Patents

Literature

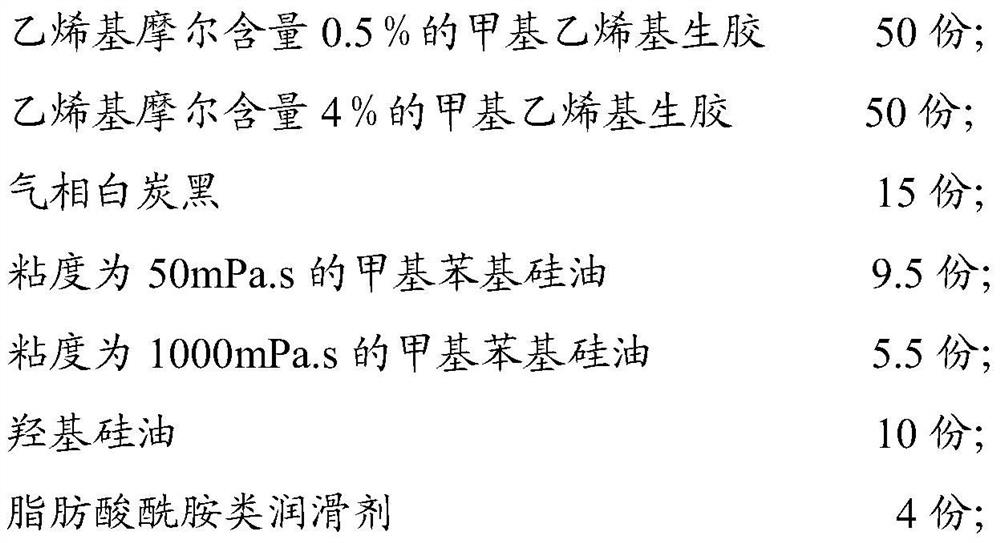

36results about How to "Total control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

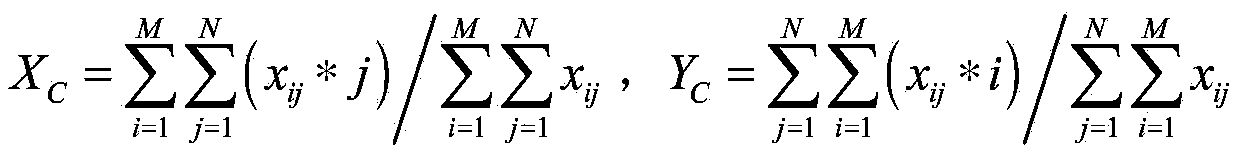

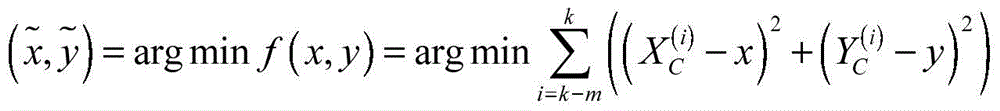

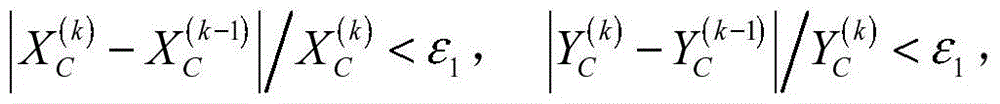

Method for extracting video key frame

ActiveCN103942751AEfficient extractionTotal controlImage analysisGeometric image transformationPattern recognitionFrame sequence

The invention discloses a method for extracting a video key frame, and belongs to the field of video data processing. The method for extracting the video key frame comprises the steps that the gray level mass centers of video frames are calculated, a video frame sequence is segmented into a plurality of frame sequences with vision similarity continuity according to the distance of the gray level mass centers of the adjacent frames and the distance between the gray level mass center of a current video frame and the average gray level mass center of presequence vision similar frame sequences, and the key frame is selected from the vision similar frame sequences. The problems that an existing key frame extraction technology is complex in computation process and large in computation quantity are solved.

Owner:MINZU UNIVERSITY OF CHINA

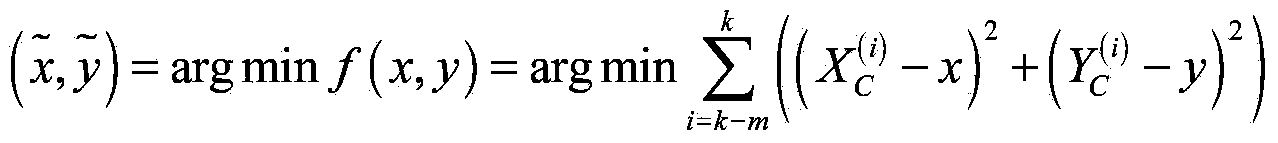

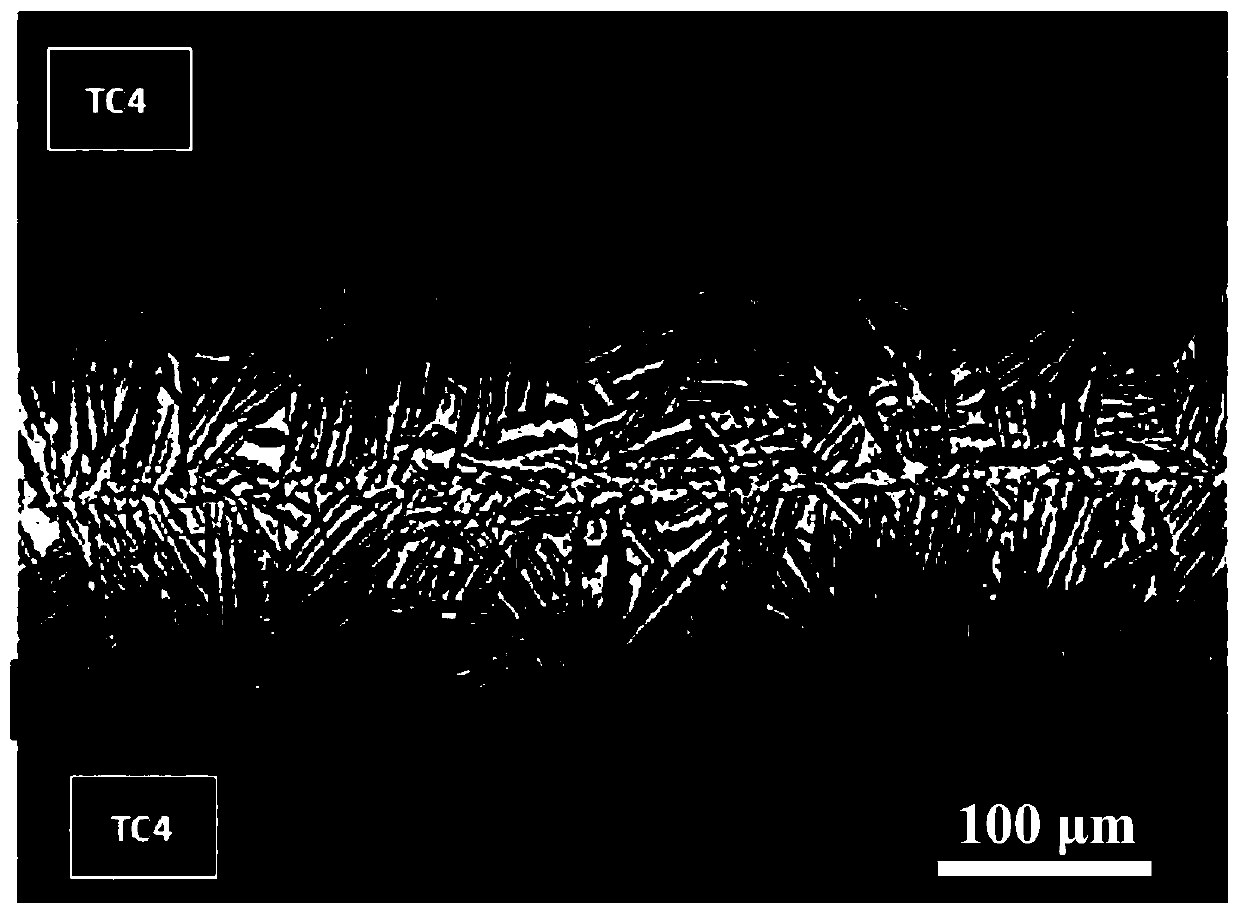

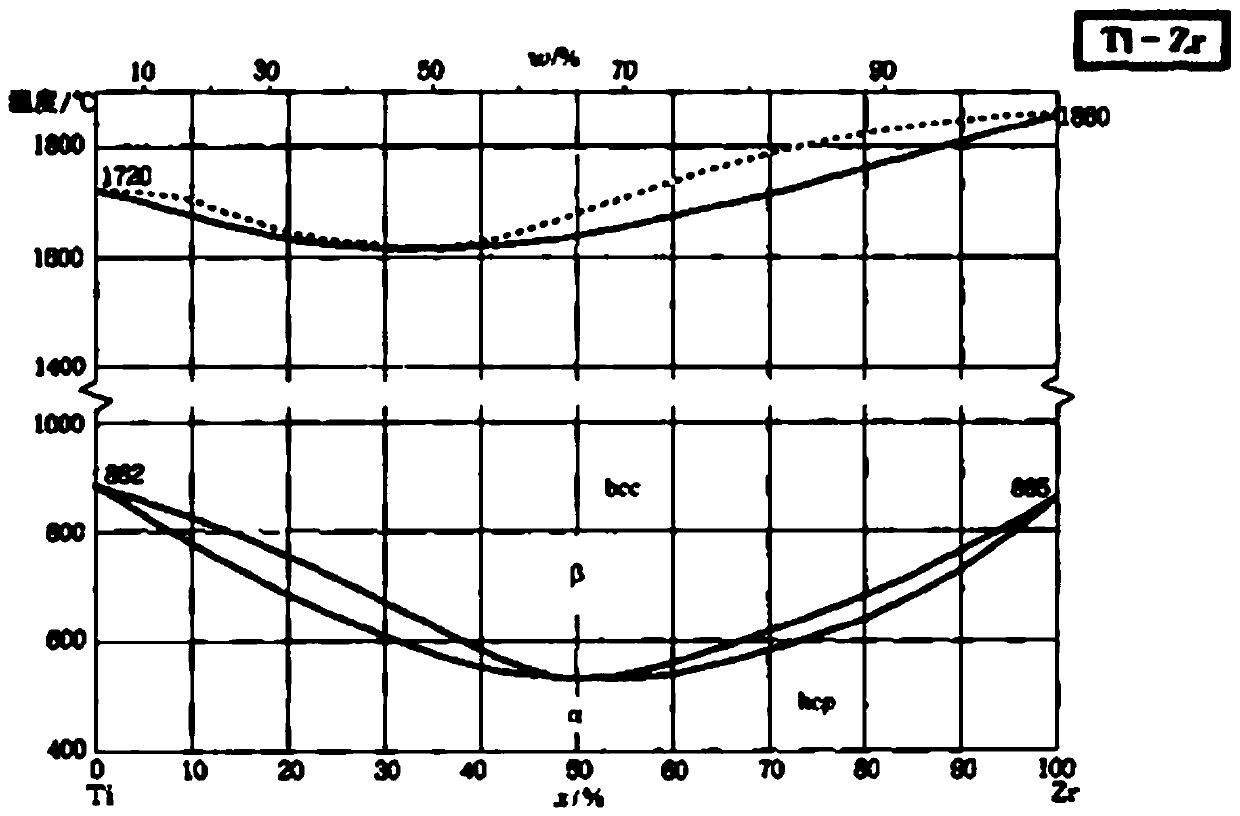

Belt-shaped brazing material for medium and low temperature brazing of titanium alloy, and preparation method and brazing method thereof

InactiveCN110666396AImprove diffusion abilityLow costWelding/cutting media/materialsSoldering mediaMetallurgyBrazing

The invention provides a belt-shaped brazing material for medium and low temperature brazing of titanium alloy, and a preparation method and a brazing method thereof. The belt-shaped brazing materialfor the medium and low temperature brazing of the titanium alloy consists of Ti element, Zr element, Cu element and Ni element, wherein all the element compositions are compounded by following weightpercentage: Ti greater than or equal to 51.0% and less than or equal to 60.0%, Zr greater than or equal to 15.0% and less than or equal to 19.0%, Cu greater than or equal to 12.0% and less than or equal to 14.0%, Ni greater than or equal to 13.0% and less than or equal to 16.0%, and Cu+Ni greater than or equal to 25.0% and less than or equal to 30.0%. By improving a Ti-Zr-Cu-Ni brazing material, optimizing the content of the Zr element, and controlling the total content of the Cu element and the Ni element, the belt-shaped brazing material for the medium and low temperature brazing of the titanium alloy realizes the purpose of reducing the melting point to a range from 830 DEG C to 880 DEG C, improves diffusivity of the brazing material so as to reduce the quantity of interfacial compounds, realizes that the level of tensile strength of a Ti2AlNb-TC4 dissimilar brazed joint reaches 905MPa, and the level of tensile strength of a TA2 brazed joint reaches 463MPa, meanwhile facilitates forming of a brazing material foil belt, reduces cost of the brazing material, and improves applicability of the brazing material.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Silicon-containing heat-resistant rare earth magnesium alloy and preparation method thereof

The invention discloses a silicon-containing heat-resistant rare earth magnesium alloy and a preparation method thereof, wherein the alloy comprises the following components by weight percentage: 5-10% of Gd, 2-8% of Y, 0.3-2% of Si, 0.35-0.8% of Zr, 1-13% of Gd+Y1, less than 0.02% of impurities and the balance of magnesium. The invention also relates to a preparation method of the silicon-containing heat-resistant rare earth magnesium alloy; and the method comprises the steps of raw material preheating, smelting and subsequent heat treatment, wherein the smelting is carried out under protection of the mixed gases of SF6 and CO2; and the subsequent heat treatment comprises solid-solution treatment and aging treatment on the silicon-containing heat-resistant rare earth magnesium alloy. The preparation method of the silicon-containing heat-resistant rare earth magnesium alloy is simple in process, low in content of rare earth, and capable of guaranteeing excellent plasticity while improving the strength of the alloy; and a high-strength high-tenacity heat-resistant wearable magnesium alloy can be obtained by adjusting the constituents of the alloy and the heat treatment process; besides, the obtained magnesium alloy can be applied to a plurality of fields of automobile, aerospace, war industry and the like, and thereby is capable of meeting the requirements of a plurality of application occasions.

