Patents

Literature

111 results about "Ammonium pentaborate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aluminium electrolytic capacitor working electrolyte and capacitor obtained thereof

ActiveCN1744247AGood high pressureImprove high temperature resistanceElectrolytic capacitorsAmmonium pentaborateSolvent

The electrolyte includes solvent, solute, additive for corrosion resistance and property modifying additive. The additive for corrosion resistance includes 8-hydroxy quinoline, mannitol, phosphate monoester and one or more matters selected from organic acids. Compositions of property modifying additive include polyvinyl alcohol and / or carbowax, boracic acid and / or ammonium pentaborate, and glycol etc. Moreover, the electrolyte also includes dehydrogenation agent and waterproof mixture. The electrolyte improves capabilities of high temperature and high pressure resistant, and corrosion proof for aluminum electrolytic capacitor, reduces generation of hydrogen so as to prevent capacitor from blowing up, and hydration causing invalidation of capacitor. The invention also discloses the aluminum electrolytic capacitor of using the electrolyte. The capacitor is operable under rated operational voltage 315V-500V, and temperature 125 deg.C as upper limit.

Owner:GUANGDONG FENGHUA ADVANCED TECH HLDG

Ammonium borate containing compositions for stripping residues from semiconductor substrates

InactiveUS6875733B1Efficient removalExcellent peelabilityOrganic detergent compounding agentsDetergent mixture composition preparationHalogenOrganic solvent

The present invention comprises formulations for stripping wafer residues which originate from a halogen based plasma metal etching followed by oxygen plasma ashing. The formulations contain the following general components (percentages are by weight): an organic amine or mixture of amines 15-60 %, water 20-60 %, ammonium tetraborate or ammonium pentaborate 9-20 %, an optional polar organic solvent 0-15 %.

Owner:ENTEGRIS INC

Chip type high-voltage aluminum electrolytic capacitor, electrolyte thereof and preparation method of electrolyte

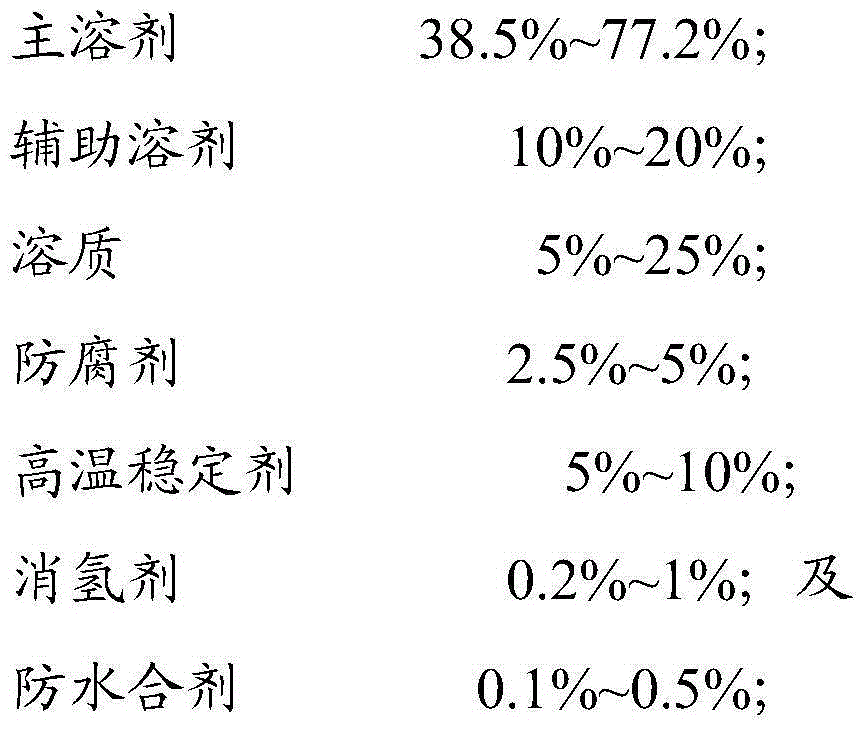

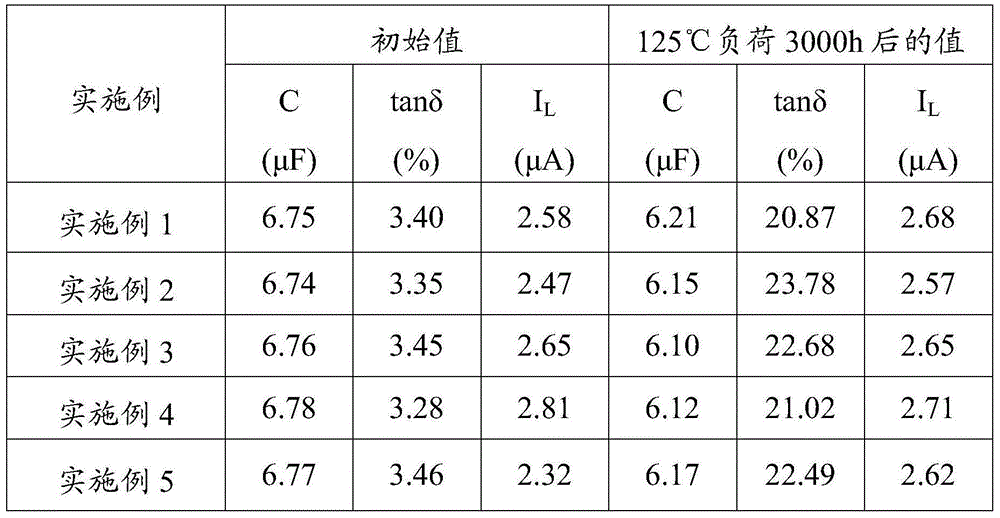

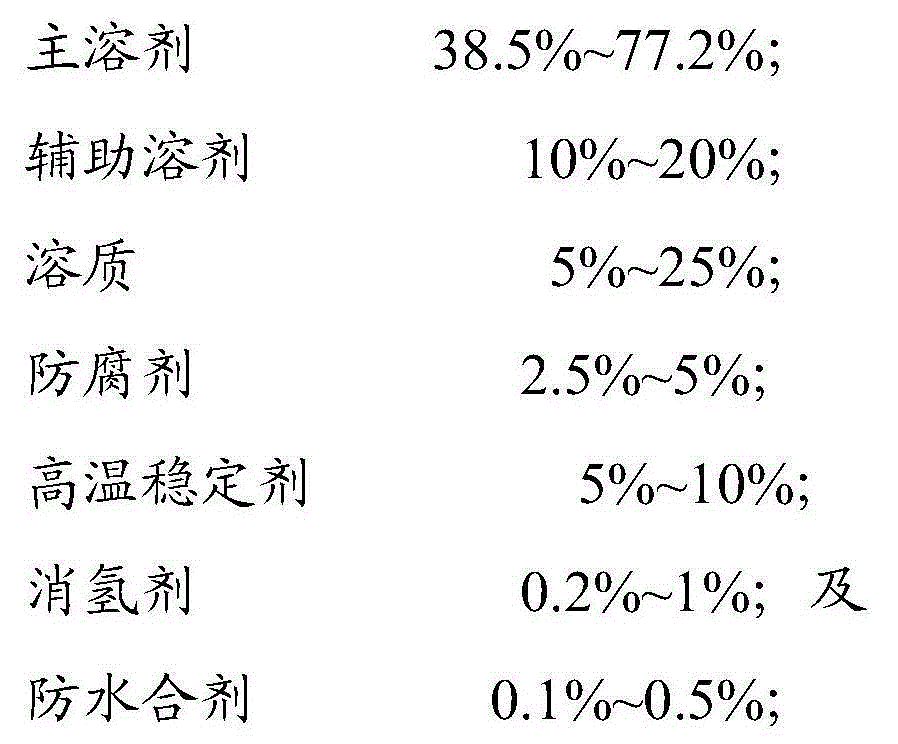

The invention relates to a chip type high-voltage aluminum electrolytic capacitor, an electrolyte thereof and a preparation method of the electrolyte. The electrolyte comprises the following components of 38.5-77.2% of a main solvent, 10-20% of an auxiliary solvent, 5-25% of a solute, 2.5-5% of an antiseptic, 5-10% of a high-temperature stabilizing agent, 0.2-1% of a hydrogen removal agent and 0.1-0.5% of a hydration-proof agent by weight. The solute is at least one selected from ammonium 2-n-hexyl adipate, ammonium octaned icarboxylate acid, butly octanedioic acid, ammonium 2-n-hexyl adipate oxalate, ammonium sebacate, sebacic acid, ammonium hydrogen azelate, ammonium azelate and ammonium pentaborate. The high-temperature stabilizing agent is at least one selected from polyvinyl alcohol, polyvinyl acetaldehyde, polyvinylpyrrolidone, polyvinyl alcohol succinate and sulfanilic acid. The high temperature resistance is high.

Owner:GUANGDONG FENGHUA ADVANCED TECH HLDG

Forming process of anode foils for extra-high voltage aluminium electrolytic capacitors

InactiveCN101777432AImprove compactnessHigh capacitance per unit areaAnodisationElectrolytic capacitorsAmmonium pentaborateChemistry

The invention provides a forming process of anode foils for extra-high voltage aluminium electrolytic capacitors, comprising the following steps: placing aluminium foils which undergo electrolytic corrosion in pure water at 90 DEG C or above to carry out pretreatment; then carrying out first-stage formation on the pretreated aluminium foils in aqueous solution containing 1-9wt% of boric acid and 0.01-0.6wt% of ammonium adipate; then treating the foils which undergo first-stage formation with phosphoric acid solution at the concentration of 1-10wt%; then treating the foils which undergo phosphoric acid treatment at high temperature; then carrying out second-stage formation on the foils which undergo high temperature treatment in the aqueous solution containing 2-10wt% of boric acid and 0.01-0.09wt% of ammonium pentaborate; then treating the foils which undergo second-stage formation in the phosphoric acid solution at the concentration of 1-10wt%; then treating the foils which undergo phosphoric acid treatment at high temperature; finally carrying out third-stage formation on the foils which undergo high temperature treatment in the mixed aqueous solution containing 2-10wt% of boric acid and 0.01-0.09wt% of ammonium pentaborate and carrying out post-treatment on the foils which undergo third-stage formation in the aqueous solution containing 1-13wt% of phosphoric acid and 0.1-6wt% of ammonia, and cleaning and then drying the foils which undergo post-treatment.

Owner:YANGZHOU HONGYUAN ELECTRONICS

Electrolyte of aluminum electrolytic capacitor, preparation method thereof and aluminum electrolytic capacitor

