Automatic inflow control device and pipe column

A technology of inflow control and control devices, which is applied in the direction of mining fluid, wellbore/well components, earthwork drilling and production, etc., can solve the problems of complex flow channels, abrasion, valve body channel blockage, etc., and achieve good chemical stability and flow channel Simple structure and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

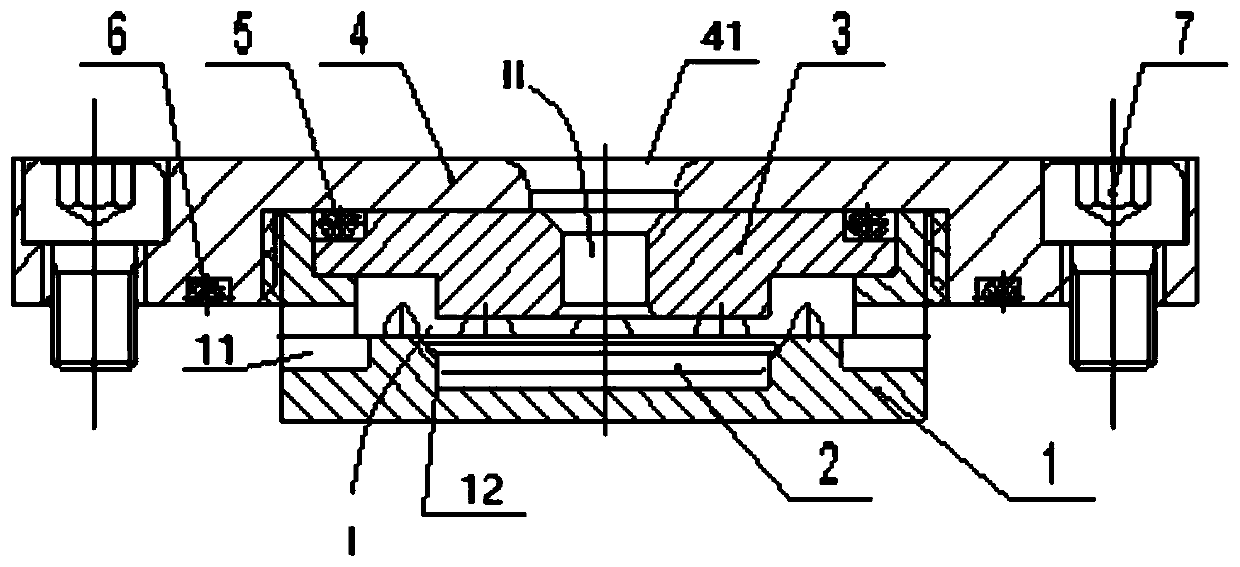

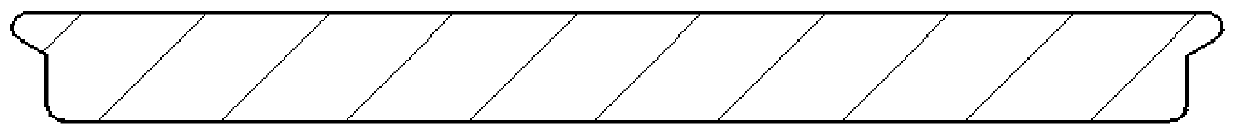

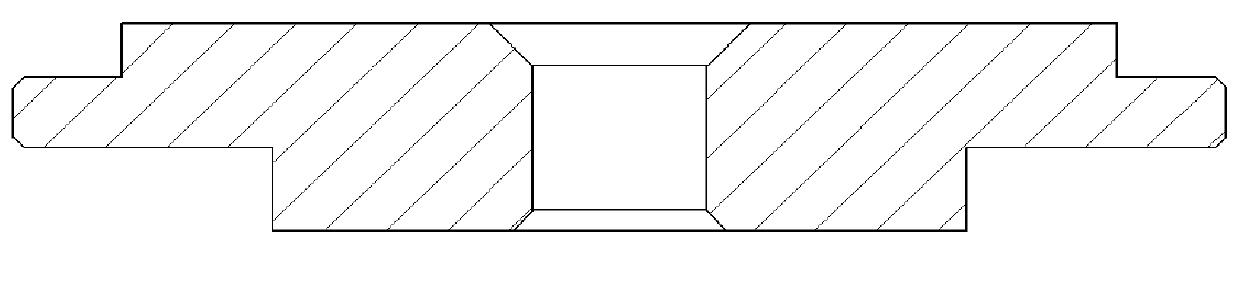

[0039] According to one embodiment of the present invention, the inner bottom surface of the lower housing 1 is provided with a groove 12, and the upper edge of the groove 12 is a tapered mouth, and the diameter of the mouth becomes larger along the direction of the taper. The outer peripheral surface of the lower end of the disc 2 is adapted to the inner peripheral surface of the groove 12, and the outer edge of the upper edge of the disc 2 is a tapered flange, and the outer tapered surface of the flange is compatible with the inner peripheral surface of the groove. The upper edge matches the inner side, and the depth of the groove 12 is greater than the height of the lower end of the disc 2 . This technical solution further increases the pressurization chamber III between the disc 2 and the lower case 1, that is, the cavity between the bottom of the disc 2 and the bottom of the lower case, as image 3 As shown, thus allowing the AICD (Automatic Inflow Control Device) to withs...

Embodiment

[0076] As shown in Figures 1 to 3, the automatic inflow control device of this embodiment consists of a lower casing 1, a disc disc 2, a middle cover 3, an upper casing 4, a sealing ring 5, a sealing ring 6, a screw 7, and an opening. Base pipe 8 is composed. When assembling, the disc disc 2 is installed in the middle of the lower housing 1, and then the middle cover 3 and the sealing ring 5 are loaded into the upper housing 4, and the connection between the lower housing 1 and the upper housing 4 is completed. It can be a threaded connection or other lockable mechanical connection, and the sealing ring 6 and the screw 7 are installed after the assembly is completed. The automatic inflow control unit is assembled.

[0077] Install the assembled automatic inflow control device on the perforated base pipe 8, and process it into an automatic inflow control nipple, so that the fluid can only flow from the upper casing 4 through the middle cover 3, into the flow control chamber, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com