Owner:SHANGHAI JIAO TONG UNIV

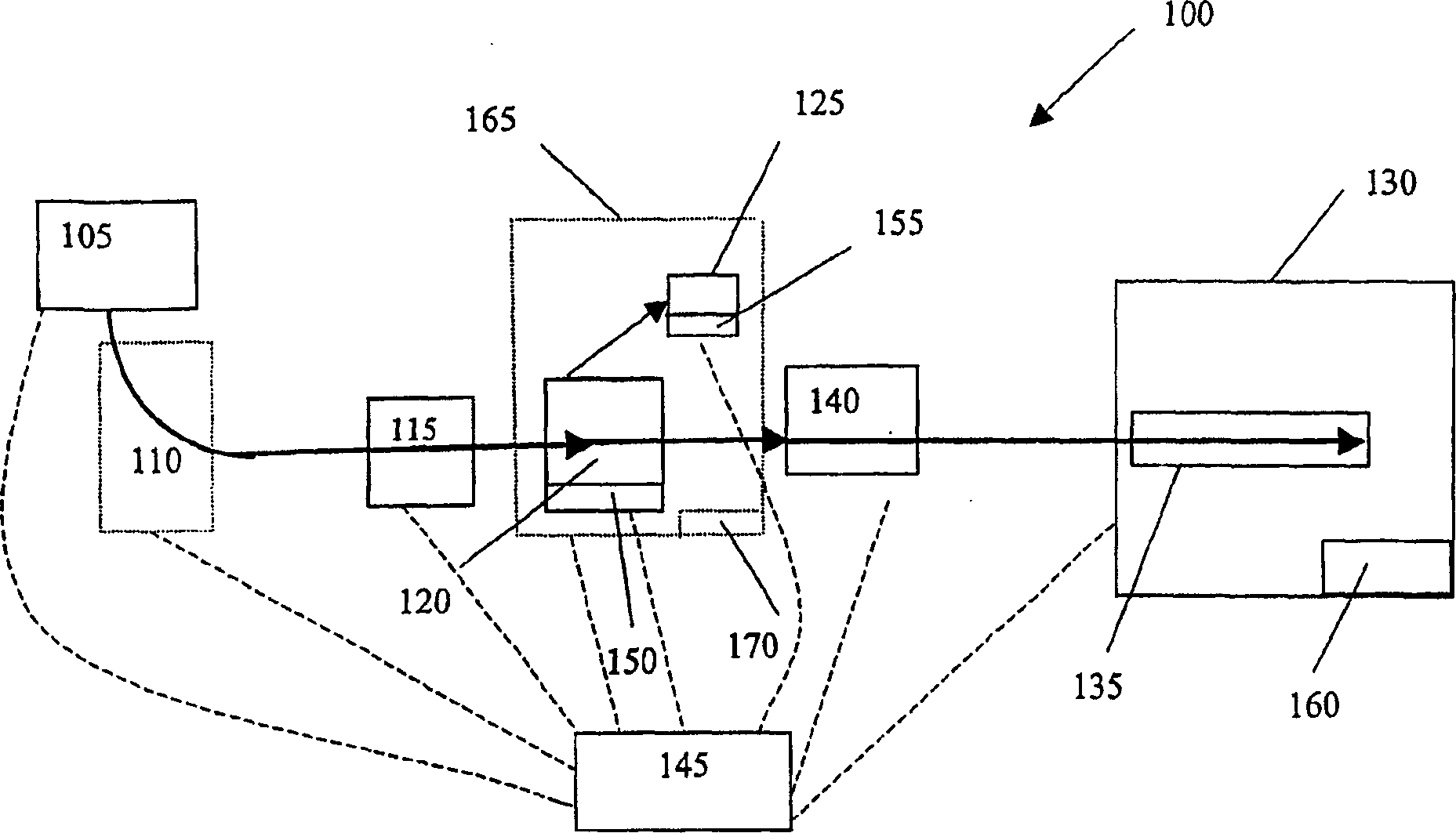

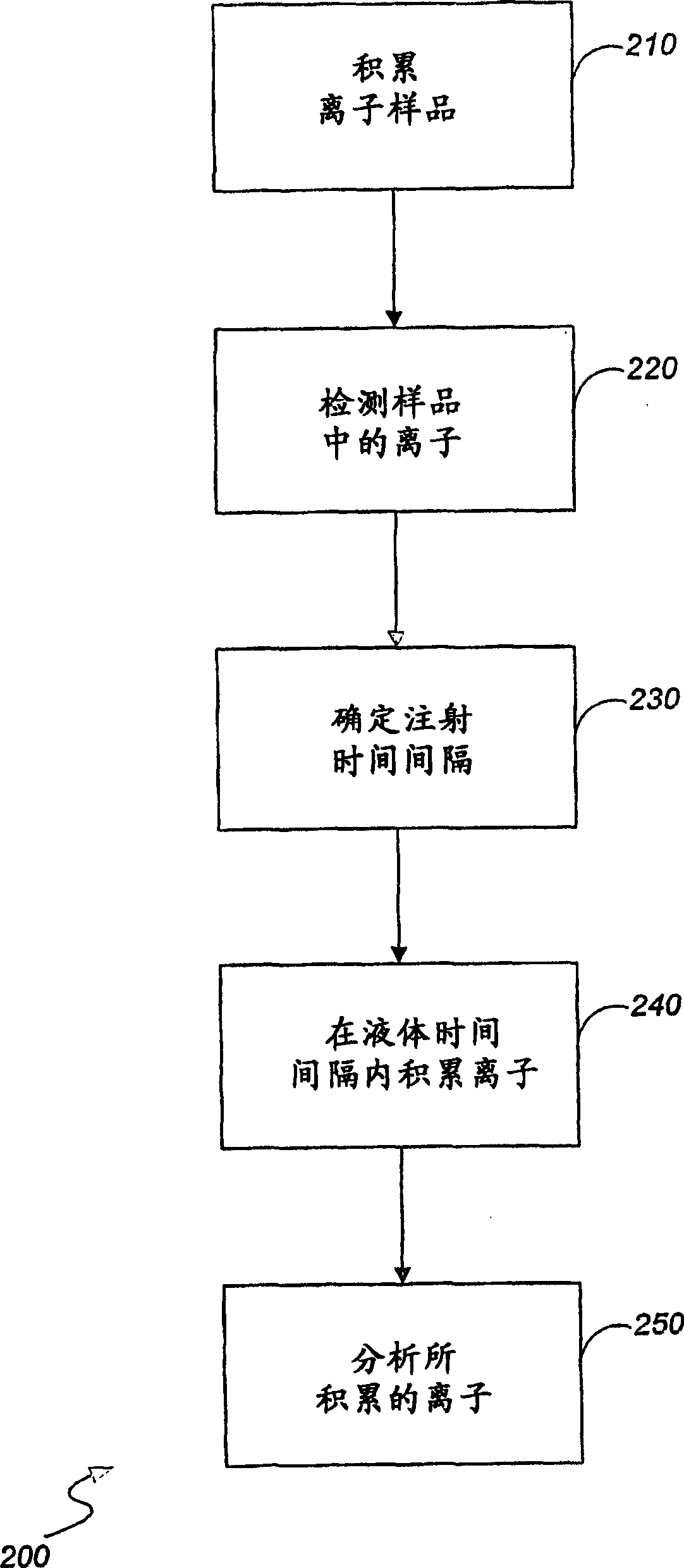

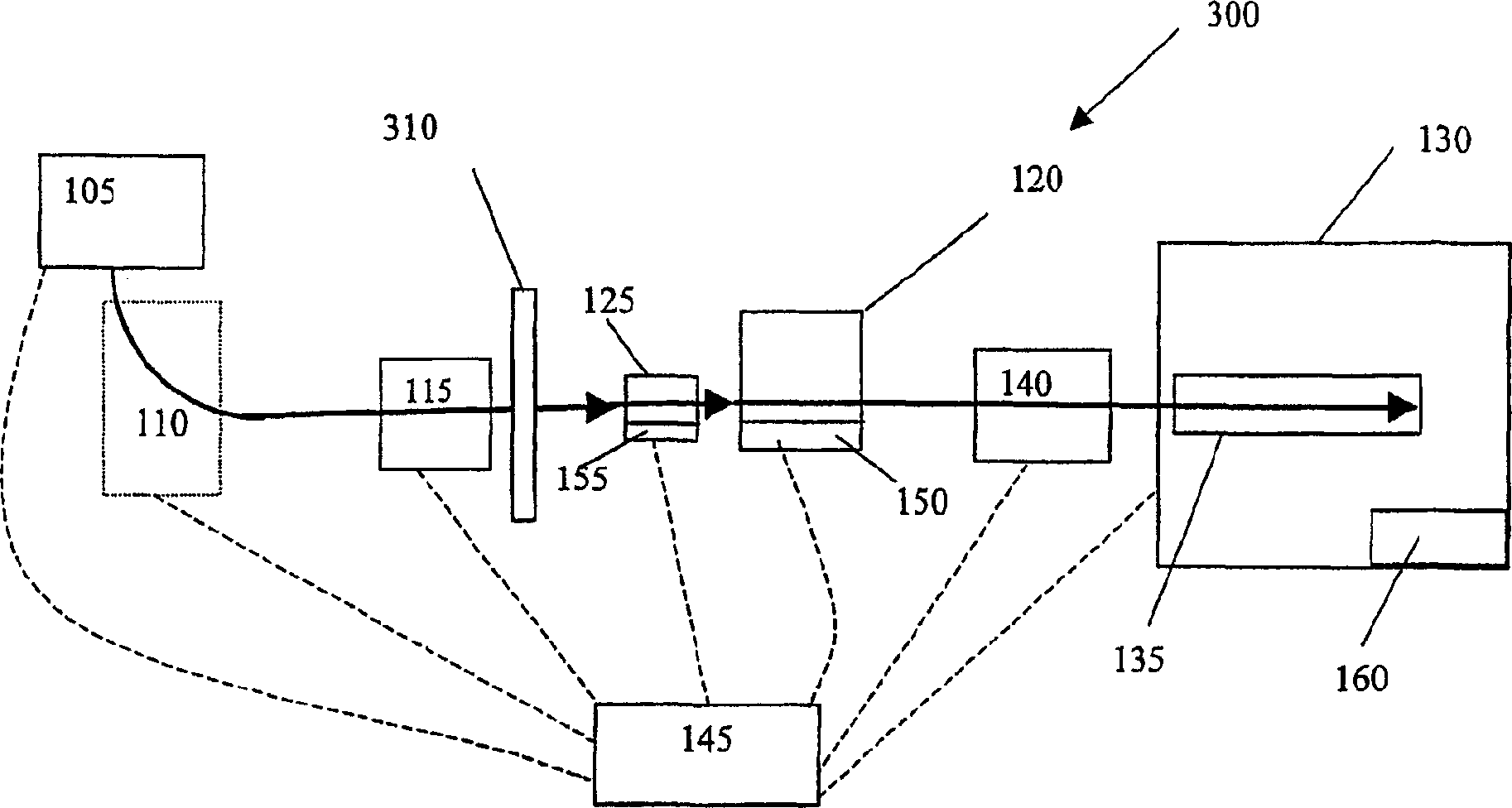

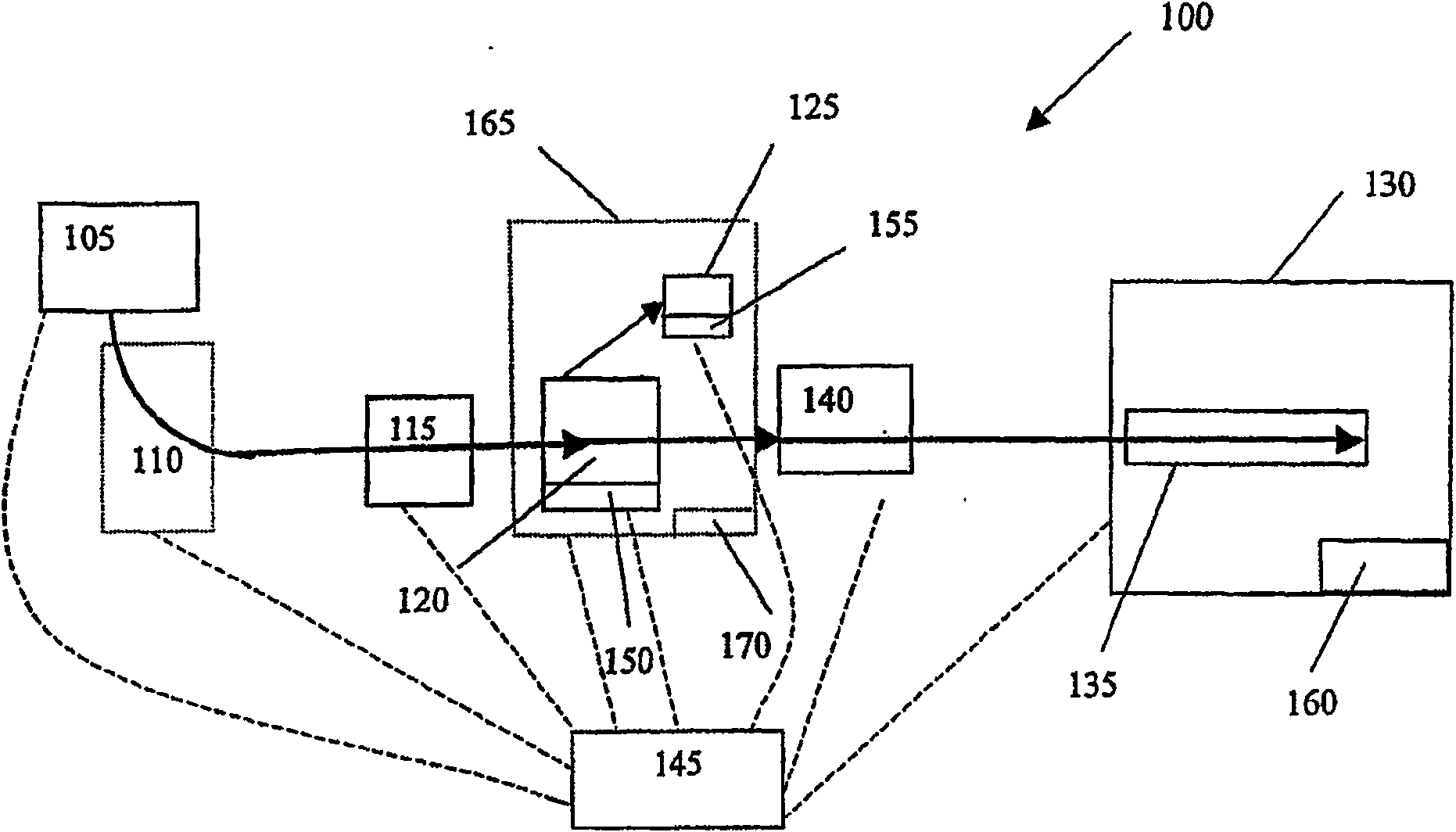

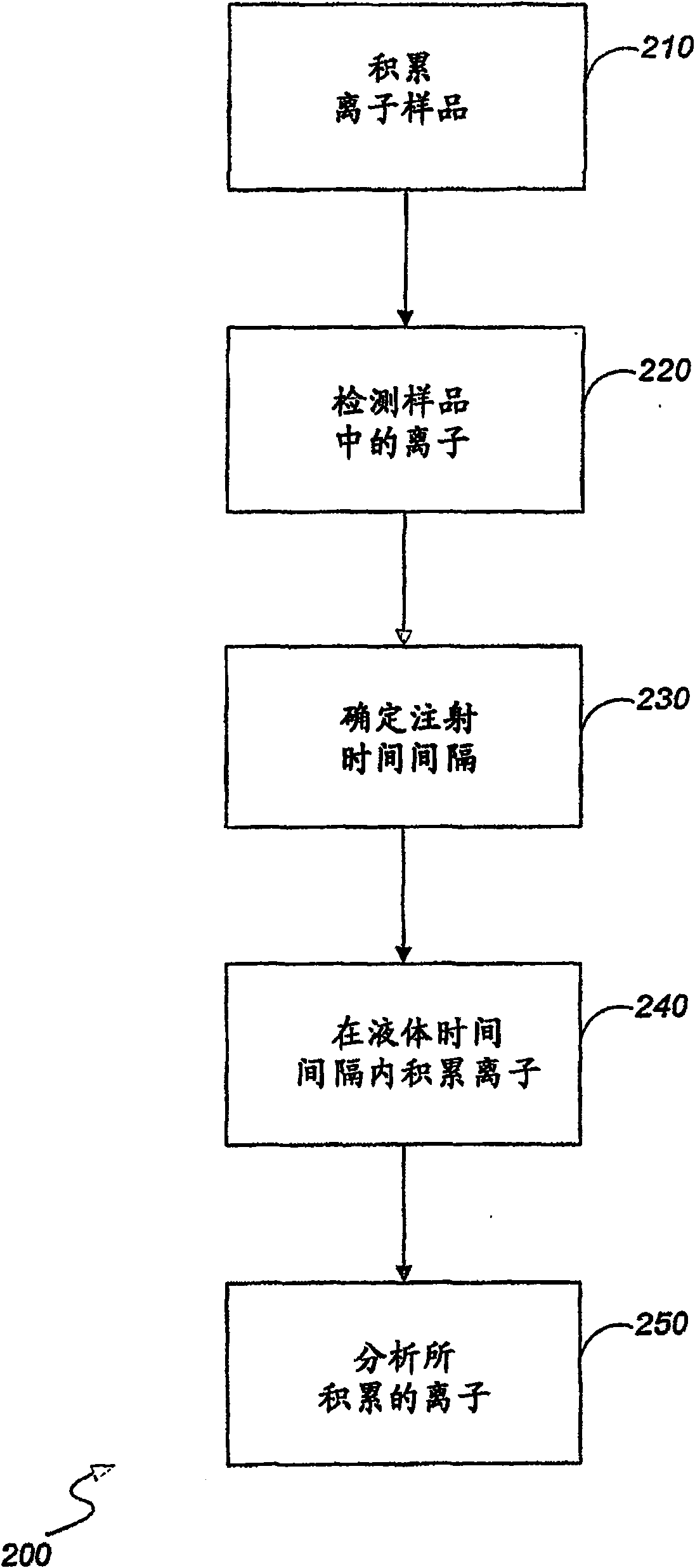

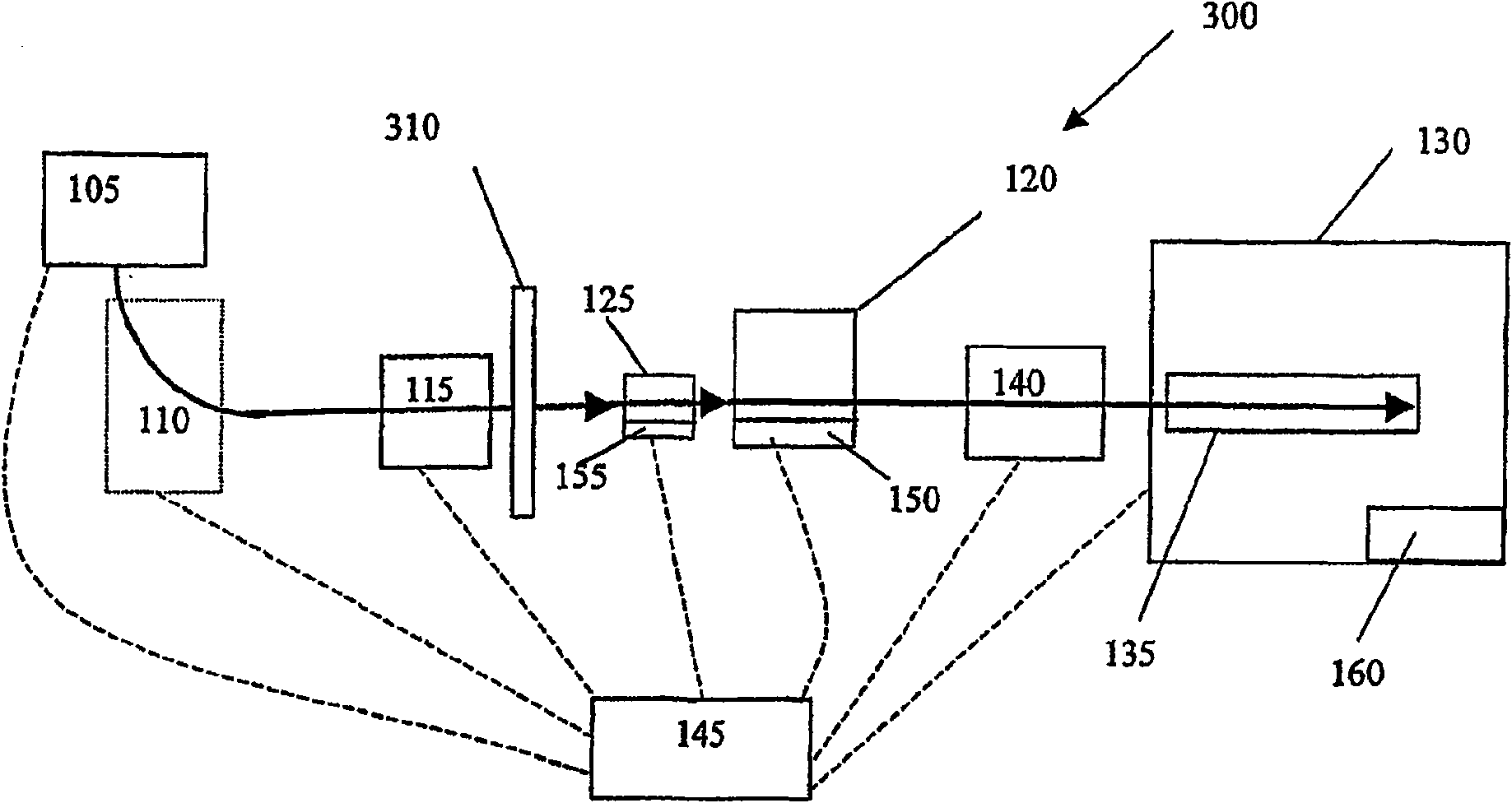

Controlling ion populations in a mass analyzer

ActiveCN1777975ATotal controlHigh sensitivityStability-of-path spectrometersTime-of-flight spectrometersPhysical chemistryMass analyzer

Methods and apparatus for controlling the number of ions to be analyzed in a mass analyzer are disclosed. Ions are accumulated over an injection time interval determined as a function of ion accumulation rate and a predetermined desired number of ions. Accumulation velocity represents the flow rate of ions from the ion source into the ion collector. Ions from the accumulated ions are introduced into a mass analyzer for analysis.

Owner:THERMO FINNIGAN

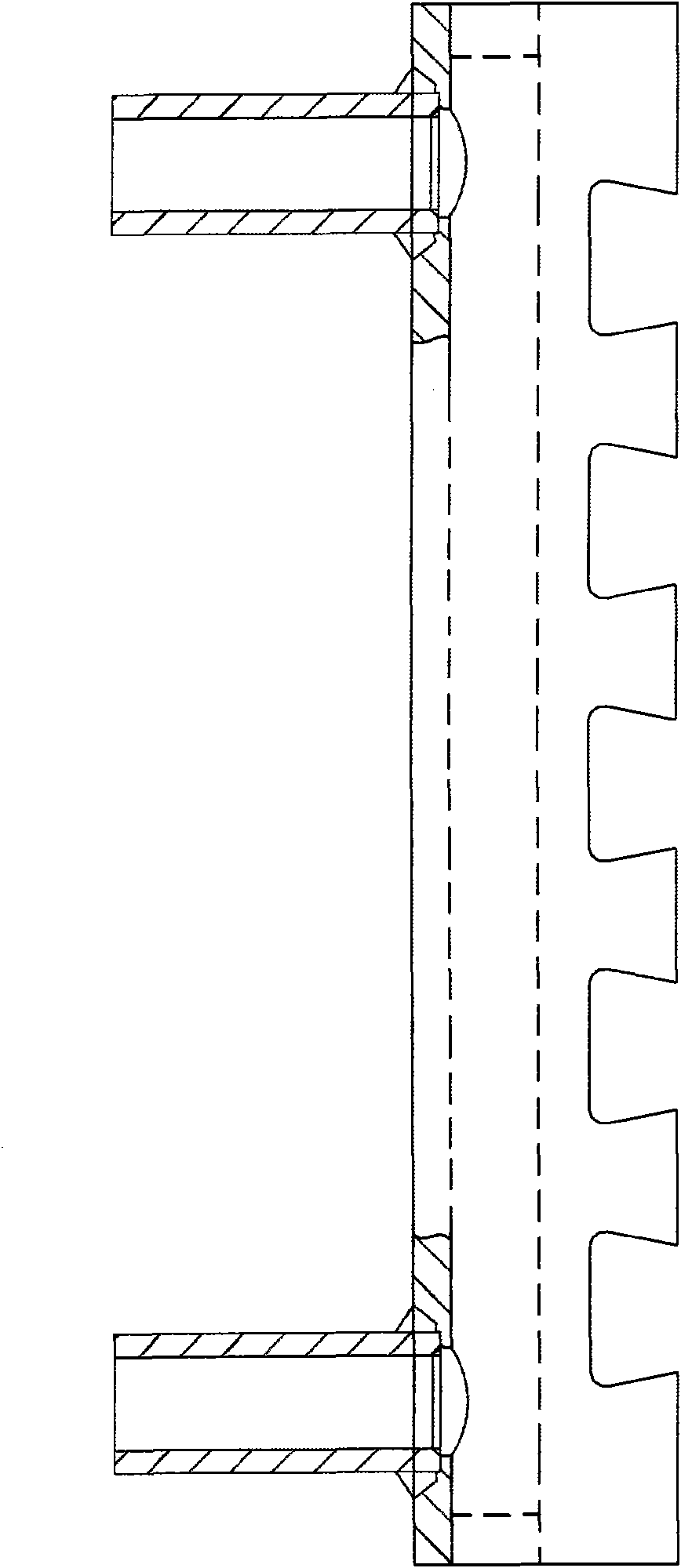

Copper cooling wall with reinforced piping structure

ActiveCN101935723AStressfulIncrease the stress pointCooling devicesManufacturing convertersStress conditionsWater channel

The invention provides a copper cooling wall with a reinforced piping structure. The copper cooling wall comprises a copper cooling wall body, at least one water inlet pipe and at least one water outlet pipe, wherein at least one cooling water channel is reserved in the copper cooling wall body; the water inlet pipe is welded on the cool surface of the copper cooling wall body, and is connected with the inlet of the cooling water channel; the water outlet pipe is welded on the cool surface of the copper cooling wall body, and is connected with the outlet of the cooling water channel; the water inlet pipe is inserted into the inlet of the cooling water channel, and is in threaded connection with the inner wall of the inlet of the cooling water channel; and the water outlet pipe is inserted into the outlet of the cooling water channel and is in threaded connection with the inner wall of the outlet of the cooling water channel. The copper cooling wall has the advantages of increasing stress points of the water pipe, and improving the stress condition of the water pipe to ensure that the stress of the water pipe is more uniform and a welding seam is hard to destroy; and because of lugs, the quality and the strength of the welding seam can be effectively improved, the consumption of copper can be greatly reduced, and the manufacturing cost of the copper cooling wall can be effectively controlled on the premise of ensuring the performance.

Owner:SHANTOU HUAXING METALLURGICAL EQUIP CO LTD

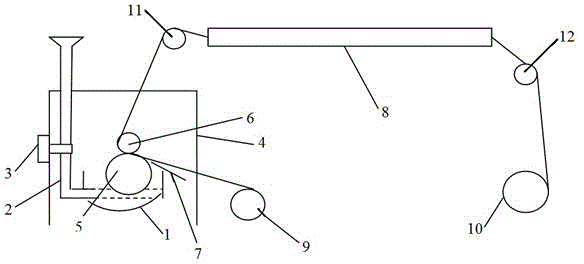

Novel safe and environment-friendly coating equipment

InactiveCN103143481AReduce harmReduce pollutionLiquid surface applicatorsCoatingsBiochemical engineeringSolvent evaporation

