Patents

Literature

80results about How to "Reduce water production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Well treating fluids and methods

InactiveUS6070664AReduce water productionSimple methodFluid removalDrilling compositionChemistryReactive polymer

The present invention provides a method for reducing the amount of water produced from a subterranean formation as a result of stimulation of the subterranean formation. The method comprises the introduction of a first and second reactive polymer which leak-off into the formation and which are capable of subsequently reacting together to form a reaction product which selectively reduces the permeability of the formation to water flow through the formation. The reactive polymers react in situ to form a reaction product that binds to the formation in such a manner that the flow of water is selectively retarded through the matrix while the flow of oil is substantially unaffected.

Owner:HALLIBURTON ENERGY SERVICES INC

Fully integrated NF-thermal seawater desalination process and equipment

InactiveUS20060157410A1High yieldEffectively and efficiently dealGeneral water supply conservationReverse osmosisDistillationEngineering

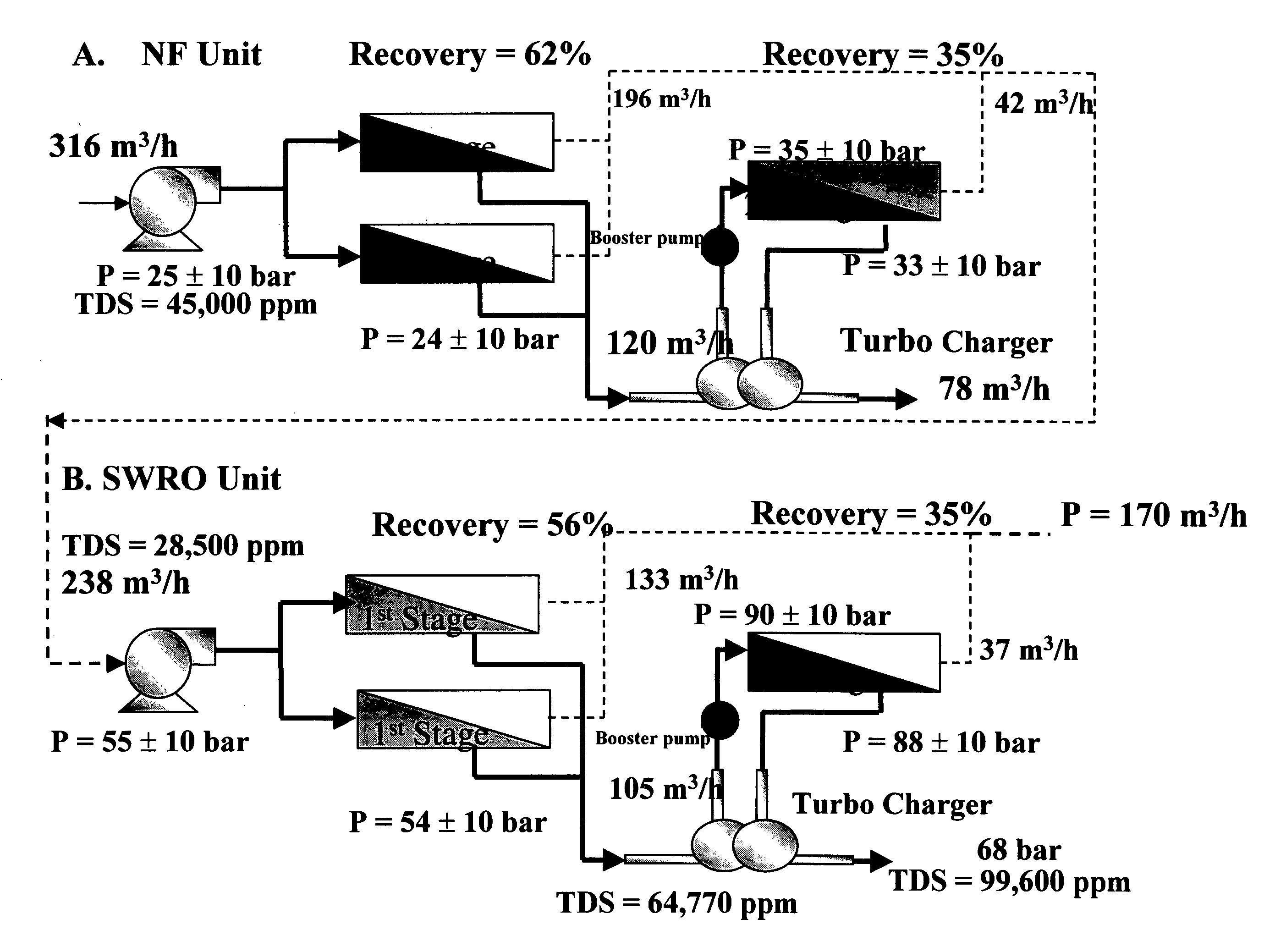

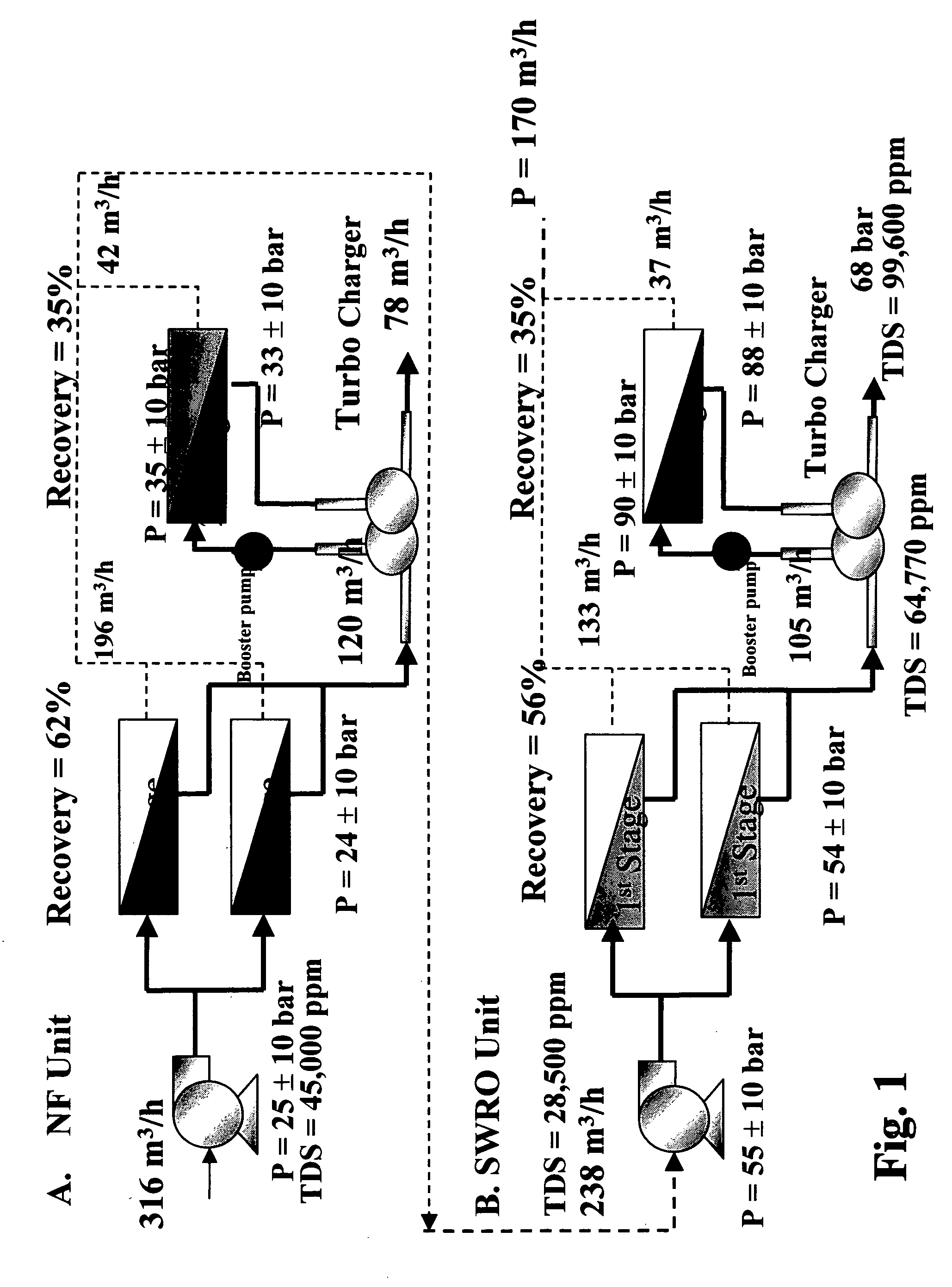

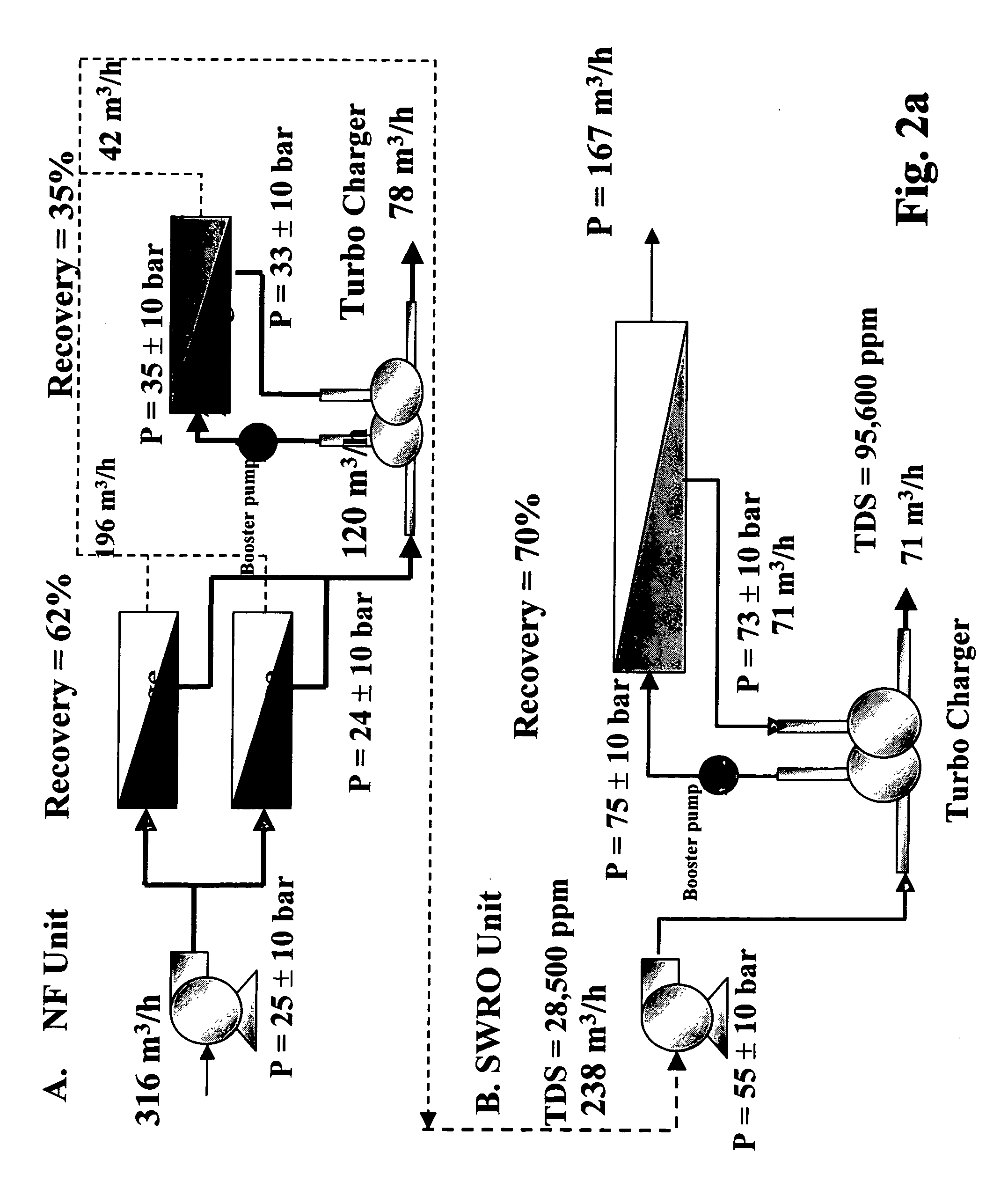

An optimal thermal seawater desalination process is disclosed, which combines two or more substantially different water pretreatment processes in a unique manner and in a special configuration, hereto unknown to prior desalination arts, to produce a high yield of high quality fresh water, including potable water. In this process a two stage NF membrane pretreatment unit (NF2) with an energy recovery turbo charger (TC) device in between the stages or equipped with an energy recovery pressure exchanger (PX) is synergistically combined with at least one thermal desalination unit to form a dual hybrid of NF2-Thermal (FIG. 4 ), or alternatively the two stage NF2 unit is synergistically combined with a two stage SWRO unit (SWRO2) with an energy recovery TC in between the stages or combined with one stage SWRO (SWRO1) equipped with an energy recovery TC or PX system and the reject from the SWRO2 or SWRO1 unit is made make-up to a thermal unit to form a tri-hybrid of NF2-SWRO2 reject-Thermal (FIG. 5 ). In both the cases of di- or trihybrids the thermal unit is equivalent to a multistage flash distillation (MSFD) or multieffect distillation (MED) or vapor compression distillation (VCD) or thermal reheat (RH) evaporator. Typically a process of this invention using the two stage NF2 initial pretreatment step will perform a semi-desalination step by reducing feed TDS by about 35 to 50%, but most important, especially to the thermal seawater desalination process, it removes the water recovery limiting, scale forming hardness ions of Ca++ and Mg++ by better than 80% and their covalent anions of sulfate to better than 95% and bicarbonate to about 65%. The removal of scale forming hardness ions, especially SO4=, and bicarbonates allowed for the operation of thermal unit in the above hybrids at top brine temperature (TBT) much greater than its present TBT limit by the singular conventional process of 120° C. for MSFD and operation of MED or VCD or RH unit at TBT much higher than their present TBT limit of 65-70° C., with many advantages gained by this process over prior art sweater desalination processes. The process of this invention exceeds all prior thermal seawater desalination arts in efficiency, including water yield, product water recovery ratio and unit water cost as well as in energy consumption per unit product which is equivalent or less than other efficient prior art seawater thermal desalination processes. By this process, an NF product recovery ratio of 75 and 80% or better is achieved from the high salinity Gulf sea (TDS≈45,000 ppm) and about an equal product recovery ratio is also obtained from the SWRO or thermal unit when it is operated on NF product for a total water recovery ratio in excess of 52% for seawater

Owner:SALINE WATER CONVERSION CORP SWCC

Methods and compositions for reducing the production of water and stimulating hydrocarbon production from a subterranean formation

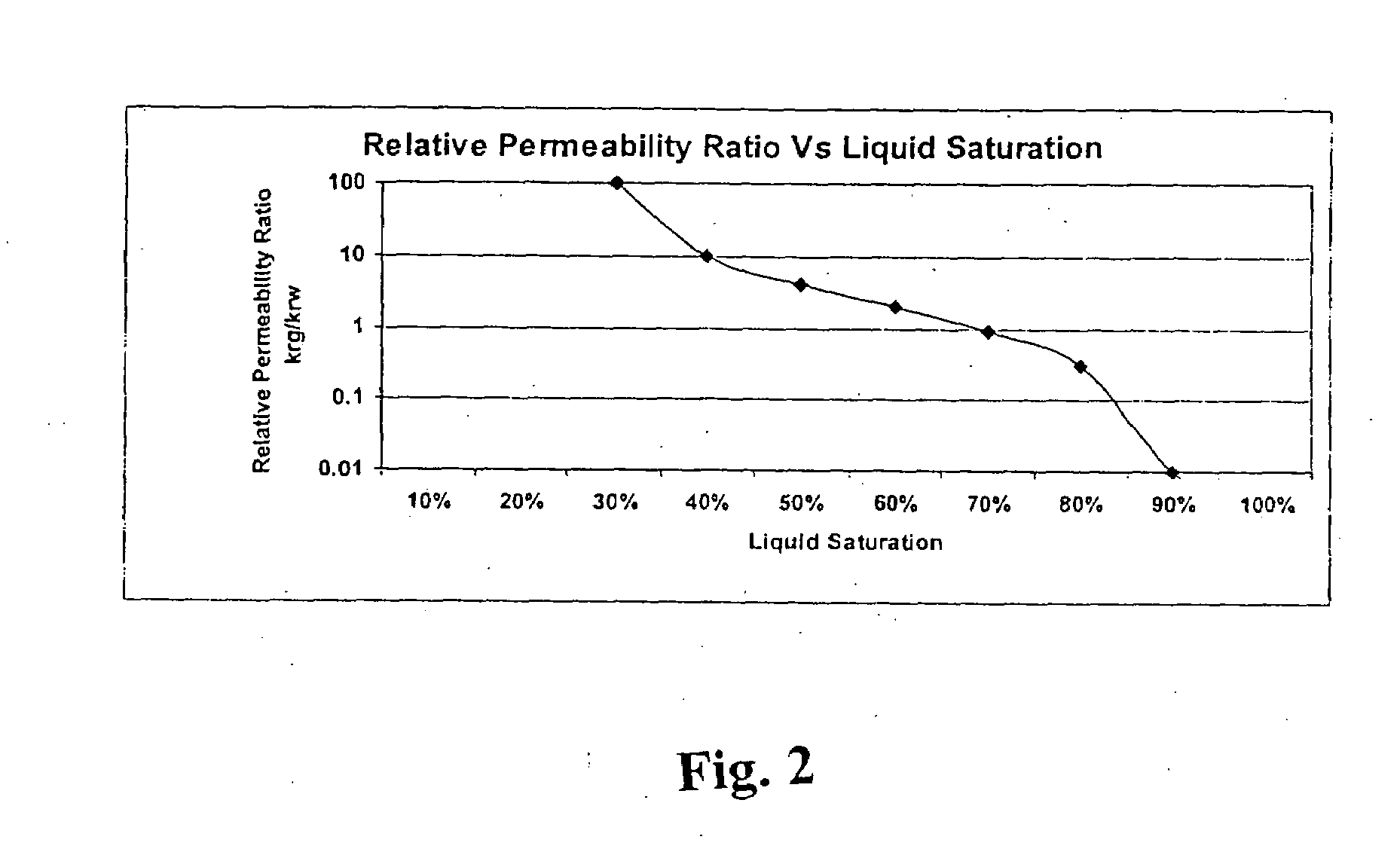

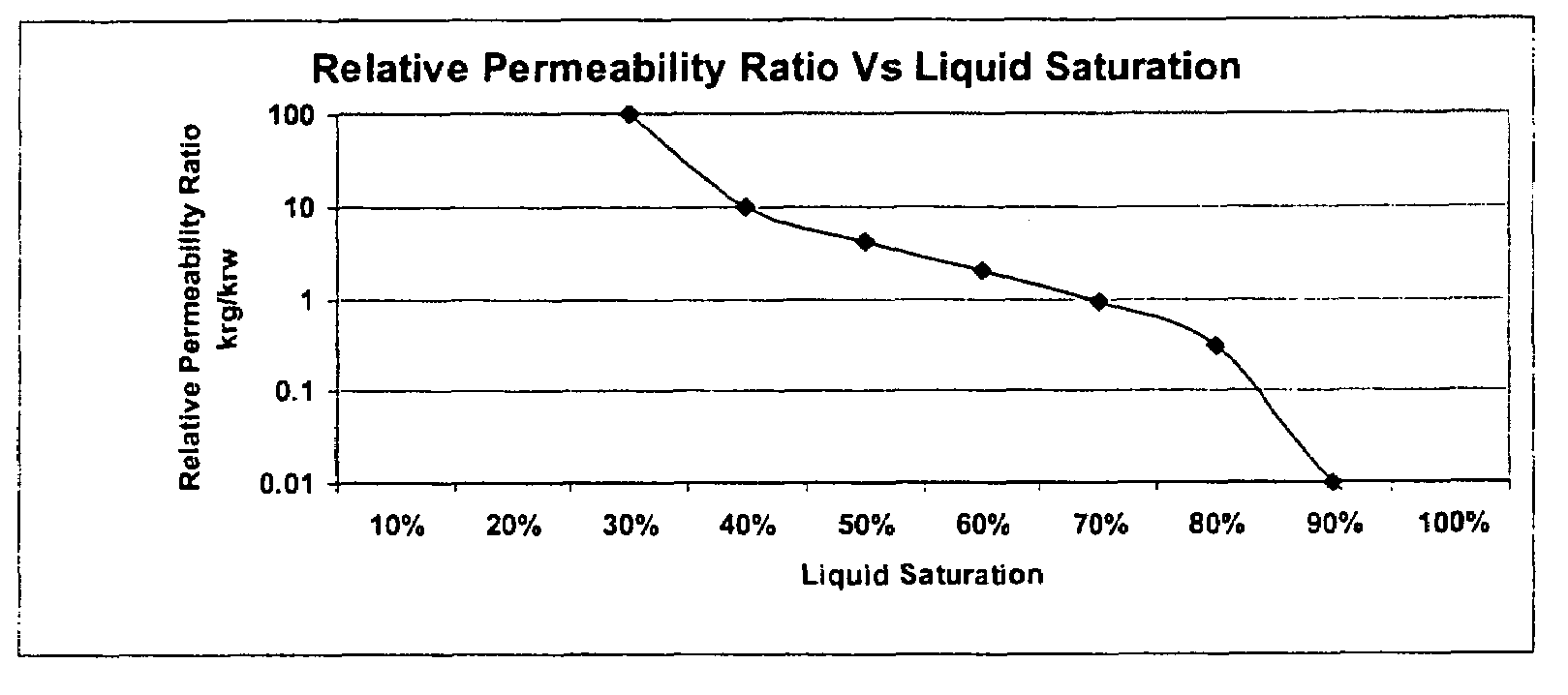

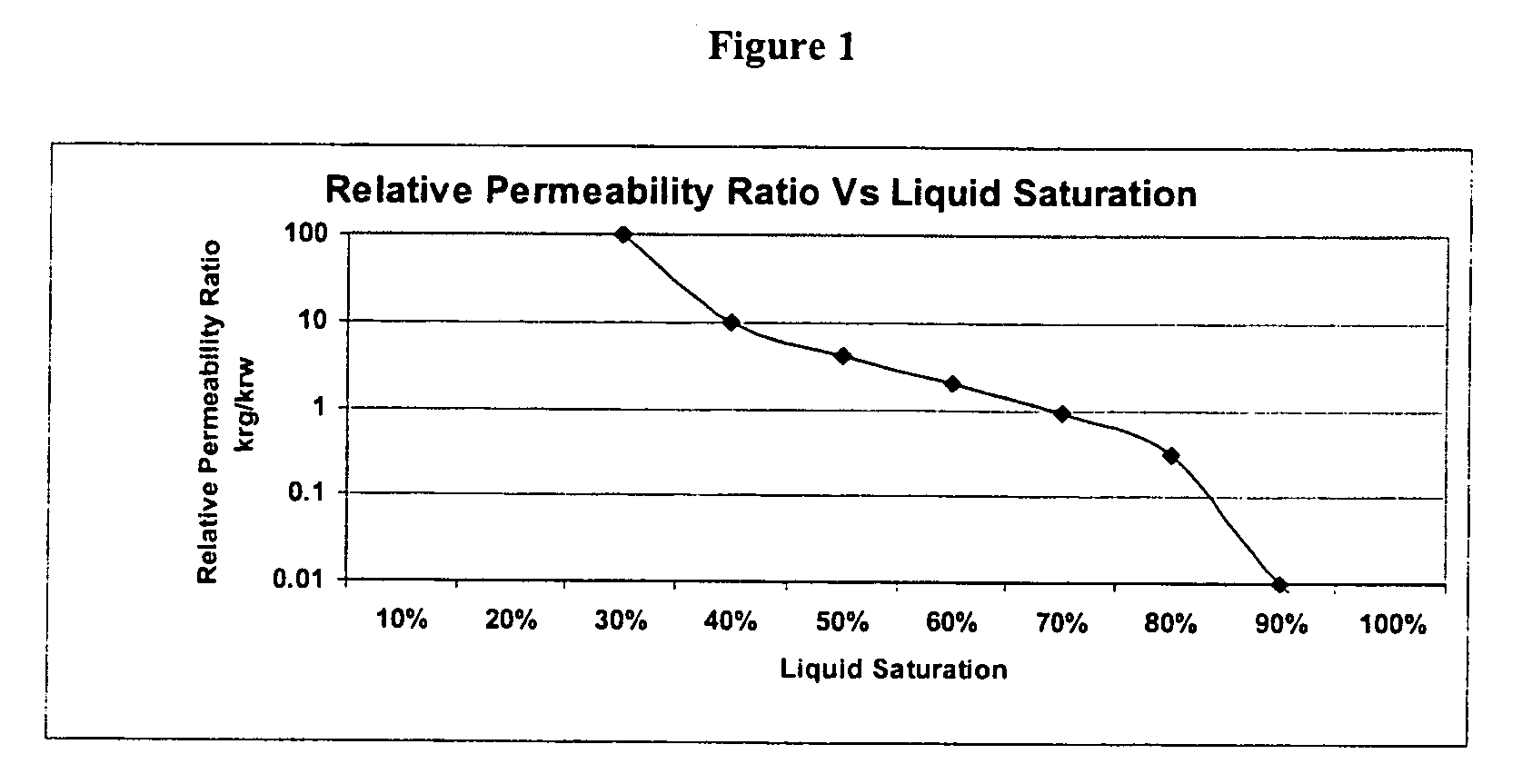

InactiveUS20060234874A1Reduce water productionPromote productionFluid removalFlushingRelative permeabilityHydrocarbon

The present invention relates to subterranean treatment fluids, and more particularly, the present invention relates to subterranean treatment fluids comprising relative permeability modifiers and methods for using such subterranean treatment fluids in subterranean operations to reduce the production of water from and stimulate hydrocarbon production in a subterranean formation. In certain embodiments, the methods of the present invention generally comprise the steps of providing a permeability-modifying aqueous treatment fluid comprising a relative permeability modifier and contacting a subterranean formation with the permeability-modifying aqueous treatment fluid. Optionally, the permeability-modifying aqueous treatment fluid may be injected in the subterranean formation at a pressure sufficient to create or enhance at least one fracture therein. In another embodiment, the relative permeability modifier may be provided by appropriate reaction in situ.

