Fracturing and cavern integrated completion method for coal-bed gas reservoir

A technology for coalbed methane and caves, which is applied in the fields of fluid extraction, earth-moving drilling, wellbore/well components, etc., can solve the problem that cave completion technology has not been improved accordingly, the mechanism of cave completion reformation has not been clearly recognized, and the reformation has not been achieved. Coal seam and other problems, to achieve the effect of increasing production capacity, improving permeability, and enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

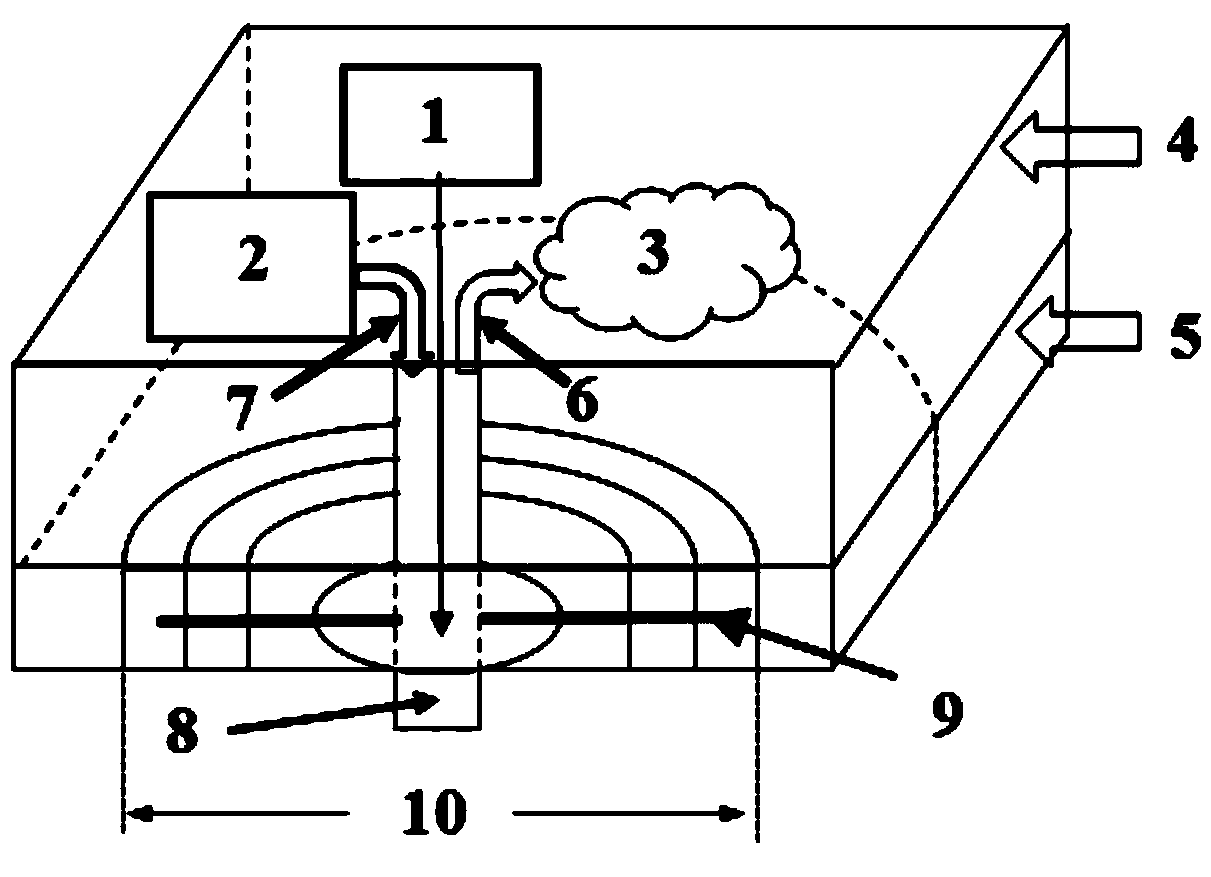

[0023] The present invention proposes an integrated well completion method for fracturing caves in coalbed methane reservoirs, such as figure 1 As shown, the method firstly uses hydraulic fracturing equipment 1 to form fracturing fractures 9 connected to the wellbore 8 in the coal seam, and then utilizes the fluid booster equipment 2, the booster pipeline 7, the fluid pressure relief equipment 3, and the pressure relief pipeline 6 to carry out cavitation. Completion operations, forming a large-scale permeability growth zone10 in the coal seam, thereby increasing the production of coalbed methane; figure 1 The middle mark 4 is the overlying rock formation, and the mark 5 is the coalbed methane reservoir.

[0024] The integrated w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com