The invention discloses novel safe and environment-friendly coating equipment, which mainly comprises an unreeling device, a coating device, a drying device and a wrap-up device, wherein the coating device comprises a coating roller, a rubber roller and a scrapper, the coating roller and the rubber roller are in rolling connection, a first traction roller is arranged between the coating device and the drying device, a second traction roller is arranged between the drying device and the wrap-up device, a protective hood is installed on the coating device, and two clearances for releasing and winding thin films and parallel to the coating roller are respectively arranged on the upper surface and the side surface of the protective hood. The novel safe and environment-friendly coating equipment has the beneficial effects that a transparent protective hood made of a polymer composite is installed outside the coating device and is used for reducing the harm to the health of production staff and reducing the contamination to the environment due to solvent evaporation. Furthermore, the feeding manner is improved, so that the direct contact possibility among constructors and coating liquor is lowered, the safety is enhanced, on the other hand, the total quantity of the coating liquor in a trough is controlled, so that the equipment is beneficial to uniform coating of base materials.

Owner:WUXI ZHONGYI FILM TECH

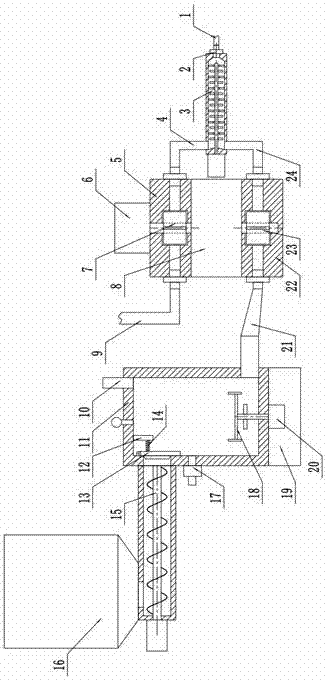

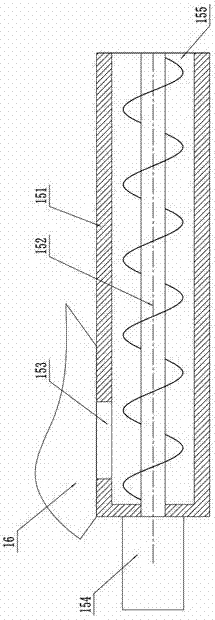

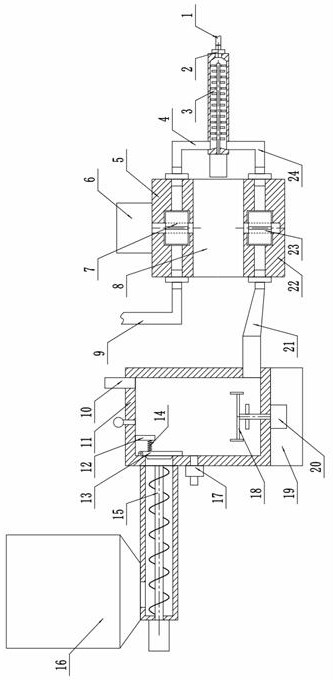

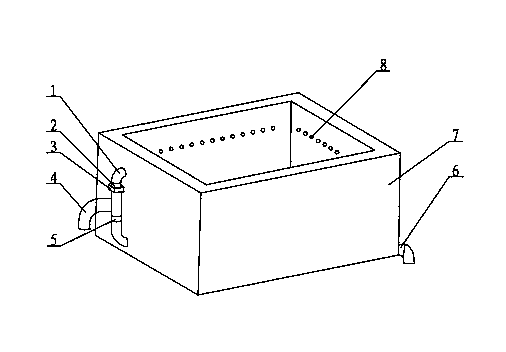

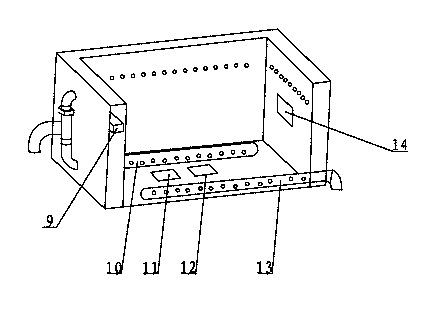

Farmland-garden water and fertilizer integrated irrigation equipment

ActiveCN107484483ATotal controlImprove the effect of real-time mixingPressurised distribution of liquid fertiliserImpellerInlet valve

The invention discloses farmland-garden water and fertilizer integrated irrigation equipment which comprises an irrigation pipeline, a connection head, a mixing device, a first connection pipe, a first shell, a first motor, a first impeller, a speed reducer, a water inlet pipe, a high-pressure air pipe, a preprocessing tank, a fixed stopping block, a sealing cover, a spring, a quantitative conveying device, a fertilizer storage tank, a water inlet value, a stirring paddle, a base, a second motor, a conveying pipe, a second shell, a second impeller and a second connection pipe. The farmland-garden water and fertilizer integrated irrigation equipment disclosed by the invention has the advantages of reasonable and simple structure, low production cost and convenience in installation. Firstly, the quantitative conveying device can convey a fertilizer stored in the fertilizer storage tank into the preprocessing tank; then the water inlet valve is started to add the defined proportion of water into the preprocessing tank; then compressed air is sent into the preprocessing tank by the high-pressure air pipe; the arranged speed reducer can guarantee that the output proportions of the water and the fertilizer are the same; finally, the water and the fertilizer are further mixed by the mixing device and then conveyed into the irrigation pipeline to irrigate farmland and gardens.