Owner:HALLIBURTON ENERGY SERVICES INC

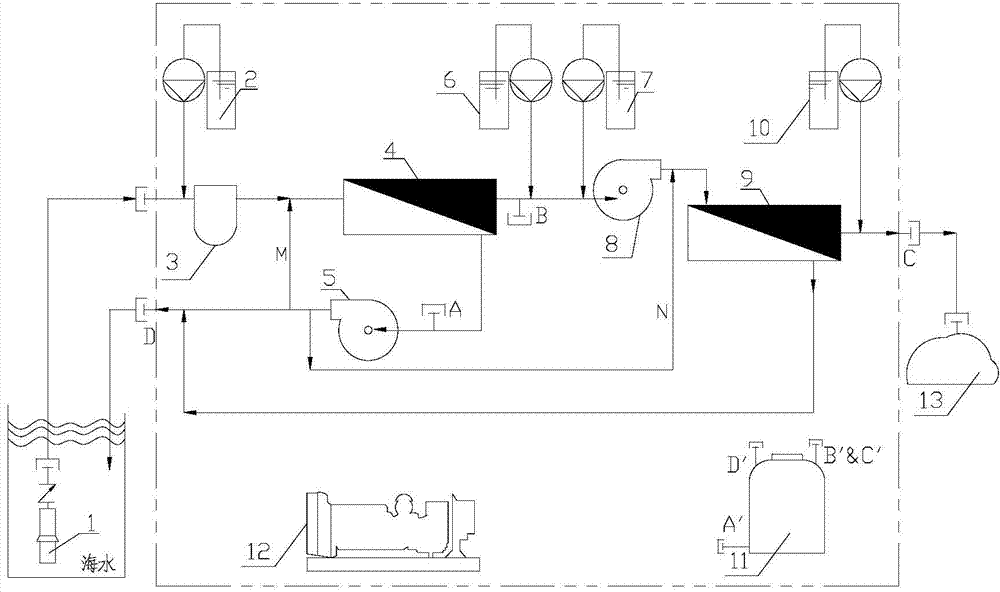

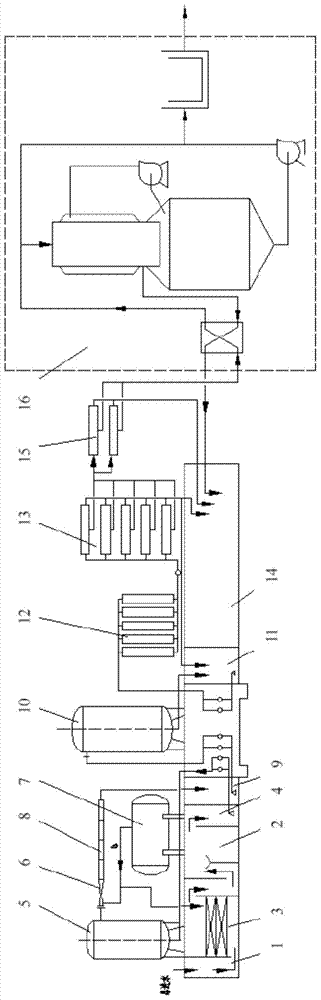

Full-membrane method seawater desalting integration system adopting ultrafiltration-nanofiltration-reverse osmosis, and full-membrane method seawater desalting integration process adopting ultrafiltration-nanofiltration-reverse osmosis

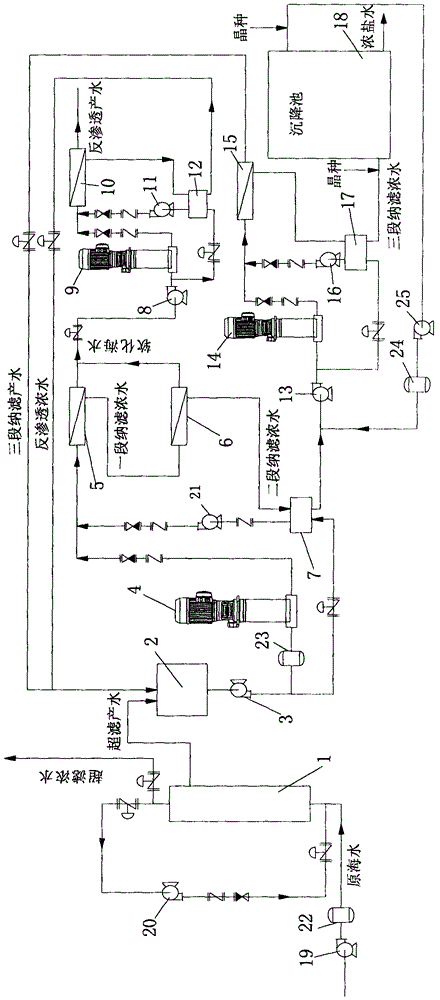

InactiveCN104817134AReduced fouling tendencyReduce energy consumptionGeneral water supply conservationSeawater treatmentMembrane methodThree stage

The invention relates to a full-membrane method seawater desalting integration system adopting ultrafiltration-nanofiltration-reverse osmosis, and a full-membrane method seawater desalting integration process adopting ultrafiltration-nanofiltration-reverse osmosis, wherein the nanofiltration seawater softening recovery rate can be increased, and the membrane surface scaling tendency can be reduced. According to the present invention, the nanofiltration system is a three-stage nanofiltration system, wherein the first-stage nanofiltration membrane assembly and the second-stage nanofiltration membrane assembly are adopted as the pretreatment of the reverse osmosis, and the third-stage nanofiltration membrane assembly further treats the concentrated water obtained through the first-stage nanofiltration and the second-stage nanofiltration, such that the seawater recovery rate is increased, and the scaling tendency on the nanofiltration membrane surface of the first-stage nanofiltration membrane assembly and the second-stage nanofiltration membrane assembly is reduced so as to reduce the seawater desalting cost and reduce the scaling tendency of the third-stage nanofiltration membrane assembly during the high salinity concentrated water treatment.

Owner:OCEAN UNIV OF CHINA

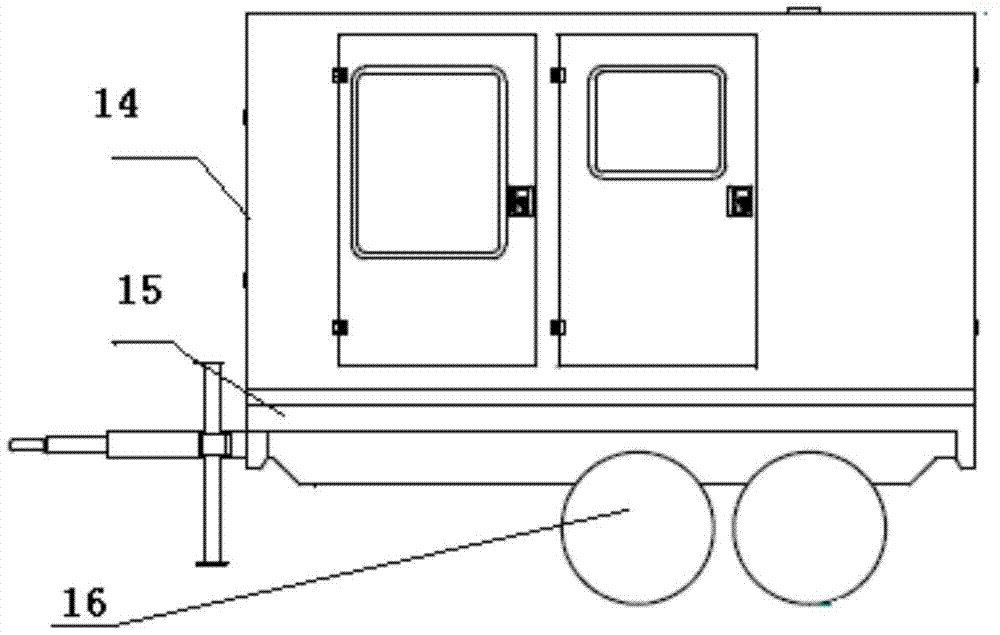

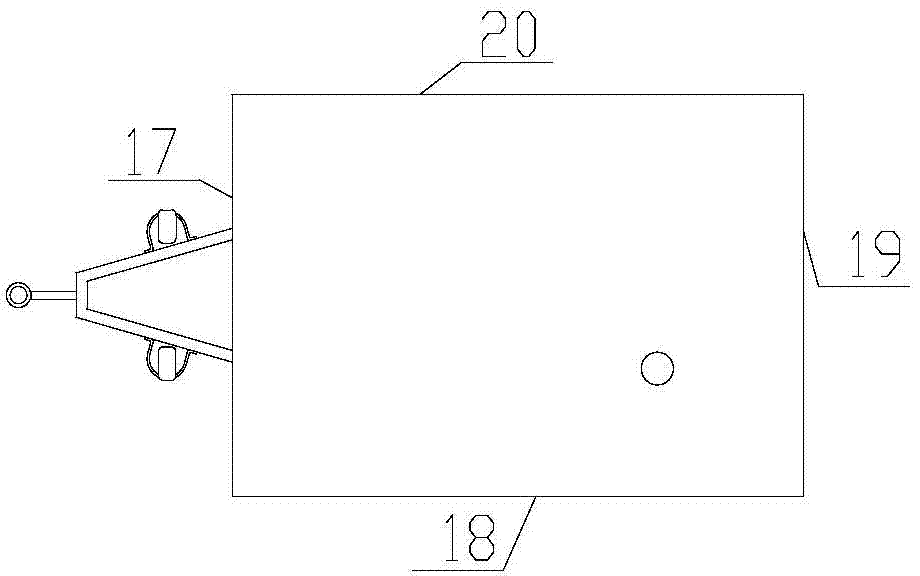

Modular portable reverse osmosis seawater desalination integration apparatus and use method thereof

InactiveCN104326591AReduce volumeReduce weightWater treatment parameter controlGeneral water supply conservationAviationWhole body

The invention relates to the field of seawater desalination, and concretely relates to a modular portable reverse osmosis seawater desalination integration apparatus and a use method thereof. The apparatus is characterized in that a water intake pump, a bactericide dosing device, a filter, an ultrafiltration membrane assembly, a circulating pump, a reducing agent dosing device, a scale inhibitor dosing device, a high pressure pump, a reverse osmosis membrane assembly, a post-treatment dosing system, a cleaning water tank and a foldable water storage bag form a reverse osmosis seawater desalination system, the above devices except the water intake pump, the cleaning water tank and the foldable water storage bag all are fixedly installed in a trailer box body, and the whole body is a reverse osmosis desalination module. A pretreatment unit, a reverse osmosis desalination unit, a chemical dosing unit, a chemical cleaning unit and an electric and control unit are compactly, stably and reasonably integrated in the trailer with a closed box body trough a filter + ultrafiltration + reverse osmosis double membrane process, so the apparatus has the advantages of small size, light weight, flexible movement, and realization of transportation through aviation, highway, railways and ships.

Owner:沈阳远大固废处理有限公司

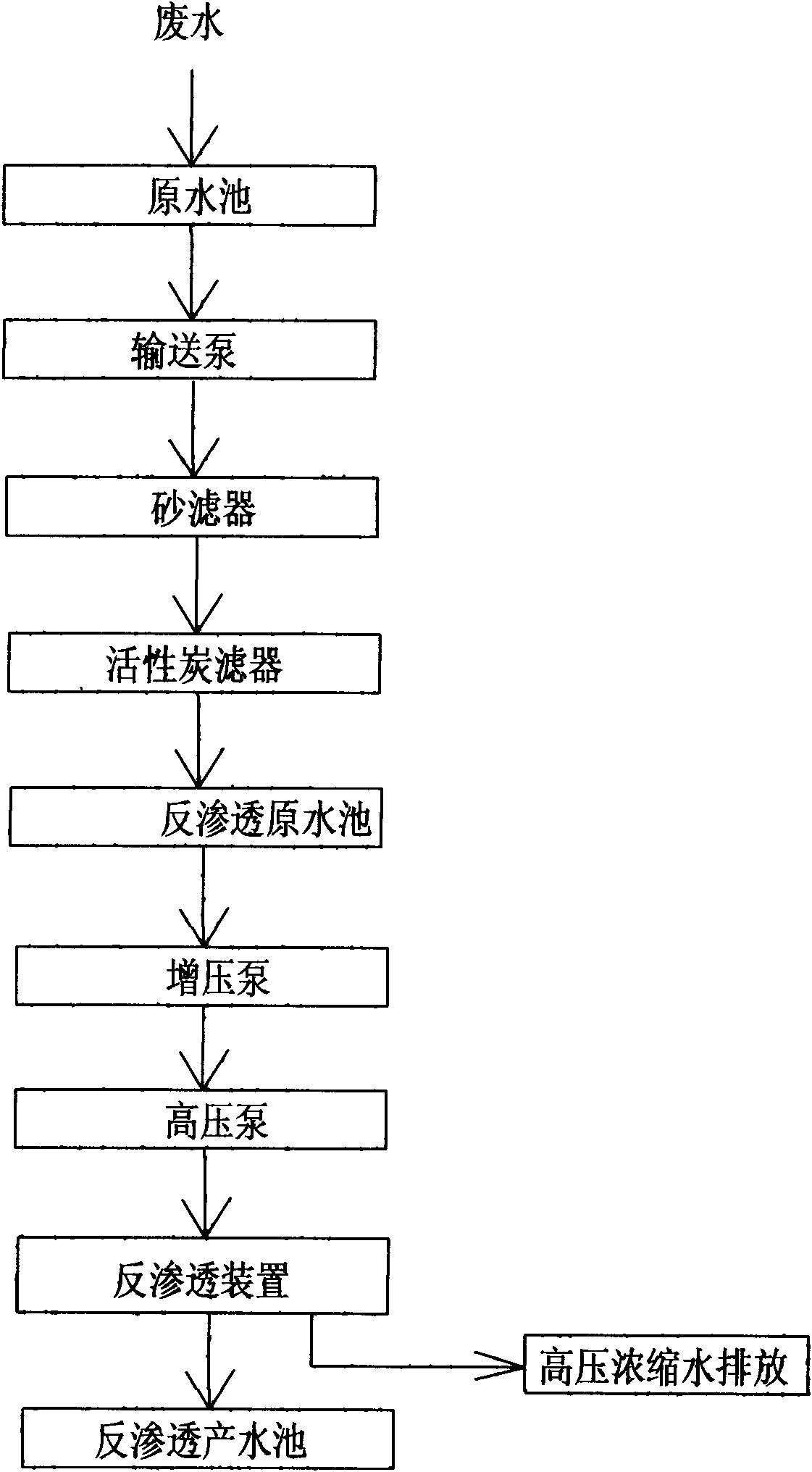

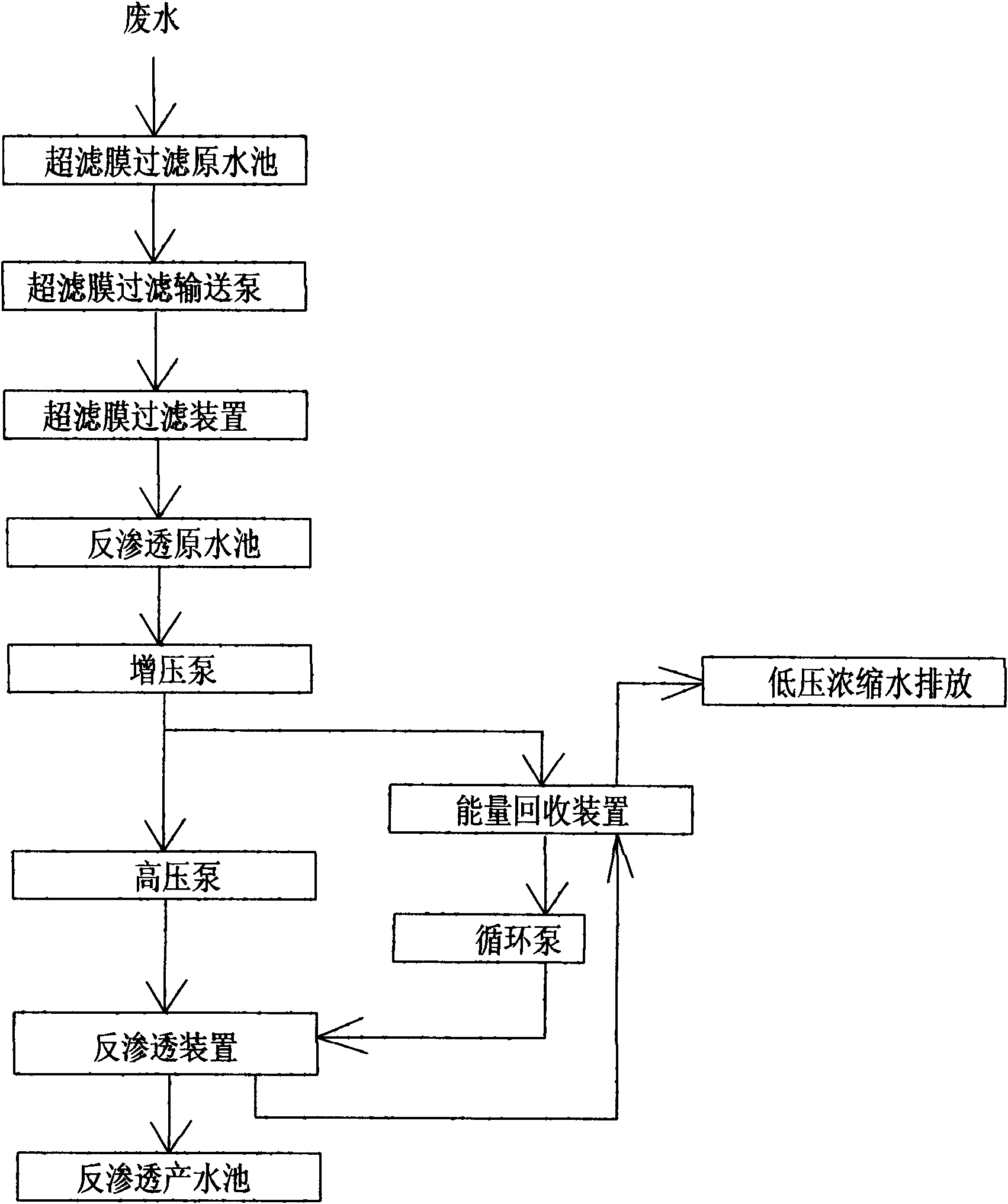

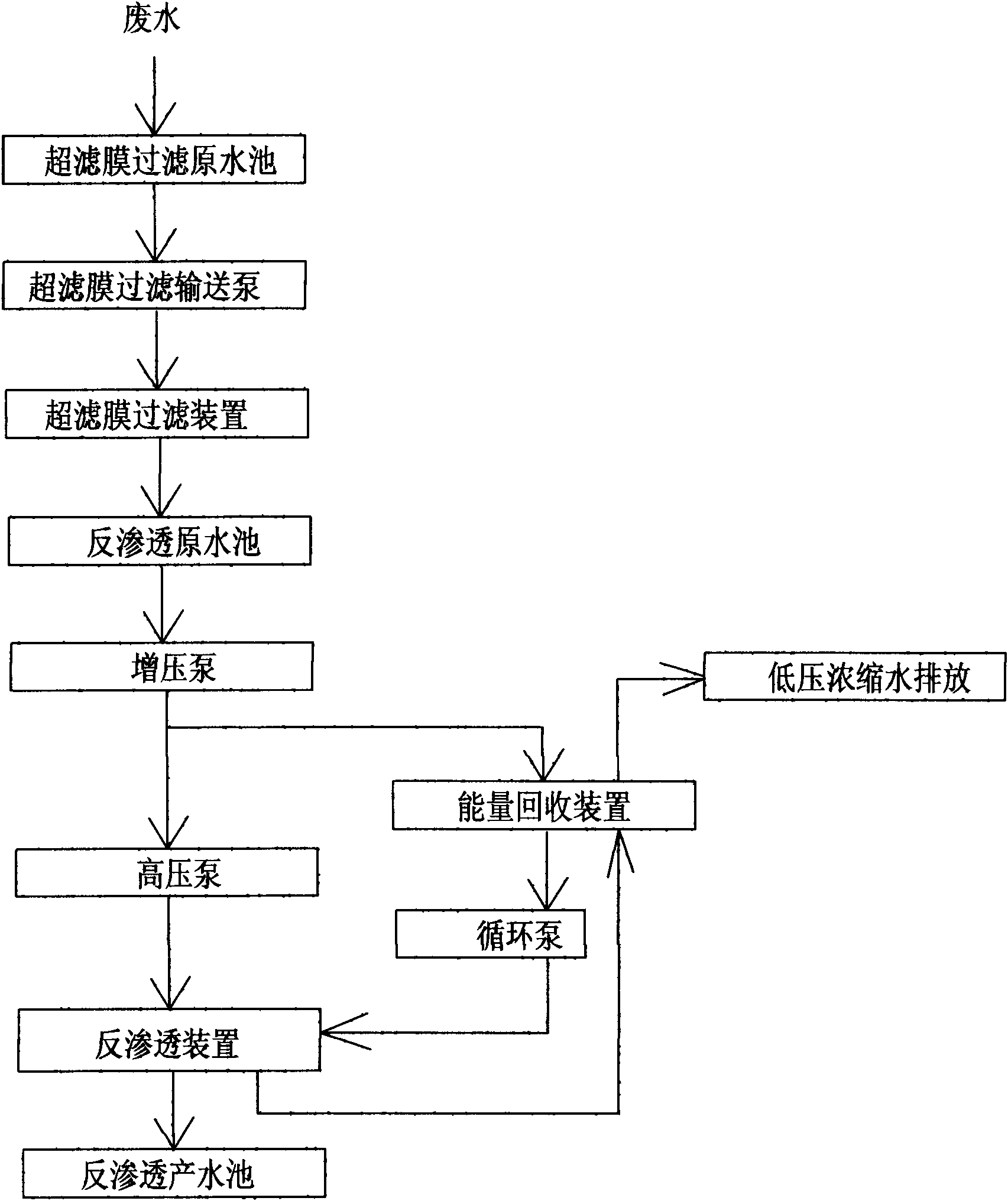

Electroplating wastewater reverse osmosis membrane treatment method adopting energy recovery device

InactiveCN102010033AEfficient recyclingReduce energy consumptionWaste water treatment from metallurgical processWater/sewage treatment bu osmosis/dialysisFiltrationWater filter

The invention discloses an electroplating wastewater reverse osmosis membrane treatment method adopting an energy recovery device. Key points of the technical scheme are that: the method comprises the following steps that: electroplating wastewater sequentially passes through an ultrafiltration membrane filtering raw water tank, an ultrafiltration membrane filtering delivery pump, an ultrafiltration membrane filtering unit, a reverse osmosis raw water tank, a booster pump and a security filter, and is divided; one branch enters a reverse osmosis device after being boosted by a high pressure pump, wherein the energy recovery device for recovering the energy of high-pressure reverse osmosis concentrated water flowing out of the reverse osmosis device is connected to the reverse osmosis device; and the other branch enters the reverse osmosis device through a circulating pump after the energy is recovered by the energy recovery device, filtered water filtered by the reverse osmosis device flows into a reverse osmosis product water tank, and after filtration, the concentrated water is treated and discharged.