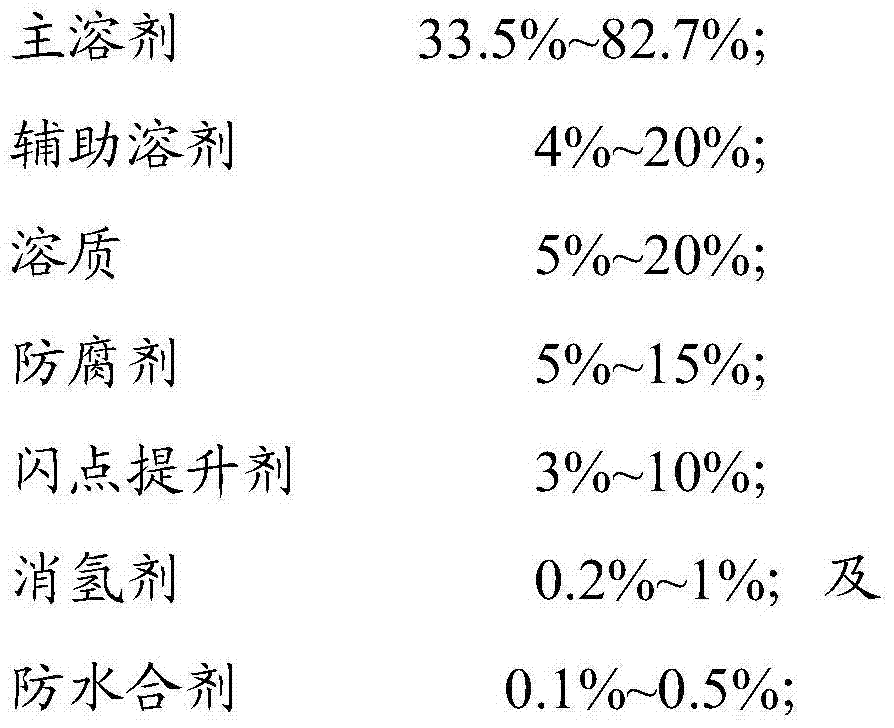

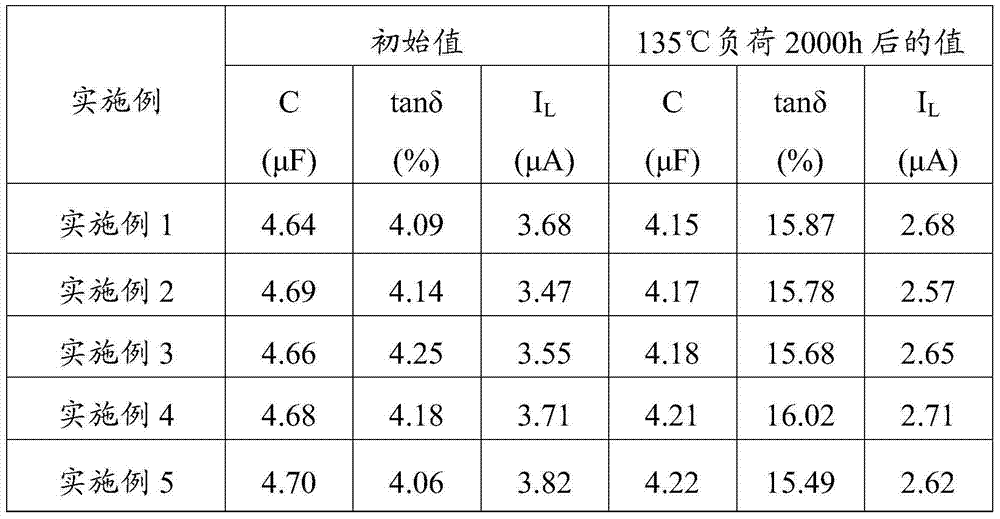

The invention relates to electrolyte of an aluminum electrolytic capacitor, a preparation method thereof and the aluminum electrolytic capacitor. The electrolyte of the aluminum electrolytic capacitor includes the following components by mass: 33.5-82.7% of a main solvent, 4%-20% of an auxiliary solvent, 5%-20% of a solute, 5%-15% of a corrosion remover, 3%-10% of flash point promotion agent, 0.2%-1% of hydrogen elimination agent and 0.1%-0.5% of water-mixture-proof agent, wherein the solute is at least one of isodecyl ammonium sebate, 2-butyl-cork-acid-ammonium, 2- ethyl ammonium oxalate, 5, 6-ammonium sebate, potassium sebate, sebacic acid, azelaic acid, ammonium azelate, ammonium pentaborate and potassium carboxylate with chains with the number of carbon chains as 24-35. Experiments show that the aluminum electrolytic capacitor using the electrolyte has good high temperature resistance, the service life can be 2000 hours under the environment with the temperature high as 135 DEG C, and the service life is longer.

Owner:GUANGDONG FENGHUA ADVANCED TECH HLDG

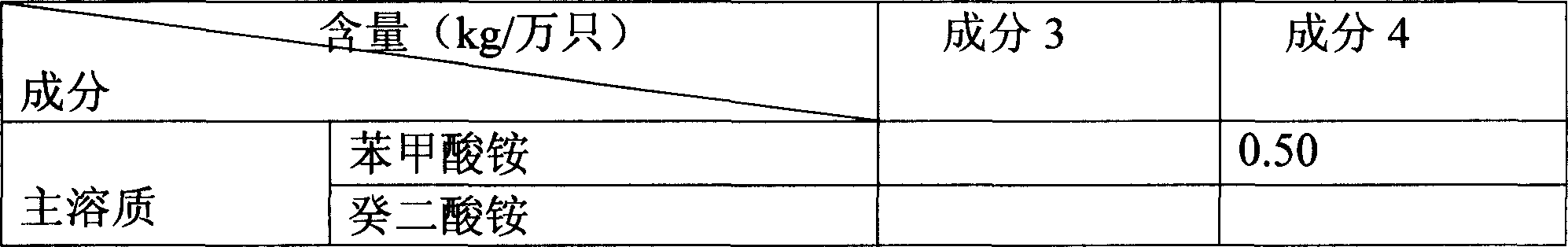

Aluminium electrolytic capacitor for flash lamp and preparing method tereof

ActiveCN1862728AImprove pressure resistanceReduce leakage currentElectrolytic capacitorsPhosphatePolyethylene glycol

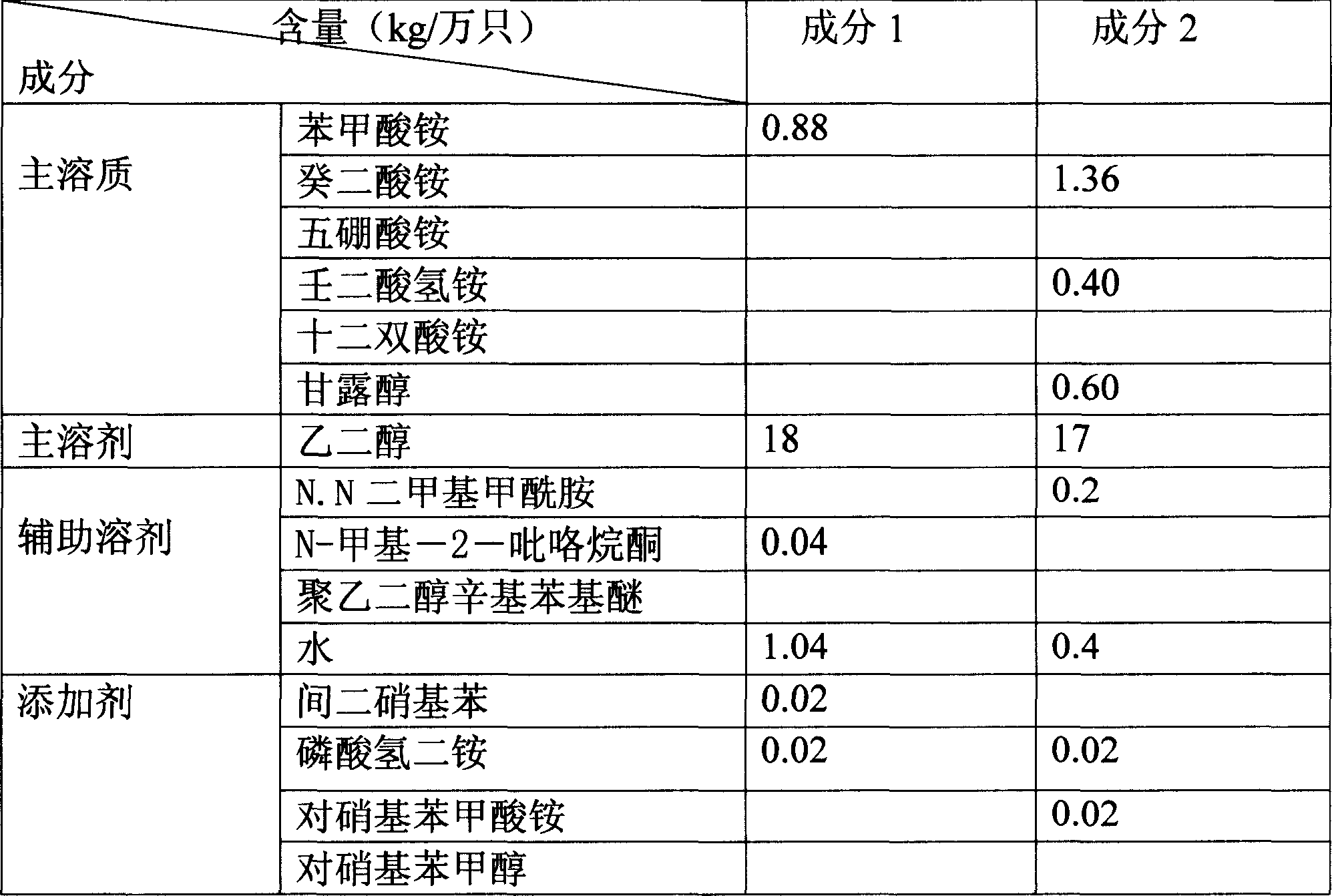

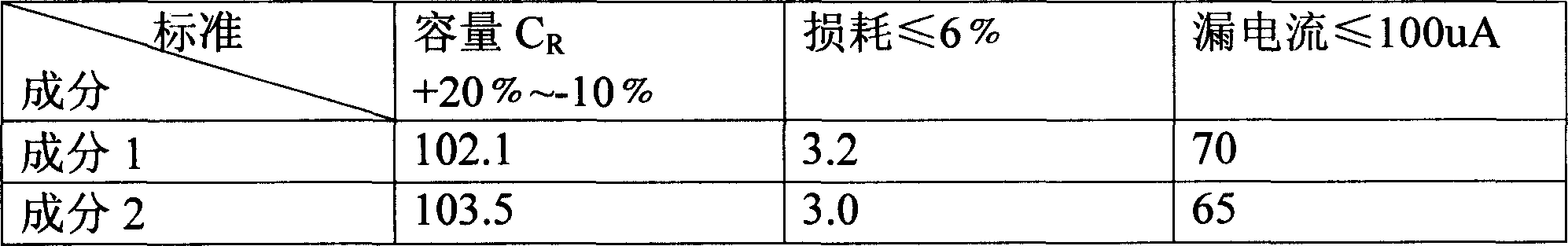

This invention relates to aluminum electrolytic capacitor and its preparation method, especially relates to aluminum electrolytic capacitor used in flashing light and its preparation method. Its work electrolyte components is that main solvent is ethylene glycol. Secondary solvent is one or mixture N.N dimethyl formamide, N-methyl-2- pyrrolidone, polyethylene glycol octyl phellyl ether and water. The main solute is one or mixture of ammonium benzoate, ammonium sebacate, ammonium pentaborate, azelaic acid hydrogen ammonium, dodecandioic acid ammonium, mannitol. The additive is one of mixture of m-dinitrobenzene, ammonium dibasic phosphate, nitrodracylic acid ammonium and amphi nitryl benzoic alcohol. The capacitor in this invention is good in pressure resistance, the leakage current is little, the slow leakage rally can be used to make flashing light aluminum electrolytic capacitor of rated voltage keep around 330V.

Owner:横店集团东磁有限公司

Ultrahigh-pressure anode aluminum foil formation method

InactiveCN101964257AReduce concentrationGuaranteed formation effectElectrolytic capacitorsUltra high voltageAluminum foil