Owner:YANTAI ZHIXING INTPROP CONSULTATION SERVICES CO LTD

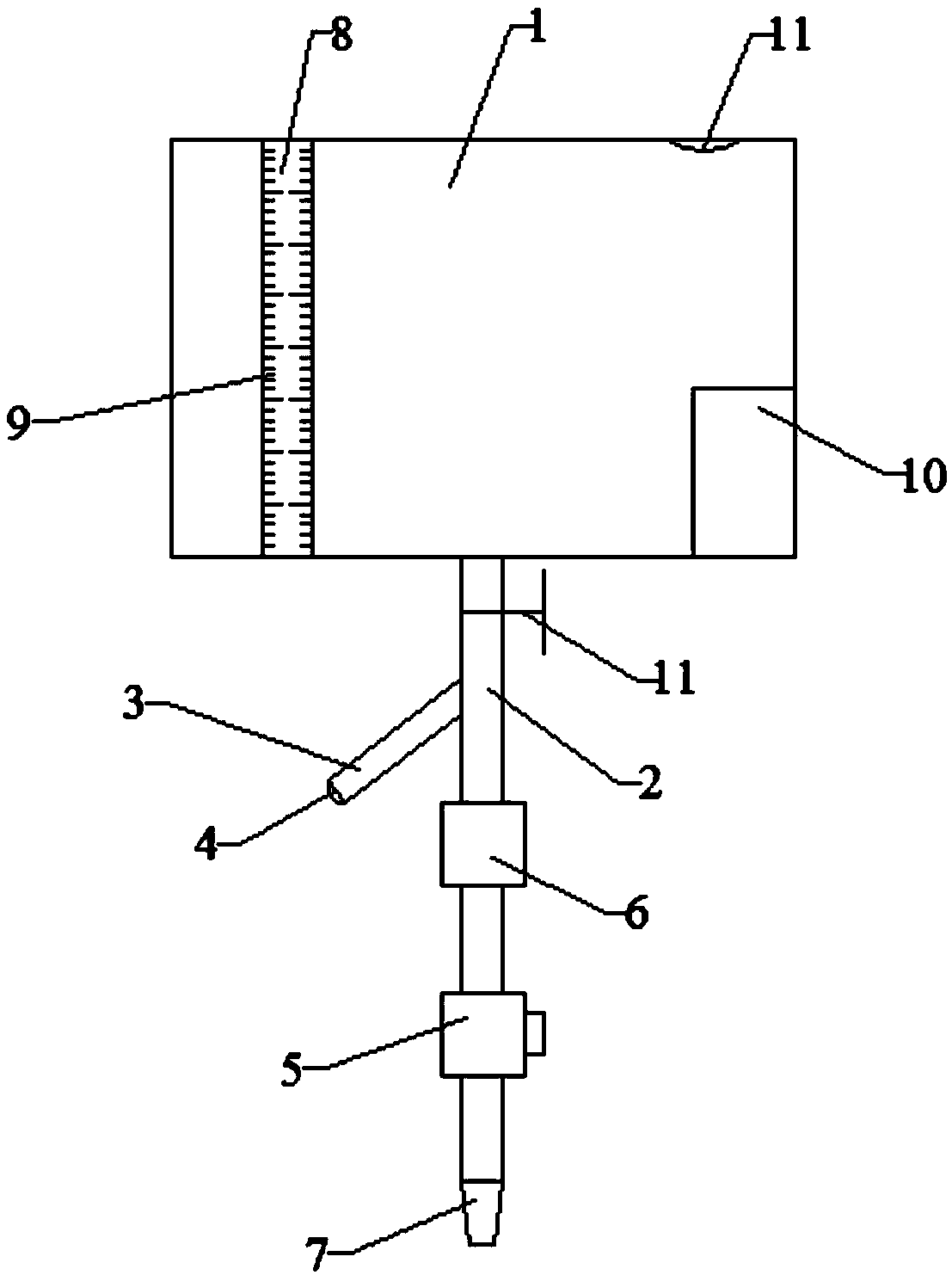

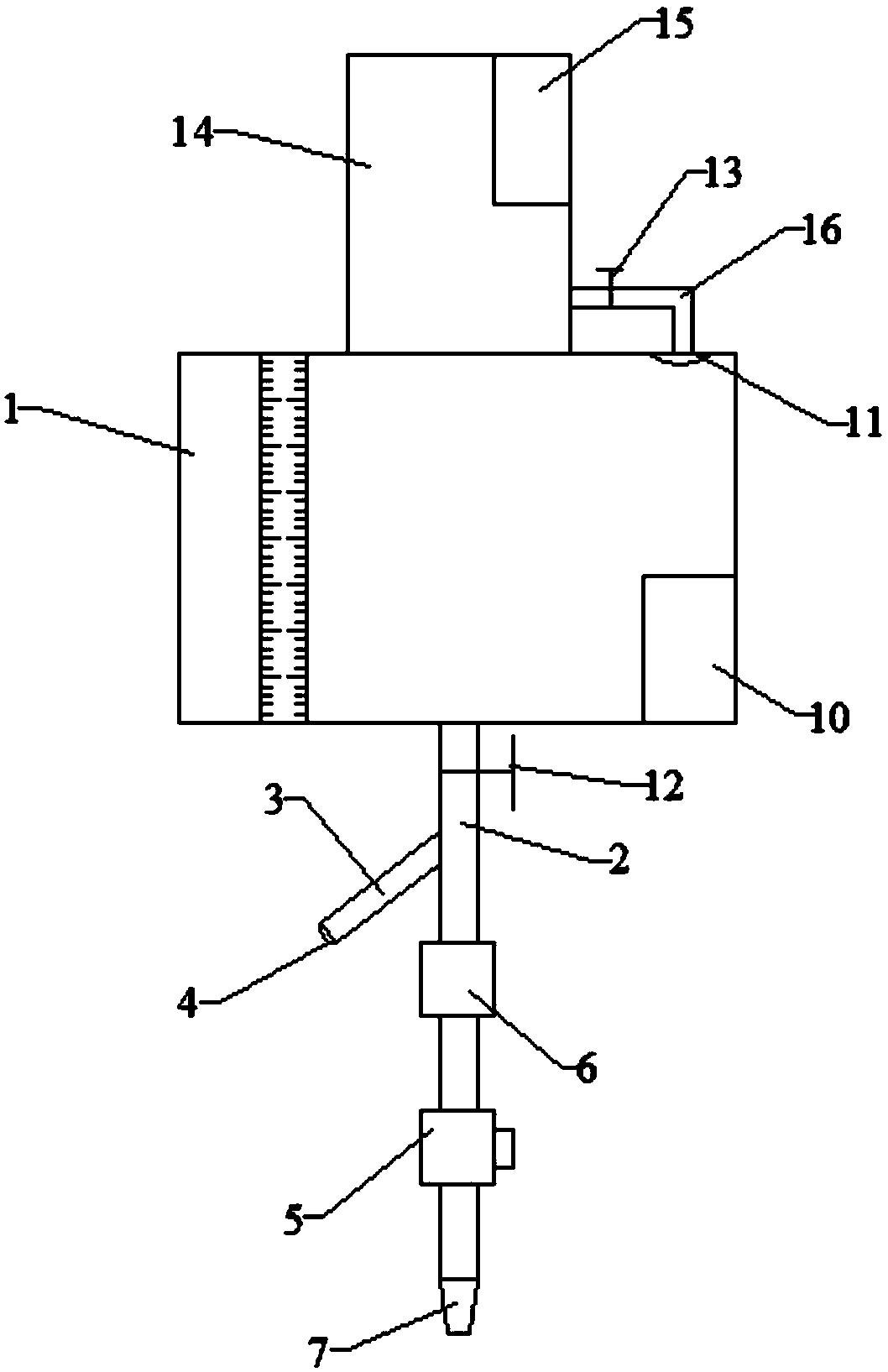

Gravity feeding device for premature infants

InactiveCN108652982ASuitable temperatureProtect stomachFeeding-bottlesDomestic articlesEngineeringToughened glass

The invention belongs to the technical field of medical appliances, and particularly relates to a gravity feeding device for premature infants. The gravity feeding device for the premature infants comprises a constant temperature box and a fixed device for vertically suspending the constant temperature box, wherein an injection opening is formed in the upper surface of the constant temperature box, a sealing cover is arranged on the injection opening, toughened glass is embedded on the front side wall of the constant temperature box, the toughened glass is vertically arranged, a scale line isarranged on the toughened glass, a first display screen is arranged on the front side wall of the constant temperature box, a controller, a power switch and an adjusting button are arranged on the rear side wall of the constant temperature box, the controller is electrically connected with the first display screen, the power switch and the adjusting button, a Murphy dropper is arranged at the bottom of the constant temperature box, and a dropper, an infusion regulator and a connector are sequentially arranged from top to bottom. Compared with the prior art, the gravity feeding device for premature infants has the advantages of simple operation, heat preservation function, accurate control of feeding amount and feeding speed and more scientific feeding.

Owner:THE FIRST AFFILIATED HOSPITAL OF HENAN UNIV OF SCI & TECH

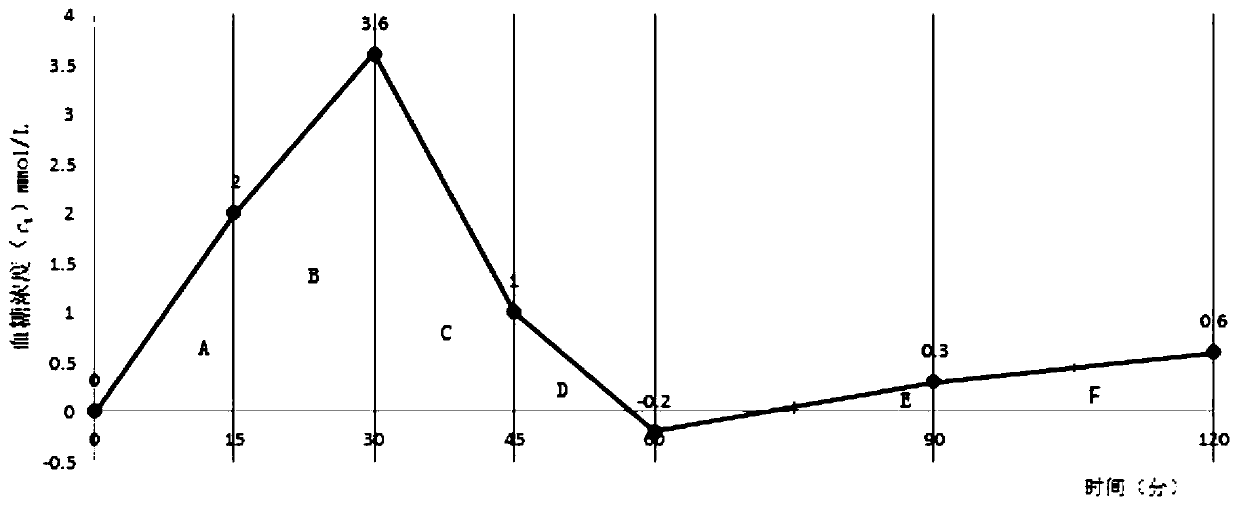

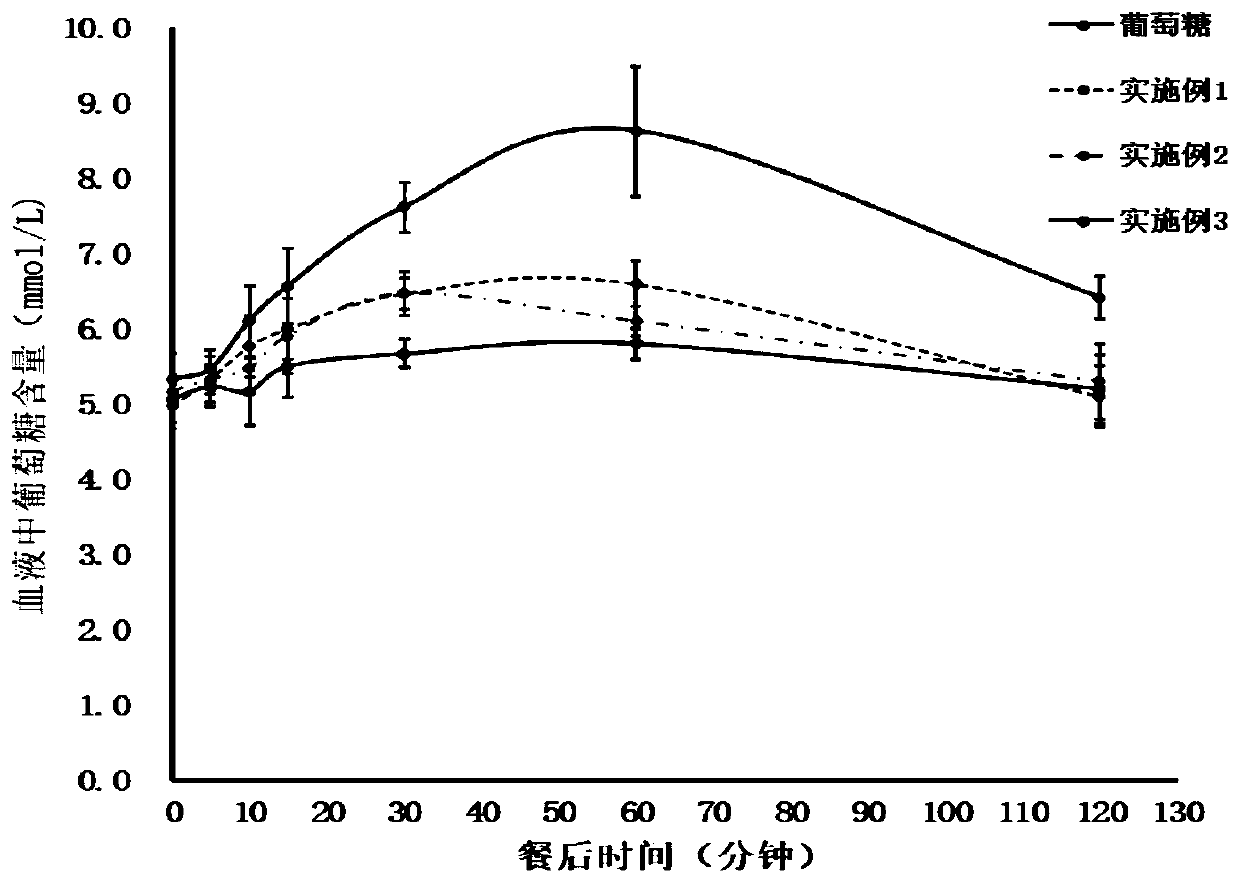

Quinoa meal replacement composite food with low GI value and low GL value and preparation method and application of quinoa meal replacement composite food

PendingCN110692676ATotal controlEnsure the proportionDough treatmentLeguminous plant bakery productsBiotechnologyPolygonum fagopyrum

The invention discloses a quinoa meal replacement composite food with low GI value and low GL value and a preparation method and application of the quinoa meal replacement composite food. The quinoa meal replacement composite food with low GI value and low GL value is prepared from raw materials comprising wheat, quinoa, oat, buckwheat, white kidney beans, chickpea and resistant starch. After a diabetic patient eats the quinoa meal replacement composite food with low GI value and low GL value, the postprandial blood sugar of the diabetic patient can be effectively controlled, the GI value ranges from 19.8 to 33.7, the GL value ranges from 10.6 to 18.2, namely, the GI value is less than 55, the GL value is less than 19, and thus, the quinoa meal replacement composite food with low GI valueand low GL value is medium or low load food, and belongs to the field of food which have little influence on blood glucose or do not affect the blood glucose.

Owner:博生众康(厦门)医药生物技术股份有限公司

Preparation method of high conductive aluminum alloy plate belt

The invention belongs to the technical field of aluminum alloy manufacturing and relates to a preparation method of a high conductive aluminum alloy plate belt. An aluminum alloy ingot is prepared from the following compositions in percentage by mass: less than or equal to 0.15% of Si, less than or equal to 0.20% of Fe, 0.3-0.5% of Cu, less than or equal to 0.01% Mn, less than or equal to 0.02% ofMg, less than or equal to 0.01% of Cr, less than or equal to 0.03% of Zn, 0.03-0.05% of Er, 0.008-0.015% of Ti, less than or equal to 0.01% of B, less than or equal to 0.05% of remaining individual impurities and the balance of Al; and the total content of the impurities is less than or equal to 0.15%. In the process of aging heat treatment, a cold-rolled aluminum alloy plate is subjected to dual-stage aging heat treatment, wherein first stage aging heat treatment is conducted at a temperature of 280-310 DEG C and the thermal insulation duration is 30-140 min, and second stage aging heat treatment is conducted at a temperature of 180-220 DEG C and the thermal insulation duration is 10-20 h. The preparation method solves the problems that, according to the prior art, semi-continuous casting and rolling preparation technology of high conductive aluminum alloy plates is insufficient, rigidity and conductivity are difficult to balance, and high alloying casting is highly difficult and hashigh production cost.

