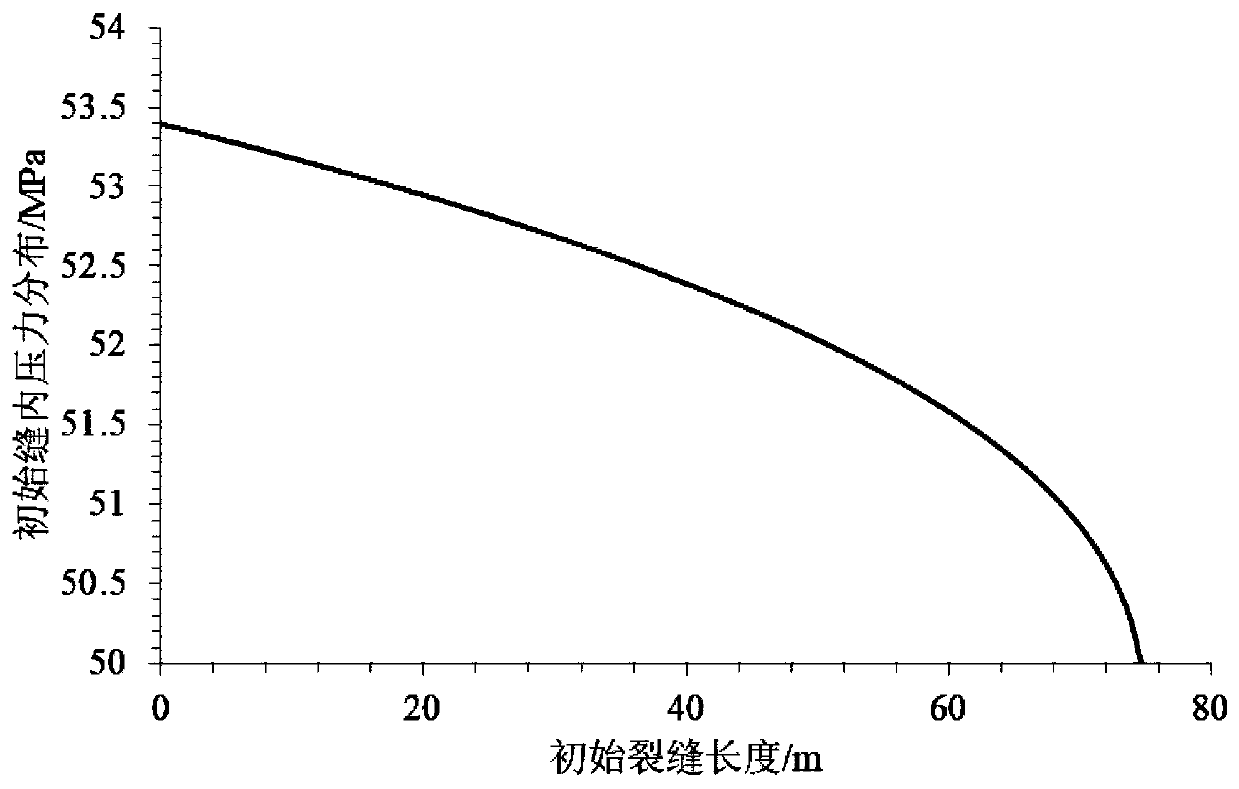

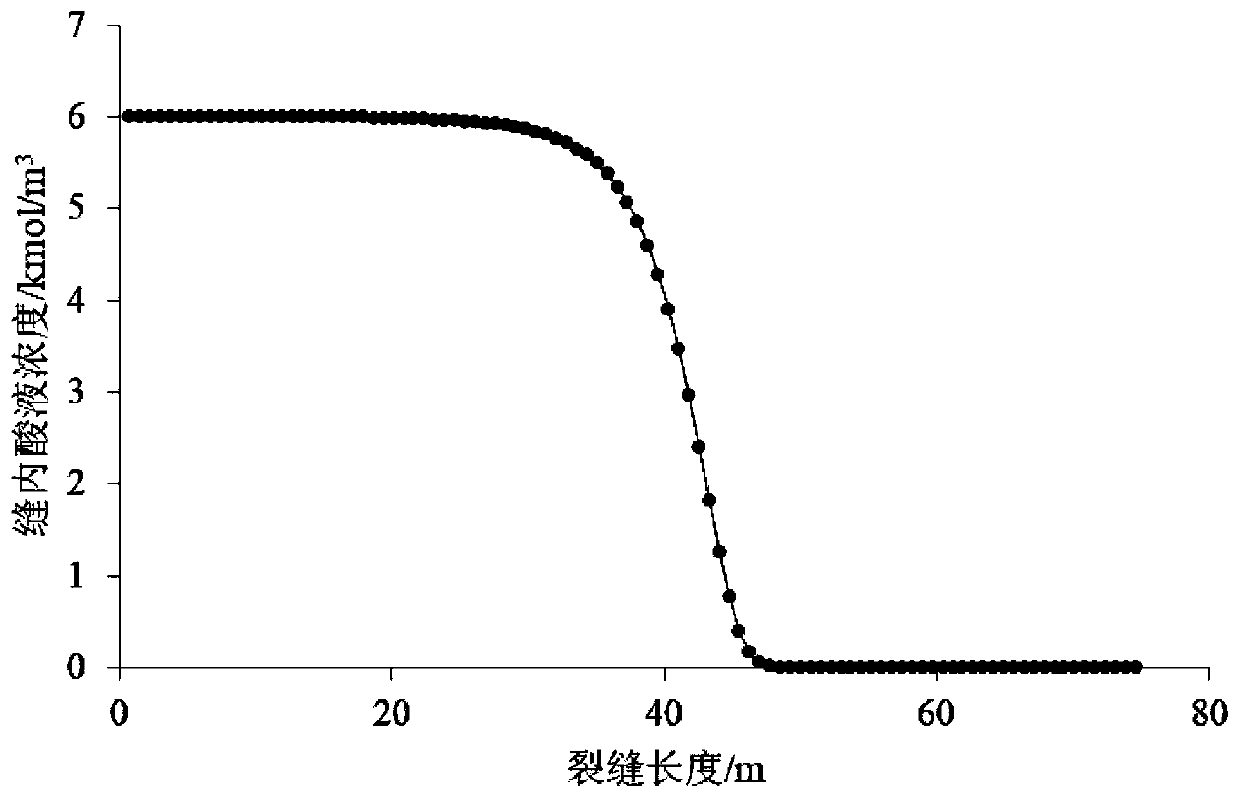

ActiveCN110397430AAccurately obtain crack width distributionUpdate flow rate in real timeFluid removalSpecial data processing applicationsAcid fracturingCarbonate rock

The invention relates to a method for predicting pad-acid-fracturing crack flow conductivity distribution of carbonate rock. The method comprises steps as follows: a pad-acid-fracturing process is divided into a fracturing crack making period and an acid injection period, a crack extension process of the fracturing crack making period is simulated by adopting a two-dimensional PKN crack extensionmodel, and crack length, crack width and pressure p0 in the crack when the fracturing crack making period t1 is ended are obtained; in the acid injection period t2, t2 is equally divided into n time steps, and concentration of acid liquor in the crack, acid-corroded crack width and flowing pressure p1 of acid liquor in the crack in the crack length direction when the first time step is ended are obtained; the concentration of acid liquor in the crack, the acid-corroded crack width and the flowing pressure pj (j=1,2,3,...,n) of acid liquor in the crack when any time step in the acid injection period t2 is ended are obtained; fracture flow conductivity distribution wkf after the pad-acid-fracturing crack is closed is calculated. With the adoption of the method, the flow conductivity distribution of the acid-corroded crack in the crack length direction can be accurately predicted, the pad-acid-fracturing design scheme of the carbonate rock is optimized, and the development effect of the carbonate rock is improved.

Owner:SOUTHWEST PETROLEUM UNIV

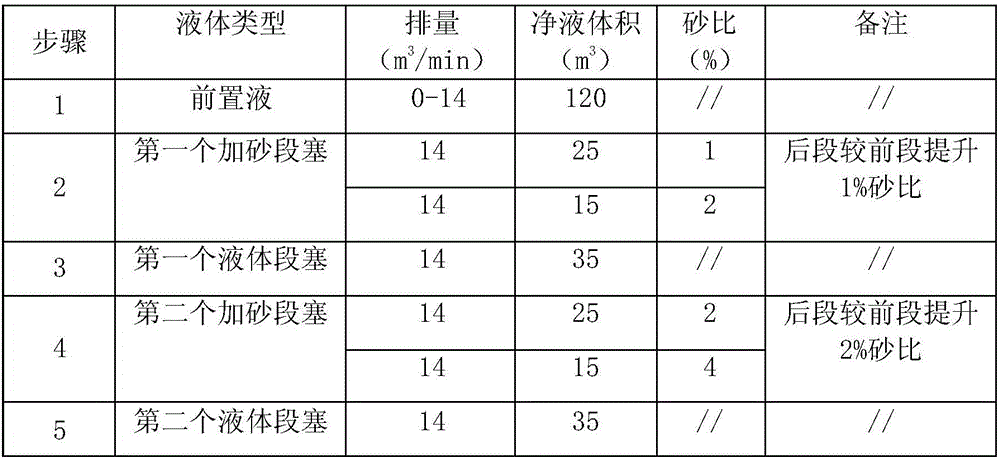

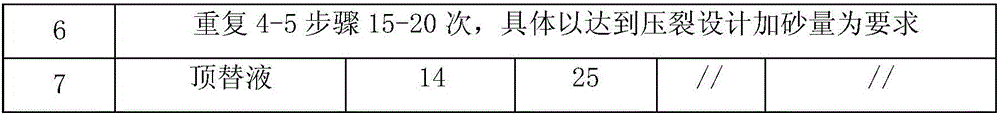

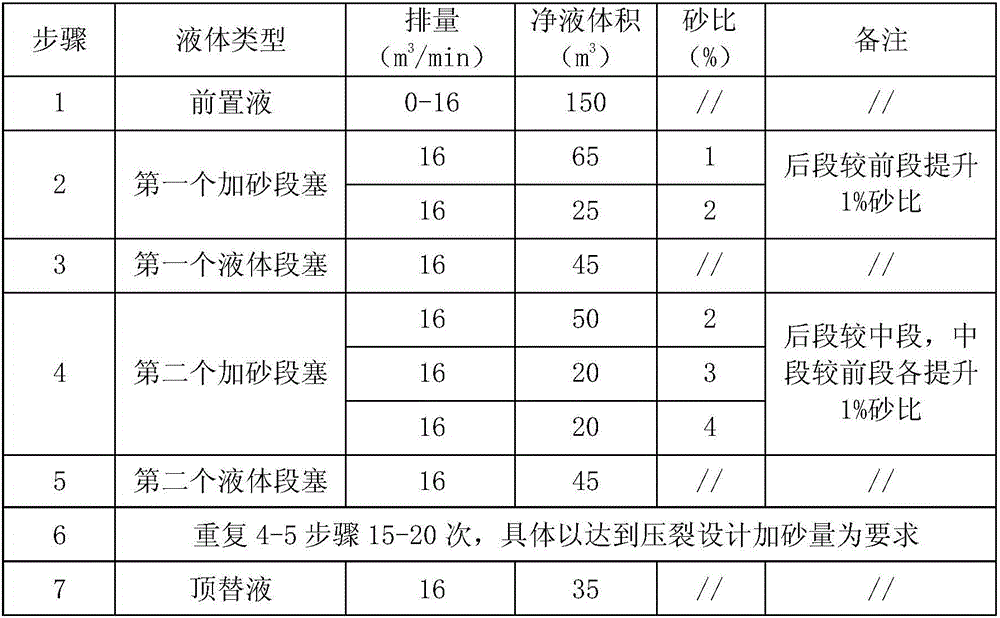

Shale gas fracturing stepping sand-adding method

InactiveCN106593394AImprove the efficiency of liquid sand carryingIncrease net pressureFluid removalShale gasEnvironmental geology

The invention relates to a shale gas fracturing stepping sand-adding method which comprises the following steps: (1) pumping a prepared fluid into a shaft and causing the fluid enter into ground gaps; (2) pumping a first sand-adding section plug and performing the stepping sand adding; (3) pumping a first fluid section plug, and if the pressure shows as diagonal rising, confirming that the pressure change is mild and the sand ratio has a rising potential, and then skipping to the step (4), and if the pressure shows as the sand ratio rising unsuitable for the present stage, further pumping the fracturing fluid for forming gaps and then skipping to the step (1); (4) pumping a second sand-adding section plug and performing the stepping sand adding; (5) pumping a second fluid section plug and observing the pressure variation trend of the sand-adding section plug at different sand ratios after entering into the stratum; and (6) repeating the steps (4)-(5) for 15-20 times till meeting the requirement for designed fracturing sand-adding volume, completing the sand adding in each stage, and lastly, pumping the displacing liquid and completing the whole fracturing construction task. According to the invention, the stepping sand-adding method is adopted for effectively preventing reservoir sand blocking, reducing the construction risk and guaranteeing the smooth construction.

