Nanofiber composite filter membrane for water treatment and preparation method of nanofiber composite filter membrane for water treatment

A nanofiber membrane and composite filtration technology, applied in the direction of osmosis/dialysis water/sewage treatment, chemical instruments and methods, membranes, etc., can solve the problems of increasing energy consumption, cleaning chemical consumption, reducing water production, etc., to increase energy consumption and cleaning chemical consumption, reducing water production and increasing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

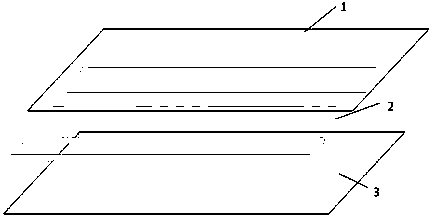

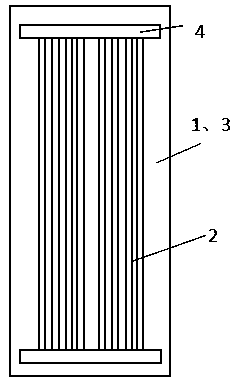

Method used

Image

Examples

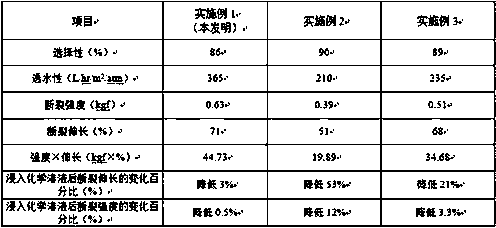

Embodiment 1

[0048] Embodiment 1 A kind of preparation method of the nanofiber composite filter membrane that is used for water quality treatment, described preparation method comprises the following steps:

[0049] (1) Preparation of non-woven fabric: take 40wt% polyester fiber, 30wt% polypropylene fiber, 35wt% polyvinyl formal fiber and 15wt% viscose fiber, mix and beat, add water to dilute to 0.005 The fiber concentration of wt% is obtained to obtain a slurry, and the slurry is subjected to electrospinning to obtain a non-woven fabric;

[0050] (2) Preparation of hollow nanofiber membrane: 12 parts of polyacrylonitrile, 3.5 parts of acrylonitrile-butadiene-styrene terpolymer, 1.2 parts of acrylonitrile-vinyl acetate copolymer, and 10 parts of polyvinylpyrrolidone , 1.0 parts of nano-silver particles, 1.5 parts of polycarboxylate superplasticizer modified graphene and 80 parts of dimethylacetamide are mixed, stirred and dissolved at 20°C to form a uniform film-making liquid; water at 25°...

Embodiment 2

[0052] Embodiment 2 A kind of preparation method of the nanofiber composite filter membrane that is used for water quality treatment, described preparation method comprises the following steps:

[0053] (1) Preparation of non-woven fabric: take 40wt% polyester fiber, 30wt% polypropylene fiber, 35wt% polyvinyl formal fiber and 15wt% viscose fiber, mix and beat, add water to dilute to 0.005 The fiber concentration of wt% is obtained to obtain a slurry, and the slurry is subjected to electrospinning to obtain a non-woven fabric;

[0054] (2) Preparation of hollow nanofiber membrane: 12 parts of polyacrylonitrile, 3.5 parts of acrylonitrile-butadiene-styrene terpolymer, 1.2 parts of acrylonitrile-vinyl acetate copolymer, and 10 parts of polyvinylpyrrolidone , 1.0 parts of nano-silver particles and 80 parts of dimethylacetamide are mixed, stirred and dissolved at 20°C to form a uniform film-making solution; water at 25°C is used as the core liquid, and the film-making solution at 2...

Embodiment 3

[0056] Example 3 A method for preparing a nanofiber composite filter membrane for water quality treatment, the preparation method comprising the following steps:

[0057] (1) Preparation of non-woven fabric: take 40wt% polyester fiber, 30wt% polypropylene fiber, 35wt% polyvinyl formal fiber and 15wt% viscose fiber, mix and beat, add water to dilute to 0.005 The fiber concentration of wt% is obtained to obtain a slurry, and the slurry is subjected to electrospinning to obtain a non-woven fabric;

[0058] (2) Preparation of hollow nanofiber membrane: 12 parts of polyacrylonitrile, 3.5 parts of acrylonitrile-butadiene-styrene terpolymer, 1.2 parts of acrylonitrile-vinyl acetate copolymer, and 10 parts of polyvinylpyrrolidone , 1.0 parts of nano-silver particles, 1.5 parts of graphene and 80 parts of dimethylacetamide were mixed, stirred and dissolved at 20°C to form a uniform film-making solution; water at 25°C was used as the core liquid, and the film-making solution at 20°C It...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com