Owner:TIANJIN ZHONGWANG ALUMINUM IND CO LTD

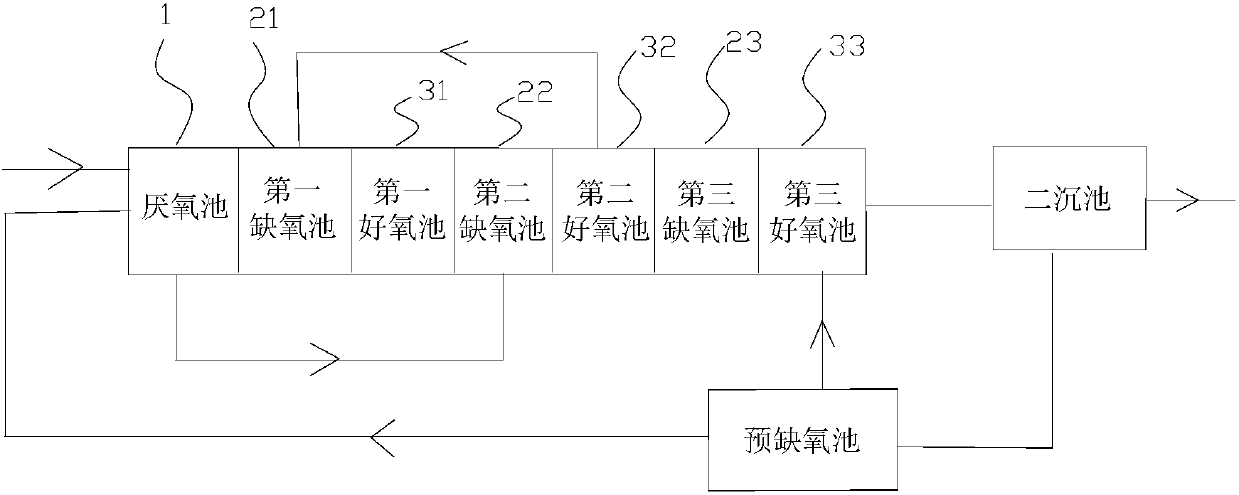

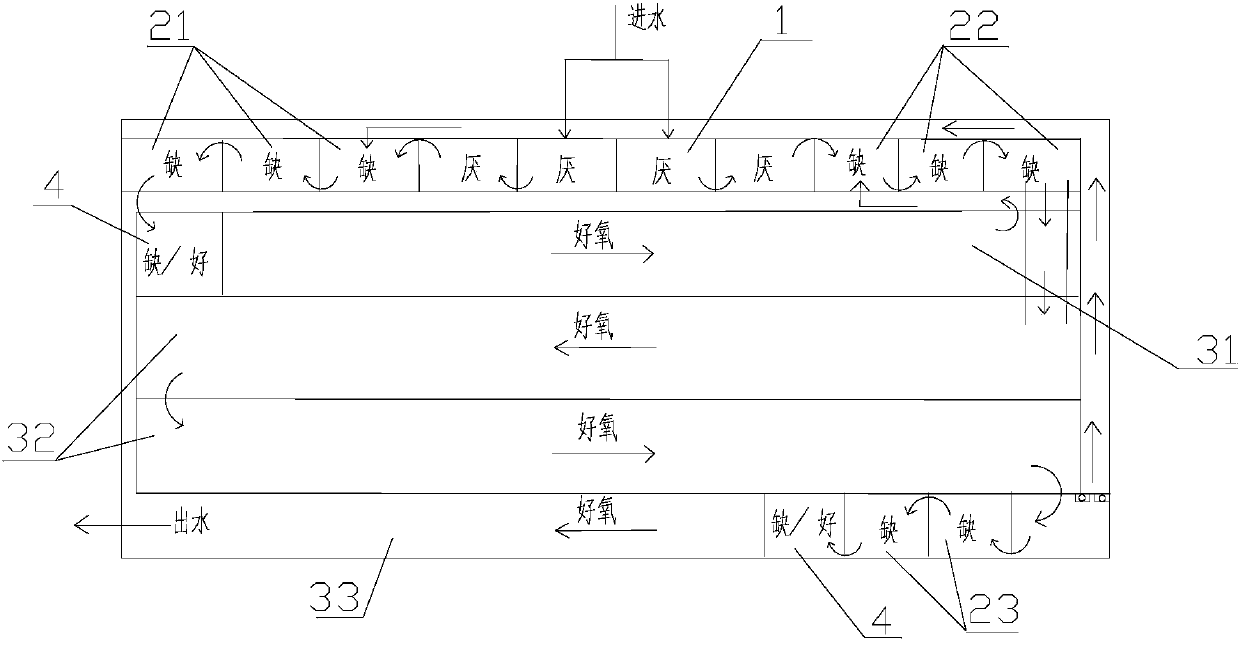

Novel sewage treatment system and process

PendingCN107746159AIncrease concentrationReduce dilutionWater treatment parameter controlWater contaminantsSludgeSewage

The invention discloses a novel sewage treatment system and process. The novel sewage treatment system comprises an anaerobic pool, a first anoxic pool, a first aerobiotic pool, a second anoxic pool,a second aerobiotic pool, a third anoxic pool, a third aerobiotic pool, a secondary sedimentation tank and a pre-anoxic pool, wherein the anaerobic pool, the first anoxic pool, the first aerobiotic pool, the second anoxic pool, the second aerobiotic pool, the third anoxic pool, the third aerobiotic pool and the secondary sedimentation tank are sequentially communicated with one another; the pre-anoxic pool is communicated with the secondary sedimentation tank, the anaerobic pool and the third aerobiotic pool; sludge at the middle part of the secondary sedimentation tank flows into the pre-anoxic pool, and supernatant of the pre-anoxic pool flows back to the third aerobiotic pool; concentrated sludge in the pre-anoxic pool flows back to the anaerobic pool; part of sewage in the second aerobiotic pool flows back to the first anoxic pool; part of sewage in the anaerobic pool is directly diverted to the second anoxic tank. According to the scheme, the reaction rate and the efficiency of the whole system are optimized, and the functions of denitrification and phosphorous removal are enhanced, so that a more efficient treatment effect is achieved within a limited reaction volume.

Owner:青岛娄山河水务有限公司

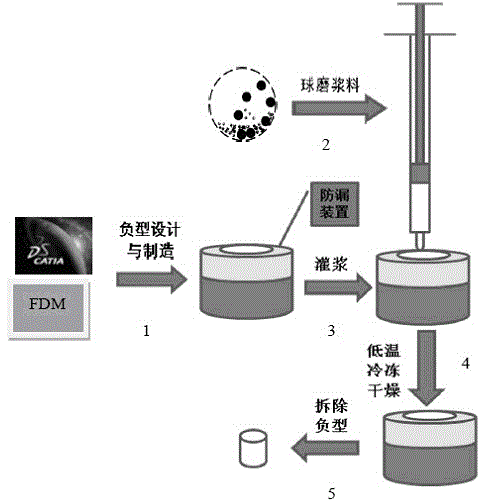

Preparation method of nano material-based bionic bone scaffold

The invention discloses a preparation method of a nano material-based bionic bone scaffold. The preparation method comprises following steps: a negative die is prepared via fused deposition modeling; dissolved biomaterial PLGA is mixed with nano-grade beta-TCP powder, and an obtained mixture is mixed uniformly using a vibration grinder; an obtained slurry is injected into the negative die via negative pressure method, and the negative die is delivered into a freeze dryer for freeze drying; and the negative die is removed so as to obtain the nano material-based bionic cone scaffold. The nano material-based bionic cone scaffold is capable of satisfying requirements on scaffold materials, structures, and strength; controllable adjustment on appearance and porosity is realized; customized manufacturing of scaffolds implanted at bone defect parts is realized; success rate of complex bone defect treatment in clinic is increased effectively; and application prospect in clinic is promising.

Owner:SHANGHAI UNIV

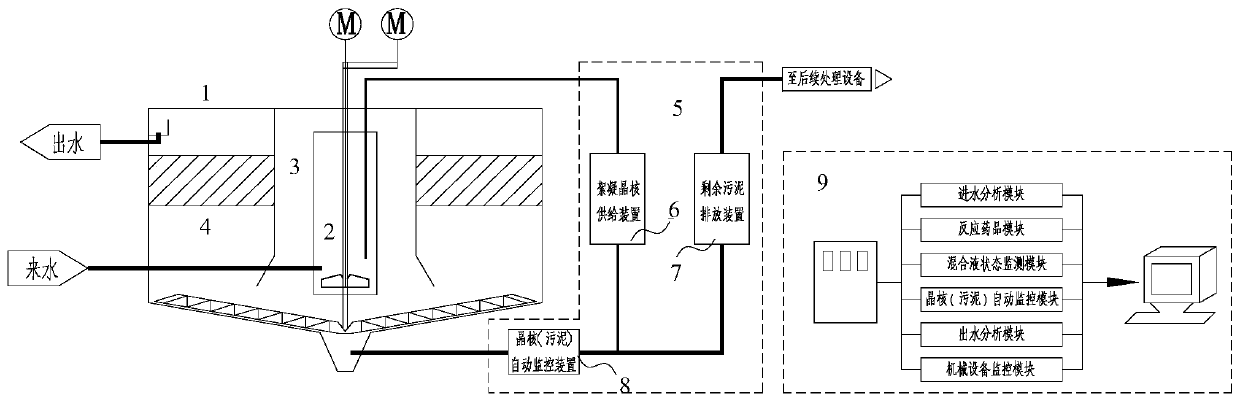

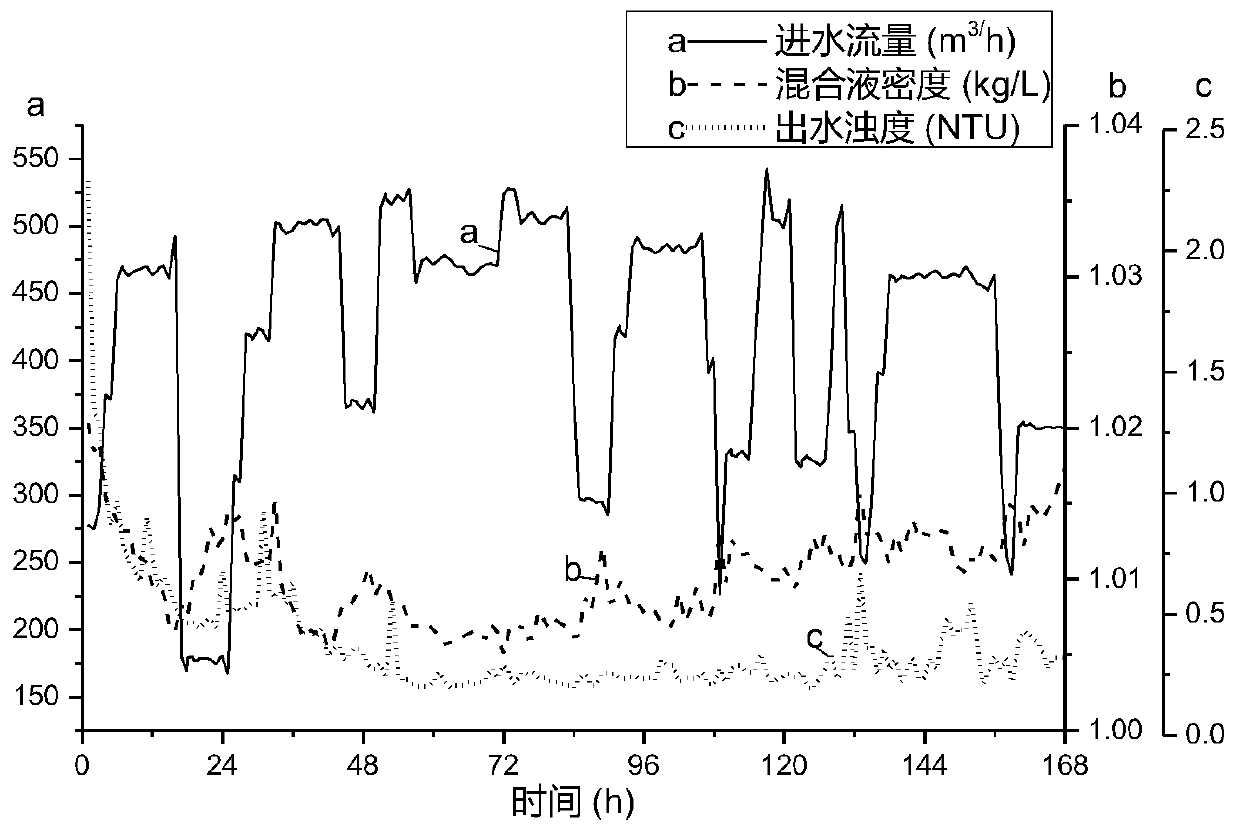

Forced reaction coagulation clarification system capable of realizing intelligent regulation and control

PendingCN110316801APromotes crystal growthStable crystal growthWater treatment parameter controlWater/sewage treatment by flocculation/precipitationStable stateFlocculation

The invention discloses a forced reaction coagulation clarification system capable of realizing intelligent regulation and control. The system comprises a clarification tank, a forced coagulation regulation and control unit and an analysis unit and is particularly applicable to the operation condition of frequently fluctuant water inflow. According to the system operation condition monitored and collected in real time by each functional module, the analysis unit accurately calculates the sludge generation amount of the clarification tank and the flocculation reaction degree of mixed liquid ina reaction area, analyzes the real-time operation state of the clarification tank and takes corresponding regulation and control measures. Through the forced coagulation regulation and control unit, the flocculation crystal nucleus quantity and sludge discharge amount of a forced coagulation reaction are accurately regulated and controlled, an optimized forced coagulation reaction environment is constructed, the growth and adsorption precipitation of flocculation crystal nuclei are effectively controlled, and it is ensured that the physical and chemical properties of floc in the reaction areastay in a good stable state. The system realizes automatic control over the intelligent and precise forced coagulation reaction environment, automatic control over the discharge of residual sludge, automatic control over a flushing device and the like and ensures the stable operation of the clarification tank, the effluent quality of the system is improved, and the operation benefits of the systemare increased.

Owner:XIAN TPRI WATER & ENVIRONMENTAL PROTECTION

Controlling ion populations in a mass analyzer

ActiveCN100550275CTotal controlHigh sensitivityStability-of-path spectrometersTime-of-flight spectrometersPhysical chemistryMass analyzer

Methods and apparatus for controlling the number of ions to be analyzed in a mass analyzer are disclosed. Ions are accumulated over an injection time interval determined as a function of ion accumulation rate and a predetermined desired number of ions. Accumulation velocity represents the flow rate of ions from the ion source into the ion collector. Ions from the accumulated ions are introduced into a mass analyzer for analysis.

Owner:THERMO FINNIGAN

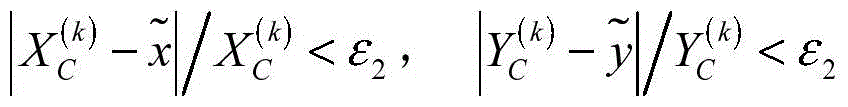

Method for manufacturing steelmaking converter steel slag deoxidization balls

InactiveCN108842035ATake away lower utilizationQuality improvementManufacturing convertersSteelmakingOxygen

The invention discloses a method for manufacturing steelmaking converter steel slag deoxidization balls. Coke powder, fluorite powder and a binder are used as raw materials, a mixing device is used for even mixing, the raw materials are pressed into finished products with the diameter being 15-20 mm through a ball pressing machine, and the finished products are naturally dried for standby use. After gun lifting of converter steelmaking, the deoxygenation balls are added into the converter through a feeding system, since the density of the deoxygenated balls is approximate to that of steel slag, the deoxygenated balls float on the surface of the steel slag, carbonaceous materials in the deoxygenated balls react with oxygen in steel, carbon dioxide is produced and removed, and the fluorite powder in the deoxidization balls can effectively inhibit formation of foam slag during the reaction. Compared with the deoxidization method, the steelmaking steel slag deoxidization balls do not causesecondary pollution during the deoxidization process, the manufacturing cost is low, molten steel is not polluted either, the manufacturing method is simple and rapid, and the metal loss in the steelmaking production process can be effectively reduced, the adding amount of light burnt dolomite is decreased, the corrosion resistance of a slag splashing protection layer is improved, thereby the steelmaking cost is reduced, and the quality of steelmaking molten steel is improved.

