Patents

Literature

45results about How to "Control soaking time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

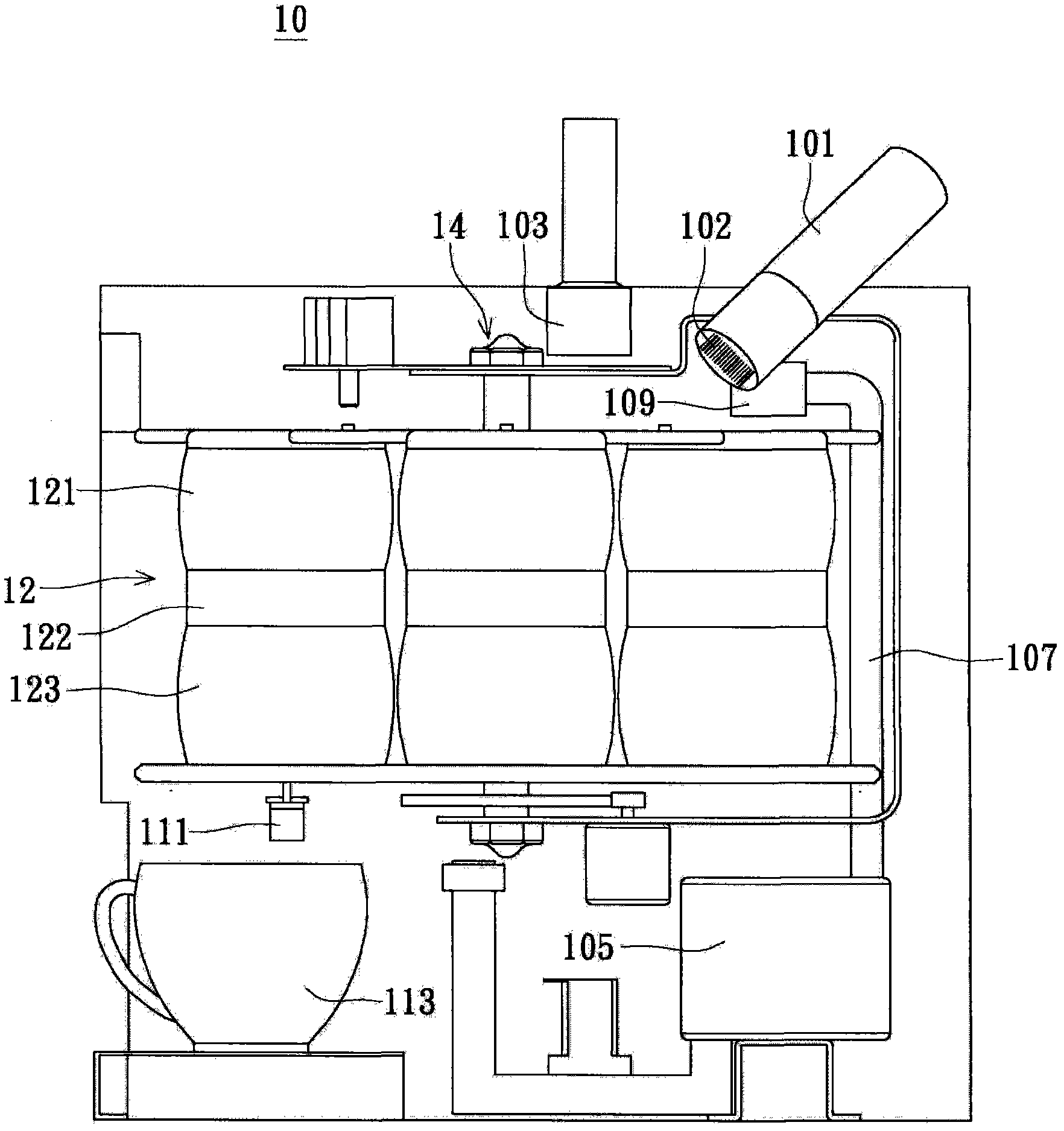

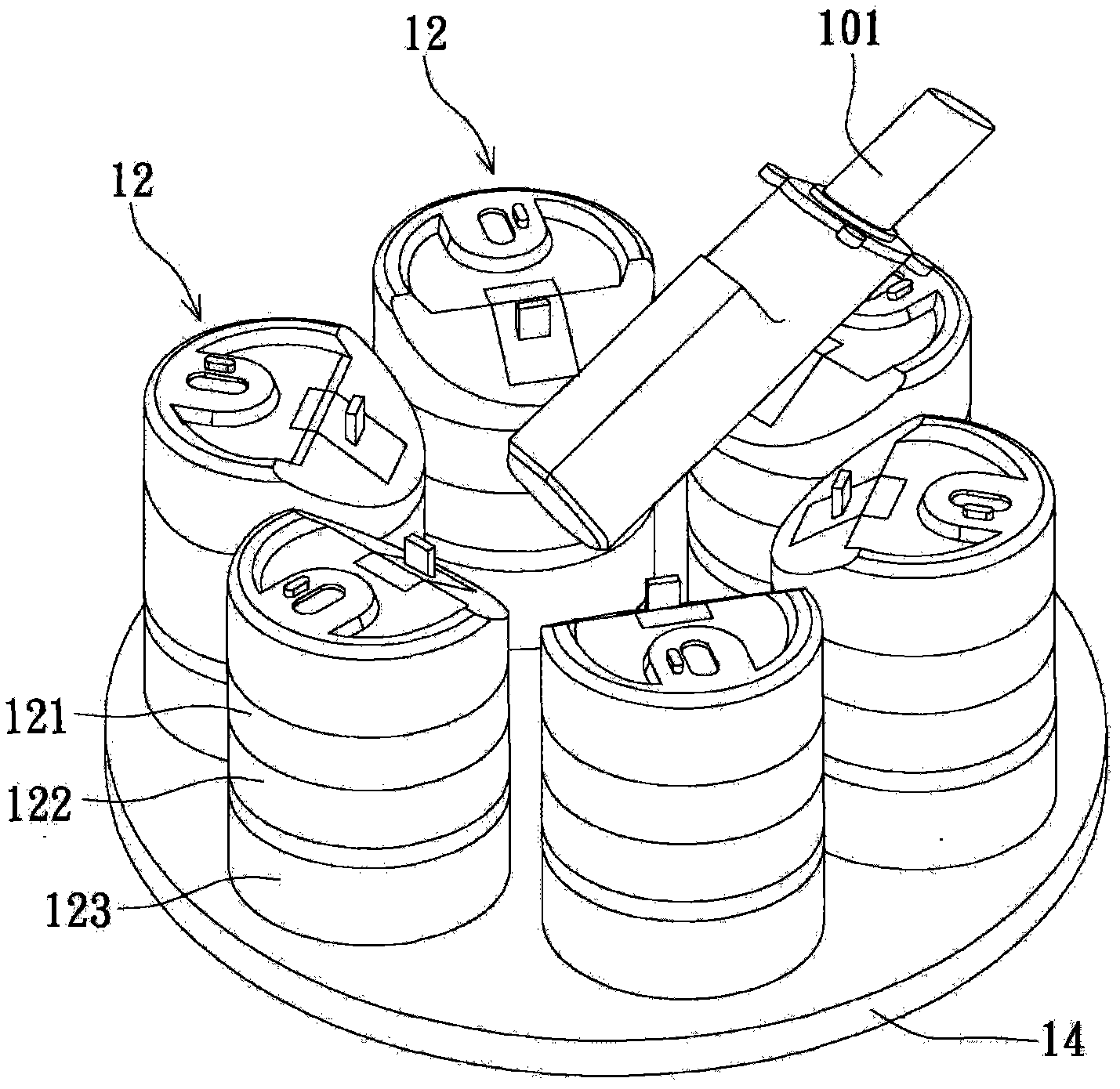

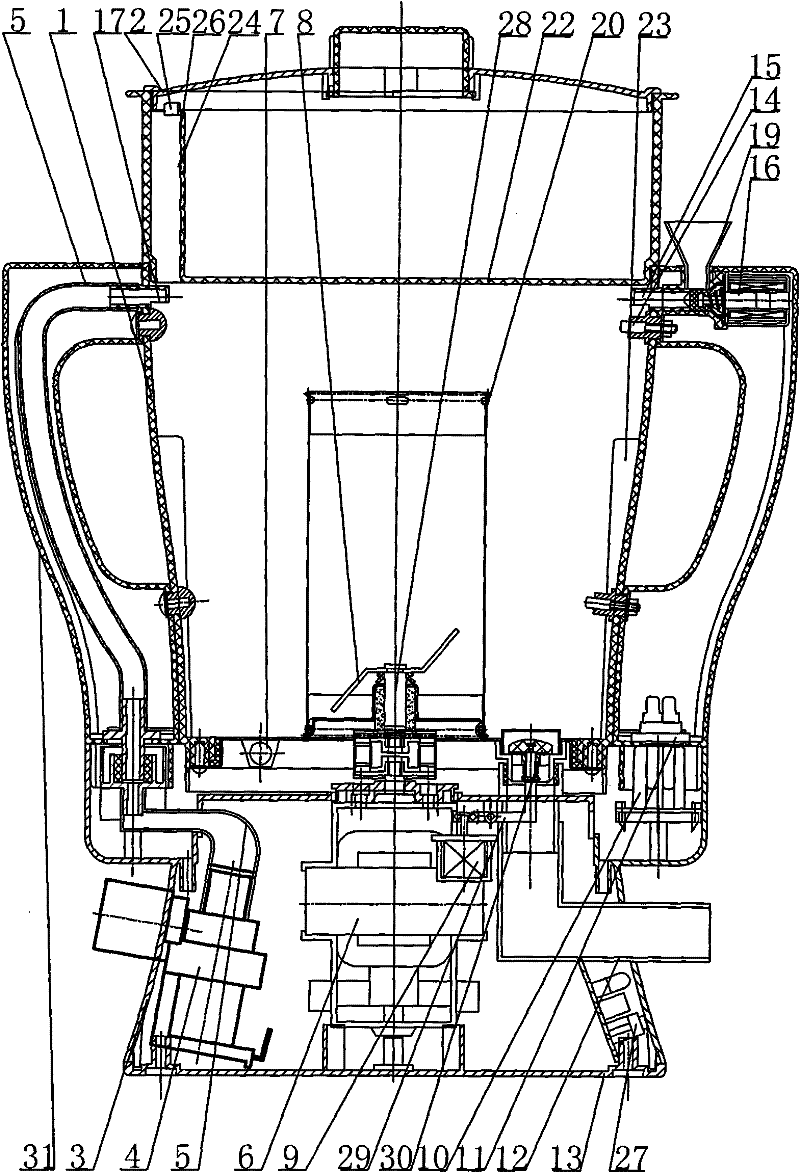

Beverage brewing system, brewing procedure establishing method and brewing method

InactiveCN103251310AControl brewing temperatureControl soaking timeBeverage vesselsProcess engineeringWater temperature

The invention discloses a beverage brewing system, a brewing procedure establishing method and a brewing method which are primarily applicable to brewing tea with a complex brewing procedure. Raw brewing materials are filled into a raw brewing material sealing device loaded with custom identification codes; after the raw brewing material sealing device is combined with the beverage brewing system, the custom identification codes are read by a code reader, and loaded raw material information and brewing parameters are acquired; and the brewing procedure is established by the system according to a series of brewing controlling signals generated according to the brewing parameters. The brewing parameters include brewing container types, brewing water temperatures and the raw brewing material soaking time in water. The brewing temperature and the soaking time are controlled by the system according to the parameters to obtain beverage matching with the characteristics of the brewing materials.

Owner:TEATASTER INT

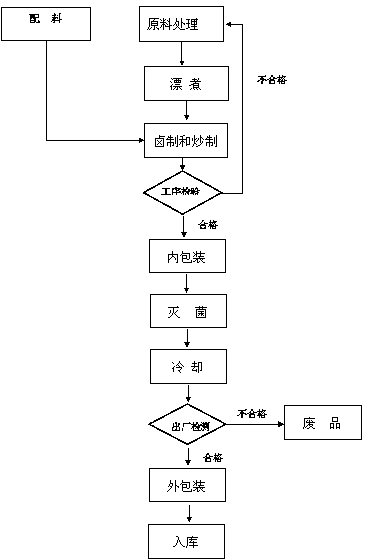

Processing technology of chilli oil bamboo shoots

InactiveCN103385435AQuality improvementControl soaking timeFood preparationAdditive ingredientBamboo shoot

The invention discloses a processing technology of chilli oil bamboo shoot and relates to a food processing technology, wherein the processing technology comprises the following steps: processing raw materials, bleaching, preparing ingredients and spicing, wherein the step of preparing ingredients comprises preparation of the chilli oil ingredients and brine. Another pot is selected after the spicing, the chilli oil ingredients of appropriate amount is poured into the pot, the spiced bamboo shoots are into the pot, and the mixture is fried for 5 to 10 minutes to obtain the finish product. The processing technology of chilli oil bamboo shoots has a uniform salt deduction effect, can save water and can make uniform salinity. The formula is regulated based on a lot of experiments and according to tastes, is beneficial to process and mass production, ensures a stable and uniform taste, has a relatively popular taste, is adaptable to consumer demands and has good practicability.

Owner:CHONGQING XUANRUI FOOD

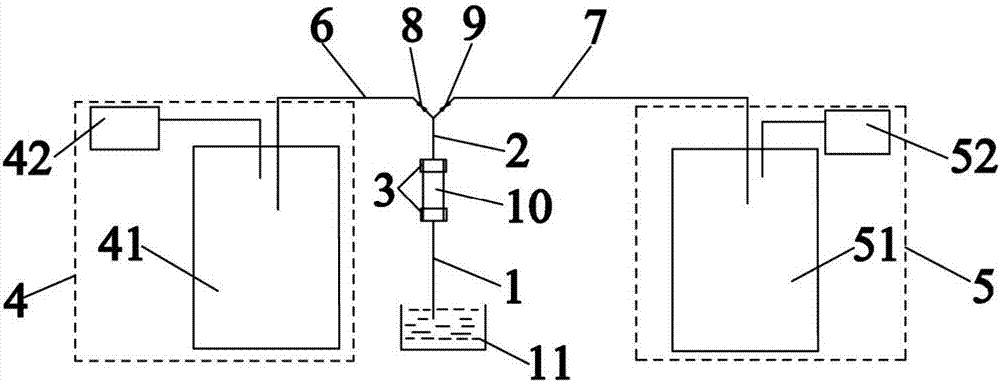

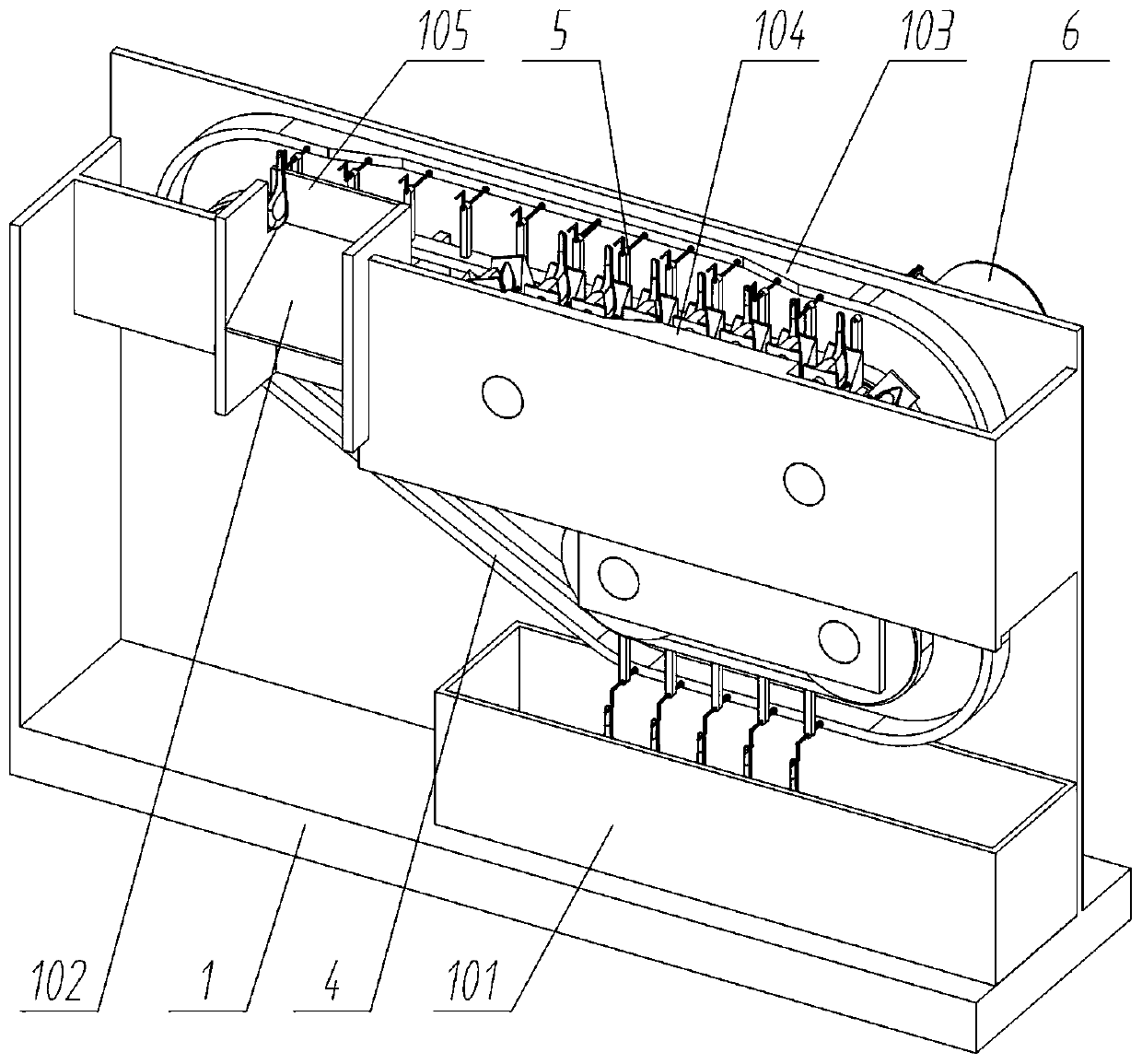

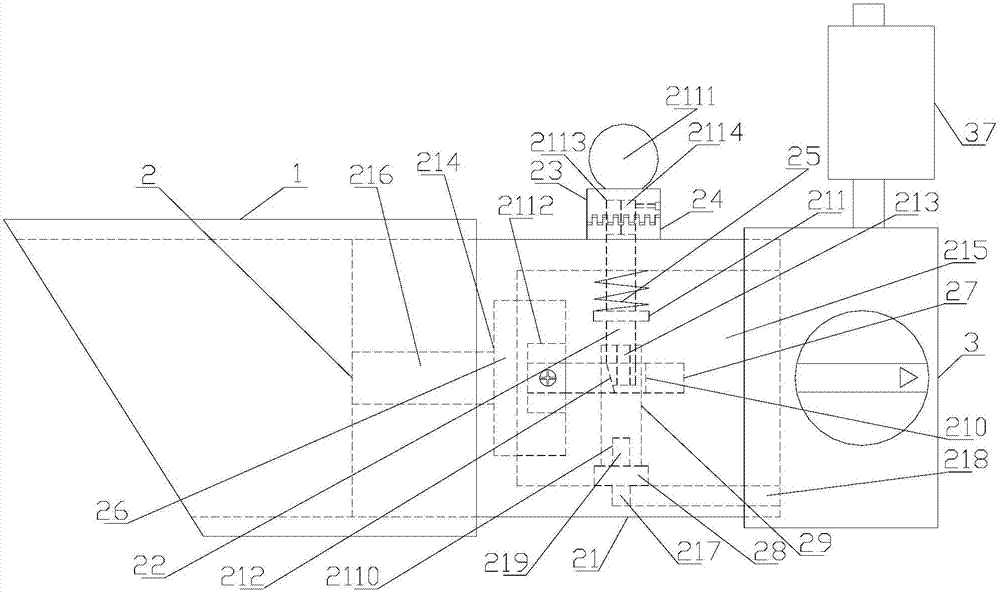

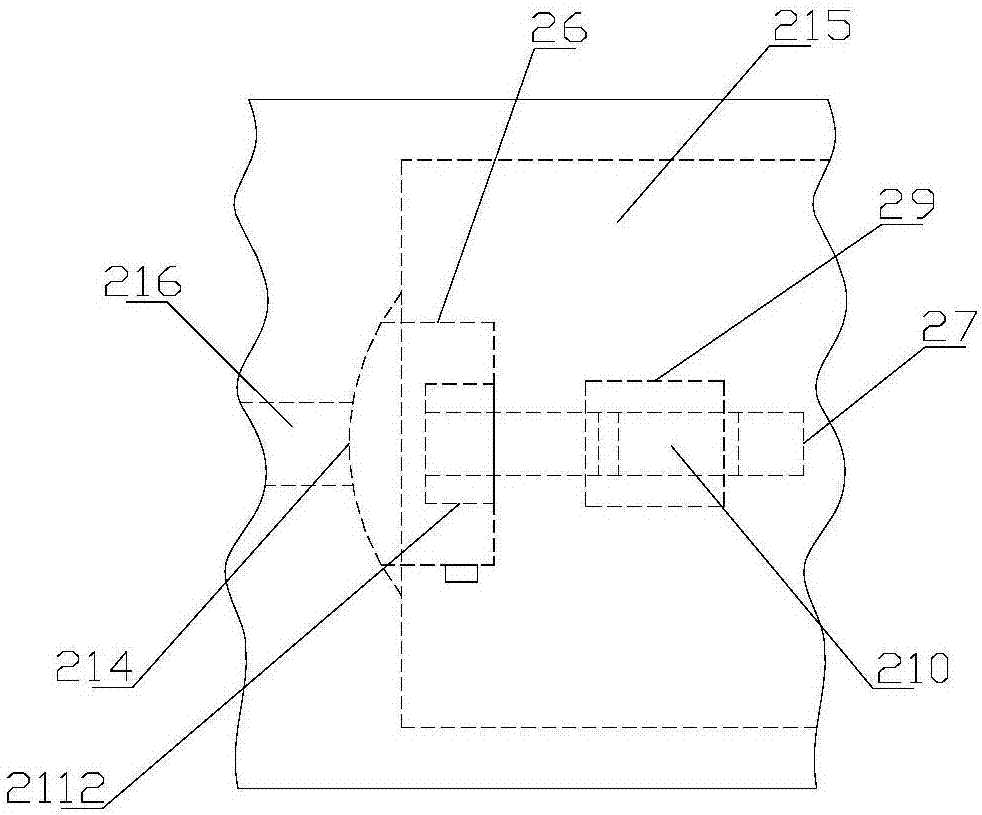

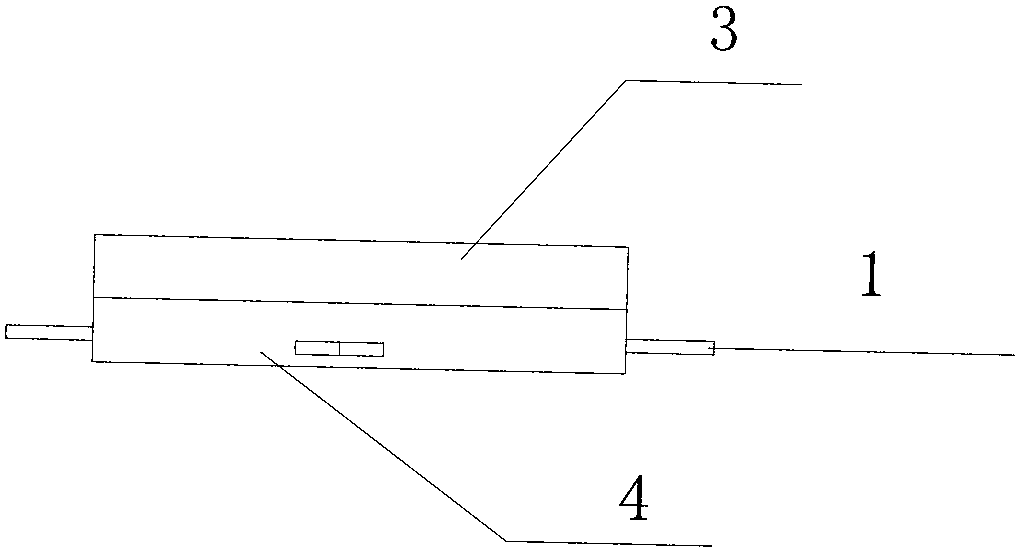

Honeycomb ceramic carrier catalyst miniature coating machine and using method thereof

PendingCN107159523AEasy to operateImprove coating quality and efficiencyPretreated surfacesCoatingsComposite materialPtru catalyst

The invention belongs to the technical field of coating equipment, and particularly relates to a honeycomb ceramic carrier catalyst miniature coating machine. The honeycomb ceramic carrier catalyst miniature coating machine comprises a first conveying pipe, a second conveying pipe, clamping dies, a drawing mechanism and an air blowing mechanism; the first conveying pipe is communicated with the second conveying pipe, clamping dies are arranged at the output end of the first conveying pipe and the input end of the second conveying pipe, the output end of the second conveying pipe is provided with a drawing branch pipe and an air blowing branch pipe, the drawing branch pipe is connected with the drawing mechanism, and the air blowing branch pipe is connected with the air blowing mechanism. In addition, the invention further provides a using method of the honeycomb ceramic carrier catalyst miniature coating machine, operation is simple, the soaking time of slurry in a honeycomb ceramic carrier hole can be controlled, the slurry can be coated into the honeycomb ceramic carrier hole quantitatively and evenly, and the coating quality and efficiency are improved.

