Patents

Literature

67 results about "M-dinitrobenzene" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The biotransformation of m-dinitrobenzene was studied in rabbits. The animals recieved a single oral dose of radiocarbon-labeled m-DNB in the range of 50 to 100 mg/kg. Urine was collected for two days after dosing for analysis of metabolites.

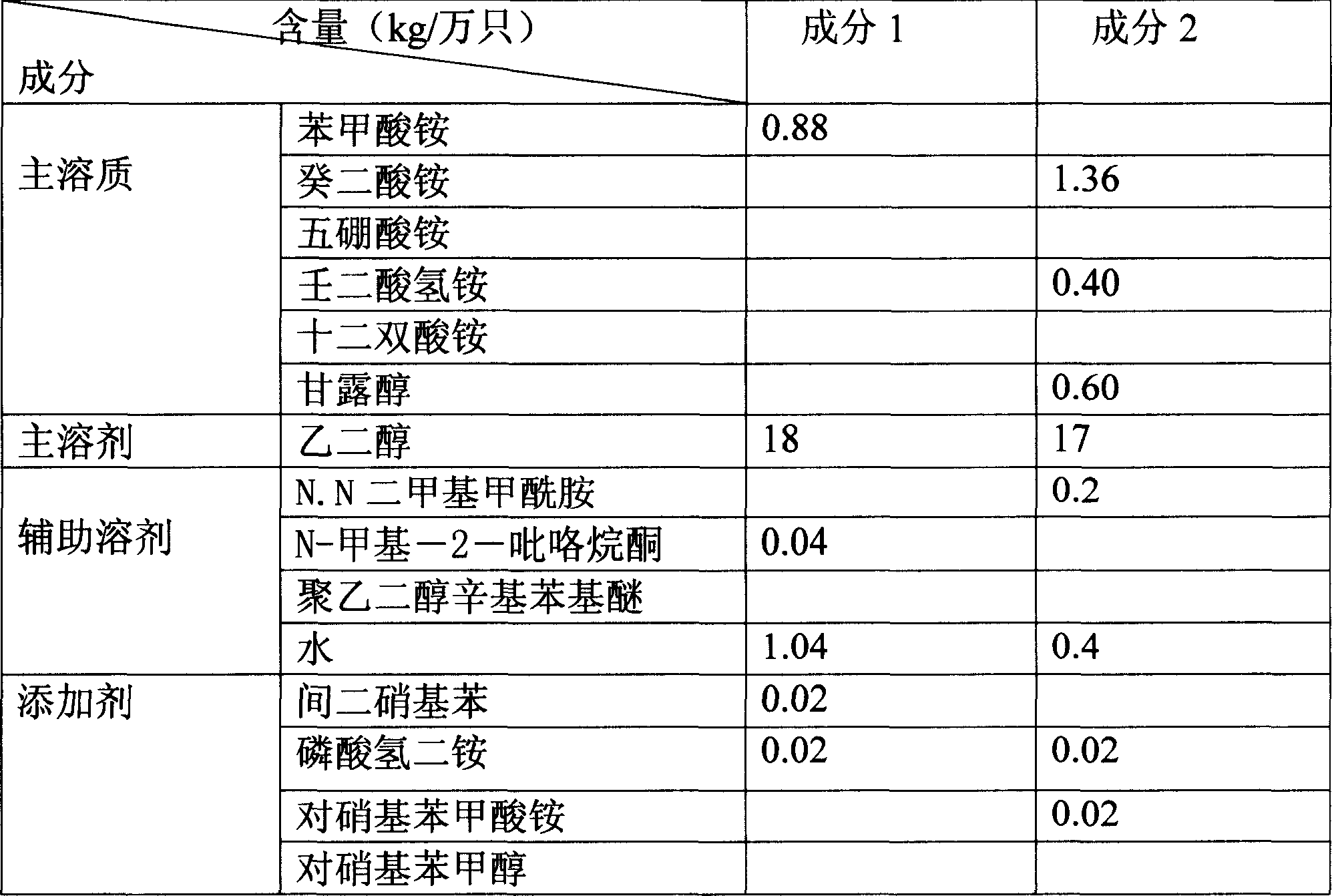

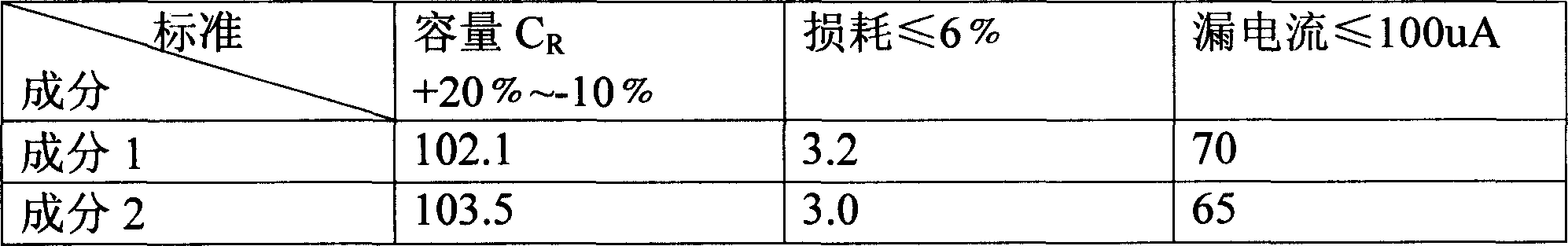

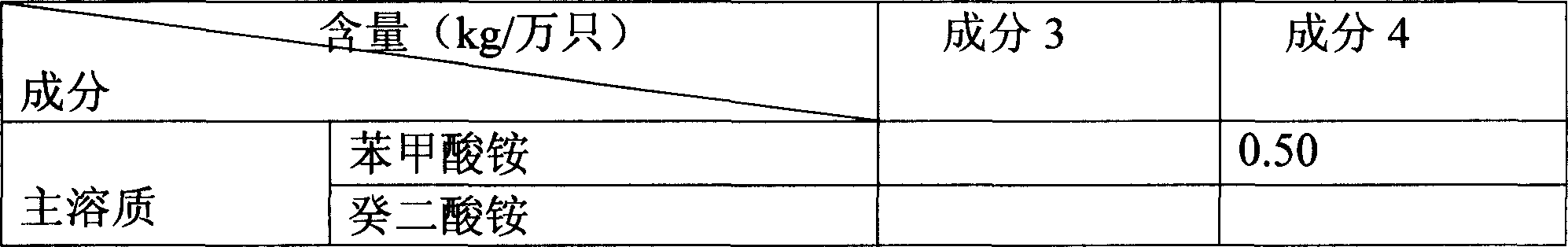

Aluminium electrolytic capacitor for flash lamp and preparing method tereof

ActiveCN1862728AImprove pressure resistanceReduce leakage currentElectrolytic capacitorsPhosphatePolyethylene glycol

This invention relates to aluminum electrolytic capacitor and its preparation method, especially relates to aluminum electrolytic capacitor used in flashing light and its preparation method. Its work electrolyte components is that main solvent is ethylene glycol. Secondary solvent is one or mixture N.N dimethyl formamide, N-methyl-2- pyrrolidone, polyethylene glycol octyl phellyl ether and water. The main solute is one or mixture of ammonium benzoate, ammonium sebacate, ammonium pentaborate, azelaic acid hydrogen ammonium, dodecandioic acid ammonium, mannitol. The additive is one of mixture of m-dinitrobenzene, ammonium dibasic phosphate, nitrodracylic acid ammonium and amphi nitryl benzoic alcohol. The capacitor in this invention is good in pressure resistance, the leakage current is little, the slow leakage rally can be used to make flashing light aluminum electrolytic capacitor of rated voltage keep around 330V.

Owner:横店集团东磁有限公司

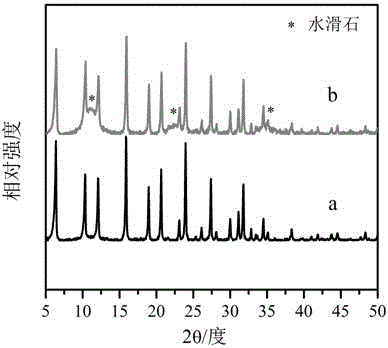

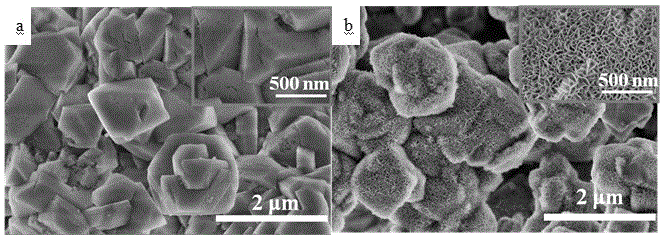

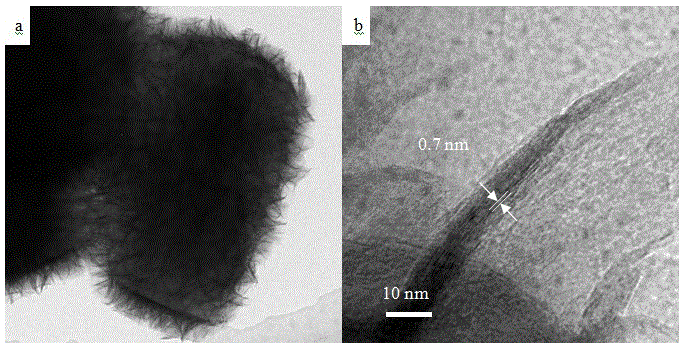

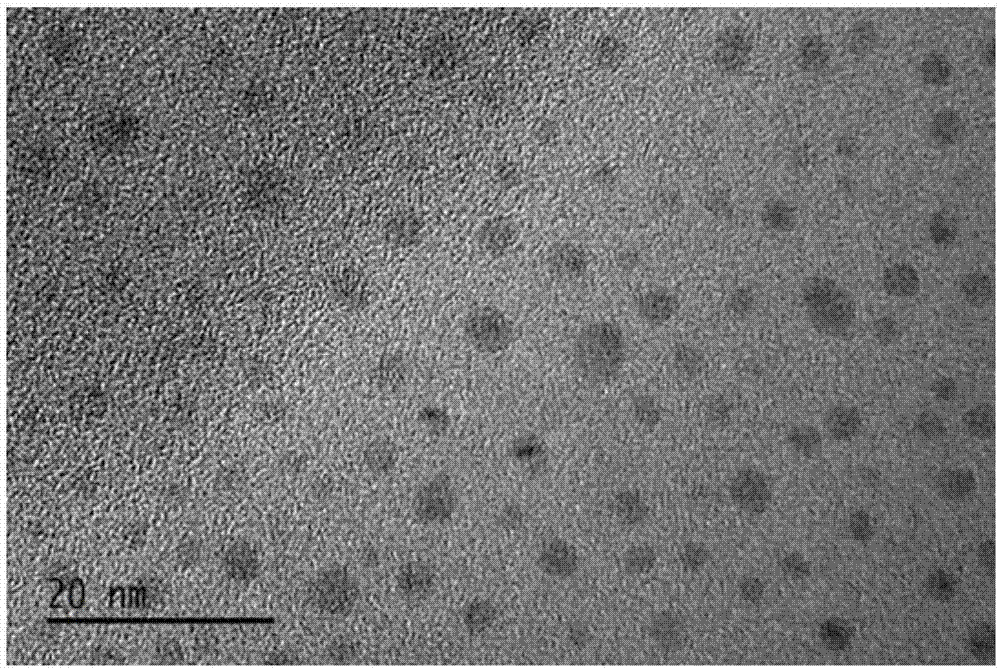

Core shell catalyst by taking hydrotalcite as shell and molecular sieve as core as well as preparation and application thereof

ActiveCN106475134AGood dispersionImprove stabilityMolecular sieve catalystsOrganic compound preparationMolecular sieveDivalent metal

The invention discloses a core shell catalyst by taking hydrotalcite as a shell and a molecular sieve as a core as well as a preparation and an application thereof. According to the invention, divalent metal source and aluminum species in a core-shell molecular sieve are used for forming a hydrotalcite compound on the surface of the molecular sieve, and the core-shell structure molecular sieve by taking the molecular sieve as the core and the petal hydrotalcite as the shell is formed; after the molecular sieve is reduced, the nano-grade metal-modified molecular sieve catalyst having uniform size, high dispersibility, excellent heat stability and high universality is obtained, and can be used for a catalytic reaction for hydrogenation synthesis of m-dinitrobenzene to obtain m-phenylenediamine. compared with the prior art, the preparation process is simple, the metal atom utilization rate is high, applied metal source is almost completely reacted, no loss is generated, cost is reduced, and pollution on environment is reduced, industrial production is easy, and a series of different metal-modified molecular sieve catalysts can be prepared according to the modifiable character of the composition elements of the hydrotalcite and diversity of a topological structure of the molecular sieve.