Owner:重庆矿产资源开发有限公司 +1

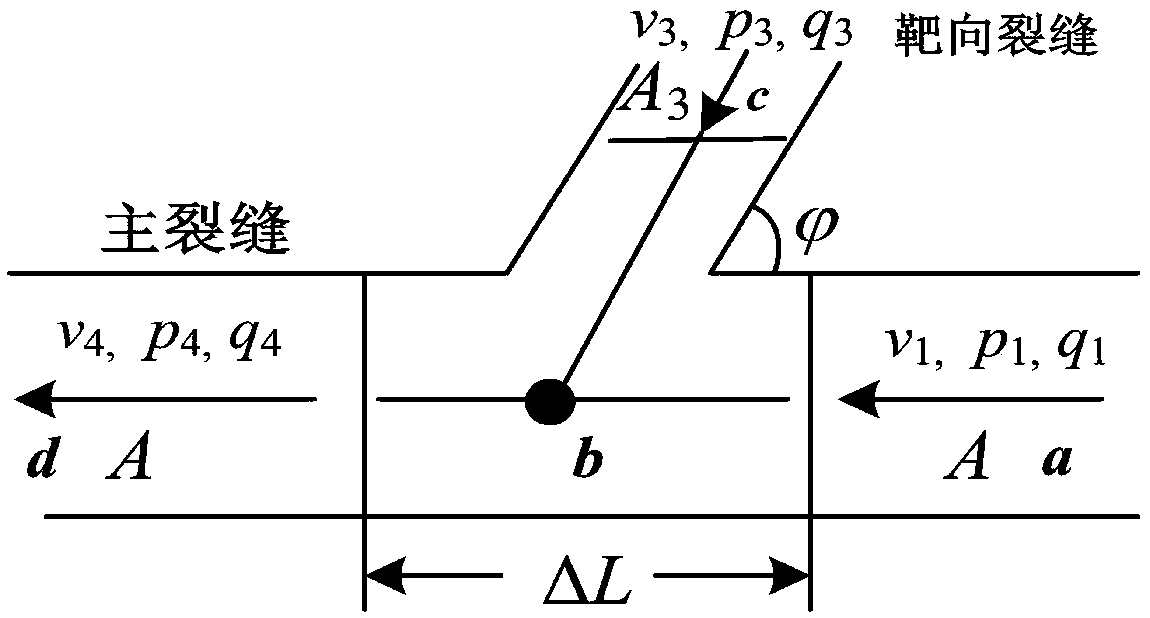

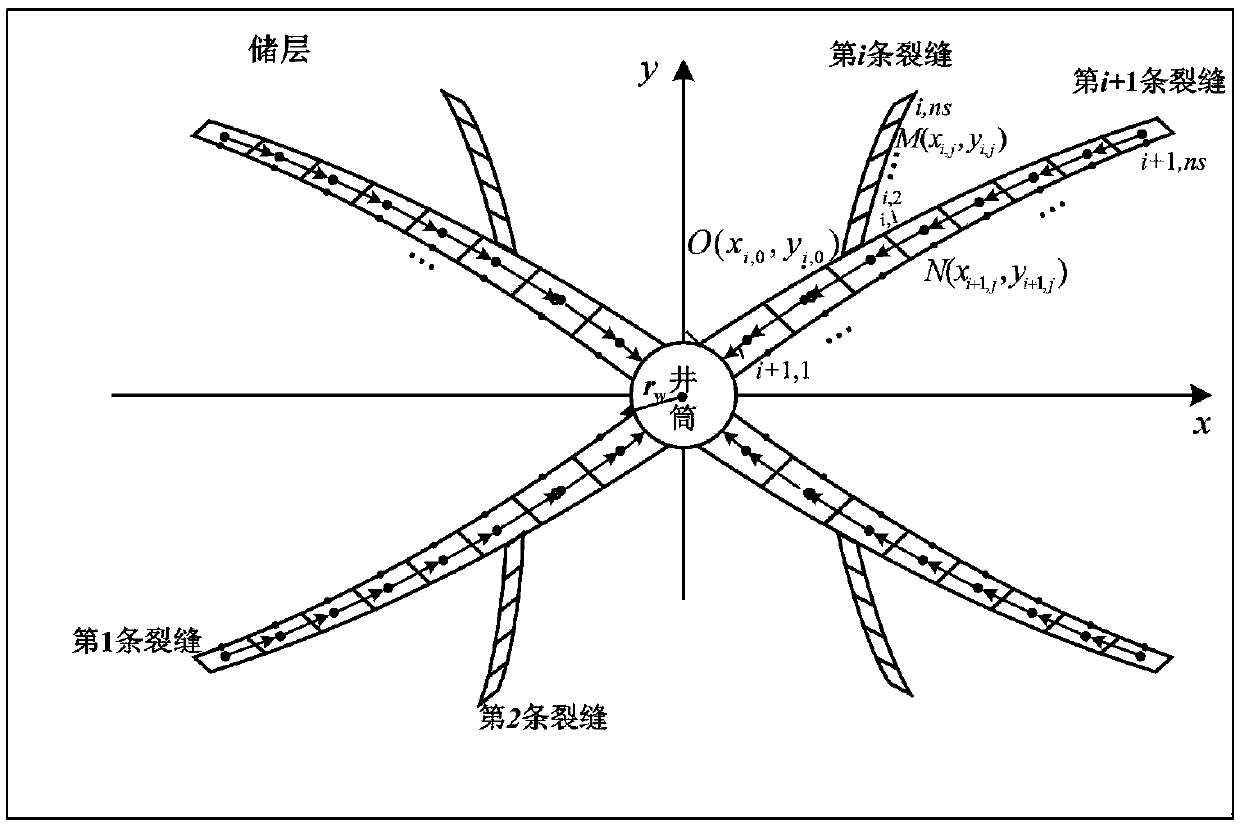

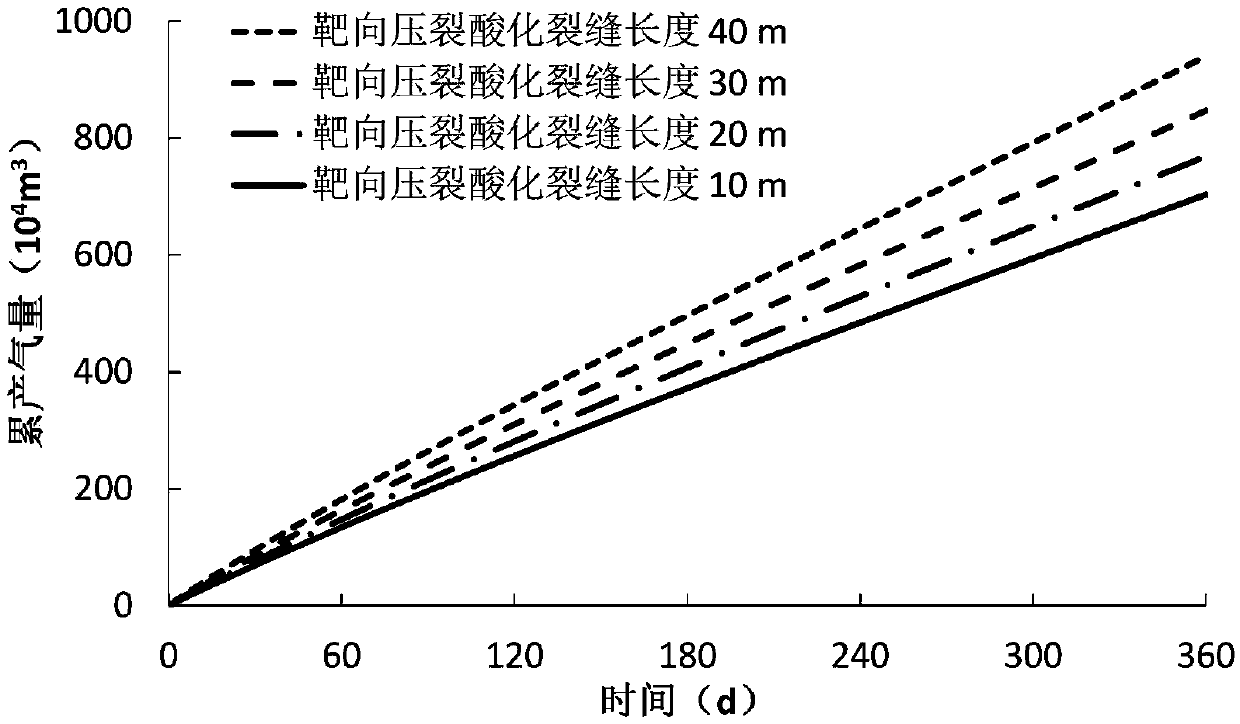

Method for optimizing fracture parameters of target fracturing acidizing well

ActiveCN109033674AImprove the transformation effectFluid removalDesign optimisation/simulationProduction rateEnvironmental geology

A method for optimizing fracture parameters of target fracturing acidizing well includes such steps as uniformly dividing branch fractures into ns line confluence with equal length through space dispersion for single wing of main fracture, and establishing reservoir percolation model with reservoir boundary effect and stress sensitivity for each line confluence; considering the heterogeneous flowof fluid along irregular fracture surface into the main fracture, targeted fracturing acidizing branch fractures, targeted fracturing acidizing branch fractures into the main fracture, considering theheterogeneous conductivity distribution in the main fracture, and the influence of high-speed heterogeneous Darcy effect in the main fracture, the pressure drop model of fluid in the hydraulic fracture being established. A production calculation model of fracturing acidizing wells with high velocity and non-Darcy flow of coupled fluid in reservoir matrix and targeted fracturing acidizing fractures is established. Fracture parameters of targeted fracturing acidizing wells are optimized to increase cumulative production rate of targeted fracturing acidizing wells for 360 days. The invention provides a reasonable basis for optimizing design of fracture parameters of targeted fracturing acidizing wells and improves the effect of reservoir reconstruction.