Owner:DONGUANN INNOVATIVE NEW MATERIALS

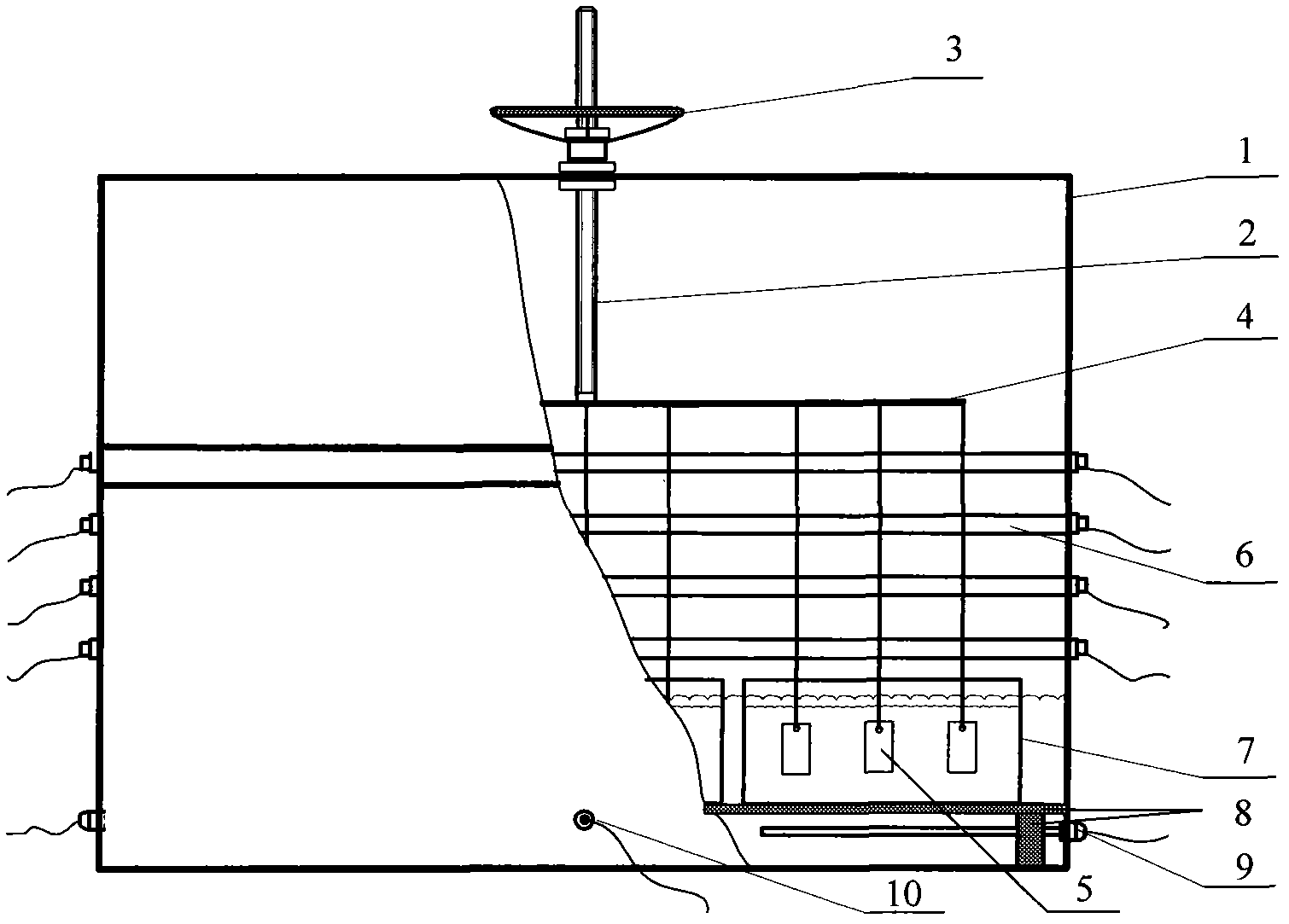

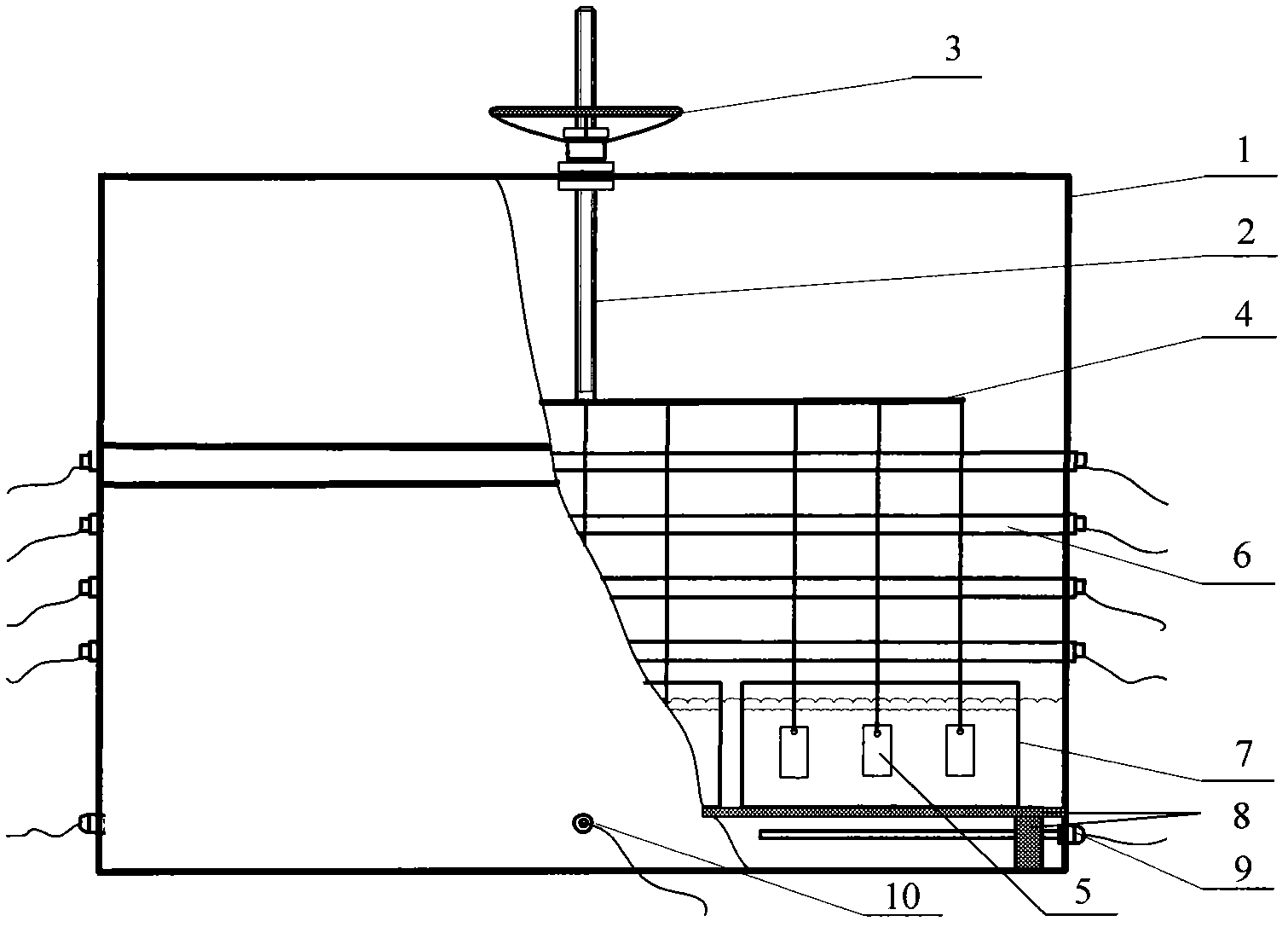

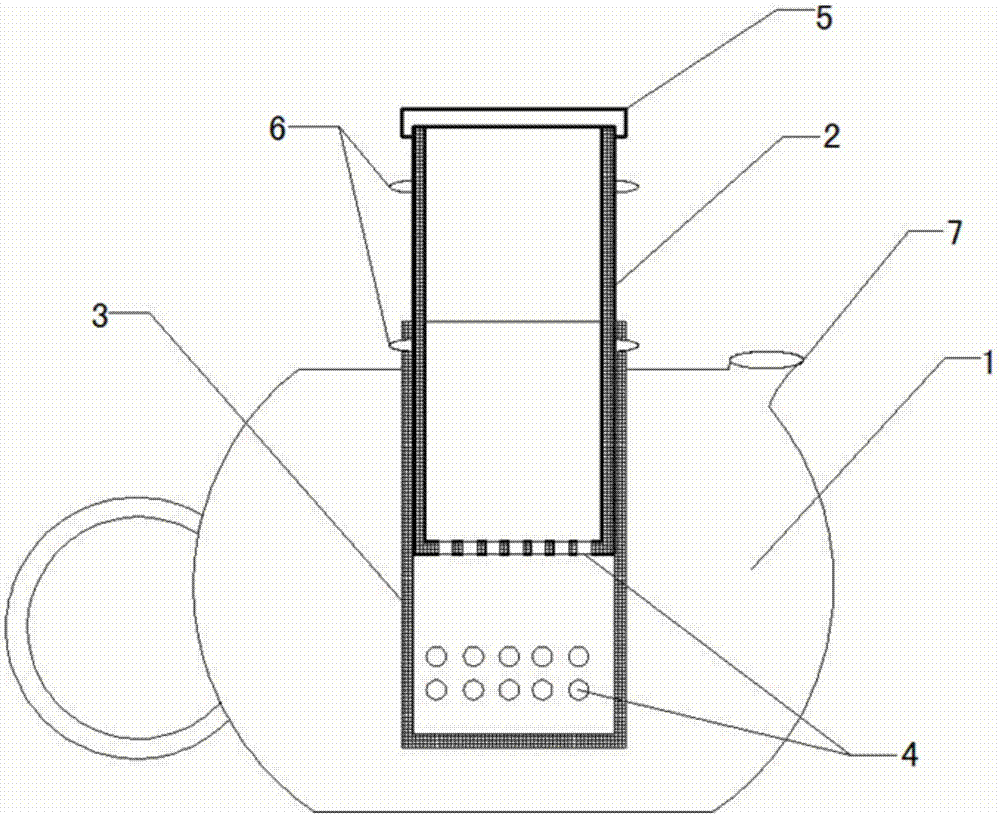

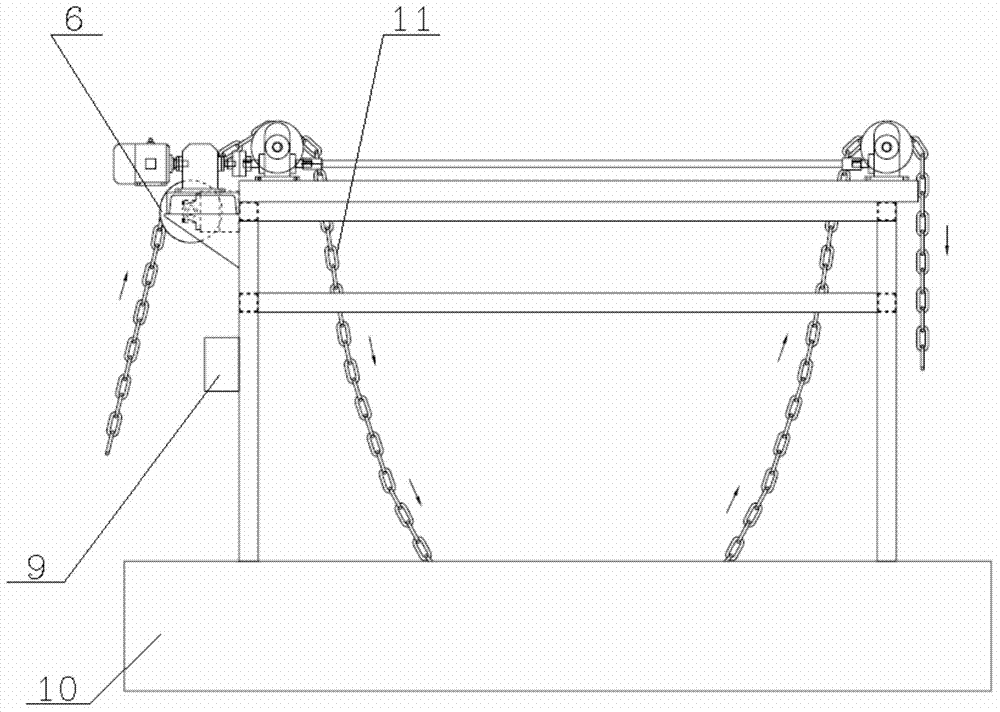

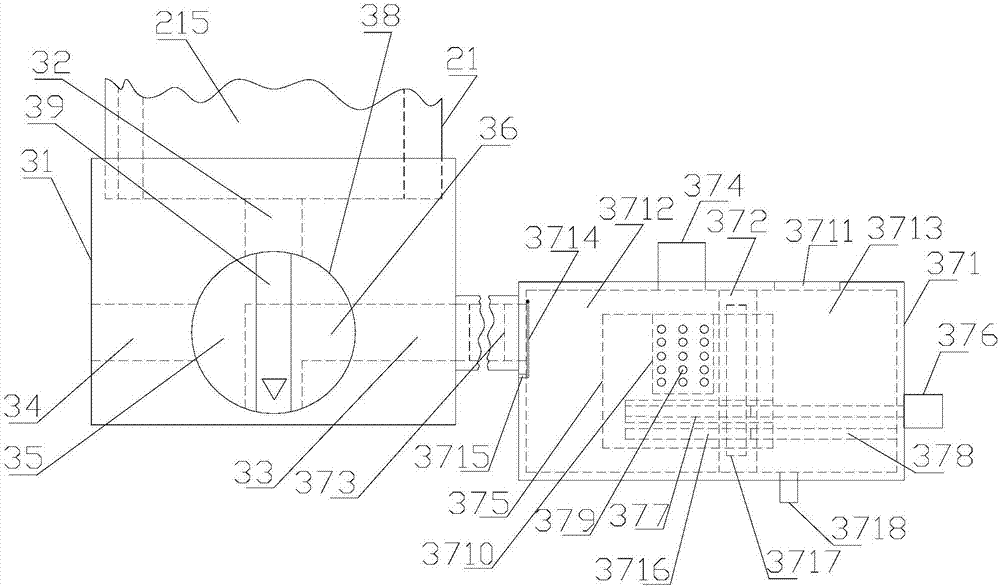

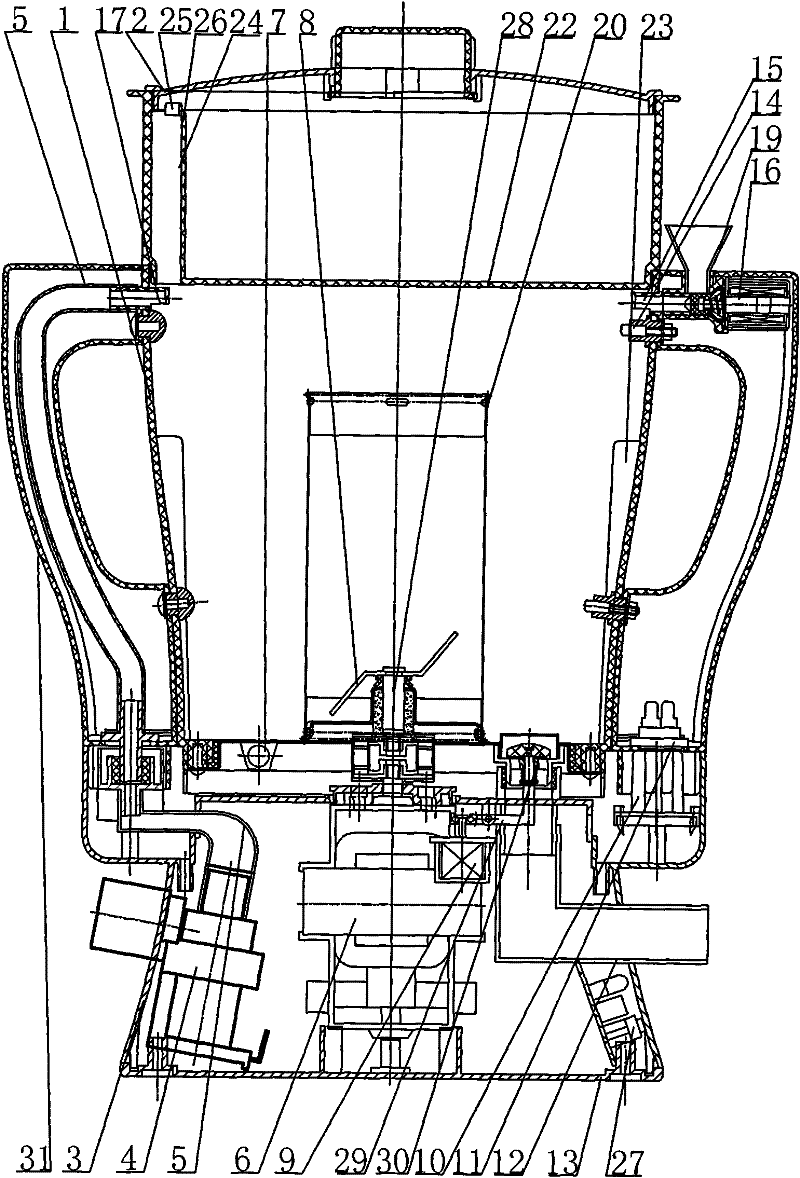

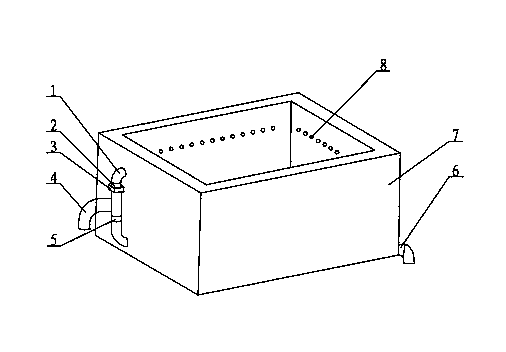

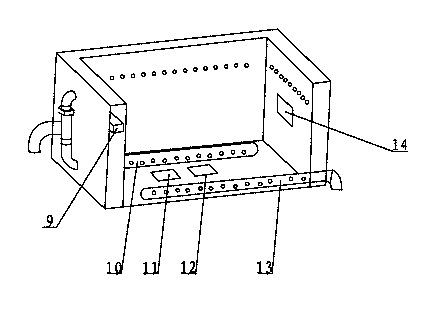

Experimental apparatus for simulating corrosion in ocean tide range region

InactiveCN102323202AControl soaking timeControl exposure timeWeather/light/corrosion resistanceWater bathsUltraviolet lights

The invention discloses an experimental apparatus for simulating a corrosion environment in a tide range region in the ocean environment. A main body of the apparatus is a test box body. A top panel of the box body is provided with a lifting device. A test sample hanger, ultraviolet lamp tubes and corrosion medium testing tanks are arranged in the box body. The bottom of the test box body is provided with a clapboard with holes. The testing tanks for containing corrosion mediums are arranged on the clapboard with the holes. Seawater or other corrosion mediums are contained in the corrosion medium testing tanks. A heater and a temperature sensor are arranged in a space between the clapboard with the holes and the bottom surface of the box body. Clear water is filled in a testing box to carry out water bath temperature control; when test samples are all soaked in the corrosion mediums, the corrosion environment in the tide rising process of the ocean is simulated; and when the test samples are lifted up to leave from the liquid levels and are irradiated by ultraviolet light, the corrosion environment irradiated by the sunlight in the tide ebbing process of the ocean is simulated. Therefore, according to the experimental apparatus, the influence of alternation of wetting and drying of the seawater and the sunlight irradiation is comprehensively considered, the simulated corrosion environment is closer to the actual corrosion environment, and the experimental foundation is provided for researching a tide range region corrosion protection technology.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