Owner:EAST CHINA NORMAL UNIV

Process for preparing 2,2-di-[4-(3-nitro phenoxy) phenyl] propane

InactiveCN1425644ALow toxicityConvenient sourceOrganic chemistryOrganic compound preparationToluenePhenyl group

The present invention relates to the preparation process of 2,2-di-[4-(3-nitro phenoxy) phenyl] propane. Under the action of anhydrous potassium carbonate as salt forming agent, N,N-dimethyl formamide as solvent, toluene as dewatering agent and triethylamine as catalyst, bisphenol A and m-dinitrobenzene are reflux reacted at 110-180 deg.c to prepare 2,2-di-[4-(3-amino phenoxy)phenyl] propane, which is purified through re-crystallization in toluene. The said process has 2,2-di-[4-(3-nitro phenoxy) phenyl] propane yield of 90-96%, and the product has smelting point of 111-113 deg.c.

Owner:SHANGHAI RES INST OF SYNTHETIC RESINS

Method for treating waste water from meta dinitro benzene production

InactiveCN1781859AEasy to handleTreatment methods that can effectively treat emissions effectivelyWater/sewage treatment by ion-exchangeMultistage water/sewage treatmentActivated carbonBenzene

The process of treating waste water from m-dinitrobenzene production includes the following main steps: regulating acidity of the waste water, standing, filtering and adsorbing in macroporous resin filling adsorption tower; stopping adsorption after reaching the first falloff point and desorption regenerating with sodium hydroxide aqua as desorbent; regulating acidity for the second time and adsorbing in macroporous resin filling adsorption tower for the second time; stopping adsorption after reaching the second falloff point and desorption regenerating with sodium hydroxide aqua as desorbent; and regulating acidity, decolorizing in adsorption tower filled with active carbon to obtain colorless transparent water. The said process can treat waste water from m-dinitrobenzene production to exhaust standard, and the adsorption resin may be regenerated for reuse.

Owner:NANJING UNIV

Application of Chinese lacquer original nickel in the preparation of m-phenylene diamine with m-dinitrobenzene liquid phase hydrogenation

InactiveCN101161339AEasy to prepareHigh catalytic activityOrganic compound preparationAmino compound preparationNickel saltAlcohol

The present invention discloses a method of using the urushibara nickel to catalyze the m-dinitrobenzene liquid phase hydrogenation to prepare the m-phenylenediamine, and the method belongs to the preparing technique of the m-phenylenediamine. The method includes the following steps: adding the nickel salt solution with a definite concentration to the suspension of the zinc dust at a definite temperature, developing the solution with the developing agent with a certain concentration when the reaction has reacted for a certain time, then washing with the deionized water and absolute ethyl alcohol for a plurality of times and the urushibara nickel catalyst. Adding the urushibara nickel catalyst and the m-phenylenediamine and absolute ethyl alcohol or the mixture of the absolute ethyl alcohol and water according to a certain mass ratio to the high-pressure reaction still, the temperature is 60 to 100 DEG C, and the pressure is 1 to 2.5 MPa, the feed stock conversion and product selectivity are all larger than 99% when the reaction has completed. The invention has the advantages of simple technique, simple reaction operation, short reaction time, high product yield and purity and less environmental pollution.

Owner:NANKAI UNIV

Method for preparing m-phenylenediamine

InactiveCN101323579AHigh activityGood choiceOrganic compound preparationAmino compound preparationPolymer scienceSolvent

The invention discloses a method for preparing metaphenylene diamine by catalytic hydrogenation of m-dinitrobenzene, comprising the following steps of: taking m-dinitrobenzene as a raw material, and carrying out hydrogenation reduction in the solvent of alcohol or benzene under the existence of a palladium-ruthenium loaded catalyst. The reaction conditions are temperature of 20 DEG C to150 DEG C, pressure of 0.1MPa to 6.0MPa and input amount of catalyst of 0.1g to 1.0g / 100g nitryl materials. The method for preparing the metaphenylene diamine provided by the invention has advantages of simple production technology, moderate operation conditions and easy control. The catalyst used for the reaction has high activity, good selectivity, low cost and long service life.

Owner:中国中化股份有限公司 +1

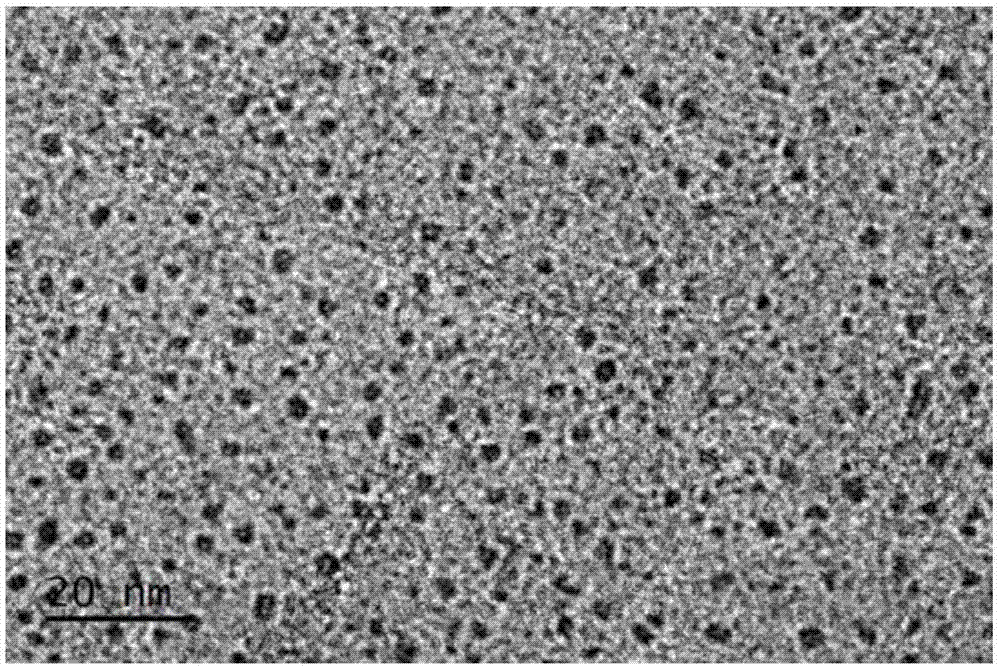

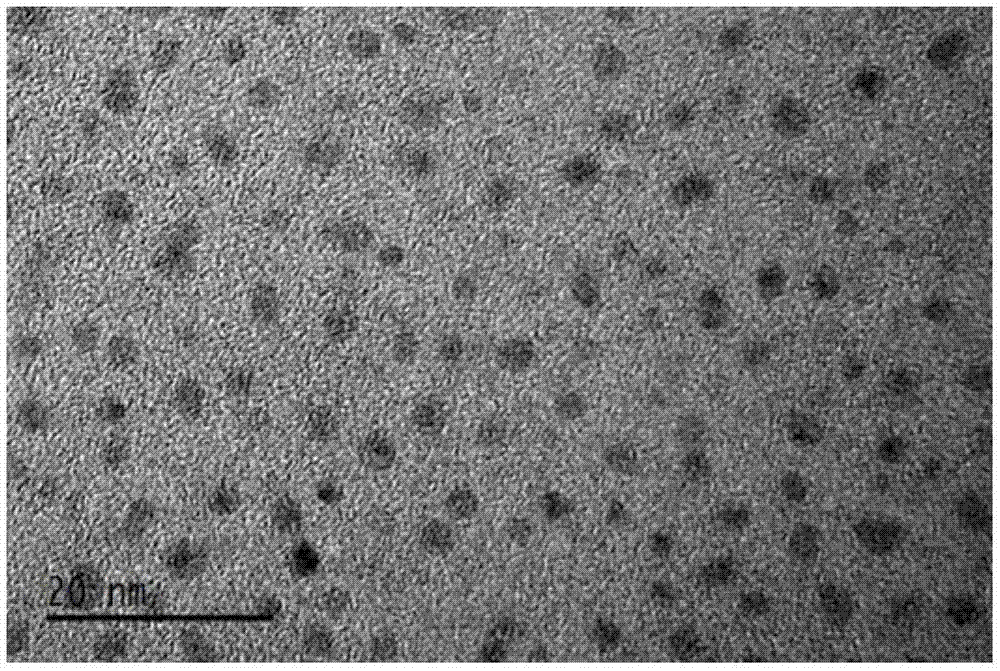

Extremely small particle size nano-silver loaded graphene aerogel and preparation method and application thereof

ActiveCN107096529ASmall particle sizeComplete macrostructureOrganic compound preparationAerogel preparationCvd grapheneSilver Nano

The invention discloses an extremely small particle size nano-silver loaded graphene aerogel, a preparation method and an application thereof. According to the preparation method, graphene serves as a substrate for forming aerogel under the conditions of normal temperature and pressure and ultrasound, and the nano-silver serves as a catalyst to be loaded on the graphene; the particle size of the nano-silver in the aerogel is about 1nm; the nano-silver has superhigh catalytic conversion rate for nitrobenzene and m-dinitrobenzene; and the particle size of the nano-silver can be adjusted and controlled by adjusting the loading capacity of the nano-silver. According to the properties, the nano-silver catalyst is synthesized by adopting a green and environment-protection method, has a superhigh catalytic performance for pollutants, is convenient to recover after being used and can be applied to the fields of environmental protection, chemical engineering and the like.

