Operation method of hollow fiber membrane module

An operation method and fiber membrane technology, applied in the direction of chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of poor flushing effect, high energy consumption, and failure to consider waste water recycling, etc., to prevent dead zone areas , the effect of preventing drift

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

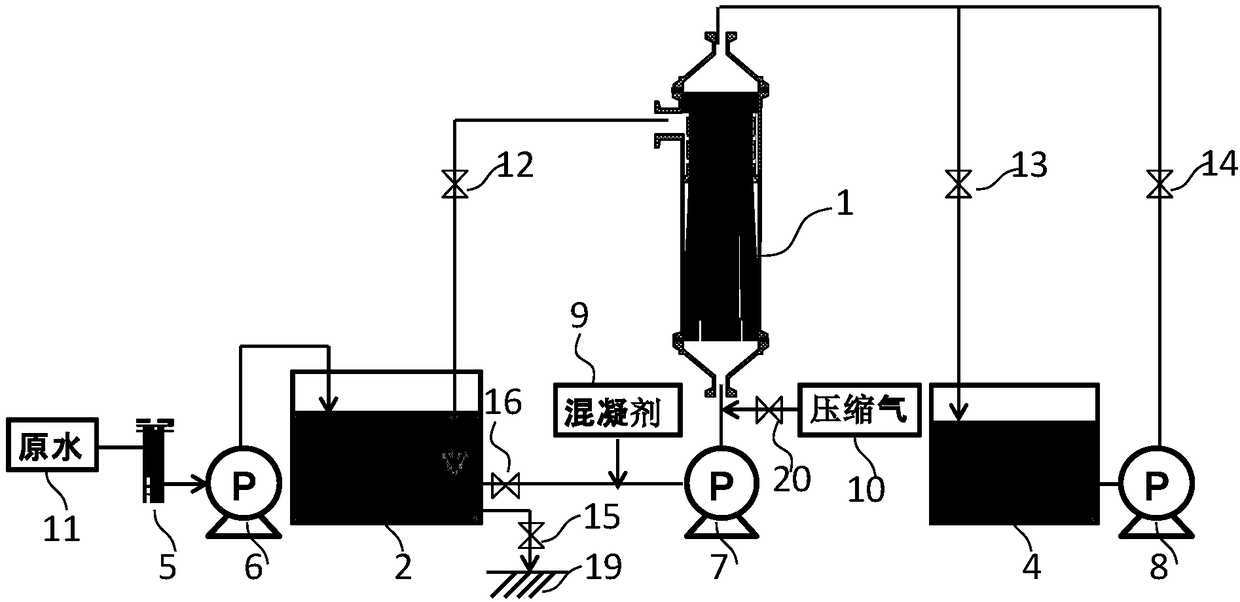

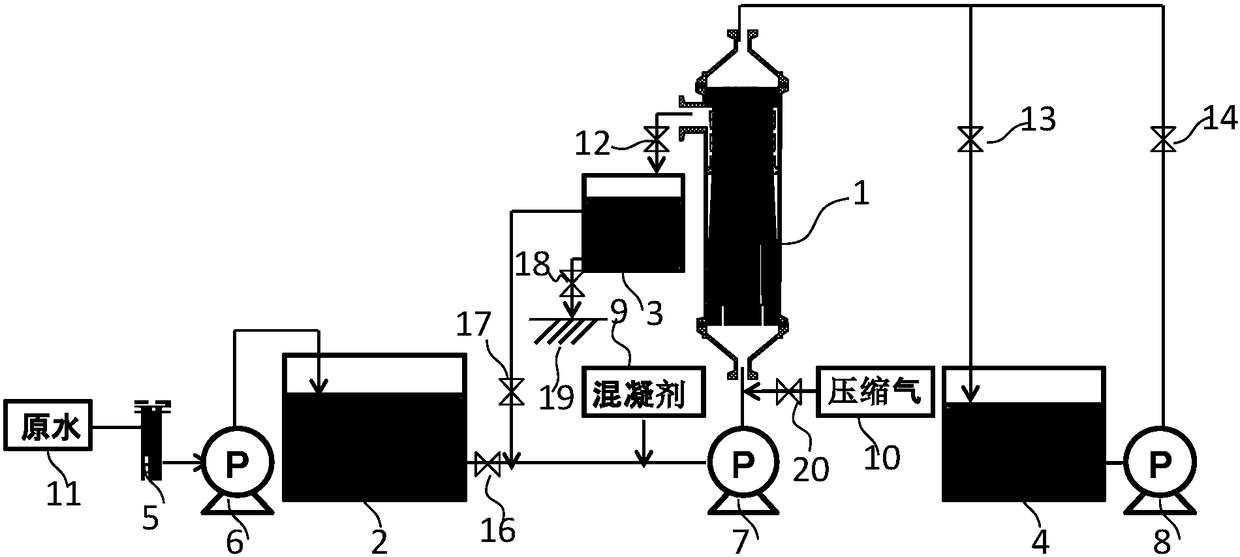

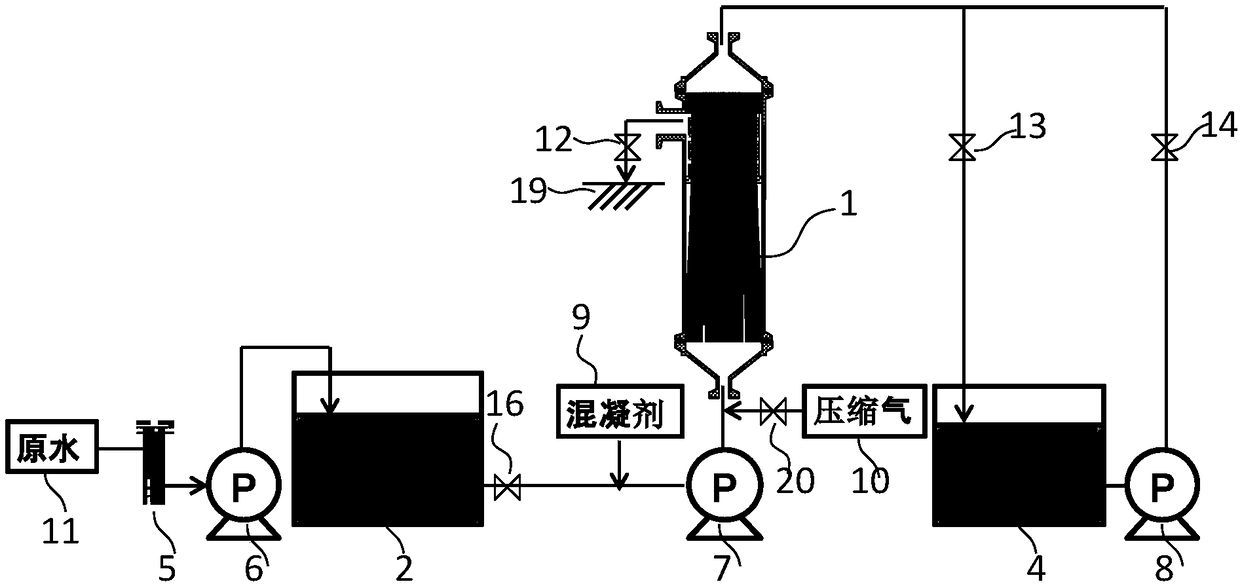

Method used

Image

Examples

reference example 1

[0141] To make hollow fiber membranes with a spherical structure, first make a polymer solution that is dissolved at 160 degrees after mixing 38 parts by mass of fluorinated polyvinylidene chloride fiber homopolymer with an average weight molecular weight of 417,000 and 62 parts by mass of γ-butyrolactone. This polymer solution, using 85% by weight γ-butyrolactone aqueous solution as the hollow part forming liquid, is sprayed from the cover of the double pipe, and 30mm below the cover is provided with 85% by weight γ-butyrolactone aqueous solution The composition is solidified in a cooling bath.

[0142] Next, 14 parts by mass of fluorinated polyvinylidene chloride fiber homopolymer with an average weight molecular weight of 284,000, 1 part by mass of cellulose acetate propionate (manufactured by Istman Chemical Co., Ltd., CAP482-0.5), and N-methyl-2-pyrrolidone Mix 77 parts by mass, sorbitan polyoxyethylene fatty acid ester (manufactured by Sanyo Chemical Industry Co., Ltd., ...

Embodiment 1

[0144] (Hollow fiber membrane module production)

[0145] The hollow fiber membrane of Reference Example 1 was soaked in 30% glycerol aqueous solution by weight for 1 hour and then air-dried. One end of the hollow fiber membrane was sealed with silicone glue (SH 850A / B glue manufactured by Toray Dou Corning Co., Ltd., mixed at a weight ratio of 1:1).