Owner:SOUTHWEST PETROLEUM UNIV

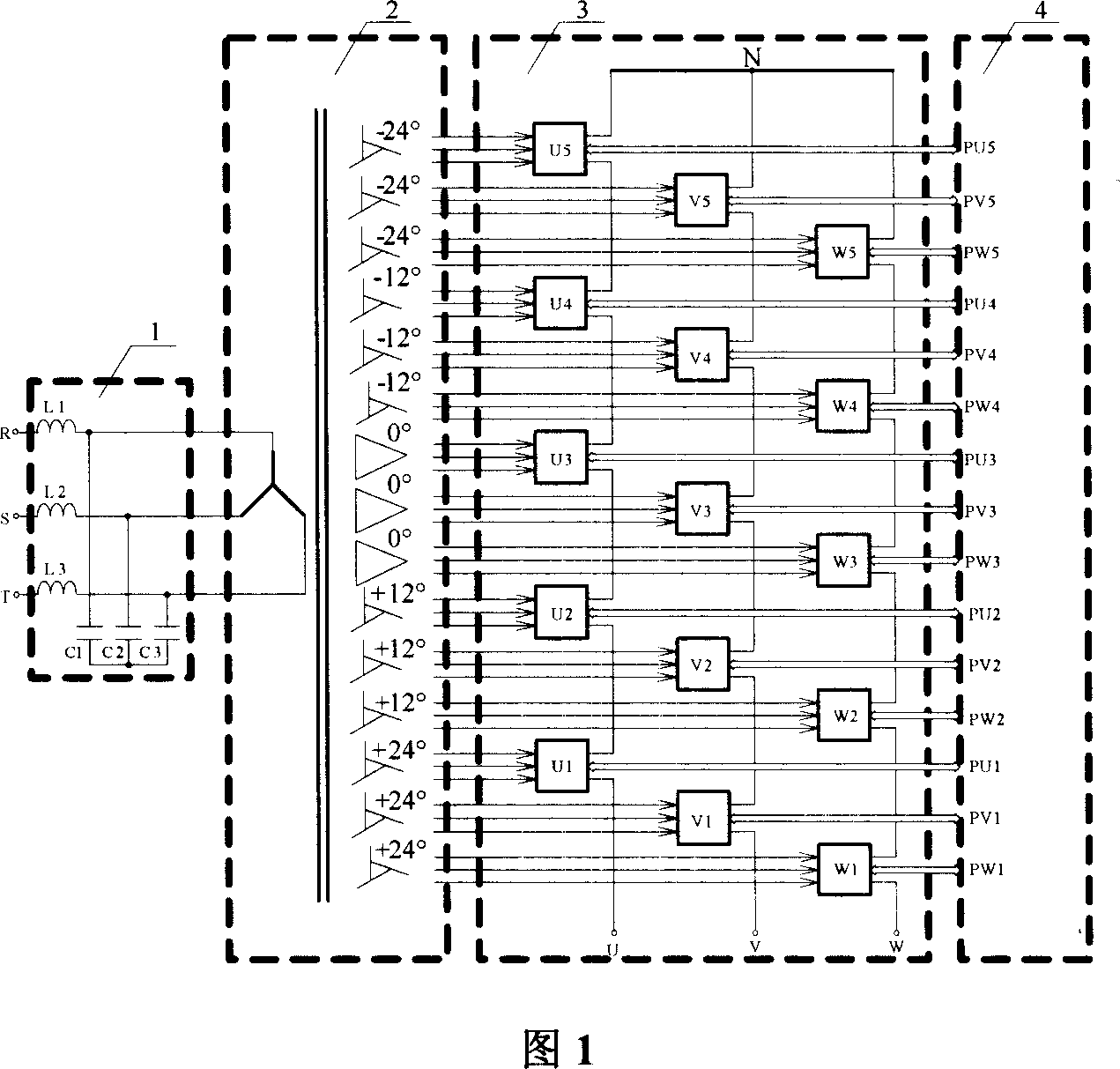

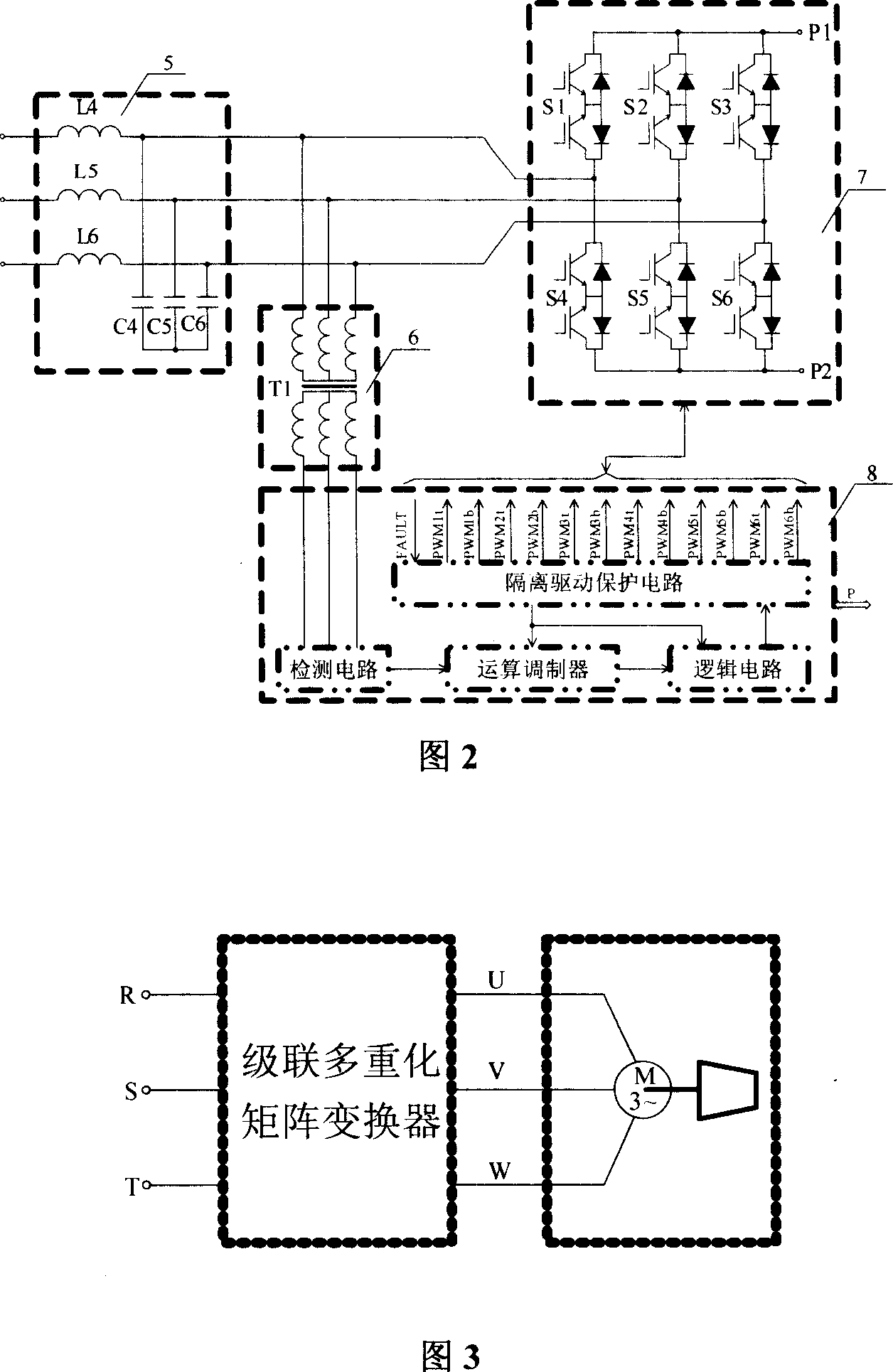

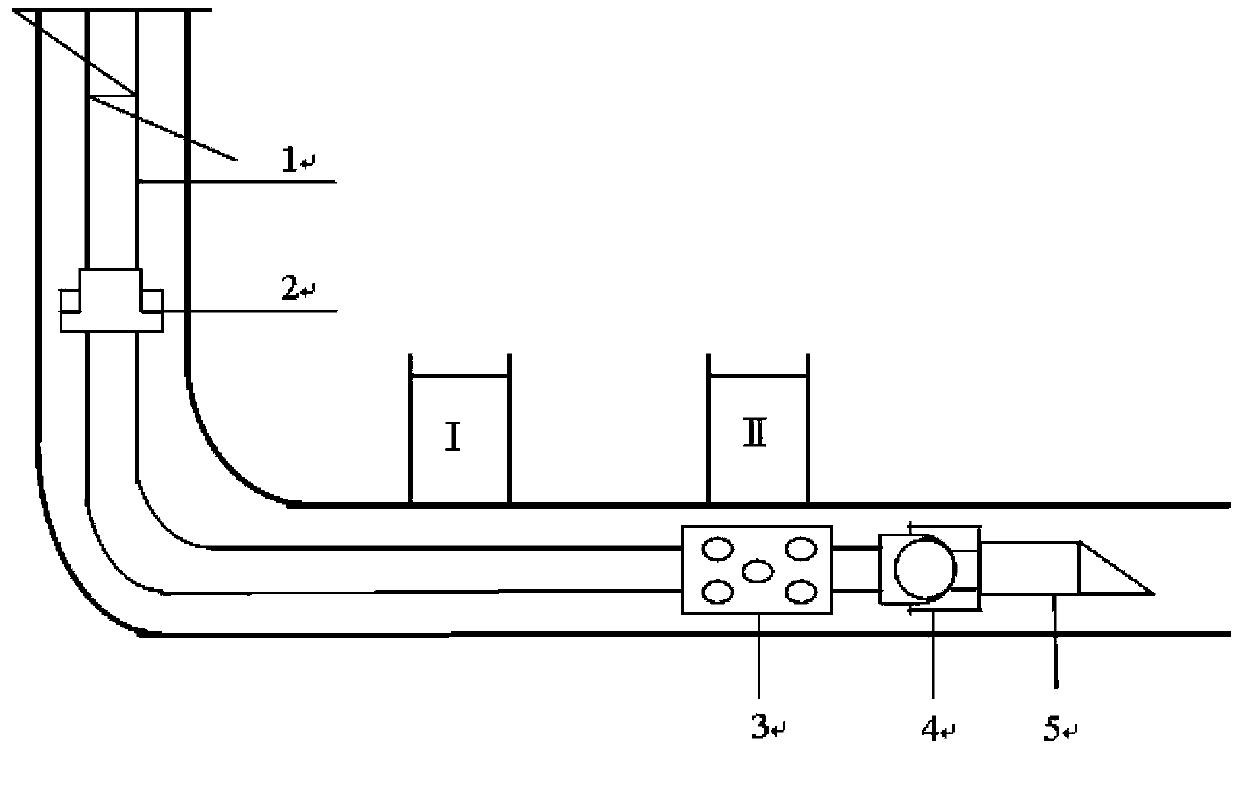

Cascaded multiple matrix converter

InactiveCN101013856ARealize cascade multiplexingCascade multiplexingAc-ac conversionMatrix convertersTransformer

The invention relates to one cross multiple array integral device, wherein, the bus input filter is connected between electrical net and release transducer for filter to get sine wave input current; release transducer has n secondary sets with different phases with difference for 60degree / n; integral array is distributed by n integral device unit into one row and n levels with each level connected to the transducer secondary set; the array integral device unit outputs series to form one path of direct output for whole system control.

Owner:SHANGHAI JIAO TONG UNIV +1

Hydraulic sand jet perforation, fracture and sand filling integrated technological method

ActiveCN104213895AAvoid damageImprove the transformation effectFluid removalFlushingSand blastingEngineering

The invention discloses a hydraulic sand jet perforation, fracture and sand filling integrated technological method which is designed for meeting the requirement for hydraulic sand jet perforation and fracture integrated work and ensuring the construction capacity of a pipe column under the large discharge capacity condition. The method of fracturing the lower layer through hydraulic jet, filling the lower layer with sand, sealing the lower layer and then conducting upper layer section hydraulic jet fracture construction is adopted, and therefore it is ensured that the lower layer is effectively refitted, a pipe column packer is prevented from being damaged, dragging and fracture of multiple sections of a horizontal well of an oil field can be executed, large-discharge-volume fracture refitting, with the high anisotropism, the large physical difference and the dense oil deposit, between reservoirs can be achieved, the refitting effect of the horizontal well with the dense oil deposit is improved, and the aim of increasing the yield is achieved. By means of a hydraulic safe connector on the technological pipe column, the pipe column above the connector can be conveniently jacked up when the pipe column is stuck.