Owner:ZHEJIANG UNIV

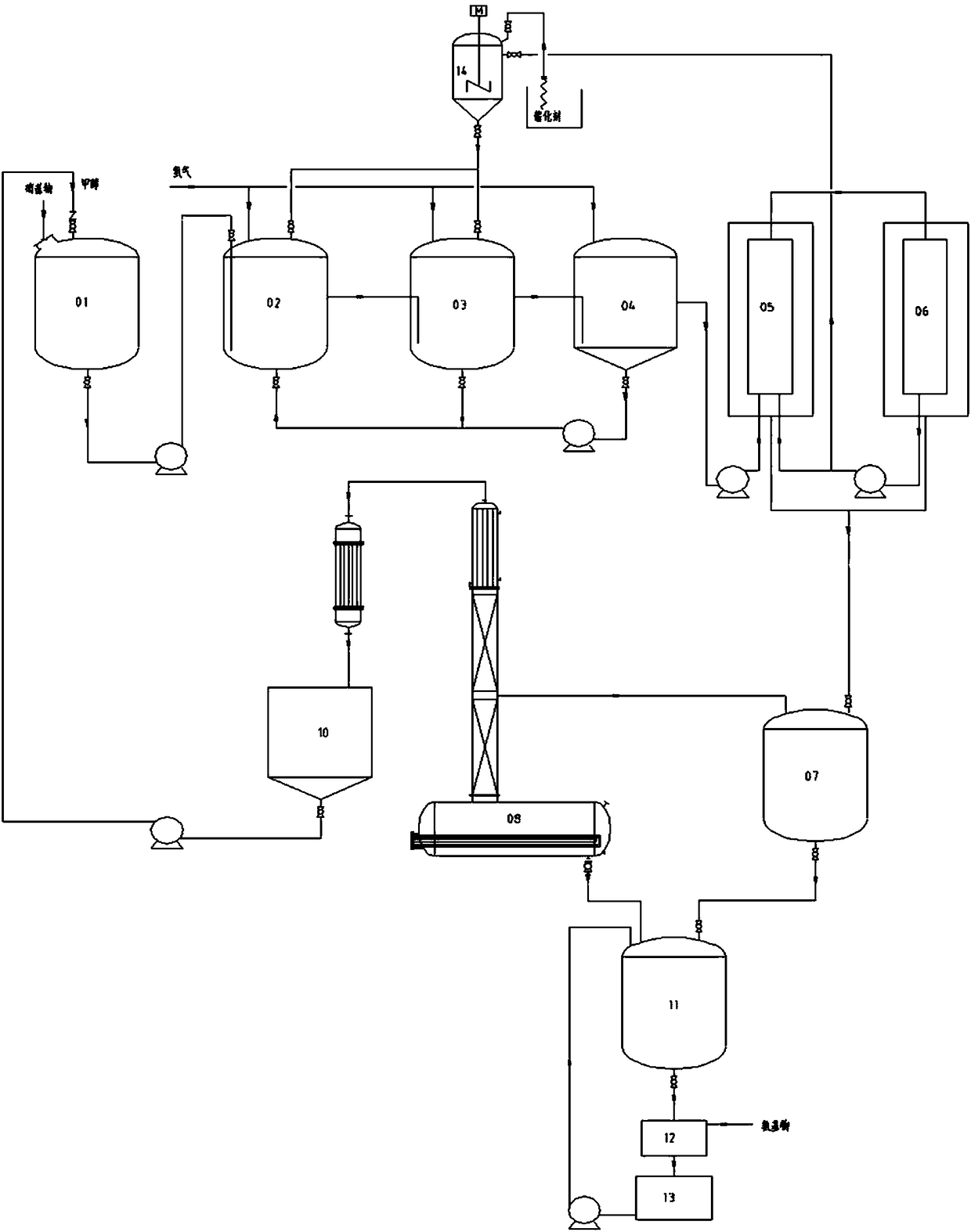

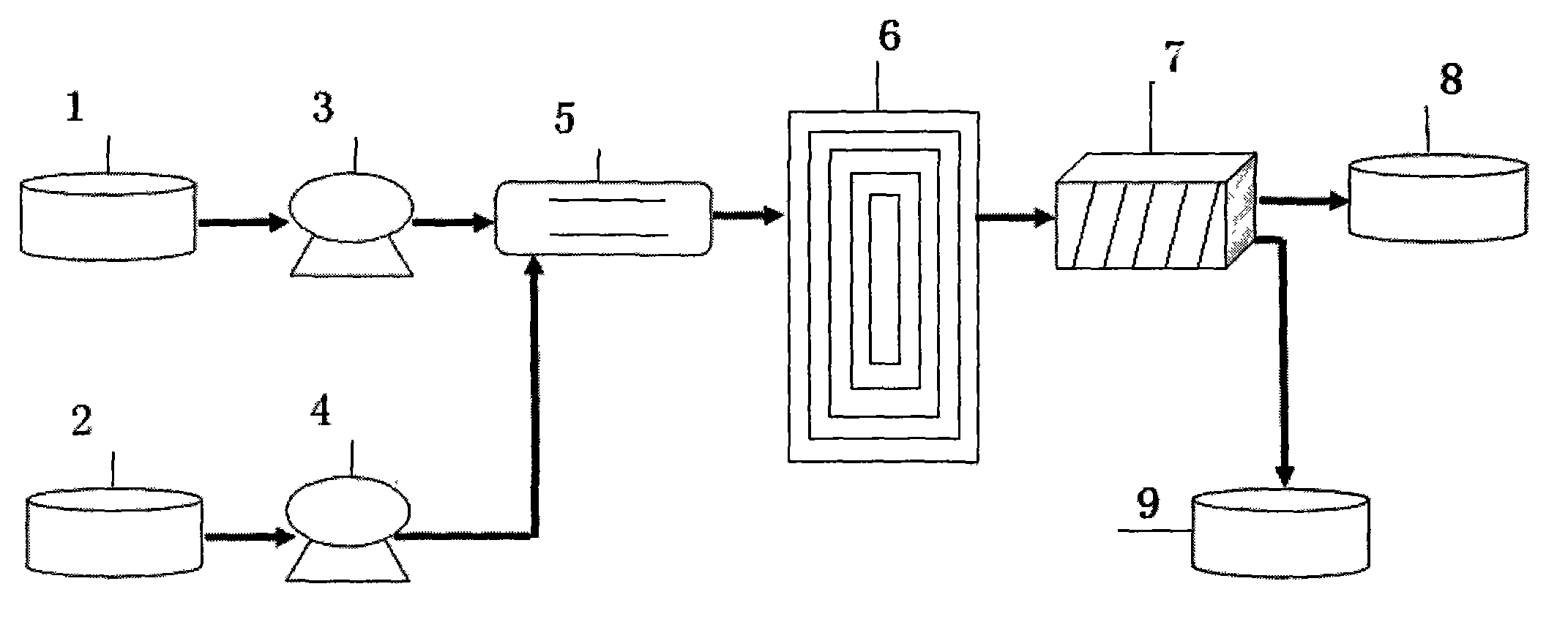

Preparation method of m-phenylenediamine

InactiveCN108164425AReduce lossReduce pollutionAmino compound purification/separationOrganic compound preparationFiltrationNitrobenzene

The invention discloses a preparation method of m-phenylenediamine. M-dinitrobenzene is subjected to continuous catalytic hydrogenation, settlement and membrane filtration, and m-phenylenediamine is obtained. The method is simple to operate and high in safety, can be used for continuous production, can achieve the effects of high production efficiency, high product quality, low labor intensity, environmental friendliness and high utilization rate of a catalyst, and is beneficial to the effect of industrialization.

Owner:YANTAI ANOKY FINE CHEM CO LTD +4

Method for preparing m-phenylenediamine through hydrogenating m-dinitrobenzene

ActiveCN107540554APhysical/chemical process catalystsOrganic compound preparationFixed bedNitrobenzene

The invention provides a method for preparing m-phenylenediamine through carrying out catalytic hydrogenation on m-dinitrobenzene in a fixed bed reactor with a supported Ni2P as a catalyst. The methodhas the advantages of simple process, mild reactions and high yield, and the conversion rate of the m-dinitrobenzene and the selectivity of the m-phenylenediamine respectively reach 100%.

Owner:NANJING UNIV

Nickel catalyst, process for the preparation thereof, process for hydrogenation of m-dinitro benzene to m-phenylene diamine

InactiveUS20050070740A1Speed up the processLong catalyst lifeMolecular sieve catalystsOrganic compound preparationSolventSilicon dioxide

Owner:COUNCIL OF SCI & IND RES

Nickel-based structured catalyst for synthesizing m-phenylenediamine through hydrogenation of m-dinitrobenzene and its preparation method

InactiveCN102350361AImprove hydrogenation activityHigh selectivityOrganic compound preparationAmino compound preparationNickel saltPtru catalyst

The invention relates to a nickel-based structured catalyst for synthesizing m-phenylenediamine through hydrogenation of m-dinitrobenzene, which takes cordierite honeycomb ceramic as a matrix, gamma-Al2O3 as a composite carrier of a coating and La modified Ni as an active component. The preparation method comprises the following steps: taking cordierite as a substrate and active alumina as a coating, preparing the gamma-Al2O3 / cordierite composite carrier by using an immersion method; selecting appropriate nickel salt and lanthanum salt, immersing, drying and calcining to obtain a catalyst precursor, reducing through hydrogen to obtain the structured catalyst. The cordierite structured catalyst is capable of keeping the characteristics of an original particles supported Ni catalyst and preparing a structured reactor, so that hydrogenation reaction is carried out under continuous state. Simultaneously, an auxiliary agent La is introduced in the catalyst for inhibiting the interacting effect of the active component and the carrier, and weakening the formation of NiAl2O4 which is not beneficial to the hydrogenation reaction activity. So that the conversion rate and selectivity of m-dinitrobenzene hydrogenation reaction can be enhanced further.