Owner:GANSU JIU STEEL GRP HONGXING IRON & STEEL CO LTD

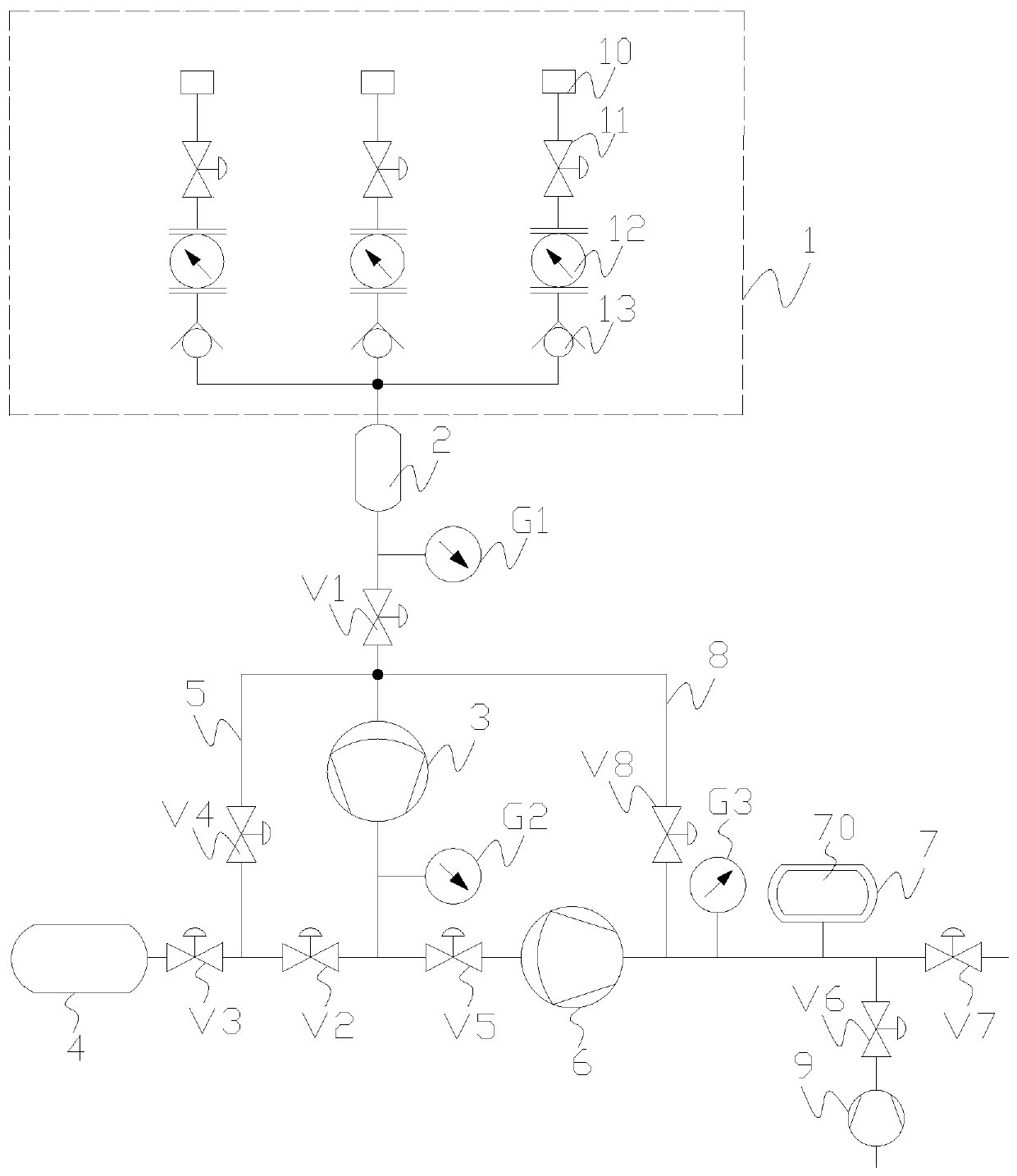

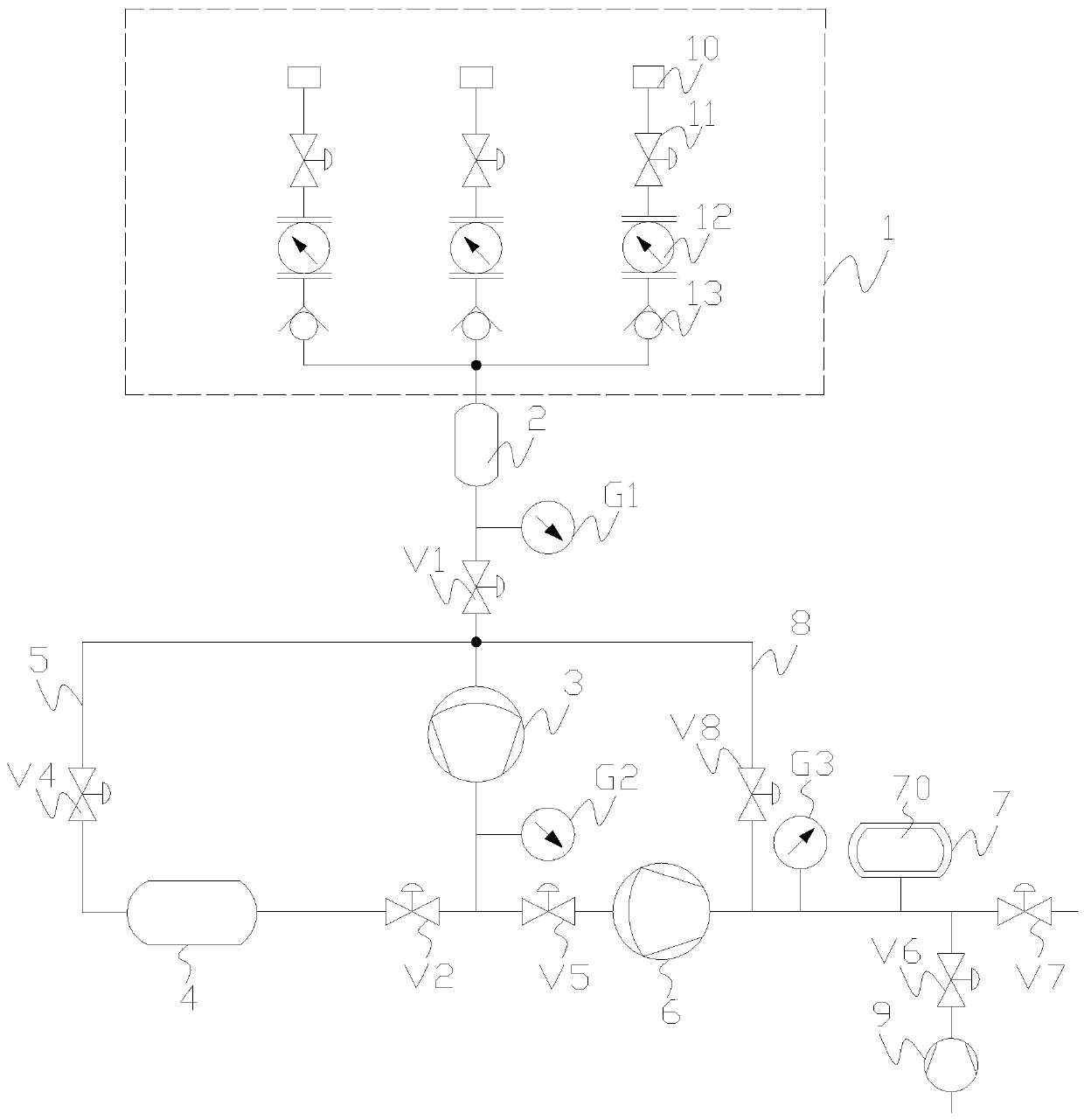

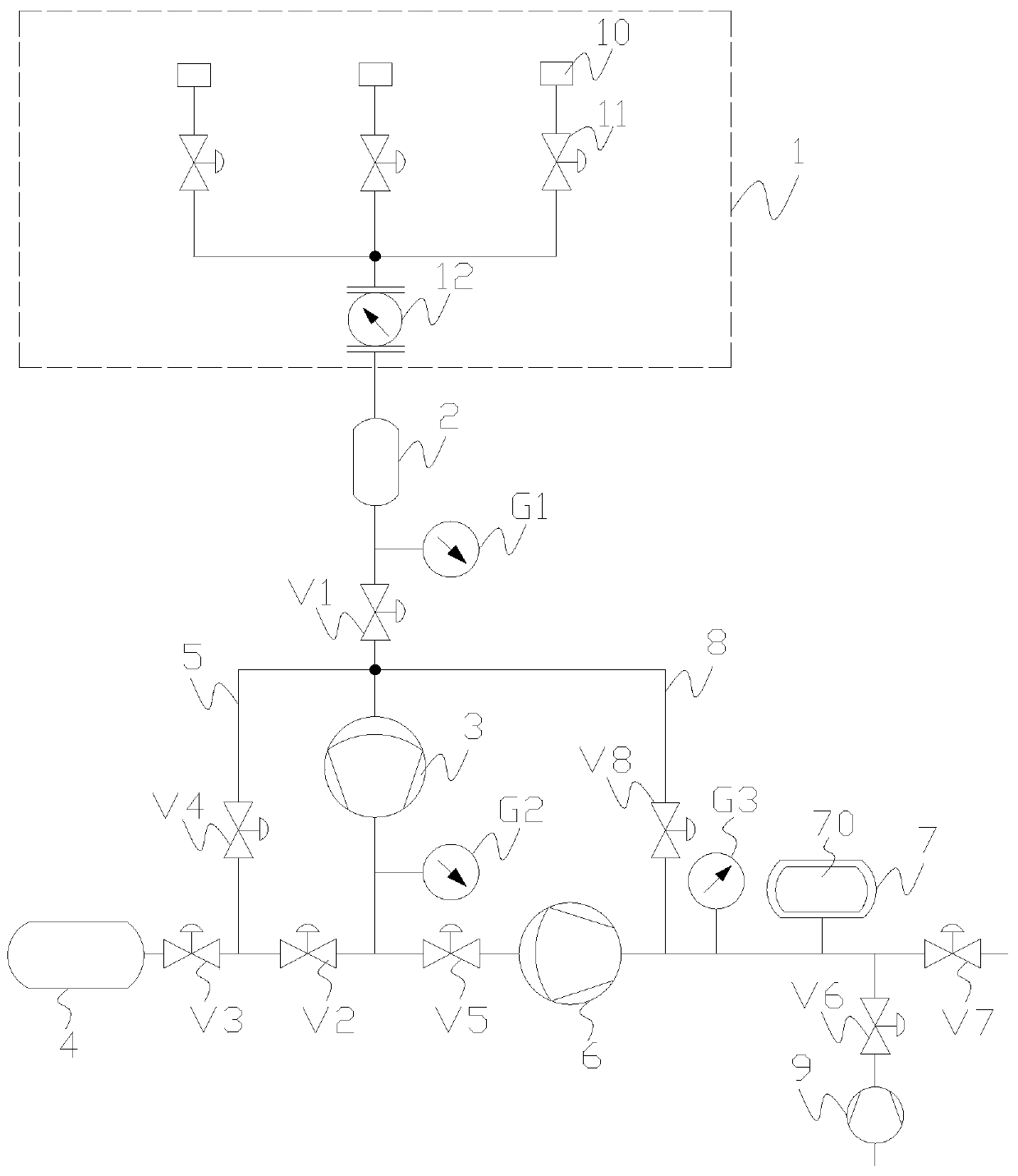

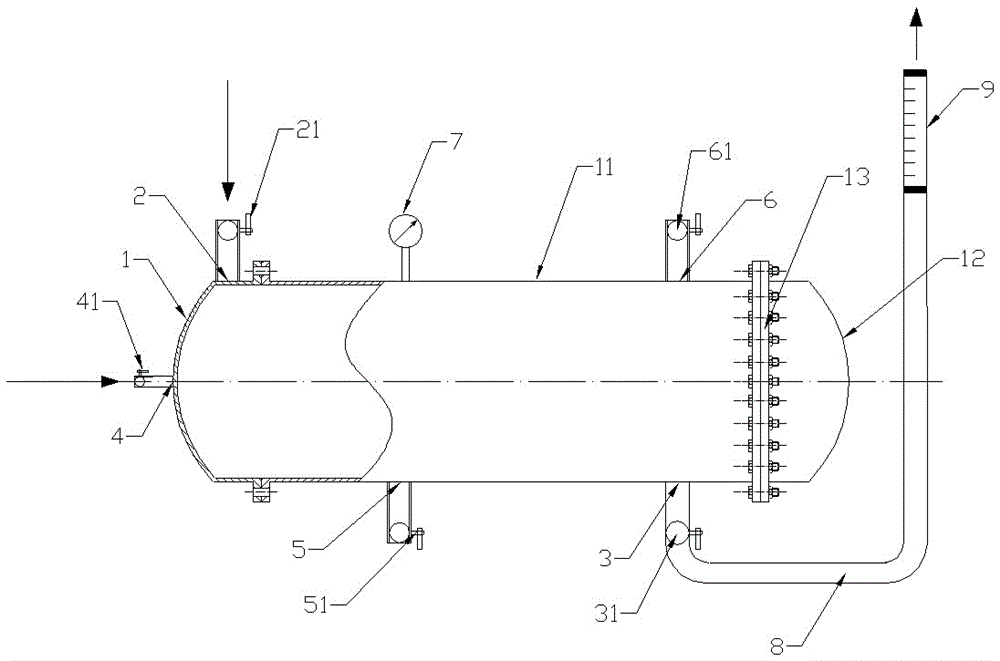

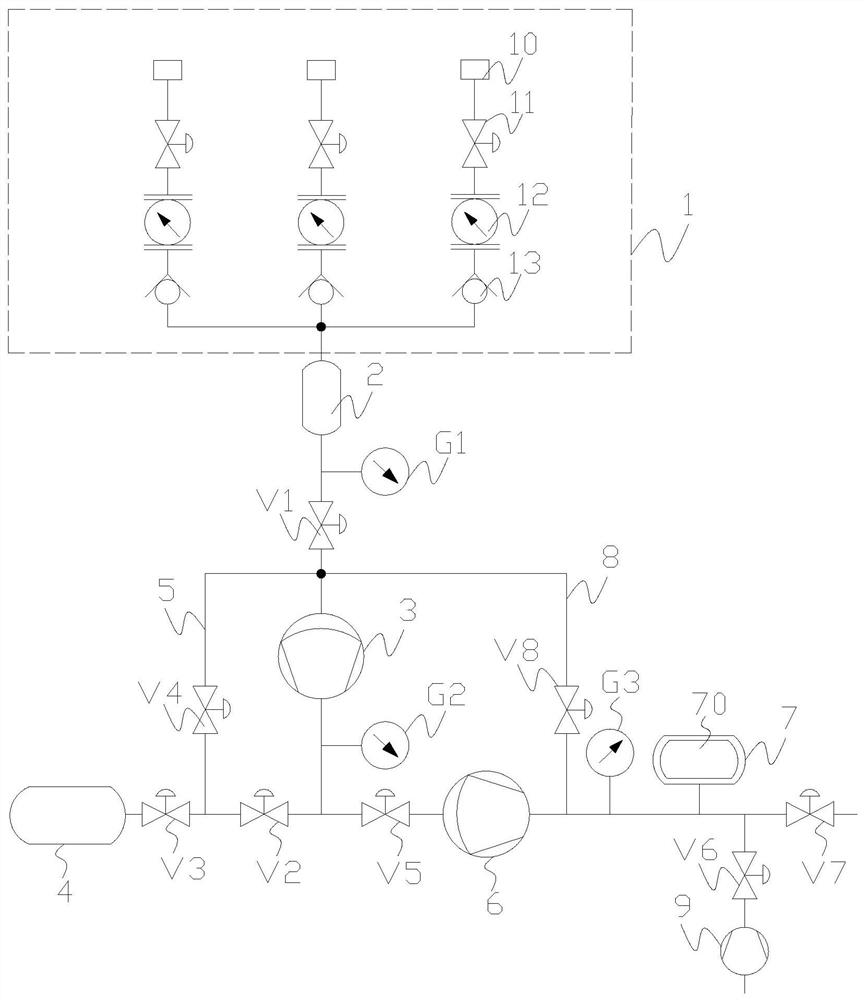

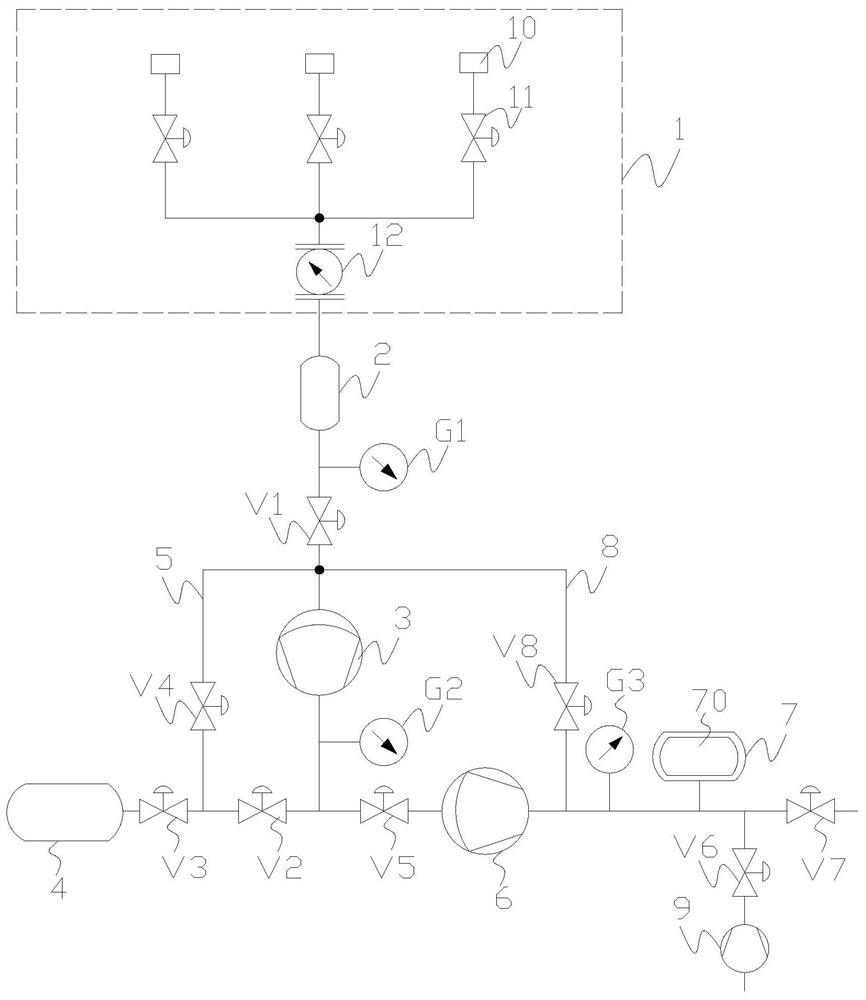

Preparation system and use method of high-pressure mixed gas

ActiveCN110801769ASolve the problem of excessive pressure requirementsSolve the problem of inaccurate matchingTransportation and packagingMixer accessoriesThermodynamicsProcess engineering

The invention relates to the field of preparation of a high-pressure gas, in particular to a preparation system and a use method of a high-pressure mixed gas. The preparation system comprises a gas source control part, a first pressurizer, a mixed gas container, a second pressurizer and a sampling bin, wherein the gas source control part is used for providing various gases required for preparing the mixed gas, wherein a gas outlet of the gas source control part is communicated with a gas inlet of the first pressurizer, a gas outlet of the first pressurizer is communicated with a mixed gas container, and the first pressurizer and the mixed gas container are matched with each other and are used for carrying out primary supercharging on a gas exhausted by the gas source control part. A gas conveying pipeline is communicated between the mixed gas container and the gas inlet of the first pressurizer; the gas outlet of the first pressurizer is further communicated with the gas inlet of the second pressurizer, the gas outlet of the second pressurizer is communicated with the sampling bin, and the first pressurizer, the second pressurizer and the sampling bin are matched with one another and used for carrying out secondary supercharging on a gas exhausted from the mixed gas container.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Integrated water and fertilizer irrigation equipment for farmland and gardens

ActiveCN107484483BTotal controlImprove the effect of real-time mixingPressurised distribution of liquid fertiliserInlet valveEnvironmental engineering

The invention discloses an integrated water and fertilizer irrigation equipment for farmland and gardens, which comprises an irrigation pipeline, a connecting head, a mixing device, a connecting pipe 1, a casing 1, a motor 1, an impeller 1, a reducer, a water inlet pipe, a high-pressure air pipe, and a pretreatment Tank, fixed block, sealing cover, spring, quantitative delivery device, fertilizer storage tank, water inlet valve, stirring paddle, base, motor two, delivery pipe, shell two, impeller two and connecting pipe two; the invention has a reasonable structure Simple, low production cost, and easy installation. Here, the fertilizer in the fertilizer storage tank is firstly transported to the pretreatment tank through the quantitative delivery device, and then the water inlet valve is started to enter an appropriate proportion of water into the pretreatment tank, and then through the high-pressure air pipe to the pretreatment tank. Compressed air enters the pretreatment tank, and the reducer installed here can ensure that the output ratio of water and fertilizer solution is consistent. Finally, the water and fertilizer solution are further mixed by the mixing device and then sent to the irrigation pipeline for farmland. Gardens are irrigated.