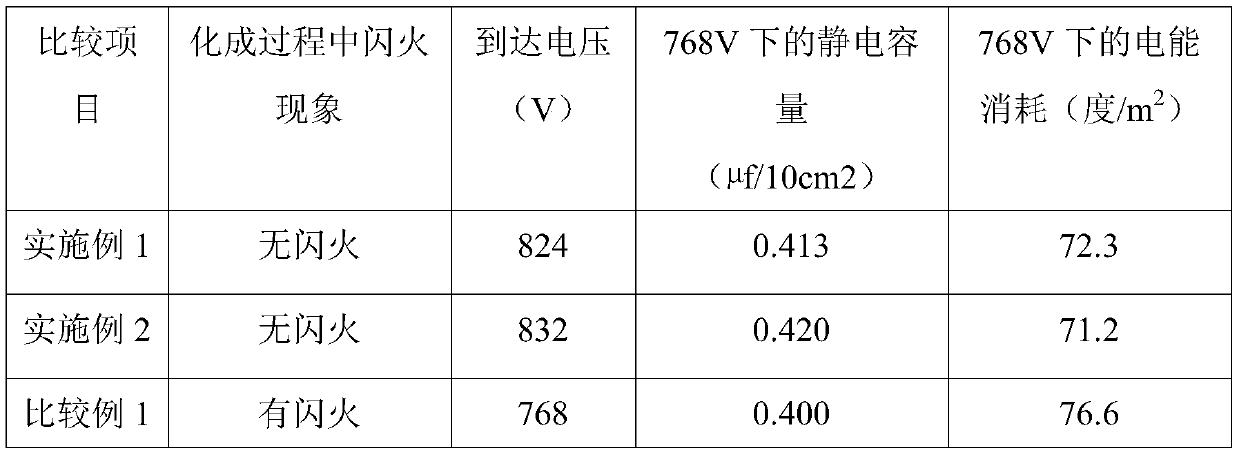

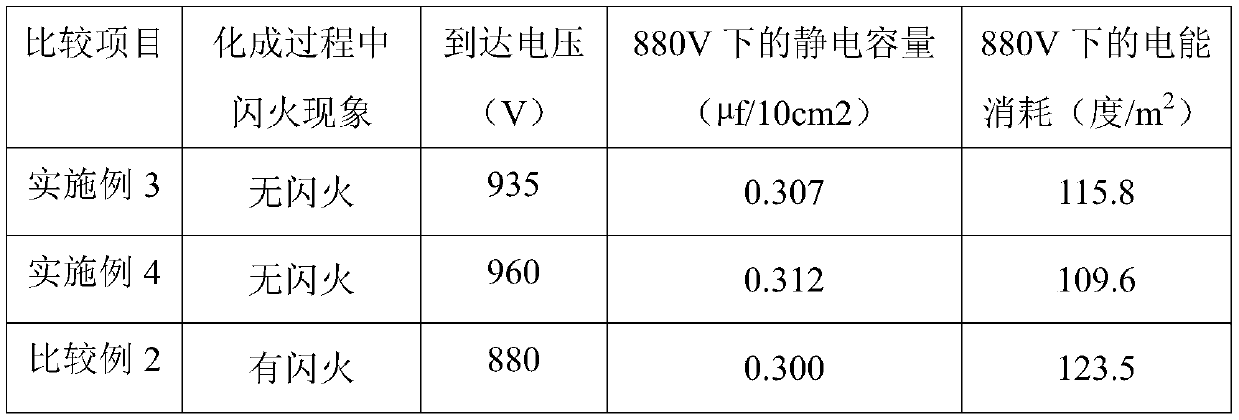

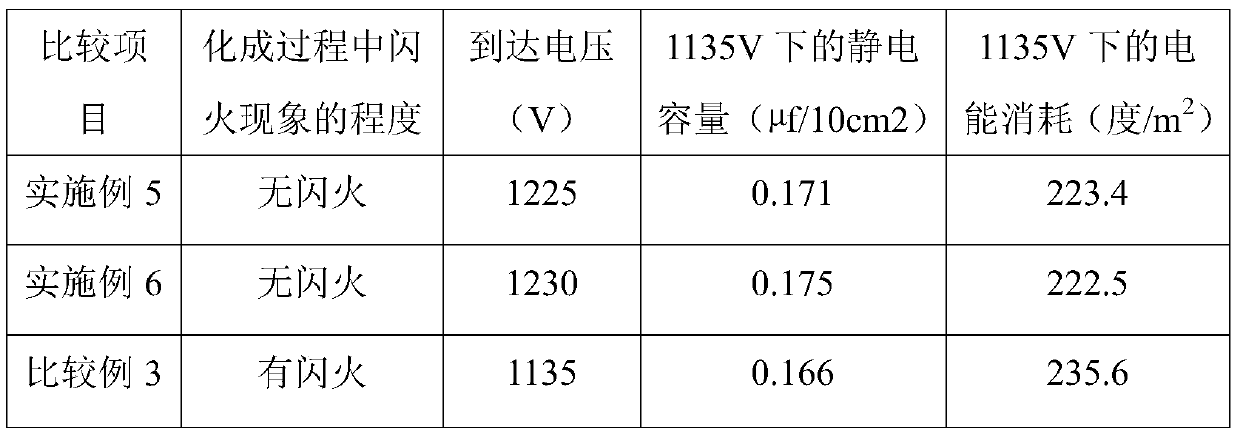

The invention discloses an ultrahigh-pressure anode aluminum foil formation method. The method comprises the steps of preprocessing, forming an oxide film on the surface of the aluminum foil by multi-stage voltage energization, and repeatedly destroying and repairing the oxide film at the constant voltage, wherein the energization voltage is 120 to 1,000V, the formation stage is 4 to 6, and the multi-stage voltage energization is performed in a mixing tank solution which consists of 0.2 to 80 weight percent of boric acid and 0.01 to 0.5 weight percent of ammonium dihydrogen phosphate, and then subsequent voltage energization and repeated destroying and repairing is performed in a mixing solution which consists of 0.2 to 80 weight percent of boric acid and 0.01 to 0.5 weight percent of ammonium pentaborate. In the ultrahigh-pressure anode aluminum foil formation method provided by the invention, ammonium dihydrogen phosphate concentration or ammonium pentaborate concentration in the mixing tank solution is correspondingly reduced as the energization voltage continuously rises, so not only the formation effect is guaranteed, but also the flashing phenomenon in the formation process is avoided and the yield is improved.

Owner:南通华冠电子科技有限公司

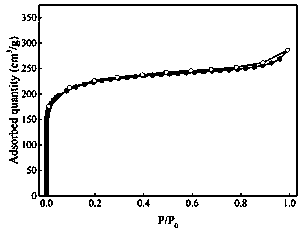

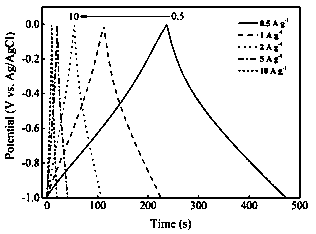

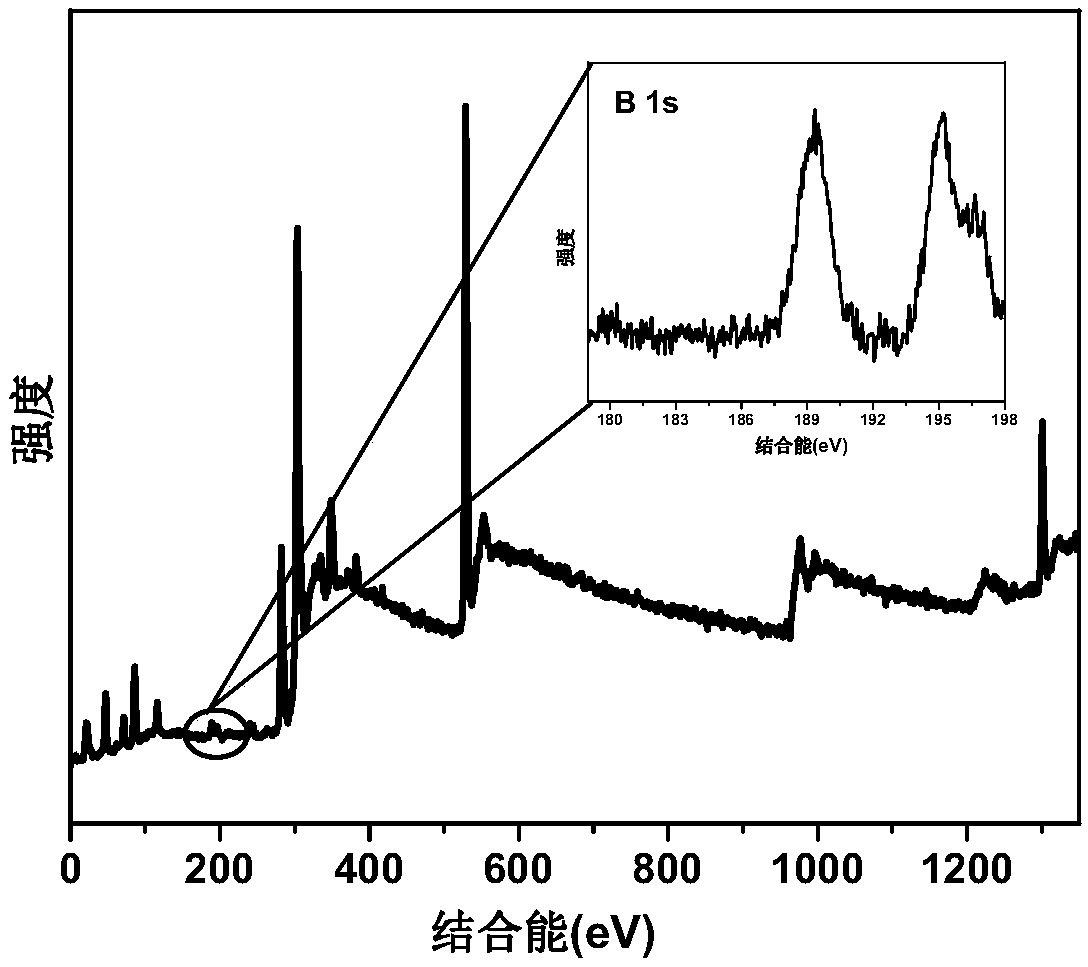

Method for preparing boron-nitrogen-doped porous carbon material applied to super capacitor under microwave hydrothermal assistance

InactiveCN109251031AHigh nitrogen contentHigh specific capacitanceHybrid capacitor electrodesCeramicwareMetallurgyPorous carbon

The invention relates to a method for preparing a boron-nitrogen-doped porous carbon material applied to a super capacitor under microwave hydrothermal assistance. The method is characterized in thatChinese fir bark is taken as a raw material, and ammonium pentaborate tetrahydrate is taken as a boron source and a nitrogen source. The method comprises the following steps: firstly, performing boron-nitrogen heteroatom doping under microwave hydrothermal assistance; performing high-temperature pyrolysis to obtain the boron-nitrogen-doped porous carbon material, which is 10.19 to 13.05 percent byweight in boron content, is 15.13 to 19.5 percent by weight in nitrogen content, and can be up to 820 to 955m<2> / g in specific surface area. By adopting method, heteroatom doping is realized under microwave hydrothermal assistance through high-temperature pyrolysis, and a carbon material with a large specific surface area is prepared. The method is easy and convenient to operate, and the preparation time of the carbon material is shortened greatly. Meanwhile, strong acid, strong alkali and toxic reagents are not used in the preparation process, so that the process is environmentally friendly,and the prepared boron-nitrogen-doped porous carbon material has a certain application prospect in the field of super capacitors.

Owner:FUJIAN AGRI & FORESTRY UNIV

Formation method of anode aluminum foil for high-voltage aluminum electrolytic capacitor

InactiveCN101748462AIncrease capacityPractical craftAnodisationElectrolytic capacitorsPhosphateMetallurgy

The invention relates to a formation process of an anode aluminum foil for a high-voltage aluminum electrolytic capacitor, which comprises the following steps sequentially: pretreatment, 100-240V first order formation treatment, 300-450V second order formation treatment, 400-600V third order formation treatment, 500-620V fourth order formation treatment, depolarizing treatment and drying, wherein in the pretreatment step, the aluminum foil after erosion pore expanding is put in de-ionized water of 92-100 DEG C for soaking treatment, and the treating solution of the formation treatment is a mixed water solution of some materials of boric acid, phosphate and ammonium pentaborate. The invention has the beneficial effects that the process is practical and can improve the volume of the anode aluminum foil by 8-10% for the high-voltage aluminum electrolytic capacitor with voltage of 400-650V.

Owner:YIDU DONGYANGGUANG FORMED FOIL

Formation method of high-specific-volume, high-flexibility and low-electric-leakage electrode foil

InactiveCN107287639AIncrease specific volumeImprove flexural strengthElectrolytic capacitorsSpecific volumeBoric acid

The invention discloses a formation method of a high-specific-volume, high-flexibility and low-electric-leakage electrode foil. The formation method comprises first-grade formation, second-grade formation, third-grade formation, fourth-grade formation and fifth-grade formation of an aluminum foil, wherein the first-grade formation of the aluminum foil is performed in water solution containing azelaic acid and ammonium azelaic acid; the second-grade formation is performed in water solution containing azelaic acid, ammonium azelaic acid and boric acid; the third-grade formation is performed in water solution containing lemons, boric acid and ammonium azelaic acid; and the fourth-grade formation and the fifth-grade formation are both performed in water solution containing boric acid and ammonium pentaborate. The electrode foil manufactured by using the method is high in specific volume, high in bending strength and low in electric leakage; and the quality of the electrode foil is effectively improved.