Owner:WUHAN INSTITUTE OF TECHNOLOGY +1

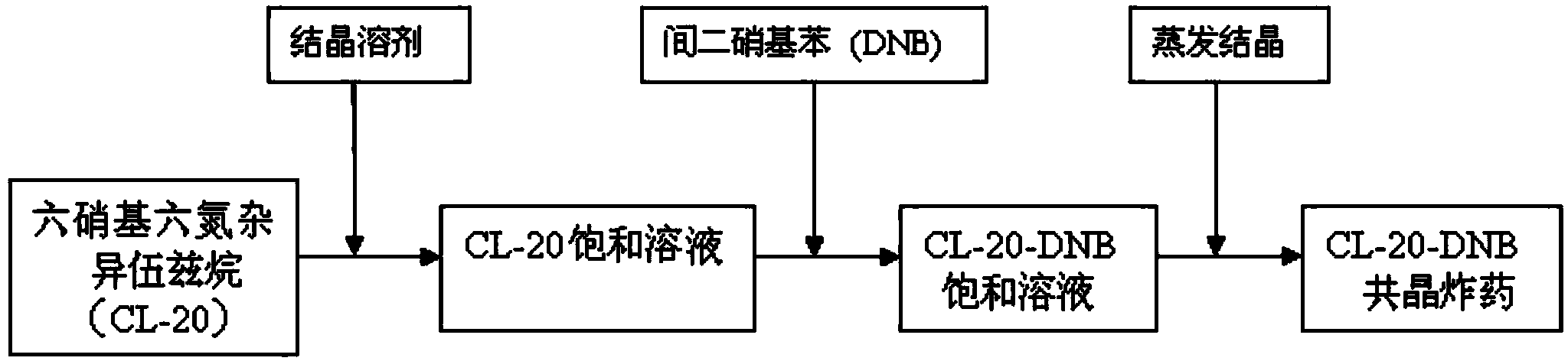

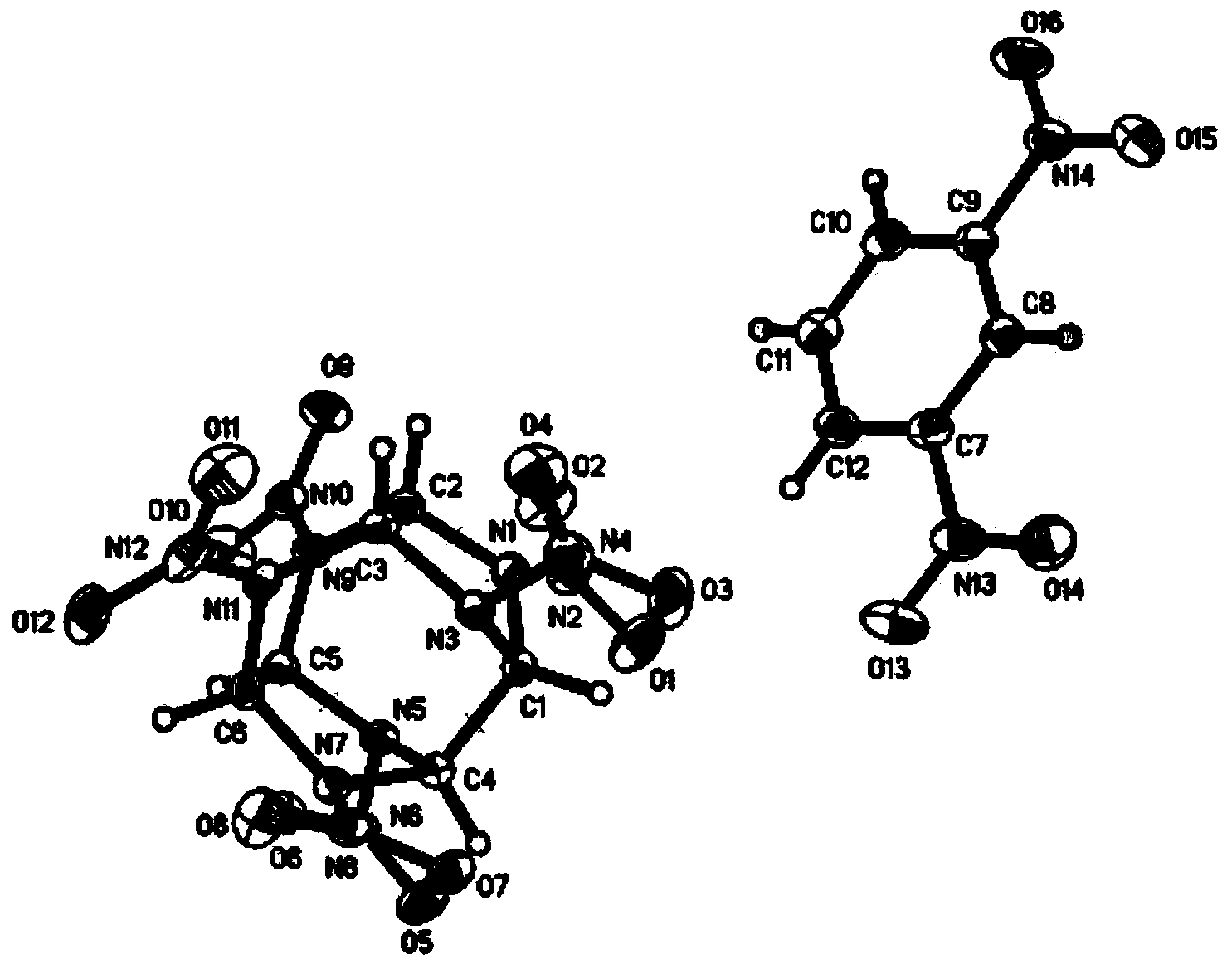

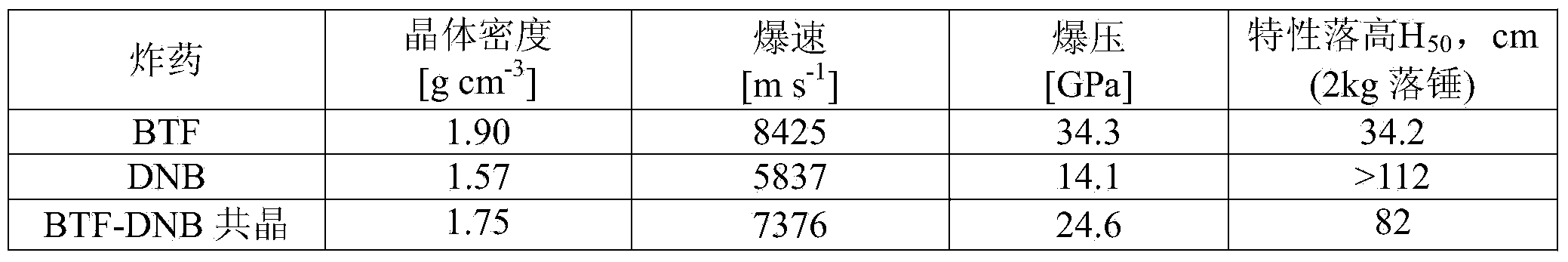

Preparation method for hexanitrohexaazaisowurtzitane and m-dinitrobenzene co-crystallized explosive

ActiveCN103396274AHigh detonation velocityIncrease burst pressureNitroparaffin explosive compositionsSolvent evaporationSolvent

The present invention discloses a preparation method for a hexanitrohexaazaisowurtzitane and m-dinitrobenzene co-crystallized explosive, wherein a crystallization solvent is adopted to prepare a hexanitrohexaazaisowurtzitane and m-dinitrobenzene saturated solution, and a constant temperature incubator is adopted to perform solvent evaporation and crystallization to obtain the hexanitrohexaazaisowurtzitane and m-dinitrobenzene co-crystallized explosive. According to the present invention, crystal density of the hexanitrohexaazaisowurtzitane and m-dinitrobenzene (CL-20-DNB) co-crystallized explosive is significantly increased by 19.6% compared with crystal density of DNB, detonation velocity and detonation pressure of the CL-20-DNB co-crystallized explosive are respectively increased by 46.2% and 147.5% compared to detonation velocity and detonation pressure of DNB, and the CL-20-DNB co-crystallized explosive has characteristics of a good detonation performance and high safety performance, and can be used for preparing low sensitivity ammunition.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

Method for synthesizing 3,5-diamido benzoic acid by industrial continuous hydrogenation

ActiveCN102249942AMeet conversion rate requirementsMild reaction conditionsOrganic compound preparationAmino-carboxyl compound preparationBenzoic acidPtru catalyst

The invention discloses a method for synthesizing 3,5-diamido benzoic acid by industrial continuous hydrogenation. The method comprises the following steps: by taking m-dinitrobenzoic acid and hydrogen as raw materials and water as a reaction solvent, adding water and a catalyst in a reduction kettle, in addition, respectively adding the raw material, namely m-dinitrobenzoic acid and hydrogen for reduction reaction; carrying out further reaction on a reaction liquid in second and third reduction kettles until the conversion rate of the raw materials reaches 100%; and then crystallizing the reaction liquid so as to obtain the product 3,5-diamido benzoic acid. In the method, three reduction kettles which are successively connected are adopted so as to complete the reduction reaction, the contact time of the raw materials is long, the conversion rate of the raw materials can reach 100%, the appearance of the obtained product is of grey white powder, the chromatograph purity of the product is above 99%, the content of the product is above 95%, and the yield of the product is above 97%.

Owner:济宁市金泰利华化工科技有限公司

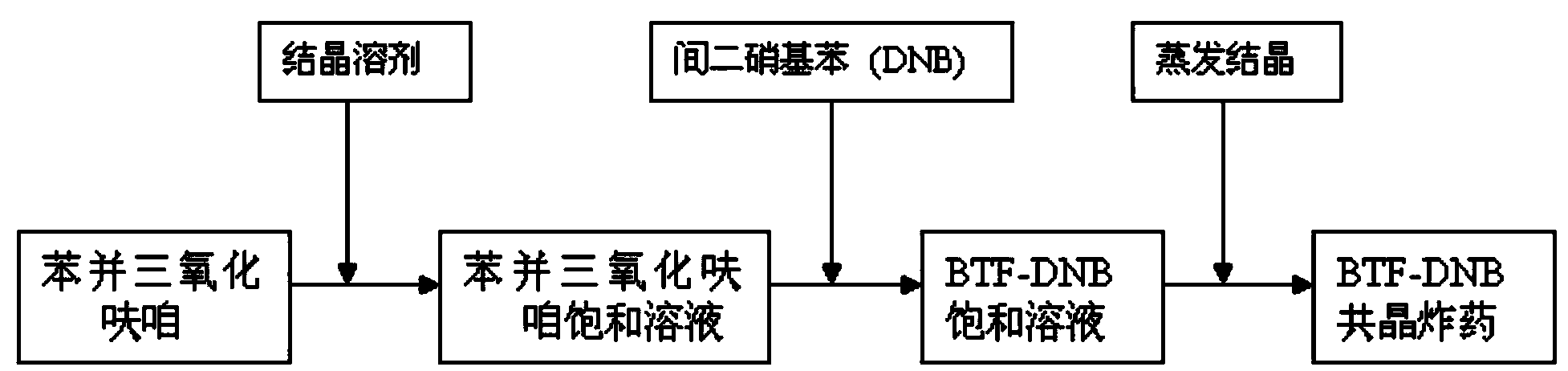

Preparation method for benzotrifuroxan and m-dinitrobenzene eutectic explosive

ActiveCN103435426AImprove securityImprove detonation performanceExplosive working-up apparatusNitrated aromatic explosive compositionsBenzeneDetonation

The invention discloses a preparation method for a benzotrifuroxan and m-dinitrobenzene eutectic explosive. The preparation method comprises the following steps: firstly, preparing a benzotrifuroxan and m-dinitrobenzene saturated solution through a crystallization solvent; secondly, evaporating the solvent of the saturated solution by a constant temperature incubator and crystallizing to form the benzotrifuroxan and m-dinitrobenzene eutectic explosive. The benzotrifuroxan and m-dinitrobenzene eutectic explosive has the benefits of excellent safety, good detonation performance and good free-running property, can serve as a component of a novel booster explosive, has a good application prospect in high-energy low-sensitive ammunitions, and is simple and stable in preparation method and process flow, convenient to operate, moderate in reaction conditions, good in safety and high in quality.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

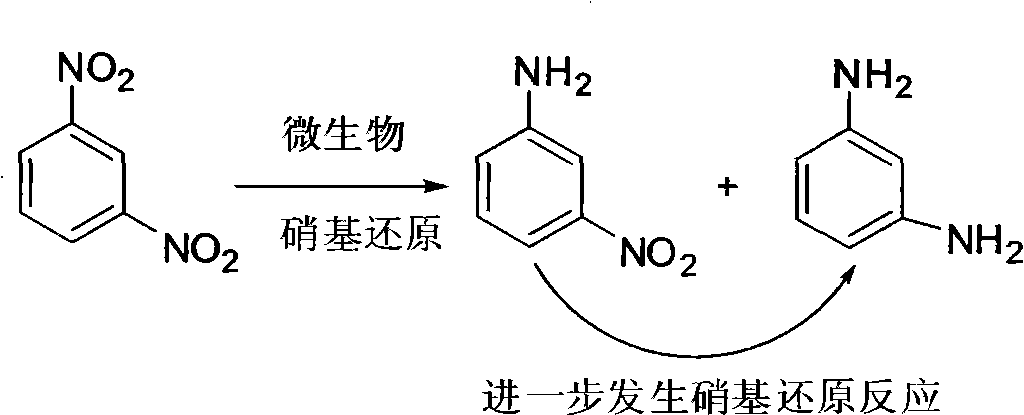

Conversion method for m-dinitrobenzene, process for producing meta-nitroaniline and m-phenylenediamine

InactiveCN101402978ALow costMild conditionsMicroorganism based processesFermentationChromatographic separationFermentation

The invention discloses a transformation method of m-dinitrobenzene and a preparation method of m-nitroaniline and m-phenylenediamine. The transformation method adopts microorganisms to carry out the transformation and specifically comprises: the microorganisms are cultured, the m-dinitrobenzene is added in a fermentation culture medium, the microorganisms adopt an organic solvent for extracting the transformed products after the transformation of the m-dinitrobenzene, an extract of the transformed products is obtained by low temperature concentration; and the chromatographic separation is carried out on the extract of the transformed products, while the m-nitroaniline and the m-phenylenediamine are obtained by elution. The transformation method has the advantages of low cost, mild conditions, high efficiency, environmental friendliness, and the like, thereby having high popularization and application value.

