Aluminium electrolytic capacitor for flash lamp and preparing method tereof

A technology of aluminum electrolytic capacitors and flash lamps, applied in electrolytic capacitors, capacitors, circuits, etc., can solve the problems of insufficient withstand voltage, large leakage current, and inability to make flash lamp aluminum electrolytic capacitors, etc., and achieve small leakage current and withstand voltage performance. Good, overcome the effect of product burst

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] (1) Cutting: Cut the anode foil, cathode foil and electrolytic paper for the aluminum electrolytic capacitor of the flash lamp into coils, and the cutting speed is 10 minutes / 10,000 pieces; the cutting machine (model, manufacturer) used

[0037] (2) Winding: Put the anode foil and cathode foil and the lead wire into the riveting machine, and automatically rivet the lead wire at the specified position of the anode foil and cathode foil. The number of riveting points is 5. After riveting, the cathode aluminum foil and anode aluminum foil The middle folder is wound up with electrolytic paper, and then glued with tape to form an aluminum electrolytic capacitor core package; the winding speed is 8 hours / 10,000 pieces / set;

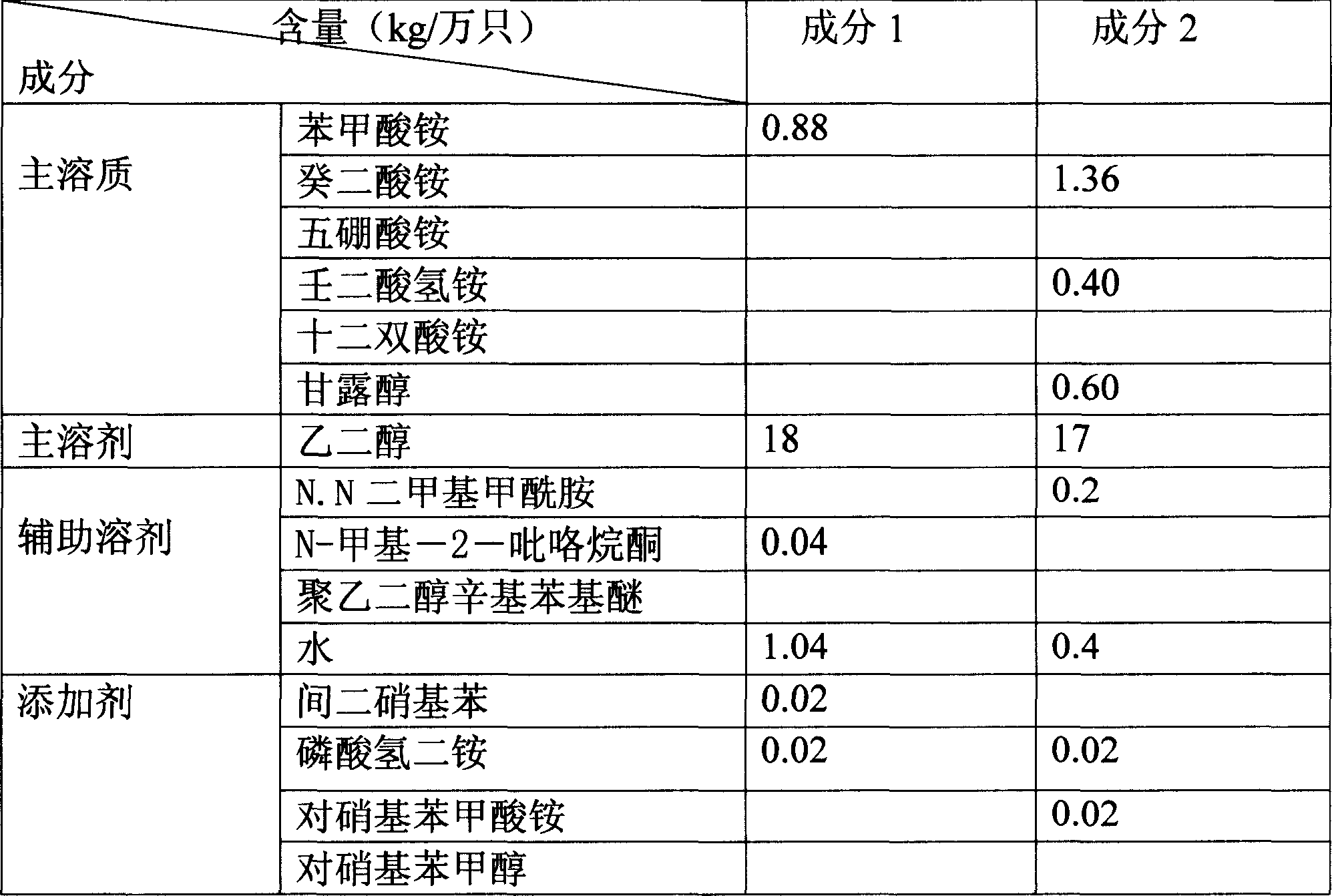

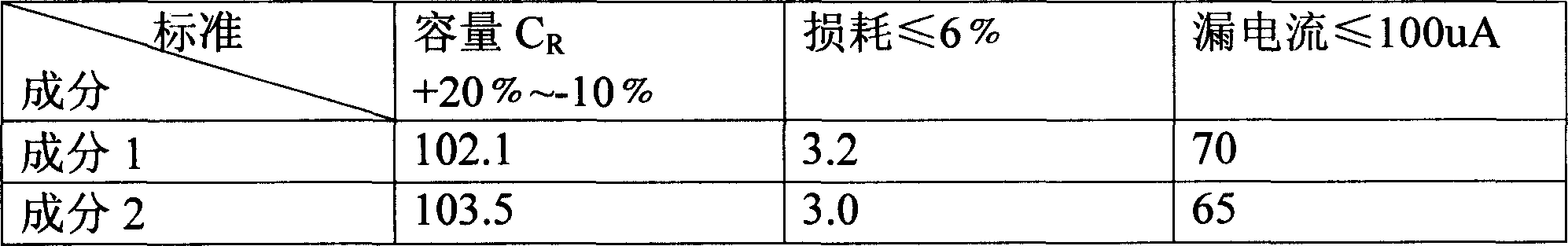

[0038] (3) Impregnation: Immerse the above wound core package in the working electrolyte for 2 hours; the composition of the working electrolyte is shown in Table 1

[0039] (4) Assembling and sealing: sealing the impregnated core package in the aluminum ...

Embodiment 2

[0048] (1) Cutting: Cut the anode foil, cathode foil and electrolytic paper for the aluminum electrolytic capacitor of the flash lamp into coils, and the cutting speed is 20 minutes / 10,000 pieces; the cutting machine (model, manufacturer) used