Owner:中山市三角镇环保科技创新中心

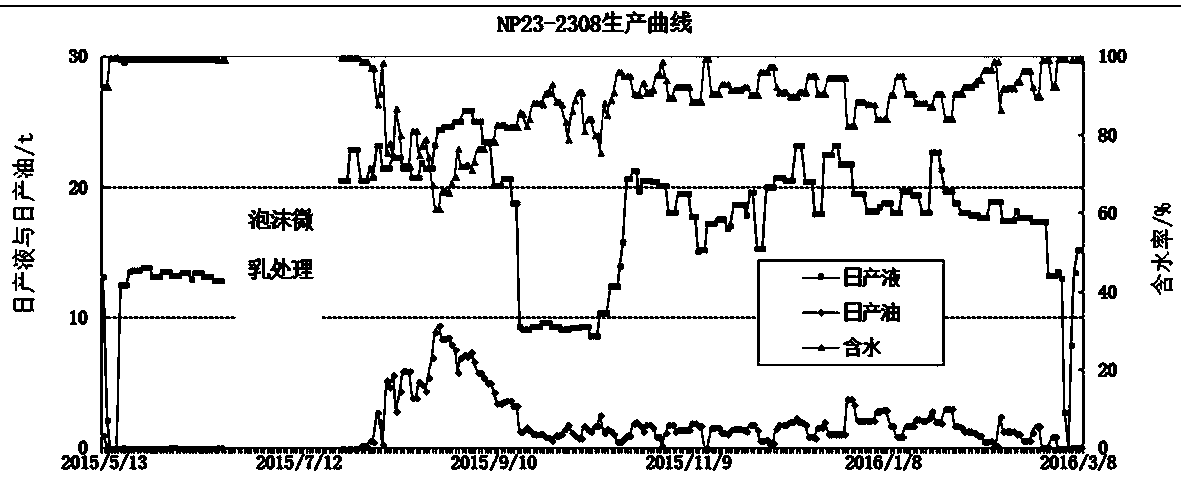

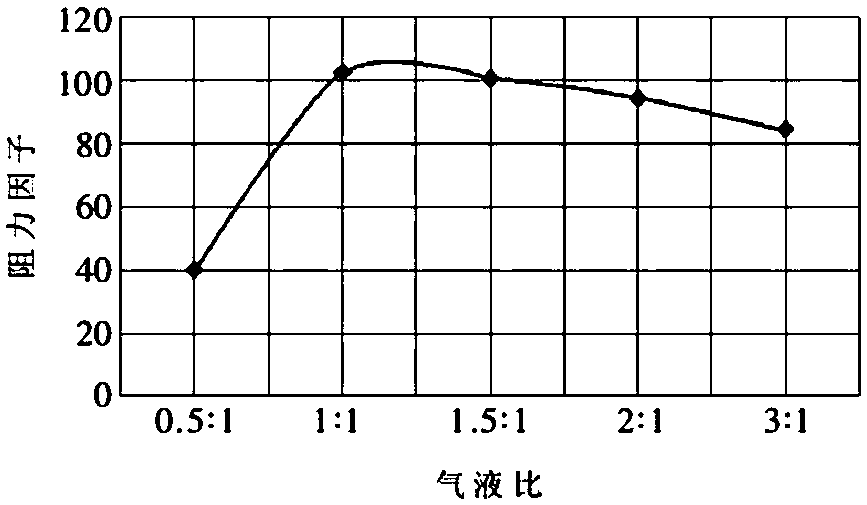

Method for increasing yield of oil well through combined application of gel foam and in-situ micro-emulsion

The invention discloses a method for increasing the yield of an oil well through combined application of gel foam and in-situ micro-emulsion. The method comprises the following steps: injecting a pre-built nitrogen section plug, a gel nitrogen foam section plug, a polymer nitrogen foam section plug, an in-situ micro-emulsion section plug and a gel nitrogen foam section plug sequentially into the oil well. According to the method disclosed by the invention, the yield of crude oil of the oil well can be greatly improved, and the water output of the oil well can be reduced.