Owner:SUN YAT SEN UNIV

Method for preparing diaminobenzene from dinitro benzene

InactiveCN101434548AReduce consumptionAvoid generatingOrganic compound preparationAmino compound preparationBenzeneContinuous use

The invention discloses a method for preparing diaminobenzene by using dinitro benzene which refers to paradinitrobenzene or m-dinitrobenzene. The method comprises the steps as follows: the dinitro benzene is added into a kettle firstly and then ethanol and a supported catalyst are added; the kettle is closed and air in the kettle is replaced by using hydrogen; then normal pressure is maintained in the kettle and heating and mixing are carried out; the hydrogen is introduced into the kettle after temperature in the kettle reaches 60 DEG C so as to lead the pressure in the kettle to be maintained at 1.0 MPa to 3.0 MPa and then hydrogenation reaction is started; a conversion ratio can reach 95 percent to more than 99 percent after the hydrogenation for about 3 hours to 8 hours and then a reacted mixture and the catalyst are separated out; the catalyst separated is returned to the kettle for continuous use to supplement the lost catalyst; reaction product separation is carried out to the reacted mixture which is a clear solution so as to obtain the diaminobenzene.

Owner:甘肃中科药源生物工程股份有限公司

Pd-Pt alloy structural catalyst, and preparation method and application thereof

InactiveCN102350343AEfficient mass productionOvercoming productivityOrganic compound preparationAmino compound preparationBenzeneActive component

The invention belongs to the technical field of catalytic hydrogenation, and particularly relates to a Pd-Pt alloy structural catalyst, and preparation and application thereof. The invention provides the Pd-Pt alloy structural catalyst, and a carrier is cordierite honeycomb ceramics. The Pd-Pt content in the Pd-Pt alloy structural catalyst is 0.01 to 20 weight percent, and the molar ratio of Pd to Pt is 1:(0.01-10). A preparation method comprises the following steps of: (1) pre-treating the carrier; (2) preparing a coating; (3) coating active components; and (4) reducing. The Pd-Pt alloy structural catalyst has better performance than the conventional Pd / C and Pt / C catalysts during m-dinitrobenzene catalytic hydrogenation reaction.

Owner:WUHAN INSTITUTE OF TECHNOLOGY +1

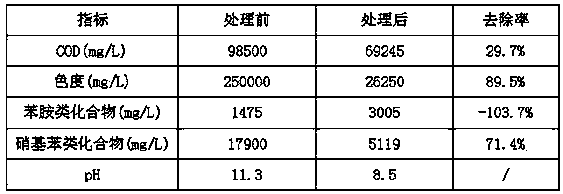

Pretreatment method of m-dinitrobenzene production wastewater

InactiveCN104355464ATreatment involving filtrationMultistage water/sewage treatmentPretreatment methodNitrobenzene

The invention relates to a pretreatment method of m-dinitrobenzene production wastewater, and belongs to the field of wastewater treatment methods. The pretreatment method comprises the following steps: filtering the m-dinitrobenzene production wastewater by grids, adjusting the pH values of the wastewater by hydrochloric acid, continuously adding the wastewater into a water inlet in the lower end of a microelectrolytic reactor by a constant-flow pump, adding a certain amount of iron-carbon mixture for reacting in the reactor for a certain time, adjusting the pH value of outlet water at a water outlet in the upper end of the reactor to be 8-9 by lime, settling, and discharging supernatant liquid, namely the pretreated wastewater, thereby providing favorable conditions for subsequent biochemical treatment. According to the pretreatment method, the m-dinitrobenzene production wastewater is pretreated by a microelectrolytic process and can be biochemically treated after being subjected to microelectrolysis-coagulation sedimentation pretreatment, and the favorable conditions are provided for subsequent biochemical treatment.

Owner:SHAANXI HUALU CHEM ENVIRONMENTAL PROTECTION

Preparation method of high-dispersibility m-dinitrobenzene hydrogenation structuring catalyst

InactiveCN103263922AGood dispersionControl soaking timeOrganic compound preparationCatalyst activation/preparationPtru catalystCordierite

The invention discloses a preparation method of a high-dispersibility m-dinitrobenzene hydrogenation structuring catalyst, which comprises the following steps: (1) impregnating a cordierite honeycomb ceramic matrix coated with gamma-Al2O3 in a nickel nitrate impregnation liquid; (2) performing vacuum suction; (3) drying, and performing constant-temperature roasting to obtain a Ni / gamma-Al2O3 / cordierite structuring catalyst precursor; (4) repeatedly loading until the load mass percent of the active component Ni is 12-14%; and (5) reducing the catalyst precursor with H2 to obtain the high-dispersibility m-dinitrobenzene hydrogenation structuring catalyst. By changing the concentration of the impregnation liquid, controlling the impregnation time and introducing the vacuum suction action, the metal dispersion degree is increased from 9.3% (in the traditional method) to 38.4%; and a nickel-based structuring catalyst having excellent dispersibility, namely the high-dispersibility m-dinitrobenzene hydrogenation structuring catalyst, can be prepared.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Method for preparing m-nitroaniline by m-dinitrobenzene selectivity reduction

InactiveCN101121667ALow costSolve pollutionOrganic compound preparationAmino compound preparationBenzeneCelsius Degree

The invention relates to a preparation method for the m-nitroaniline by selectively deoxidize the m-dinitrobenzene nitrobenzene; the m-dinitrobenzene is used as the raw material and the iron is used as the reductant; with the carbon dioxide / water - ethanol system, the temperature of 40 to 130 Celsius system, and the pressure of 1.6 to 10.0 MPa, the reaction can be done to make the m-nitroaniline; the conversion rate of the reaction is more than 98 percent; the selectivity of the m-nitroaniline is more than 99 percent. In the method of the invention, the carbon dioxide, water, ethanol and the left iron in the reaction can be reused; the invention avoids the problem of the wastewater discharge. At the same time, the invention has the advantages of the high collection rate of the reaction and the good selectivity of the product.

Owner:DALIAN UNIV OF TECH

Catalyst for synthesizing m-phenylenediamine from m-dinitrobenzene by hydrogenation reaction and application thereof

InactiveCN103638940AHigh activityExtend your lifeOrganic compound preparationAmino compound preparationCore shellMetal

The invention provides a catalyst for synthesizing m-phenylenediamine from m-dinitrobenzene by hydrogenation reaction, wherein the catalyst comprises a core structure and a shell structure, the core structure is a MnO2-NiO-ZrO2 composite metal oxide, and the shell structure is MnO2-NiO-ZrO2-SiO2-TiO2. The catalyst with a core-shell structure has advantages of simple preparation technology and low cost, a special structure and mutual effects of Mn, Ni and Zr greatly raise the activity of the catalyst, and the conversion rate of m-dinitrobenzene and the yield of the m-phenylenediamine are all higher than 97%.

Owner:王善良

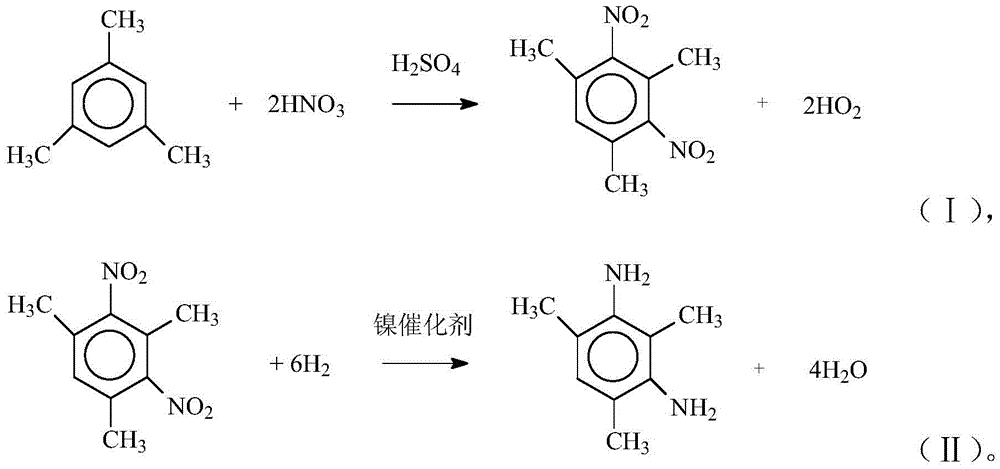

Synthesis method of 2,4,6-trimethyl-m-phenylenediamine

InactiveCN105461567ALow costExtend the life cycleOrganic compound preparationAmino compound preparationSynthesis methodsNitration

The invention relates to a synthesis method of 2,4,6-trimethyl-m-phenylenediamine. The method is characterized by comprising the steps of: (1) dropwise adding mixed acid into mesitylene for nitration and generation of 2,4,6-trimethyl-m-dinitrobenzene; after the reaction, standing for layering; neutralizing and washing an obtained organic layer to obtain 2,4,6-trimethyl-m-dinitrobenzene; (2) adding the 2,4,6-trimethyl-m-dinitrobenzene the obtained the step (1) to an autoclave, then adding a catalyst and a solvent, replacing the air in the autoclave with nitrogen gas, introducing hydrogen gas and conducting hydrogenation reduction to form 2,4,6-trimethyl-m-phenylenediamine, wherein the hydrogenation temperature is 50-120 DEG C, and the catalyst is a nickel catalyst; discharging hydrogen after the hydrogenation reduction, discharging the materials, removing methanol, cooling, crystallizing, and filtering to obtain the 2,4,6-trimethyl-m-phenylenediamine. The method has the advantages of short synthetic route, high product purity, high yield, few reaction steps, and long usage period of a hydrogenation reduction catalyst.