[0146] Case 22 made of polyvinyl chloride resin (inner diameter 77 mm, inner diameter of rectifier outer periphery 90 mm, length 1900 mm, inner diameter of discharge port on case side 24 mm), rectifier 29 (outer diameter 75 mm, inner diameter 71 mm), hollow tube 31 (outer 24mm diameter, 20mm inner diameter), the area bonded with pouring filler, pre-filed with sandpaper (#80) and degreased with ethanol.

[0147] To the water-producing end on the upper side of the assembly of the housing 22 ( Figure 13 The end on the right end) on the sealing side is equipped with hollow fiber membranes, and a solidification cover 35 at the per...

Embodiment 2

[0166] 12 first rectifying holes with a height of 10 mm and a width of 8 mm (rectangular) are uniformly arranged on the surface of the rectifying cylinder for pouring and filling at the lower side of the pouring and filling part 23 of the module water production end. Adopt 0.2m / s liquid phase and 0.2m / s gas phase mixed positive flushing method. The positive flushing time is 120s. Positive flush water flow to raw water tank. After the positive flushing, perform membrane filtration with a flux of 80LMH and a filtration time of 120min, and backwash after filtration. After backwashing, the liquid in the module is emptied, and then the 0.2m / s liquid phase and 0.2m / s gas phase are mixed to perform a circular operation of positive flushing, filtration, and backflushing. Others are the same as in Example 1. The turbidity removal rate of the hollow fiber membrane module can be Reached 93%, as shown in Table 1 for details.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com