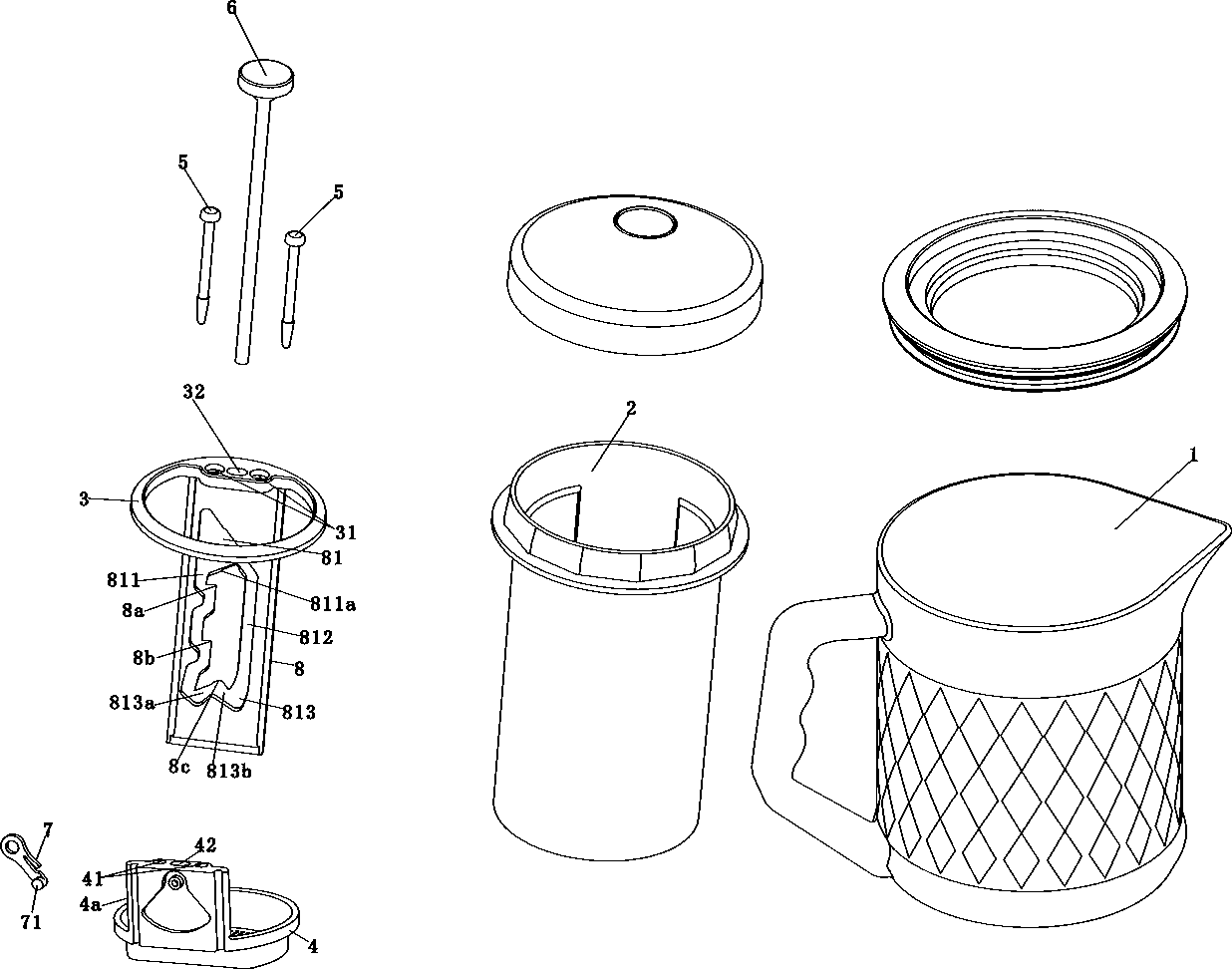

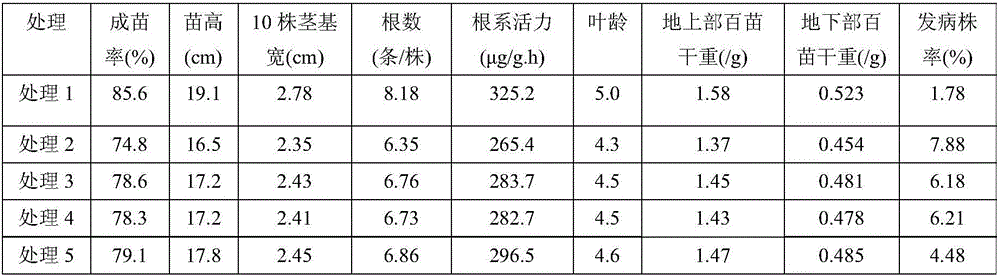

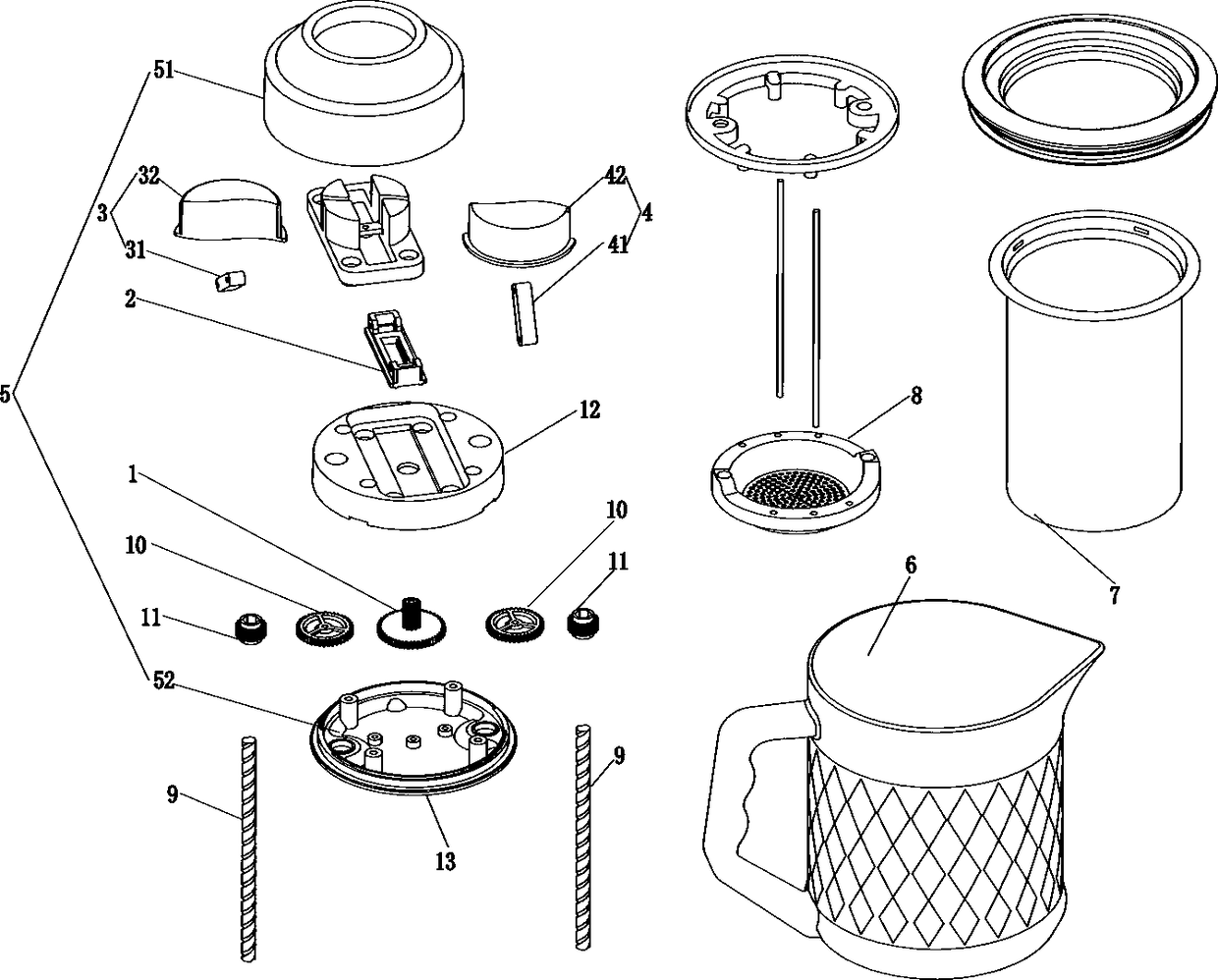

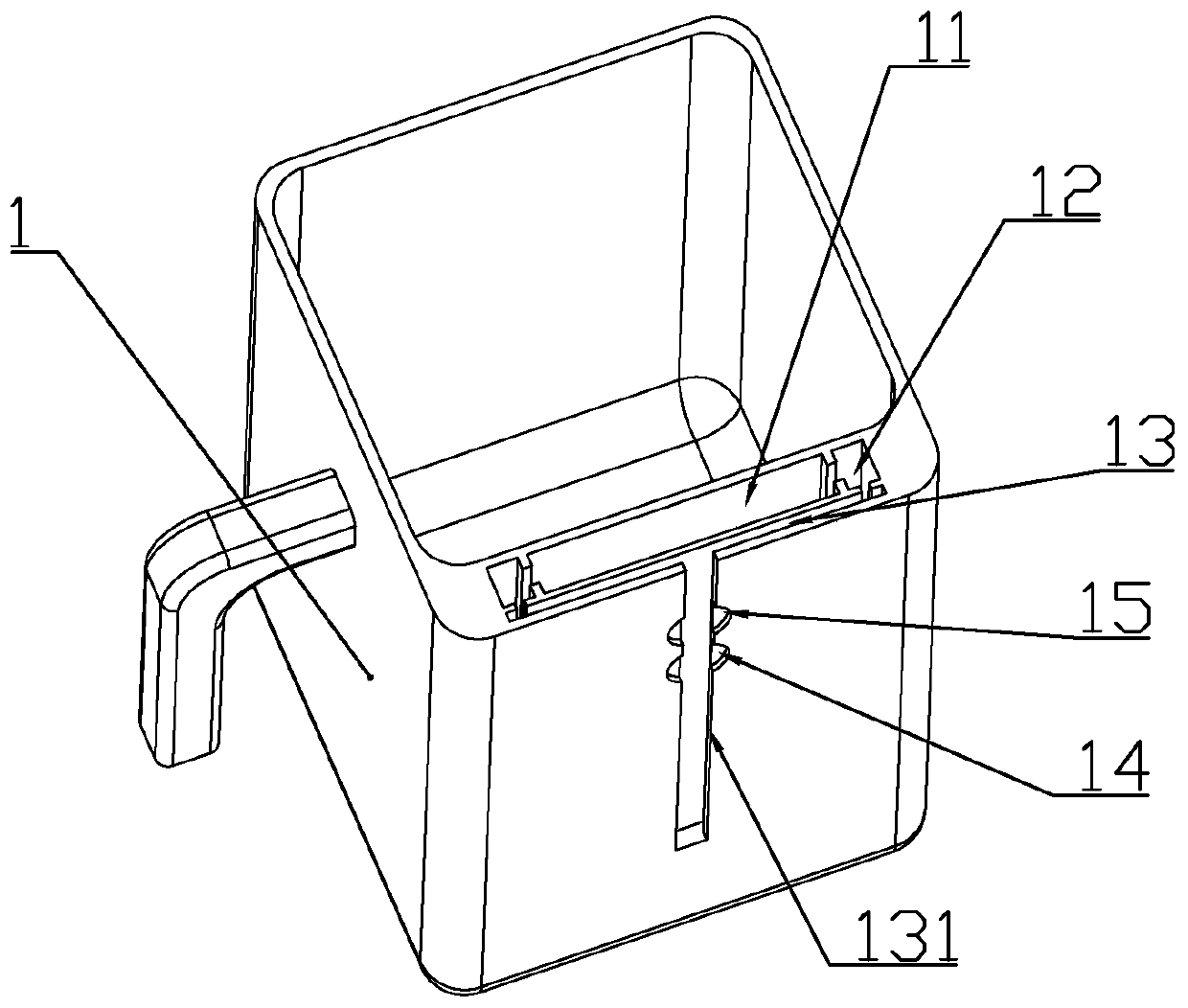

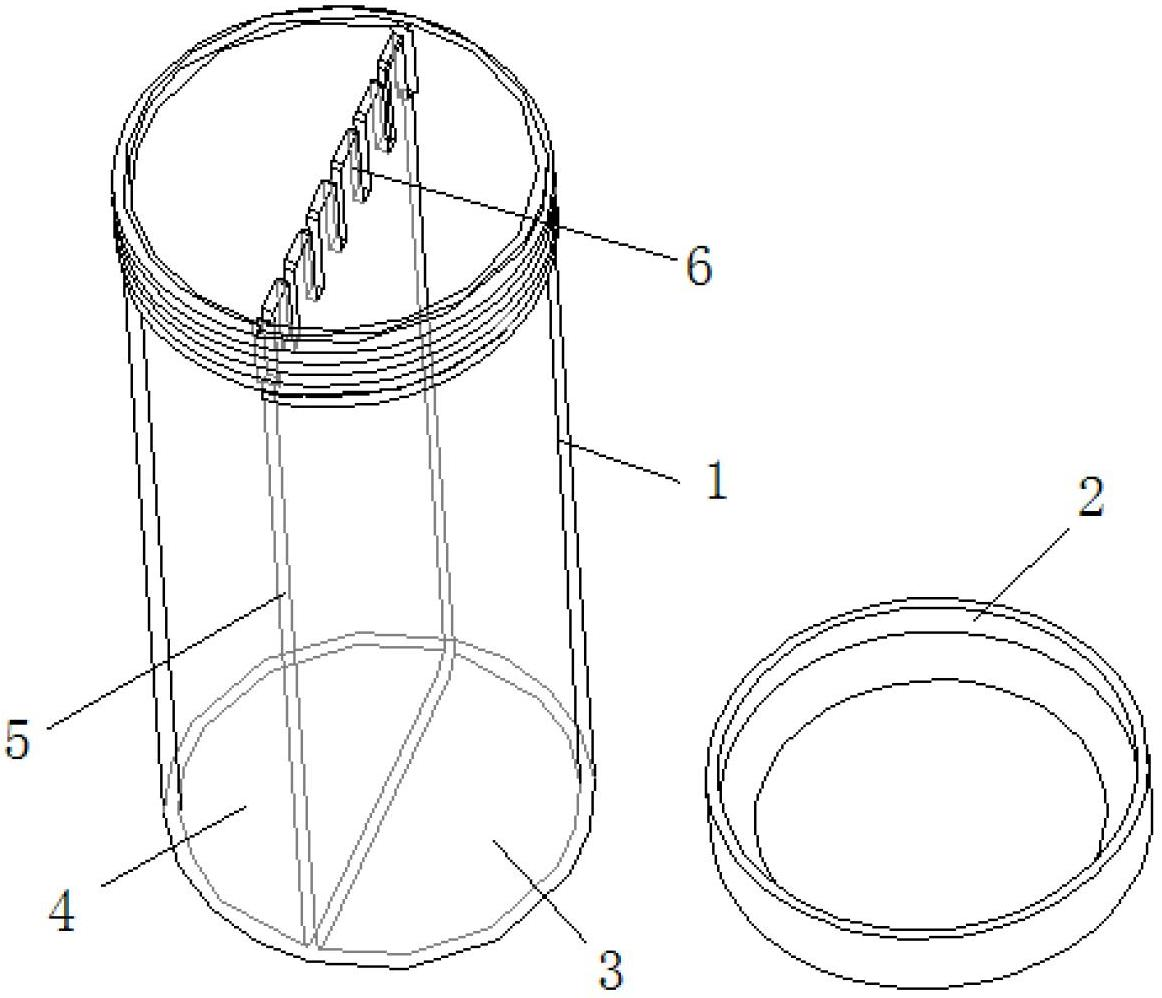

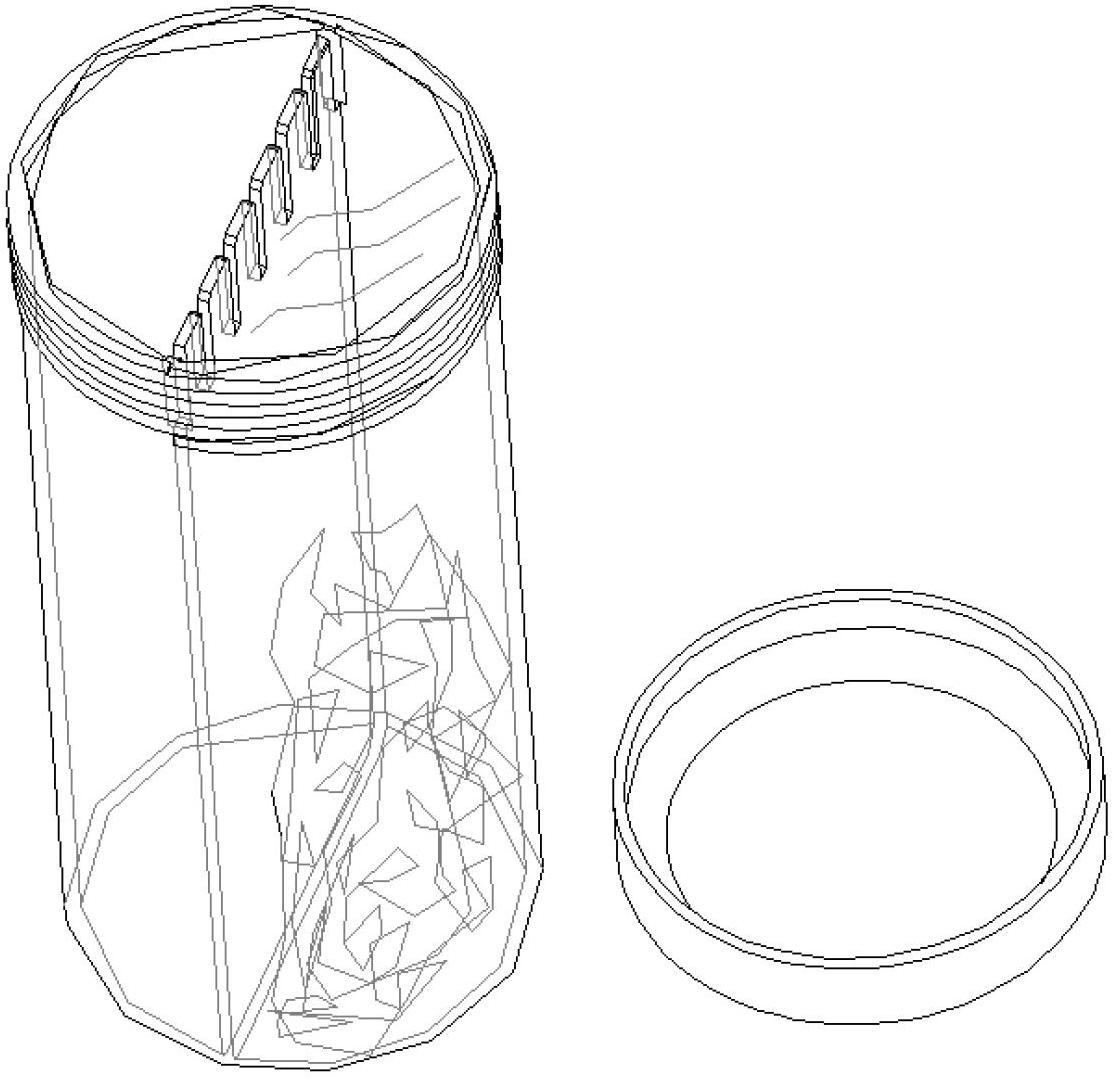

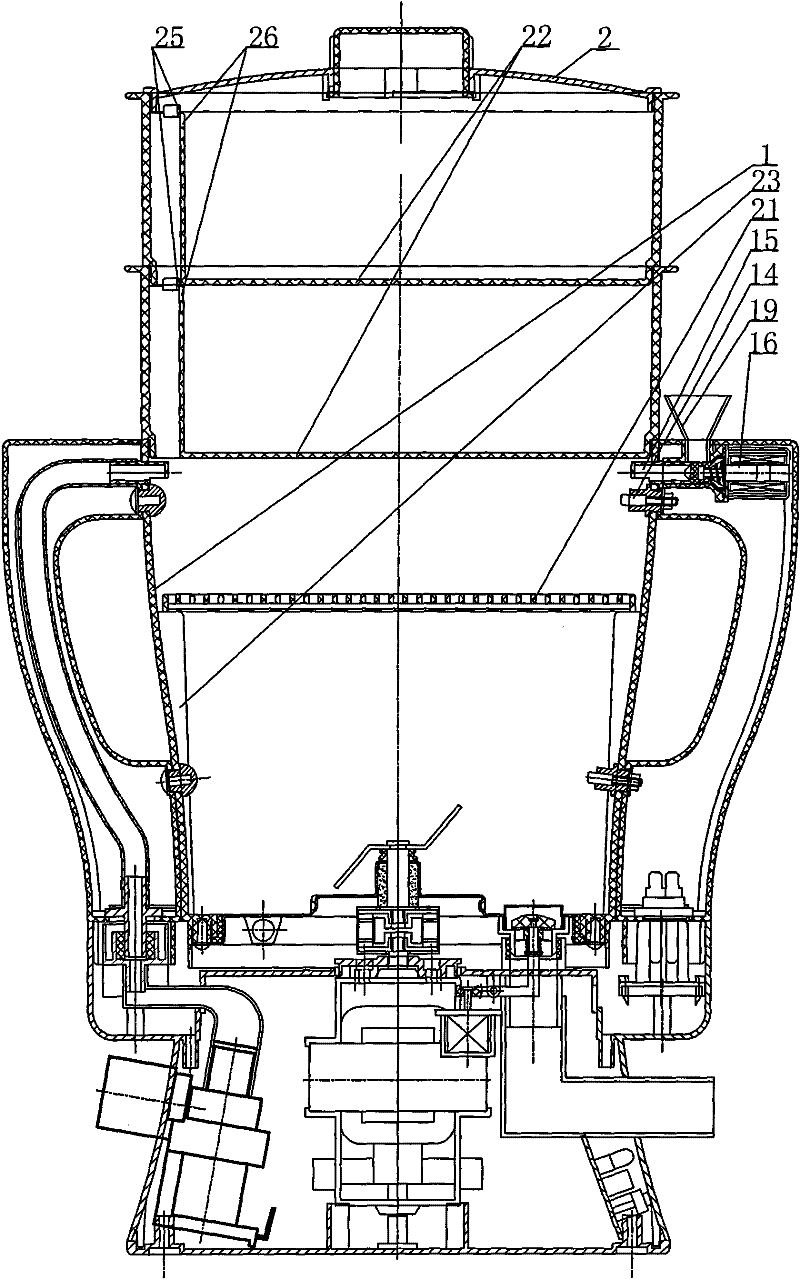

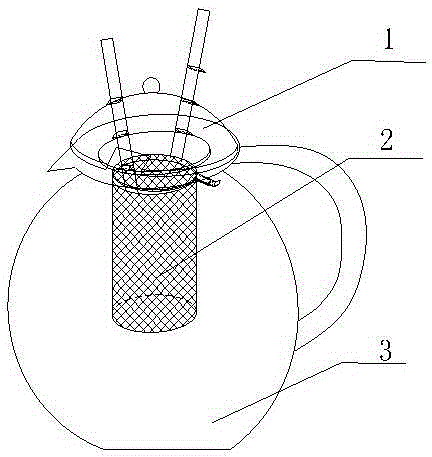

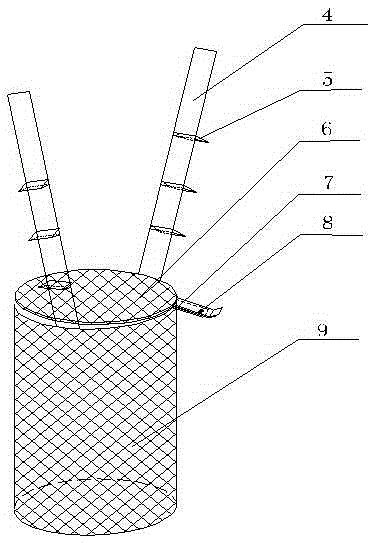

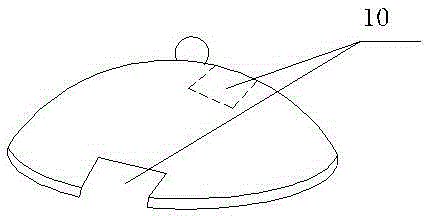

Teapot

InactiveCN109008512AControl soaking timeAchieve separationBeverage vesselsDomestic vesselsEngineeringMechanical engineering

Owner:GUANGDONG XINGONG ELECTRICAL APPLIANCES

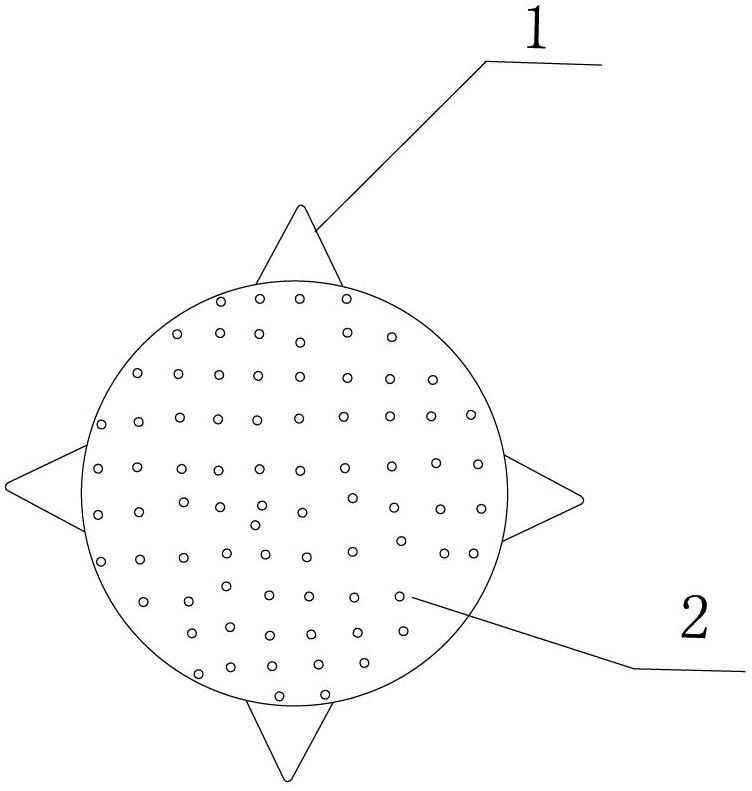

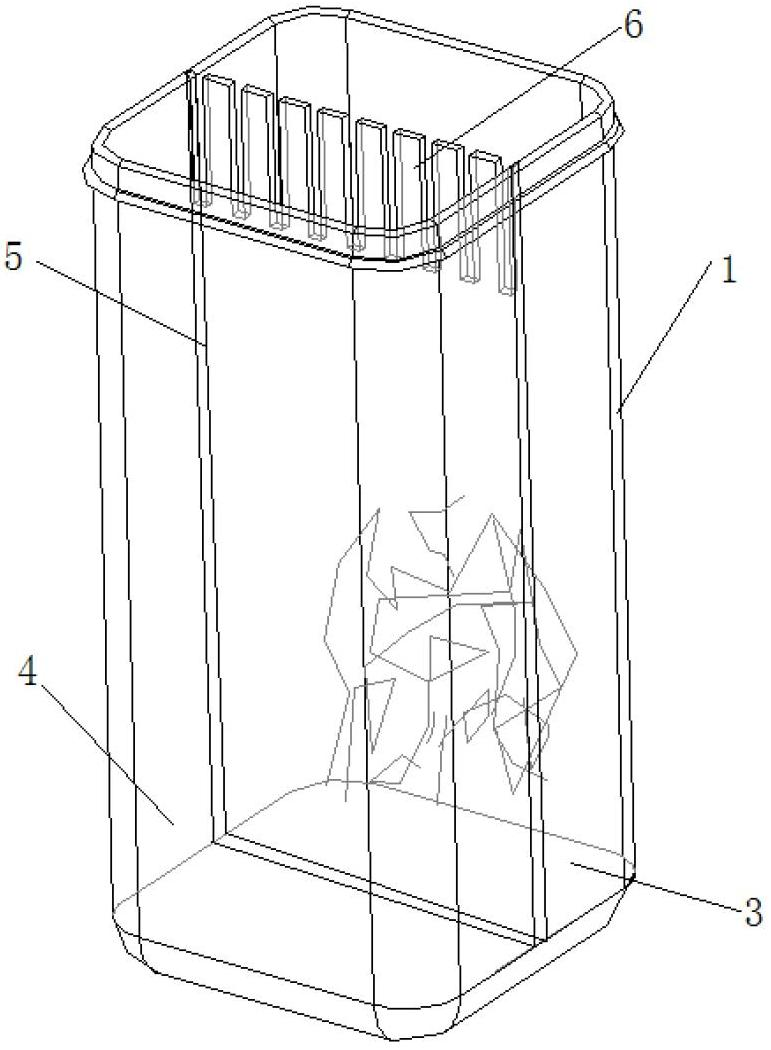

Height-adjustable tea making device

InactiveCN107157238AHeight adjustableControl soaking timeBeverage vesselsDomestic vesselsEngineeringWater level

The invention discloses a height-adjustable tea making device, which comprises a pot body, the top of the pot body is concaved downward to form a bracket, the top of the bracket protrudes from the pot body, and the bracket protrudes symmetrically in the same circumferential direction as the pot body. There are a pair of through holes, filter holes are set around the bracket, a filter tea box is placed in the bracket, filter holes are set at the bottom of the filter tea box, and spring buckles matching the through holes are arranged symmetrically on the outer wall of the filter tea box at different heights , There is a water outlet on one side of the top of the kettle body. The invention adjusts the height of the filter tea box relative to the support through the cooperation of the spring buckle and the through hole, which can effectively and conveniently control the soaking time of the tea, prevent the tea from being soaked for too long and cause the taste of the tea to be too deep and affect the taste, and ensure the freshness of the tea It is very convenient to use, and at the same time, because the height of the filter tea box for placing tea leaves is adjustable, it does not need to meet the high water level requirement when making tea, so as to meet people's diverse tea making needs.