Owner:PETROCHINA CO LTD

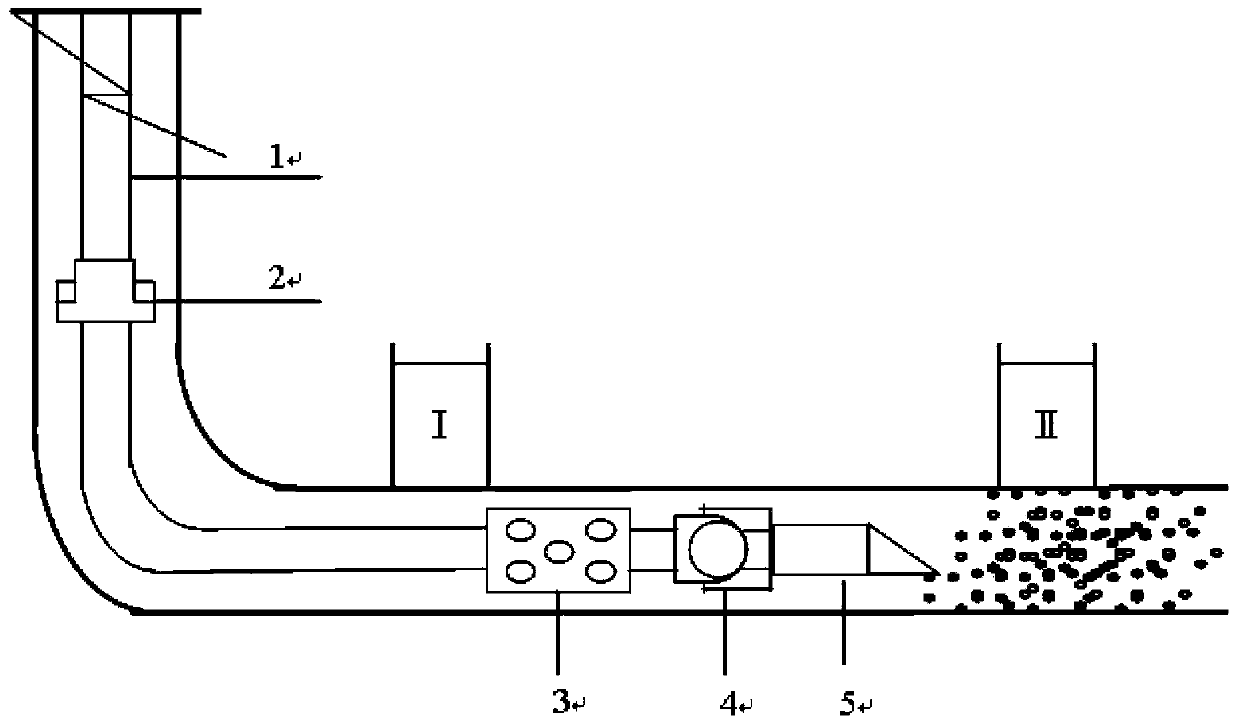

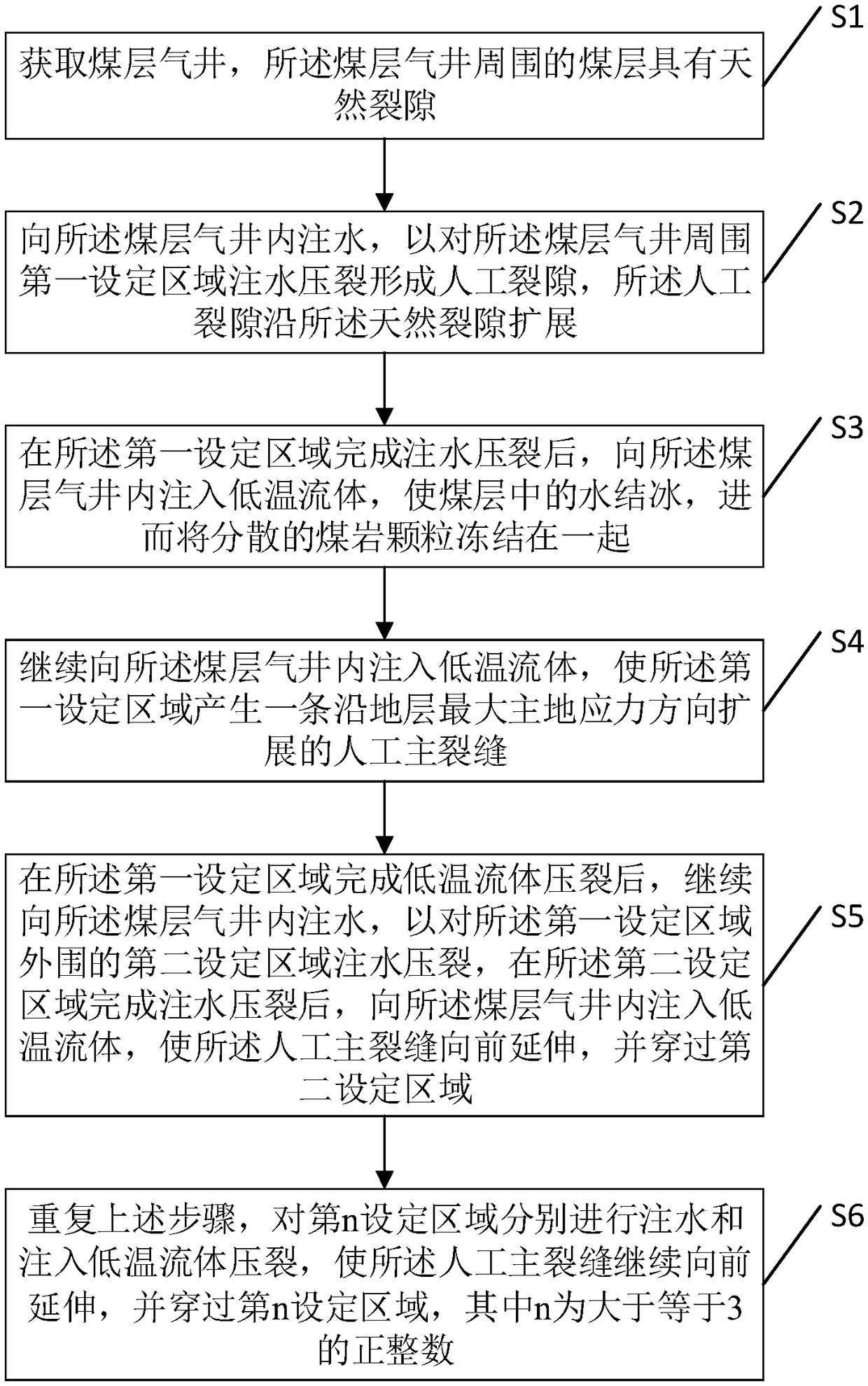

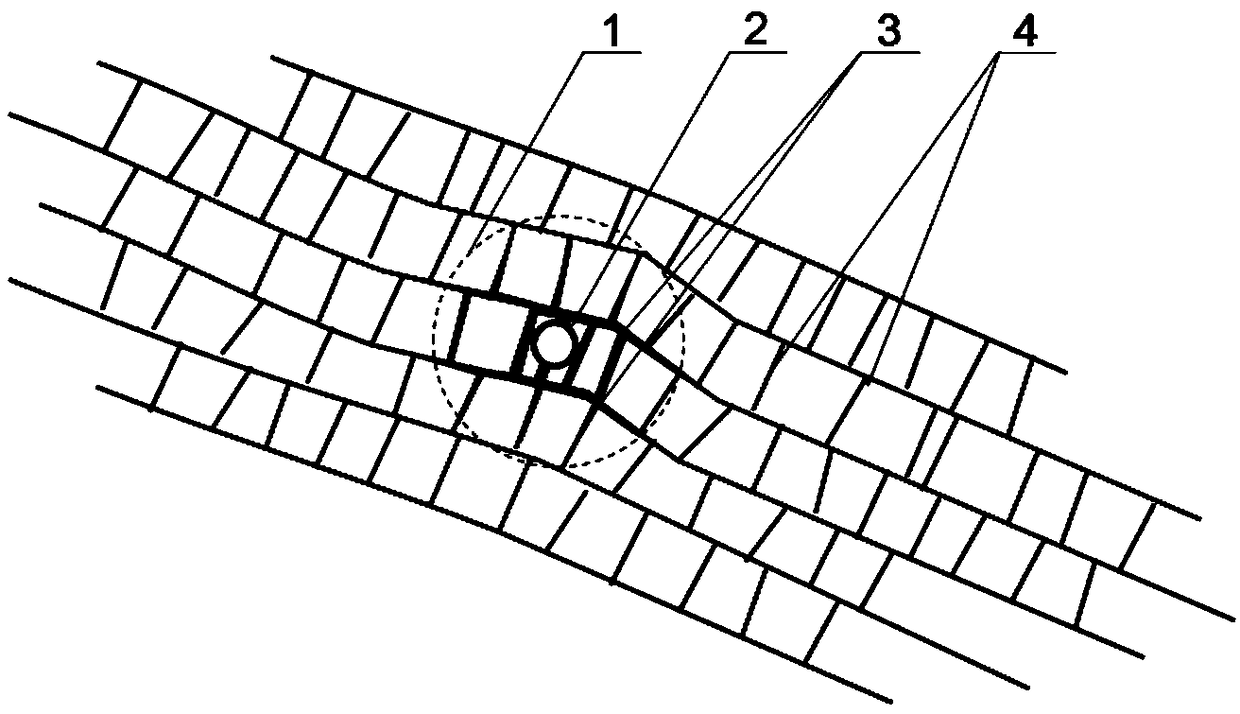

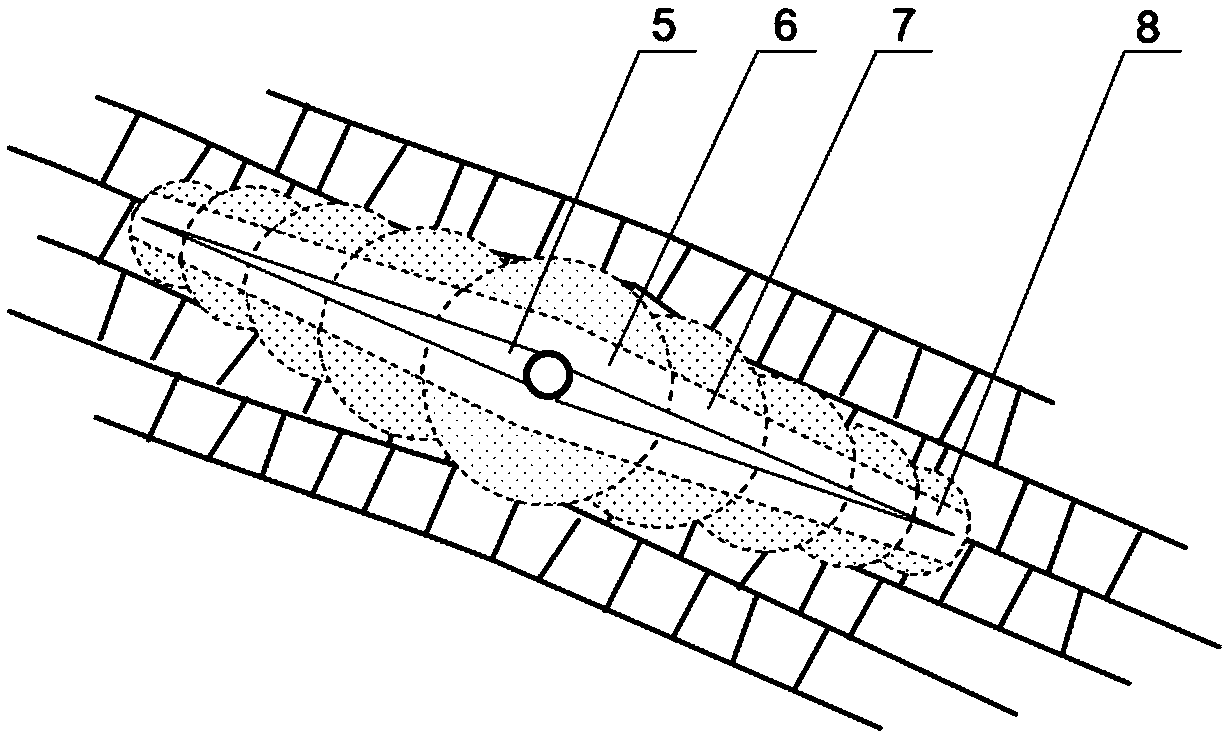

Device and method for controlling coal bed crack propagation by water and cryogenic fluid alternate fracturing

ActiveCN109252847AEnhanced gas recoveryImprove the transformation effectFluid removalGas removalCrack spreadCoal

The invention provides a device and method for controlling coal bed crack propagation by water and cryogenic fluid alternate fracturing. The method includes steps: injecting water into a coal bed gaswell to form artificial cracks propagated along natural cracks through water injection fracturing in a first set area; then, injecting cryogenic fluid into the coal bed gas well to freeze water in a coal bed, wherein dispersed coal rock particles can be frozen together, and a main artificial crack spreading along a maximum main ground stress direction of the stratum is generated in the first set area; continuing water injection into the coal bed gas well to realize water injection fracturing in a second set area, injecting the cryogenic fluid into the coal bed gas well to enable forward spreading of the main artificial crack to penetrate the second set area; repeating the steps, subjecting an nth set area to water injection and cryogenic fluid injection fracturing to enable the main artificial crack to penetrate the nth set area. By water and cryogenic fluid alternate fracturing for segmental freezing of the coal bed, artificial crack trend control is realized, and accordingly reservoir reformation effects can be improved.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Method for increasing fracturing volume in tight sandstone reservoir

ActiveCN110761762AIncrease in sizeImprove seepage capacityFluid removalMicro fractureHydraulic fracturing

The invention discloses a method for increasing the fracturing volume in a tight sandstone reservoir. The method includes the steps that (1) micro-fractures are formed in the tight sandstone reservoir; step (2) the micro-fractures are expanded and communicated; step (3) hydraulic fracturing is performed to form main fractures; and step (4) a proppant is turned from temporary blocking to form branch fractures. The method is suitable for fracturing transformation production increase operation of the tight sandstone reservoir with micro-fractures not developed. Through innovative process ideas, first, a large number of radial micro-fractures are artificially generated in a sandstone reservoir with the micro-fractures not developed and a dense matrix, then the main fractures penetrating through the micro-fractures are formed through hydraulic fracturing, and in the extension process, the main fractures are turned for multiple times, so that a complex fracture system is formed, and the fracturing transformation volume is increased and the production increase effect is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