Owner:南阳忠兴石油工程技术服务有限公司

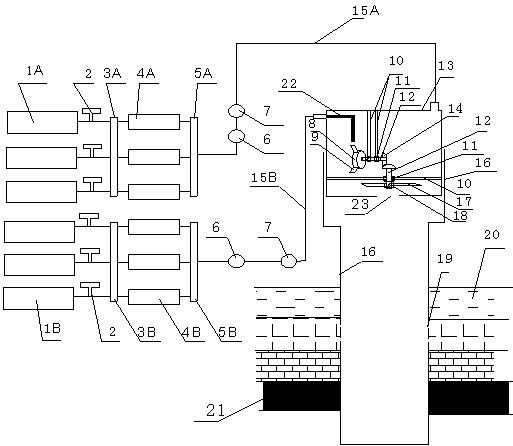

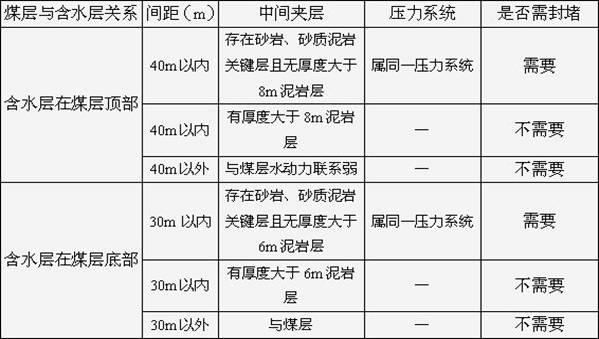

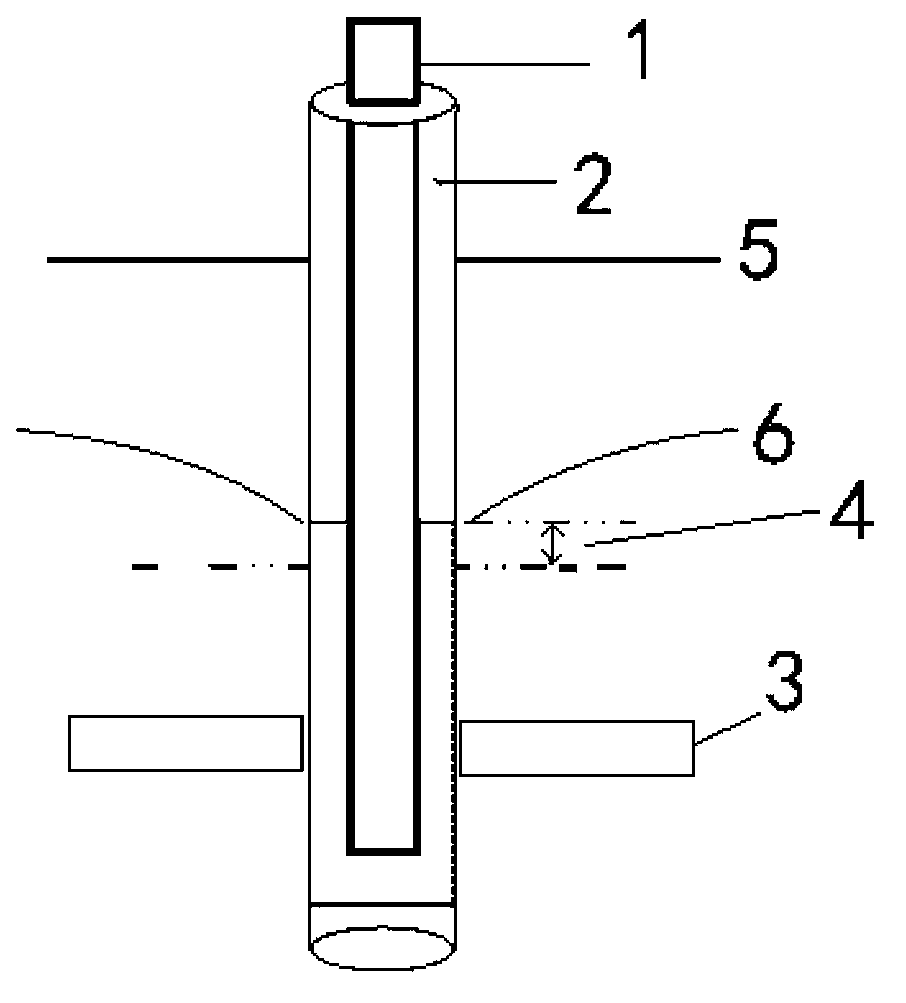

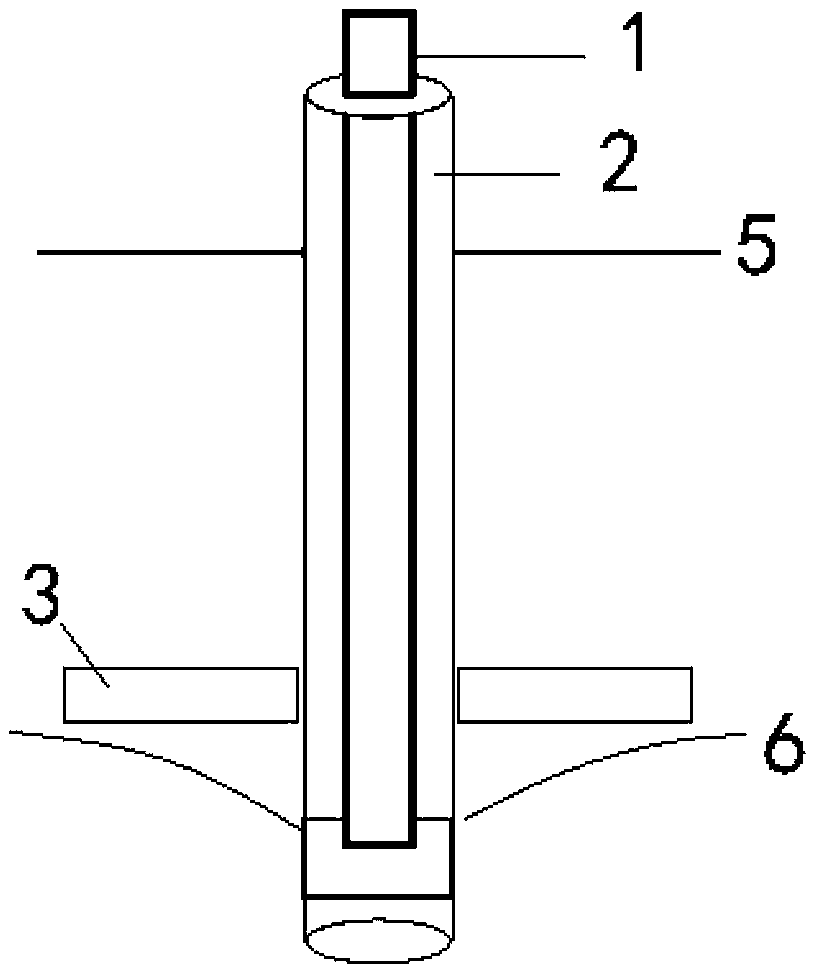

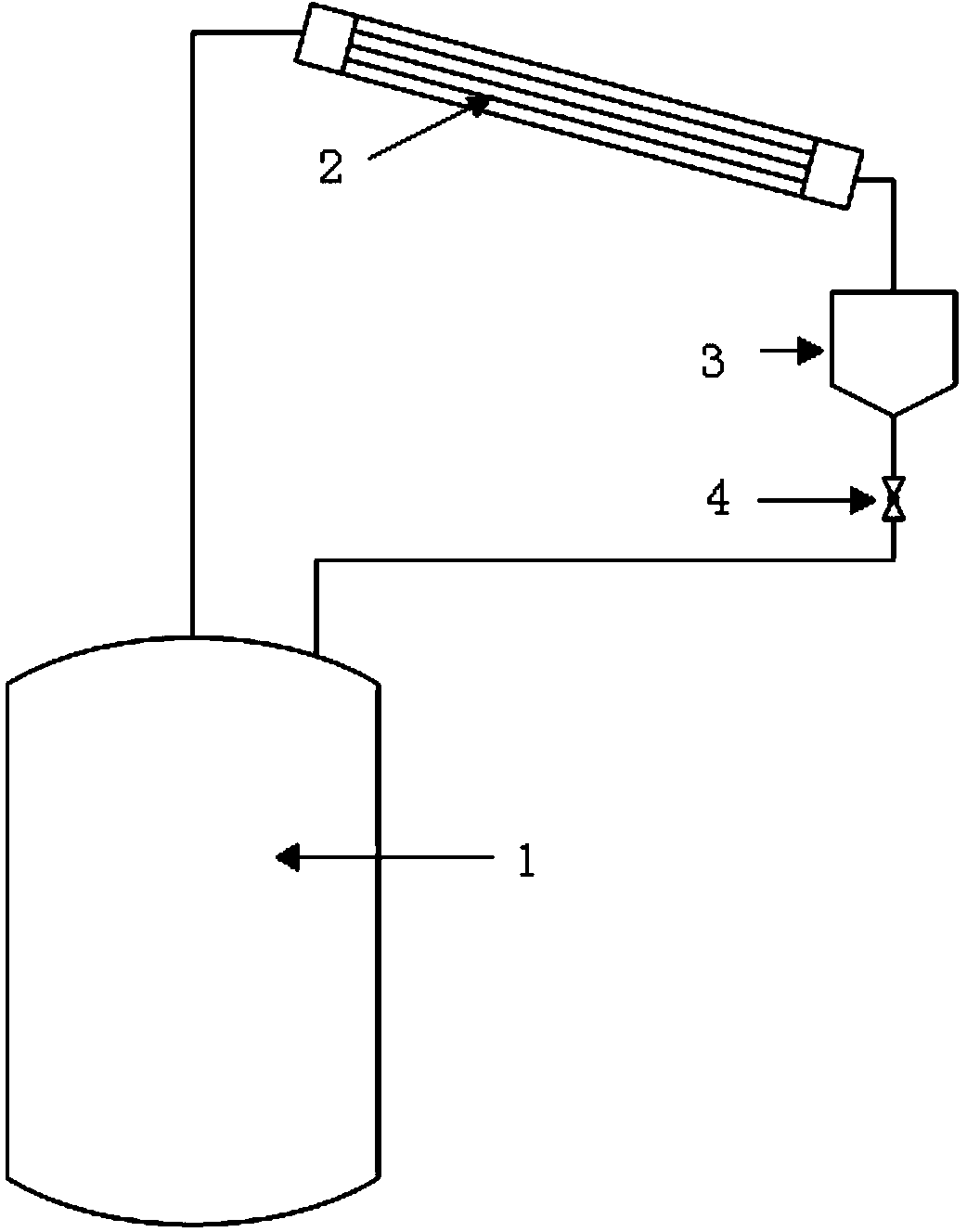

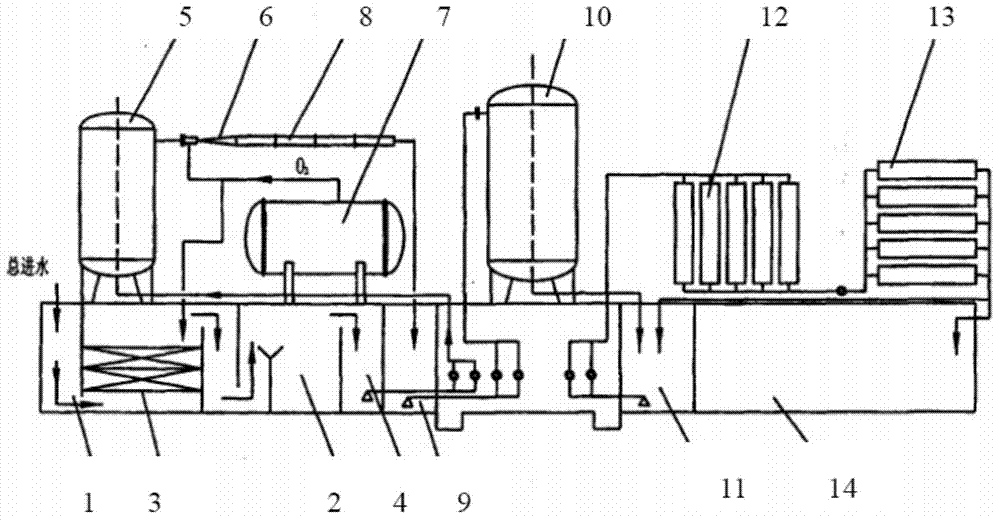

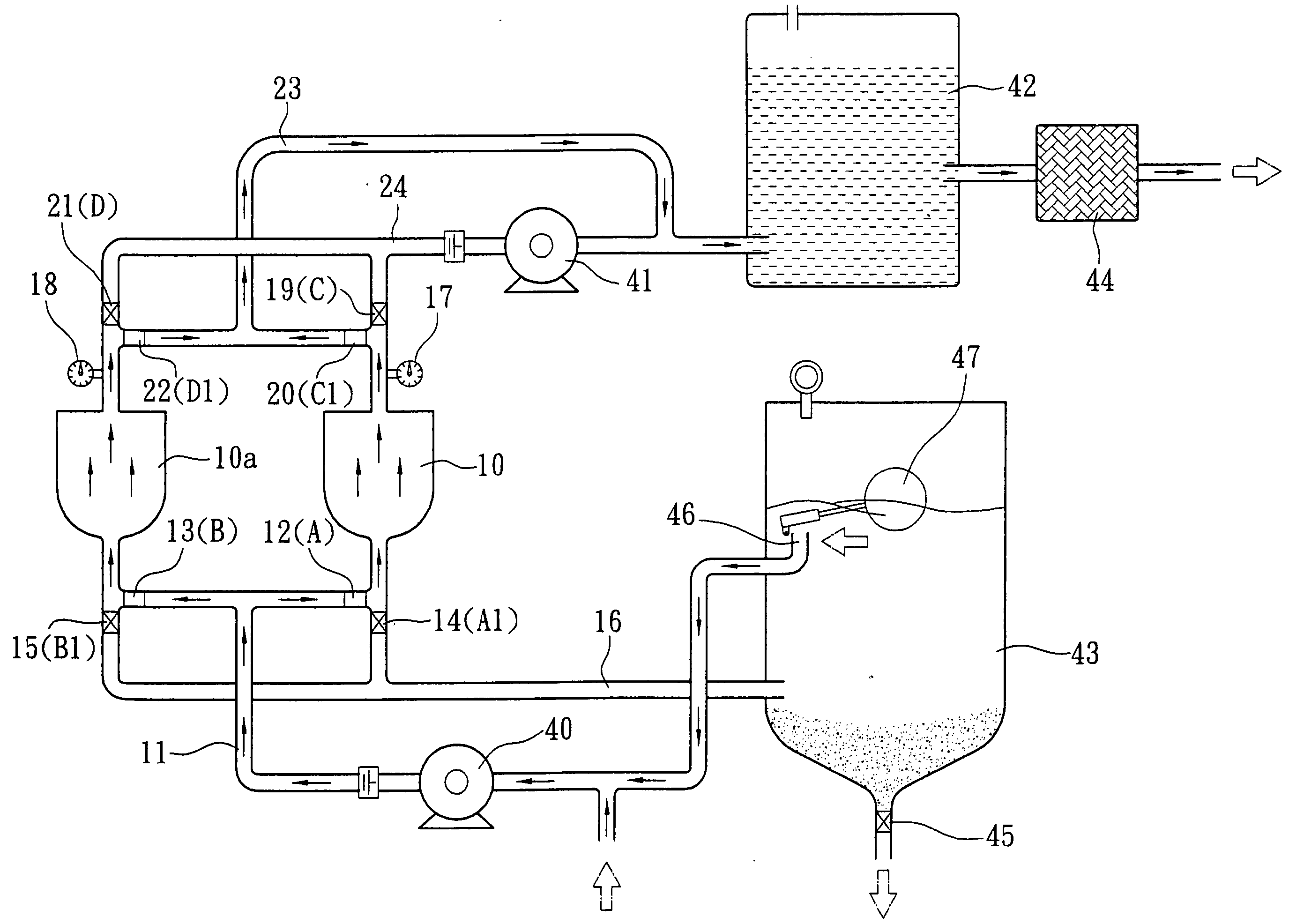

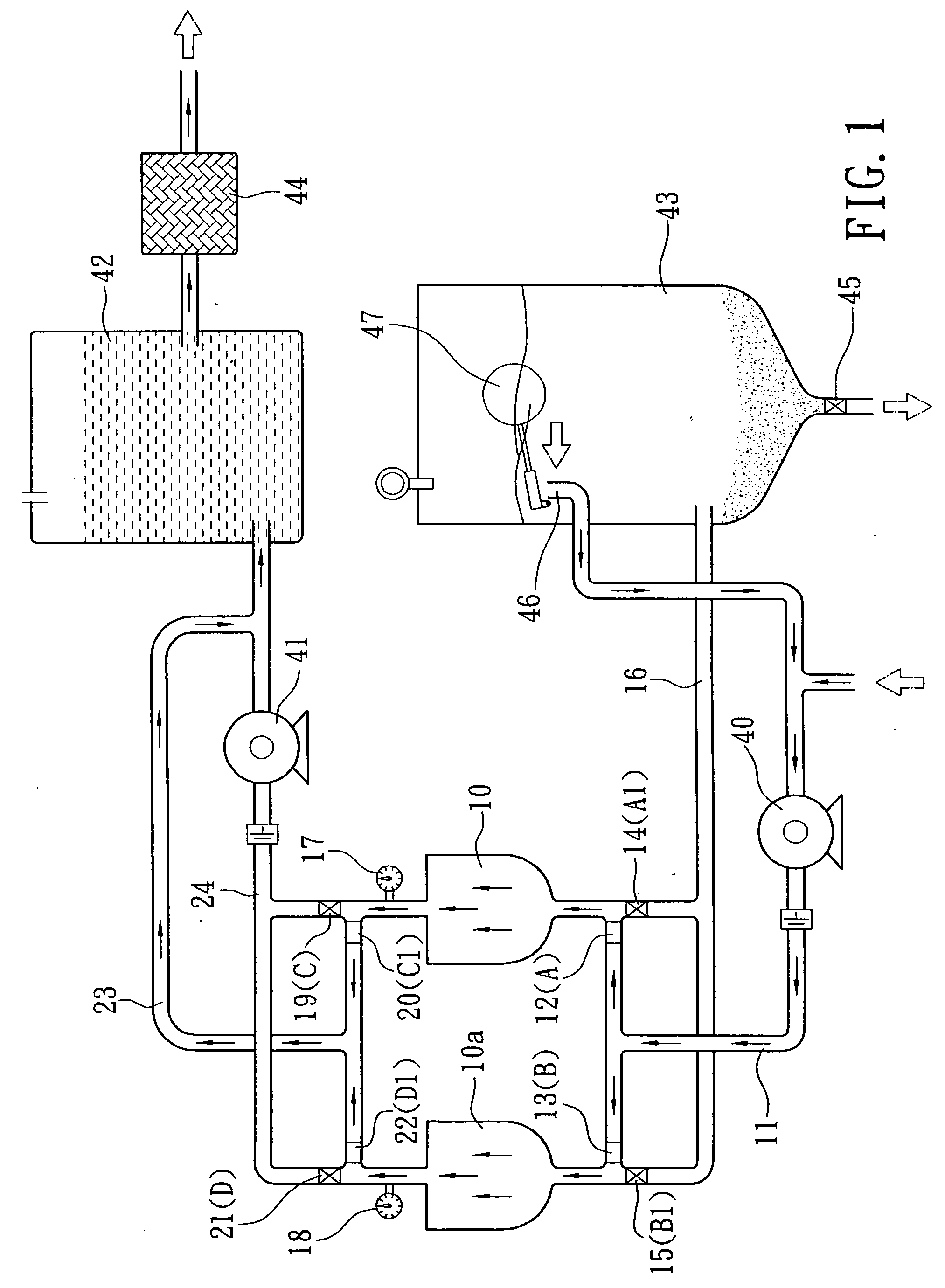

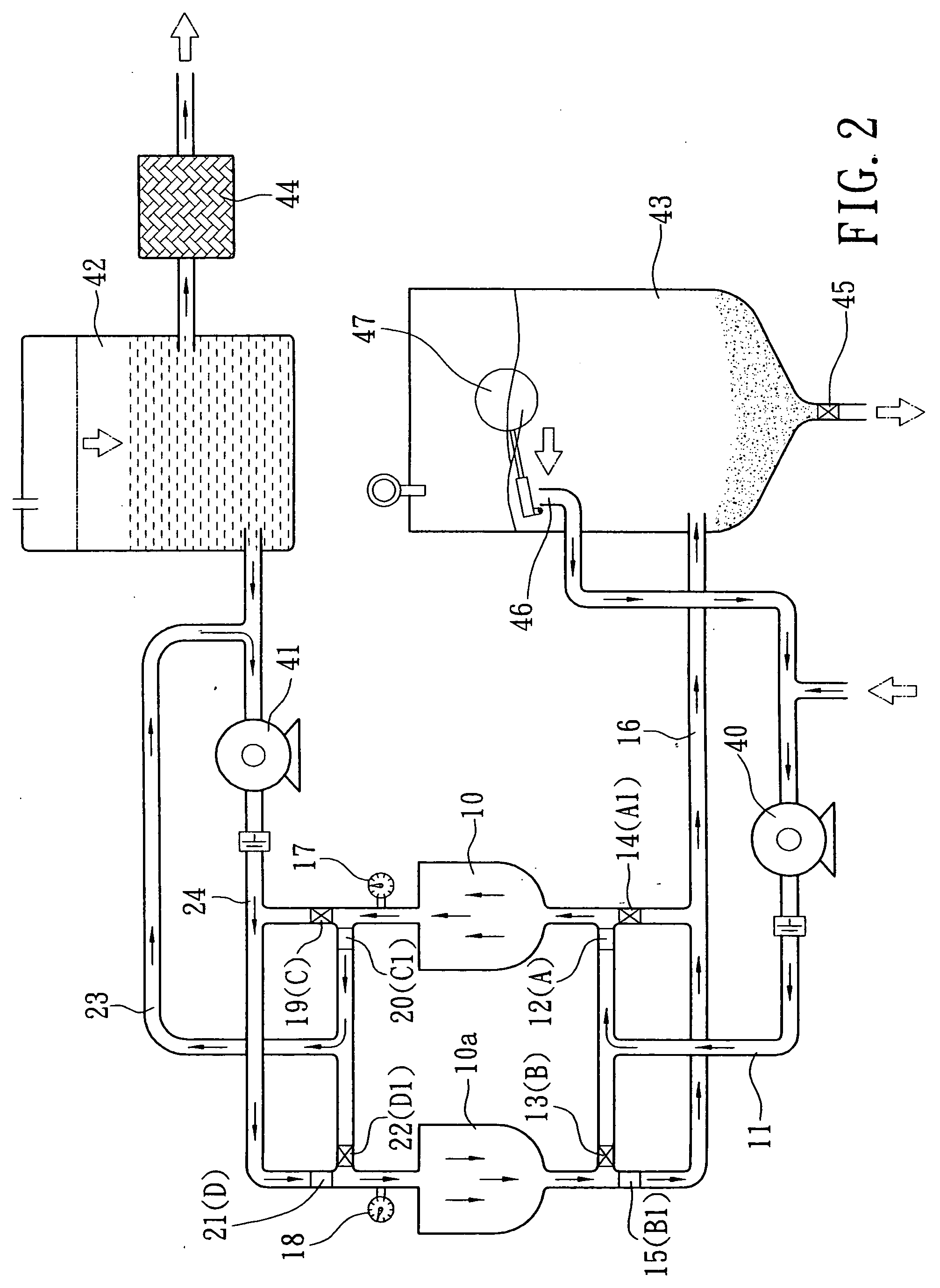

Plugging equipment for ground fracturing plugging water-bearing stratum

InactiveCN102102499AEasy to drop pressureReduce water productionSealing/packingHydraulic fracturingLiquid tank

The invention discloses plugging equipment for a ground fracturing plugging water-bearing stratum. The plugging equipment comprises a fracturing plugging feed system, a stirring system and a discharge system, wherein the fracturing plugging feed system comprises two feed pipelines; the first feed pipeline comprises a first fracturing pumper which is connected with a first liquid tank; the second feed pipeline comprises a second fracturing pumper which is connected with a second liquid tank; the stirring system comprises a stirring cabin which is arranged at a well head; stirring blades which are connected with a power device are arranged in the stirring cabin; the discharge system comprises a bushing which is positioned below the stirring cabin and is communicated with the stirring cabin;the wall of the lower part of the bushing is provided with a hole; the lower part of the bushing is positioned in a well; and the first fracturing pumper and the second fracturing pumper are communicated with the stirring cabin through a first high-pressure hose and a second high-pressure hose respectively. The plugging equipment aims to solve the problem that the water-bearing stratum is possibly communicated with a coal seam in a fracturing process because the water-bearing stratum is closer to the coal seam; and in order to guarantee that the coal seam is not communicated with the water-bearing stratum of a surrounding rock during hydraulic fracturing, the plugging equipment for the ground fracturing plugging water-bearing stratum for fracturing and reconstructing of a coal reservoir is realized.

Owner:HENAN POLYTECHNIC UNIV

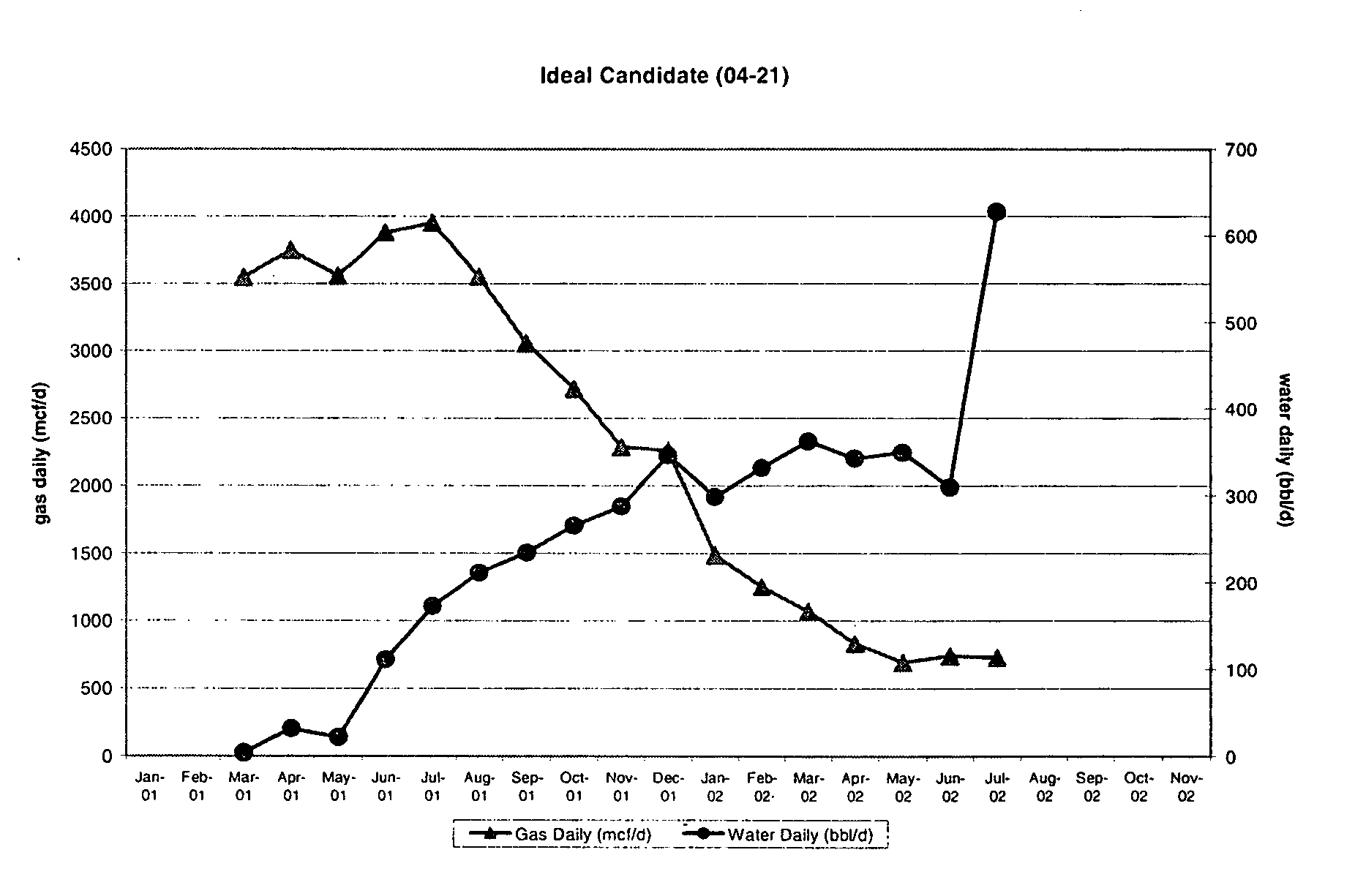

Draining and mining method for coal-bed gas well

ActiveCN104100237AHigh daily gas productionMaintain pure liquid-phase flowFluid removalLiquid waterWellhead

The invention discloses a draining and mining method for a coal-bed gas well, and belongs to the technical field of coal-bed gas development. A working liquid level quickly descends to 10-30 meters above the coal-bed gas analysis pressure according to an analysis pressure value of coal-bed gas. By the intelligent draining and mining method, the working liquid level is always controlled to 10-30 meters above the analysis pressure; if the working liquid level descends quickly, the draining and mining system is lowered; if the working liquid level rises again, the draining and mining system is raised; therefore gas is not analyzed, and a single-phase flowing state of liquid water with the maximum pressure difference on a coal bed is kept; when the water yield is obviously reduced, about 70 percent of water in the coal bed is drained at the moment, and a pressure drop funnel with a larger area is formed; the liquid level is controlled to 5-10 meters below the bottom boundary of the coal bed so as to ensure that the coal bed section is all exposed above the water in the coal bed; the gas and water two-phase flow, taking the coal-bed gas as a main body and the water as an auxiliary body, of the coal bed is kept, and the generated gas can bring away about 30 percent of the residual water in the coal bed; meanwhile, the flowing pressure at the bottom of the well is controlled by controlling the casing pressure at a wellhead, so that the aim of reasonably adjusting the gas yield is fulfilled.

Owner:PETROCHINA CO LTD

Modification and viscosity reduction method for in-situ combustion heavy oil recovery

The invention belongs to the technical field of heavy oil recovery and provides a modification and viscosity reduction method for in-situ combustion heavy oil recovery. The modification and viscosity reduction method comprises adding heavy oil and a mixture of a catalyst and a hydrogen donor to a combustion tube simultaneously and injecting air and igniting; turning off an igniter after the air is injected for 8 to 12 minutes and reacting for 5 to 7 hours; enabling the reaction formula of the high temperature oxidation process to be as follows. The modification and viscosity reduction method for the in-situ combustion heavy oil recovery has the advantages of reducing the viscosity and density of the heavy oil to enabling the heavy oil to meet the mining and or gathering and transportation requirements; reducing the recovery and gathering and transportation cost due to a hydrogen catalytic chemical system; being wide in applicability and being applicable to different oil fields and different viscosity ranges of heavy oil; being capable of increasing the H / C (Hydrogen / Carbon) atomic ratio due to chemical agents and capable of reducing the water production rate to a certain extent and improving the quality of the heavy oil; enabling metal additives to be introduced to change dynamical characteristics of oxidation reaction and having the effect of fuel deposition.

Owner:NORTHEAST GASOLINEEUM UNIV

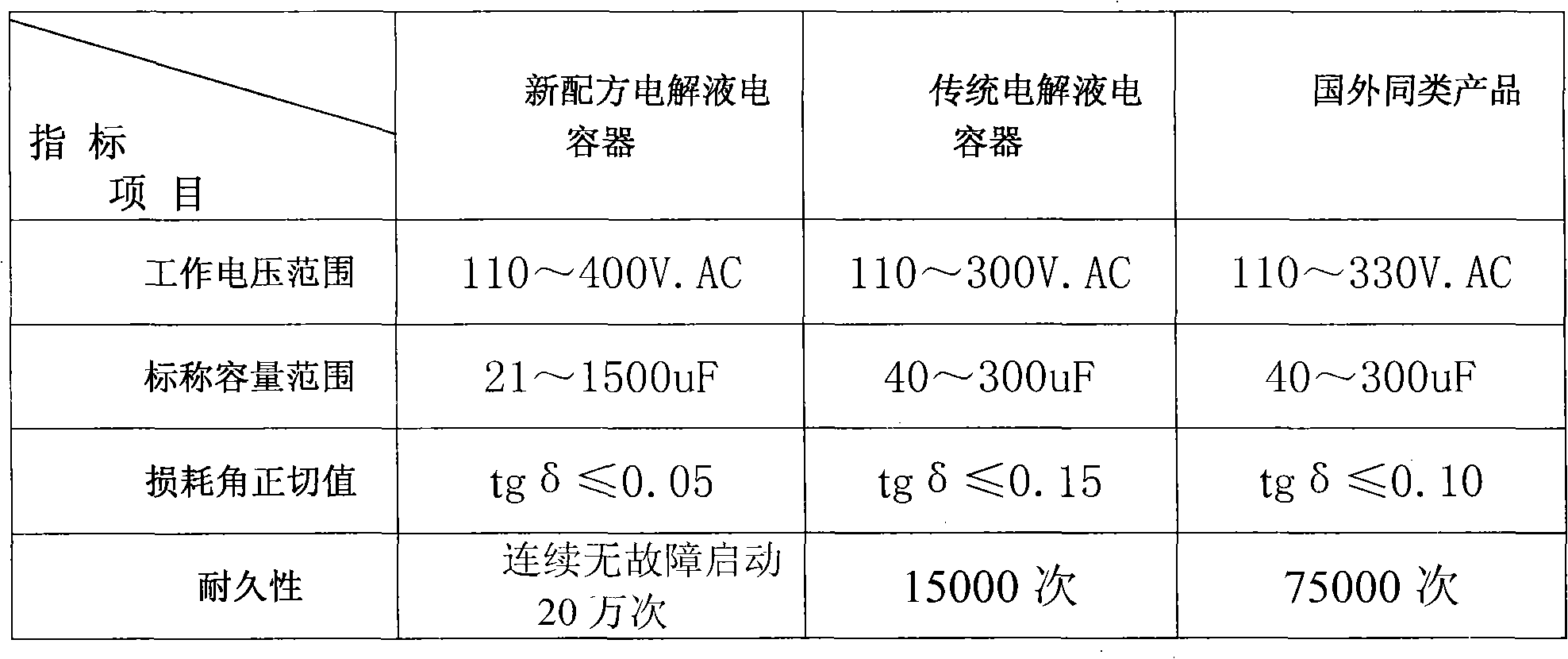

Aluminum electrolytic capacitor electrolyte and preparation method thereof

ActiveCN101894673AReduce water productionReduce hydrogen evolutionElectrolytic capacitorsAmmonium pentaborateAmmonium adipate

The invention relates to an aluminum electrolytic capacitor electrolyte and a preparation method thereof, wherein the electrolyte is prepared from the following raw materials in percentage by weight: 70% of glycol, 1.5% of ammonium dihydrogen phosphate, 8% of ammonium pentaborate, 14% of ammonium adipate, 4.5% of breakdown voltage enhancing agent, 1% of phosphorous acid and 1% of deionized water. The preparation method comprises the following steps: taking and adding 70kg of glycol and 1kg of deionized water into a container, uniformly stirring, and heating to 110 DEG C; weighing 4.5kg of breakdown voltage increasing agent, 1.5kg of ammonium dihydrogen phosphate, 1kg of phosphorous acid, 8kg of ammonium pentaborate and 14kg of ammonium adipate by using a scale, and then, sequentially adding the materials into the container and stirring; and keeping the mixture at the constant temperature of 110 DEG C for 30 minutes, naturally cooling the mixture to the room temperature, and then discharging. The invention has the advantages of enhancing the breakdown voltage of the electrolyte, improving the capacity of repairing aluminum foil oxidation films by oxygen ions of the electrolyte, reducing generation of water and precipitation of hydrogen gas in the working process, and obviously improving the service performance of the aluminum electrolytic capacitor.

Owner:黄山振州电子科技股份有限公司

Method for Terminating or Reducing Water Flow in a Subterranean Formation

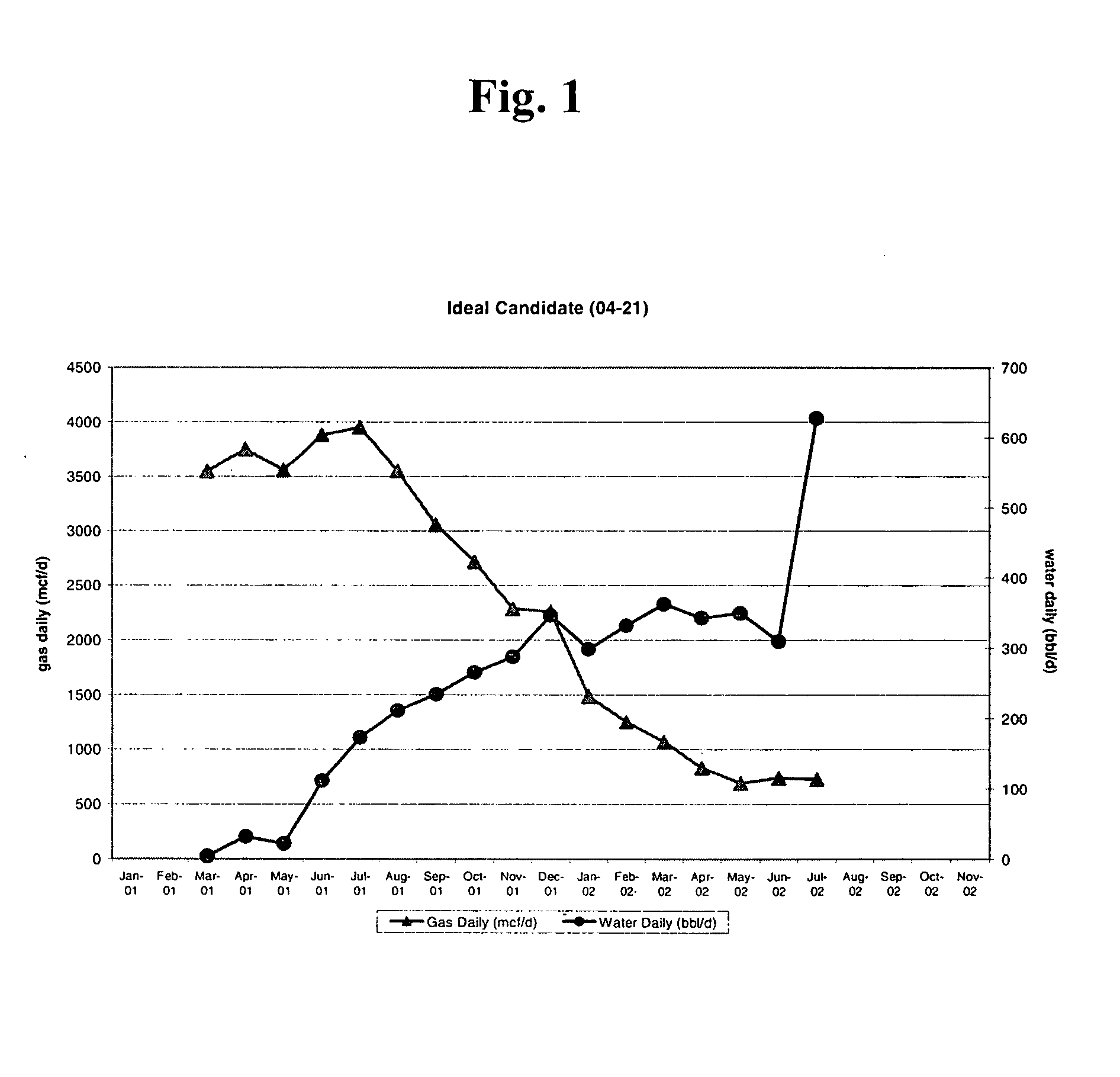

InactiveUS20090260813A1Optimize post treatment productionMinimizing and blocking waterflowFluid removalDrilling compositionWater productionPhenol

This invention relates to a method of reducing the deleterious effects of water production in a subterranean formation by placing an aqueous phase polymer and / or resin, which at a designated set up time, solidifies and blocks water conduits. This invention pertains specifically to a method of conditioning well bores and placing the polymer and displacing the polymer and / or resin to establish post treatment gas and oil permeability. Novel polymers and / or resins for use as a water barrier are disclosed, typified by phenoformaldehyde containing 1-2 weight % of at least one of sodium bisulphite, sodium metabisulphite or mixtures thereof. The method includes selecting a well having sizable hydrocarbon reserves with a production history of decrease of oil or gas production with concurrent increase of water production.