Owner:陶象余

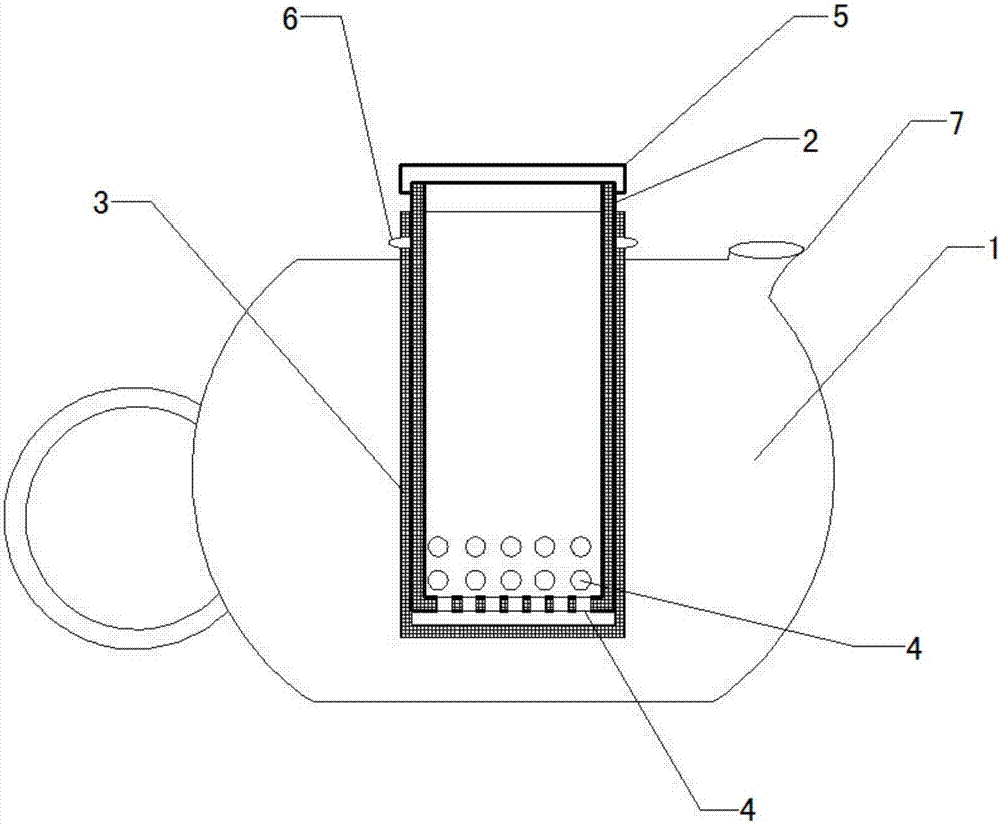

Rice seed cold-resistant germination-promoting seedling-strengthening agent and use method thereof

The invention relates to a rice seed cold-resistant germination-promoting seedling-strengthening agent and a use method thereof, and belongs to the technical field of crop cultivation, quick lime (with the content >= 95%), a Bacillus subtilis commodity strain (10 billion live Bacillus bacteria / gWP), plant ash powder and ginkgo leaf or ginkgo fruit peel extract are mixed according to the mass ratio of 80-150:1.0-2.5:100-200:5-15, clean water is added to completely dissolve the mixture into a 1%-3% water solution, rice seeds are soaked in the water solution for 45-60 minutes for accelerating germination in accordance with the seed-soaking germination-accelerating technology in the prior art; when in seeding, the 1%-3% water solution is prepared according to the mass ratio, the 1%-3% water solution is uniformly poured onto the surface of pieces of a water cultivation seedling field or a seedbed of dry land seedling cultivation, or uniformly applied and mixed into seedling throwing plate nutrient soil, or applied to the surface of pieces of a direct sowing paddy field, and then seeding is performed. The rice seed cold-resistant germination-promoting seedling-strengthening agent can effectively solve the problems that rice seeds are slow to sprout and germinate, and not irregular to germinate, seedlings are weak, seedlings are susceptible to diseases, and the like, and can improve germination rate, seedling-forming rate and seedling rate of the rice seeds and strong seedling rate.

Owner:HUNAN AGRICULTURAL UNIV

Automatic glazing device for ceramic spoon production

ActiveCN111168823AAchieve separationAvoid manual loading and unloadingCeramic shaping apparatusMechanical engineeringIndustrial engineering

The invention discloses an automatic glazing device for ceramic spoon production, and relates to the technical field of ceramic production. The automatic glazing device for ceramic spoon production solves the problems that in the prior glazing process of a ceramic spoon, a spoon needs to be manually hung on a workpiece, a glazing machine is used for glazing, and after the glazing is completed, thespoon is removed again, the operation is troublesome, the mounting and dismounting time is long, and the working efficiency is low. The automatic glazing device comprises a bracket body, wherein a group of glazing conveying belts and a group of positioning conveying belts are arranged on the inner side of the bracket body, and a plurality of groups of hanging devices are uniformly arranged on theouter side of the glazing conveying belt. According to the device, the actions such as automatic hanging of the spoon, glazing of the spoon and automatic separation of the spoon can be realized, manual operation is greatly simplified, the workload of workers is reduced, and the working efficiency is improved; and meanwhile, the soaking time of the spoon in glaze can be better controlled, the thickness of the glaze can be better guaranteed, and the product quality is guaranteed.

Owner:平邑仁安中医药产业发展有限公司

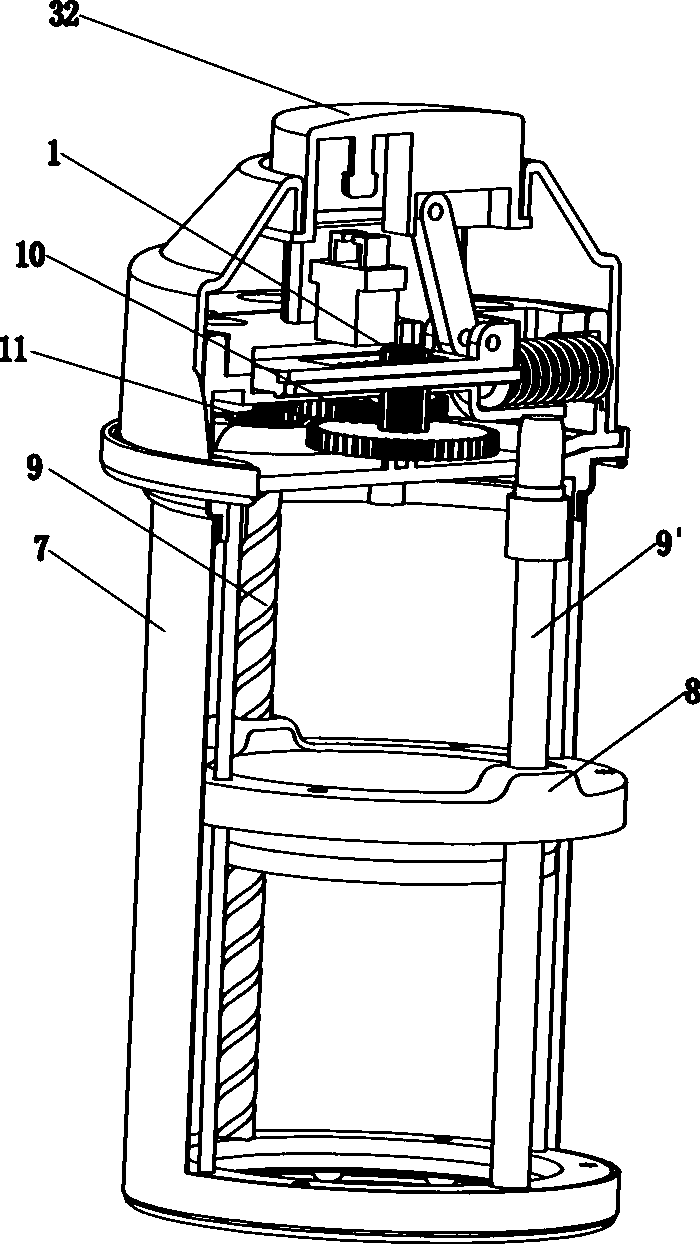

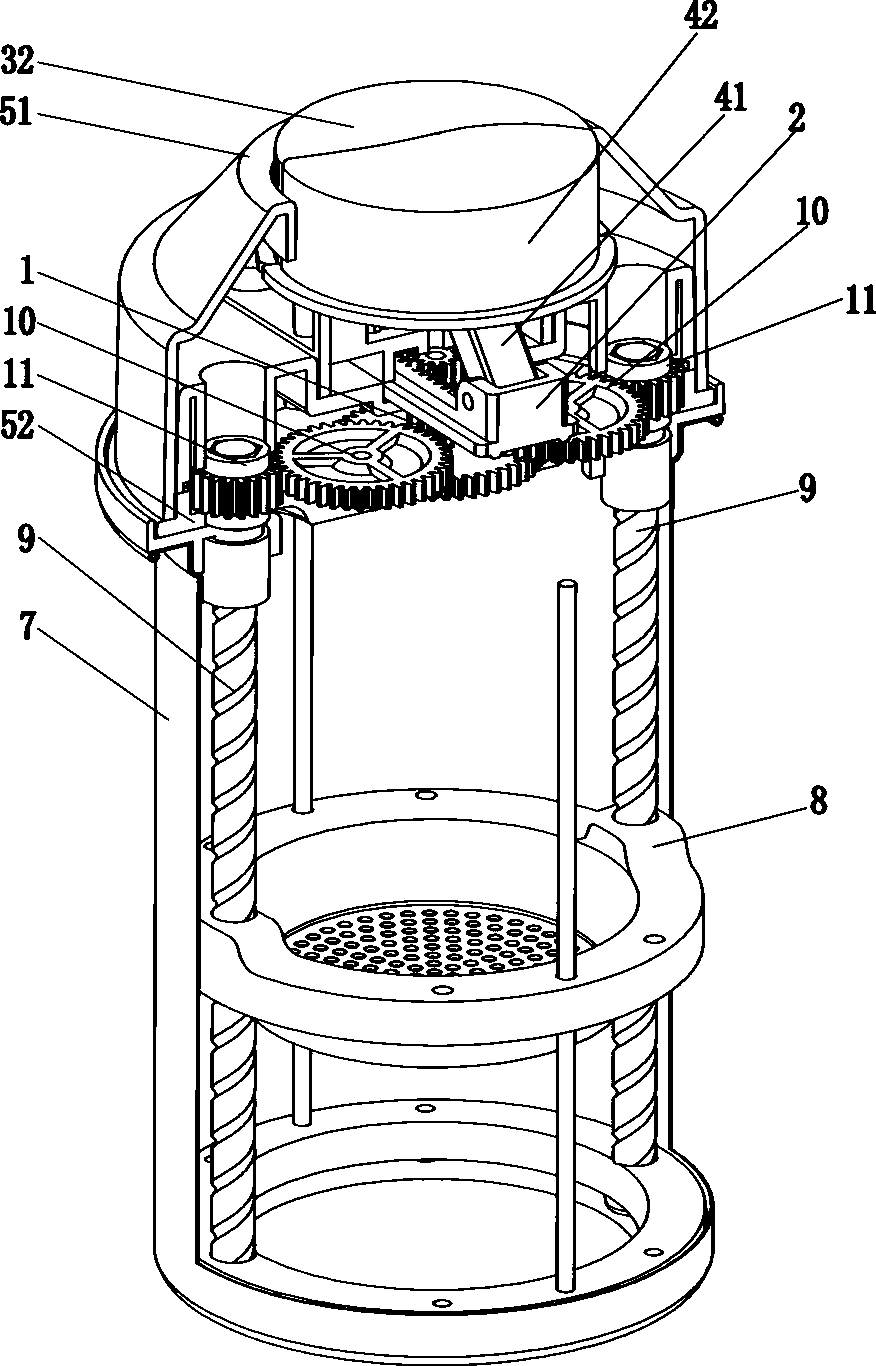

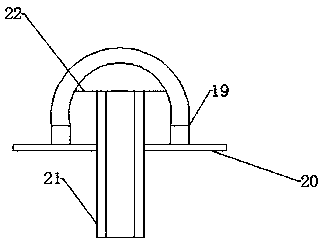

Button mechanism capable of converting pushing into rotation and teapot with mechanism

InactiveCN109044036AAchieve liftingEasy to operateBeverage vesselsDomestic vesselsKey pressingGear wheel

The invention discloses a button mechanism capable of converting pushing into rotation and a teapot with the mechanism. The button mechanism includes a first gear, a rack, a first button and linking member group and a second button and linking member group; the first gear is meshed with the rack; in the first button and linking member group, one end of a first linking member is movably connected with a first button, and the other end of the first linking member is movably connected with one end of the rack; in the second button and linking member group, one end of a second linking member is movably connected with a second button, and the other end of the second linking member is movably connected with the other end of the rack. The first and second button and linking member groups can drive the rack to move left and right separately, correspondingly the first gear is driven to rotate clockwise and counterclockwise through the movement of the rack, the first gear of the button mechanismcan control the rotation of a screw rod through a gear set to make a filter core ascend or descend, thus soaking of tea can be controlled, and the tea can be filtered.

Owner:GUANGDONG XINGONG ELECTRICAL APPLIANCES

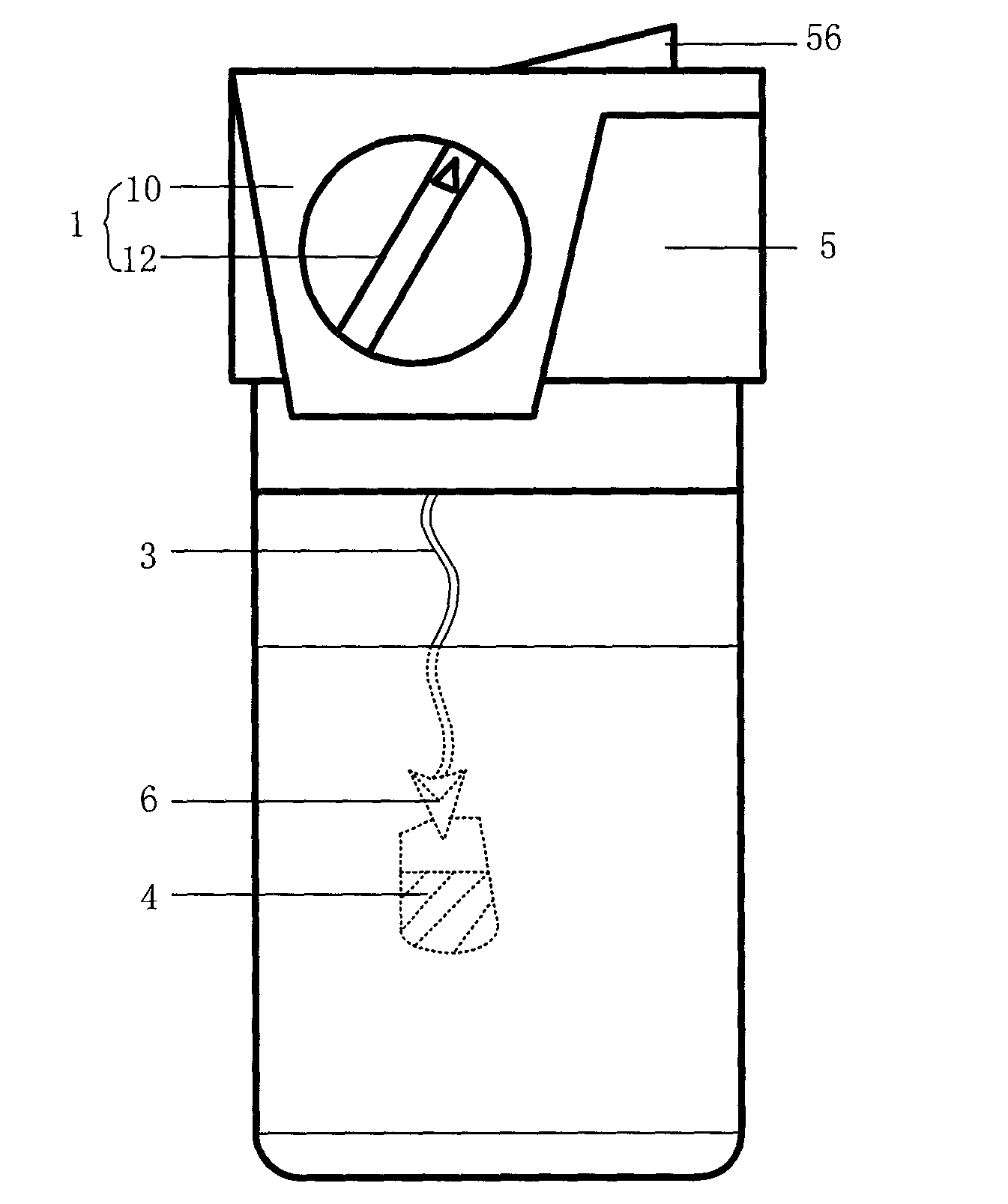

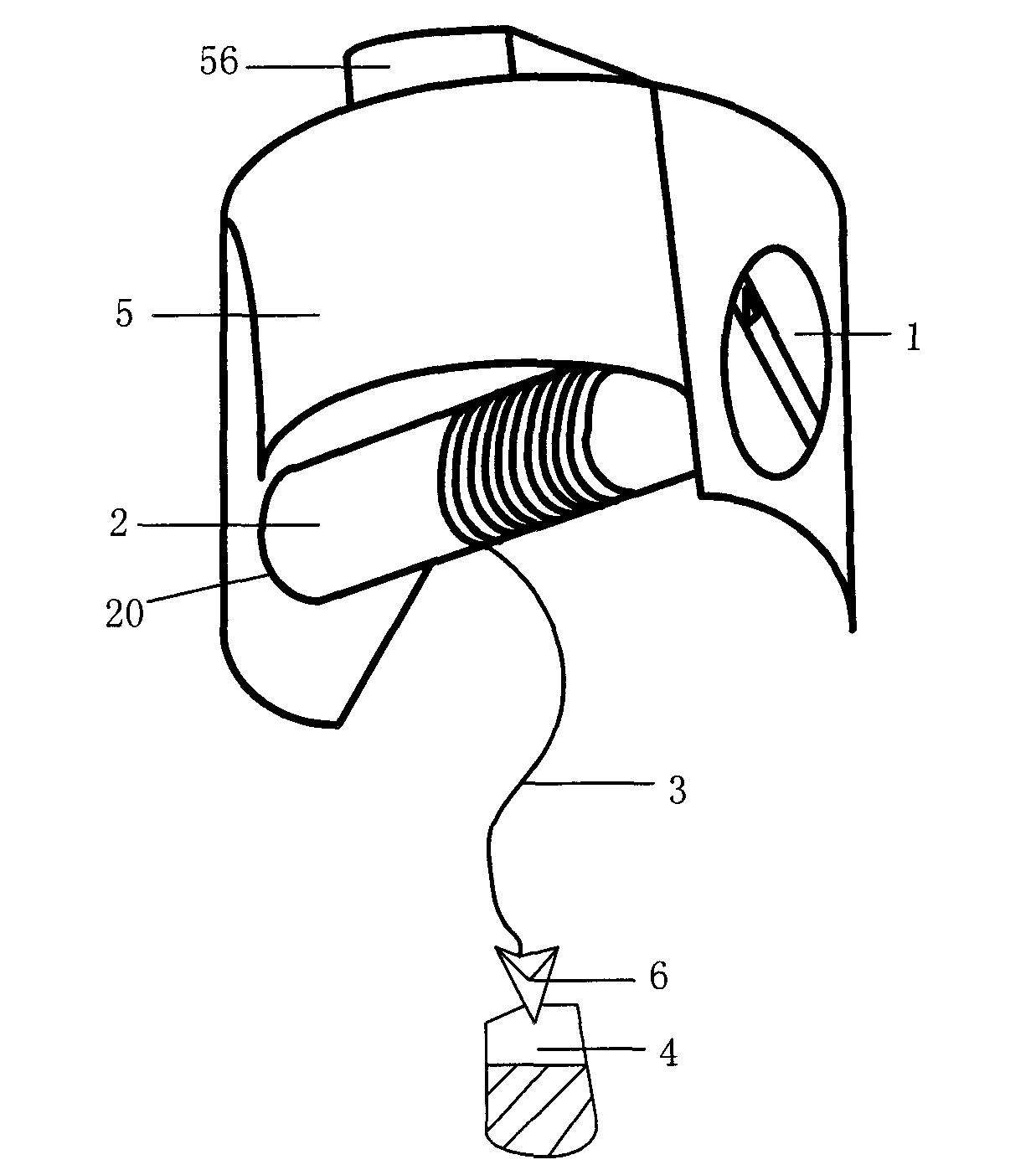

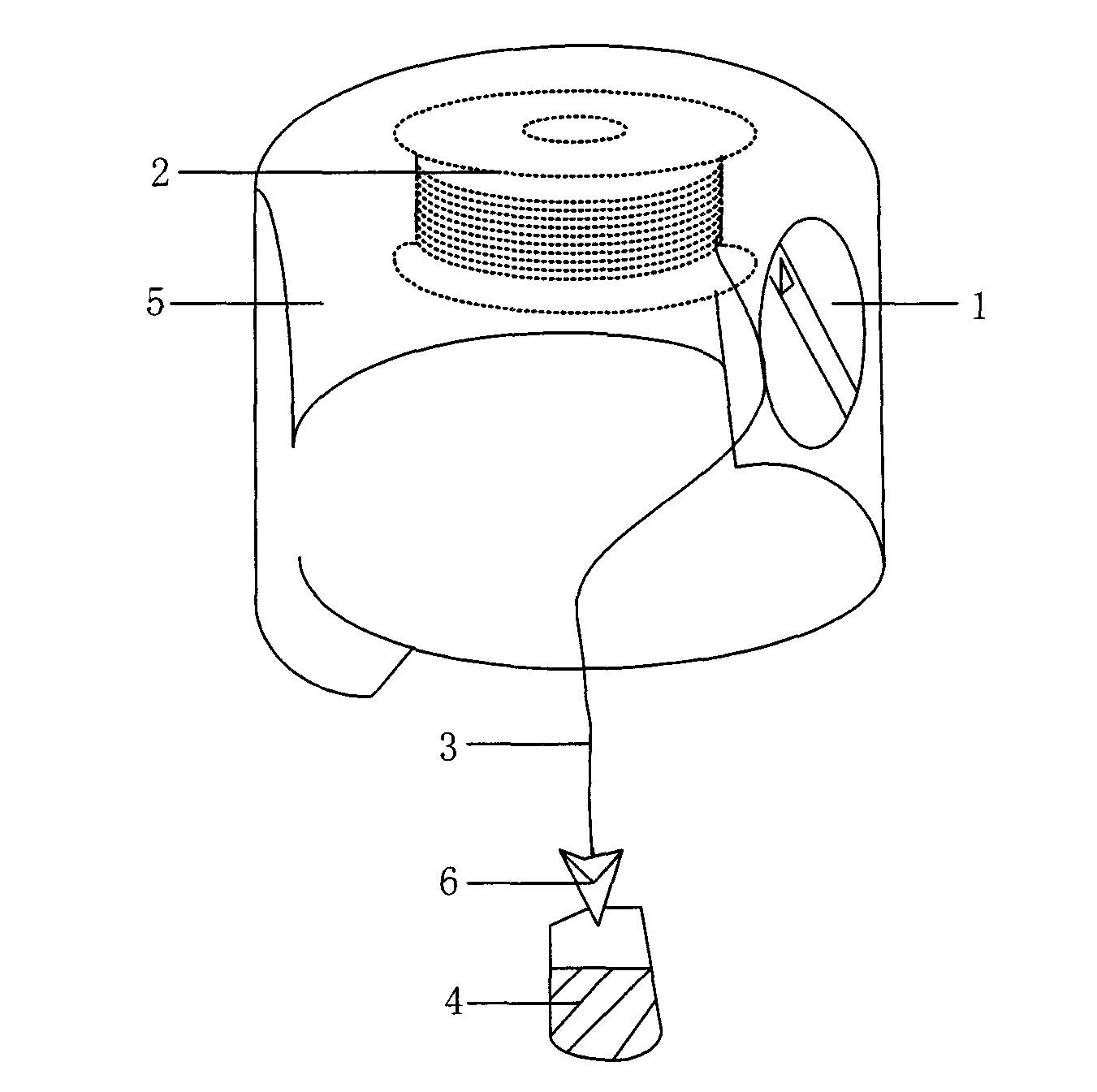

Tea soaking timer

InactiveCN102793442AExcellent tea effect and tasteControl soaking timeDomestic vesselsTime interval measurement with driving mechanismMouthfeelSetting time

The invention provides a tea soaking timer, which comprises a timing dial, a rotating shaft and a chain which is wound on the rotating shaft, wherein the rotating shaft is connected with the timing dial; one end of the chain is wound on the rotating shaft, and the other end of the chain is connected with a tea bag; and the rotating shaft can be driven to rotate by turning the timing dial and the chain can be driven to be folded or extended accordingly. When the set time is up, the tea bag is got away from the water level. Thus, according to different requirements, for example, habits of users or tea tasting requirements of different kinds of tea, the soaking time of the tea bag in water can be controlled to achieve the optimal tea tasting effect and mouthfeel.

