Electroplating wastewater reverse osmosis membrane treatment method adopting energy recovery device

An energy recovery device and electroplating wastewater technology, which is applied in metallurgical wastewater treatment, osmosis/dialysis water/sewage treatment, etc., can solve the problem of losing the protective effect of reverse osmosis membrane elements, affecting the service life of reverse osmosis membrane elements, and being unable to be popularized and applied on a large scale and other problems to achieve the effect of prolonging the cleaning cycle and service life, reducing replacement costs and improving operational stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

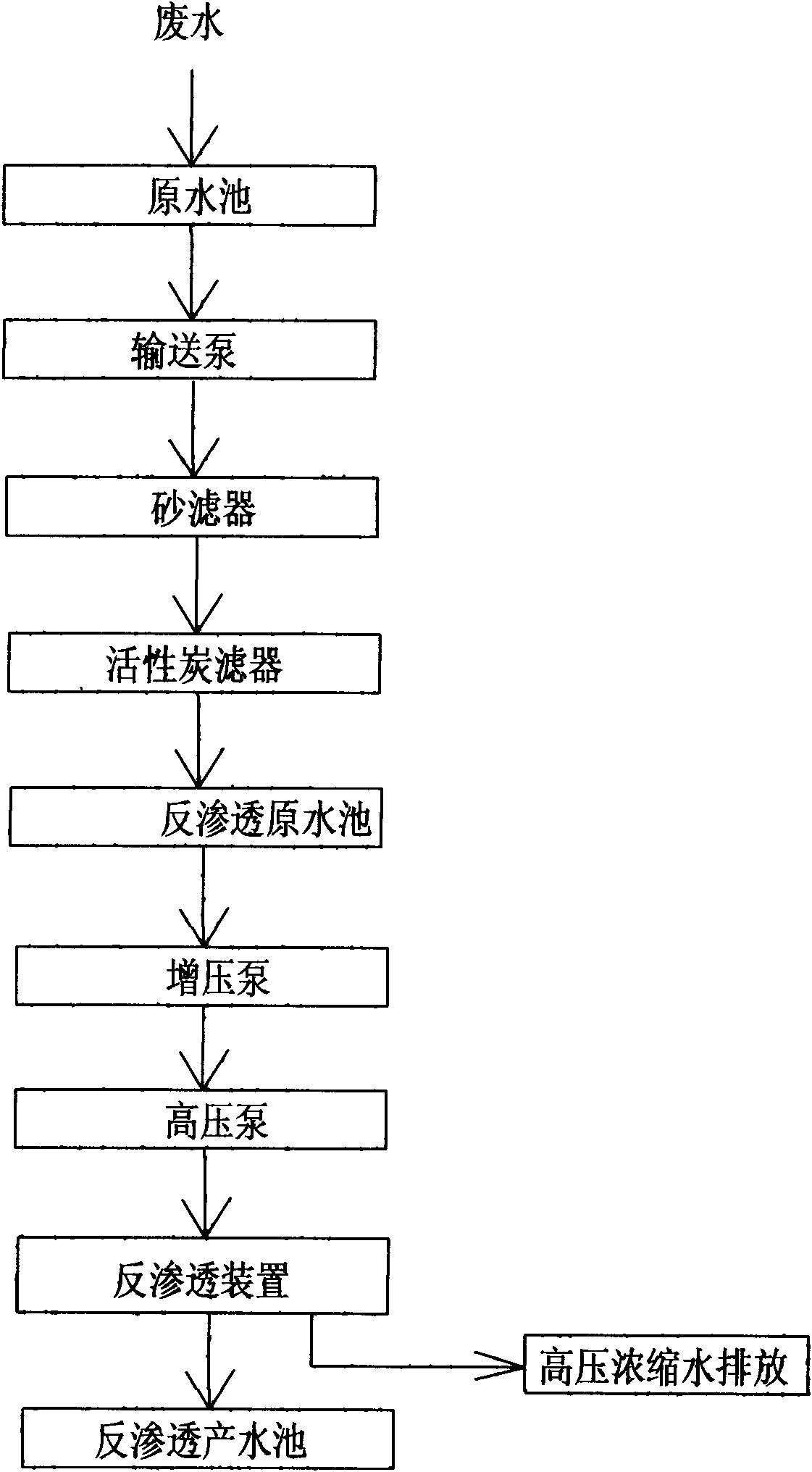

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

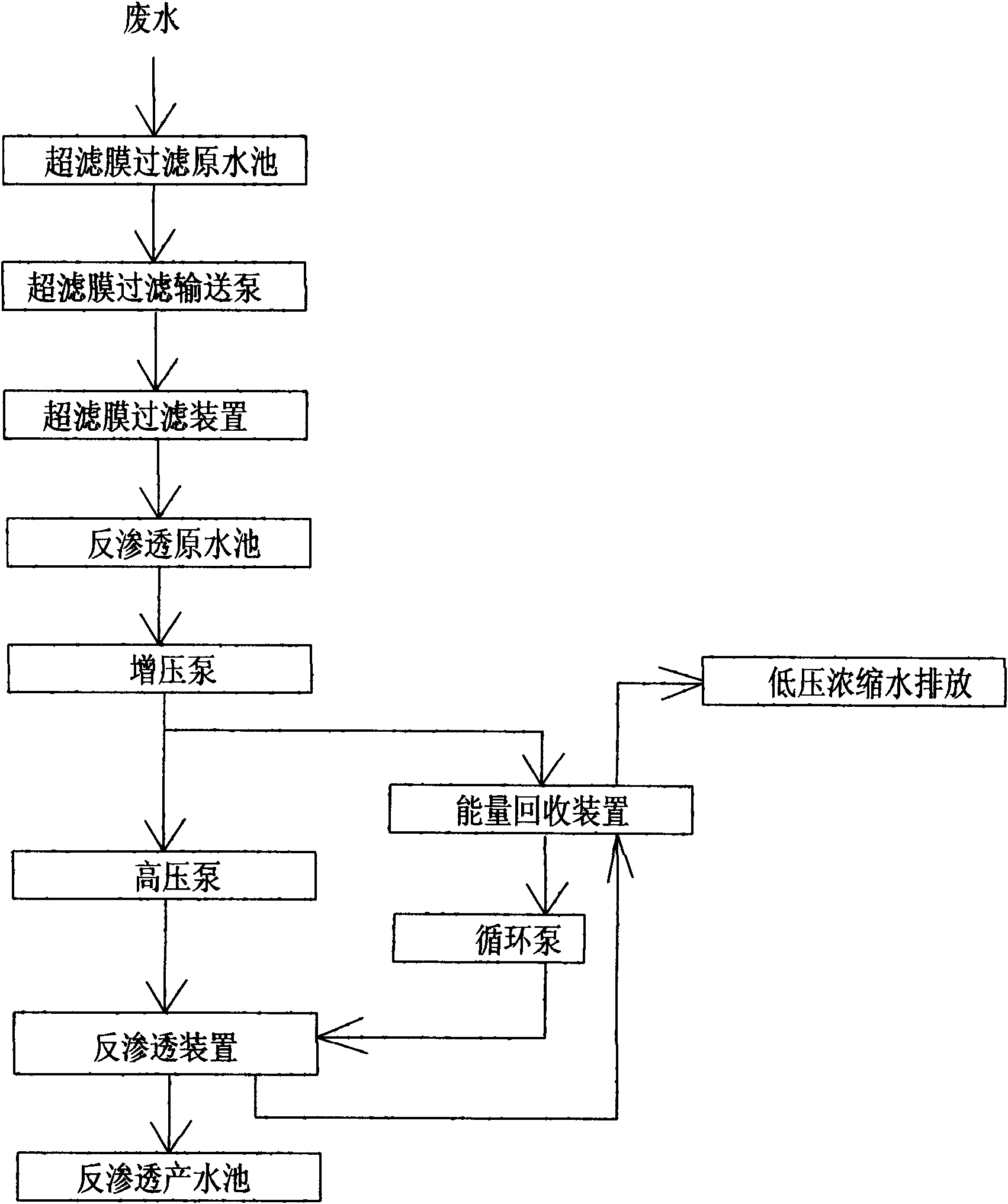

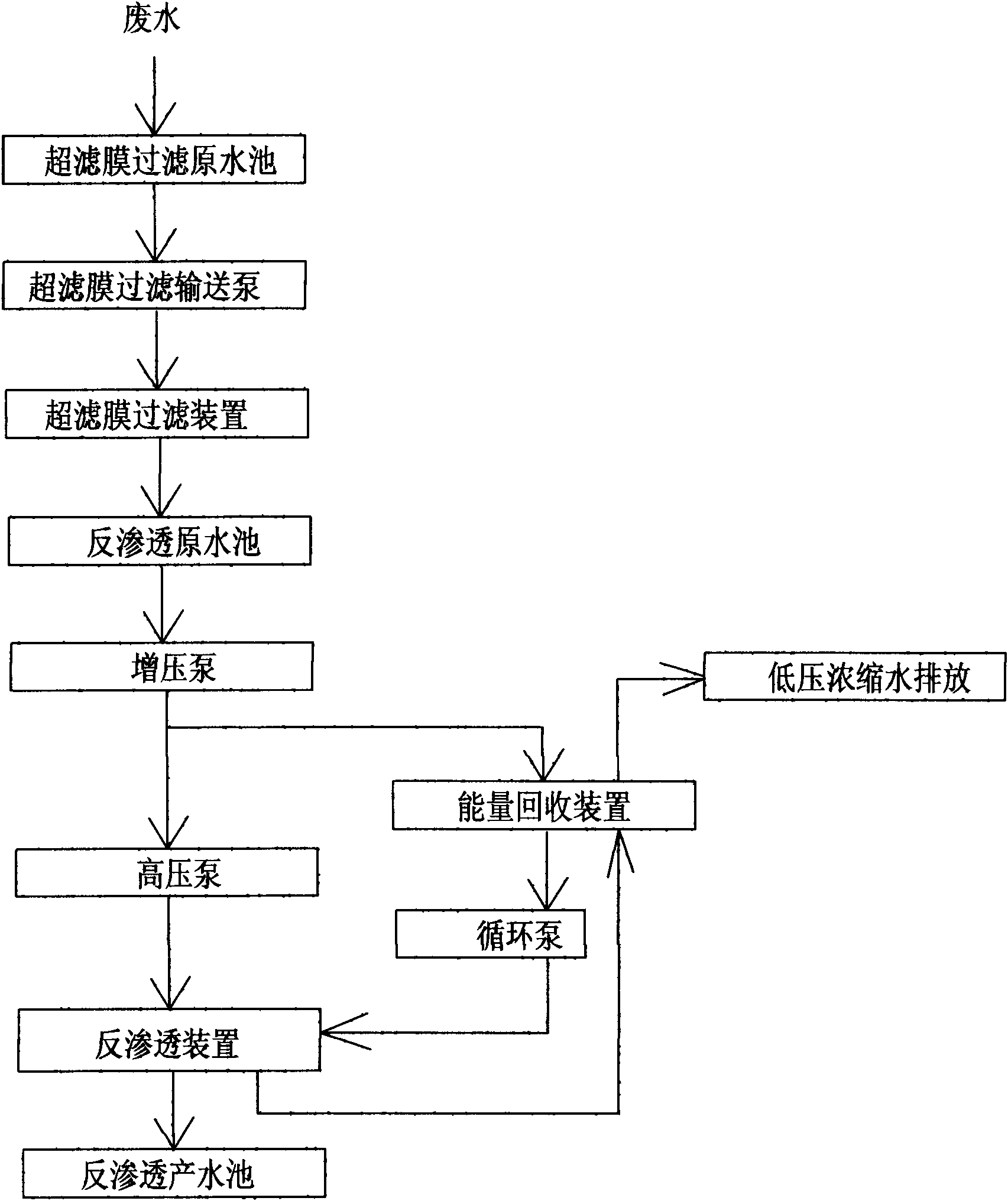

[0015] A reverse osmosis membrane treatment method for electroplating wastewater using an energy recovery device, comprising the following steps: the electroplating wastewater passes through an ultrafiltration membrane filtration raw water tank in sequence, an ultrafiltration membrane filtration delivery pump, an ultrafiltration membrane filtration device, a reverse osmosis raw water tank, and pressurization Pump, security filter, and then a branch branch is pressurized by a high-pressure pump and then enters the reverse osmosis device. After the energy is recovered by the energy recovery device, it enters the reverse osmosis device through the circulating pump, and the filtered water passed through the reverse osmosis device flows into the reverse osmosis production pool, and the concentrated water is treated and discharged after filtration.

[0016] The ultrafiltration membrane is a hollow fiber membrane, and the inner diameter of the membrane is 340-380 μm, the thickness of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com