Owner:TERVITA

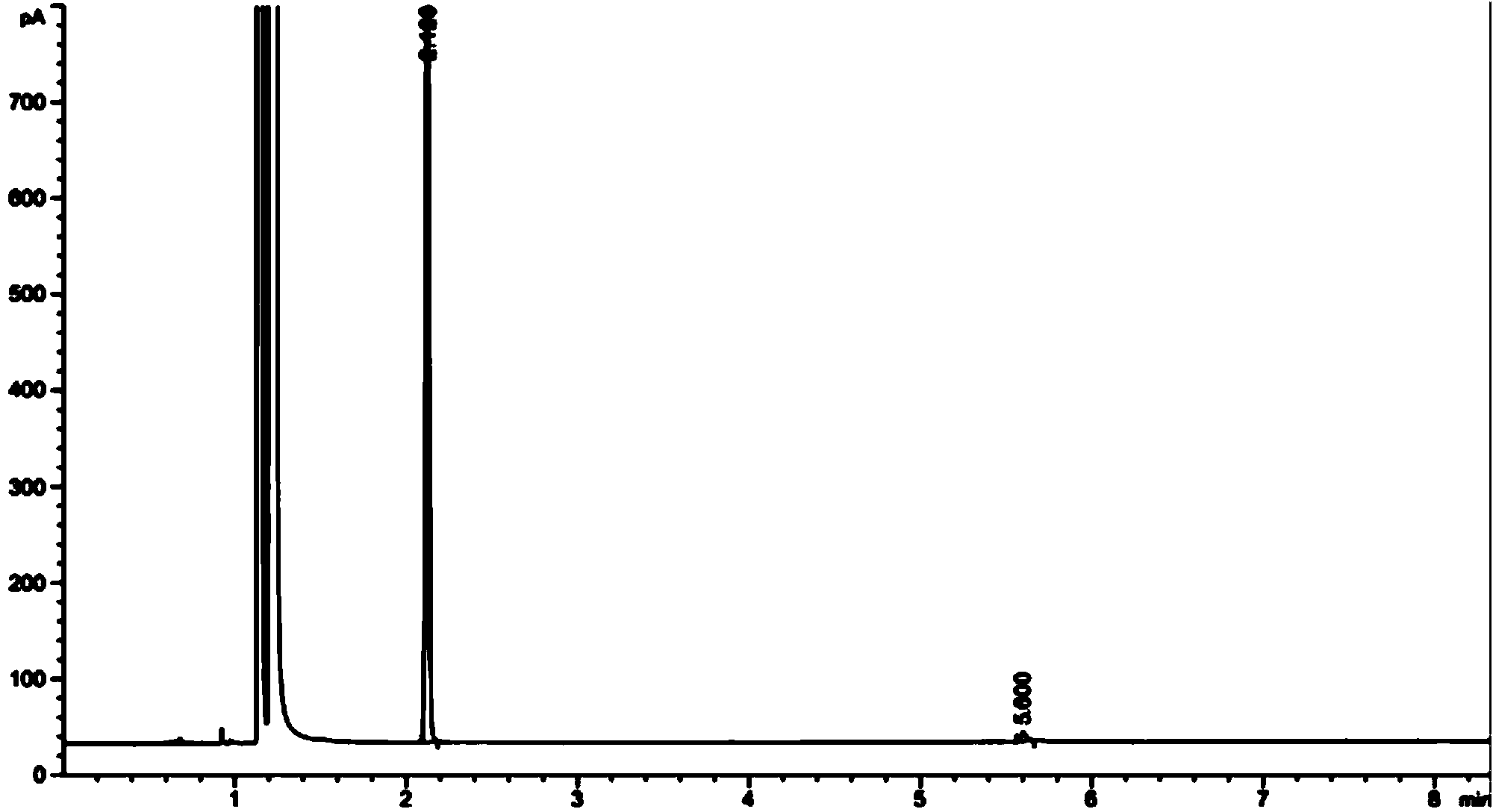

Preparation method of dioctyl sodium sulfosuccinate

ActiveCN103709078AReduce water productionInhibition of hydrolysis reactionSulfonic acids salts preparationSulfonic acid preparationMaleic anhydrideFine chemical

The invention belongs to the technical field of fine chemical production, and discloses a preparation method of dioctyl sodium sulfosuccinate. The preparation method mainly comprises the steps of an esterification stage: implementing alcoholysis reaction to isooctanol and maleic anhydride, adding a catalyst and a color fixative, implementing primary dual-esterification reaction at 115 DEG C, increasing temperature to 185-205 DEG C and carrying out reaction to generate diisooctyl maleate; and a sulfonation stage: implementing reflux reaction to diisooctyl maleate, sodium hydrogen sulfite and water, and removing residual isooctanol in a refluxing process to obtain dioctyl sodium sulfosuccinate. The preparation method disclosed by the invention is low in isooctanol addition, thus reducing raw material cost, and is free from vacuum reaction and isooctanol removal under high vacuum, so as to greatly reduce requirement on equipment; the isooctanol is removed in the sulfonation reaction, thus effectively reducing residue. The prepared dioctyl sodium sulfosuccinate is light in color, small in smell, good in wettability and low in isooctanol content.

Owner:广州星业科技股份有限公司

Production control method for discharge and mining stage of coal-bed methane well in southwest

ActiveCN107558963AIncrease gas productionLarge gas production dataFluid removalBottom hole pressureCoal water

Disclosed is a production control method for a discharge and mining stage of a coal-bed methane well in the southwest. The production control method comprises the steps that a law of coal-bed water production is gradually found out in an early stage of drainage; water production and pulverized coal production are observed; the decreasing amplitude of a dynamic liquid surface is controlled to be within the 1-6m / d by using a bottom hole pressure gauge; if the dynamic liquid surface drops fast, a discharge and mining system is lowered; if the dynamic liquid surface picks up, the discharge and mining system is raised, it is ensured that the pulverized coal is not produced in large quantities, when the water yield is obviously decreased, by this time, water in a coal bed is discharged in largequantities, a large area of a pressure drop funnel is formed, and the liquid surface is controlled to be above 10-15m of a coal bed top boundary, so that it is ensured that all the coal bed sections are below the coal bed water; two-phase gas-liquid flow which maintains the fact that in the coal bed, coal-bed methane is major and the water is minor is beneficial to carry out the remaining water inthe coal bed during gas producing, and the output pulverized coal is carried to the ground and avoided piling up in a wellbore and a pump barrel; and meanwhile, and bottom hole flow pressure is controlled by controlling wellhead casing pressure, and the purposes that the stable production period is prolonged and the gas yield of a single well is increased are achieved.

Owner:重庆矿产资源开发有限公司 +1

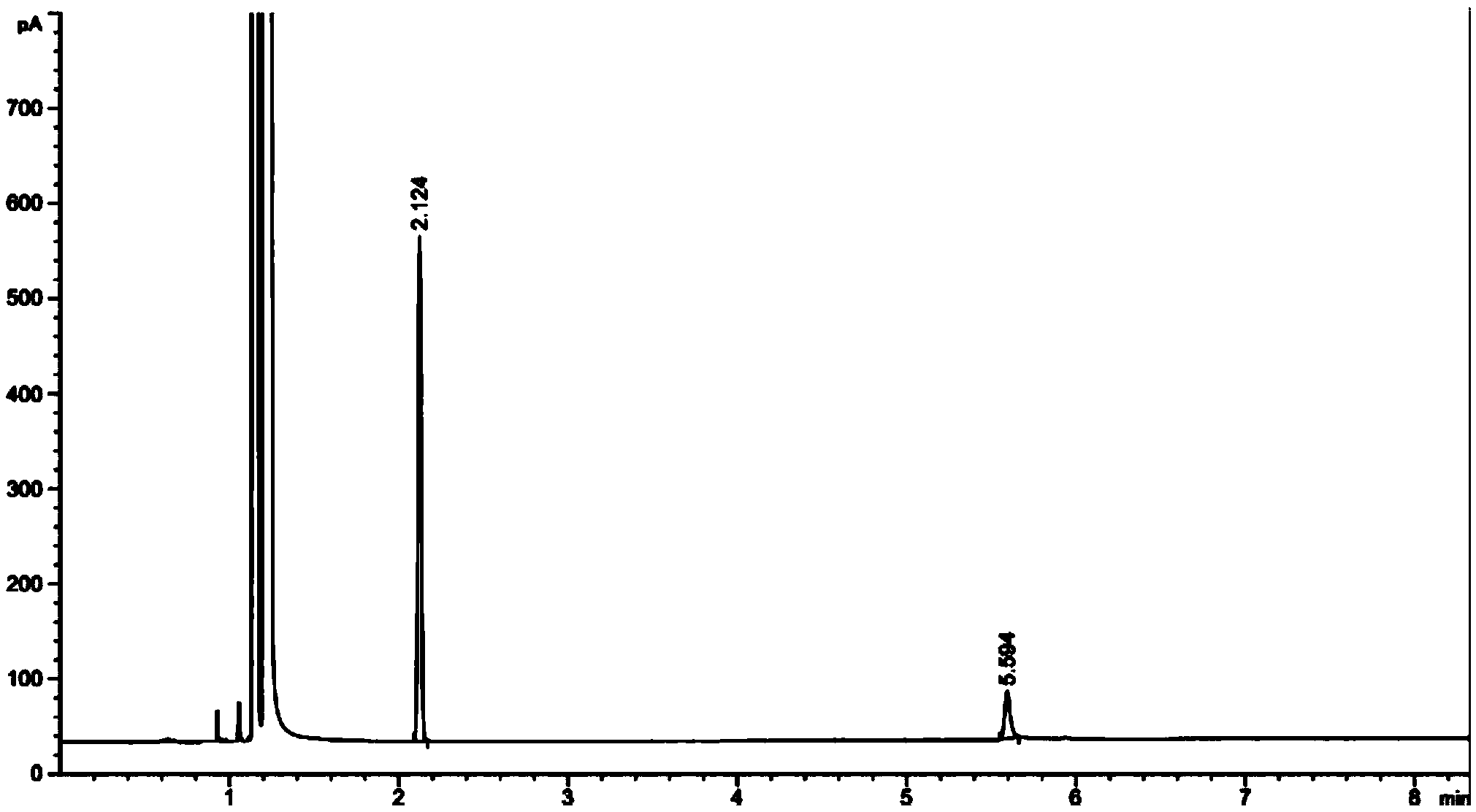

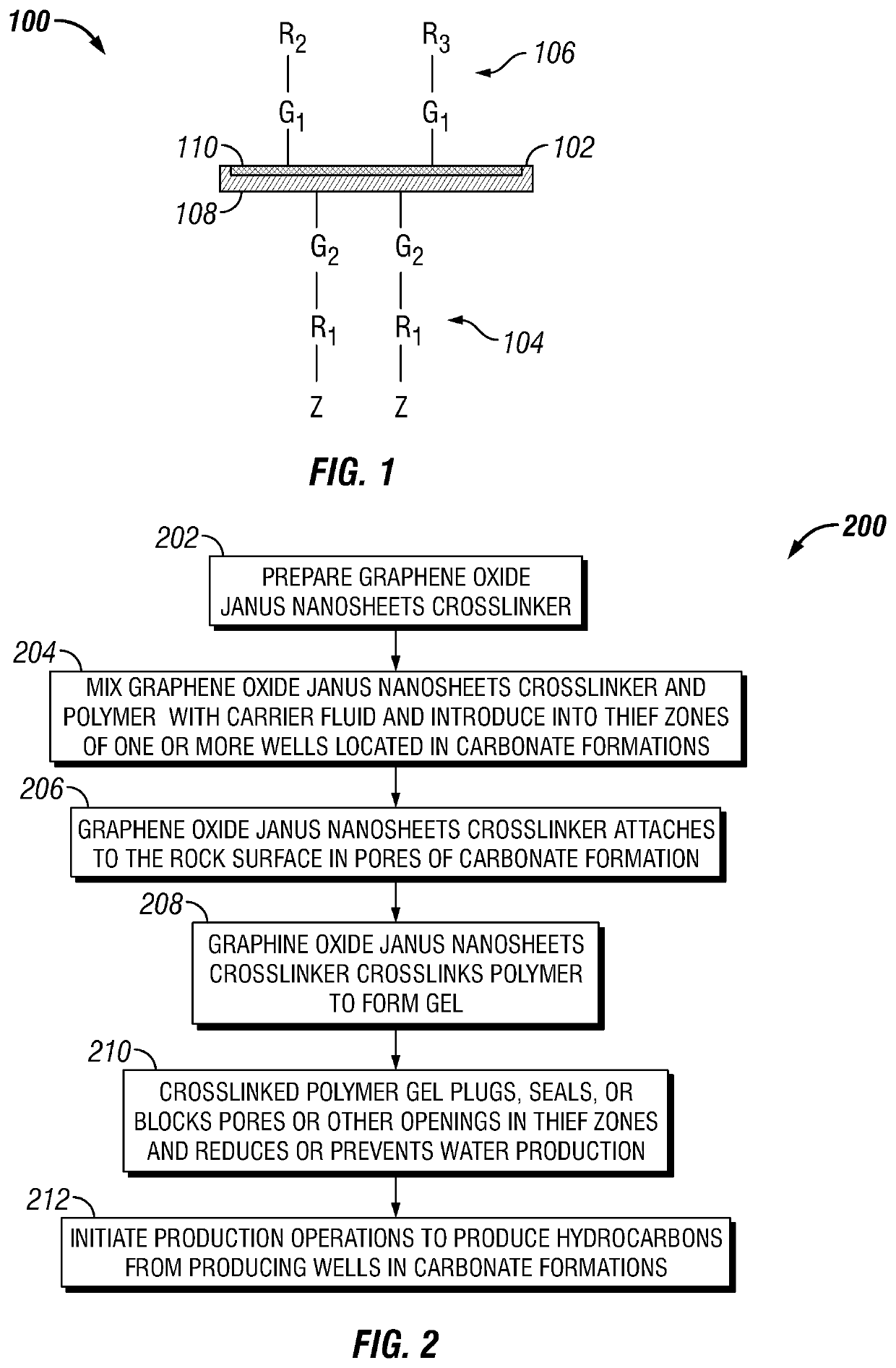

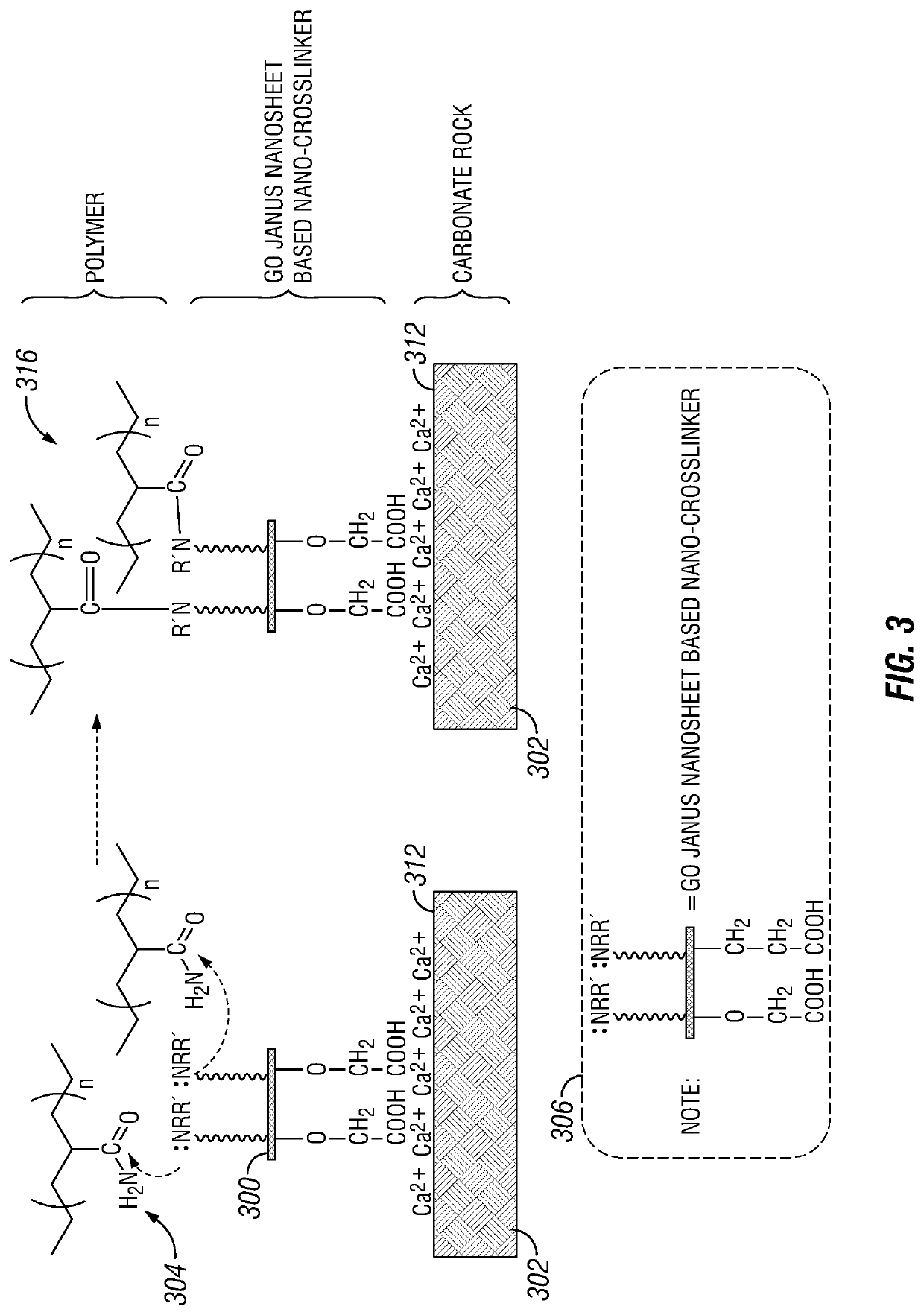

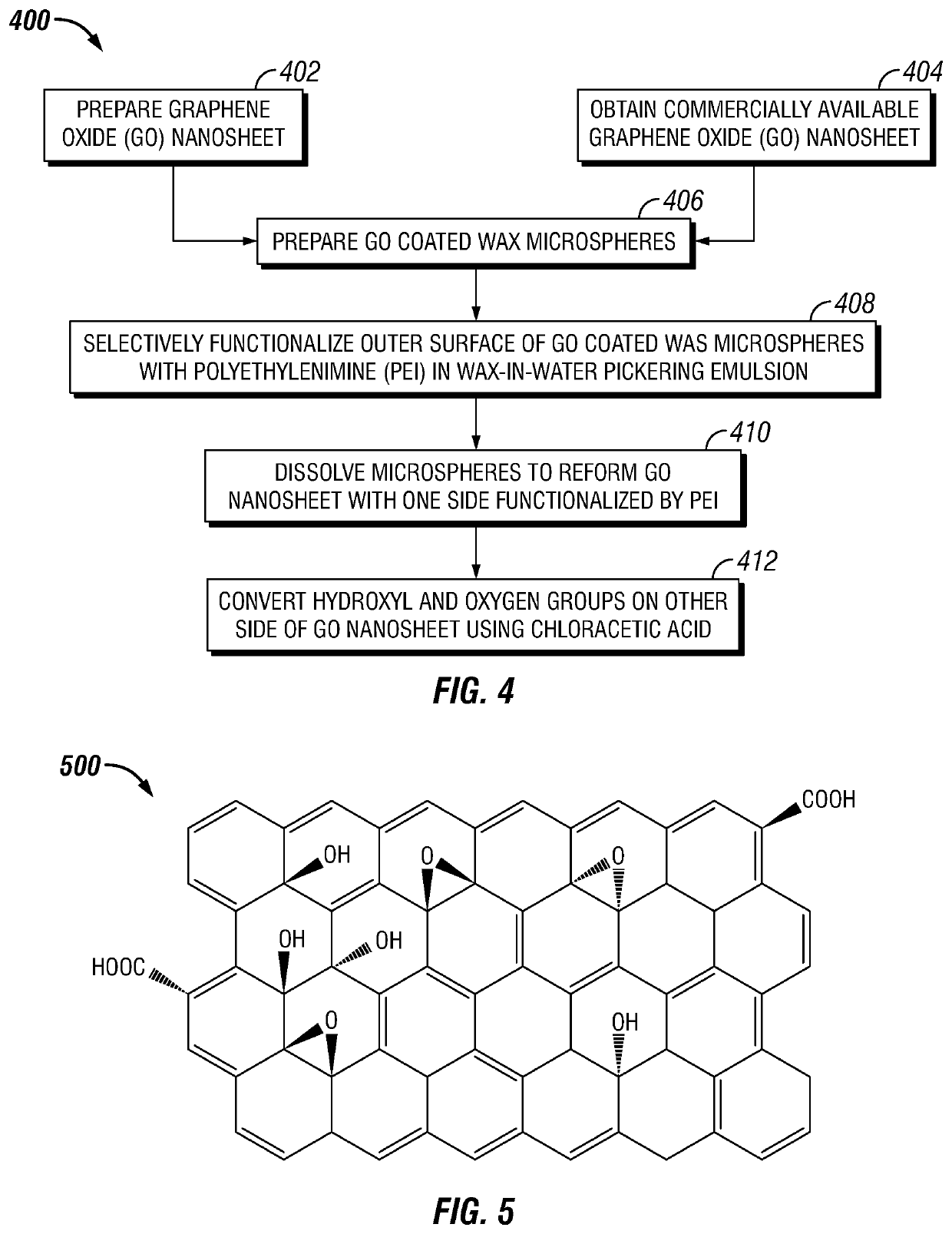

Methods and Compositions for Treating Thief Zones in Carbonate Formations Using Crosslinked Polymeric Systems With Graphene Oxide Janus Nanosheets Crosslinker

ActiveUS20210395093A1Suppress water productionEnhanced overall recoveryGrapheneNanotechnologyWater productionCross linker

A chemical gel system having a polymer and a graphene oxide Janus nanosheets crosslinker for treating thief zones in carbonate formations. The polymer and graphene oxide Janus nanosheets crosslinker may form a crosslinked polymer gel to reduce or prevent water production via thief zones during hydrocarbon production. The graphene oxide Janus nanosheets crosslinker includes a first side having negatively charged functional groups and a second side having amines. The negatively charged functional groups may include carboxyl groups, negatively charged oxygen groups, and hydroxyl groups. Methods of reducing water production in a thief zone using the graphene oxide Janus nanosheets crosslinker and methods of manufacturing the graphene oxide Janus nanosheets crosslinker are also provided.