Owner:陈华

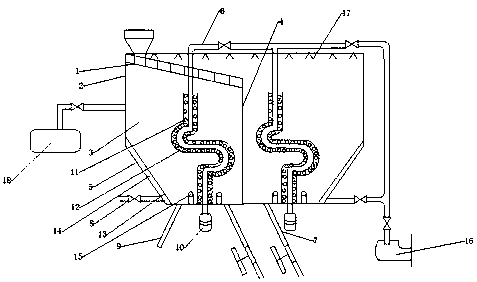

Automatic navel orange peel shearing and heating and cleaning device

InactiveCN109588654AWell mixedEvenly heatedCleaning using liquidsMoving filtering element filtersWater flowNavel orange

The invention discloses an automatic navel orange peel shearing and heating and cleaning device. The automatic navel orange peel shearing, heating and cleaning device comprises a shearing mechanism and a heating and cleaning mechanism; the heating and cleaning mechanism comprises a water supply system, a cleaning system and a discharge system; the water supply system comprises a primary filter tank, a secondary filter tank and a tertiary filter tank; the primary filter tank, the secondary filter tank and the tertiary filter tank are sequentially communicated with one anther and are separated by a first filter plate and a second filter plate; the cleaning system comprises a feed hopper, a cleaning tank is arranged at the lower end of the feed hopper, a water inlet pipe is arranged on the edge of one side of the cleaning tank in the tangential direction and communicated with the water supply system; the discharge system comprises a filter tank communicated with the cleaning tank; a plurality of cross beams are arranged at the upper end of the filter tank and connected with a filter screen plate through a spring; and the filter screen plate slides up and down in the filter tank. The provided automatic navel orange peel shearing and heating and cleaning device is provided with the heating and cleaning mechanism, can clean and boil the peel by using the power of the water flow, andsaves energies.

Owner:ZIGUI COUNTY QUGU FOOD

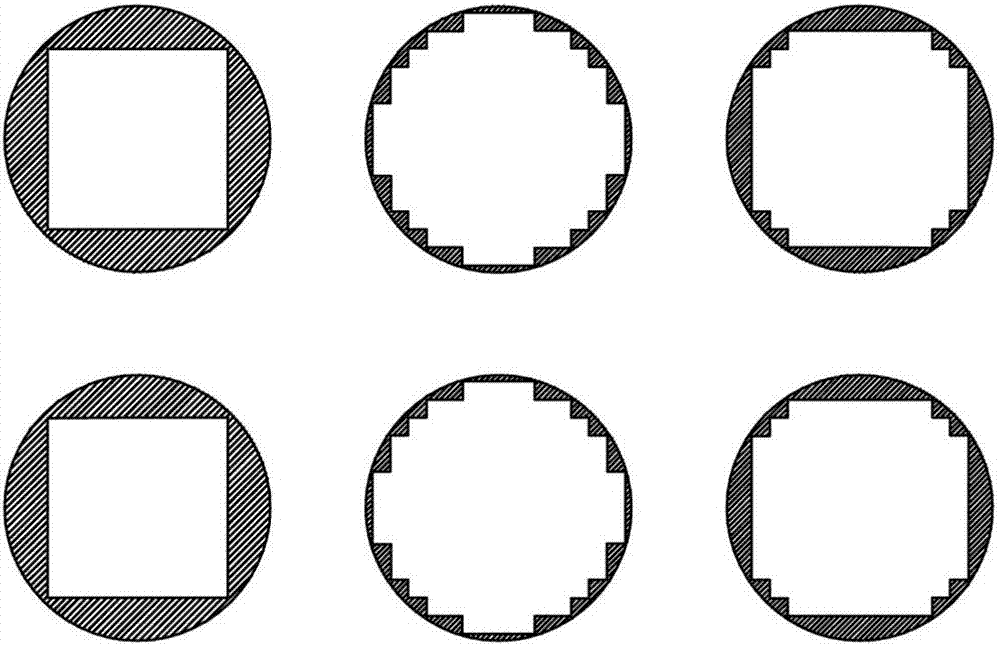

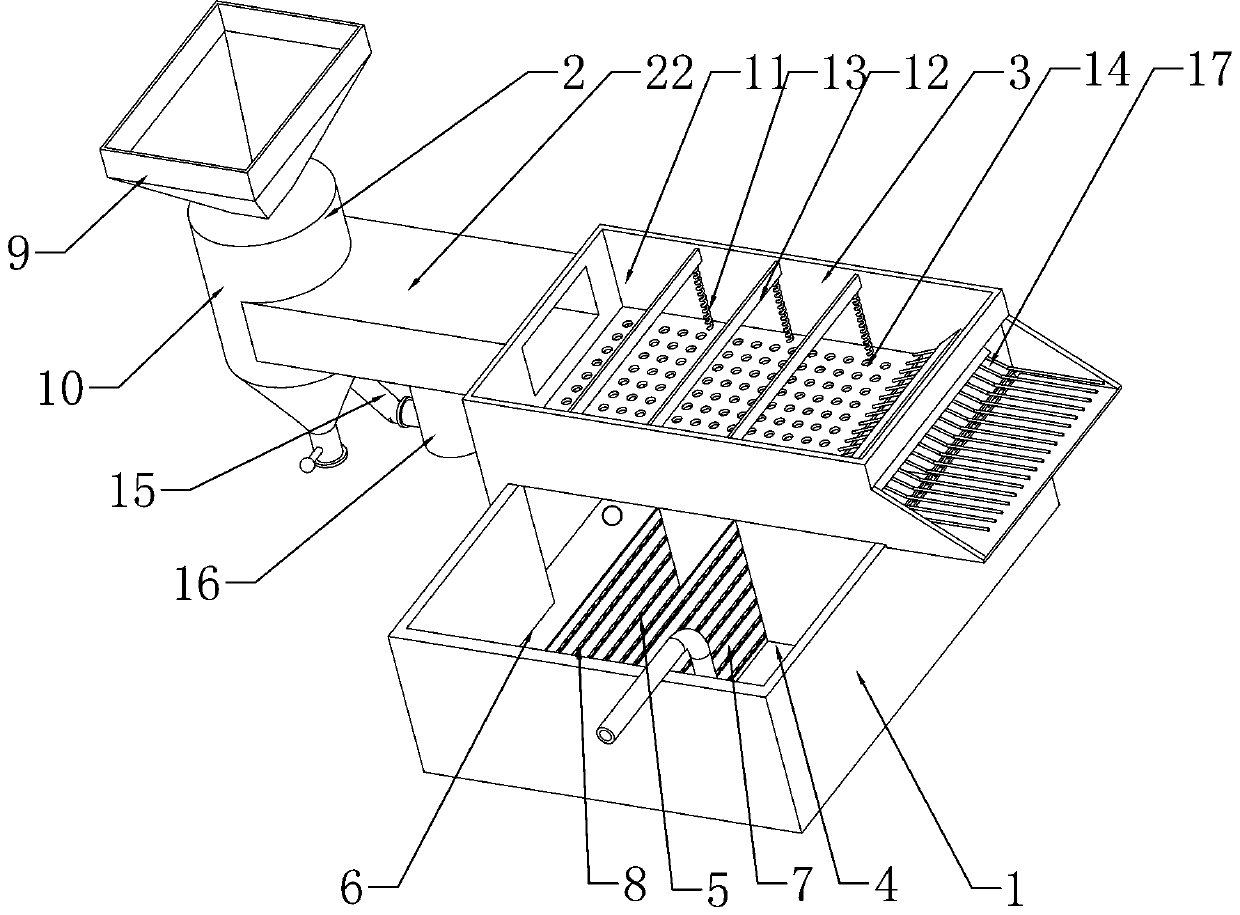

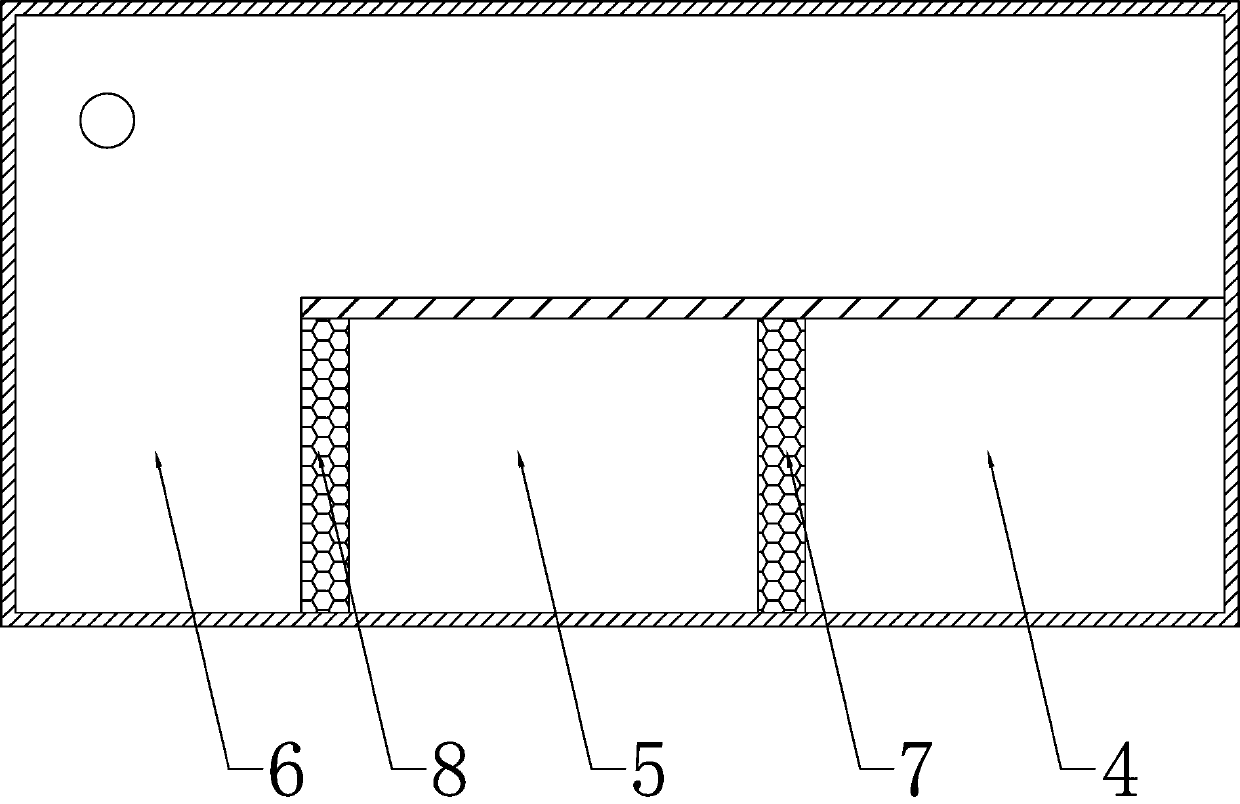

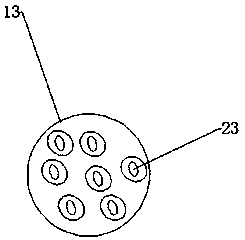

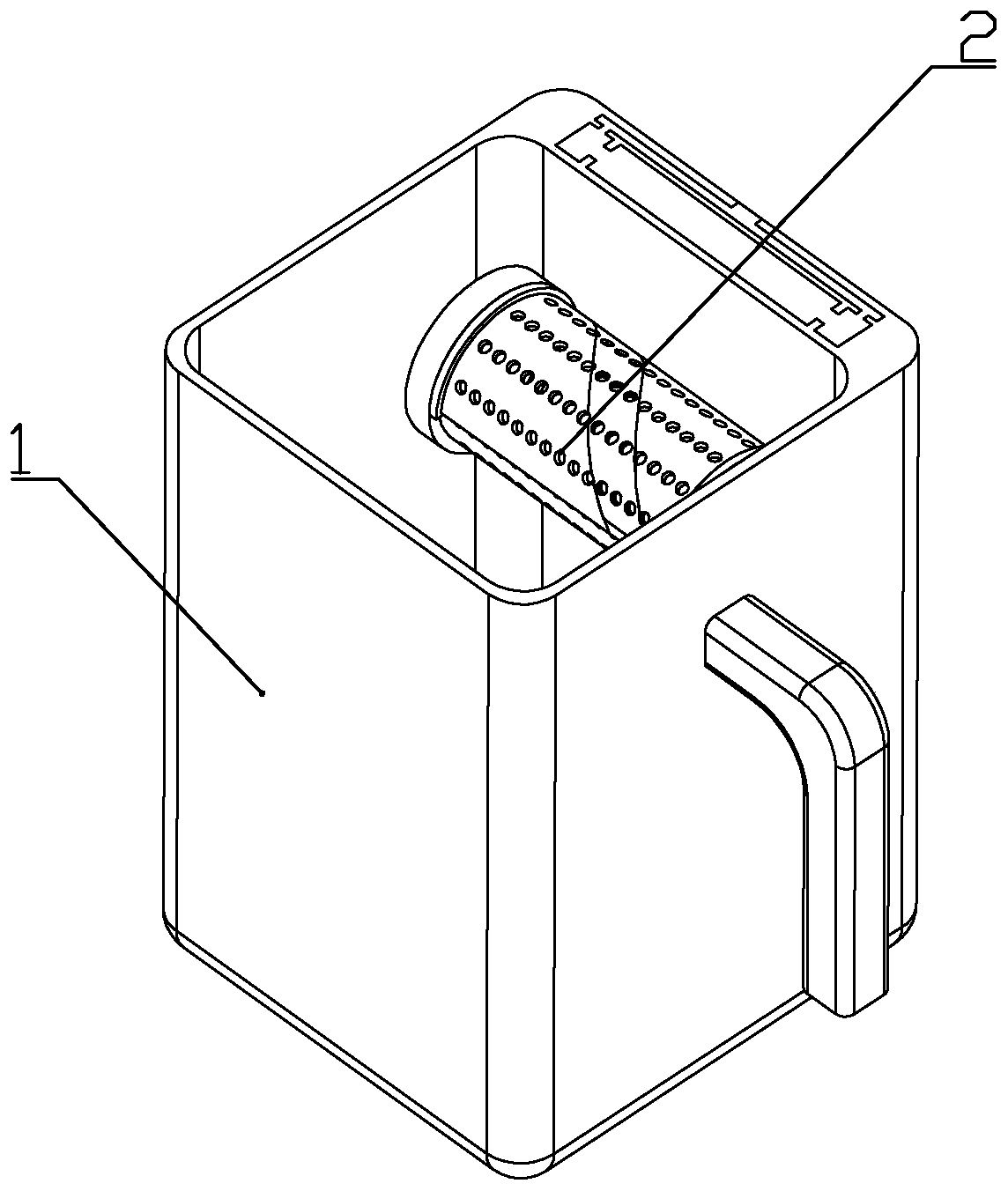

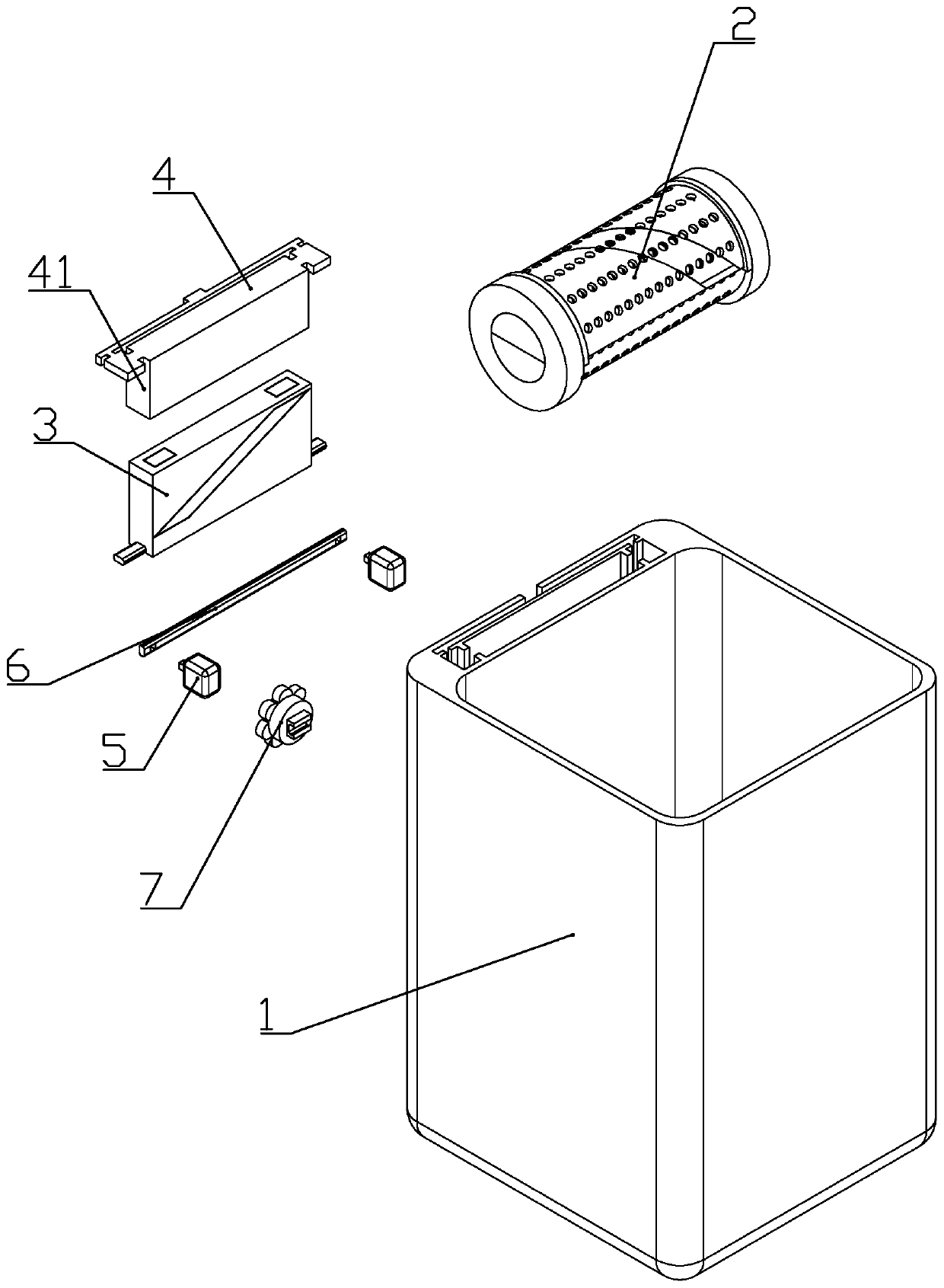

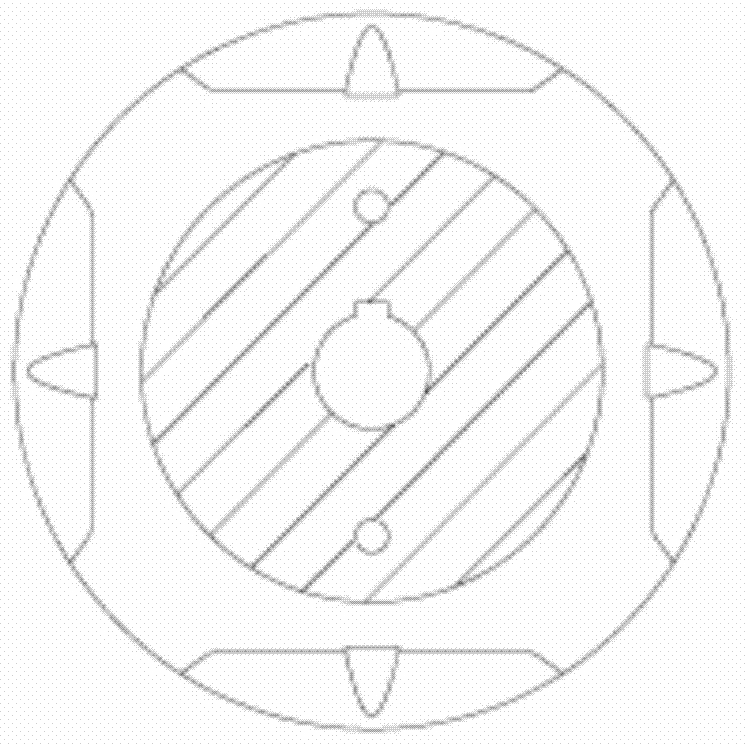

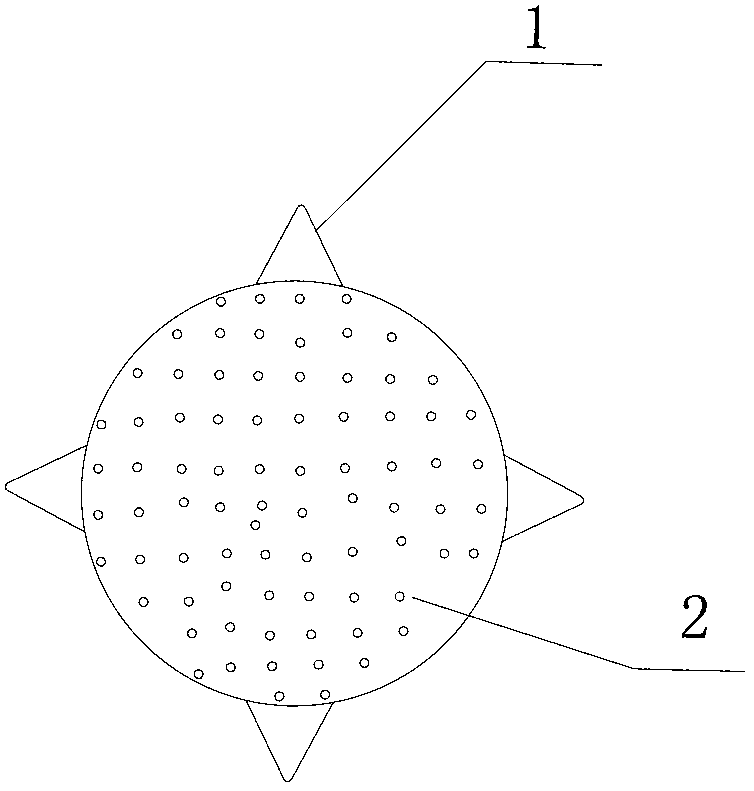

Wheat steeping device with classifying function

InactiveCN107711484AHierarchical implementationControl soaking timeSievingScreeningSteepingEngineering

The invention discloses a wheat steeping device with a classifying function, comprising a classifying screen and a wheat steeping slot, wherein the classifying screen is arranged at the top of the wheat steeping slot and is obliquely arranged, the wheat steeping slot is divided into two wheat steeping chambers; the lower part of the cylinder of the wheat steeping slot is a circular truncated conebottom, the circular truncated cone bottom is in a funnel shape and the bottom is in a circular arc shape, ventilation pipes are arranged in the two wheat steeping chamber, each ventilation pipe is formed by two straight pipes and a flat S-shaped pipe, the two ends of the flat S-shaped pipe are connected with the straight pipes, the two straight pipes respectively penetrate through the top and thebottom of the wheat steeping slot, the flat S-shaped pipe is positioned in the middle of the circular truncated cone bottom, and the bottom of the wheat steeping slot is fixedly connected with a discharge pipe, an exhaust pipe and a drain pipe. The wheat steeping device with a classifying function, disclosed by the invention, can steep wheat of different sizes separately, so that the two kinds ofwheat both achieve a good steeping quality, and further the overall growth quality of the wheat can be improved; and meanwhile, uniform ventilation of the wheat steeping slot is realized, and waste gas such as CO2 can be exhausted timely.