Owner:新疆金泰新材料技术股份有限公司

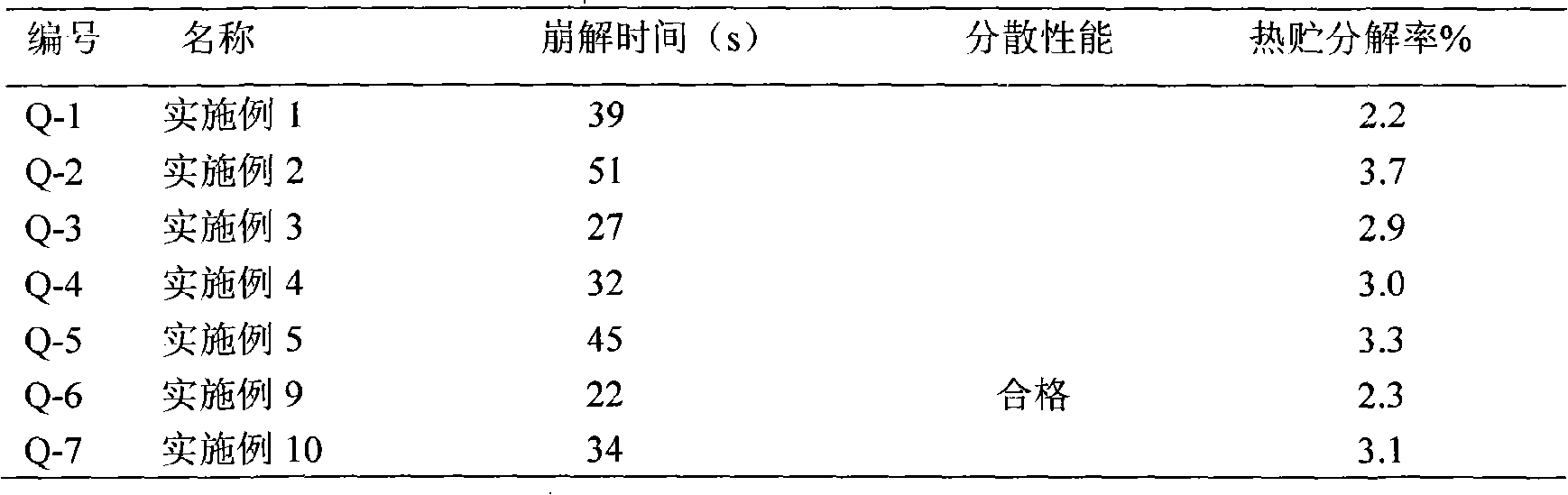

Boron fertilizer effervescence granule and method of producing the same

InactiveCN101550040AFast disintegrationImprove solubilityFertilizer mixturesMagnesium phosphateManganese

The invention relates to a boron fertilizer effervescence granule and method of producing the same, pertaining to a novel boron fertilizer. The boron fertilizer effervescence granule includes one or more boron fertilizer and one or more compounds contacted with water to generate gas, wherein, the weight part scope of the boron fertilizer is from 61 to 95. The preferred scheme of the invention is that the boron fertilizer includes one of boric acid, boron oxide, ammonium pentaborate, sodium tetraborate, calcium metaborate, sodium metaborate, tetrahydate octa sodium borate, magnesium diboride, sodium perborate, zinc borate, manganese borate, sodium perborate, potassium metaborate, boron magnesium fertilizer, boron and magnesium phosphate, and boron mud, or a mixture of two or more of the above. The preparation method of the invention includes: weighing the formulation material, mixing, grinding, granulating, and drying to obtain. The inventive boron fertilizer effervescence granule has a fast disintegrating velocity in the water; completely dissolving(dispersing); non-clogging of nozzle and drip irrigation pipeline; no need of heating when in use; no absorption of moisture; low packaging, storage and transportation, measurement and use cost; wide application in food crops, cash crops, horticulture, lawns and urban greening; and very broad market prospect.

Owner:SHENZHEN LANGTAI BIOTECH

Preparation method of boron oxide-modified microporous molecular sieve shape-selective catalyst

InactiveCN104084233AHigh activityHigh shape selectivityOrganic chemistryMolecular sieve catalystsAlkyl transferBoron oxide

The invention relates to a preparation method of a boron oxide-modified microporous molecular sieve shape-selective catalyst. The preparation method comprises the following step of with a microporous molecular sieve ZSM-5 or MCM-22 as a supporter and ammonium pentaborate as a precursor of boron oxide, supporting boron oxide on the outer surface of the microporous molecular sieve by virtue of dipping and temperature programming roasting methods, wherein the mass ratio of ammonium pentaborate to the microporous molecular sieve is (1:2)-(1:8). The catalyst prepared by virtue of the preparation method has good shape selective catalysis performance in processes of compounding p-cresol and paraethyl phenol by virtue of para-phenol alkylation.

Owner:CHANGZHOU UNIV

Electrolyte of high-voltage aluminum electrolytic capacitor and preparation method of electrolyte

The invention discloses electrolyte of a high-voltage aluminum electrolytic capacitor. The electrolyte is characterized by comprising a main solvent, an auxiliary solvent, a solute and a spark voltage increasing agent, wherein the main solvent comprises one or more of ethylene glycol, gamma-butyrolactone, DMF and diglycol monobutylether; the auxiliary solvent comprises two or more of polyethylene glycol 200, polyethylene glycol 400, a nanosilicon dioxide solution, glycerol, propylene carbonate and ethylene carbonate; the solute comprises two or more of ammonium sebacate, ammonium adipate, adipic acid, boracic acid, ammonium pentaborate, ammonium azelate, ammonium dodecanedioate, ammonium formate, ammonium benzoate, mannitol, sorbitol, citric acid and quadrol. The electrolyte can be applied to 600V ultrahigh voltage, is stable in performance, low in viscosity, high in conductivity and beneficial to volume production, and can reduce the production cost.

Owner:HUNAN AIHUA GRP

Formation method of high ripple current resisting electrode foil

InactiveCN107287638AImprove qualityImprove formation efficiencyElectrolytic capacitorsSurface reaction electrolytic coatingBoric acidAqueous solution

The invention discloses a formation method of a high ripple current resisting electrode foil. The formation method comprises first-grade formation, second-grade formation, third-grade formation, fourth-grade formation and fifth-grade formation of an aluminum foil, wherein the first-grade formation, the second-grade formation and the third-grade formation of the aluminum foil are all performed in ammonium dihydrogen phosphate water solution; and the fourth-grade formation and the fifth-grade formation of the aluminum foil are both performed in water solution containing boric acid and ammonium pentaborate. The electrode foil manufactured by using the method can resist high ripple current; and the quality of the electrode foil is effectively improved.

Owner:新疆金泰新材料技术股份有限公司

Preparation method of high-performance polyacrylonitrile-based carbon fibers

ActiveCN103451945AImprove mechanical propertiesReduce pre-oxidation timeFibre treatmentFibre chemical featuresPretreatment methodCarbon fibers

The invention relates to a preparation method of high-performance polyacrylonitrile-based carbon fibers. Specifically, the invention discloses a pretreatment reagent for polyacrylonitrile protofilament and a pretreatment method employing the same, wherein the reagent contains an oiling agent and ammonium pentaborate. The pretreatment method can effectively shorten the pre-oxidation time, and significantly improves the mechanical properties of the final carbon fibers.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

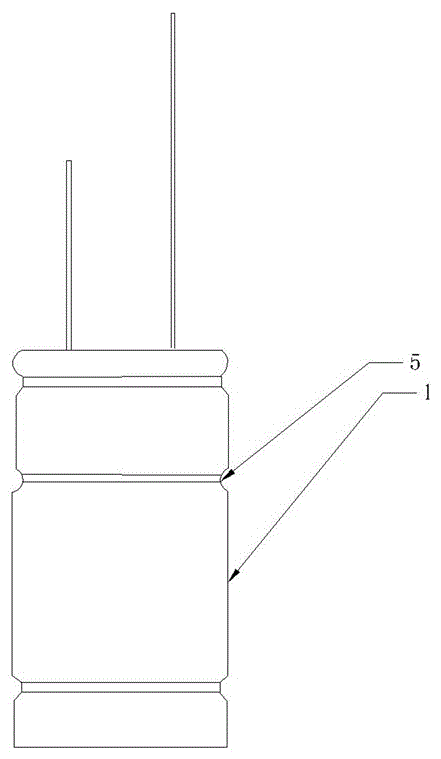

Microminiature rapid charging special-purpose aluminium electrolytic capacitor

InactiveCN106252083AGuaranteed capacityGuaranteed high withstand voltage performanceCapacitor housing/encapsulationP-nitroanisoleLightning strike

The invention provides a microminiature rapid charging special-purpose aluminium electrolytic capacitor which comprises a shell, a core bag and a rubber plug. The core bag is sealed in the shell through the rubber plug. The core bag contains electrolyte which comprises a solvent, an inorganic acid ammonium salt, an organic acid ammonium salt, and a hydrogen elimination agent. The inorganic acid ammonium salt is ammonium borate or ammonium pentaborate or the mixture of the ammonium borate or the ammonium pentaborate. The organic acid ammonium salt comprises one or more of ammonium sebacate, ammonium azelate, diammonium phthalate, and dodecyl ammonium carboxylate. The hydrogen elimination agent comprises one or more of a p-Nitrobenzyl alcohol, a p nitroanisole and p-nitrobenzoic acid. The conductivity of the electrolyte in the invention is between 2.4 ms / cm to 2.8ms / cm, the ESR value of a product can be effectively reduced, thus the ripple resistance and lightning strike resistance ability of the product are improved greatly, the flash fire voltage is above 490V, in a condition of high voltage, the breakdown of electrolytic paper caused by flash fire of the electrolyte does not appears, and thus the voltageproof performance of the product is ensured.

Owner:HUNAN AIHUA GRP

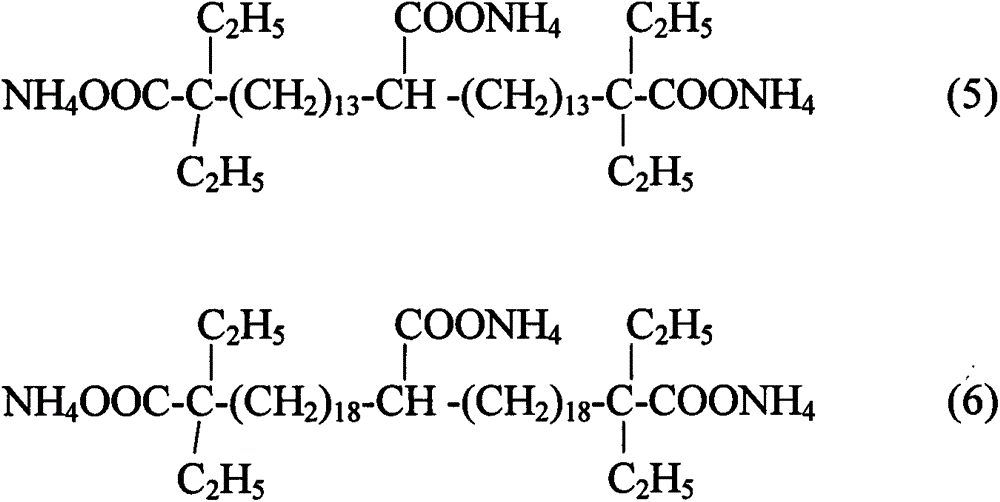

High-voltage aluminium electrolysis capacitor

InactiveCN104681278APrevent breakdownReduce in quantityLiquid electrolytic capacitorsCapacitor electrodesAluminium electrolysisPhosphate

The invention discloses a high-voltage aluminium electrolysis capacitor. The high-voltage aluminium electrolysis capacitor comprises a capacitor element, an electrolyte contained in the capacitor element, and an outer package which seals both the capacitor element and the electrolyte, wherein the capacitor element comprises an anode foil provided with an dielectric layer on the surface thereof, a cathode foil, and a diaphragm arranged between the anode foil and the cathode foil; the formation voltage of the anode foil is 950-1200vf; the electrolyte comprises the following components in percentage by weight: 63-75% of ethylene glycol or polyhydric alcohols, 4-15% of 24-50 carbon atom branched-chain binary or tricarboxylic acid ammonium salt, 1-10% of ammonium pentaborate, 1-12% of mannitol, and 0.2-1% of butyl phosphate; the conductivity of the electrolyte at 25 degrees centigrade is 0.1-0.4ms and the pH (potential of hydrogen) at 25 degrees centigrade is 5.8-7.8. As the formation voltage of the anode foil is 950-1200Vf and the electrolyte has very high flash fire voltage which can reach more than 700V, the capacitor has the working voltage of 700V, and the capacitor is effectively prevented from breakdown.

Owner:深圳市凯琦佳科技股份有限公司

Aluminum electrolysis capacitor working electrolyte for energy saving lamp and preparation thereof

ActiveCN101477899ALower specific resistanceWide operating temperature rangeElectrolytic capacitorsWorking temperatureSolvent

The invention relates to a working electrolyte for an aluminum electrolytic capacitor which is used for an energy-saving lamp, and a preparation method thereof. The working electrolyte comprises a main solvent glycol, a secondary solvent propanetriol, solute 1, 7-ammonium and ammonium pentaborate, and additives blockpolyether and p-nitrophenol. Glycol, 1, 7-ammonium, ammonium pentaborate, blockpolyether and p-nitrophenol are prepared according to the weight percentages of (80%-86%): (12%-16%): (1.5%-2.5%): (0.5%-1.5%). The steps of the preparation are as follows: glycol or the mixed liquid of glycol and propanetriol is heated to 120-125 DEG C; the mixed liquid is cooled down; 1, 7-ammonium and ammonium pentaborate are added into the cool mixed liquid and then stirred to dissolve; and then blockpolyether and p-nitrophenol dissolve after being added, and are stirred at a holding temperature. The electrolyte of the invention has low specific resistance, and the aluminum electrolytic capacitor made of the electrolyte has the advantages that the range of the working temperature is wide, the subzero temperature is negative 40 DEG C, and the service life can last for 5,000 h at positive 125 DEG C, thereby meeting the working requirements of the energy-saving lamp.