Owner:SAUDI ARABIAN OIL CO

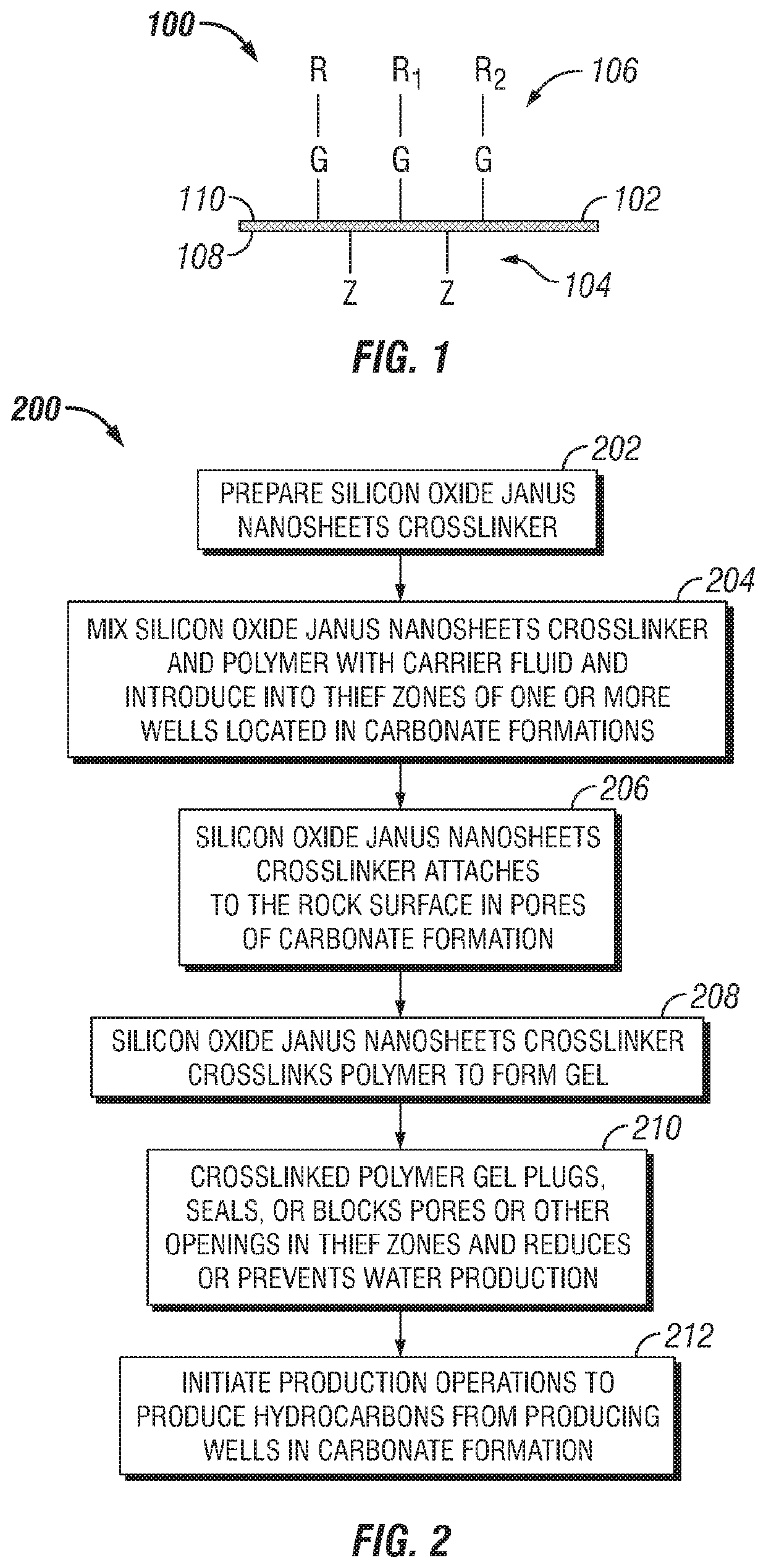

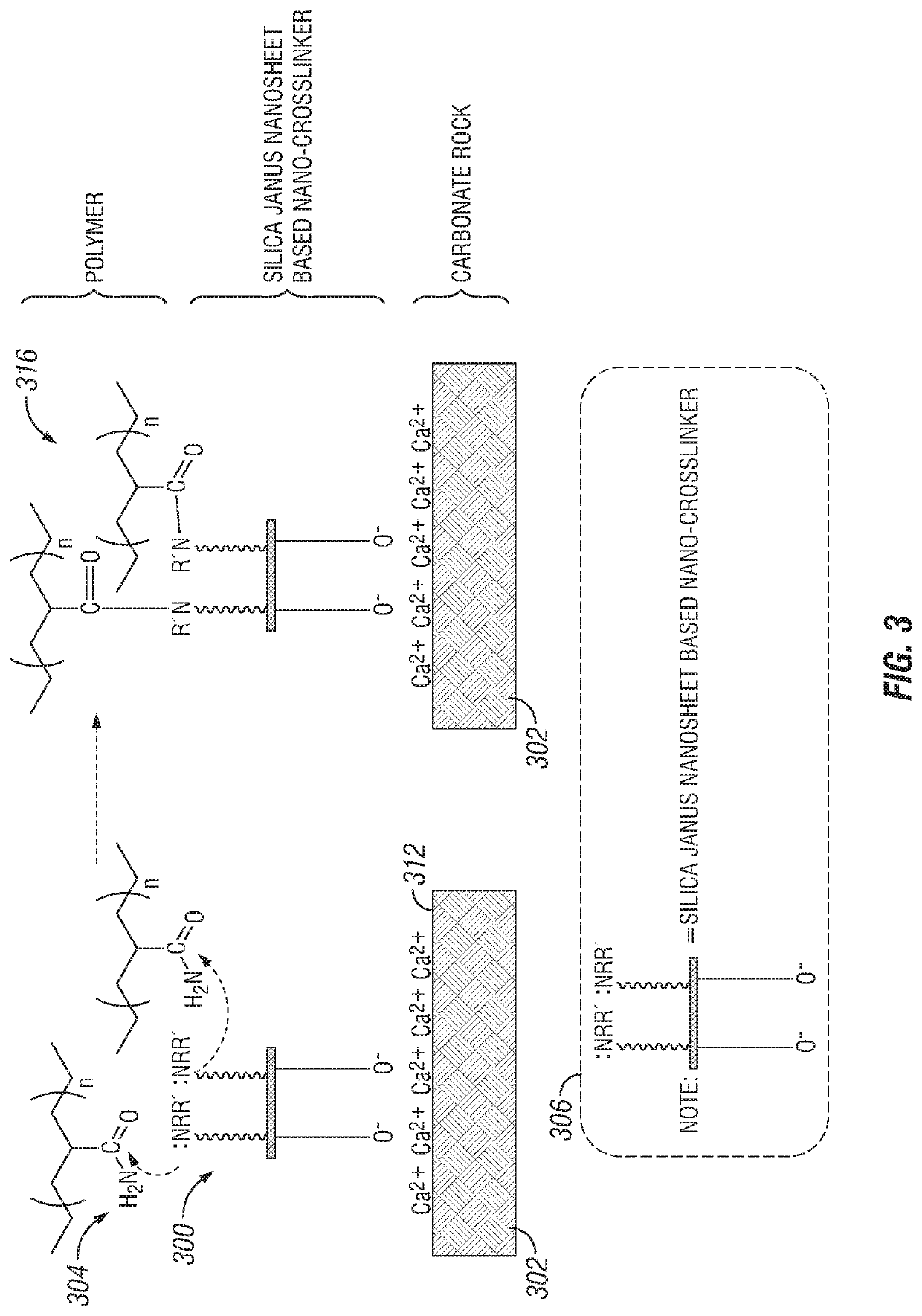

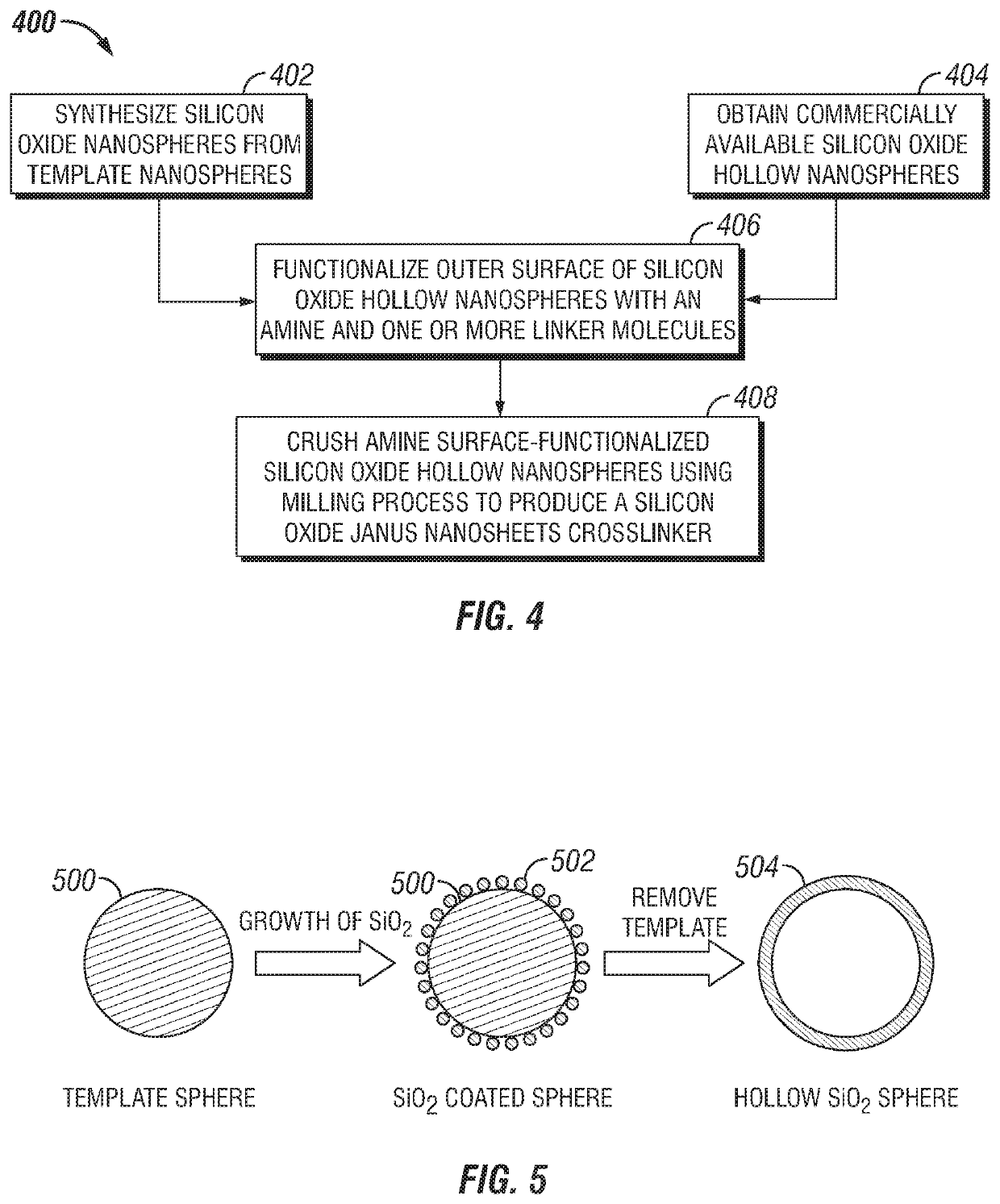

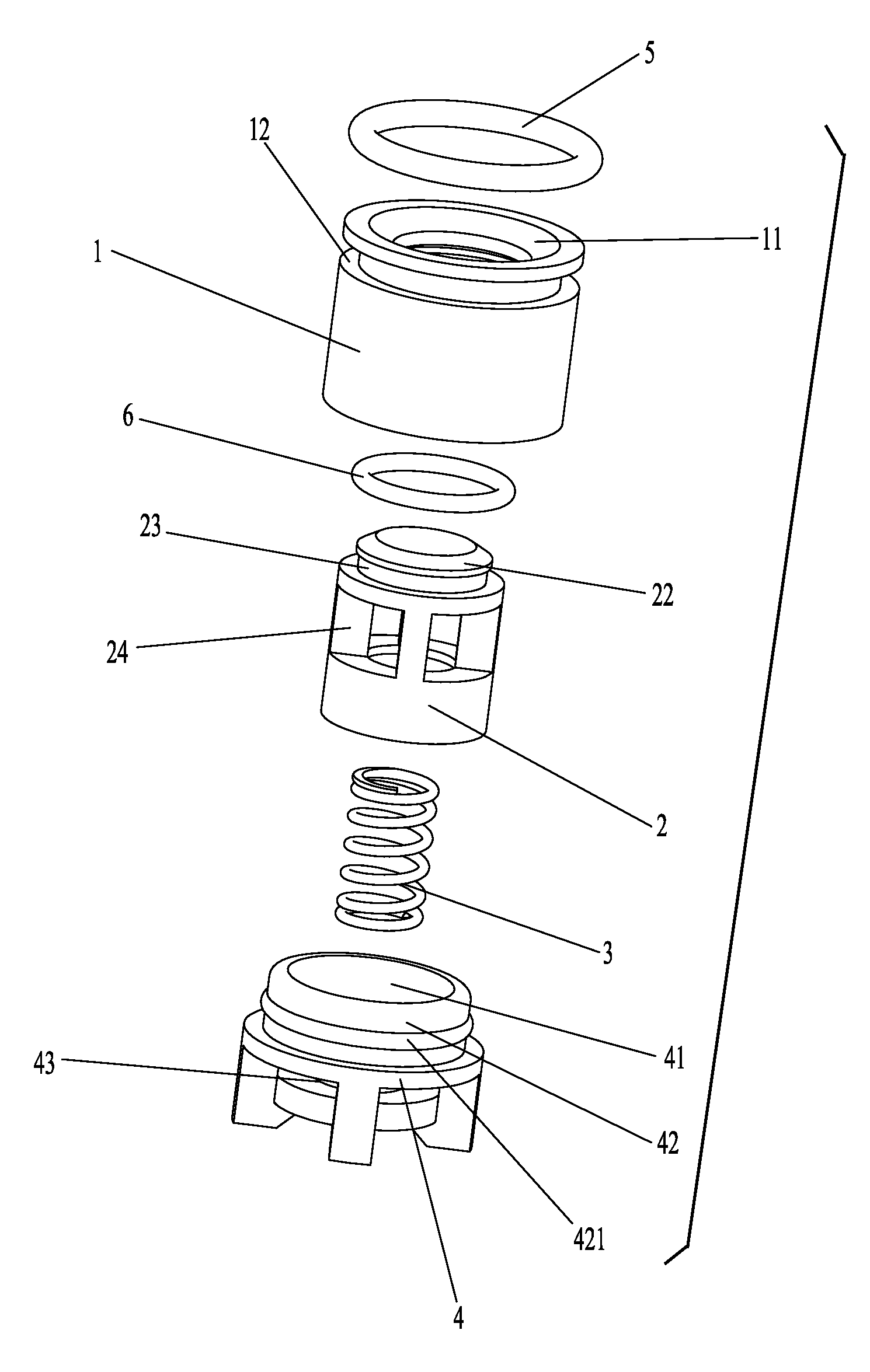

Methods and Compositions for Treating Thief Zones in Carbonate Formations Using Crosslinked Polymeric Systems with Silicon Dioxide Janus Nanosheets Crosslinker

ActiveUS20210395098A1Suppress water productionEnhanced overall recoveryMaterial nanotechnologySilicaWater productionCross linker

A chemical gel system having a polymer and a silicon oxide Janus nanosheets crosslinker for treating thief zones in carbonate formations. The polymer and silicon oxide Janus nanosheets crosslinker may form a crosslinked polymer gel to reduce or prevent water production via thief zones during hydrocarbon production. The silicon oxide Janus nanosheets crosslinker includes a first side having negatively charged functional groups and a second side having amines. The negatively charged functional groups may include negatively charged oxygen groups and hydroxyl groups. Methods of reducing water production in a thief zone using the silicon oxide Janus nanosheets crosslinker and methods of manufacturing the silicon oxide Janus nanosheets crosslinker are also provided.

Owner:SAUDI ARABIAN OIL CO

Water-saving control device and the control method thereof

InactiveUS20110155252A1Reduce water productionArea is appliedDomestic plumbingSpray nozzlesWater savingStream flow

Owner:XIAMEN SOLEX HIGH TECH IND CO LTD

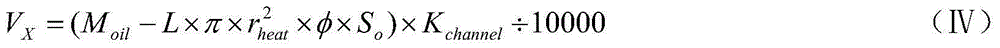

Multi-channel reservoir physical model of heavy oil thermal production well to be constructed and application thereof

The invention relates to a multi-channel reservoir physical model of heavy oil thermal production well to be constructed. According to the model, a filling channel group which covers three penetration rate ranges of high, middle and low levels and is filled with oil-water with different degrees is prepared by stratum sand, crude oil and stratum water, or simulation stratum sand, simulation crude oil and simulation stratum water. By use of the model, in site channel sealing and water plugging by plugging agent injecting, solidification and plugging effects in a construction well of heavy oil thermal production are accurately simulated. Thus, simulation test of channel sealing and water plugging in heavy oil thermal production well is carried out, plugging agent property is regulated and optimized, and construction control data of in site channel sealing and water plugging in heavy oil well is tested and acquired to provide guidance for compiling construction designs of channel sealing and water plugging, to increase success rate of channel sealing and water plugging construction and to increase production. By applying the physical model and corresponding test method in guiding selective channel sealing and water plugging in site of heavy oil thermal production well, great economic benefit and social benefit will be brought about and the application aspect is quite broad.

Owner:CHINA PETROLEUM & CHEM CORP +1

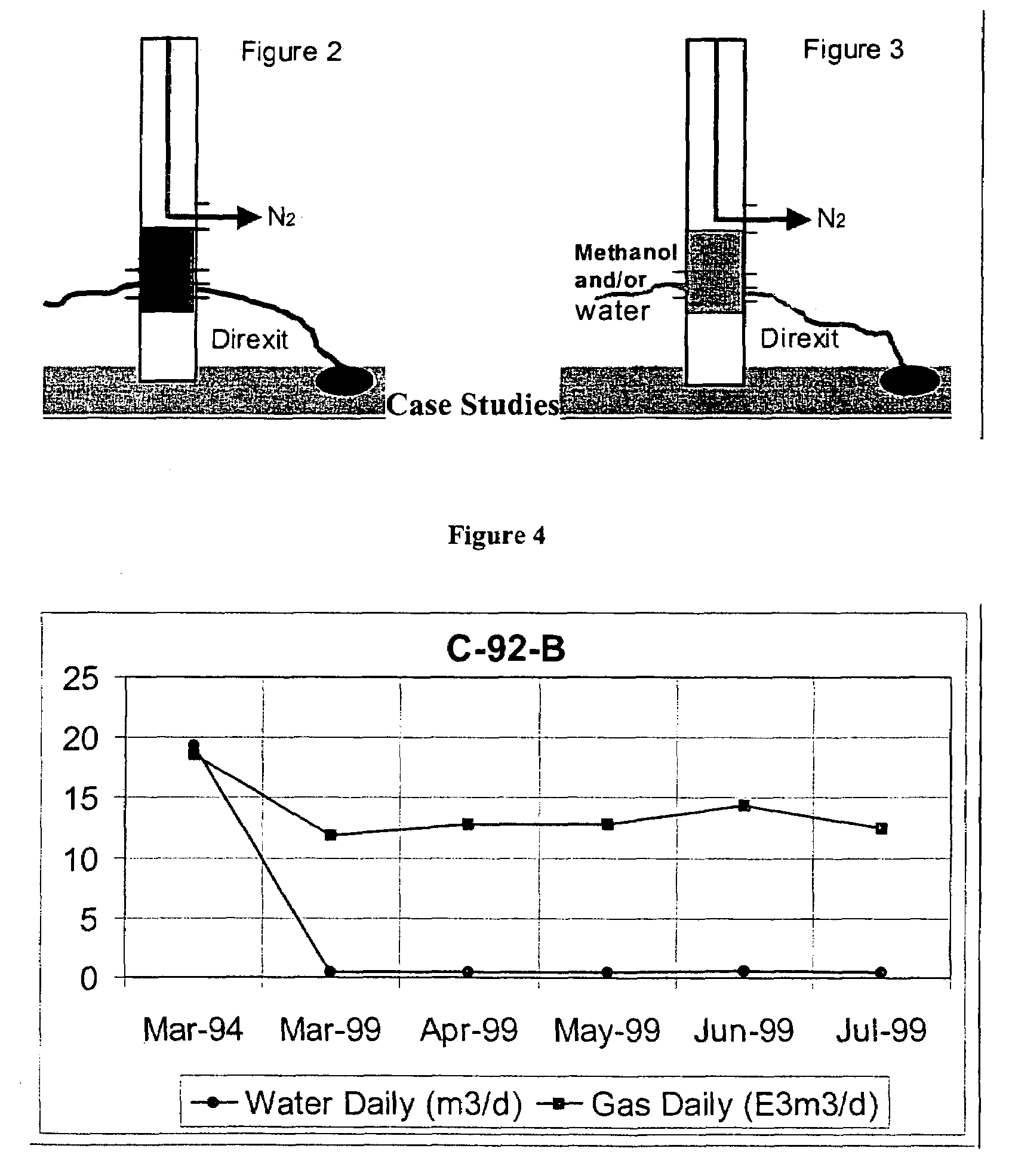

Method for terminating or reducing water flow in a subterranean formation

InactiveUS7281579B2Reduce water productionAdjustable densitySurveyFluid removalWater productionWater flow

This invention relates to a method of reducing the deleterious effects of water production in a subterranean formation by placing an aqueous phase polymer and / or resin, which at a designated set up time, solidifies and blocks water conduits. This invention pertains specifically to a method of placing the polymer and displacing the polymer and / or resin to establish post treatment gas and oil permeability.

Owner:AQUEOLIC CANADA

Oil refining and chemical sewage processing and recovering equipment and method thereof

InactiveCN104291516ANo emissionsIncrease water productionTreatment using aerobic processesGeneral water supply conservationActivated carbon filtrationBiological filter

The invention provides oil refining and chemical sewage processing and recovering equipment and a method thereof. The equipment comprises a mixing reaction tank, an anti-blocking air-floatation pool, a multistage matched biological filter tank, a clean water tank, a precision filter, an ejector, an ozone generator, a mixer, an intermediate pool, a biology activated carbon filter and a clean water reservoir which are connected in order by a mechanical mode. If desalination is not required, the reuse water can be fed into an industrial pipe network for use, if desalination is required, a hollow ultrafilter membrane or a micro filter membrane and a reverse osmosis membrane, a desalinized water pool and the reverse osmosis membrane or the nanofiltration membrane and a machinery steam compression system are added. The multistage matched biological filter tank has effects of biodegradation of organic matter and filtering, purifying degree of polluted water can be increased, the hollow ultrafilter membrane or the micro filter membrane and the reverse osmosis membrane are employed for desalination treatment on the polluted water, the reuse water is better adapted to industrial application, and condensation and crystallization treatment can be carried out on the polluted water by the reverse osmosis membrane or the nanofiltration membrane and the machinery steam compression system, so that waste water is not discharged to outside.