Owner:黄林海

Magnetic rolling type tea cup

InactiveCN111184407AControl soaking timeWon't scatterDomestic vesselsDrinking vesselsPhysicsEngineering

The invention discloses a magnetic rolling type tea cup. The magnetic rolling type tea cup comprises a cup body and a tea storage part used for containing tea, wherein a driving magnet for driving thetea storage part to longitudinally move through the magnetic force is longitudinally and slidably connected to the side wall of the rear end of the cup body, and the tea storage part comprises a teastorage tank with an upward opening; a rotating cover which is rotatably connected to the outer wall of the tea storage tank and can form a closed tubular shape with the tea storage tank; longitudinalmoving rings which are rotatably connected to the left side and the right side of the tea storage tank and attract the driving magnets. The outer wall of the rotating cover is fixedly connected witha spiral driving part, an opening and closing part capable of driving the rotating cover to rotate is mounted on the side wall of the rear end of the cup body, and the side wall, opposite to the tea storage part, of the opening and closing part is fixedly connected with an opening and closing magnet which is obliquely arranged and attracts the spiral driving part. When the tea storage part moves upwards relative to the opening and closing part, the opening and closing magnet and the spiral driving part attract each other, the rotating cover rotates forwards, and the tea storage part is opened.

Owner:张云龙

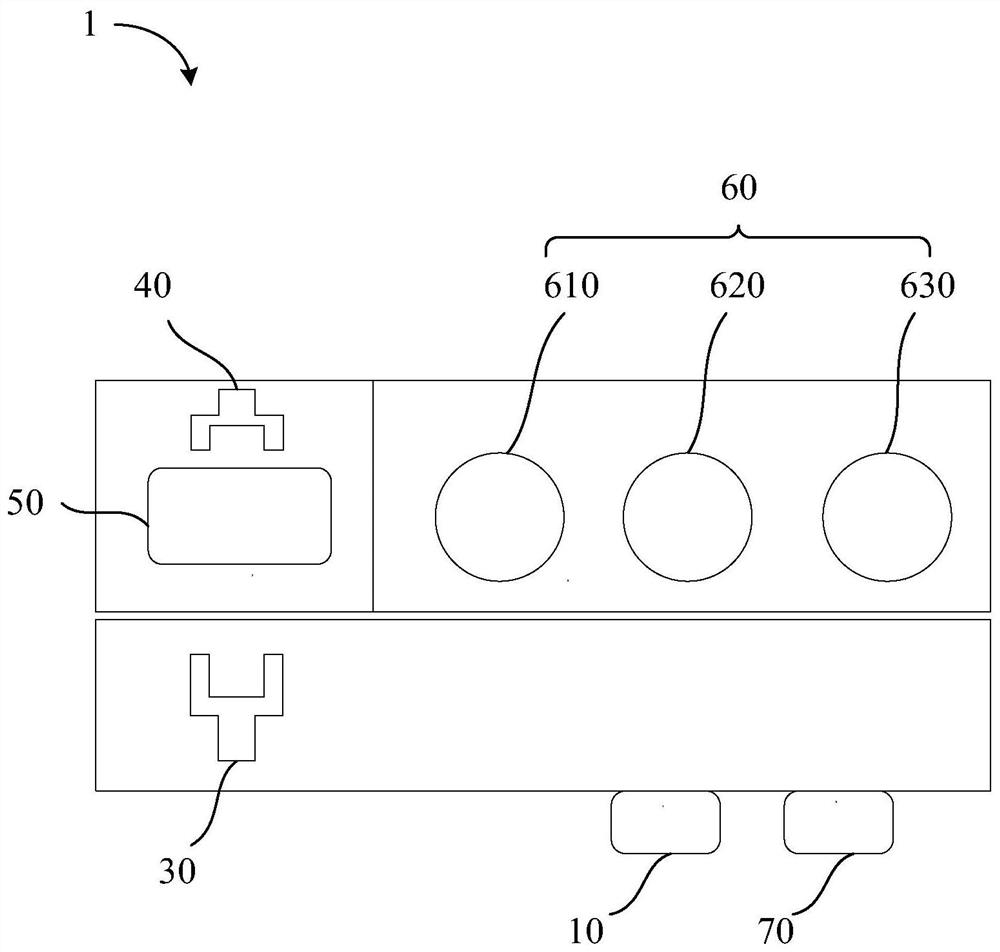

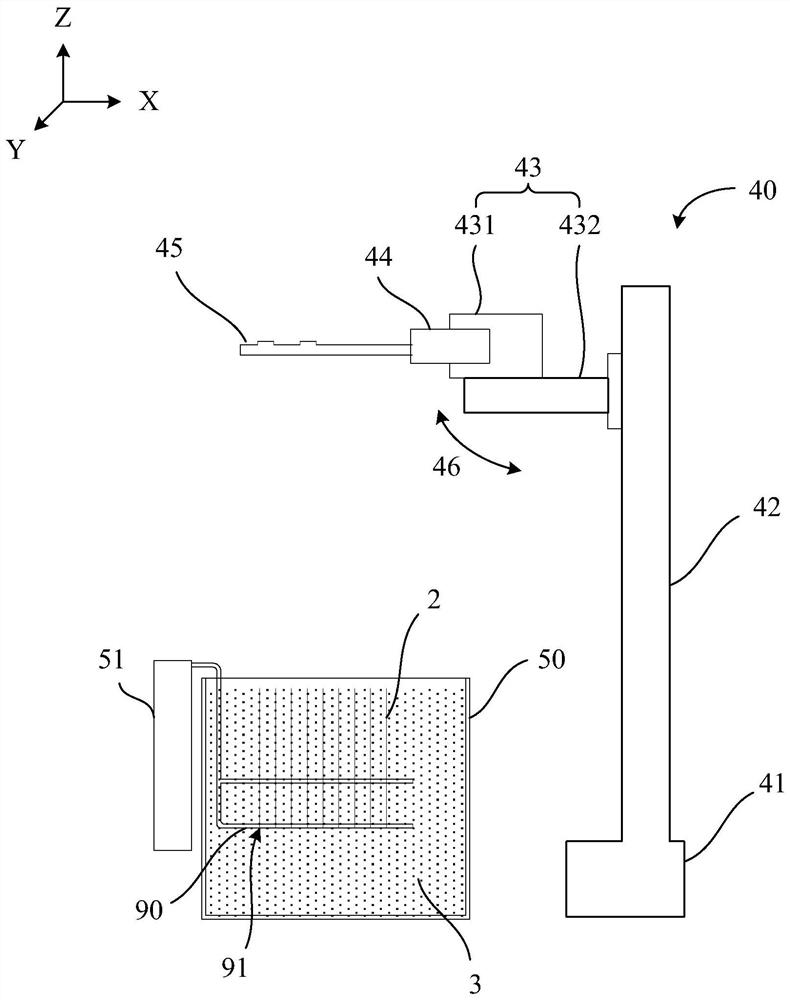

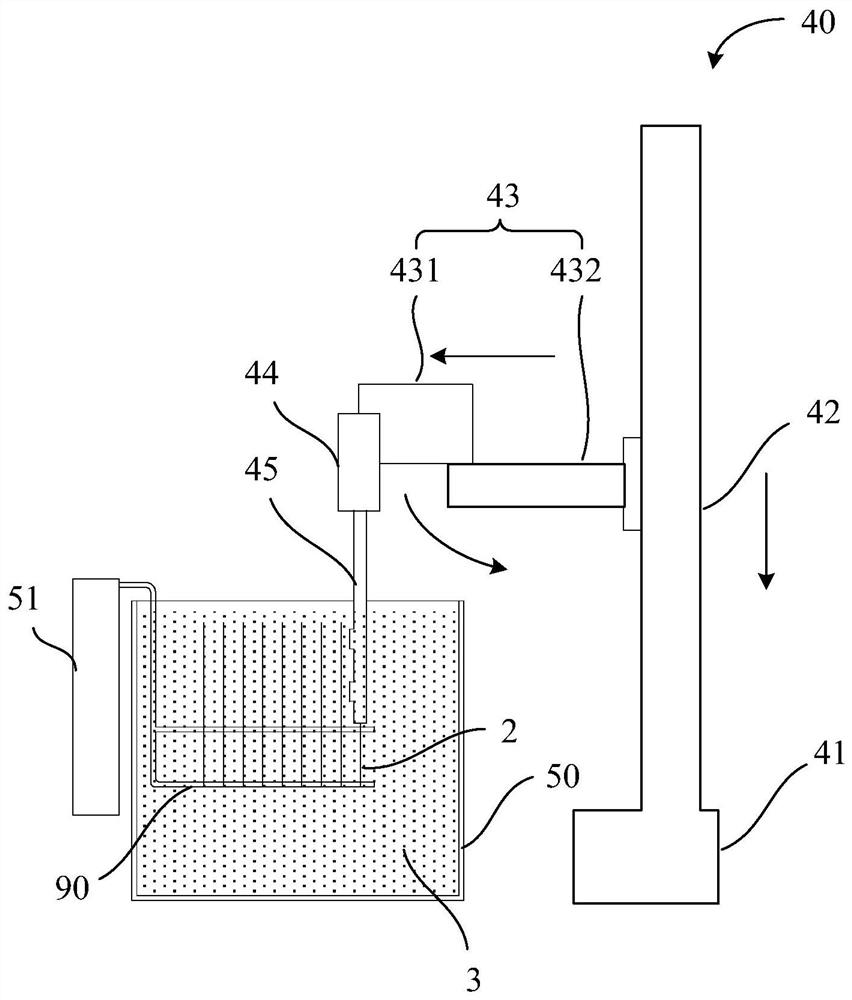

Wafer wet processing workstation

PendingCN112786481AControl soaking timeSemiconductor/solid-state device manufacturingHigh densityWafer

The utility model provides a wafer wet processing work station. The wafer wet processing work station comprises a soaking tank, a mechanical arm and single wafer processing equipment, and the wafer is immersed in the immersion tank filled with the process liquid in advance in a manner that the plate surface of the wafer is vertical to the horizontal plane. The mechanical arm comprises a holding part and an overturning part. The wafer is held on the holding part. The overturning part controls the holding part to turn over relative to the horizontal plane. The holding part is overturned by 90 degrees through the overturning part, so that the wafer is conveyed in a manner that the plate surface of the wafer is parallel to the horizontal plane. A single wafer processing apparatus applies a cleaning liquid to the plate surface of the wafer soaked in the process liquid. The wafer wet processing work station can perform a series of cleaning processes such as soaking and spray washing on the wafer so as to realize cleaning of the wafer with chip miniaturization and high-density wire layout.

Owner:GRAND PLASTIC TECH

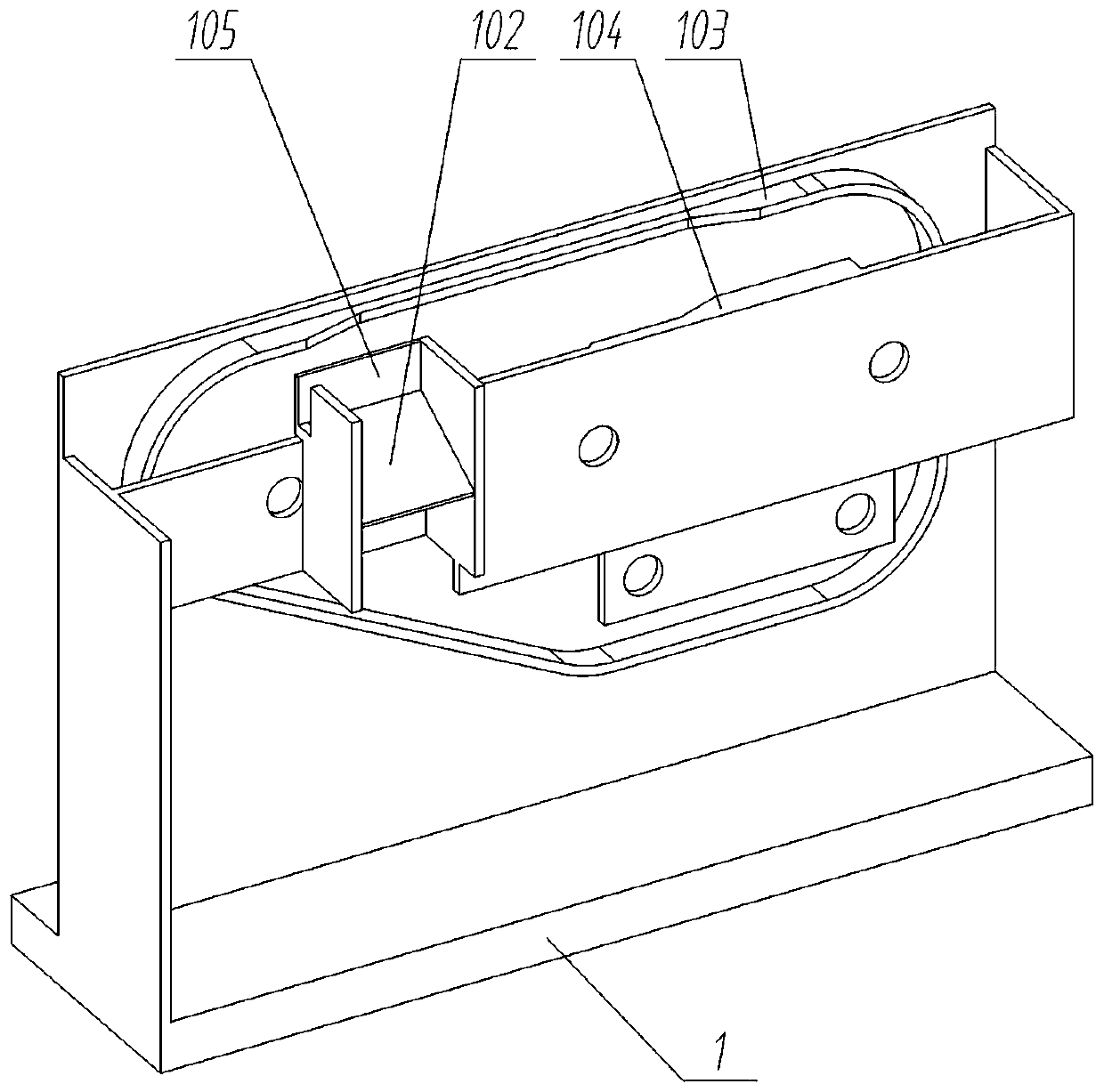

Method for manufacturing recycled aggregate of building material by recycling building solid waste

ActiveCN112110667AControl soaking timeControl timeSolid waste managementArchitectural engineeringProcess engineering

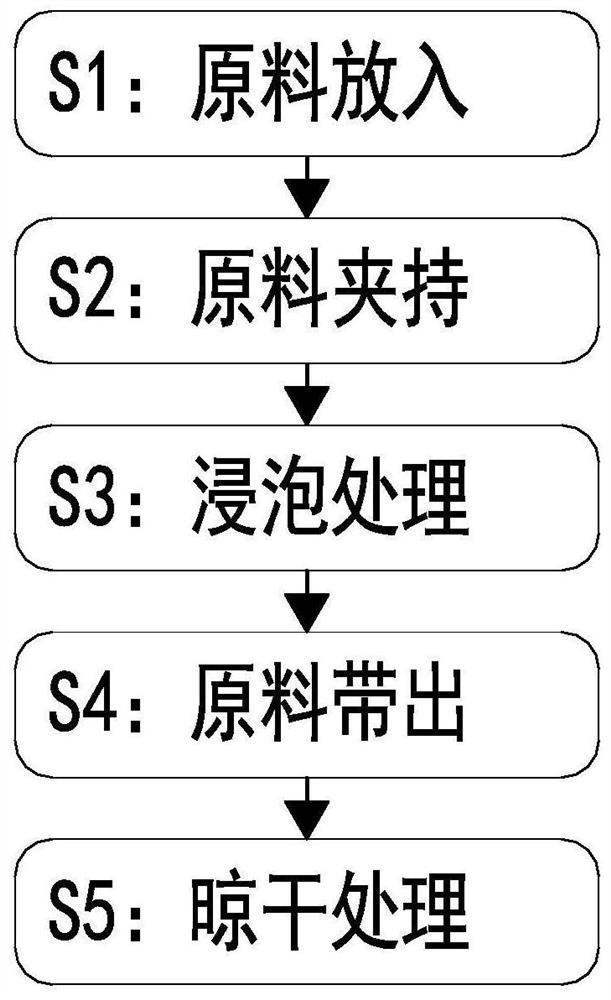

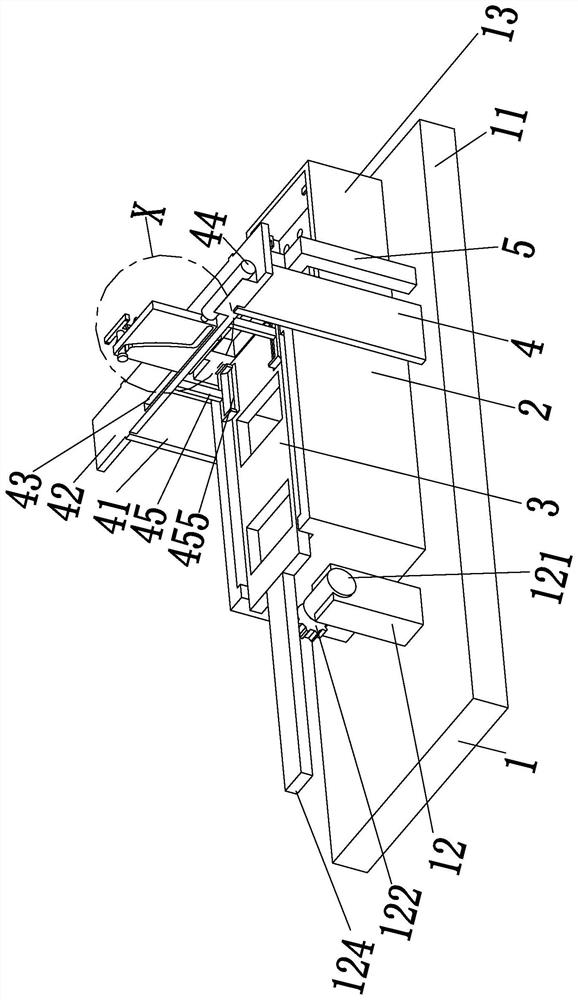

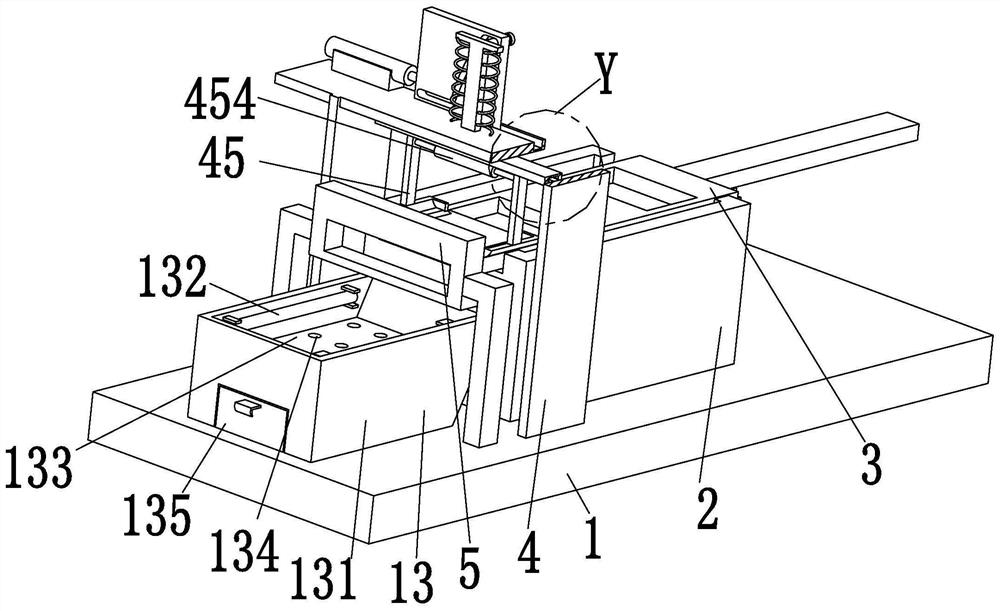

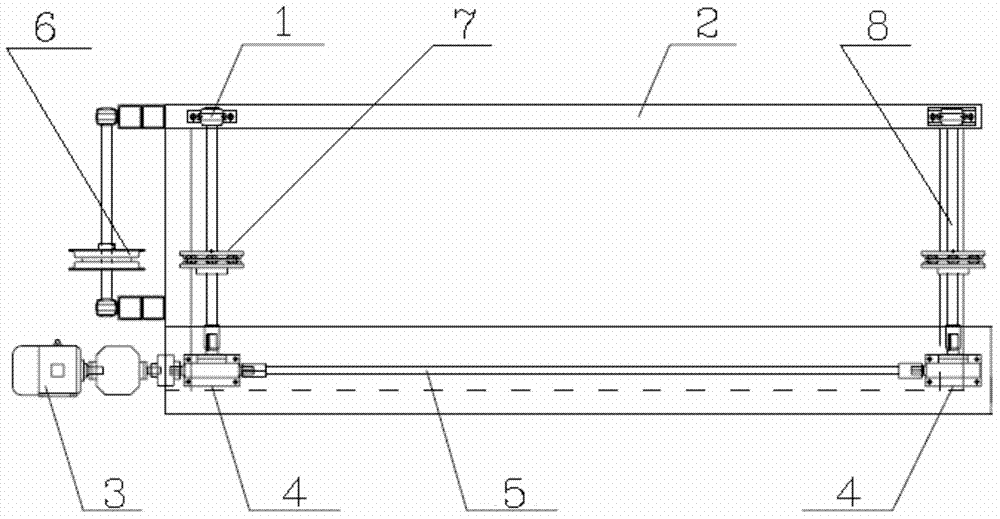

The invention relates to a method for manufacturing recycled aggregate of a building material by recycling building solid waste. The method mainly comprises the following steps of: putting of raw materials, clamping of the raw materials, soaking, taking-out of the raw materials, airing and the like. Treatment equipment used in manufacturing of the recycled aggregate of the building material by recycling building solid waste comprises a fixed base, a liquid collecting box, a sliding plate, a clamping and soaking device and a discharging plate, wherein the liquid collecting box is installed at the middle part of the upper end of the fixed base, the sliding plate is arranged at the upper end of the liquid collecting box in a sliding mode, a clamping and soaking device is arranged above the right side of the liquid collecting box, and a discharging plate is arranged on the right side of the liquid collecting box and installed at the upper end of the fixed base. The method of the inventionovercomes the problems that since raw materials generally need to be grabbed and soaked through a manually controlled machine in traditional manufacturing methods for recycled aggregate of building materials, controlled action is complex, deviation possibly occurs due to manual control, and consequently the raw materials leak out of a grabbing mechanism.

Owner:上海国烨建筑工程有限公司

Method for extracting curcumin from ginger

The invention relates to a method for extracting curcumin from ginger. The method is characterized by comprising the following steps: (1) inspection and acceptance of raw materials; (2) drying and pulverizing; (3) alkaline water extraction; (4) filtering adsorption; (5) washing desorption; (6) vacuum concentration; and (7) drying of a finished product. A solvent-extraction method is adopted, so that the soaking time and curcumin impurities are effectively controlled; the extraction rate is high, and the obtained curcumin is high in purity and has a bright color.