Owner:JIANGSU TIANJIAYI CHEM CO LTD

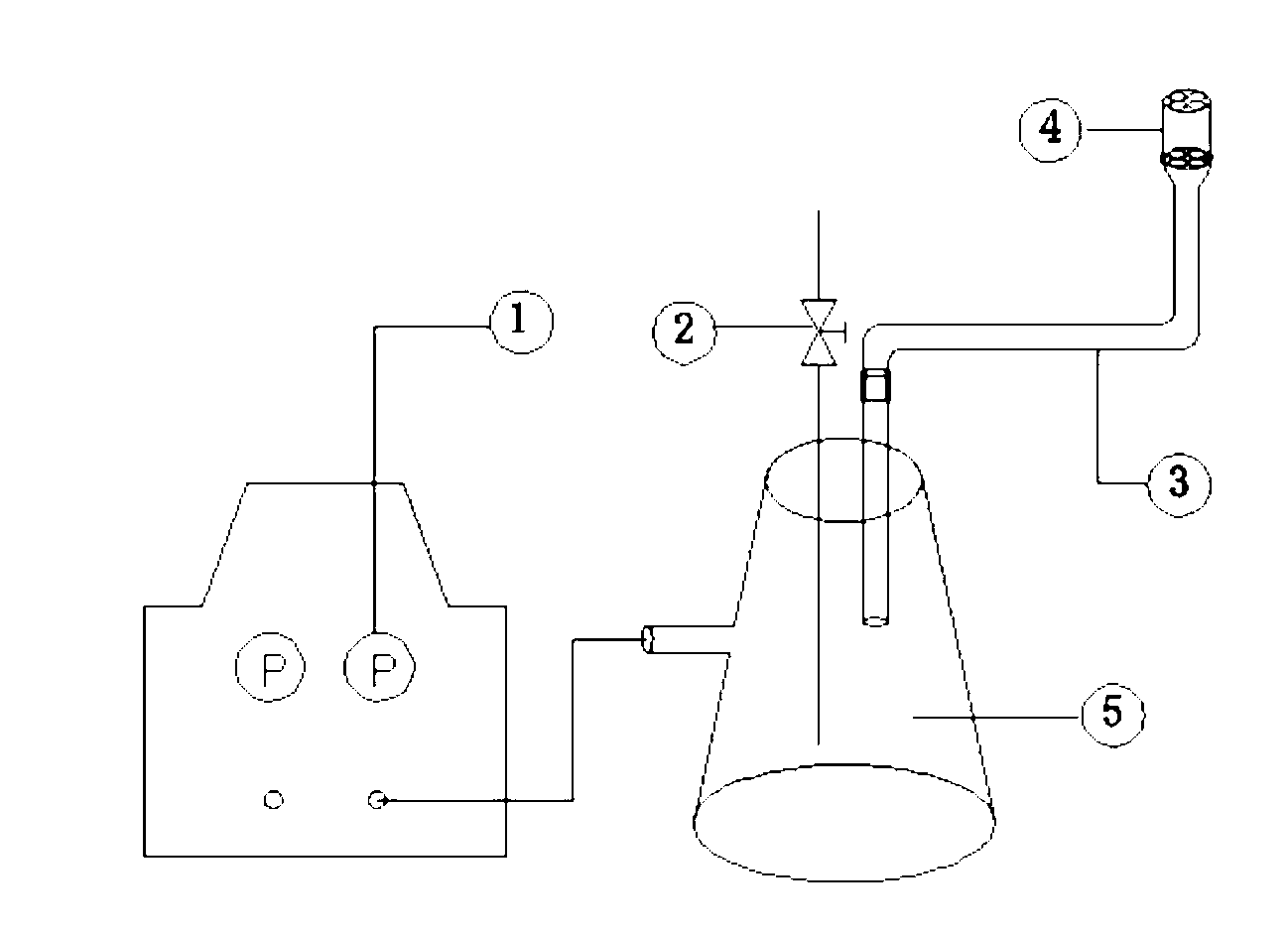

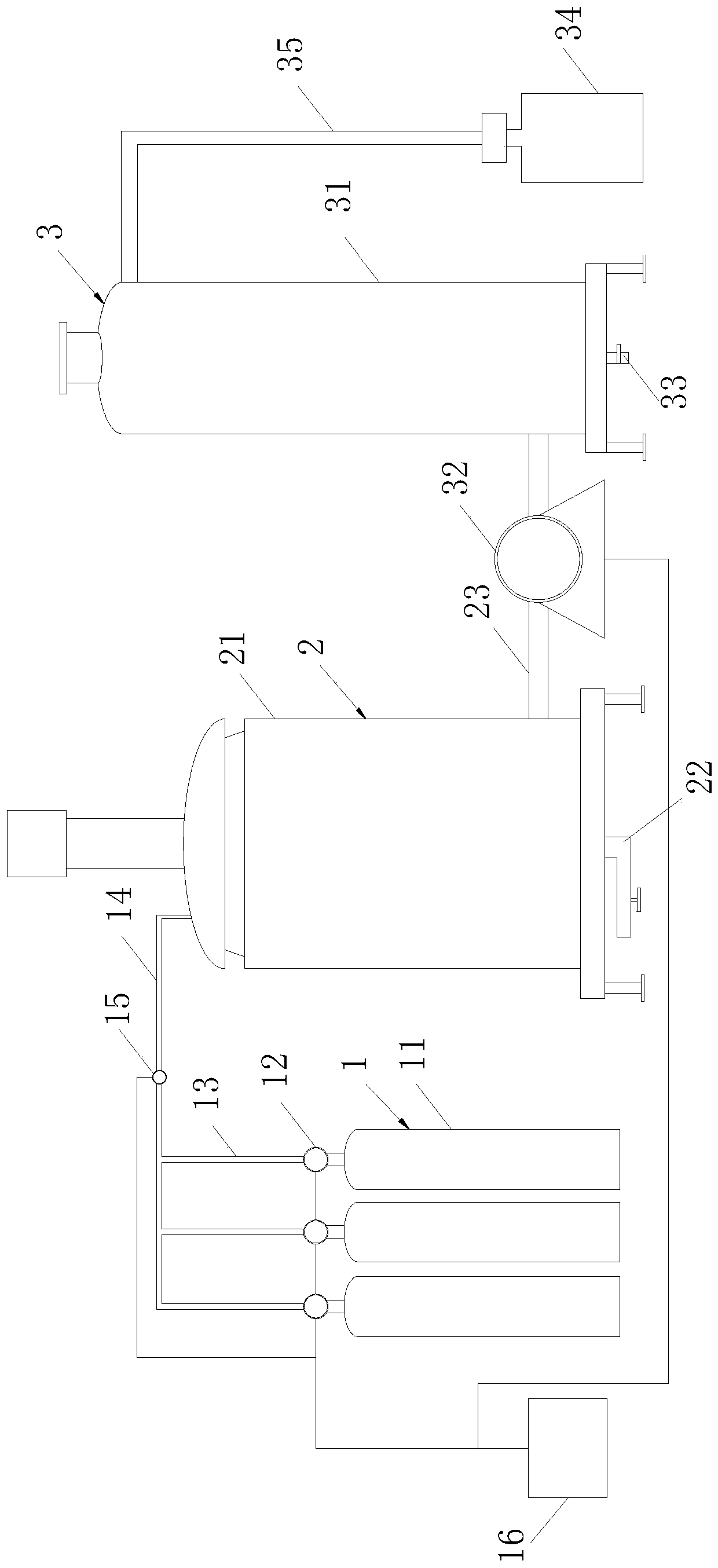

Extracting and separating method and device for waste acid generated in production procedure of m-dinitrobenzene

InactiveCN102836570AGood miscibilityReduce pollutionLiquid solutions solvent extractionNitro compoundBenzene

The invention relates to an extracting and separating method and a device for waste acid generated in the production procedure of m-dinitrobenzene, which belong to the technical field of chemical engineering. By applying the principle of an extraction technology, the invention provides a process for finishing the extraction of a nitro compound in waste acid generated in the production procedure of m-dinitrobenzene by utilizing an ejector and a static mixing pipe and also realizing liquid-liquid separation by a tilted plate separator. According to the extracting and separating method and the device for the waste acid generated in the production procedure of the m-dinitrobenzene, waste acid with the mass concentration of 68 to 75 percent, which is generated in the production procedure of benzene and m-dinitrobenzene, is mixed by the ejector, is mixed by the static mixing pipe and is separated by the tilted plate separator, so that nitrobenzene and dinitrobenzene in the waste acid are extracted, and the content of nitro matters and nitric acid in the waste acid is lowered. According to the extracting and separating method and the device for the waste acid generated in the production procedure of the m-dinitrobenzene, liquid is ejected in a fog shape after the liquid passes through the ejector, and is also mixed by the static mixing pipe fully so as to finish an extraction reaction. The content of a nitrated compound in the waste acid with the m-dinitrobenzene is lowered below 0.1 percent after separation from 0.6 to 0.7 percent before separation, the waste acid after being extracted is in concentrating treatment again, the energy consumption and the cost are low, and the pollution of the environment is lowered.

Owner:LIAONING QINGYANG SPECIAL CHEM

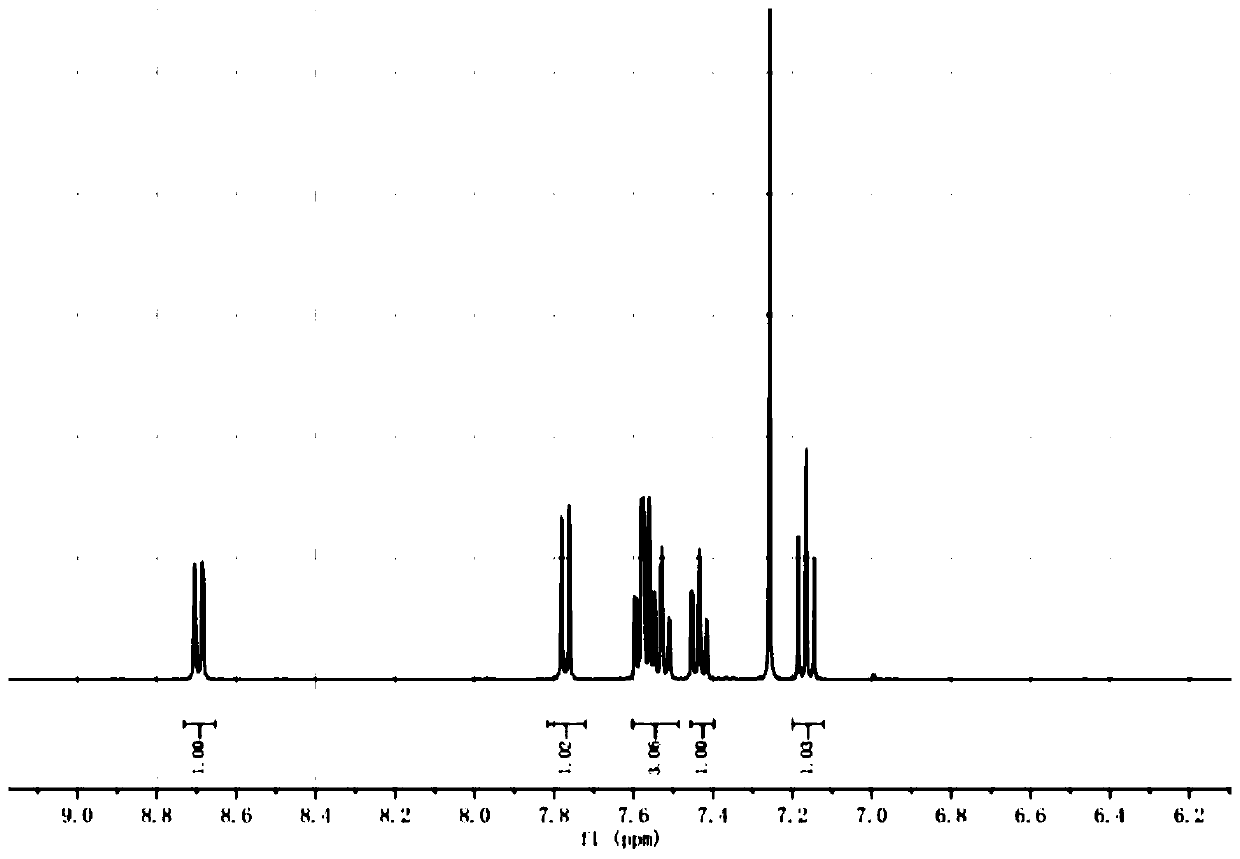

Process for photo catalytic reduction preparation of m-nitroaniline

InactiveCN1634863AStable in natureLow priceOrganic compound preparationAmino compound preparationPhotocatalytic reactionElectron donor

The invention discloses a method for reduction preparation of m-nitro aniline by photocatalysis. The lightcatalyzed reduction reaction can be carried out in photocatalysis reactor with temperature control apparatus, m-dinitrobenzene is solved by organic solvent with sacrificial electron donor with the mass ratio of m-dinitrobenzene to solvent between 1í†50 and 1í†500, said mixture and photocatalyst are added in the reactor with the concentration of photocatalyst in solvent between 0.2g / L and 8g / L, the solution is stirred to suspending liquid, then nitrogen is added for removing oxygen and the solution is irradiated for 2 hours to 12 hours by ultraviolet light at normal pressure to produce meta nitro aniline m-nitroaniline. The reduction reaction can be carried out at normal temperature without high temperature energy consumption device, and the initiation light can be natural sunlight.