Owner:韩春来 +2

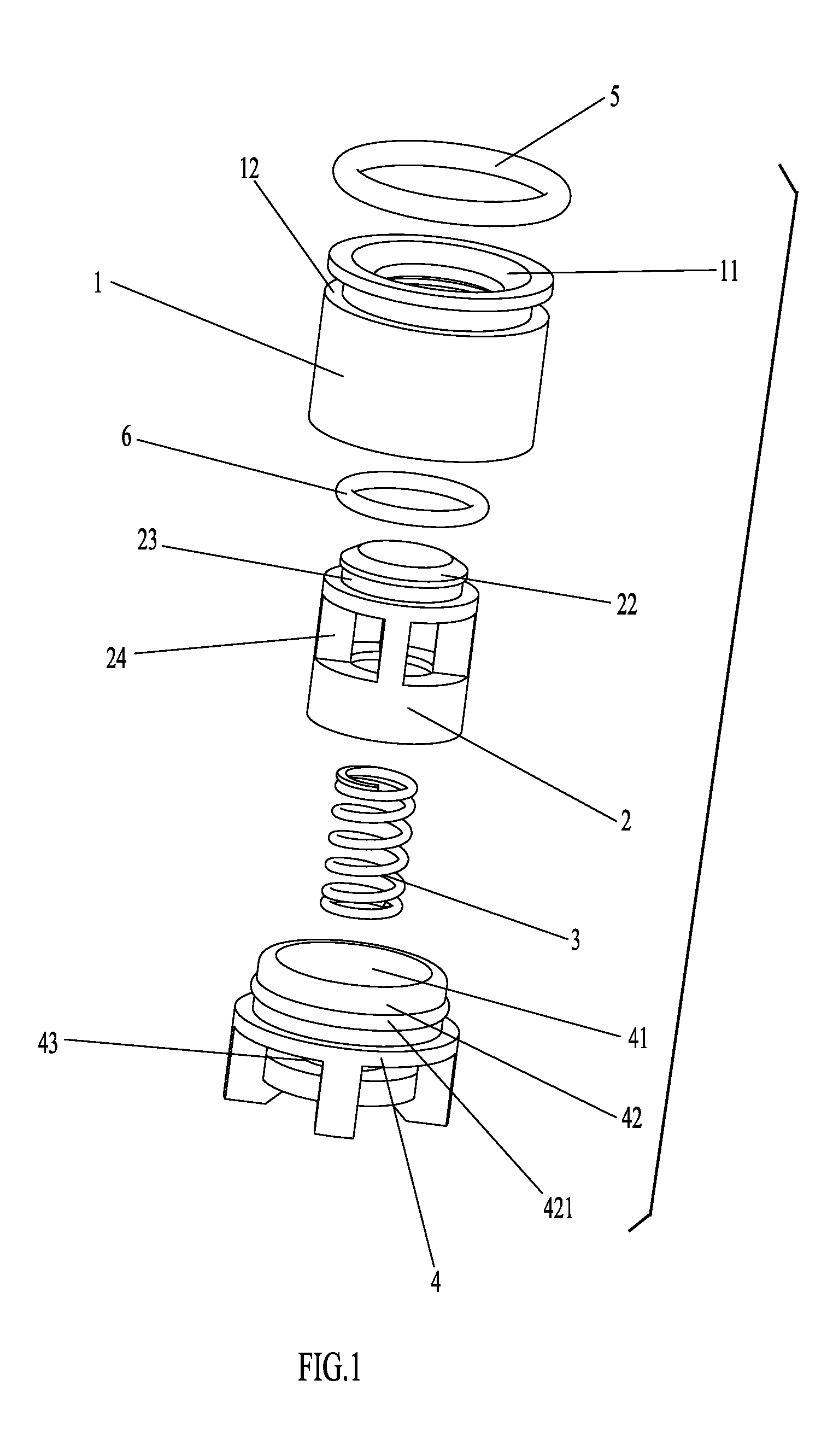

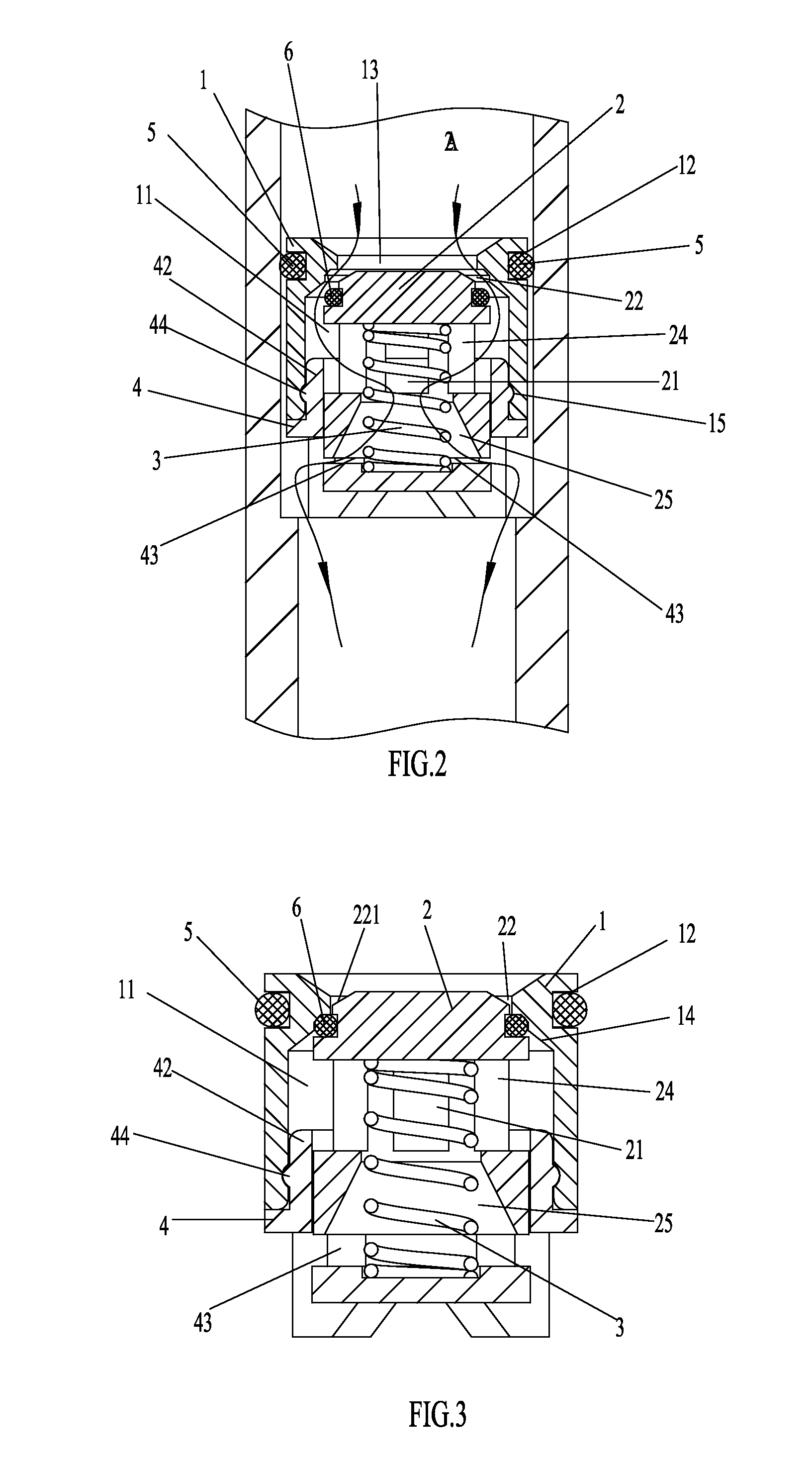

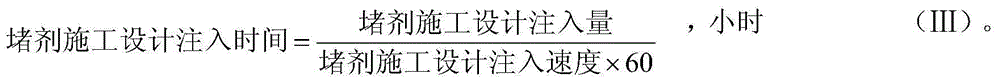

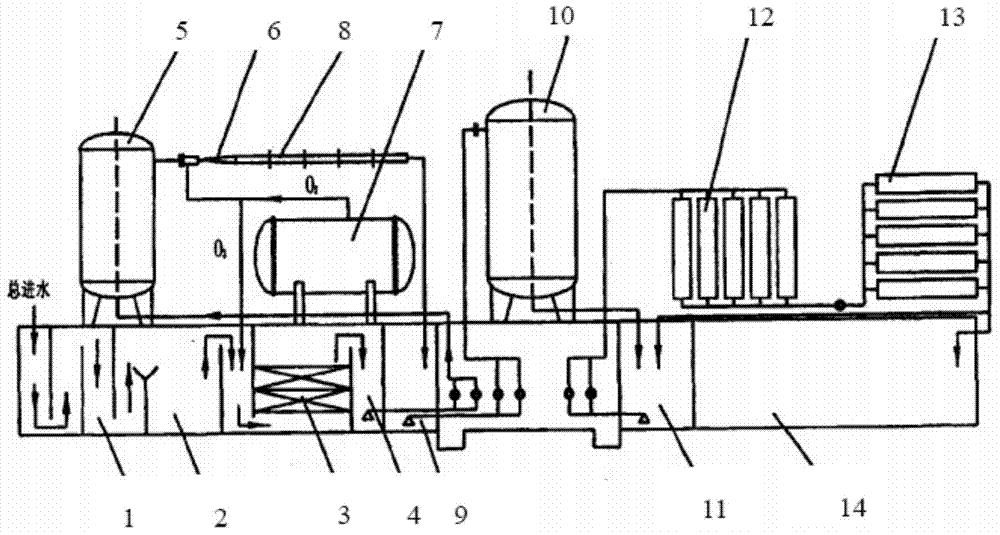

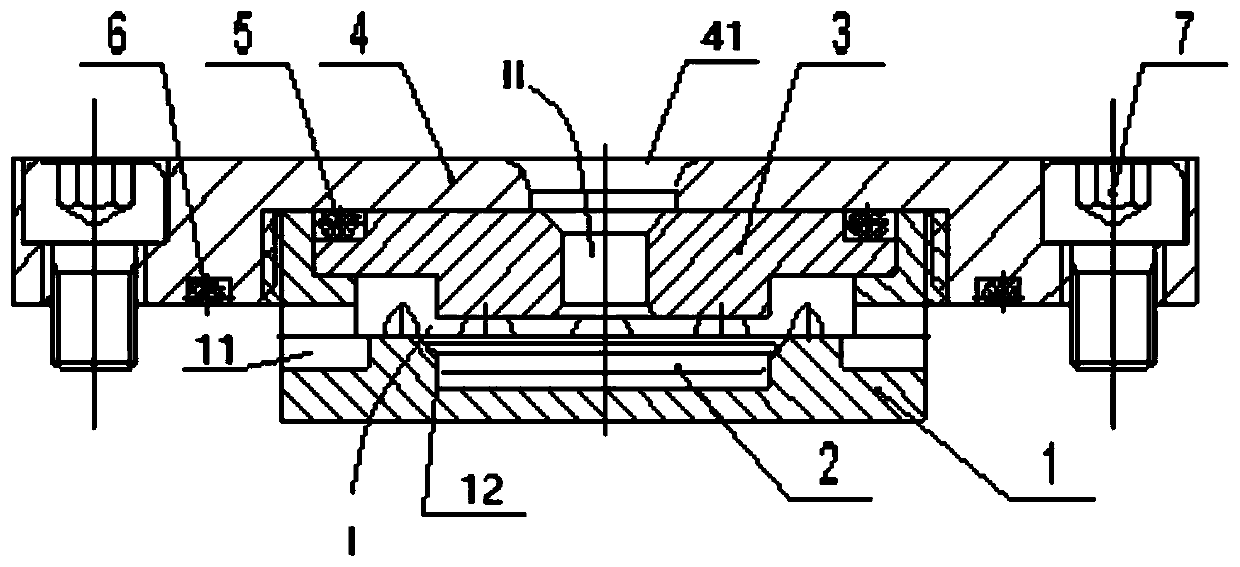

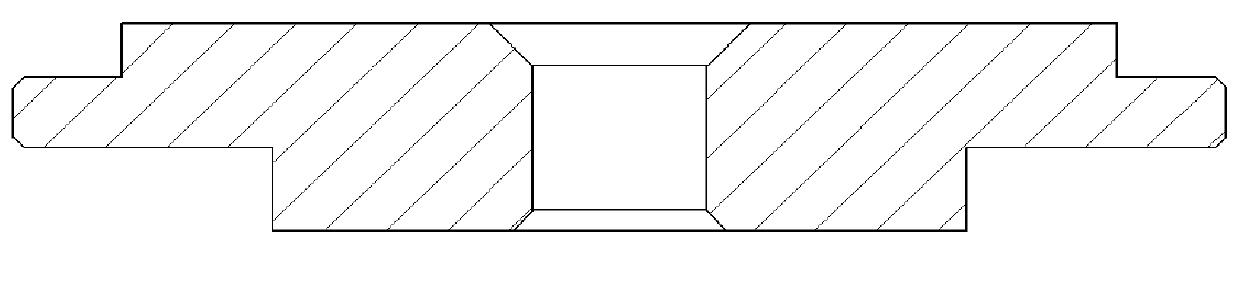

Automatic inflow control device and pipe column

The invention relates to an automatic inflow control device and a pipe column. The automatic inflow control device comprises an upper shell, a lower shell and a disc. A fluid inlet is formed in the upper shell. A cavity is formed between the upper shell and the lower shell, a fluid channel is formed between the fluid inlet and the cavity, and the disc is suitable for flowing in the cavity. Fluid outlets are formed in the side face of the cavity. The pipe column comprises sealing separation media and the automatic inflow control devices. The multiple automatic inflow control devices which are connected through a porous base pipe are arranged in the pipe column, and the corresponding sealing separation media are arranged between every two adjacent automatic inflow control devices. The automatic inflow control device and the pipe column have the advantages of blockage resistance, high pressure difference resistance and scale formation resistance, and are particularly suitable for exploitation of an oilfield which is characterized in that the nonhomogeneity is high, bottom water coning operation is fast, and the water content is high.

Owner:CHINA NAT OFFSHORE OIL CORP +2

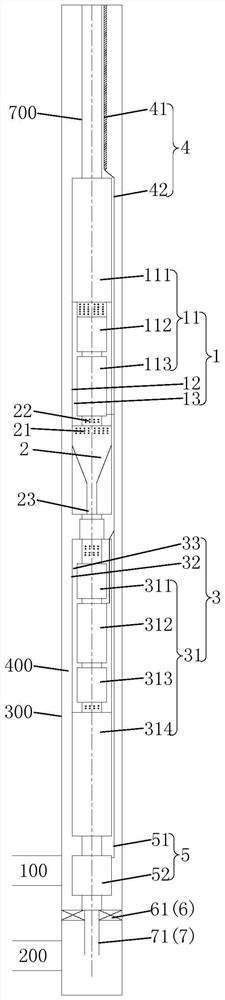

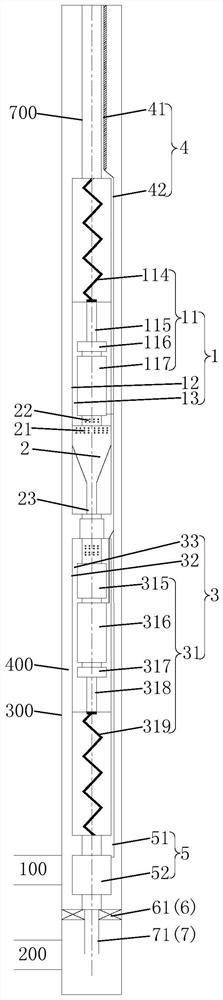

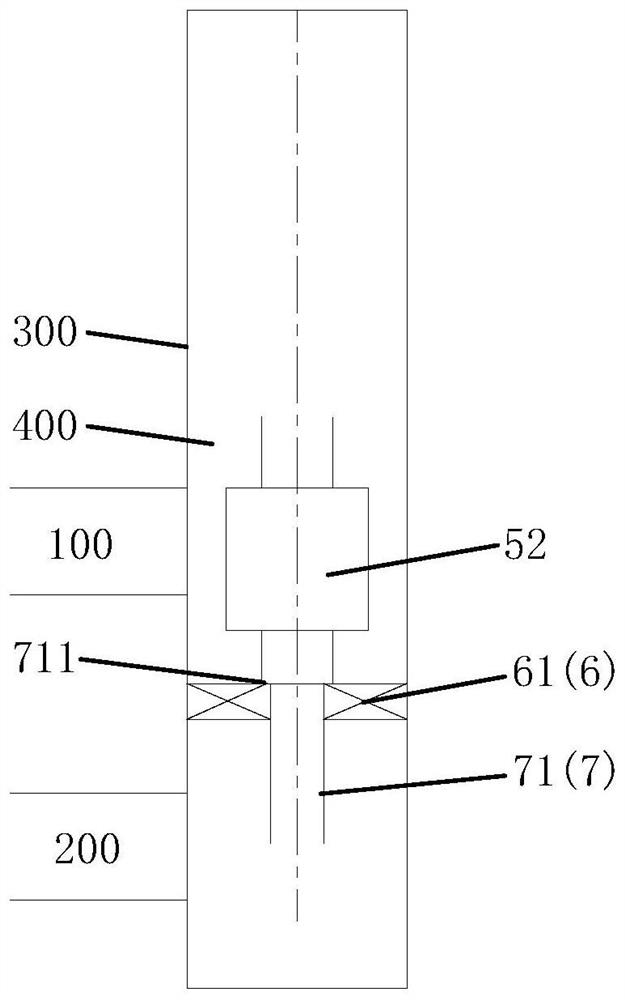

Underground oil-water separation same-well injection-production system and pipe column

ActiveCN113431529ARealize stable oil and water controlReduce water productionGeothermal energy generationFluid removalDirectional wellWater flow

The underground oil-water separation same-well injection-production system and a pipe column. The underground oil-water separation same-well injection-production system comprises a lifting system, an oil-water separation system and a reinjection system which are sequentially connected from top to bottom, wherein the oil-water separation system is provided with an oil-water inlet communicating with a production layer, an oil outlet communicating with the lifting system and a water outlet communicating with the reinjection system, the reinjection system communicates with a water injection layer, an oil-water mixture of the production layer enters the oil-water separation system through the oil-water inlet, the oil-water separation system divides the oil-water mixture into separated rich oil and separated water, the separated rich oil flows out of the oil outlet and then is extracted through the lifting system, and the separated water flows out of the water outlet and then is reinjected into the water injection layer through the reinjection system. According to the underground oil-water separation same-well injection-production system, oil-water separation, water injection and oil extraction can be achieved in one well at the same time, and the device can be tripped into special structure wells such as an inclined well, a highly-deviated well and a directional well and can be used for 51 / 2''cased wells.

Owner:PETROCHINA CO LTD

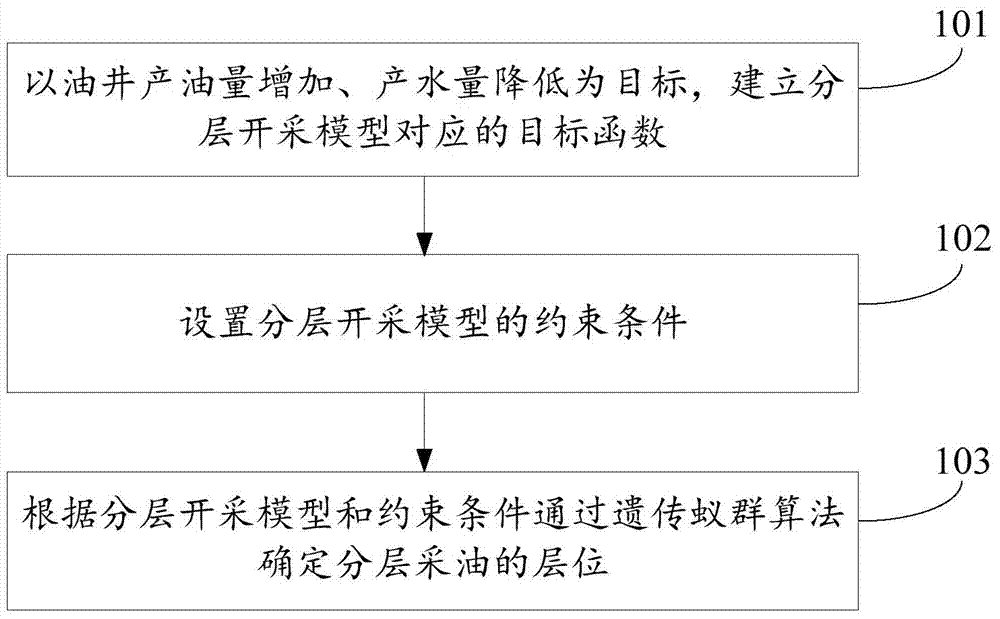

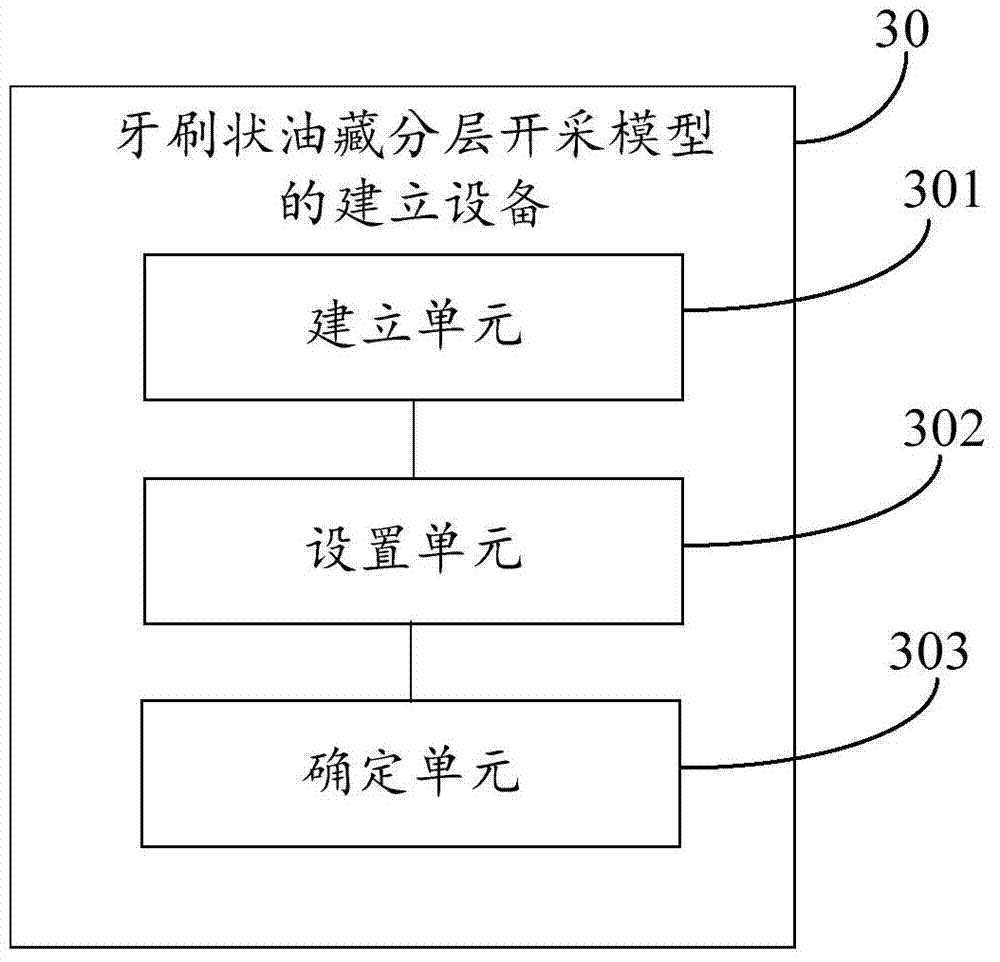

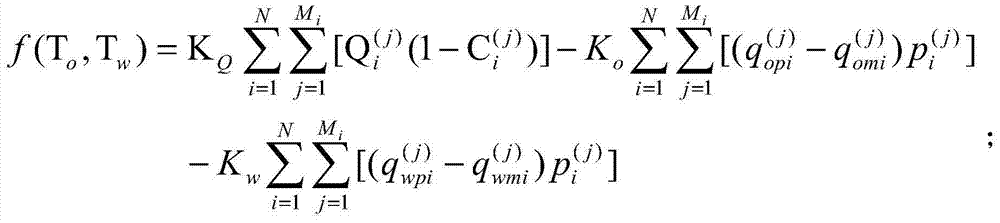

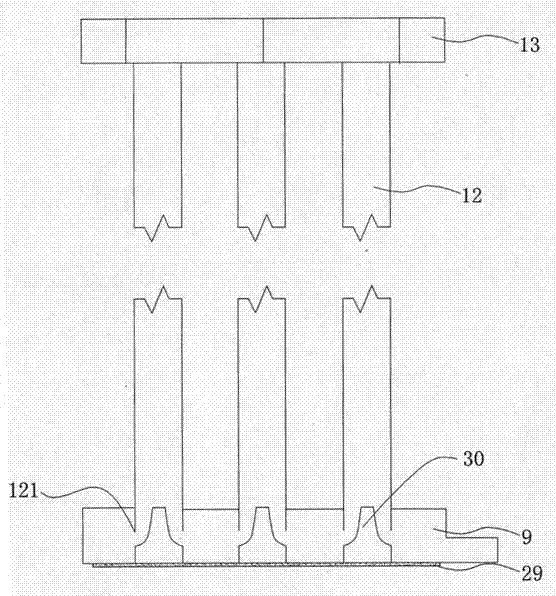

Establish method and device for toothbrush-shaped oil deposit slicing production model

ActiveCN104747141AImprove targetingIncrease oil productionFluid removalGenetic algorithmsProduction modelOil production

The invention discloses an establish method and device for a toothbrush-shaped oil deposit slicing production model, and belongs to the field of petroleum industry oil production engineering. The method includes the steps of establishing a target function corresponding to the slicing production model with the oil well oil production increase and the water yield decrease as targets, setting constraint conditions of the slicing production model, and determining the slicing production layer position through the genetic ant algorithm according to the slicing production model and the constraint conditions. The problem that the pertinence of the oil layer production is poor is solved, the effect on improving the pertinence of the oil layer production is achieved, and the method and the device are used for the slicing production of toothbrush-shaped oil deposit.