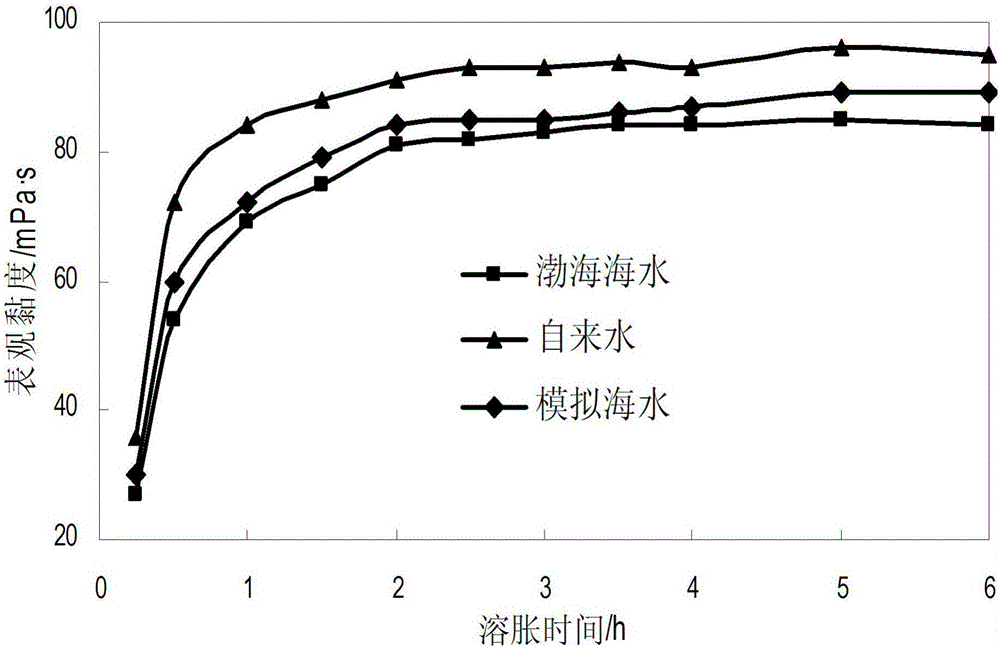

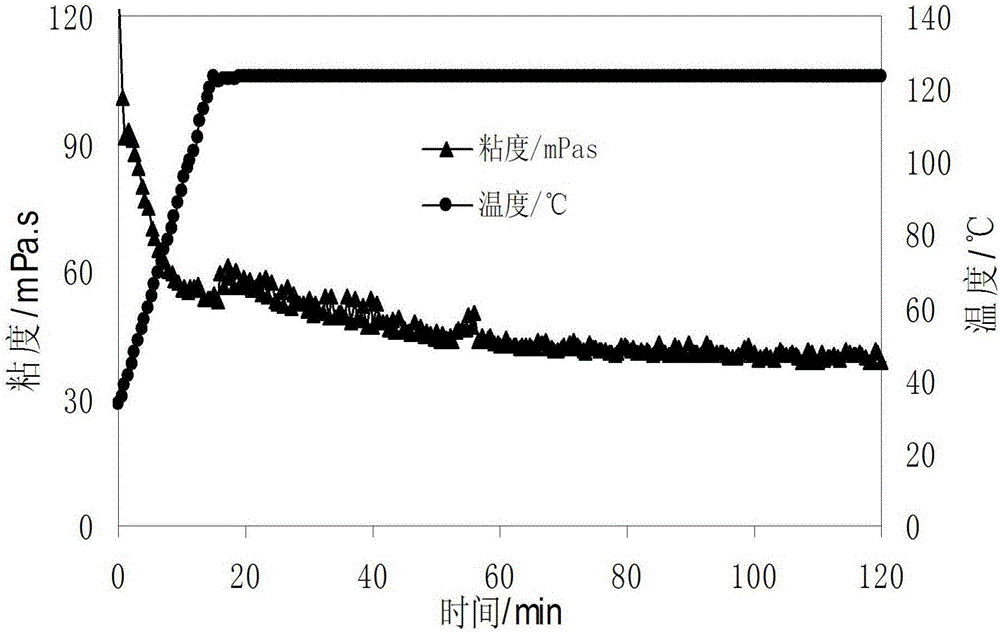

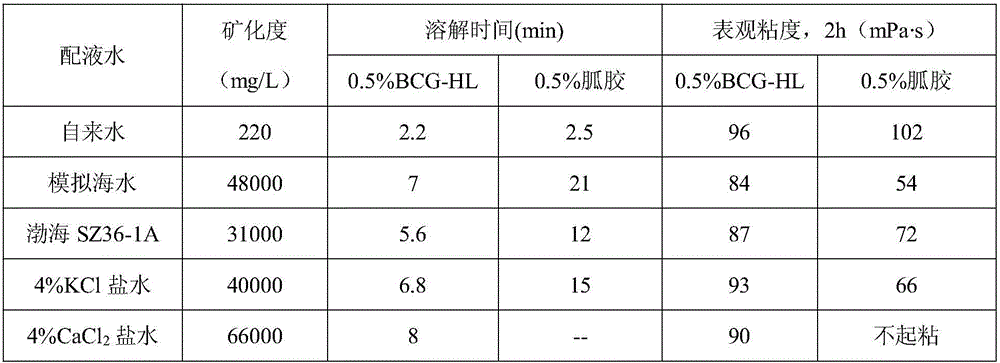

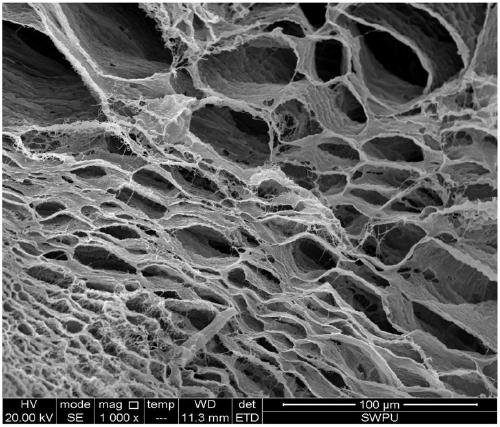

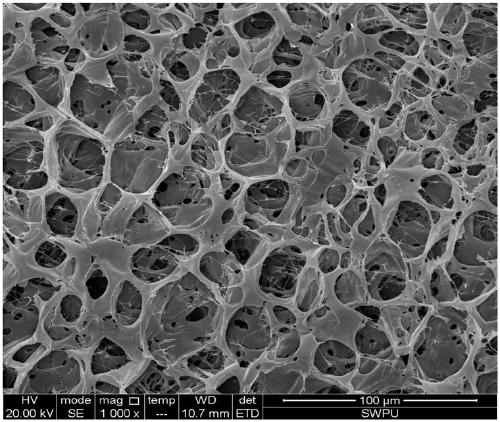

Temperature-resistant salt-resistant quick-dissolving thickening agent used for seawater-based fracturing fluid and preparation method thereof

ActiveCN106190088AStrong anti-bacterial abilityGood anti-corrosion performanceDrilling compositionIonSeawater

The invention discloses a temperature-resistant salt-resistant quick-dissolving thickening agent used for a seawater-based fracturing fluid and a preparation method thereof. The temperature-resistant salt-resistant quick-dissolving thickening agent comprises the following components in percentages by mass: 6% to 8% of acrylic acid, 5% to 6% of sodium hydroxide, 18% to 23% of acrylamide, 1% to 2% of an isolation monomer, 3% to 4% of a functional anion monomer, 3% to 5% of a functional cationic monomer, 4% to 6% of an association intermediate, and 0.4% to 0.8% of an ammonium persulfate-sodium bisulfite redox system or 0.6% to 1.0% of azobisisobutyronitrile which is used as an initiator, with the balance being deionized water. The preparation method for the temperature-resistant salt-resistant quick-dissolving thickening agent comprises the following steps: 1, synthesis of the association intermediate; 2, synthesis of a thickener colloid; and 3, colloid postprocessing. The thickening agent provided by the invention has the following advantages: salt resistance is excellent; the degree of mineralization of a solution has little influence on the rate of swelling; the viscosity-increasing capacity in seawater is strong; antibacterial stability of the solution is strong; the solution has excellent temperature resistance and shearing resistance; and the content of an insoluble substance is extremely small and can not be measured with a conventional method, so the damage of residues on reservoir strata is almost eliminated.

Owner:四川奥赛德材料科技有限公司

High-temperature-resistant full-suspension low-damage fracturing fluid and preparation method thereof

The invention discloses a high-temperature-resistant full-suspension low-damage fracturing fluid, which comprises the following components in percentage by weight: 0.3-0.5% of a low-damage thickeningagent, 0.1-0.4% of a multifunctional stabilizer, 0.1-0.3% of a regulator, 0.4-0.8% of a suspension synergist and the balance of clear water or saline water; the preparation method of the fracturing fluid comprises the following steps of: 1, adding the low-damage thickening agent, the multifunctional stabilizer and the regulator into clear water or saline water under a stirring condition, uniformlystirring, and swelling for 2 to 4 hours to obtain fracturing fluid base liquid; 2, fully mixing the fracturing fluid base liquid and the suspension synergist to form the full suspension fracturing fluid with excellent sand carrying performance and temperature resistance under the combined action of physical crosslinking and chemical crosslinking. The fracturing fluid is superstrong structure fluid formed by carrying out physical crosslinking and chemical crosslinking on acrylamide polymer and suspension synergist together, and the temperature resistance can reach 150 DEG C; the sand carryingperformance is excellent, the strong spatial structure can completely suspend a proppant, and the influence of temperature is small.