Owner:NANTONG JIANGHAI CAPACITOR CO LTD

Flame-retardant electrolyte and manufacturing method thereof

ActiveCN105140034APrevent oxide film hydration reactionReduce air permeabilityElectrolytic capacitorsElectrolysisHydrogen

The invention relates to a flame-retardant electrolyte and a manufacturing method thereof, wherein the flame-retardant electrolyte comprises, by weight percent, 63 percent to 86.5 percent of ethylene glycol, 1 percent to 3 percent of silicon dioxide, 5 percent to 15 percent of boric acid, 5 percent to 10 percent of ammonium pentaborate, 1 percent to 5 percent of mannitol, 0.5 percent to 2.0 percent of o-nitroanisole and 1 percent to 2 percent of phosphoric acid; the manufacturing method comprises: (a). heating the ethylene glycol to 60 to 75 DEG C, sequentially adding the boric acid, the ammonium pentaborate and the mannitol, continuously heating to 95 to 105 DEG C, and stirring till the boric acid, the ammonium pentaborate and the mannitol is completely dissolved; (b). adding the silicon dioxide into the solution and continuously stirring till the solution is completely clarified; (c). and cooling the solution to 65 to 70 DEG C, adding the o-nitroanisole and the phosphoric acid, and naturally cooling to acquire the electrolyte. According to the invention, the electrolyte has the performance to resist high temperature and high voltage and the hydrogen amount produced during the working process of an electrolytic capacitor is also reduced; and the vapor pressure of the electrolyte can be lowered, thus the electrolyte provided herein has flame-retardant performance.

Owner:NANTONG JIANGHAI CAPACITOR CO LTD

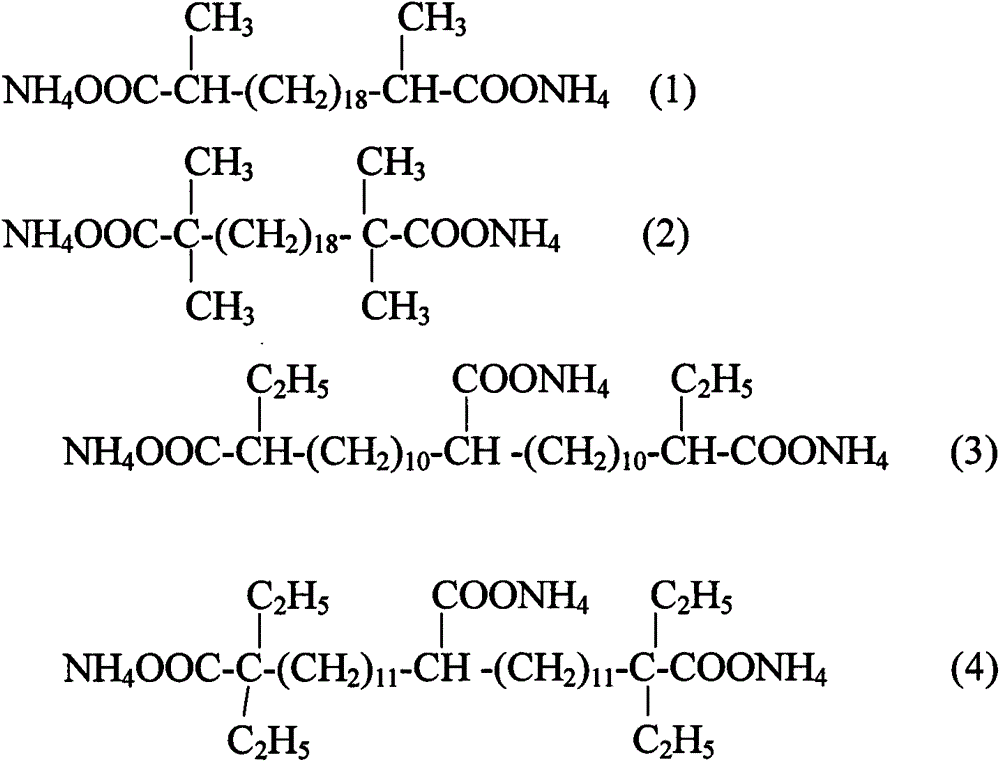

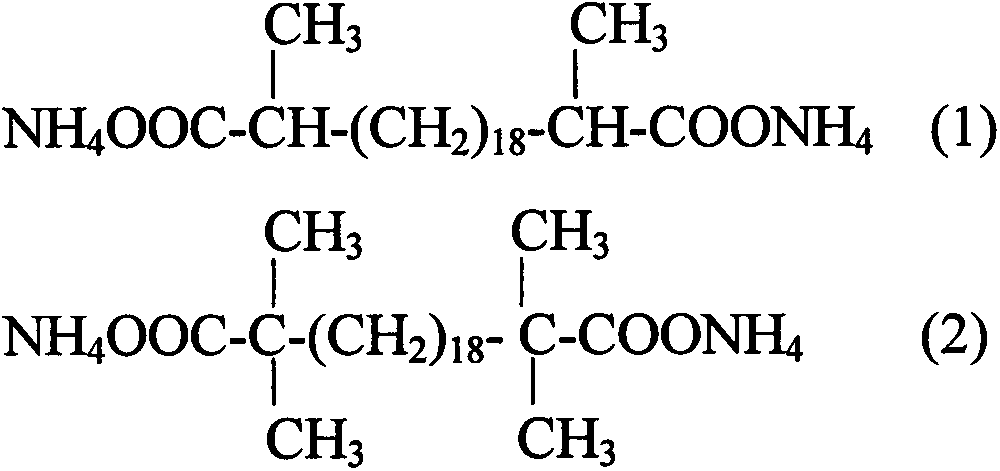

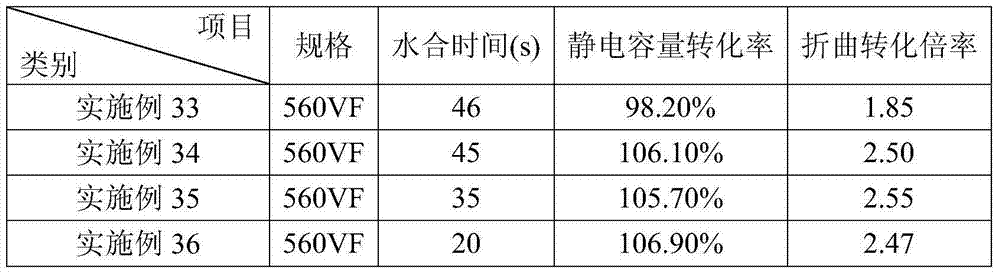

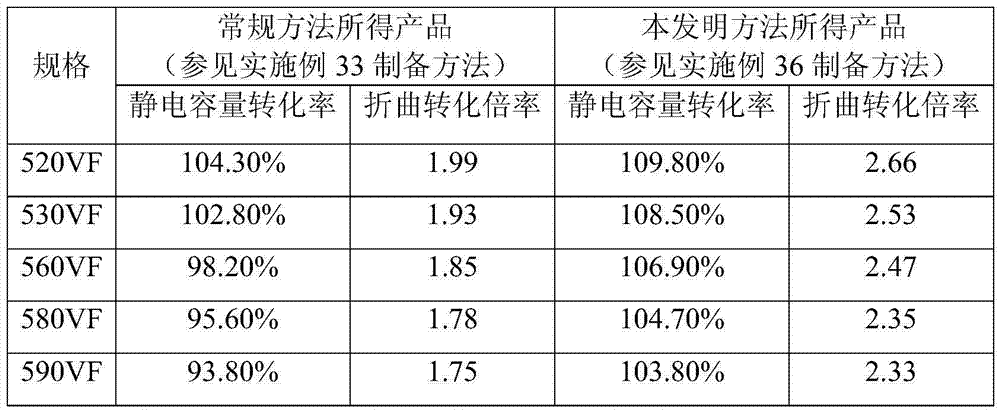

High-conversion-rate formed liquid, formed foil and forming method thereof

ActiveCN104499029ANo need to adjust the compositionNo need to adjust concentrationElectrolytic capacitorsSurface reaction electrolytic coatingMetallurgyCapacitor

The invention belongs to the field of electronic processing, and specifically relates to a high-conversion-rate formed liquid, a formed foil and a forming method thereof. The technical problem to be solved is to provide a formed liquid having high forming efficiency and capable of enhancing electrostatic capacity and flex conversion rate. The formed liquid comprises the following raw materials by weight percent: 0.55% to 0.85% of ammonium pentaborate, 0.005% to 0.025% of azelaic acid, 0.01% to 0.04% of citric acid and the balance of water. The formed liquid and a formed foil product prepared by the forming method have enhanced electrostatic capacity conversion rate and flex conversion rate, so that the volume of a capacitor can be shortened under the same production capacity condition, and thus the heat released by the capacitor in work is reduced, the power consumption is reduced, and the occupied space of an electric appliance can be reduced. According to the high-conversion-rate formed liquid, the formed foil and the forming method thereof provided by the invention, the technical scheme is simple and easy to implement, the field process flow is convenient to improve, the feasibility is strong, the application prospect is wide, and a brand-new choice is provided for the public.