Owner:QINGDAO PENGYUAN KANGHUA NATURAL PROD

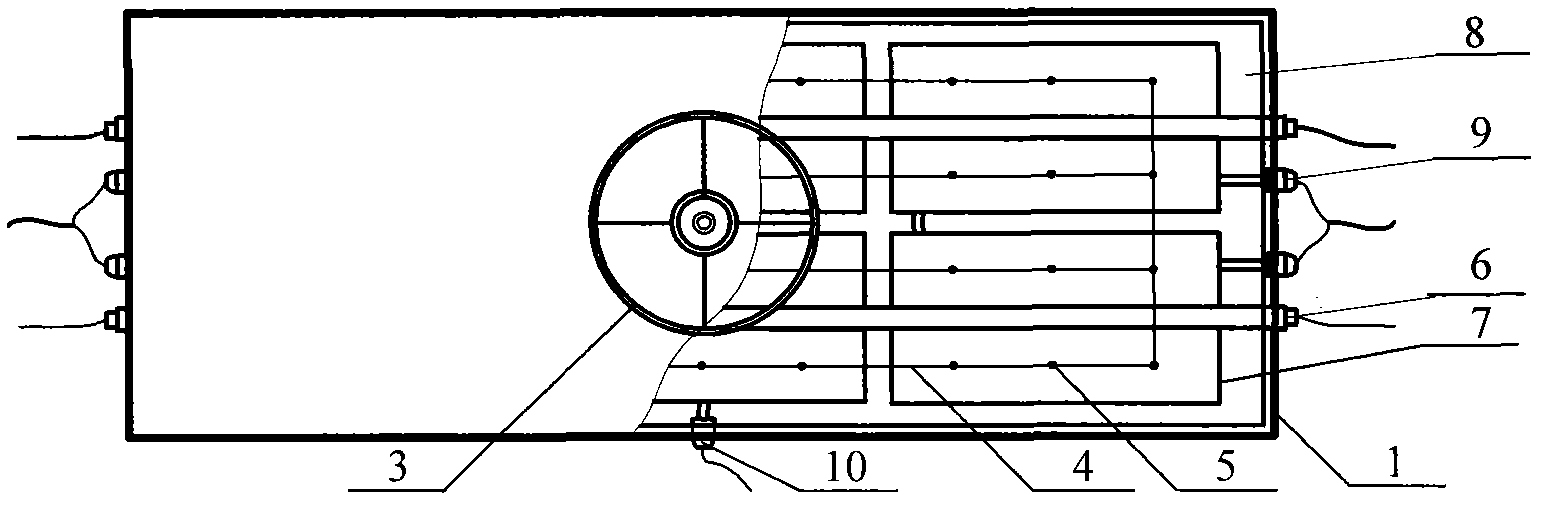

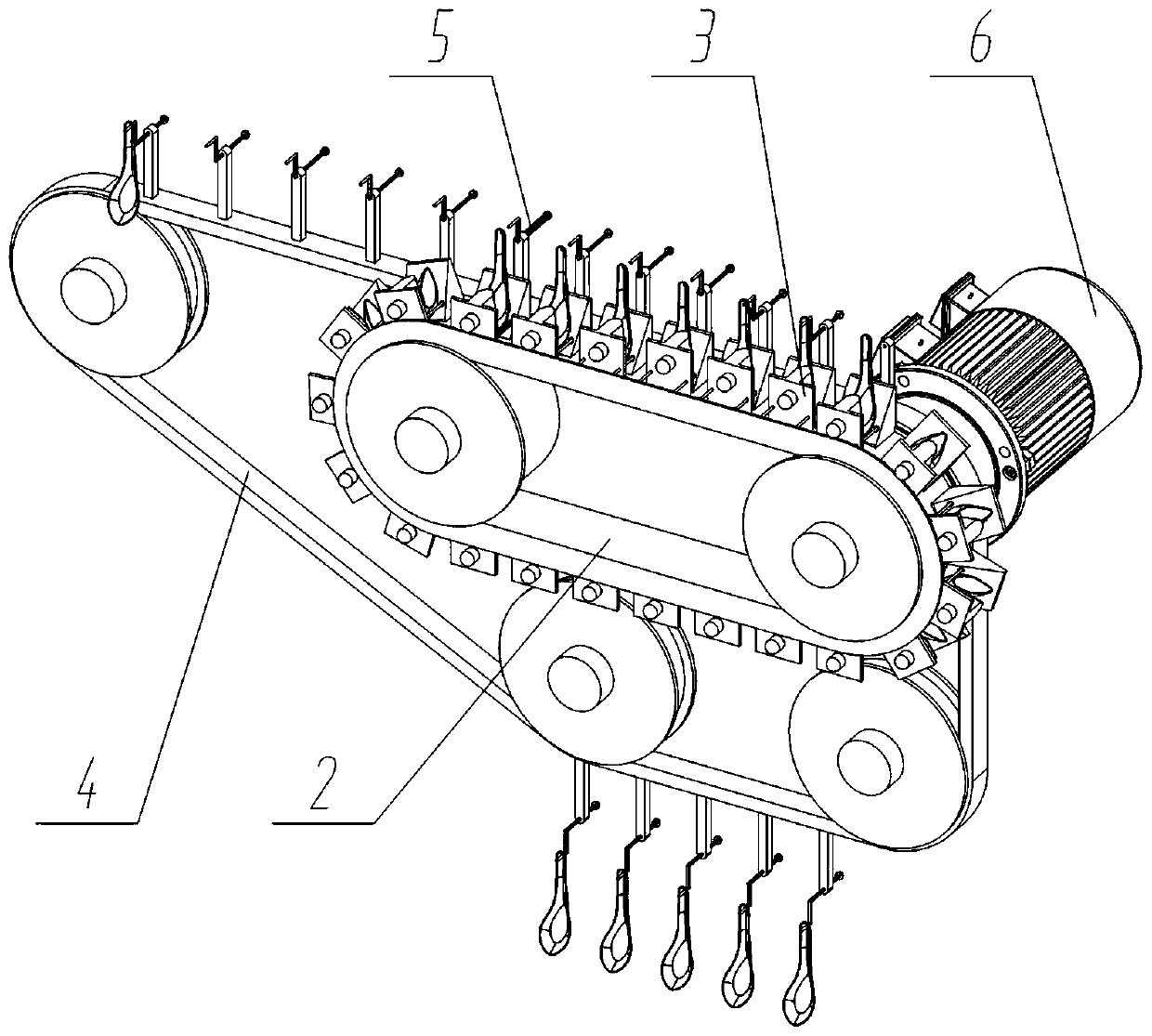

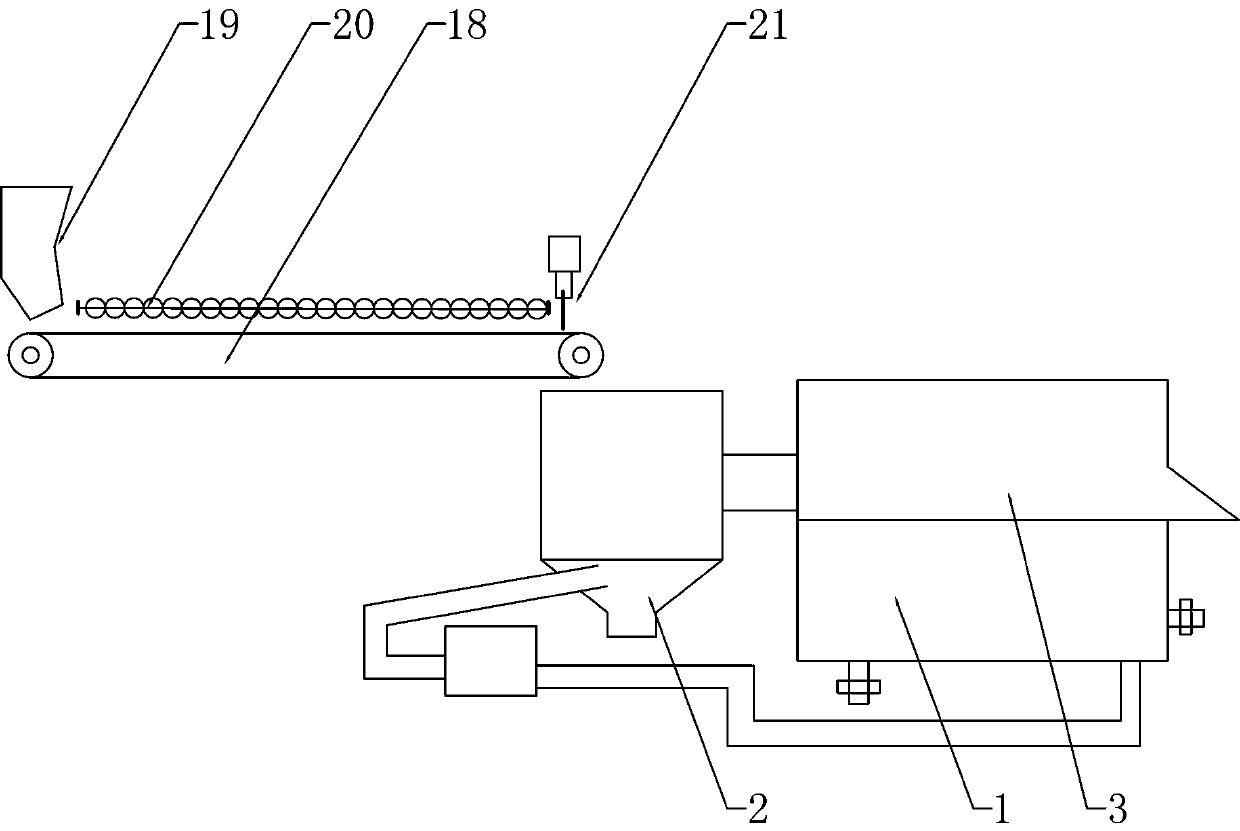

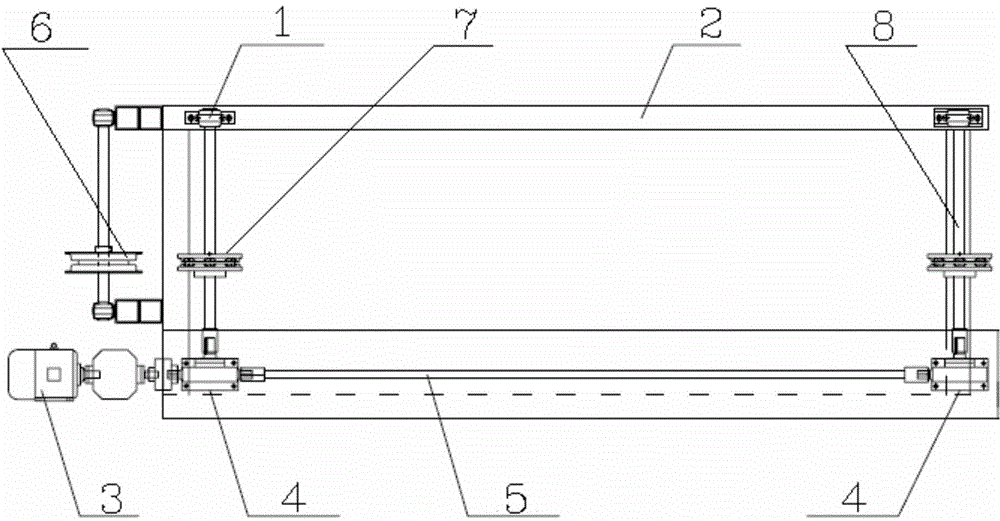

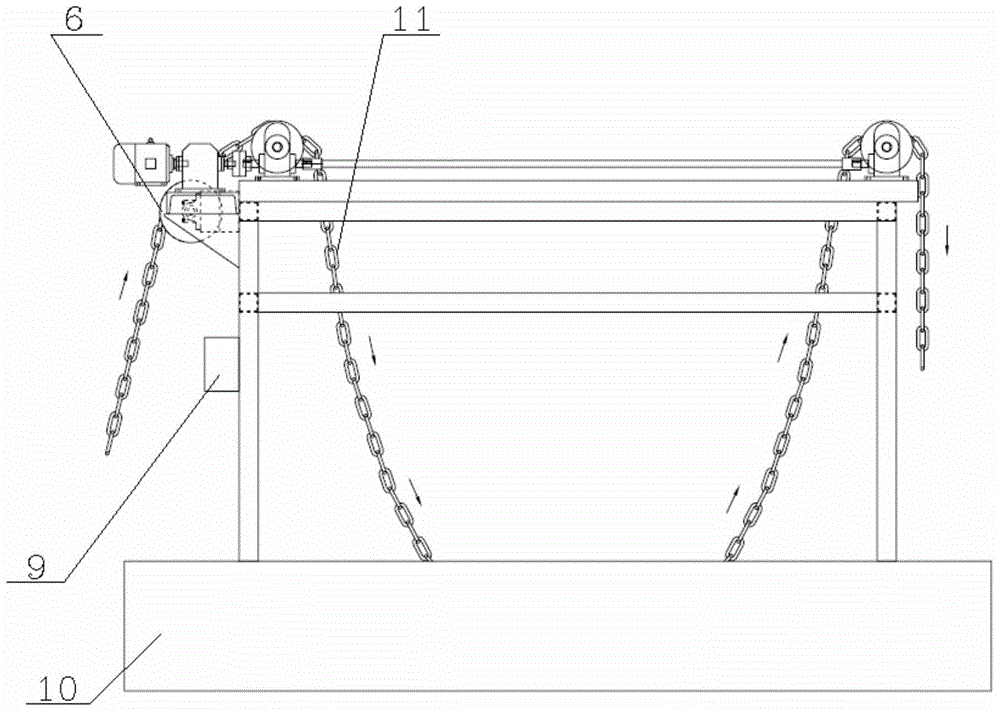

Fully-automatic galvanizing equipment for chain

InactiveCN103498123AReduce labor intensityReal-time control of process parametersHot-dipping/immersion processesDrive shaftEngineering

The invention relates to fully-automatic galvanizing equipment for a chain. The fully-automatic galvanizing equipment for the chain comprises bearing pedestals, a machine frame, a motor and a transmission shaft, wherein the machine frame is a cuboid; a zinc pool is arranged on the ground under the machine frame; a speed reducer is mounted at each of the left side and the right side of a front frame on the machine frame; the outer side of one speed reducer is connected with the output end of the motor; the speed reducers are connected through the transmission shaft; one bearing pedestal is mounted at each of the left side and the right side of a rear frame on the machine frame and corresponding to the mounting position of each speed reducer; a bearing is arranged in each bearing pedestal; each bearing pedestal and the corresponding speed reducer are connected through coordination of each bearing and each rotating shaft; a die wheel is mounted on each rotating shaft; a guide wheel is mounted at the outer side of the machine frame near one side of the motor and corresponding to the mounting position of the die wheel; and controllers are mounted at the leg parts of the machine frame. The fully-automatic galvanizing equipment for the chain can control each process parameter of the chain in a galvanizing process in real time, guarantees that strength reduction is in a controllable range, improves the galvanizing efficiency and reduces the labor intensity of workers.

Owner:苏州卓胜工贸有限公司

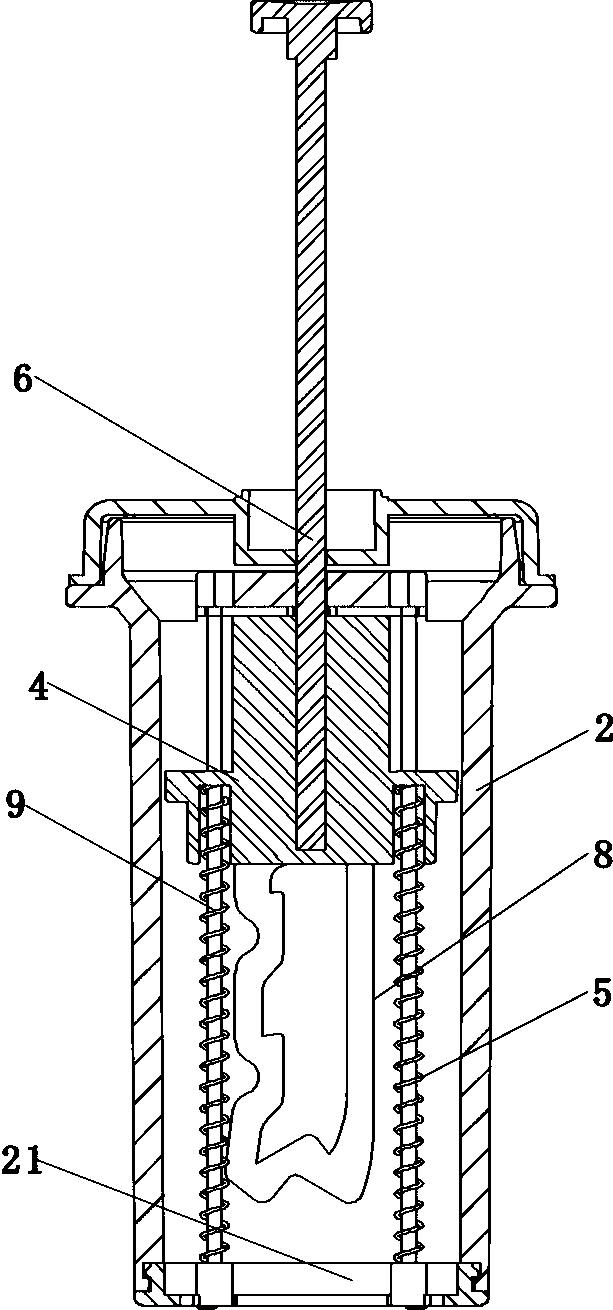

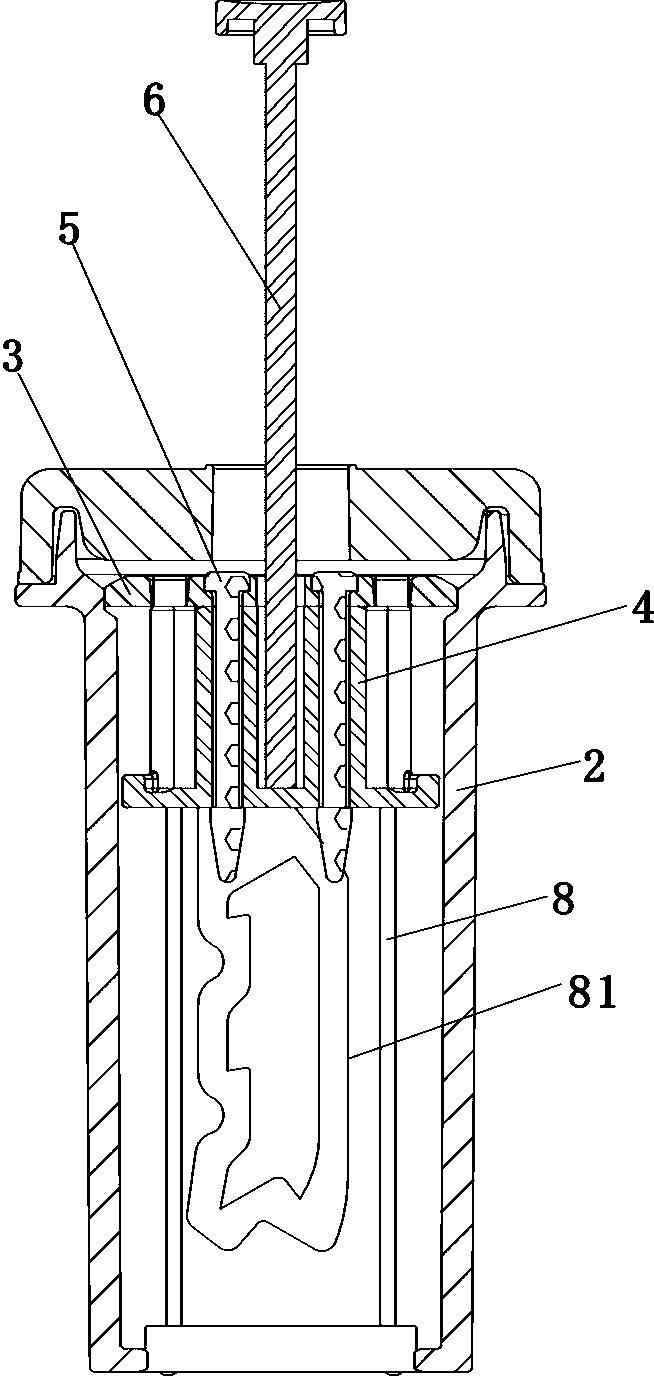

Manual water flow adjustment mechanism

InactiveCN107349100AControl brewing timeControl soaking timePlug valvesOperating means/releasing devices for valvesWater flowEngineering

The invention discloses a manual water flow adjustment mechanism comprising a water adjustment mechanism and water allocation mechanism which is connected with a rear end of the water adjustment mechanism in an inserting and sealing mode; the water adjustment mechanism comprises a sleeve body, an adjusting rod, an upper fluted disc, a lower fluted disc, a spring, a valve, a slide body, a seat body, a support body, a slot, an annular projection, an inclined plane, two planes and an arc groove; the seat body is installed inside a rear channel of the sleeve body; the seat body is provided with the rotatable support body; an upper end of the support body is provided with the slide body in a penetrating mode; a valve is installed at the front end of the slide body; the slot of the slide body is installed inside the support body; the lower fluted disc is installed on an upper end of the sleeve body; a lower end of the adjusting rod successively passes through the lower fluted disc and an upper wall body of the sleeve body and is inserted in the slot from an upper end of the support body. Compared with the prior art, the manual water flow adjustment mechanism has the advantages of convenient use and good reliability, and can not only satisfy people's needs for traditional Chinese medicine health water, but also can control Chinese medicine soaking time.

Owner:HUZHOU TEACHERS COLLEGE

Tea filter

The invention discloses a tea filter. The tea filter comprises an upper filter cover, a lower filter cover and an elastic part, wherein the upper filter cover and the lower filter cover are arranged in an engagement manner by threads; and the elastic part is arranged on the periphery of the lower filter cover and used for fixing the position relative to an inner chamber of a cup. The upper and lower filter covers are combined to achieve a simple structure, convenient to manufacture and low in cost; the elastic part can fix the position of the filter in a tea cup, so that the soaking time can be controlled, and the operation is convenient; tand he tea is separated from the boiled water for the convenience in cleaning and realizing environmental protection and sanitation.

Owner:WUJIANG KEWOKE MACHINERY EQUIP

Convenient tea making cup

The invention relates to a convenient tea making cup. The convenient tea making cup comprises a cup body and a cup cover, wherein a tea leaf chamber and a water saving chamber are transversely arranged in the cup body in parallel, a longitudinal interlayer plate is arranged between the tea leaf chamber and the water saving chamber, the height of the longitudinal interlayer plate is the same with that of the cup body, a filtering part is arranged at the upper part which is close to the cup cover, and the cup cover is tightly covered on the cup body. According to the convenient tea making cup disclosed by the invention, the way of the longitudinal interlayer plate is adopted for forming the water saving chamber and the tea leaf chamber in the cup body, the tea leaf soaking time can be effectively controlled, the taste of tea water can be kept, the cup cover is tightly covered on the cup body, the height of the longitudinal interlayer plate is the same with that of the cup body, and the filtering part is further arranged, so that the convenient tea making cup can prevent the tea water from scattering and leaking during carrying and be convenient to carry.

Owner:TAICANG ZHETAITIAN PROD DESIGN

Dipping technology for electro-ceramic cemented buffering layer coatings

InactiveCN105710012AConsistent heightConsistent thicknessPretreated surfacesCoatingsOrganic productionCeramic

The invention discloses a dipping technology for electro-ceramic cemented buffering layer coatings. According to the dipping technology, the dipping time and the dipping quantity can be effectively controlled, and the uniformity of the dipping height and the thickness of all inserts can be well guaranteed; because the inserts subjected to dipping are independently and separately suspended, bonding possibly caused by stacking between products in the traditional technology can be avoided; the dipping process can be completely automatic, and therefore direct contact between people and organic production raw material can be avoided, and the production danger can be avoided to a certain degree.