Owner:SOUTHWEST PETROLEUM UNIV +2

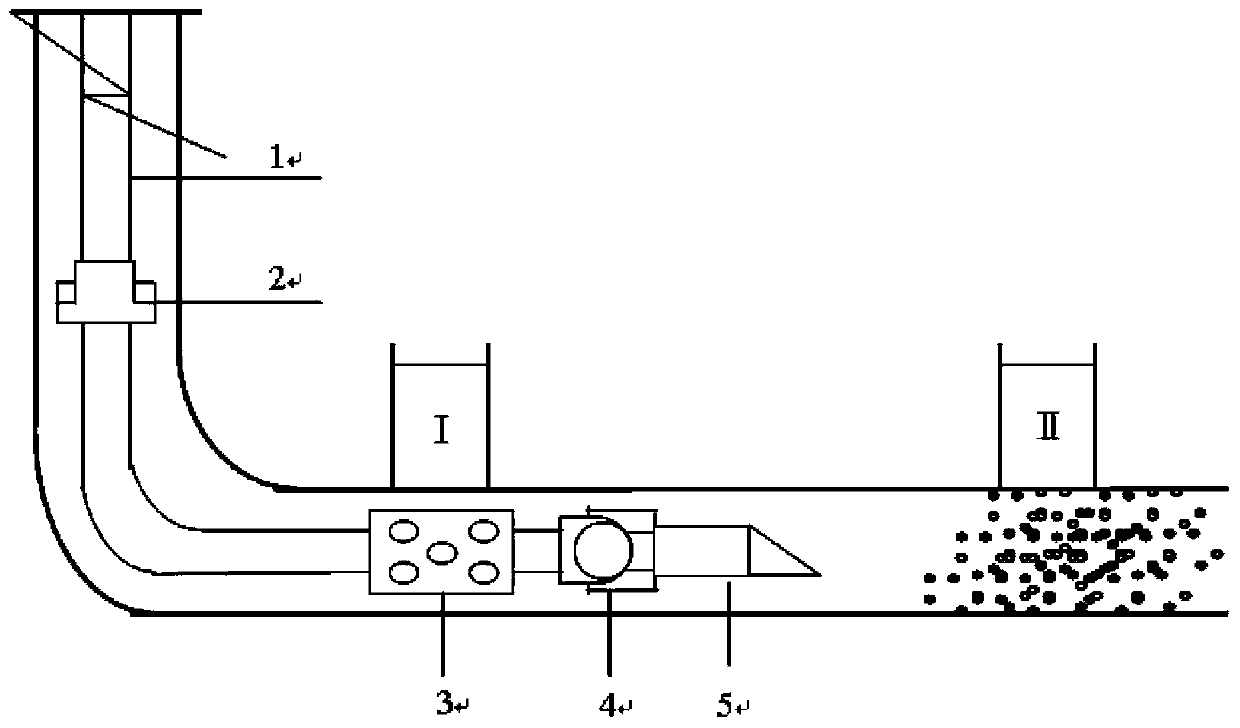

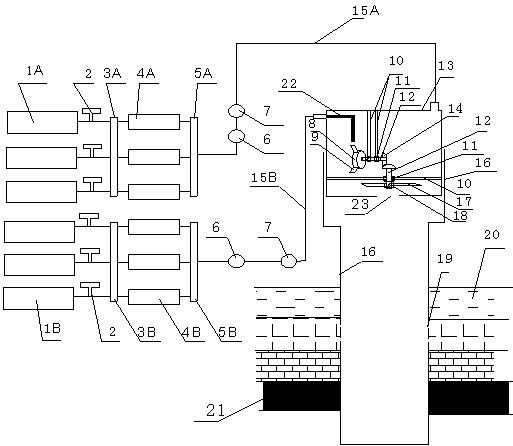

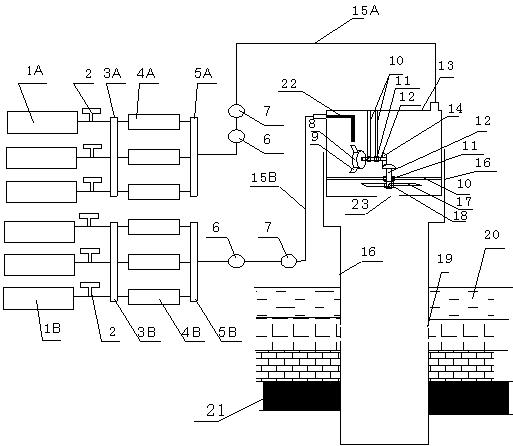

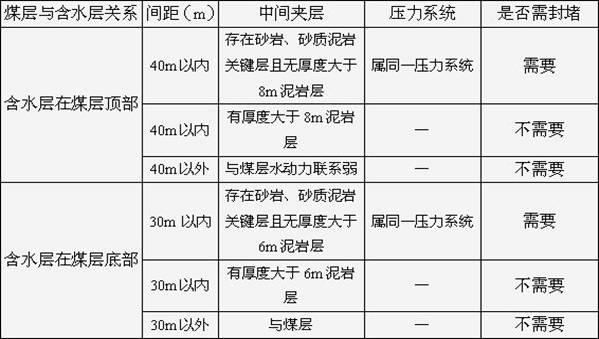

Plugging equipment for ground fracturing plugging water-bearing stratum

InactiveCN102102499AEasy to drop pressureReduce water productionSealing/packingHydraulic fracturingLiquid tank

The invention discloses plugging equipment for a ground fracturing plugging water-bearing stratum. The plugging equipment comprises a fracturing plugging feed system, a stirring system and a discharge system, wherein the fracturing plugging feed system comprises two feed pipelines; the first feed pipeline comprises a first fracturing pumper which is connected with a first liquid tank; the second feed pipeline comprises a second fracturing pumper which is connected with a second liquid tank; the stirring system comprises a stirring cabin which is arranged at a well head; stirring blades which are connected with a power device are arranged in the stirring cabin; the discharge system comprises a bushing which is positioned below the stirring cabin and is communicated with the stirring cabin;the wall of the lower part of the bushing is provided with a hole; the lower part of the bushing is positioned in a well; and the first fracturing pumper and the second fracturing pumper are communicated with the stirring cabin through a first high-pressure hose and a second high-pressure hose respectively. The plugging equipment aims to solve the problem that the water-bearing stratum is possibly communicated with a coal seam in a fracturing process because the water-bearing stratum is closer to the coal seam; and in order to guarantee that the coal seam is not communicated with the water-bearing stratum of a surrounding rock during hydraulic fracturing, the plugging equipment for the ground fracturing plugging water-bearing stratum for fracturing and reconstructing of a coal reservoir is realized.

Owner:HENAN POLYTECHNIC UNIV

Whole-course temporary blocking and fracturing method and application thereof

The invention belongs to the field of petroleum fracturing, and particularly relates to a whole-course temporary blocking and fracturing method and application thereof. The method includes the steps of fracturing and temporary blocking. An inside-seam temporary blocking material is added for sufficient transforming in the fracturing process, after fracturing is completed, wellbore area temporary blocking slug is injected for temporary blocking, and the method is suitable for pneumatic jet fracturing transforming and thin interbed multi-section pressure-combined and flow-limited fracturing. By means of the method, the whole-course temporary blocking and fracturing is achieved through the inside-seam temporary blocking material and the wellbore area temporary blocking slug, the fracturing process and a drill are simplified, construction success rate is ensured, operation risks are reduced, transforming effect is improved, and a new concept and means are provided for horizontal well multi-section transforming.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