Owner:TIANJIN UNIV

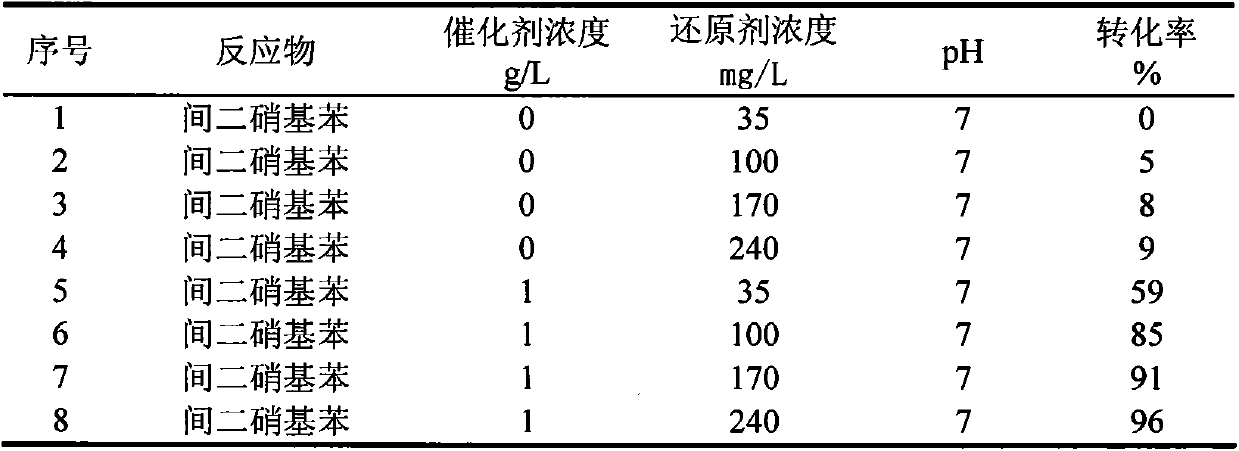

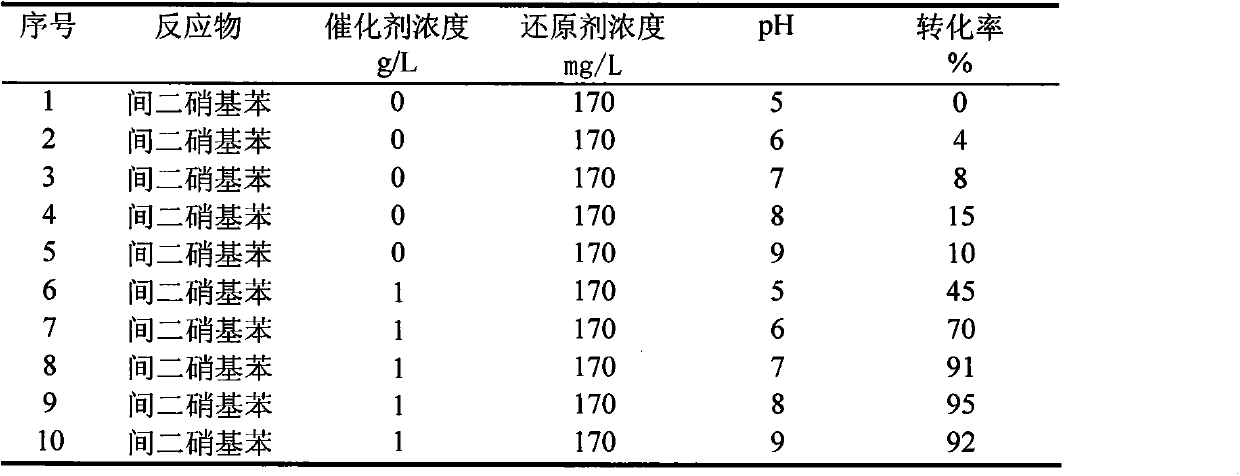

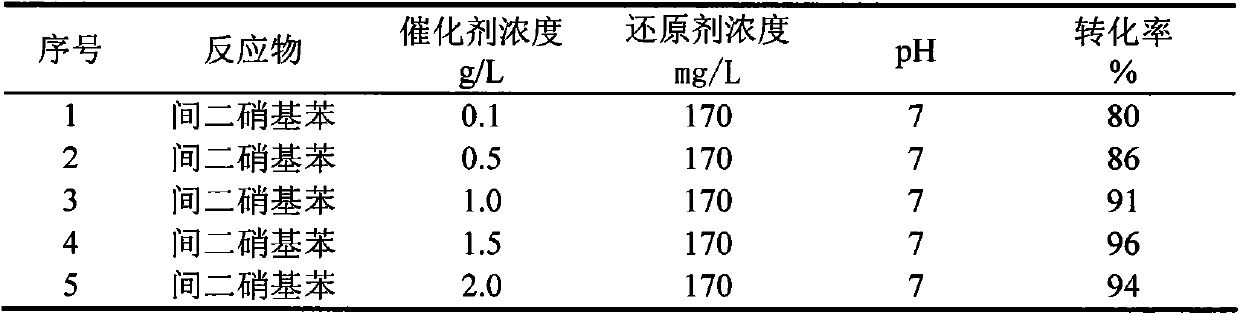

Method for treating m-dinitrobenzene wastewater through catalytic reduction

InactiveCN104045142ALower requirementReduce energy consumptionWater contaminantsWater/sewage treatment by reductionOxygenNitrogen gas

The invention belongs to the technical field of wastewater treatment for environmental protection and relates to a method for treating m-dinitrobenzene wastewater through catalytic reduction. The method comprises the following main steps: adding a buffer solution and a certain concentration of m-dinitrobenzene wastewater to an anaerobic simulation reactor containing a catalyst-black charcoal powder weighed in advance, filling 99.99% of high-purity nitrogen into a reaction system (so as to remove oxygen in the system to form an anaerobic environment), adding a certain concentration of reducing agent-sodium sulfide to the system and finally putting the reactor in a rotary oscillator and carrying out oscillating reaction at normal temperature and pressure. The method has the advantages that the reaction system is mild, reaction is quick and efficient and the treatment cost is low, so that the method can conduce to solving practical problems and has obvious economic and environmental advantages.

Owner:BEIJING NORMAL UNIVERSITY

Method for synthesizing m-dichlorobenzene from m-dinitrobenzene

InactiveCN104086352AReduce productionEasy to useHalogenated hydrocarbon preparationBenzeneChemical industry

A method for synthesizing m-dichlorobenzene from m-dinitrobenzene relates to the technical filed of the chemical industry. The method comprises the following steps: mixing m-dinitrobenzene with a catalyst, melting the obtained mixture, adding the molten mixture into a chlorination reaction kettle, heating to 210-230DEG C, introducing chlorine into the reaction kettle under a flow of 10kg / h, continuously adding m-dinitrobenzene after material condensation under a flow of 15kg / h, collecting the chlorinated condensate liquid in the reaction kettle, adding weak aqua ammonia to neutralize in order to adjust the pH value to 7, adding water, and washing to obtain crude m-dichlorobenzene; and heating to make the temperature in the kettle reach 100DEG C, carrying out reduced pressure distillation on the crude m-dichlorobenzene to obtain finished m-dichlorobenzene, packaging, and warehousing. The method has the advantages of convenient and simple preparation, small amount of generated waste acids, easily available materials, less equipment investment, high purity, convenient operation and low production cost, and the prepared m-dichlorobenzene has the advantages of good use effect, safety and reliability.

Owner:安徽佑骏商品混凝土有限公司

Process for photo catalytic reduction preparation of lentine

InactiveCN1269795CChemically stableSealing is easy to fixOrganic compound preparationAmino compound preparationPhotocatalytic reactionUltraviolet lights

The invention discloses a method for reduction preparation of m-phenylenediamine by photocatalysis. The process comprises the following steps: solving m-dinitrobenzene with organic solvent in photocatalysis reactor allowing over 300nm ultraviolet light to pass, adding photocatalyst with adding proportion of 0.2g to 9g / L(sol), adding nitrogen for removing oxygen, and irradiating for 1.5 hours to 8 hours by ultraviolet light at normal pressure. In the invention, the reduction reaction can be carried out at normal temperature or under ultraviolet radiation, initiation light can be ultraviolet light or sunlight, nano photocatalyst can be titanium dioxide or zinc oxide, etc. and reducing medium is proper solvent which can be reclaimed. The invention can prevent high oxidation and coking of m-phenylenediamine.

Owner:TIANJIN UNIV

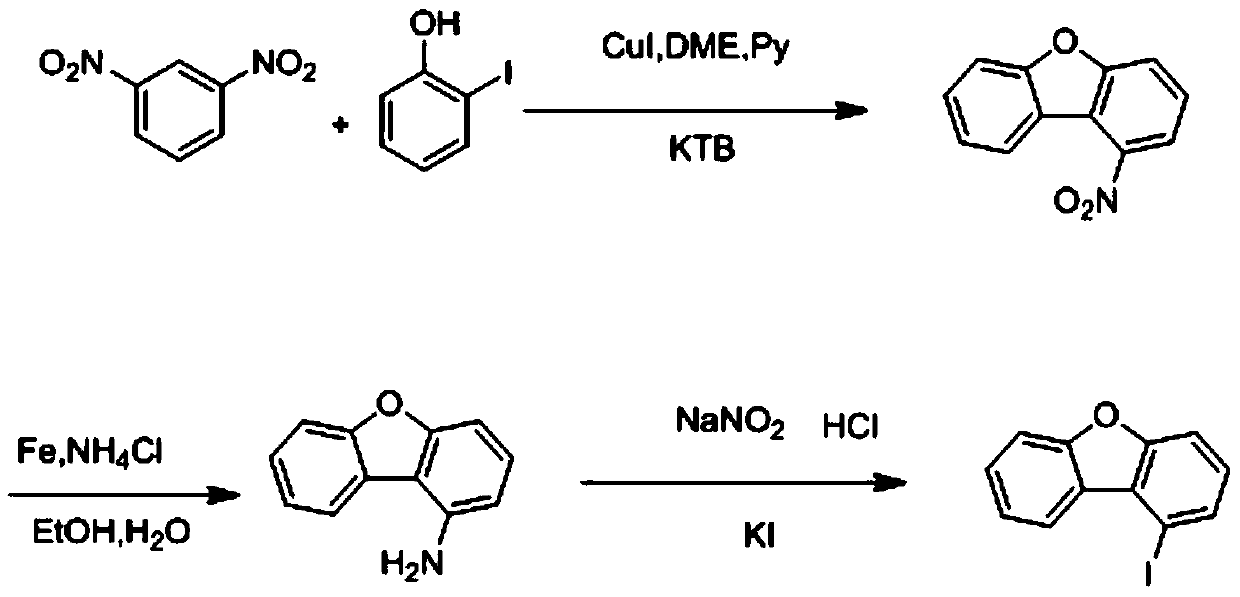

Preparation method of 1-iododibenzofuran

PendingCN110041295AThe synthesis method is simpleLower synthesis costOrganic chemistryIodideNitrogen gas

The invention provides a preparation method of 1-iododibenzofuran. The preparation method comprises the following steps: adding potassium tert-butoxide, dimethyl ether and cuprous iodide into a firstreactor, stirring the mixture under the protection of nitrogen gas, adding m-dinitrobenzene dissolved with pyridine into a system, then dissolving potassium tert-butoxide and o-iodophenol with dimethyl ether, adding the dissolved mixture into the system, fully reacting under the protection of the nitrogen gas, and separating to obtain 1-nitryldibenzofuran; then adding 1-nitryldibenzofuran into a second reactor, adding ethanol, water, iron powder and ammonium chloride, fully reacting, and separating to obtain 1-aminodibenzofuran; adding the 1-aminodibenzofuran into a third reactor, then addinghydrochloric acid, dropwise adding a sodium nitrite solution and a KI solution, fully reacting, and separating to obtain 1-iododibenzofuran. The preparation method has the beneficial effects of avoidance of carrying out the reactions under an ultralow temperature reaction condition, simple and feasible synthetic method, stable productivity, higher yield and low pollution, and has remarkable advantages on the aspect of batch production.