Owner:SICHUAN RIKE ELECTRONICS

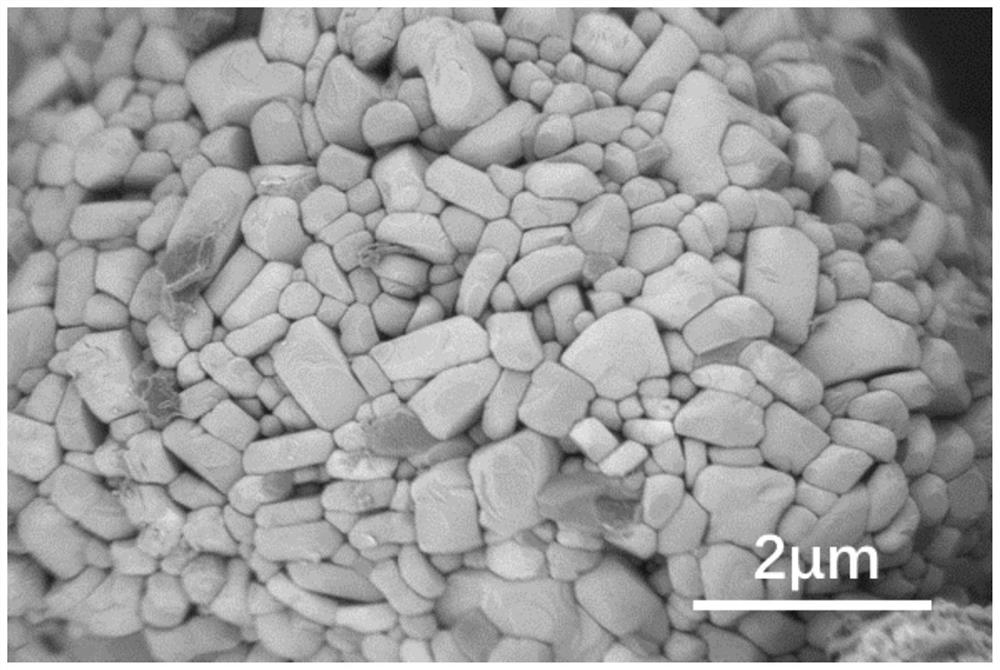

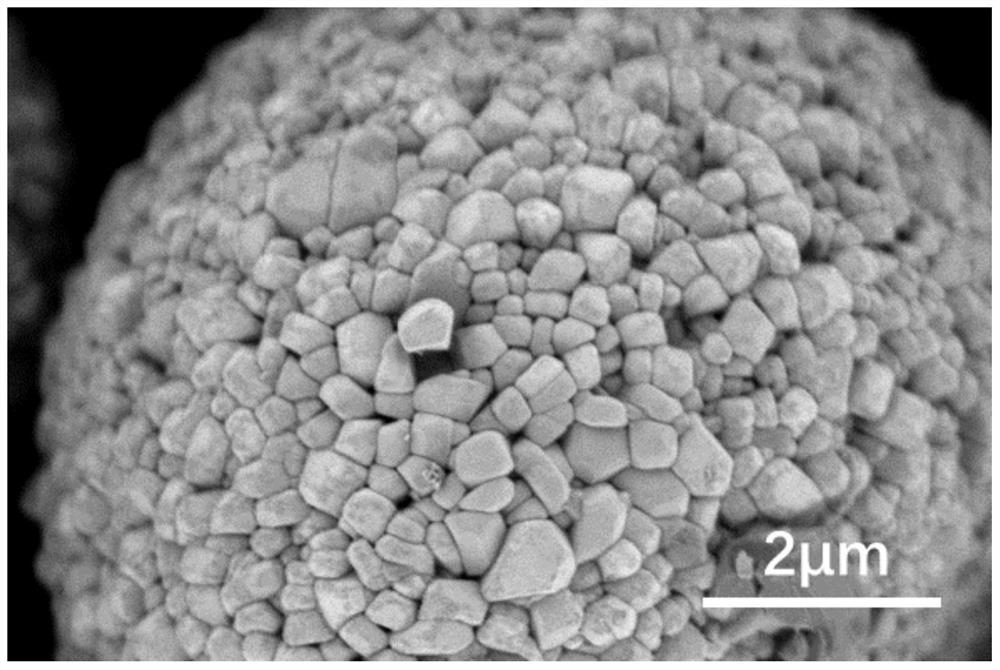

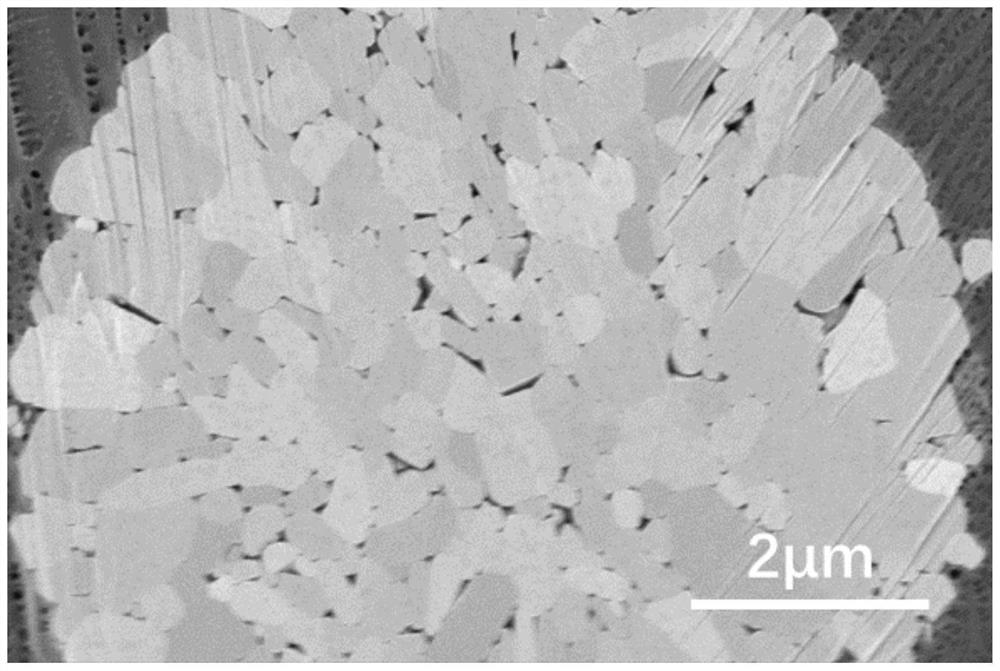

High-nickel ternary positive electrode material as well as preparation method and application thereof

InactiveCN112614991AImprove cycle stabilityReduce stressPositive electrodesLi-accumulatorsElectrical batteryManganese

The invention belongs to the technical field of lithium ion batteries, and provides a high-nickel ternary cathode material and a preparation method and application thereof, the chemical formula of the high-nickel ternary cathode material is LiNixCoyMnzBiO2, B is at least one of diboron trioxide, boric acid, lithium tetraborate, ammonium pentaborate, ammonium fluoborate or boron carbide, x > / = 0.9, y>0, z>0, i is not smaller than 0.001 and is not greater than 0.1, and x+y+z+i=1. The preparation method comprises the following steps of ball-milling and mixing a nickel-cobalt-manganese hydroxide precursor, a lithium source and a boron source, sintering and sieving to obtain the high-nickel ternary positive electrode material. Primary particles of the high-nickel ternary positive electrode material of the lithium battery are slender, interiors of secondary particles are looser, the high-nickel ternary positive electrode material of the lithium battery has higher first-circle capacity and better cycling stability, and the loose internal structure can reduce stress in the material in the cycling process, inhibit generation of microcracks, enhance the structural stability of the material and prolong the service life of the material; thus, a material having excellent cycle stability is obtained.

Owner:GUANGDONG BRUNP RECYCLING TECH +2

Ultrahigh-pressure formed foil forming technology for aluminum electrolytic capacitor

ActiveCN110016702AMitigation of flash fireImprove hydrophilicityAnodisationElectrolytic capacitorsHydration reactionTetramethylammonium hydroxide

The invention relates to an ultrahigh-pressure formed foil forming technology for an aluminum electrolytic capacitor. An existing boric acid forming technology is improved, high-purity aluminum foil obtained after corroding and face expanding is subjected to a hydration reaction, then four-stage formation is conducted with first-stage and second-stage electrolytic liquid being a mixed solution ofboric acid, citric acid and ammonium pentaborate and third-stage and fourth-stage electrolytic liquid being a mixed solution of boric acid, tetramethyl ammonium hydroxide and mannitol. In addition, proper phosphoric acid treatment strength is selected in aftertreatment, the voltage of the formed foil can reach 1200 V, and therefore the application field of the formed foil is further expanded.

Owner:INNER MONGOLIA ULANQAB DONGYANGGUANG FORMED FOIL CO LTD

Treatment method for improving water resistance of electrode foil for aluminum electrolytic capacitor

InactiveCN106653372AImprove water resistanceShort boost timeElectrolytic capacitorsElectrolysisPhosphoric acid

The invention discloses a treatment method for improving the water resistance of an electrode foil for an aluminum electrolytic capacitor. The method comprises the steps of soaking an aluminum foil in water at 95 DEG C for 10 minutes; taking out the aluminum foil and putting the aluminum foil into 0.5% of an ammonium dihydrogen phosphate water solution for formation for 10 minutes; taking out the aluminum foil for washing; putting the aluminum foil into 0.3% of an ammonium dihydrogen phosphate water solution for formation for 10 minutes; taking out the aluminum foil for washing; putting the aluminum foil into 8% of a boric acid and 1% of an ammonium pentaborate water solution for formation for 10 minutes; putting the aluminum foil into a same tertiary water solution for formation for 30 minutes; putting the aluminum foil into a water solution with the same three-stage formation for formation for 10 minutes; carrying out treatment in 0.1%-3% of an organic phosphoric acid or organic phosphate solution at 50-80 DEG C for 5-10 minutes; taking out the aluminum foil for washing; putting the aluminum foil into a water solution with the same three-stage formation for formation for 10 minutes; putting the aluminum foil into 2% of an ammonium dihydrogen phosphate solution and steeping at 70 DEG C for 5 minutes; and taking out the aluminum foil and washing and drying the aluminum foil. The treatment method has the advantages that the electrode foil with high water resistance can be obtained, the voltage-rise time of a product after being boiled is shortened, the electrode foil is convenient to store and the storage life is prolonged.