Owner:SHANGHAI ELECTRIC PORCELAIN WORKS CO LTD

Domestic soymilk grinder

InactiveCN101862125BTake advantage ofSave operating timeBeverage vesselsMilk substitutesInlet valveMechanical engineering

Owner:林修鹏

Method for treating and fresh-keeping sciaenops ocellatus by using acidic electrolyzed water

ActiveCN102960425BControl pHTotal controlMeat/fish preservation by freezing/coolingMeat/fish preservation using chemicalsFlavorAquatic product

Owner:ZHEJIANG OCEAN UNIV

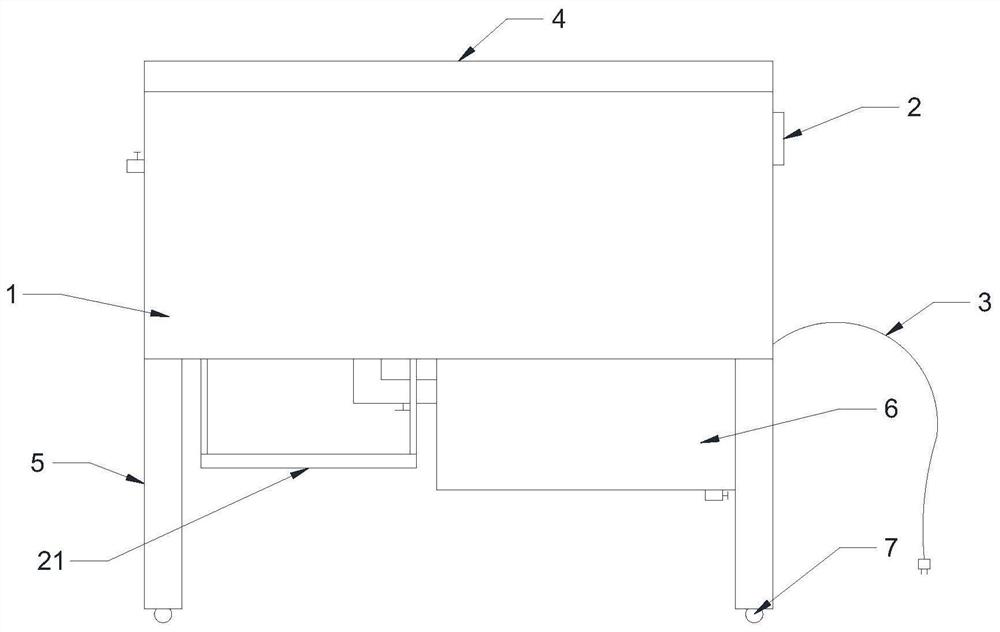

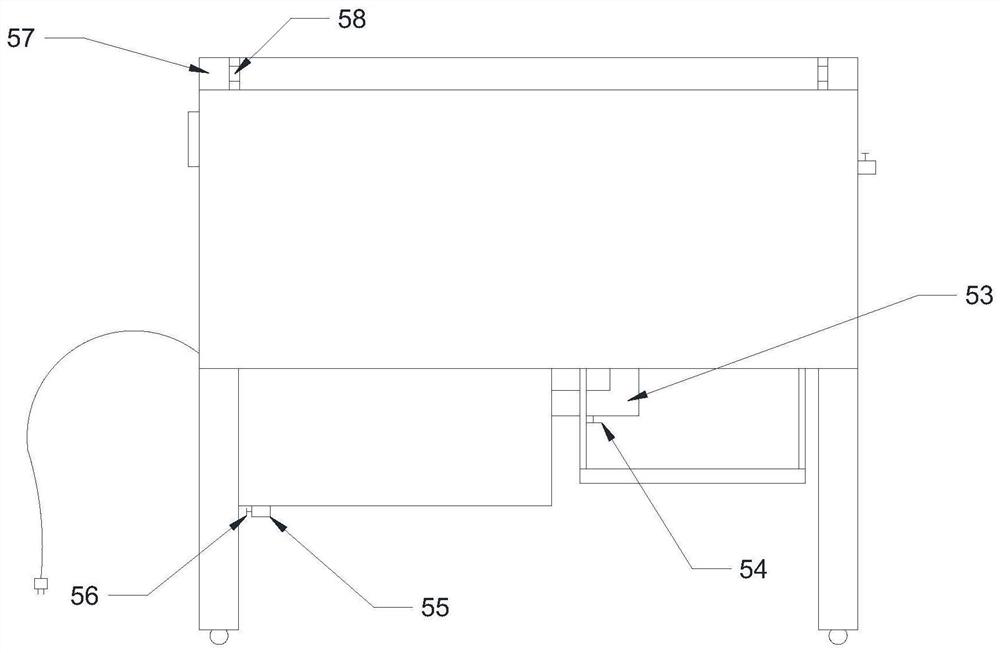

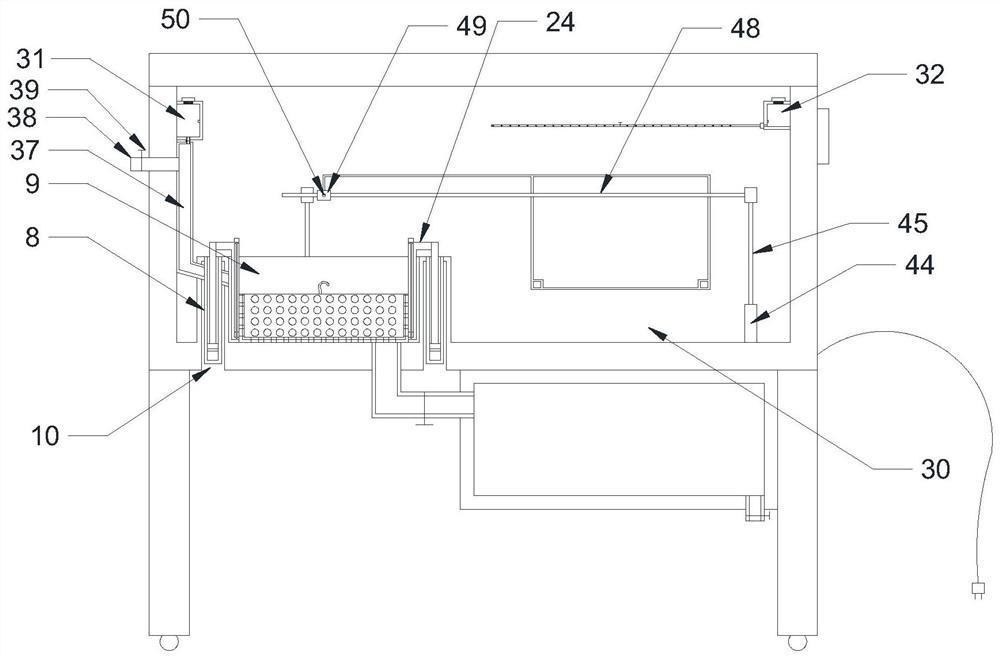

Semi-automatic surgical instrument pretreatment machine

PendingCN112157101AAvoid corrosionReduce usageDiagnosticsSurgeryElectric machineryApparatus instruments

The invention relates to the technical field of medical instruments, and discloses a semi-automatic surgical instrument pretreatment machine. The semi-automatic surgical instrument pretreatment machine comprises a treatment box, a control panel, a power line, a cover, supporting legs, a waste liquid box, wheels, a groove, a gap, a notch, a soaking tanks, voids, communicating pipes, a first pistoncylinder, a second piston cylinder, a third piston cylinder, first pistons, a second piston, first pressing rods, second pressing rods, a transverse rod, third pressing rods, a foot pressing plate, acheck block, connecting rods, fixing rods, a soaking basket, an instrument basket, arc-shaped hooks, leaking holes, a containing area, a cleaning agent containing box, a humectant containing box, telescopic motors, telescopic rods, first rotating motors, supporting blocks, first threaded rods, moving blocks, lifting rods, directional rods, first sliding grooves, a waste liquid pipe, a second electromagnetic valve, a liquid discharging pipe and a third electromagnetic valve. The soaking time can be effectively and accurately controlled, surgical instruments can be prevented from being corrodeddue to long-time soaking of the surgical instruments, meanwhile, use of a humectant can be reduced, the cost is effectively reduced, and the time and the cost are saved.

Owner:WEST CHINA HOSPITAL SICHUAN UNIV

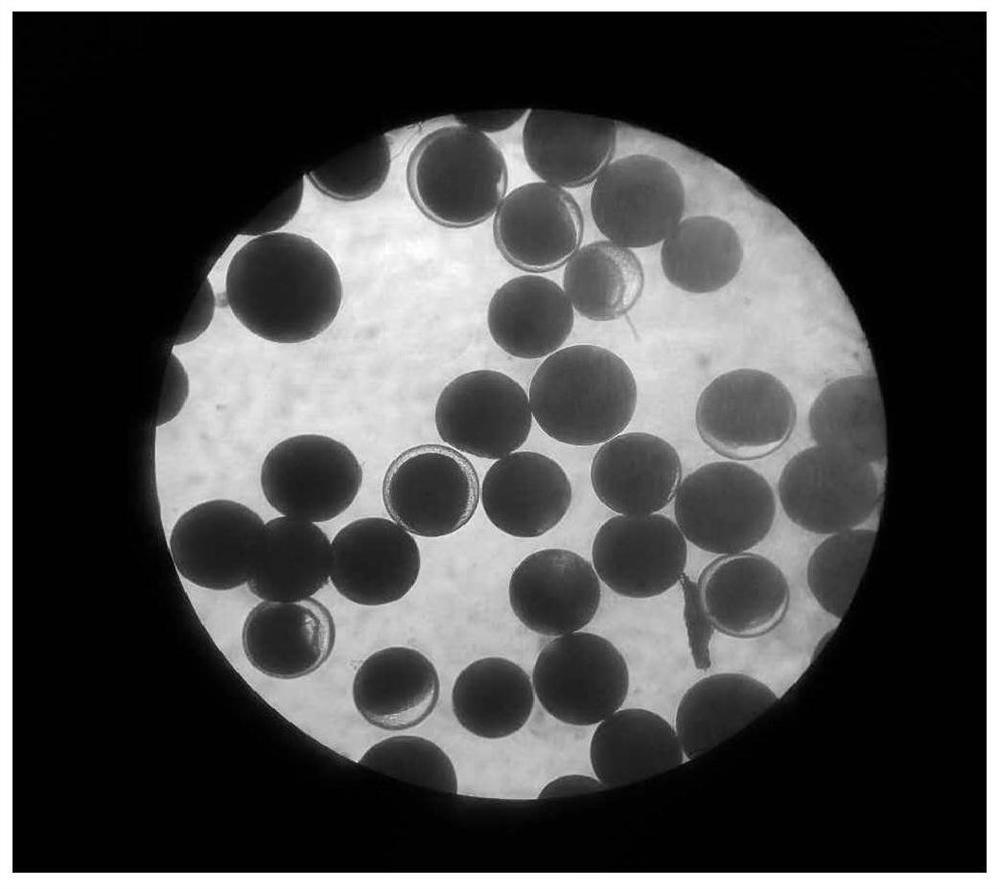

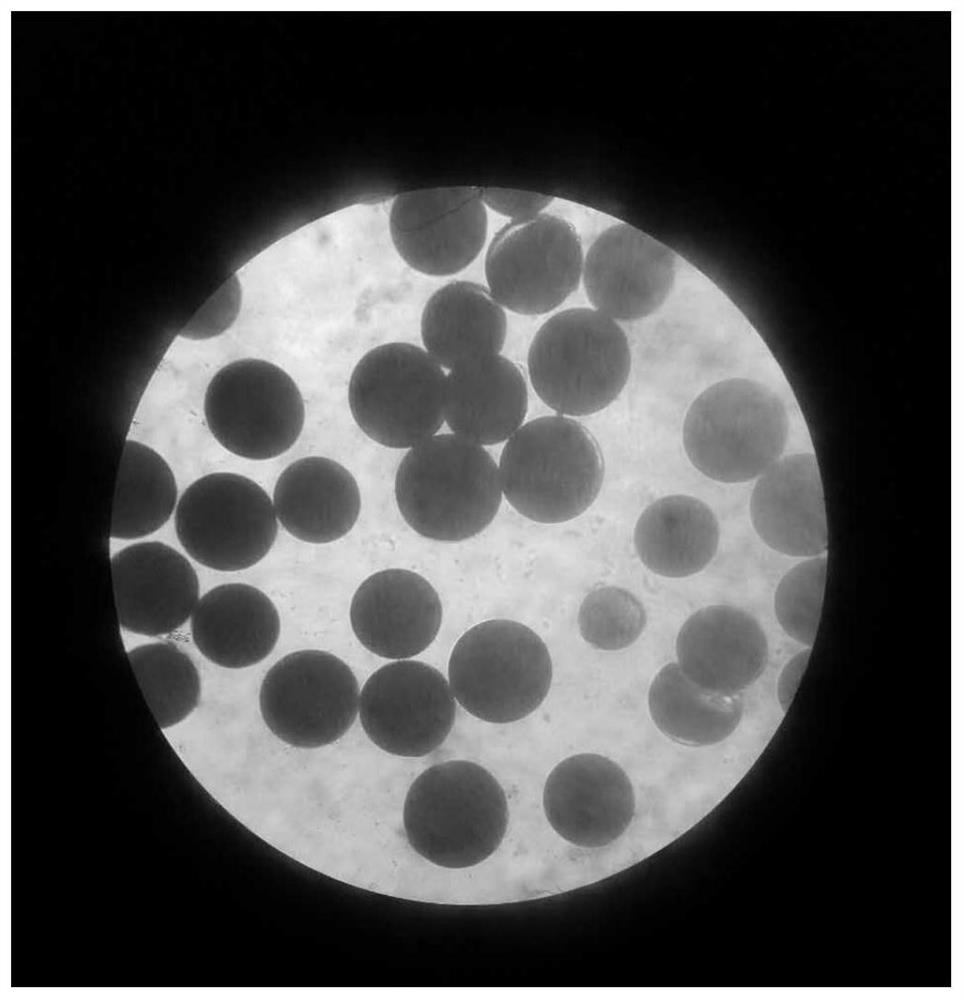

A method for highly efficient shelling of Artemia eggs

ActiveCN110089466BMaintain integrityKeep aliveClimate change adaptationPisciculture and aquariaAnimal scienceSodium hypochlorite solution

The invention discloses a method for efficiently removing shells of Artemia eggs. The commercial Artemia eggs are soaked in fresh water, then soaked in sea water and fully aerated; then the eggs are sterilized, soaked in sodium hypochlorite solution and fully aerated. When the eggs turn orange, separate the egg shells, wash the eggs to remove residual chlorine, and then soak them in an ethanol solution containing shikonin for 40‑60 minutes. After soaking, rinse with sea water to remove the residual ethanol from Artemia eggs That’s it; the present invention can further dissolve the keratin of the egg membrane after shelling the Artemia eggs, and can maintain the activity of the embryos, so that the embryos of the Artemia eggs can be fully exposed, and the early embryonic development of the Artemia eggs can be directly observed under the microscope , which has important guiding significance for the family selection of Artemia in the embryonic stage, and also for the efficient and stable hatching of Artemia eggs without pathogens, thereby providing sufficient and high-quality bait for fish and shrimp breeding and breeding, which has a good impetus to the aquatic breeding industry function and application value.

Owner:GUANGXI ACADEMY OF FISHERY SCI

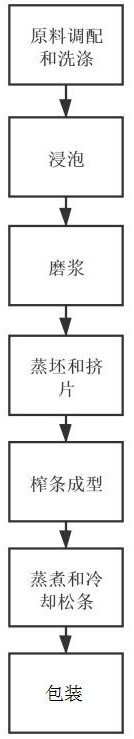

Fresh-locked rice noodle raw material treatment process

The invention discloses a fresh-locking rice noodle raw material treatment process. The process comprises the steps of raw material blending, washing, soaking, pulping, blank steaming, sheet extruding, strip pressing and forming, cooking, cooling and strip loosening and the like, and early indica rice and late indica rice are mixed, are put into water to be washed and soaked, and then are subjected to pulping to obtain rice slurry; then steaming and extruding are performed to obtain rice noodle blank sheets; the rice noodle blank sheets are pressed into strips and forming to obtain rice noodles; and finally, the rice noodles are cooked and put into cold water to cool and loosen the noodles. The early indica rice and the late indica rice are mixed according to a certain proportion, so that the prepared fresh-locking rice noodles are good in toughness; meanwhile, the early indica rice and the late indica rice are fully soaked before grinding, so that starch tissues are fully mixed; the rice slurry is dehydrated before being steamed, so that the steamed blanks are easier to form, and the production efficiency is improved; and finally, the rice noodles are cooled and loosened with cold water after being cooked and formed, so that the rice noodles are more sufficient in toughness and convenient to transport.

Owner:广西觉味之城食品科技有限公司

A chain automatic galvanizing equipment

InactiveCN103498123BReduce labor intensityReal-time control of process parametersHot-dipping/immersion processesDrive shaftEngineering

The invention relates to fully-automatic galvanizing equipment for a chain. The fully-automatic galvanizing equipment for the chain comprises bearing pedestals, a machine frame, a motor and a transmission shaft, wherein the machine frame is a cuboid; a zinc pool is arranged on the ground under the machine frame; a speed reducer is mounted at each of the left side and the right side of a front frame on the machine frame; the outer side of one speed reducer is connected with the output end of the motor; the speed reducers are connected through the transmission shaft; one bearing pedestal is mounted at each of the left side and the right side of a rear frame on the machine frame and corresponding to the mounting position of each speed reducer; a bearing is arranged in each bearing pedestal; each bearing pedestal and the corresponding speed reducer are connected through coordination of each bearing and each rotating shaft; a die wheel is mounted on each rotating shaft; a guide wheel is mounted at the outer side of the machine frame near one side of the motor and corresponding to the mounting position of the die wheel; and controllers are mounted at the leg parts of the machine frame. The fully-automatic galvanizing equipment for the chain can control each process parameter of the chain in a galvanizing process in real time, guarantees that strength reduction is in a controllable range, improves the galvanizing efficiency and reduces the labor intensity of workers.

Owner:苏州卓胜工贸有限公司

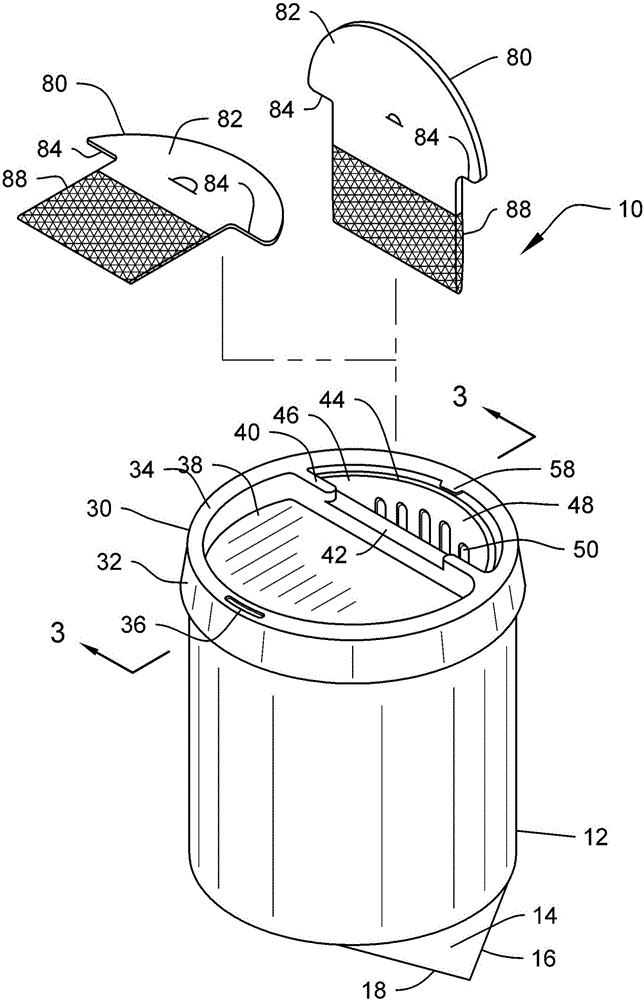

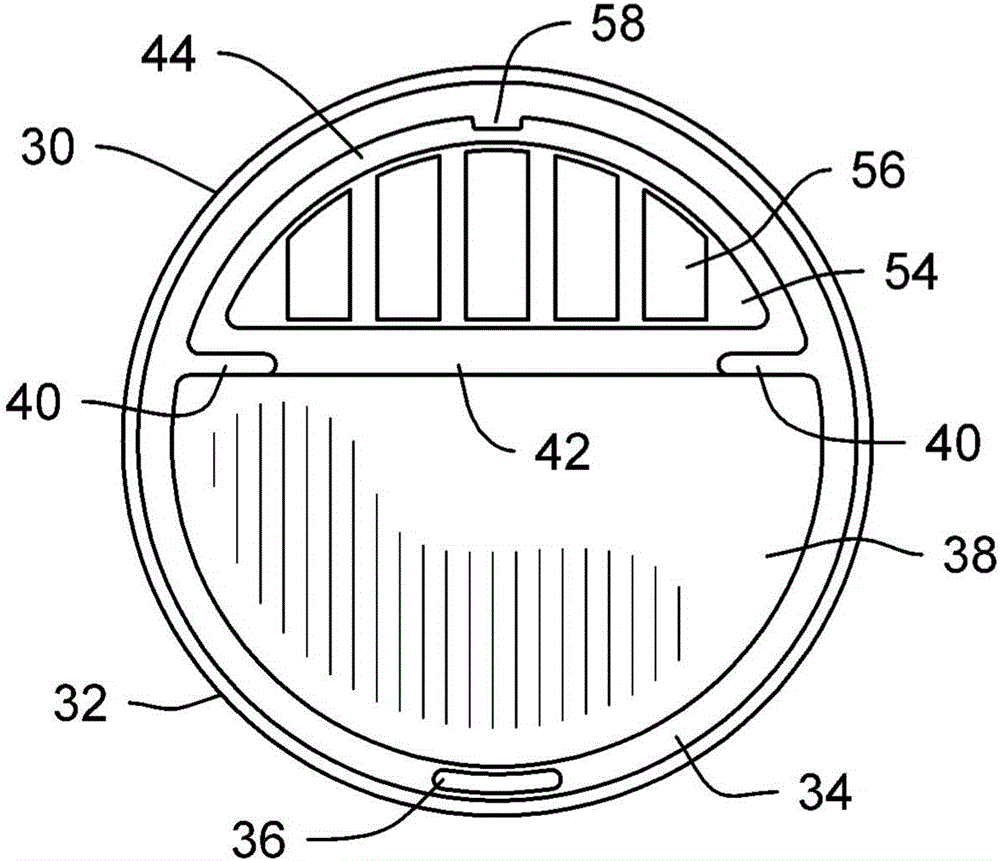

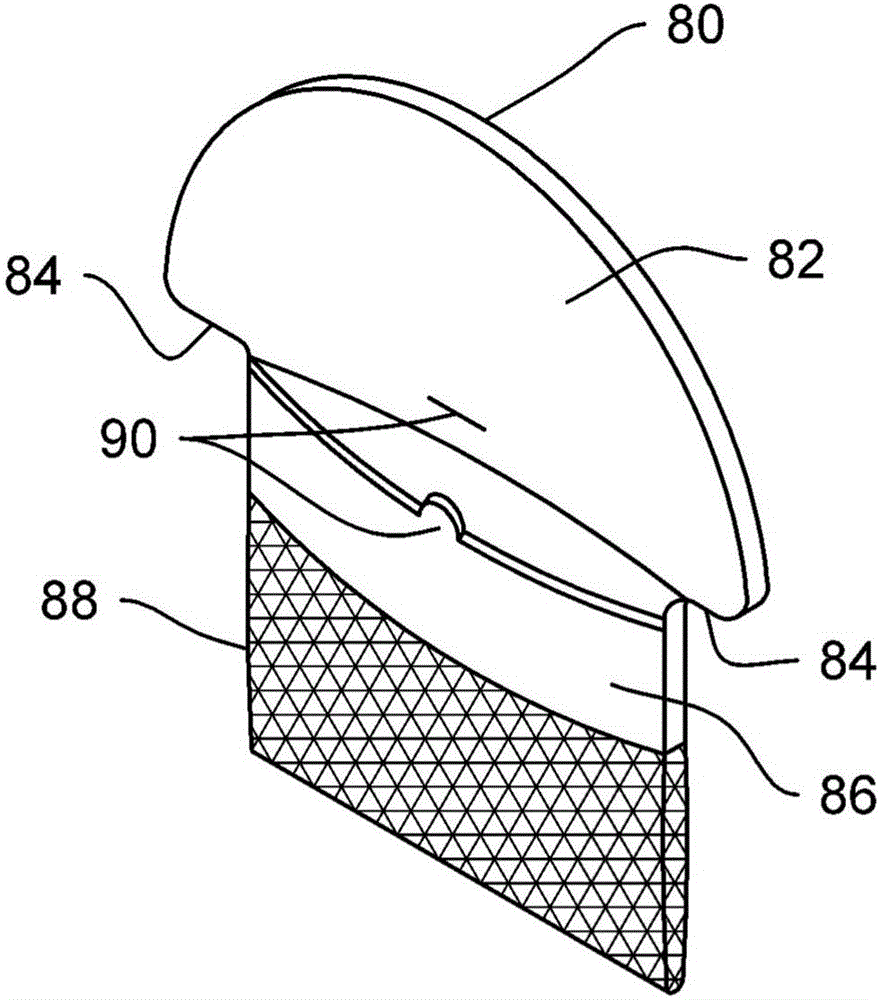

Disposable brewing container and lid

InactiveCN106659318AOvercome defectsEfficient manufacturingClosure with auxillary devicesBeverage vesselsStanding PositionsMechanical engineering

The brewing container and lid of the present invention is sued for drinking and controllably brewing a beverage. The brewing container and lid includes a container, a lid attachable to the container, and a brewing bag. The container has V-like shaped base, and an upper edge defining an opened end. The lid has an upper side, an opening defined through the upper side for drinking the beverage, and a cup extending away from the upper side. The cup is configured to receive the brewing bag allowing a liquid in the container too steep with a brewing material in the brewing bag. The V-like shaped base enables the container and the lid attached thereto to be placed in at least two separate standing positions being a brewing position when the container is standing on one of first and second angled sides, and a non-brewing position.

Owner:梅丽莎安妮特布格达诺斯

a teapot

Owner:张晓燕

Semen trichosanthis and processing method thereof

ActiveCN111543612AAccelerated destructionPromote swellingFood ingredientsFood ultrasonic treatmentCitric acidNutritional composition

The invention relates to semen trichosanthis and a processing method thereof, and belongs to the technical field of food processing. The processing method of the semen trichosanthis comprises the following steps: soaking semen trichosanthis in citric acid, carrying out ultrasonic treatment on the semen trichosanthis citric acid solution, standing the treated semen trichosanthis citric acid solution, draining, grinding skin of semen trichosanthis, boiling the semen trichosanthis subjected to skin grinding, and drying the boiled semen trichosanthis. Semen trichosanthis seeds in the prior art arethick and hard in peel, not easy to knock and difficult to be tasty. In order to solve the technical problems that in the prior art, the nutritional ingredients of the semen trichosanthis are easilydamaged by using an alkali aid, or an enzymolysis method has relatively high requirements on process conditions and is unstable in treatment effect, citric acid soaking is combined with ultrasonic treatment for skin grinding and then boiling is performed, so that the flavor goes deep into the semen trichosanthis kernels, and the prepared semen trichosanthis is easy to knock and deep in taste.

Owner:CHACHA FOOD CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com