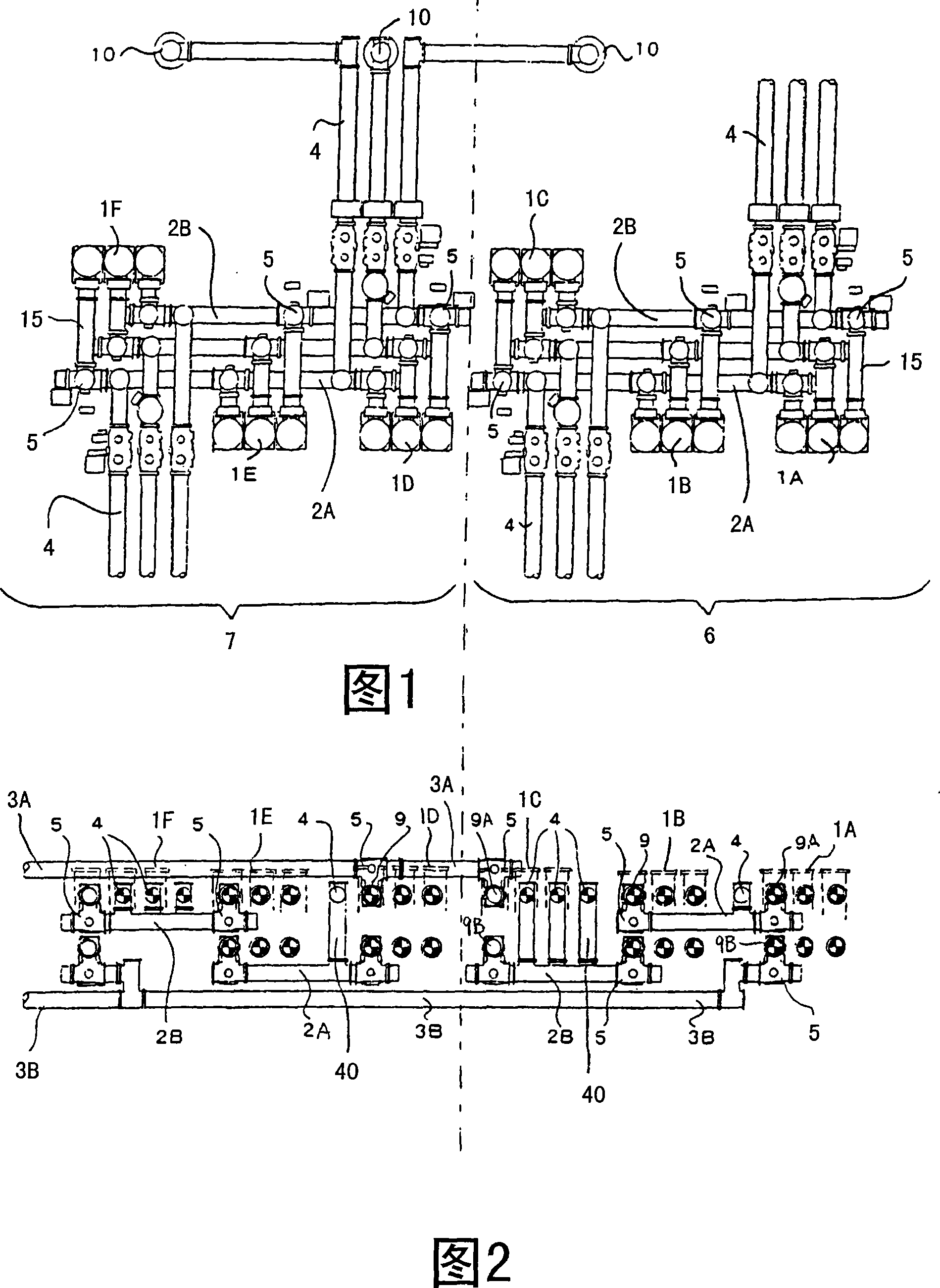

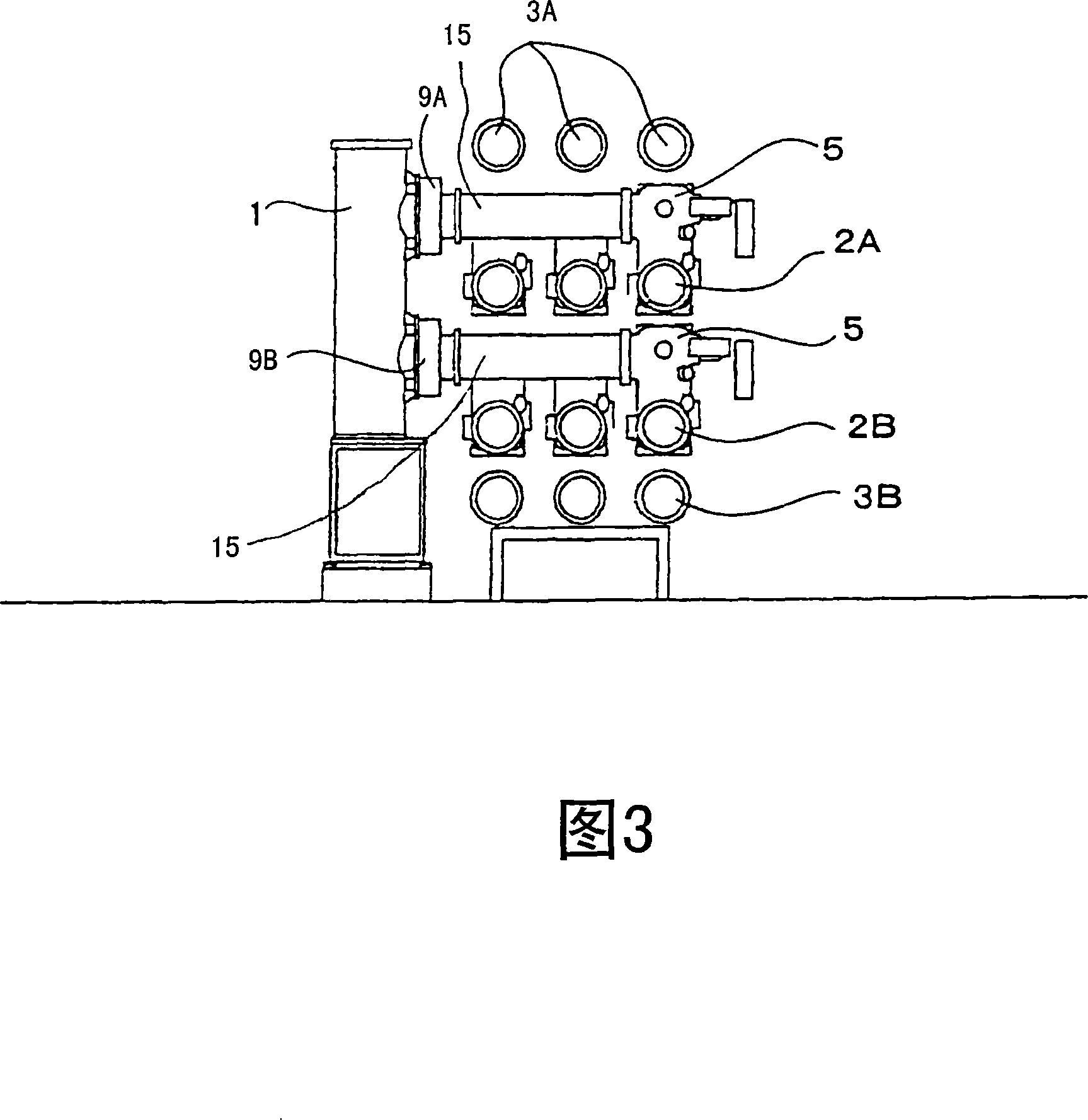

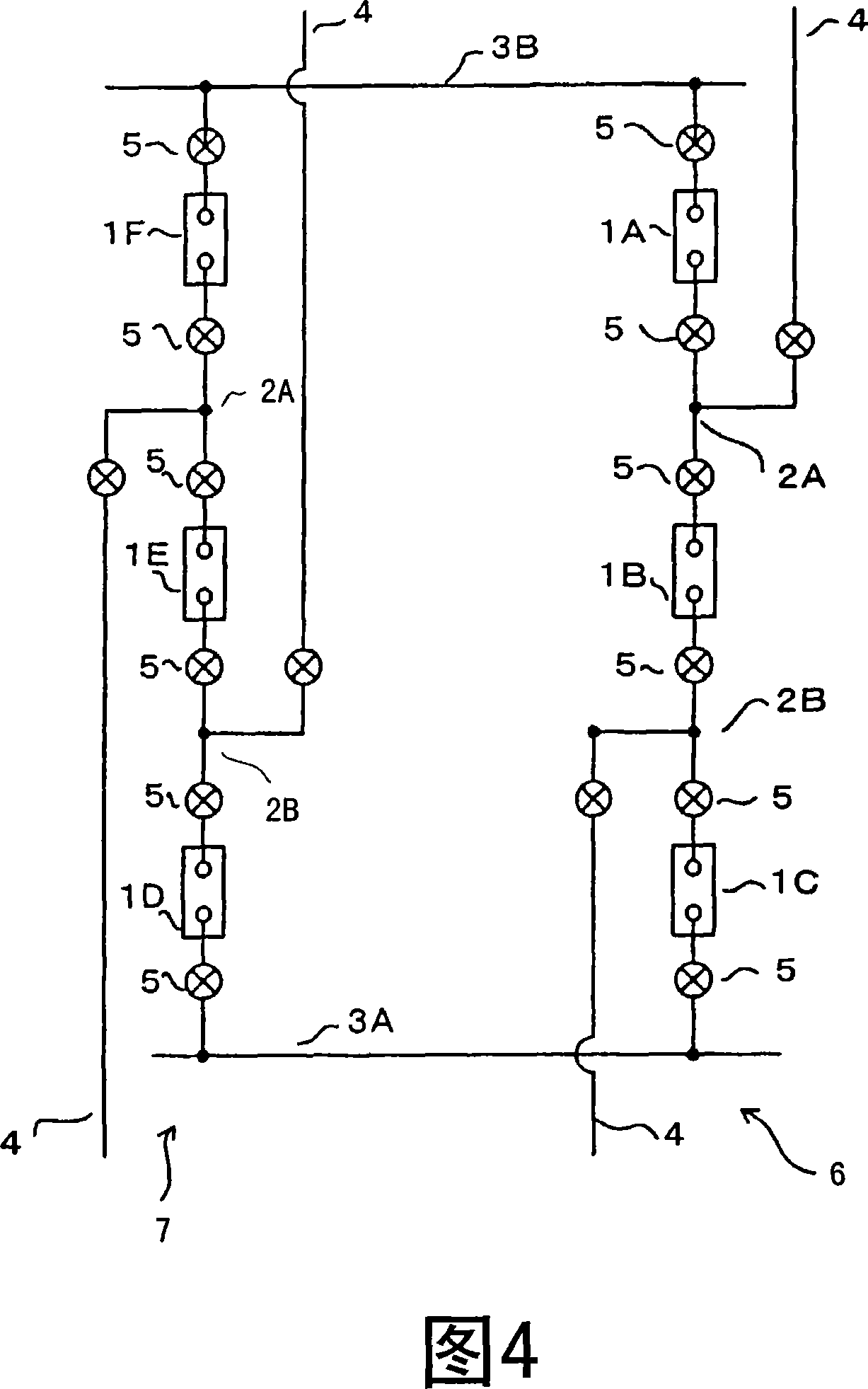

Gas insulation open-close device

InactiveCN101047304AEasy maintenanceImprove the transformation effectBus-bar/wiring layoutsSwitchgear arrangementsBusbarGas insulation

The invention provides a GIS effectively equiped with device and busbar, in order to reduce the area of applying ground and busbar length, and enhance the maintenance of breaker and recovery efficiency. The circuit in-cinnection busbar, eduction busbar, vertical breaker, and circuit among-cinnection main busbar are made by single phase device. The circuit in-cinnection busbar, vertical breaker and circuit among-cinnection main busbar make triphase divided busbar parallelly allocate on the same plane. The circuit in-cinnection busbar and circuit among-cinnection main busbar coincide up and down to make the mian axis of busbar of each phase slightly overlap at the same direction and on the same plane. The eduction busbar is coincident allocated at the direction crossed with the main axis of the circuit in-cinnection busbar and circuit among-cinnection main busbar. The vertical breaker is set beside the circuit in-cinnection busbar and circuit among-cinnection main busbar, and the orientation thereof is paralleled with the main axis of the circuit in-cinnection busbar and circuit among-cinnection main busbar.

Owner:KK TOSHIBA

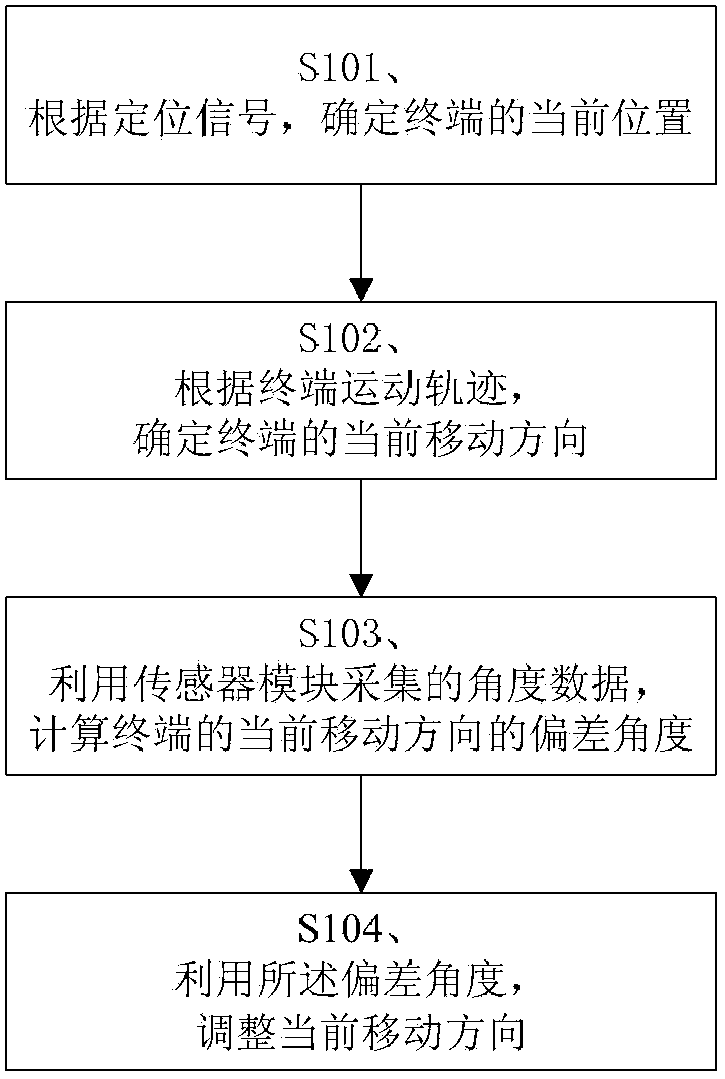

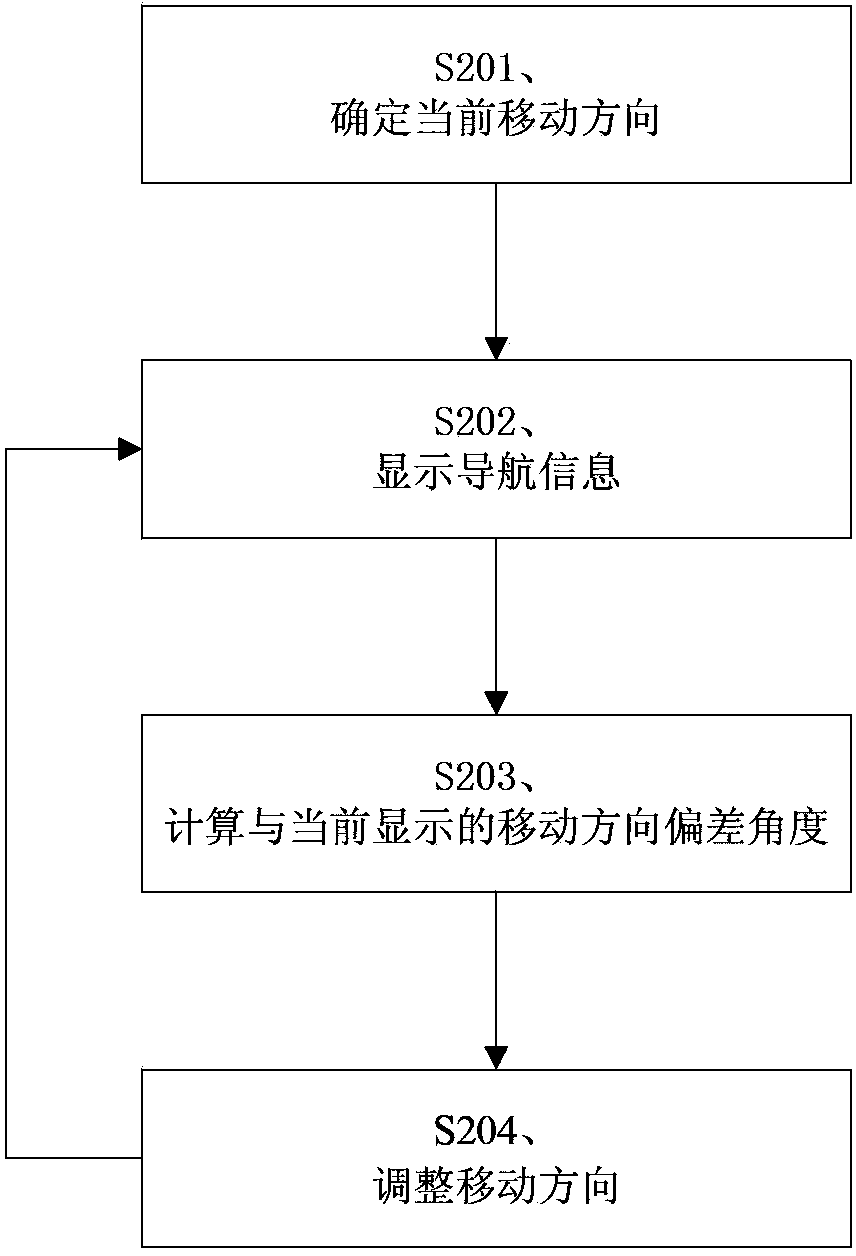

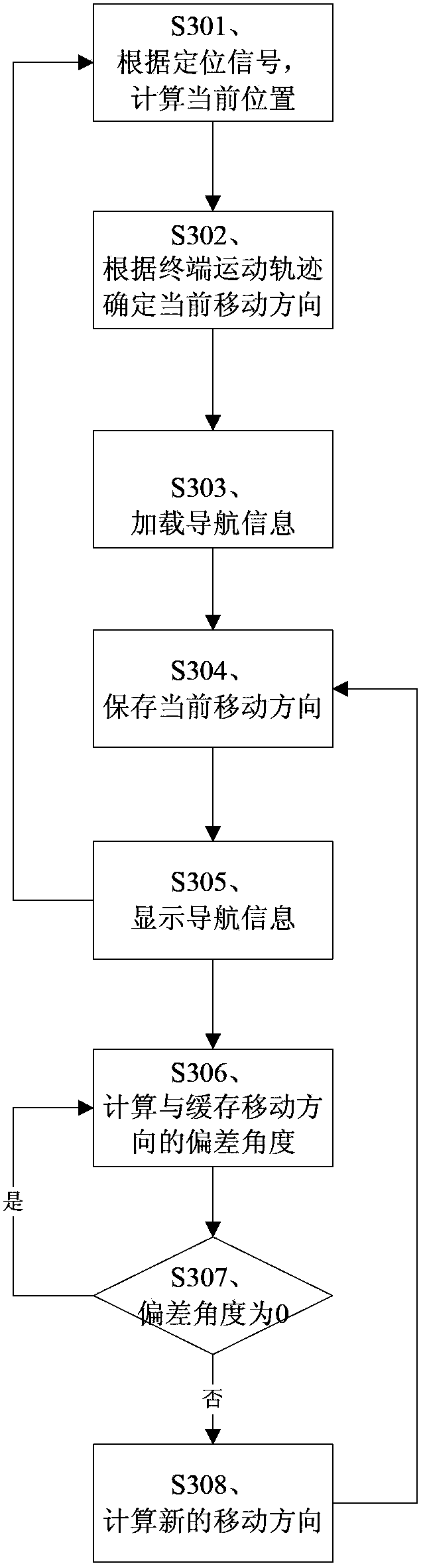

Method and device for assisting in adjusting moving direction in navigation

ActiveCN103454659AImprove the transformation effectAchieve self-regulationSatellite radio beaconingComputer scienceMarine navigation

The invention discloses a method and device for assisting in adjusting the moving direction in navigation. The method includes the steps of confirming the current position of a mobile terminal according to a positioning signal, confirming the current moving direction of the mobile terminal according to motion tracks of the mobile terminal, calculating the deviation angle of the current moving direction of the moving terminal by means of angle data collected by a sensor module, and adjusting the current moving direction according to the deviation angle so that the current position and the moving direction after adjustment can be displayed on a display screen of the mobile terminal. The method and device can be used for mobile terminals of various types and facilitate achievement of the function that the mobile terminals assist in adjusting the moving direction in navigation.

