Pretreatment method of m-dinitrobenzene production wastewater

A technology for m-dinitrobenzene and waste water production, which is applied in water/sewage treatment, natural water treatment, neutralized water/sewage treatment, etc., can solve the problem of poor biodegradability and unsatisfactory treatment effect of nitrobenzene compound waste water And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] After filtering the m-dinitrobenzene production wastewater grid, the wastewater is adjusted to pH 3-3.5 with hydrochloric acid, and then the wastewater is continuously added from the water inlet at the lower end of the micro-electrolysis reactor with a constant flow pump, and then 10g / L of weight is added The iron-carbon mixture with a ratio of 2:3, after reacting in the reactor for 60 minutes, adjust the pH of the effluent from the outlet at the upper end of the reactor to 8-9 with lime, and the supernatant water that is precipitated and discharged is the pretreated wastewater, which is used for subsequent Biochemical treatment provides favorable conditions.

Embodiment 2

[0015] Embodiment two: processing effect

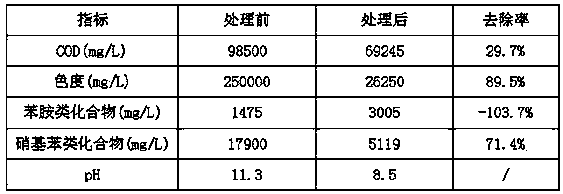

[0016] Using the pretreatment method of m-dinitrobenzene production wastewater of the present invention, the m-dinitrobenzene production wastewater of a certain chemical plant is pretreated, and the pretreatment effect is as shown in Table-1.

[0017] Table-1 Preprocessing effect

[0018]

[0019] It can be seen from Table-1 that the COD removal rate of pretreated wastewater is about 30%, the chroma removal rate is about 90%, the removal rate of nitrobenzene compounds is about 71%, and the aniline compounds increase by more than 100%. The biodegradability is greatly improved, which provides favorable conditions for the subsequent biochemical treatment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com