[0049] (2) Winding: Put the anode foil and cathode foil and the lead wire into the riveting machine, and automatically rivet the lead wire at the specified position of the anode foil and cathode foil. The number of riveting points is 5. After riveting, the cathode aluminum foil and anode aluminum foil The middle folder is wound up with electrolytic paper, and then glued with tape to form an aluminum electrolytic capacitor core package; the winding speed is 6 hours / 10,000 pieces / set;

[0050] (3) Impregnation: Immerse the wound core package in the working electrolyte for 6 hours; the composition of the working electrolyte is shown in Table 3

[0051] (4) Assembling and sealing: sealing the impregnated core package in the aluminum shell ...

Embodiment 3

[0061] (1) Cutting: Cut the anode foil, cathode foil and electrolytic paper for the flashlight aluminum electrolytic capacitor into coils, and the cutting speed is 30 minutes / 10,000 pieces; the cutting machine (model, manufacturer) used

[0062] (2) Winding: Put the anode foil and cathode foil and the lead wire into the riveting machine, and automatically rivet the lead wire at the specified position of the anode foil and cathode foil. The number of riveting points is 5. After riveting, the cathode aluminum foil and anode aluminum foil The middle folder is wound with electrolytic paper, and then glued with tape to form an aluminum electrolytic capacitor core package; the winding speed is 10 hours / 10,000 pieces / set;

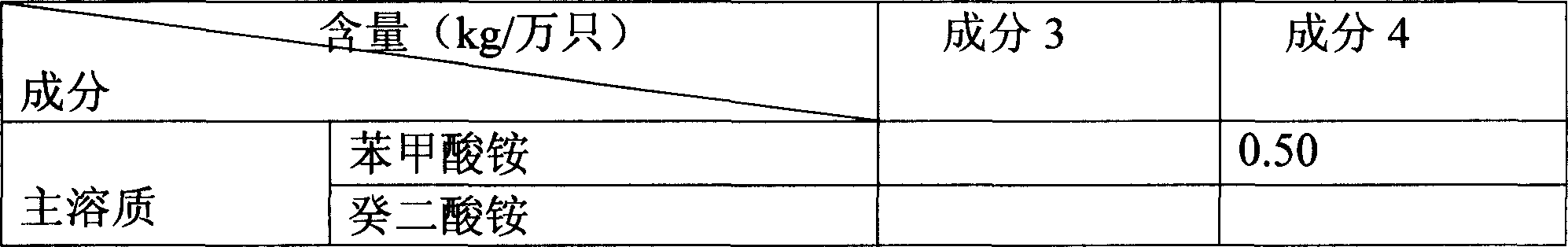

[0063] (3) Impregnation: immerse the above-mentioned wound core package in the working electrolyte for 9 hours; the composition of the working electrolyte is shown in Table 5

[0064] (4) Assembling and sealing: sealing the impregnated core package in the aluminum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com