Owner:ZTE CORP

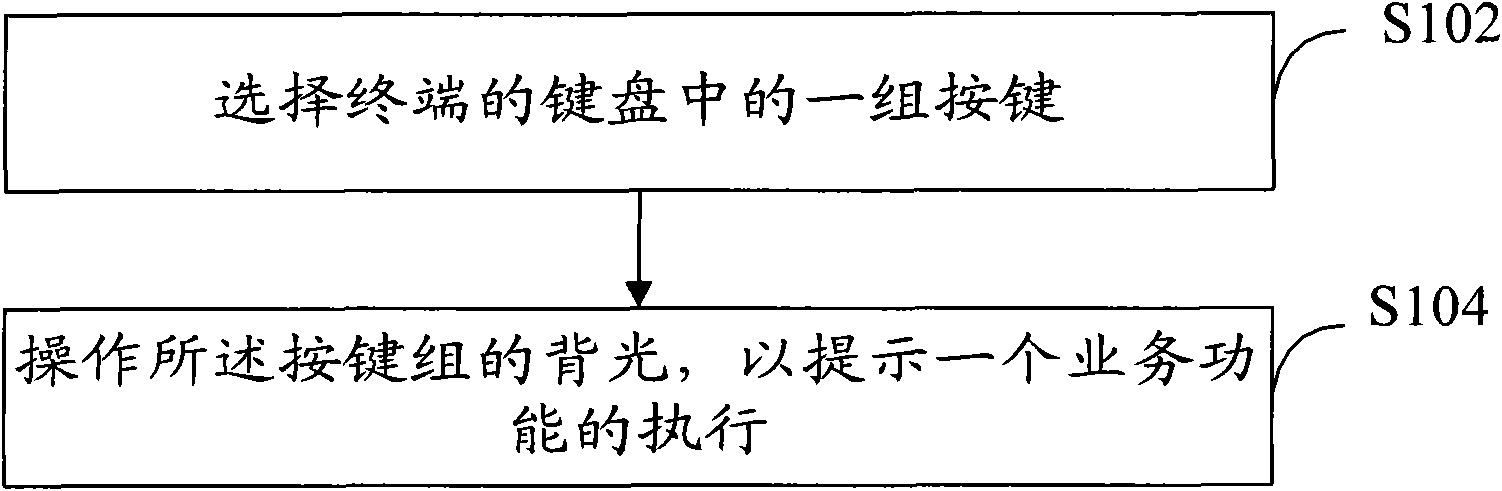

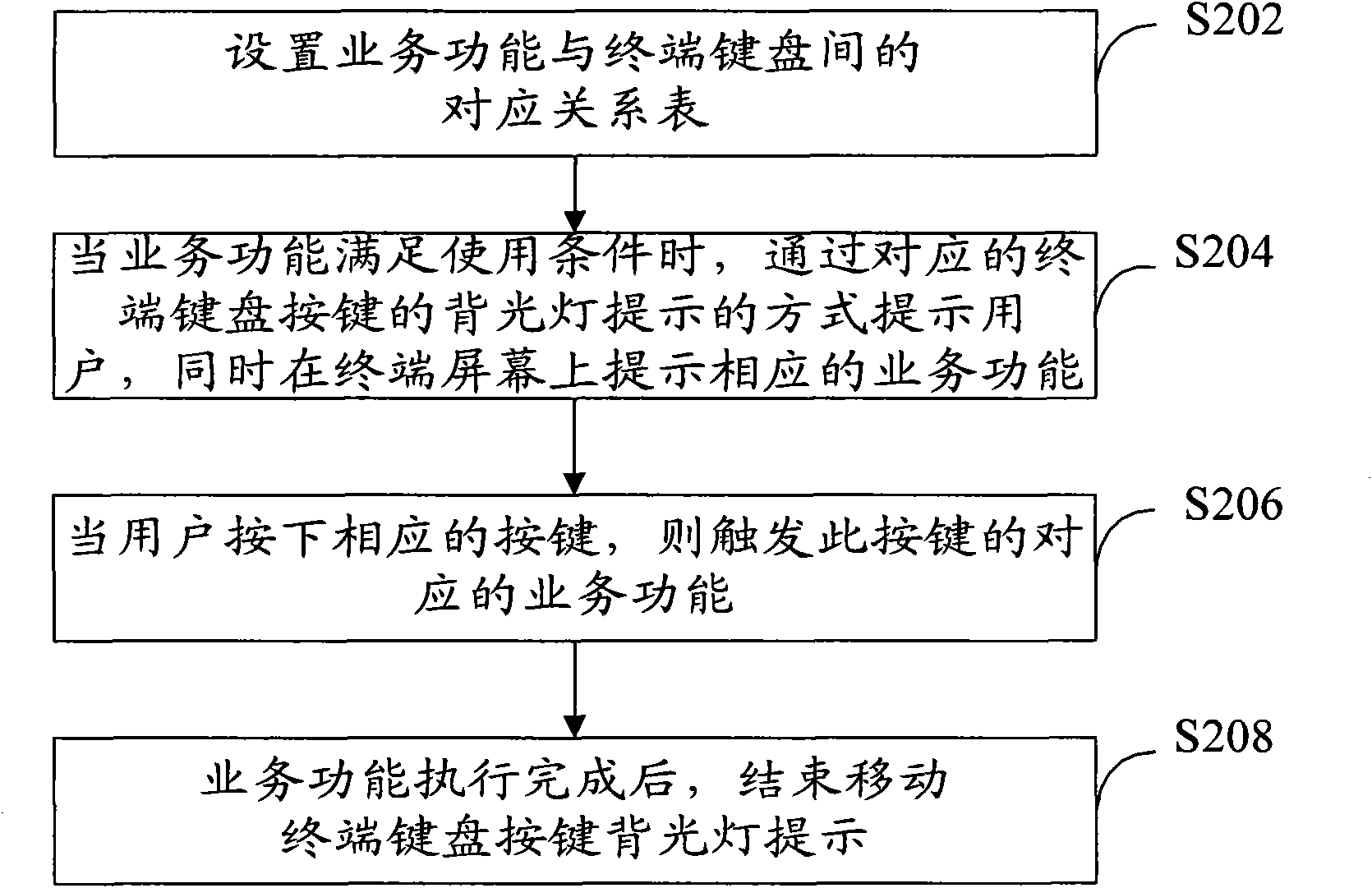

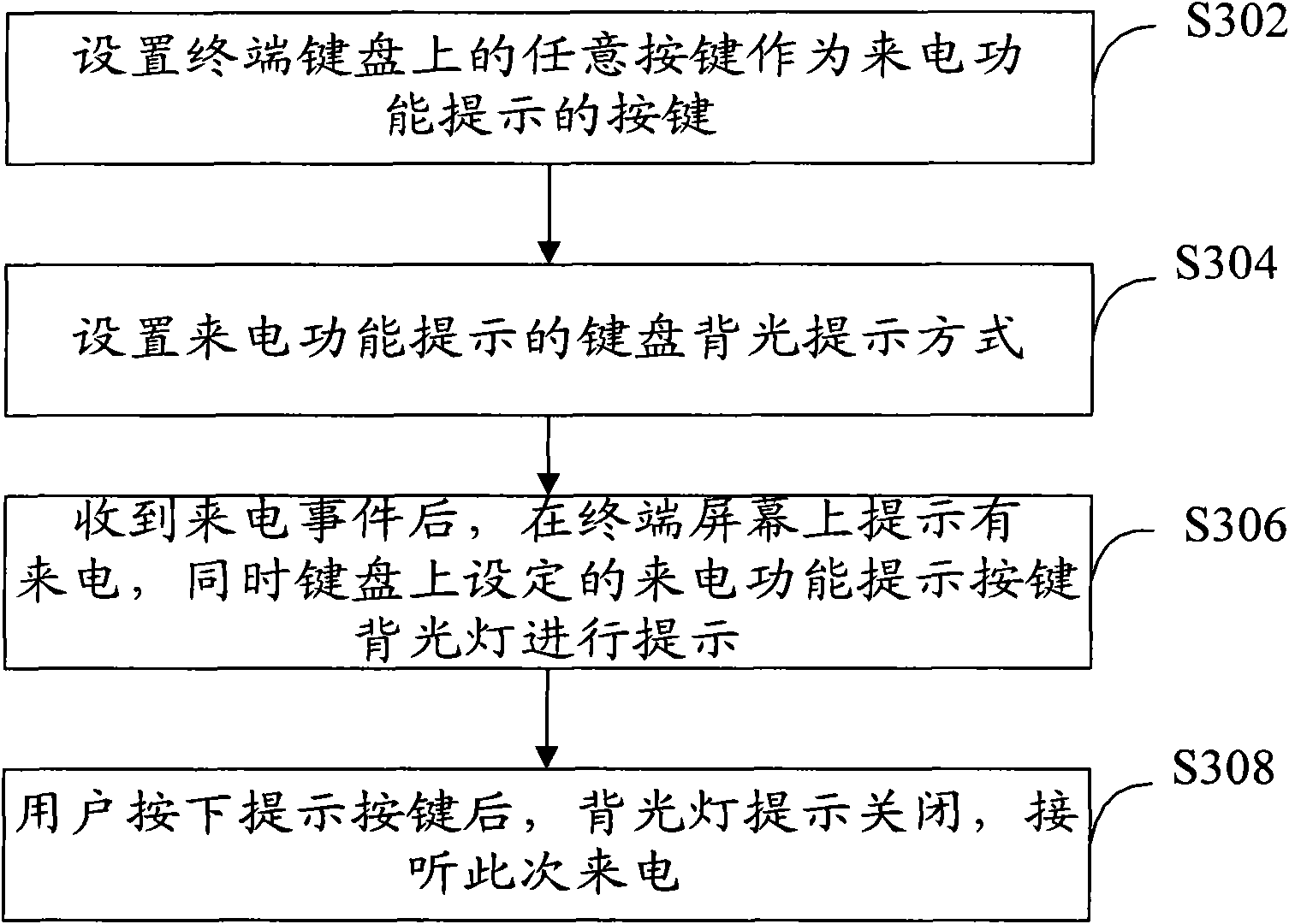

Service function prompt method and terminal

InactiveCN101867652AEasy to operateImprove user experienceTelephone set constructionsInput/output processes for data processingKey pressingSoftware engineering

Owner:ZTE CORP

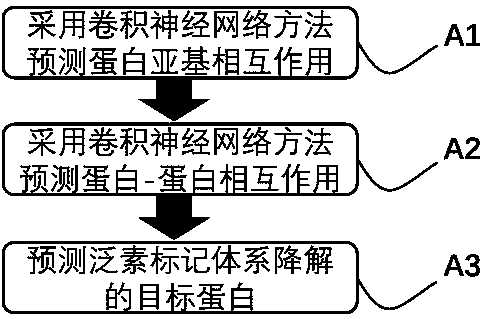

Prediction method for ubiquitination degradation of target protein

ActiveCN109785902AImprove the transformation effectCutting costsProteomicsGenomicsProtein targetProtein subunit

The invention relates to a prediction method for the ubiquitination degradation of a target protein. The prediction method comprises the following steps: A1, predicting the interaction of protein subunits by adopting a convolutional neural network method; A2, constructing a spatial three-dimensional structure of the ubiquitin marking system; A3, predicting a ubiquitination-degraded target protein,downloading a three-dimensional structure file of the target protein, complementing the three-dimensional structure of the target protein by using a homologous modeling method, and predicting the interaction between the target protein and a E3 ubiquitination marking system by using the convolutional neural network method; after that, optimizing an overall spatial three-dimensional structure of interaction between the E3 ubiquitin marking system and the target protein by adopting a molecular dynamics method, judging whether the target protein is possibly marked by the E3 ubiquitin marking system or not according to the stability of the system, and performing ubiquitin-target protein marking by virtue of the ubiquitin-target protein marking system, and degrading the protein by virtue of a ubiquitin-proteasome.

Owner:成都分迪科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com