Owner:SUZHOU SY PHARMA TECH CO LTD

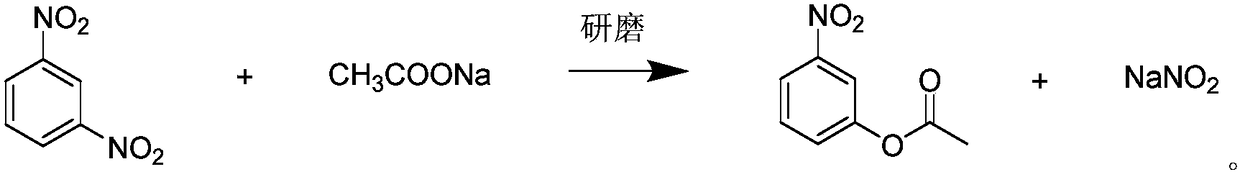

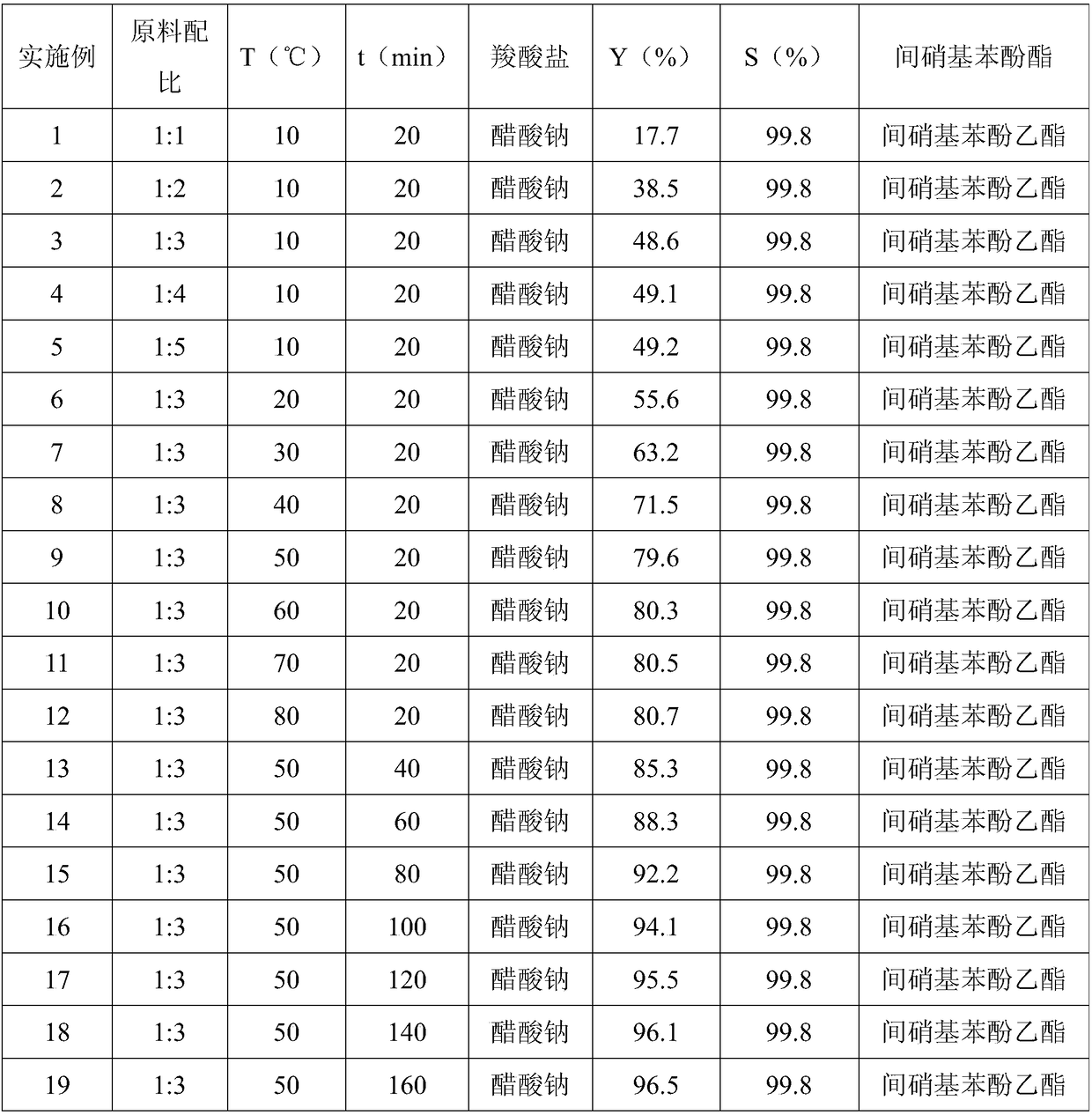

Method for preparing m-nitrophenol ester by solid-phase reaction system

InactiveCN108358790ALow priceImprove conversion rateOrganic chemistryOrganic compound preparationNitrobenzeneCarboxylic salt

The invention discloses a method for preparing m-nitrophenol ester by a solid-phase reaction system. According to the invention, m-dinitrobenzene and carboxylate are taken as raw materials, the methodcomprises the following steps: 1) m-dinitrobenzene and carboxylate are mixed and ground at the temperature of 10-80 DEG C for 20-180 min; wherein the mol ratio of m-dinitrobenzene to carboxylate 1:1-1:5; and 2) the ground material is washed with absolute methanol and then filtered, after steaming methanol of a filtrate, through column chromatography separating, ethyl acetate / petroleum ether is taken as an eluant for separation by passing a column, and an eluant is subjected to pressure reduction steaming to obtain the m-nitrophenol ester. The m-nitrophenol ester has the advantages of concisetechnology, no solvent, short reaction time, mild condition, high yield, and good selectivity.

Owner:ZHEJIANG UNIV

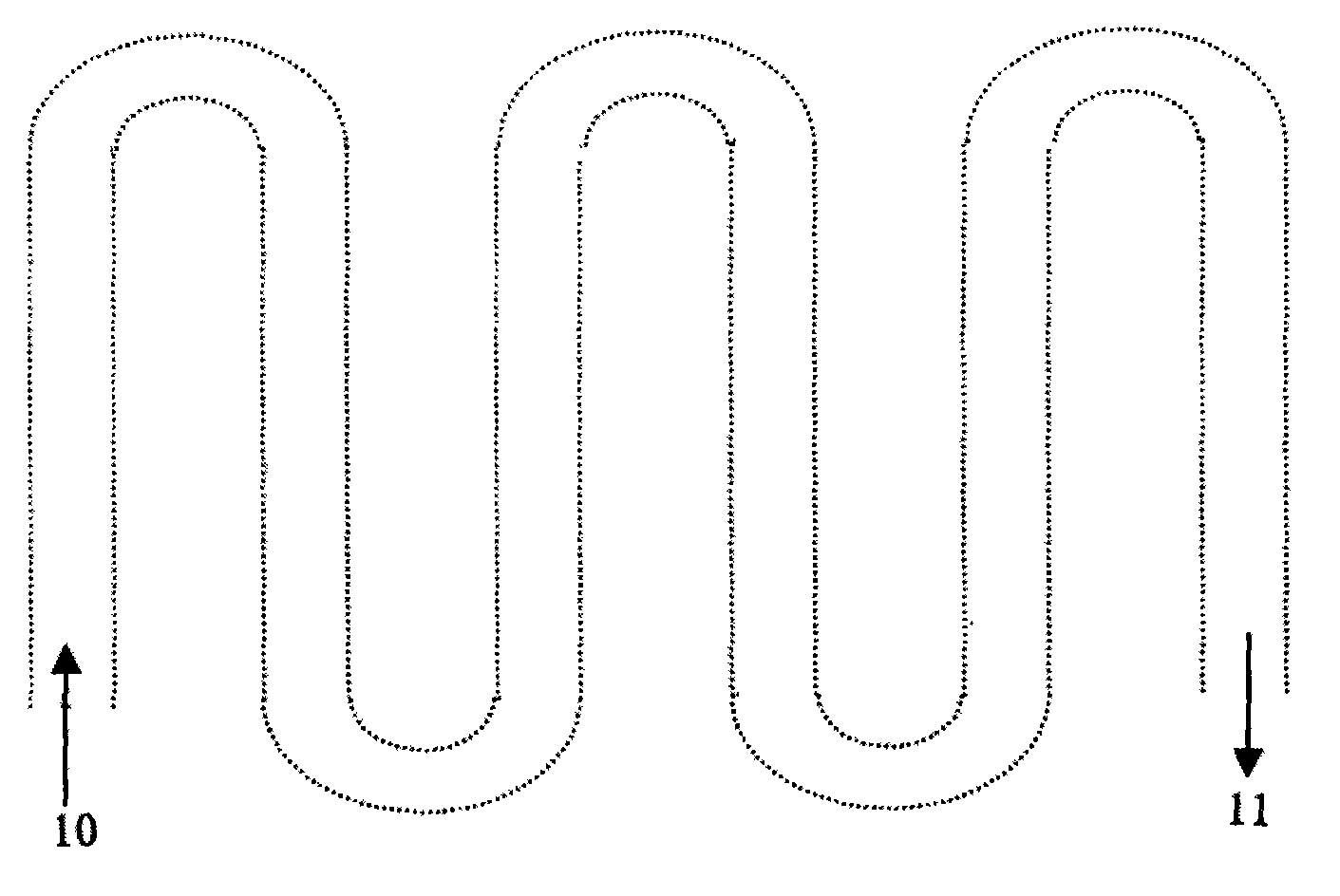

Production preparation process of m-phenylenediamine

InactiveCN110437074AImprove reaction efficiencyEasy to useAmino compound purification/separationOrganic compound preparationHydrogenNitrobenzene

The invention is applicable to the technical field of preparation of m-phenylenediamine, and provides a production preparation process of m-phenylenediamine. According to the process, a m-phenylenediamine preparation device is utilized to realize preparation of m-phenylenediamine, and the m-phenylenediamine preparation device comprises a gas supply assembly, a reaction assembly and a purificationassembly, wherein the gas supply assembly comprises a gas storage tank, a first gas valve, a branch pipe, a main pipe, a second gas valve and a controller, the reaction assembly comprises a reaction kettle and a material discharge pipe, and the reaction kettle communicates with the main pipe; one end of the material discharge pipe communicates with the reaction kettle, the purification assembly includes a rectification tower, a transfer pump, a crystallizer and a communication pipe, and the production preparation process includes the steps: adopting ethanol as a solvent in the reaction kettle,and performing a continuous catalytic hydrogenation reaction through a catalyst and hydrogen so as to reduce m-dinitrobenzene, wherein the catalyst is quaternary raney nickel; and performing rectification through the rectification tower after the reaction, and performing crystallization through the crystallizer. The process has the characteristics of continuous supply of hydrogen gas and high reaction efficiency.

Owner:上海鸿源鑫创材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com