Owner:YANTAI ZHIXING INTPROP CONSULTATION SERVICES CO LTD

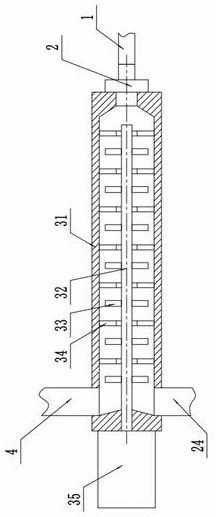

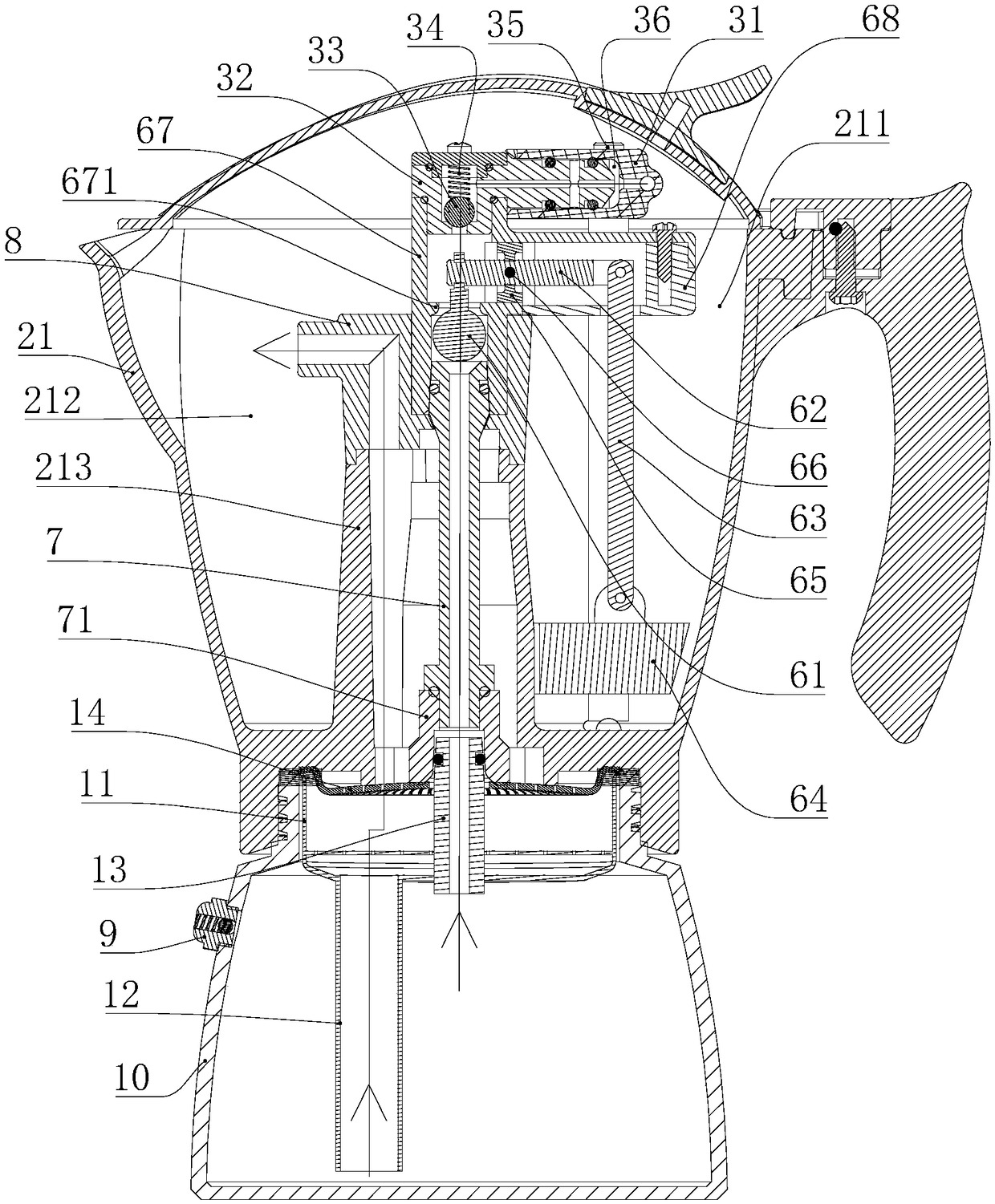

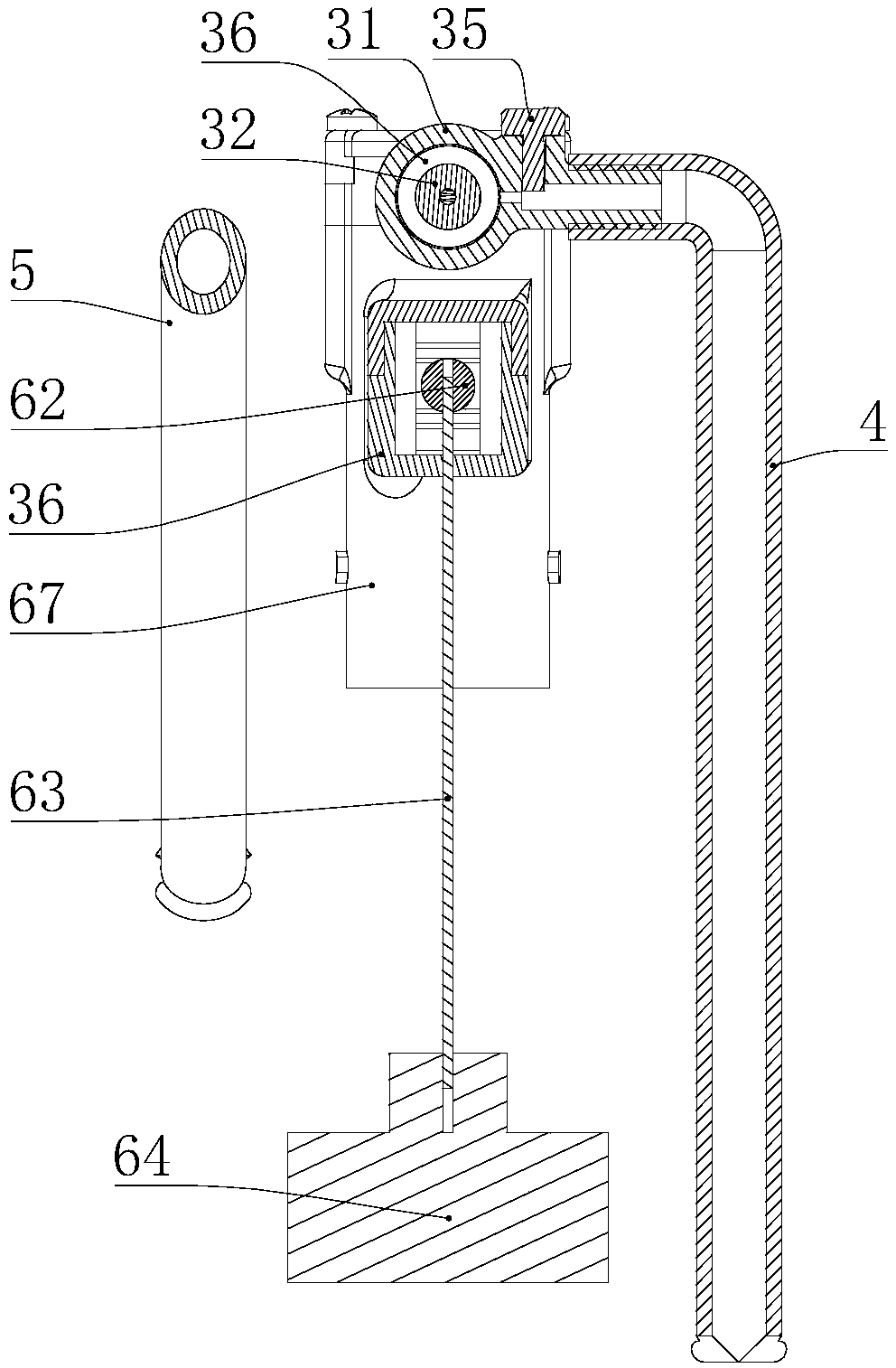

Milk coffee pot

The invention belongs to the technical field of coffee machines, in particular to a milk coffee pot capable of simultaneously brewing and brewing coffee on milk. The lower body assembly comprises a lower cup body, a funnel sleeved in the lower cup body, a water guide pipe extending downward and a steam pipe extending upward are arranged on the funnel. The upper body assembly includes an upper cupbody, a function conversion assembly disposed in the upper cup body and in communication with a steam pipe, and a milk foamer, the upper cup body including a milk chamber and a coffee milk chamber, asuction tube on the milk foamer extending to the milk chamber, and a milk outlet tube on the milk foamer extending to the coffee milk chamber. The upper cup body is also provided with a coffee water outlet communicating with a water guide pipe, and the coffee water outlet is located at the upper part of the coffee milk room. When in use, the steam in the lower cup drains the milk in the milk chamber to the coffee milk chamber through the milk sucking pipe and the milk outlet pipe through the negative pressure generated by the milk foaming device. The steam pressure created by boiling water introduces the water in the lower cup into the funnel through the water guide pipe and melts with the coffee powder and then drains to the coffee milk chamber for mixing with the milk foam.

Owner:胡剑彧

Method for treating and fresh-keeping sciaenops ocellatus by using acidic electrolyzed water

ActiveCN102960425BControl pHTotal controlMeat/fish preservation by freezing/coolingMeat/fish preservation using chemicalsFlavorAquatic product

Owner:ZHEJIANG OCEAN UNIV

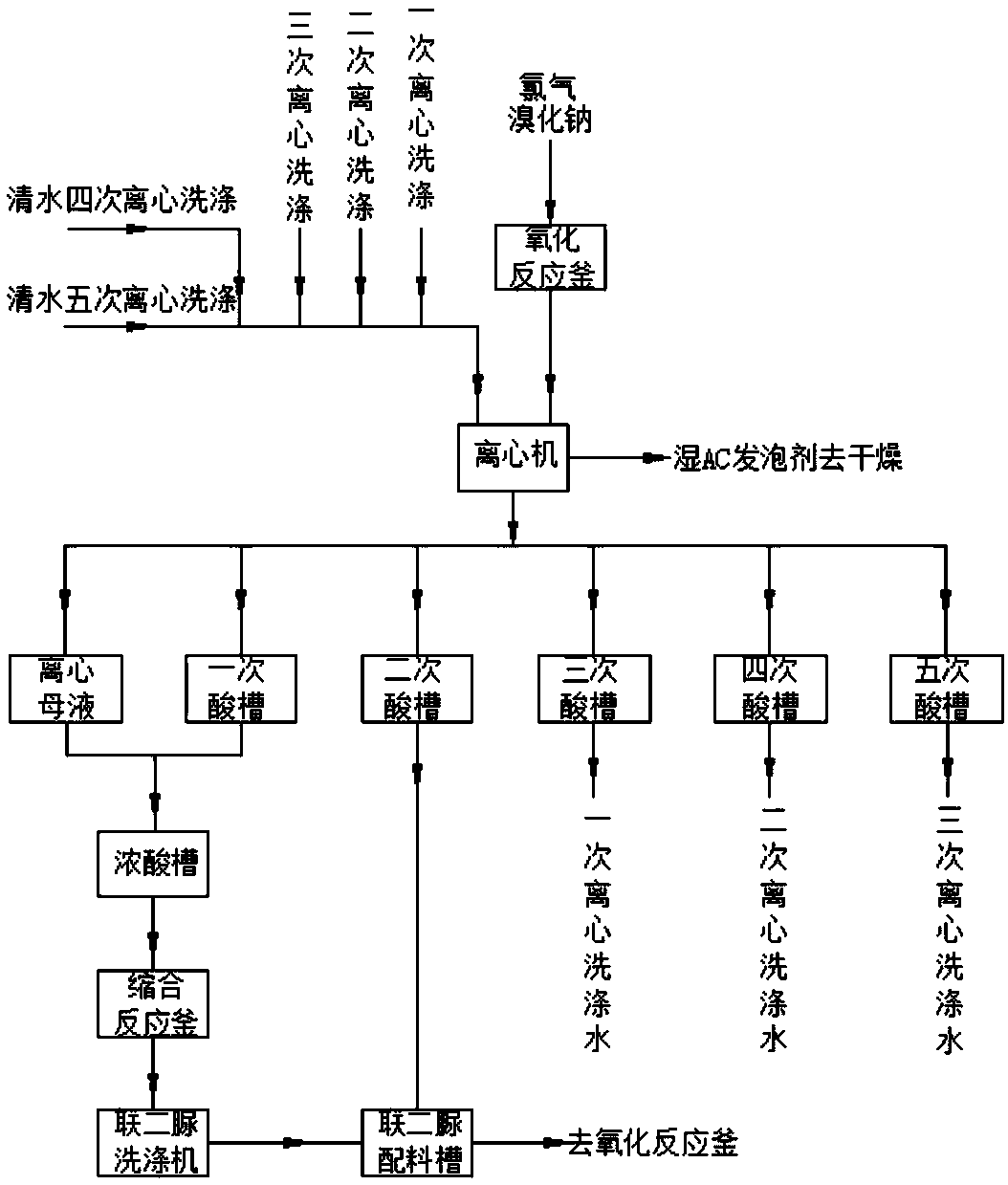

Method for recycling hydrochloric acid in production process of AC foaming agent

The invention provides a method for recycling hydrochloric acid in the production process of an AC foaming agent. The method includes the steps that (1) an oxidation mother solution is obtained by chlorine oxidizing biurea; (2) the oxidation mother solution is subjected to centrifugal separation to obtain the AC foaming agent and a centrifugal mother solution; (3) the AC foaming agent is subjectedto centrifugal washing for at least three times, removal solutions for centrifugal washing at different times are recycled to different containers correspondingly, and the removal solutions are applied to obtain primary acid and secondary acid; (4) the hydrochloric acid prepared from the centrifugal mother solution is used for a condensation reaction, wherein the mass concentration of the hydrochloric acid is 20% or above; (5) the primary acid is mixed with the high concentration hydrochloric acid to prepare the hydrochloric acid with the mass concentration of 20% or above for a condensationreaction; and (6) the secondary acid is recovered and used for preparing a biurea oxidation reactor. According to the method for recycling the hydrochloric acid in the production process of the AC foaming agent, the process is simple, the recycling rate of the hydrochloric acid is high, and great economic value is achieved.

