Plugging equipment for ground fracturing plugging water-bearing stratum

A technology for fracturing and water layers, which is applied in sealing/isolation, wellbore/well components, earthwork drilling and mining, etc. It can solve problems such as low viscosity of active water, large roof and floor of breakthrough coal seam, and restrictions on the development of the coalbed methane industry.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

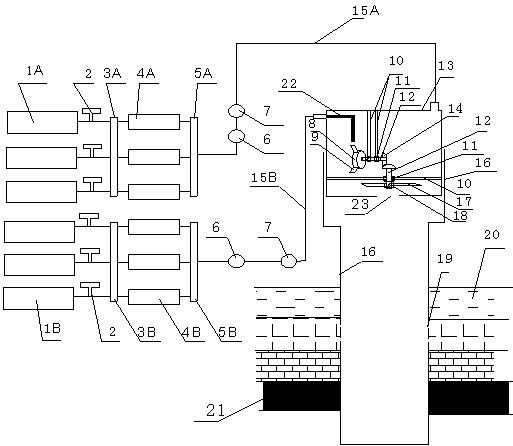

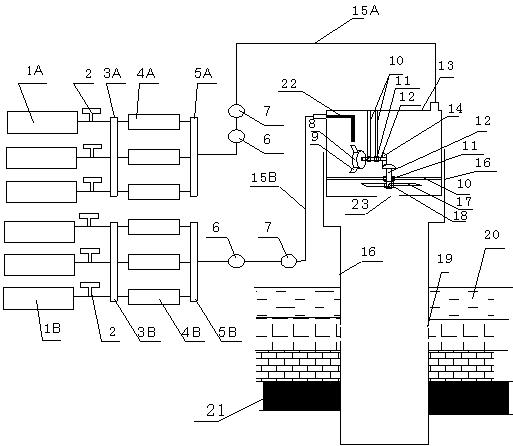

[0016] by figure 1 The shown plugging equipment for ground fracturing and plugging aquifers includes a fracturing plugging feed system, a stirring system and a discharge system. The fracturing plugging feed system includes two sets of feed pipelines. The feed pipeline includes a first fracturing pump truck 4A connected to the first tank 1A, and the second feed pipeline includes a second fracturing pump truck 4B connected to the second tank 1B. The first tank 1A is At least three are arranged in parallel, and the first fracturing pump truck 4A is also arranged in parallel at least three. The inlets of all the first liquid tanks 1A are connected to one side pipe wall of the first low pressure manifold 3A. The inlets of the fracturing pump truck 4A are all connected to the other side pipe wall of the first low pressure manifold 3A, and all the outlets of the first fracturing pump truck 4A are connected to the first high pressure manifold 5A; the second There are at least three li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com