Owner:NANTONG HAIXING ELECTRONICS +2

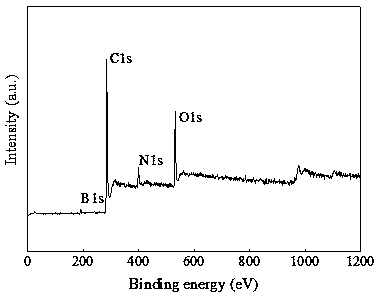

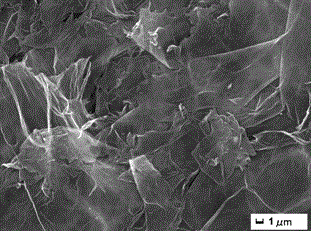

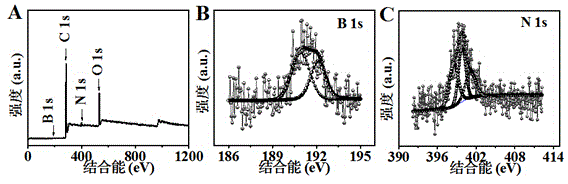

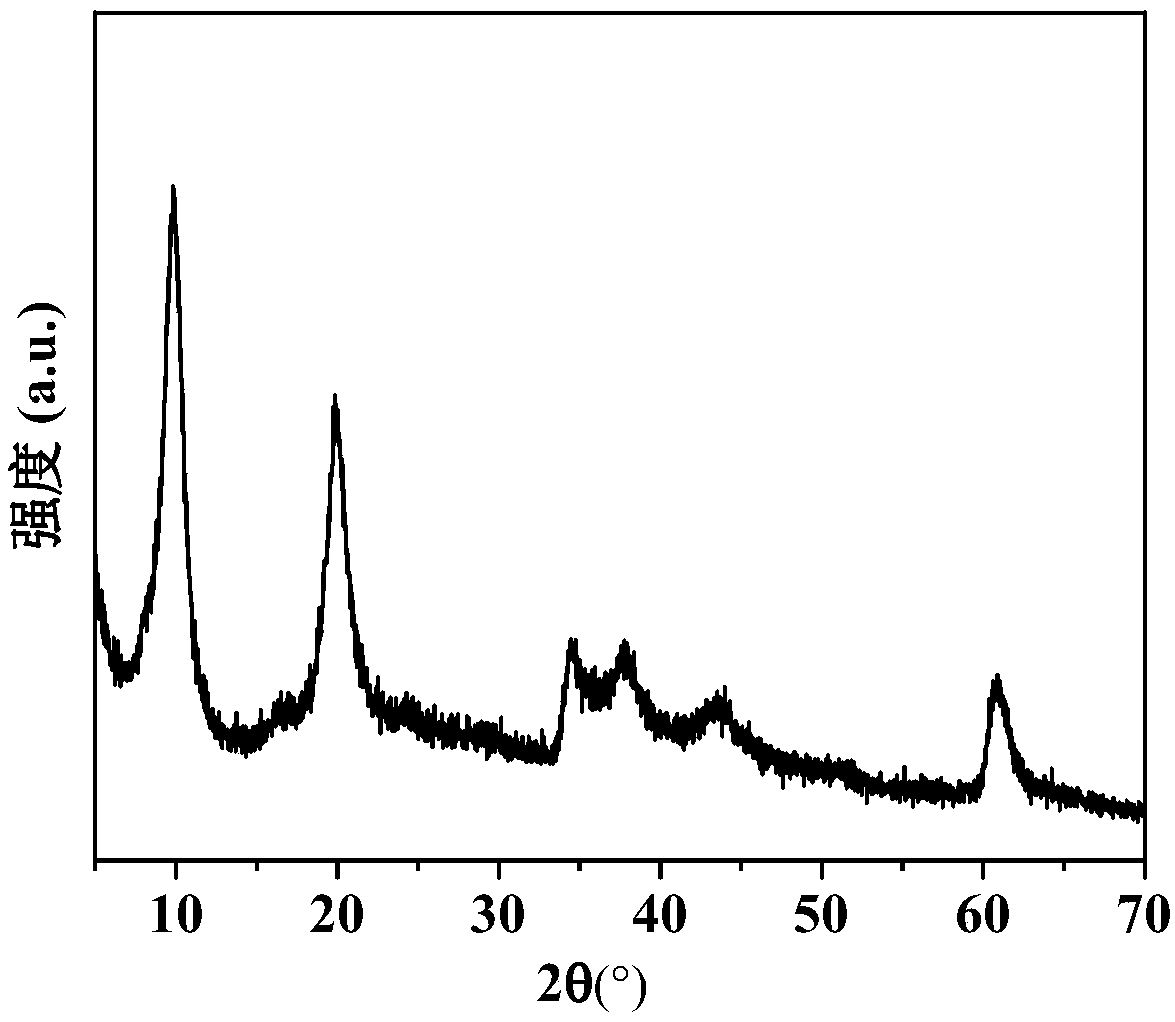

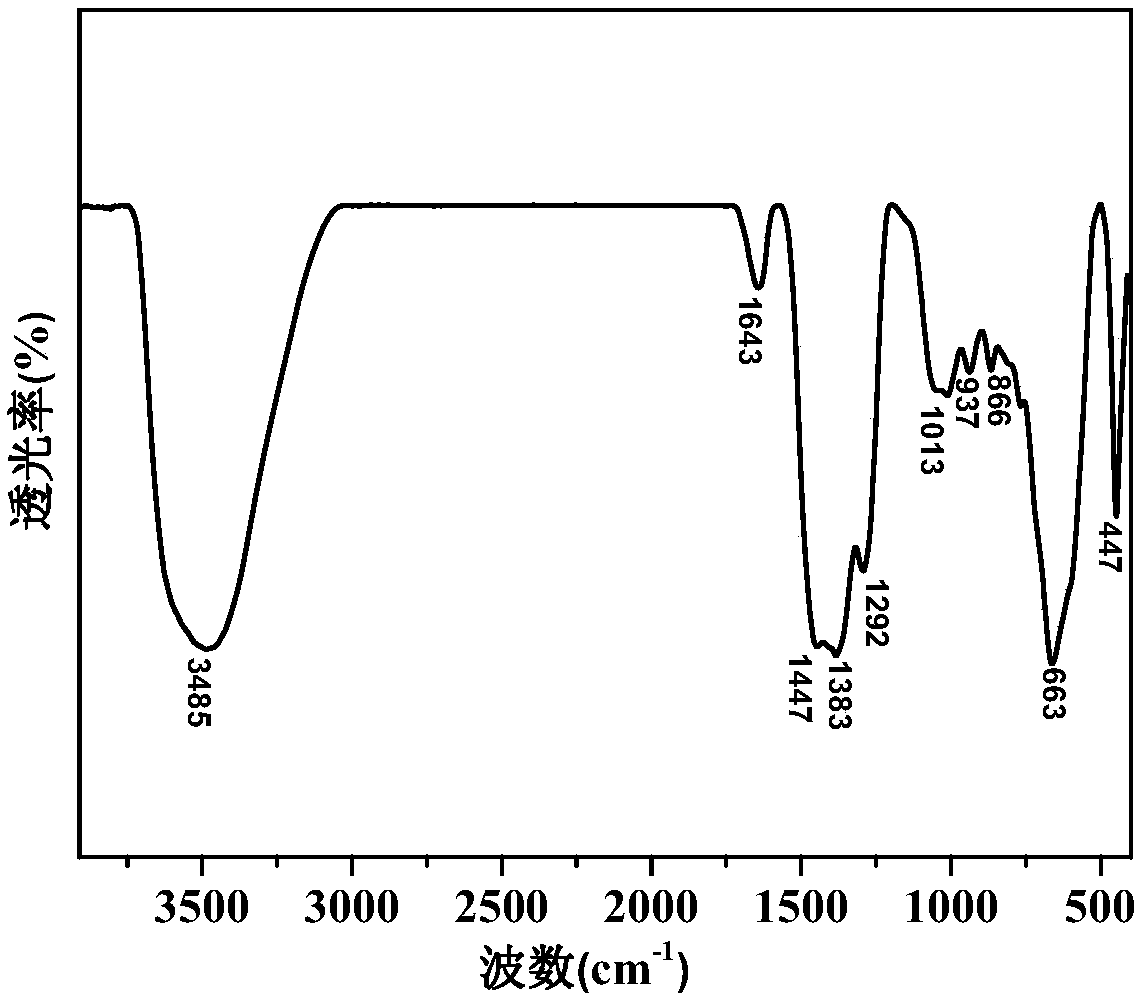

Preparation method of born-nitrogen miscellaneous graphene hydrogel

The invention relates to a preparation method of born-nitrogen miscellaneous graphene hydrogel, and belongs to the technical field of nano materials. According to the preparation method, firstly, graphite oxide is taken as a carbon source, and ammonium pentaborate is used as a born source and a nitrogen source, so that the born-nitrogen miscellaneous graphene hydrogel is prepared by one step under a gentle hydrothermal condition. The synthesis method of the born-nitrogen miscellaneous graphene hydrogel provided by the invention is simple in synthesis process; the required raw materials are low in cost; the conditions are gentle; the prepared born-nitrogen miscellaneous graphene hydrogel has a rich pore structure, and has good application prospect in the application fields such as a capacitor with double electric layers, a hydrogen storage carrier and a biological sensor.

Owner:JIANGSU UNIV

High-sparking and long-service-life electrolyte for aluminum electrolytic capacitor and preparation method therefor

ActiveCN105469991AGood electrochemical propertiesIncrease the flash voltageLiquid electrolytic capacitorsCapacitor manufactureElectrolysisPhosphate

The present invention relates to the technical field of electrolytes, in particular to a high-sparking and long-service-life electrolyte for an aluminum electrolytic capacitor and a preparation method therefor. The electrolyte comprises the following raw materials in parts by weight: 3-5 parts of ammonium sebate, 1-2 parts of ammonium pentaborate, 1-2 parts of sorbitol, 1.5-2.5 parts of ammonium dodecanedioate, 8-12 parts of a sparking boosting agent, 4-6 parts of branch-chain organic acid, 0.05-0.15 part of organic phosphate, 0.4-0.6 part of p-nitrobenzyl alcohol, 0.1-0.3 part of p-nitrophenol, 5-7 parts of ethylene glycol nano silica sol, 4-6 parts of Y-butyrolactone and 55-75 parts of glycol. The electrolyte is prepared by means of interaction among the raw materials; the sparking voltage of the prepared electrolyte can reach 535 V and the conductivity rate of the prepared electrolyte can reach 1.8 ms / cm; and the electrolyte has good electrochemical properties, has the advantages of high sparking voltage and long service life, and can be applied to manufacturing of the aluminum electrolytic capacitors.

Owner:DONGGUAN JIUZHI ELECTRONICS CO LTD

Aluminium electrolytic capacitor working electrolyte and capacitor obtained thereof

ActiveCN1744247BGood high pressureImprove high temperature resistanceElectrolytic capacitorsPolyvinyl alcoholPhosphate

The electrolyte includes solvent, solute, additive for corrosion resistance and property modifying additive. The additive for corrosion resistance includes 8-hydroxy quinoline, mannitol, phosphate monoester and one or more matters selected from organic acids. Compositions of property modifying additive include polyvinyl alcohol and / or carbowax, boracic acid and / or ammonium pentaborate, and glycoletc. Moreover, the electrolyte also includes dehydrogenation agent and waterproof mixture. The electrolyte improves capabilities of high temperature and high pressure resistant, and corrosion proof for aluminum electrolytic capacitor, reduces generation of hydrogen so as to prevent capacitor from blowing up, and hydration causing invalidation of capacitor. The invention also discloses the aluminum electrolytic capacitor of using the electrolyte. The capacitor is operable under rated operational voltage 315V-500V, and temperature 125 deg.C as upper limit.

Owner:GUANGDONG FENGHUA ADVANCED TECH HLDG

Moldable compositions and methods of using thereof

The present invention provides moldable compositions that are capable of resisting slumping and cracking when allowed to dry and harden. Embodiments of the moldable composition comprise water, fillers including arrowroot and kaolin clay, at least one polar polymeric resin (e.g., polyvinyl alcohol), at least one thickening agent (e.g., ammonium pentaborate tetrahydrate), one or more pH adjusters (e.g., triethanolamine, sodium bicarbonate), a humectant (e.g., propylene glycol, glycerin), optionally at least one releasing agent (e.g., mineral oil), and optionally at least one additive.

Owner:CRAYOLA

Preparation method of hierarchical porous ball-flower shaped borate intercalation hydrotalcite nanometer material

ActiveCN109095486ARaw materials are easy to getMild reaction conditionsAluminium compoundsNanotechnologyHydrotalciteHierarchical porous

The invention discloses a preparation method of a hierarchical porous ball-flower shaped borate intercalation hydrotalcite nanometer material, magnesium nitrate, aluminum nitrate, sodium hydroxide andurea are taken as the main materials, ammonium pentaborate is added as a boron source and a structure directing agent to prepare the hierarchical porous ball-flower shaped borate intercalation hydrotalcite nanometer material through a hydrothermal method. The method is simple, the raw materials are easy to get, the reaction condition is mild, the specific surface area of the prepared borate intercalation hydrotalcite nanometer material is relatively large, has a hierarchical porous structure, has a better adsorption capacity, and can be applied to different fields like water pollution treatment, catalysis, adsorption, and medicines.

Owner:SHAANXI NORMAL UNIV

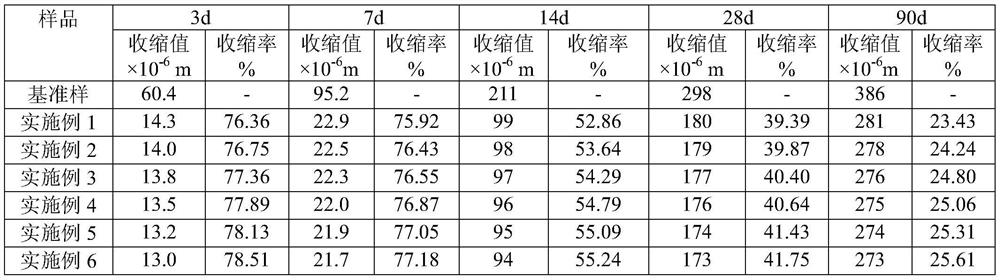

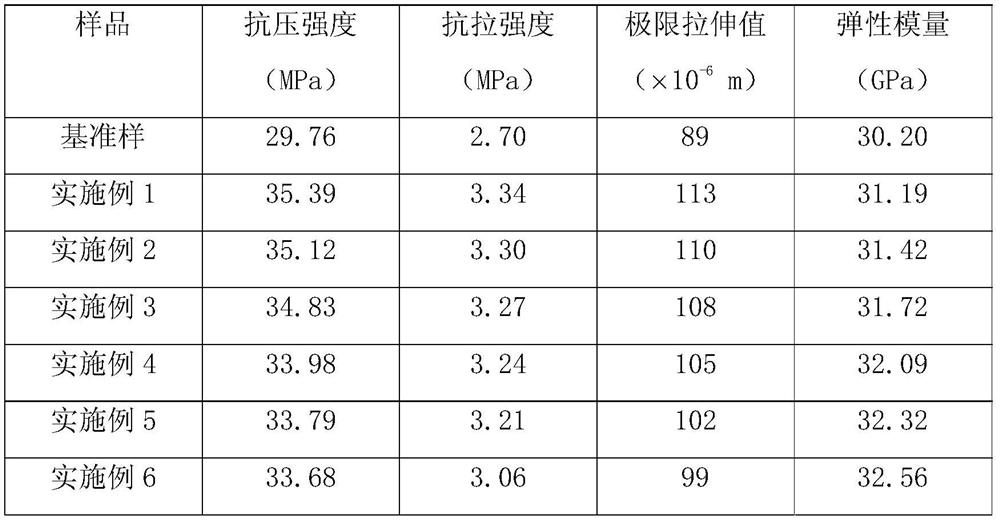

Concrete anti-cracking and anti-seepage admixture and preparation method thereof

The invention relates to a concrete anti-cracking and anti-seepage admixture and the preparation method thereof. The concrete anti-cracking and anti-seepage admixture comprises the following raw material components in percentage by mass: 0.1-1% of ammonium pentaborate, 1-10% of polyaluminum sulfate, 3-5% of ammonium sulfate, 1-5% of potassium oleate and the balance of water. The concrete anti-cracking and anti-seepage admixture provided by the invention is low in doping amount and good in anti-cracking and anti-seepage effect, has no negative influence on the comprehensive performance of concrete, can obviously prolong the service life of the concrete, can reach the anti-seepage grade of P12 when the doping amount reaches 1-5%, has the service life of 20 years without seepage, and can replace the existing anti-seepage and anti-cracking products.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

