A method for highly efficient shelling of Artemia eggs

A technology of worm eggs and harvest year, which is applied in the field of high-efficiency shelling treatment of artemia worm eggs, can solve the problems of increased production cost, low hatching rate, roughness, etc., and achieves the effects of simple operation, high nutrition, and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The shelling treatment method of Artemia ovum of the present invention comprises the following steps:

[0027] (1) Soak the commercial Artemia eggs in clean fresh water for 10 minutes, fully disperse the Artemia eggs, then soak in seawater with a salinity of 28% for 80 minutes, and fully aerate, so that the Artemia eggs can fully absorb water and swell, and separate seawater and Artemia eggs ;

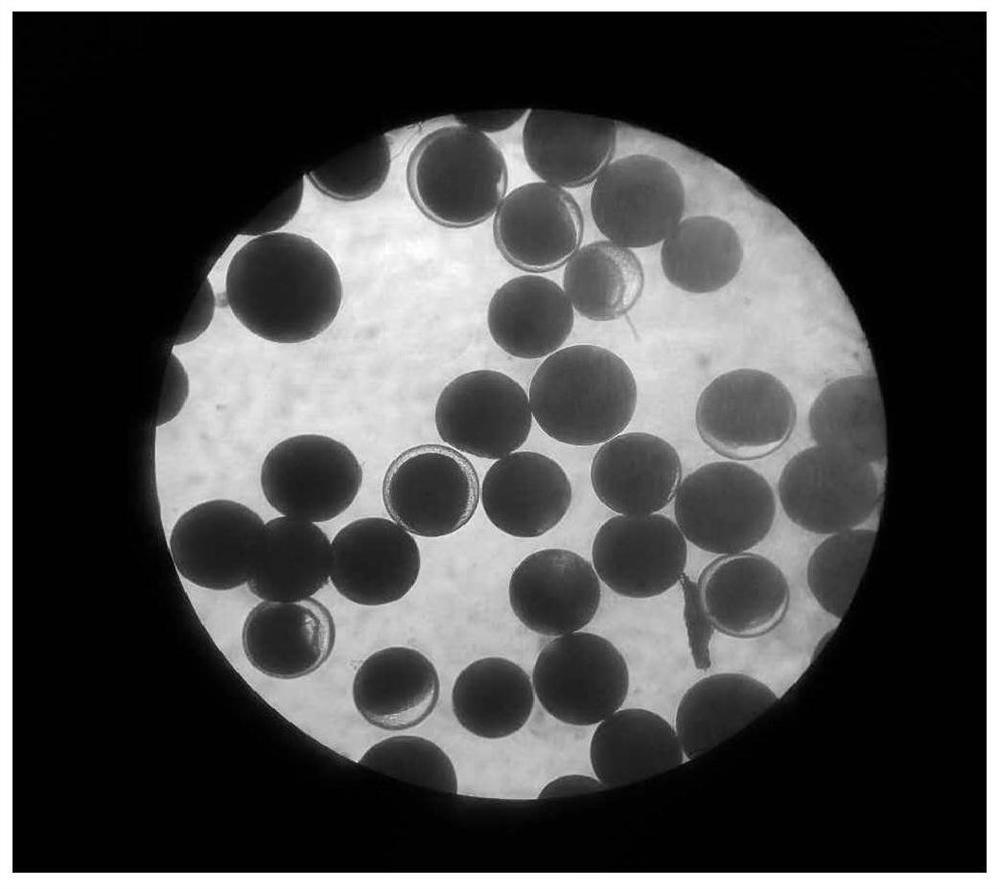

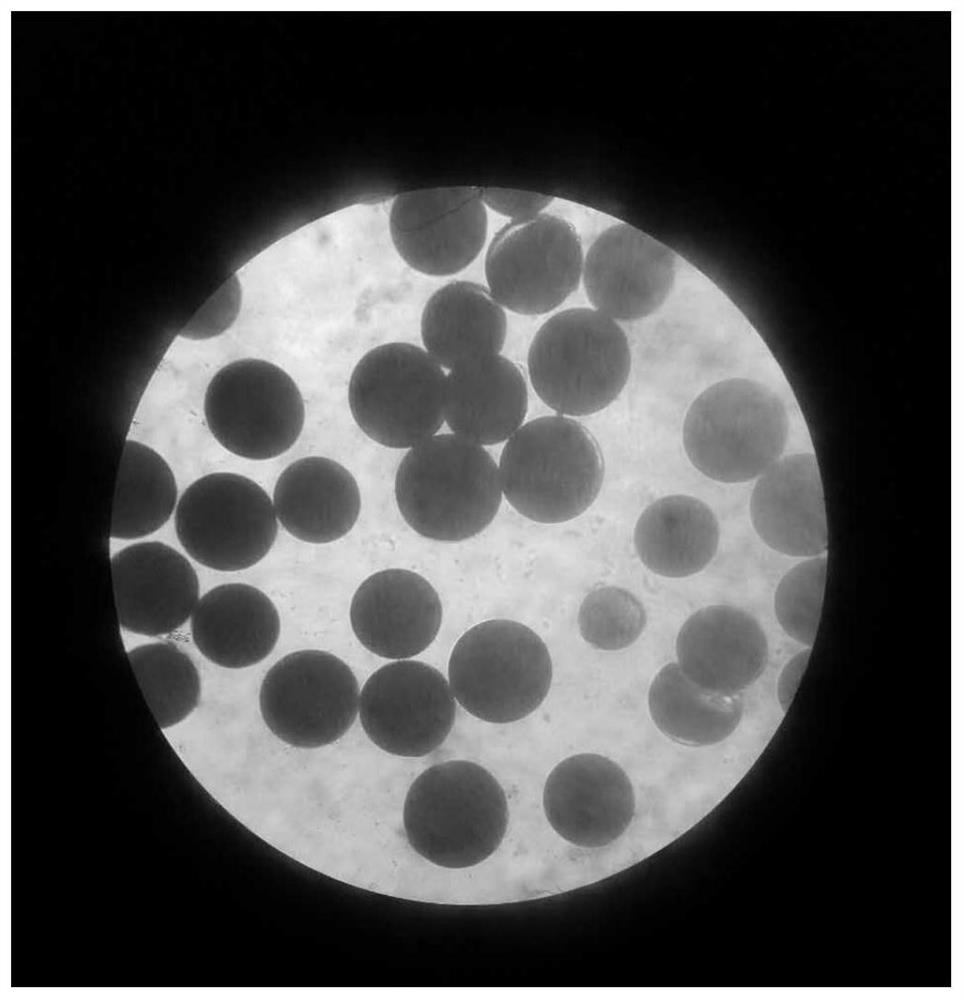

[0028] (2) the Artemia ovum of step (1) is placed in the sodium hypochlorite solution that available chlorine concentration is 4.25% to soak 10min and fully aerate after sterilizing, every 100g commodity Artemia ovum uses the sodium hypochlorite solution soaking of 500ml, observes When the black-brown Artemia eggs turn grayish white, and finally orange-red, separate the egg shells, wash the Artemia eggs with clean sea water, and obtain shelled Artemia eggs;

[0029] (3) the Artemia ovum shelled in step (2) is immediately placed on a 150-order mesh cloth for washing, and then so...

Embodiment 2

[0033] The shelling treatment method of Artemia ovum of the present invention comprises the following steps:

[0034] (1) Soak commercial Artemia eggs in clean fresh water for 11 minutes to fully disperse Artemia eggs, then soak in seawater with a salinity of 28.2% for 75 minutes, and fully aerate, so that Artemia eggs can fully absorb water and swell, and separate seawater and Artemia eggs ;