Owner:PETROCHINA CO LTD

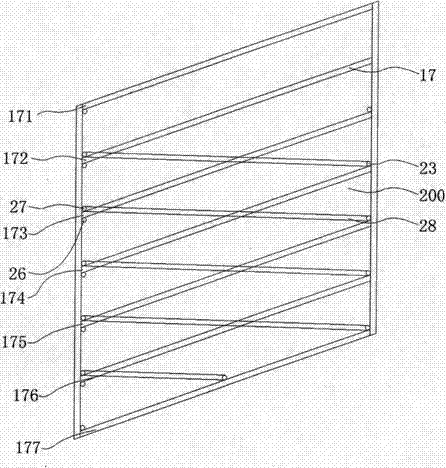

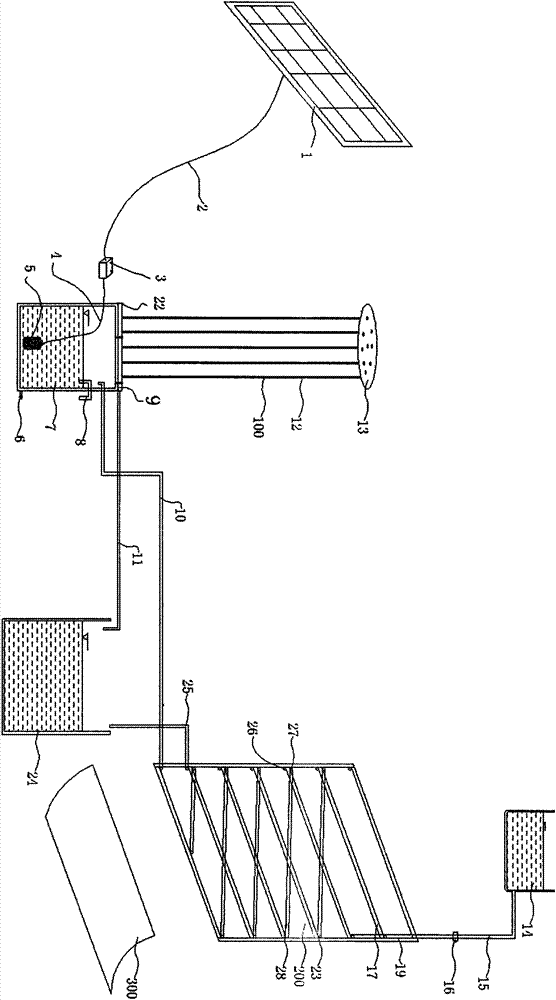

Household type solar seawater desalting system

InactiveCN103693795AEasy to installEasy to operateGeneral water supply conservationSeawater treatmentSeawaterLatent heat

The invention discloses a household type solar seawater desalting system. The household type solar seawater desalting system is characterized by comprising a solar electric plate, an electric air pump, a seawater tank, a water inlet tube, a fresh water tank, a fresh water guide tube I, a bubbling-evaporating device, a multi-stage evaporating device and a U-shaped light gathering slot, wherein the seawater tank is arranged above the multi-stage evaporating device; the U-shaped light gathering slot is arranged below the multi-stage evaporating device; the solar electric plate is connected with the electric air pump by virtue of a power wire. According to the household type solar sweater desalting system disclosed by the invention, the conventional distillation technology (passive type distillation) and a bubbling-evaporating technology (active type distillation) are combined and improved, latent heat of steam is recycled, so that not only can the defects of a passive type distillation system be overcome, but also the device is miniaturized, and therefore, the household type solar seawater desalting system is more beneficial to application of island residents.

Owner:ZHEJIANG OCEAN UNIV

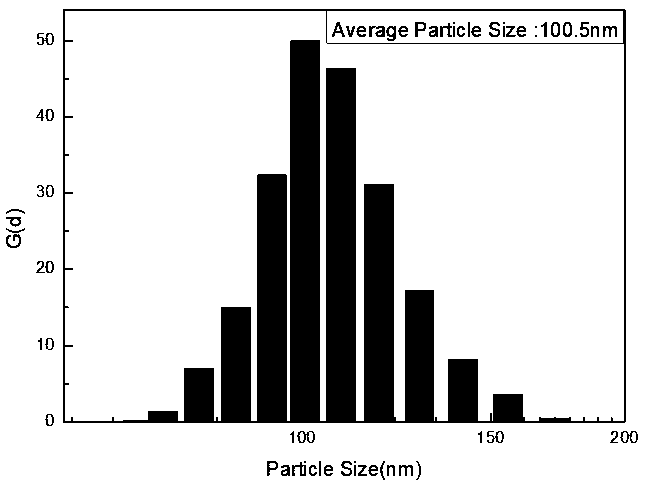

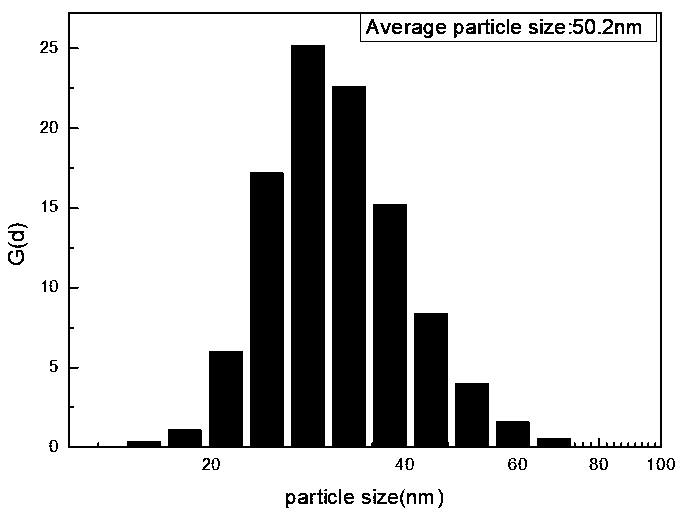

Resin microsphere plugging agent and preparation method therefor

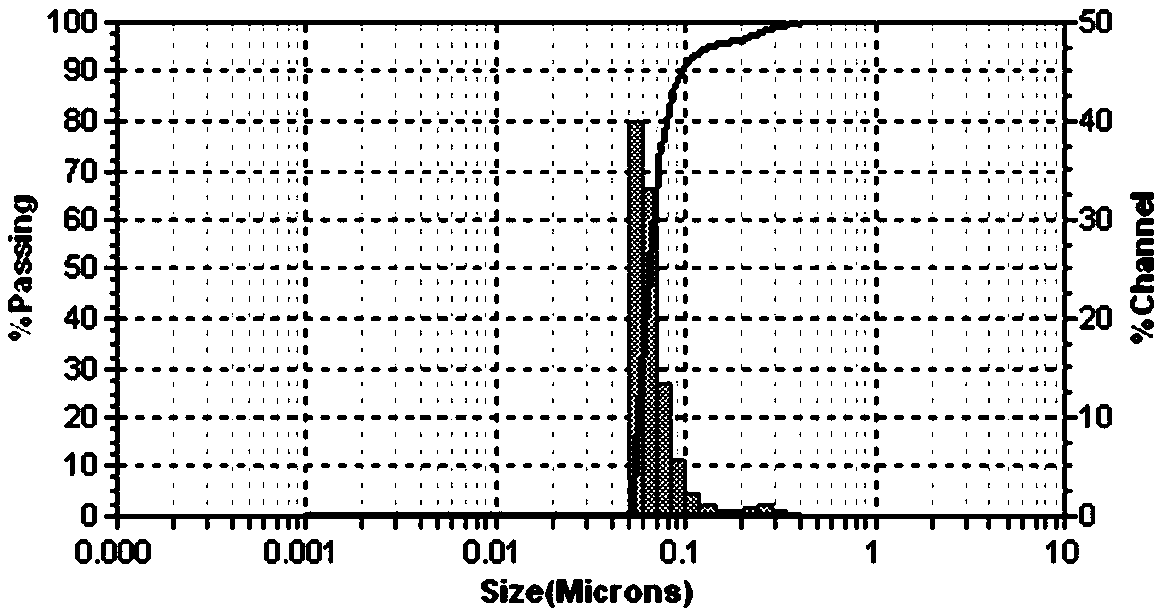

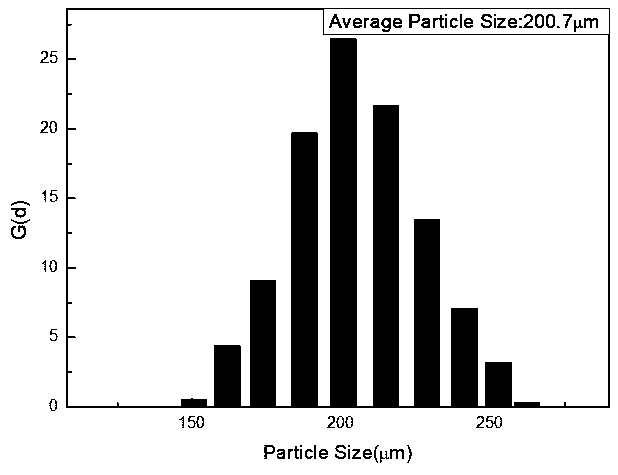

ActiveCN108929663AEvenly dispersedUniform particle sizeDrilling compositionResin microsphereFunctional monomer

The invention relates to a resin microsphere plugging agent and a preparation method therefor. The resin microsphere plugging agent is prepared from the following ingredients in parts by mass: 30-60 parts of alkene monomer, 5-40 parts of ester monomer, 5-10 parts of functional monomer, 0.1-1 part of organic dispersant, 0.3-0.5 part of inorganic dispersant, 0.6-1 part of oil-soluble initiator and 80-120 parts of distilled water. The resin microsphere plugging agent is obtained through adding the organic dispersant and the inorganic dispersant into deionized water, carrying out heating, stirringand mixing, adding the oil-soluble initiator into a mixture of the alkene monomer, the ester monomer and the functional monomer, dissolving the oil-soluble initiator, mixing all the ingredients, carrying out a polymerization reaction so as to obtain a dispersion solution of different particle sizes, and carrying out stirring to cool the dispersion solution to room temperature. According to the resin microsphere plugging agent and the preparation method therefor, the technological operations are simple, and prepared resin microspheres have the advantages of uniform particle size, easy-controlled reaction temperature, high yield, good stability, good flexibility, good transparency, good heat resistance and difficulty in degradation.

Owner:HENAN ZHENGJIA ENERGY ENVIRONMENTAL PROTECTION CO LTD

Operation method of hollow fiber membrane module

ActiveCN109420433AAvoid driftingAvoid blind areasUltrafiltrationWater/sewage treatment bu osmosis/dialysisFiberHollow fibre membrane

The invention relates to an operation method of a hollow fiber membrane module. The operation method comprises the following steps: performing the forward washing at a primary side, performing the membrane filtering of raw water, and performing the back washing for water produced by the filtering of the secondary side, wherein the forward washing at the primary side comprises liquid-phase flow orgas / liquid mixed-phase flow washing. By adopting the operation method, the excellent turbid discharging performance of the module is ensured, while the broken problem of a membrane wire can be effectively prevented. The module has a rectifying effect of fluid flowing by the outer side of a hollow fibrous membrane towards a central part of a radial direction at the lower side of an irrigation filling part of a water production end and flowing from the center part of the radial direction at the lower side of the irrigation filling part of water production to the outer side of the radial direction in a radioactive manner when in the primary side forward washing. By adopting the operation method of the hollow fiber membrane module, the bias flow phenomenon of the upper part of the module in case of the primary side forward washing can be effectively prevented, and the turbid discharging performance of the module can be further improved.

Owner:TORAY ADVANCED MATERIALS RES LAB CHINA

Quick countercurrent-type water purifier

InactiveUS20060131221A1Large quantity of waterReduce water productionWater treatment parameter controlSettling tanks feed/dischargeWater storage tankControl circuit

A quick countercurrent-type water purifier configured with two filters, two motors, a control circuit, a purified water storage tank and a waste water tank, wherein a pipe extends from the waste water tank. Moreover, a raw water inlet pipe connects to the pipe through one of the motors that thereon forces water through branch pipes into water inlets at bottoms of the two filters. A pipe branches out from each of the two water inlets, and connects to the waste water tank. A flowmeter is configured at a water outlet at a top portion of each of the filters. An electromagnetic valve subject to control by control circuit is configured at each of the water inlets and the water outlets of the two filters, thereby achieving quick reverse washing of contaminants from filter cores of the filters and providing large quantities of purified water for industrial usage.

Owner:LAI CHIEH JUNG

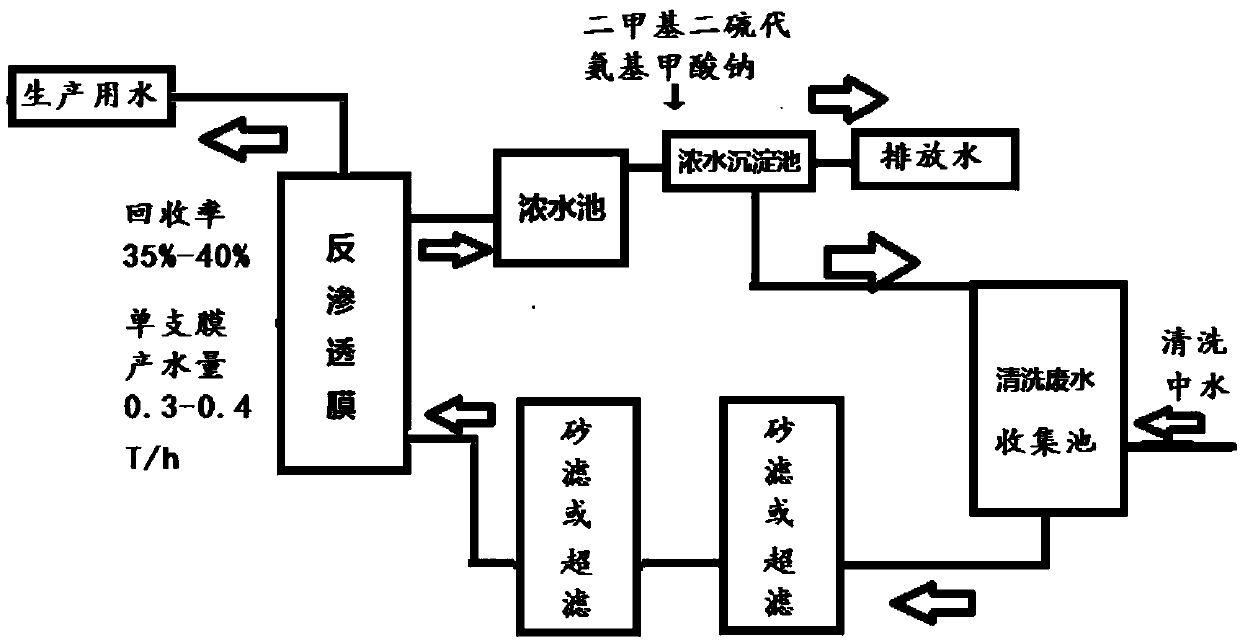

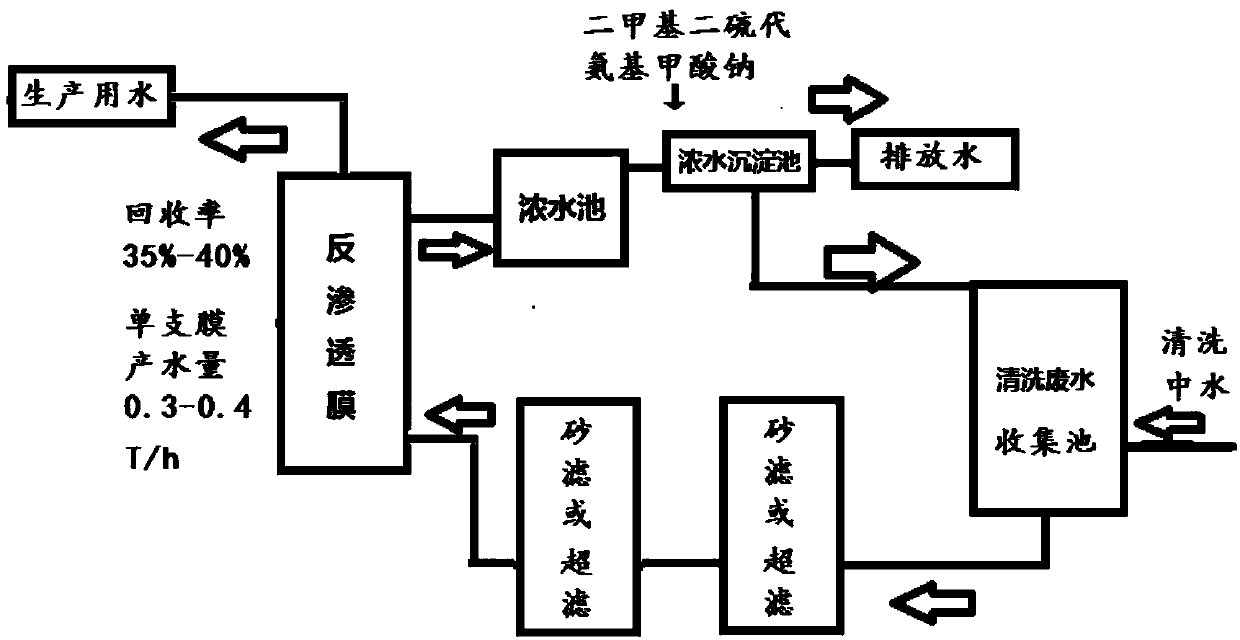

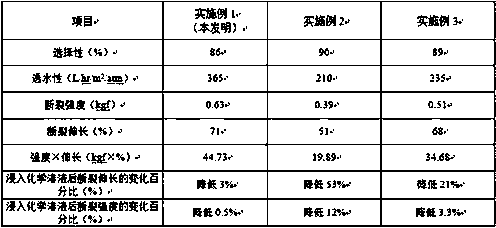

Electroplating wastewater reclaimed water recycling process and system

InactiveCN106698750AReduce conductivityStrong ability of complexation and precipitationTreatment involving filtrationWaste water treatment from metallurgical processFiltrationUltrafiltration

The invention provides an electroplating wastewater reclaimed water recycling process which is characterized by comprising the following steps: performing sand filtration or ultra-filtration on wastewater to be treated at least twice, feeding into a reverse osmosis system, collecting and depositing concentrated water treated by using the reverse osmosis system, discharging and / or combining into the wastewater to be treated, and performing further treatment, wherein the reagent for the deposition treatment is a heavy metal chelating agent. By adopting the electroplating wastewater reclaimed water recycling process, sewage blocking of the reverse osmosis system can be remarkably reduced, and the system recycling rate can be remarkably increased.

Owner:SHANGHAI FENGXIN ENVIRONMENTAL PROTECTION TECH

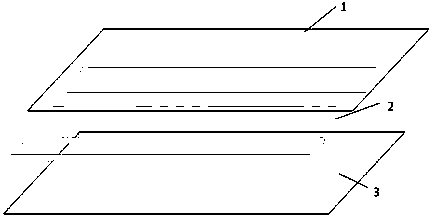

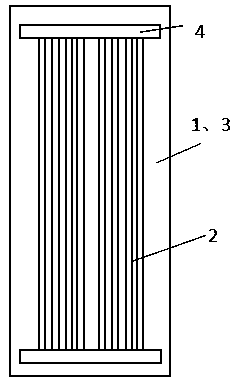

Nanofiber composite filter membrane for water treatment and preparation method of nanofiber composite filter membrane for water treatment

ActiveCN107803121AAvoid harmImprove stress resistanceMembranesSemi-permeable membranesFiltration membraneSuperplasticizer

The invention discloses a nanofiber composite filter membrane for water treatment. The nanofiber composite filter membrane comprises a nonwoven fabric isolating layer A, a hollow nanofiber membrane and a nonwoven fabric isolating layer B. By combination of the nonwoven isolating layers and the hollow nanofiber membrane and buffering through the isolating layers, high pressure resistance is realized, primary filtration is realized when water flows through the nonwoven fabric isolating layers, and direct harms caused by water quality deterioration to the filter membrane are avoided. By adoptionof a polycarboxylate superplasticizer for graphene modification, graphene modified through the polycarboxylate superplasticizer can be stably and uniformly dispersed in the hollow nanofiber membrane to play a better role in reinforcing and toughening. Due to addition of nanosilver particles in the hollow nanofiber membrane, microorganisms can be killed in water treatment, and the nanosilver composite membrane is excellent in biological pollution resistance. The composite filter membrane has advantages of high hydrophilicity, high chemical resistance and pollution resistance, remarkable selectivity and the like.

Owner:HUNAN ZHONGDA JINGWEI GEOTHERMY DEV TECH CO LTD

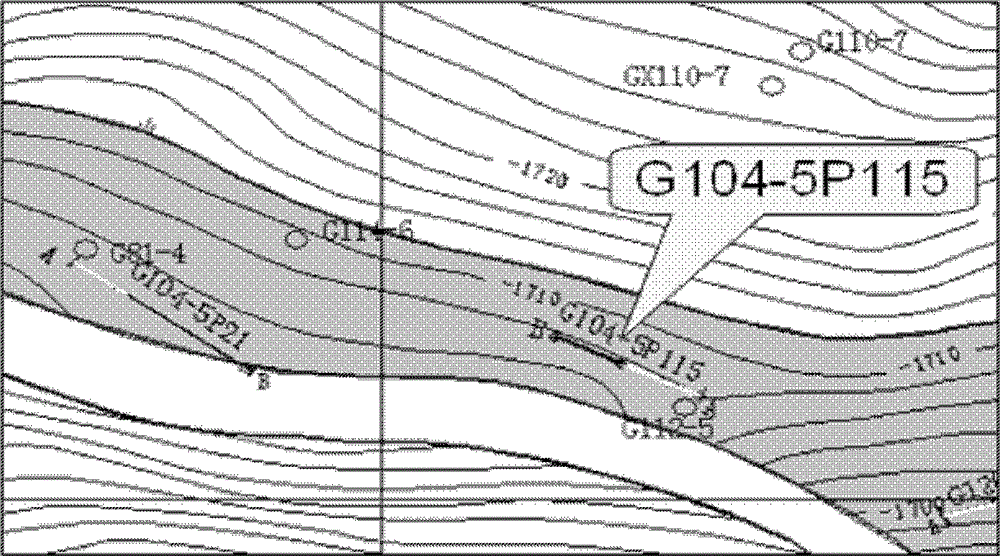

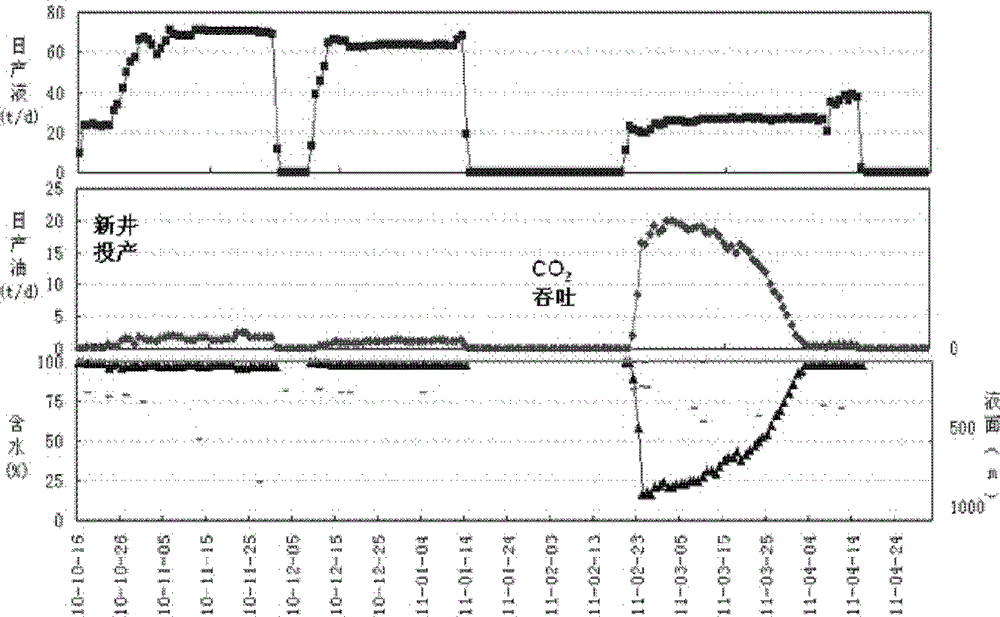

Carbon oxide huff-n-puff, water control and oil increment method for horizontal well

ActiveCN102587873BEasy constructionReduce water productionOther gas emission reduction technologiesFluid removalHorizontal wellsEnvironmental engineering

The invention relates to a CO2 (carbon oxide) huff-n-puff, water control and oil increment method for a horizontal oil well, which includes: using a process string to inject appropriate CO2 into an abnormally water flooded horizontal well with proper conditions (the abnormally water flooded horizontal well refers to an extra-high-water-cut well with a recovery percentage lower than 80% of a calibrated water displacement rate and water cut incompatible with the recovery percentage); shutting down (shutting in) the well for a certain period of time to enable the injected CO2, an oil reservoir and reservoir fluids to physically and chemically react, and accordingly swelling and thinning crude oil and reducing surface tension; carbonating water to thicken the water; and energizing the reservoir, improving permeability and the like. By means of production control after well startup, evident water-cut reduction and evident oil yield increase can be achieved for the abnormally water-flooded extra-high-water-cut horizontal wells (including high-inclination wells with deviation angles larger of from 45 DEG to 86 DEG, and water control and oil increment are achieved.

Owner:PETROCHINA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com