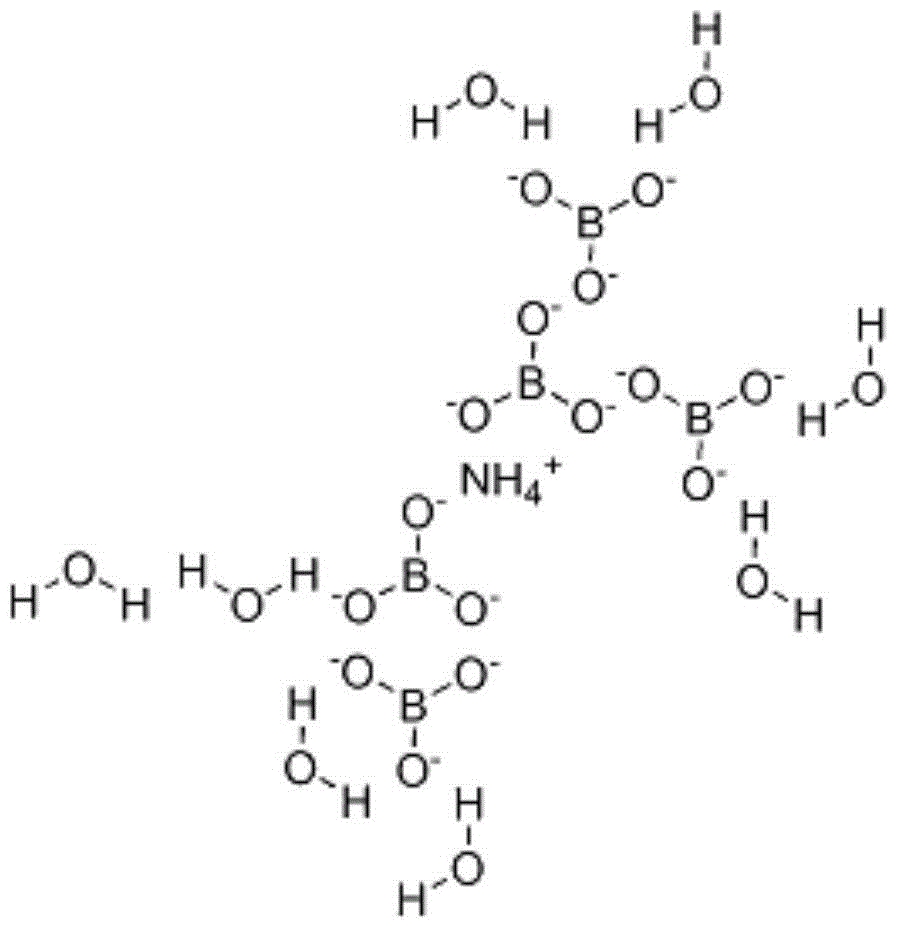

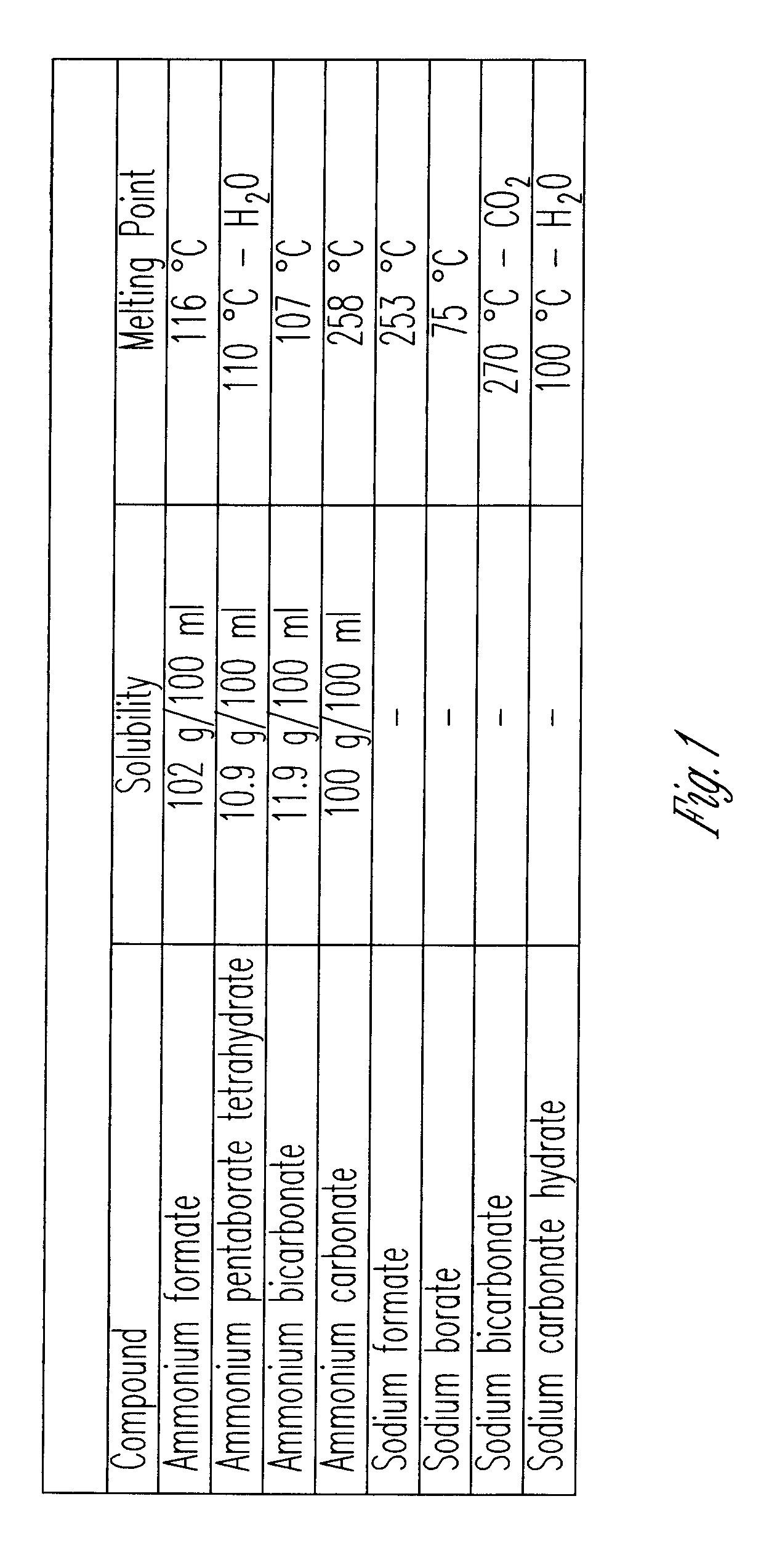

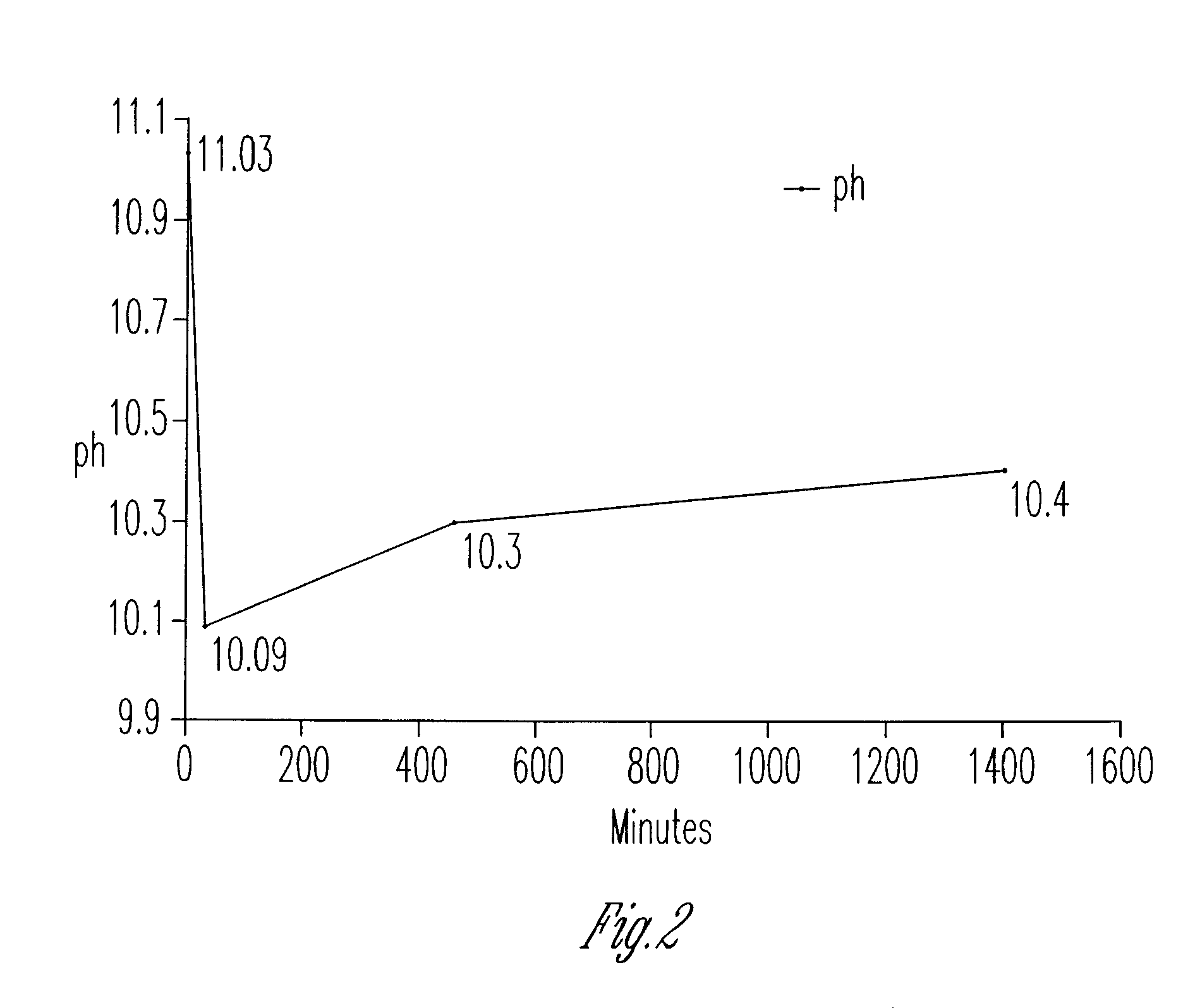

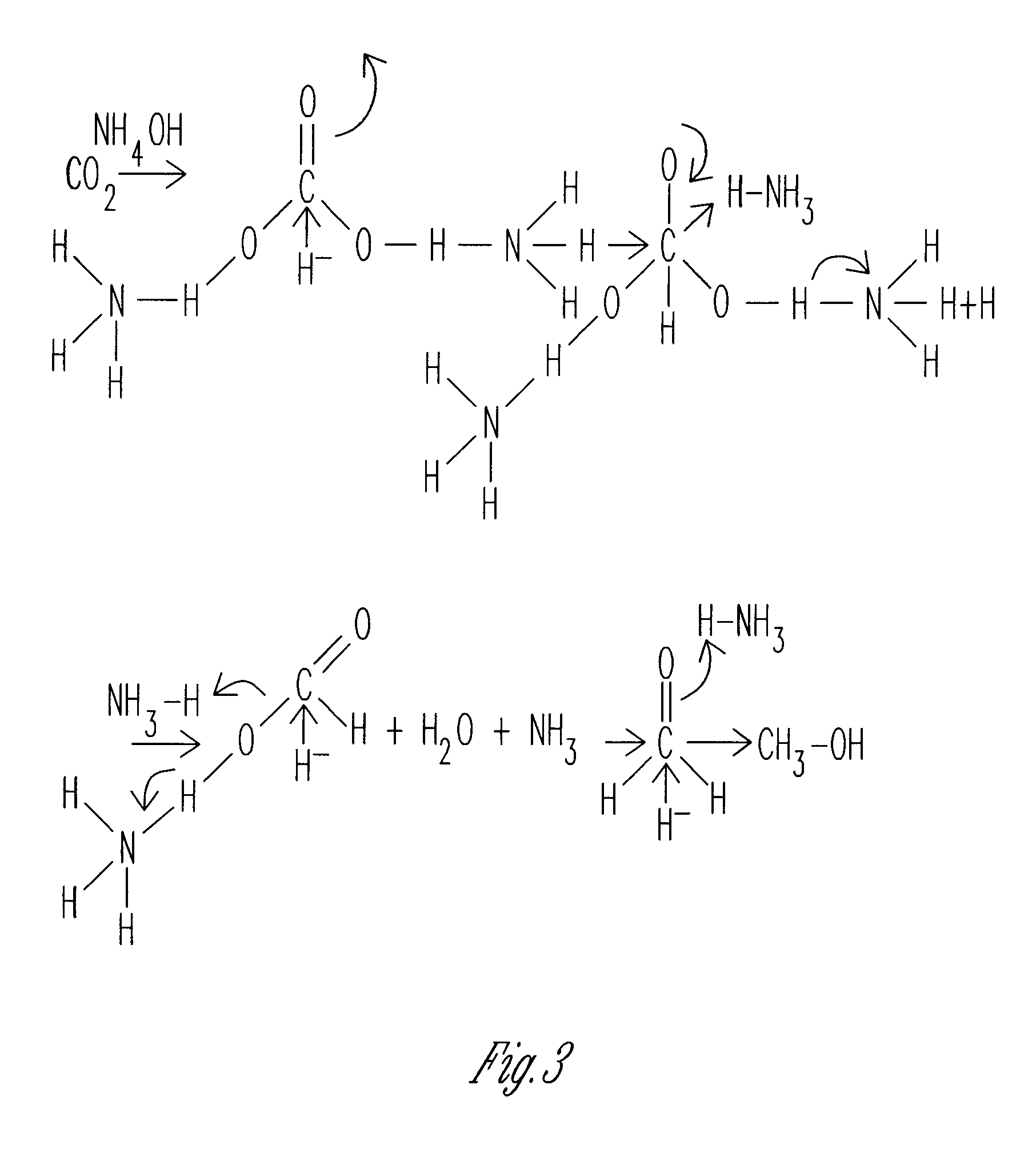

MANUFACTURING OF MeOH, FORMALDEHYDE, FORMIC ACID AND AMMONIUM PENTABORTE TETRAHYDRATE FROM CO2

InactiveUS20130053602A1Organic compound preparationOxygen compounds preparation by reductionSodium bicarbonateAlternative methods

A method of forming methanol formaldehyde, formic acid and ammonium pentaborate tetrahydrate includes the steps of providing ammonium hydroxide and producing air bubbles within the ammonium hydroxide to form a solution. Sodium borohydride is added and dissolved within the solution of air bubbled ammonium hydroxide to form methanol formaldehyde, formic acid and ammonium pentaborate tetrahydrate. An alternative method of forming methanol formaldehyde, formic acid and ammonium pentaborate tetrahydrate is also provided which includes the steps of providing ammonium hydroxide and dissolving sodium borohydride therein to form a solution. Sodium bicarbonate is added to the solution of ammonium hydroxide and sodium borohydride to form methanol formaldehyde, formic acid and ammonium pentaborate tetrahydrate.

Owner:BIOLOGISTICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com