[0035] (2) the Artemia ovum of step (1) is placed in the sodium hypochlorite solution that available chlorine concentration is 4.45% to soak 9.5min and fully aerate after sterilizing, and every 100g commercial Artemia ovum uses 520ml of sodium hypochlorite solution to soak, Observe that the dark brown Artemia eggs turn off-white, and finally orange-red, separate the egg shells, wash the Artemia eggs with clean sea water, and obtain shelled Artemia eggs;

[0036] (3) the Artemia ovum shelled in step (2) is immediately placed on a 160-mesh mesh cloth to rinse, then soak the Artemia ovum ...

Embodiment 3

[0040] The shelling treatment method of Artemia ovum of the present invention comprises the following steps:

[0041] (1) Soak the commercial Artemia eggs in clean fresh water for 12 minutes, disperse the Artemia eggs, then soak in seawater with a salinity of 28.4% for 72 minutes, and fully aerate, so that the Artemia eggs can fully absorb water and swell, and separate seawater and Artemia eggs;

[0042] (2) the Artemia ovum of step (1) is placed in the sodium hypochlorite solution that available chlorine concentration is 4.65% to soak 9min and fully aerate after sterilizing, every 100g commodity Artemia ovum uses the sodium hypochlorite solution soaking of 530ml, observes When the black-brown Artemia eggs turn grayish white, and finally orange-red, separate the egg shells, wash the Artemia eggs with clean sea water, and obtain shelled Artemia eggs;

[0043] (3) the Artemia ovum shelled in step (2) is immediately placed on a 170-mesh mesh cloth to rinse, then soak the Artemia ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com