Owner:JIANGXI SELON INDAL

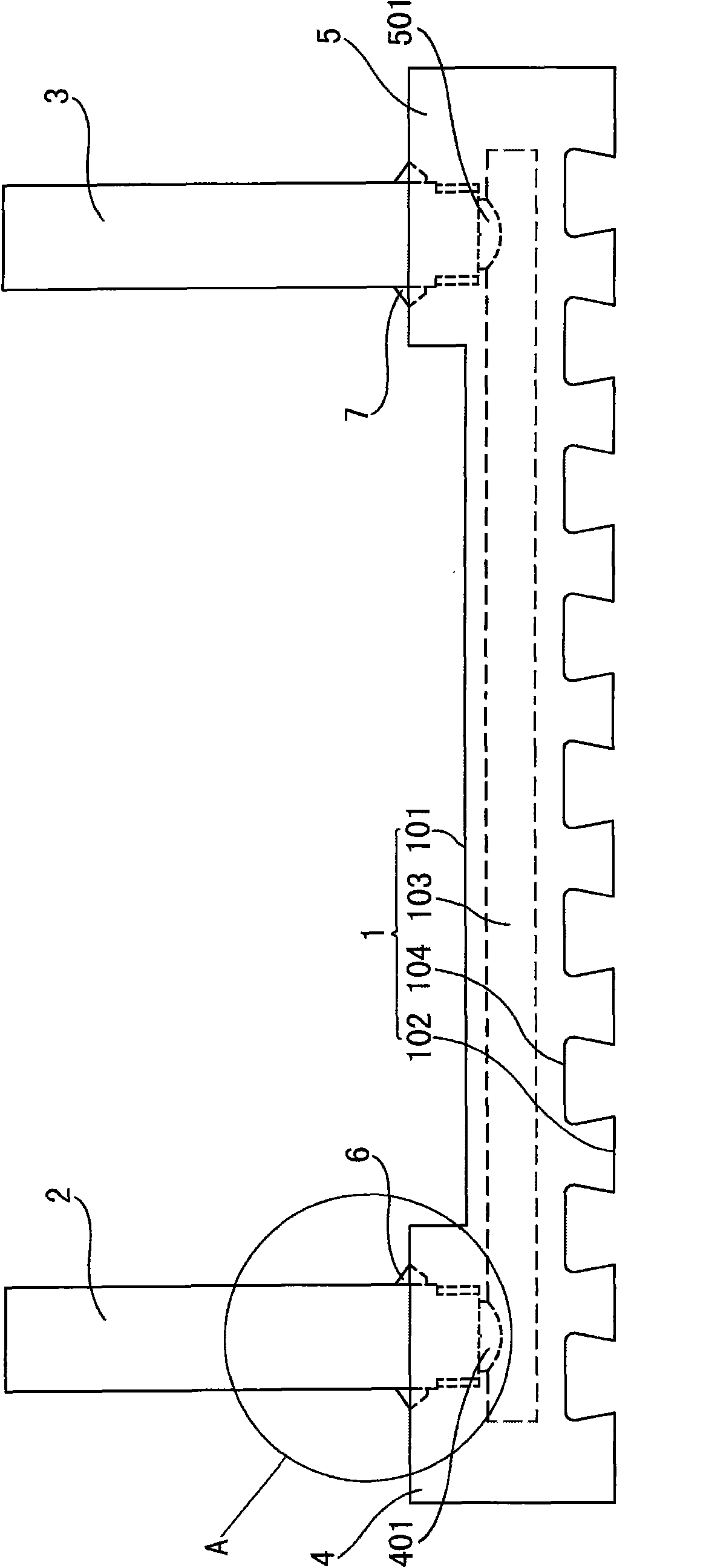

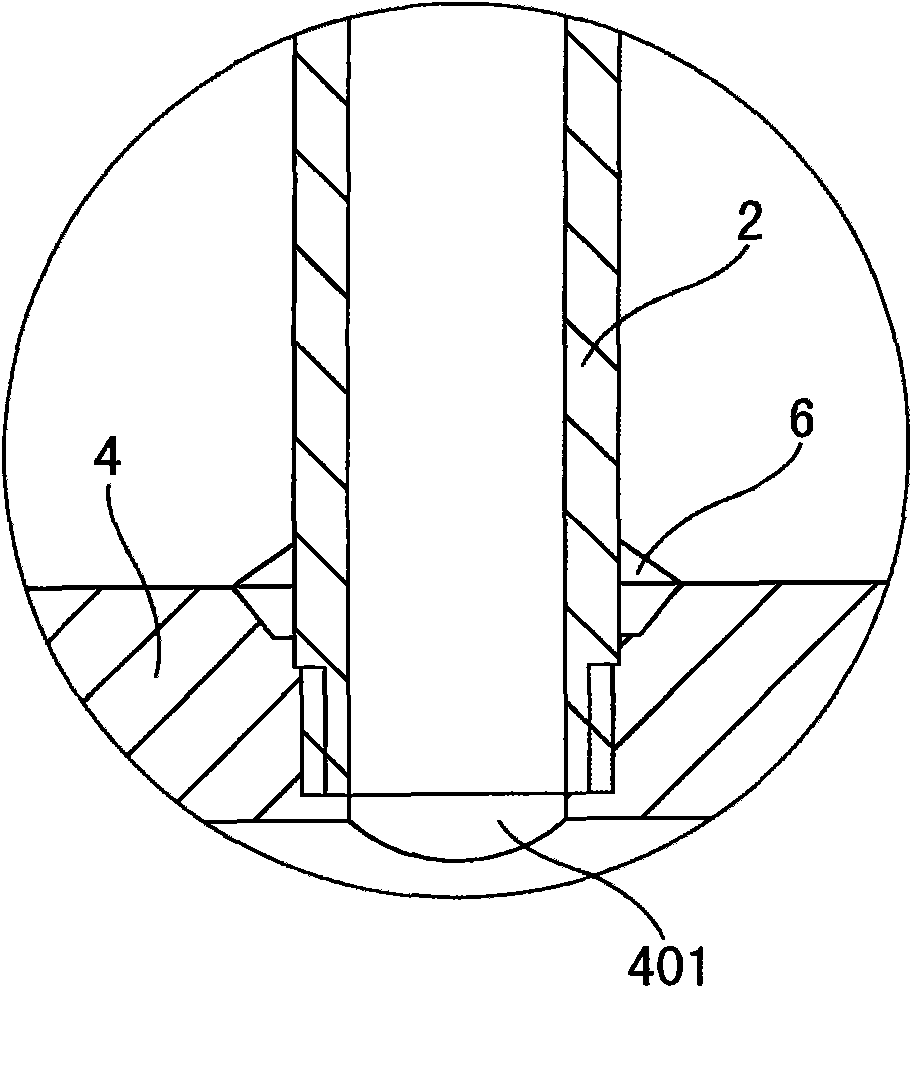

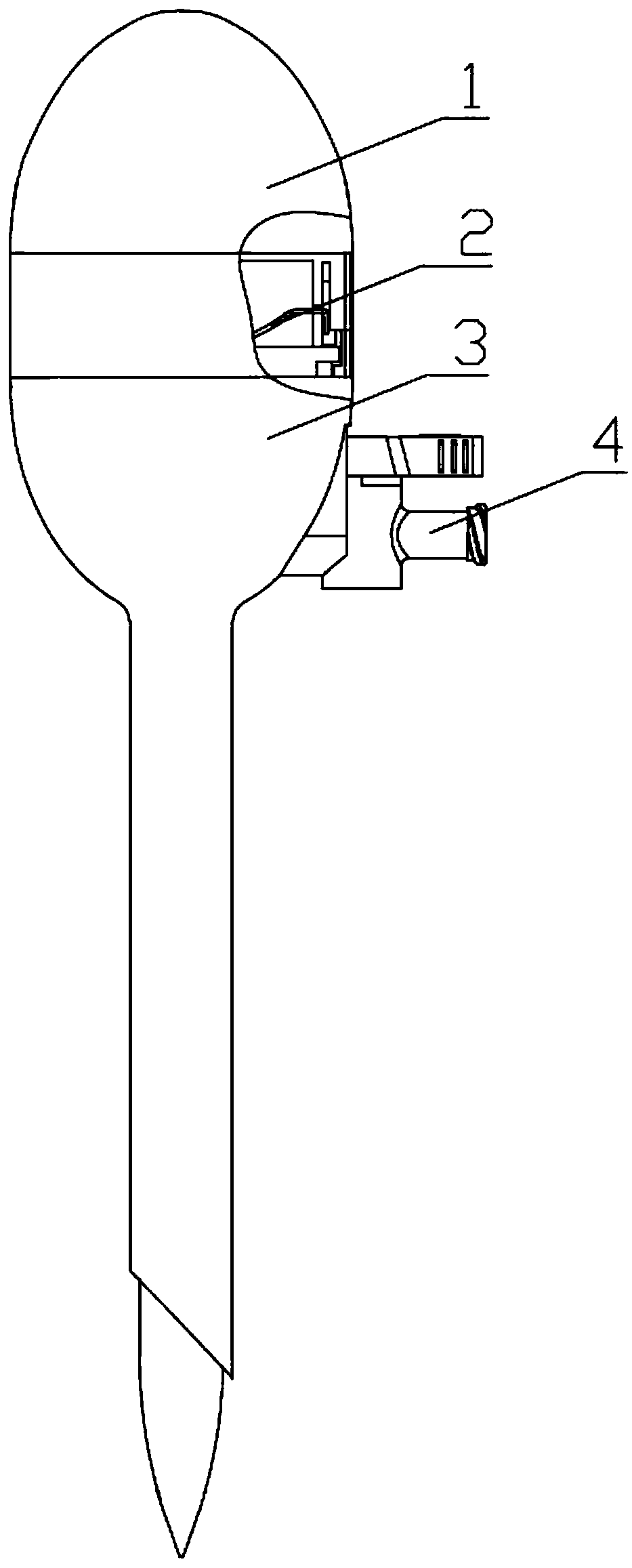

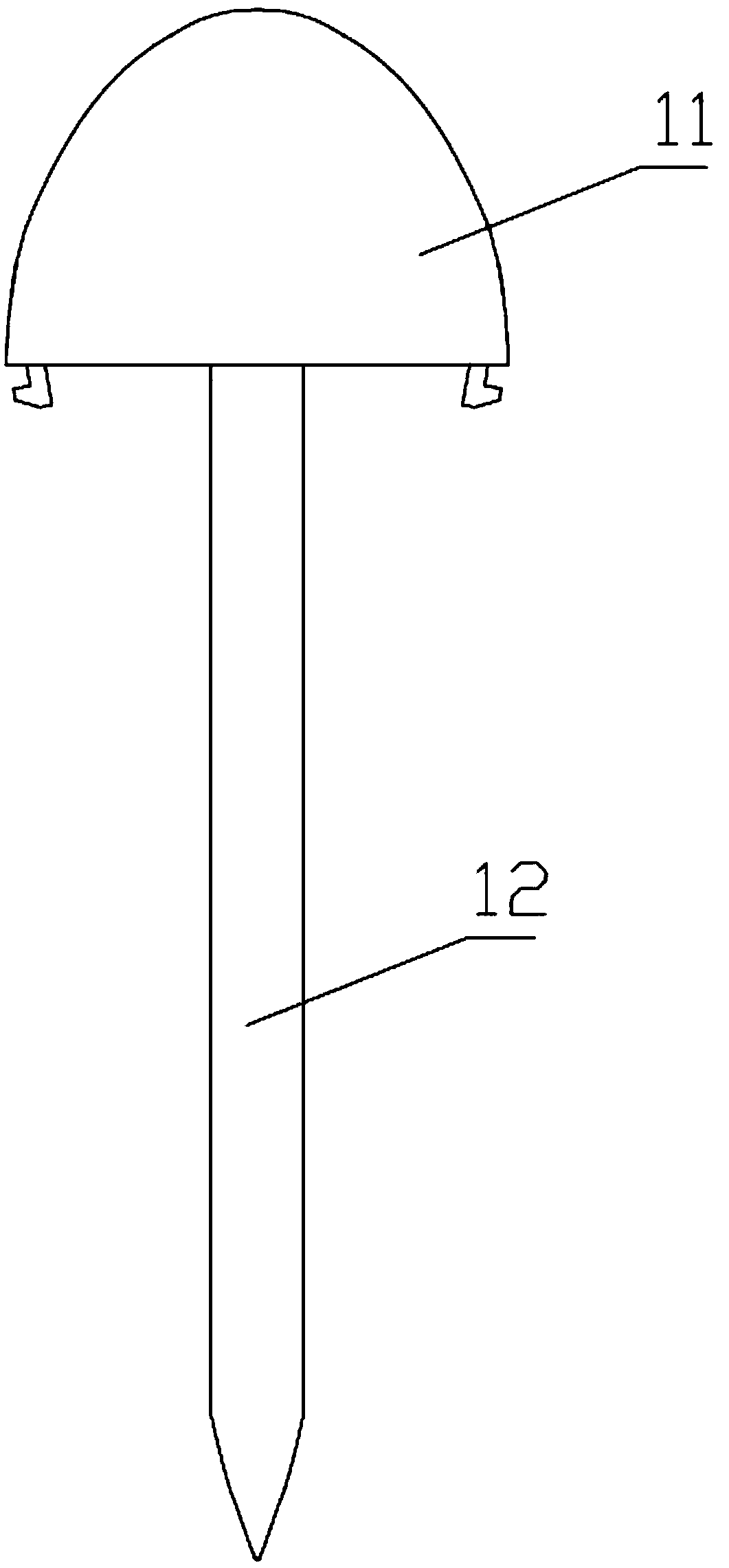

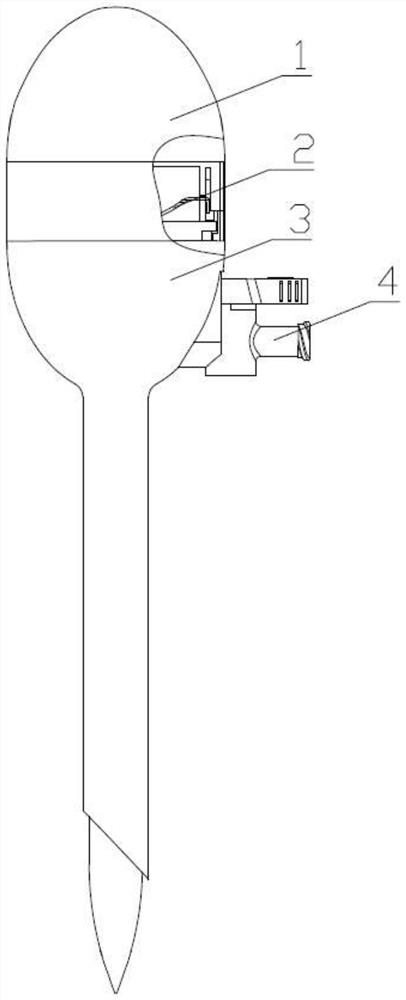

Puncture outfit for endoscope surgery

ActiveCN109288562ASmooth in and outGuaranteed smoothnessCannulasSurgical needlesSilica gelSurgery procedure

The invention discloses a puncture outfit for endoscope surgery. The puncture outfit comprises a puncture sleeve, a sealing element, a puncture rod assembly and an air inlet assembly. The sealing element is made of silica gel containing a lubricant. The puncture rod assembly comprises a puncture rod base and a puncture rod. The puncture rod is a diameter-consistent rod body. The tail end of the puncture rod is connected with the puncture rod base. The head end of the puncture rod shrinks to form a multi-edge conical shape. The head end of the puncture rod penetrates through the sealing elementand is then inserted in the puncture sleeve. The puncture rod is made of a medical high-polymer material containing an acid amide lubricant. The acid amide lubricant is made of oleamide, and the content of oleamide accounts for 1% of the total mass of the medical high-polymer material. By the combined improvement of the sealing element and the puncture rod assembly, the puncture outfit for endoscope surgery has a self-lubricating function, and the puncture rod and a surgical instrument can smoothly enter and leave the puncture sleeve under the condition of ensuring the sealing performance ofthe sealing element.

Owner:SHANGHAI KANGDELAI ENTERPRISE DEV GRP CO LTD

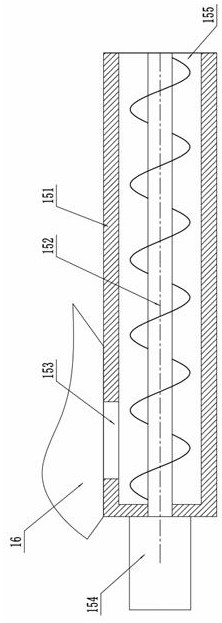

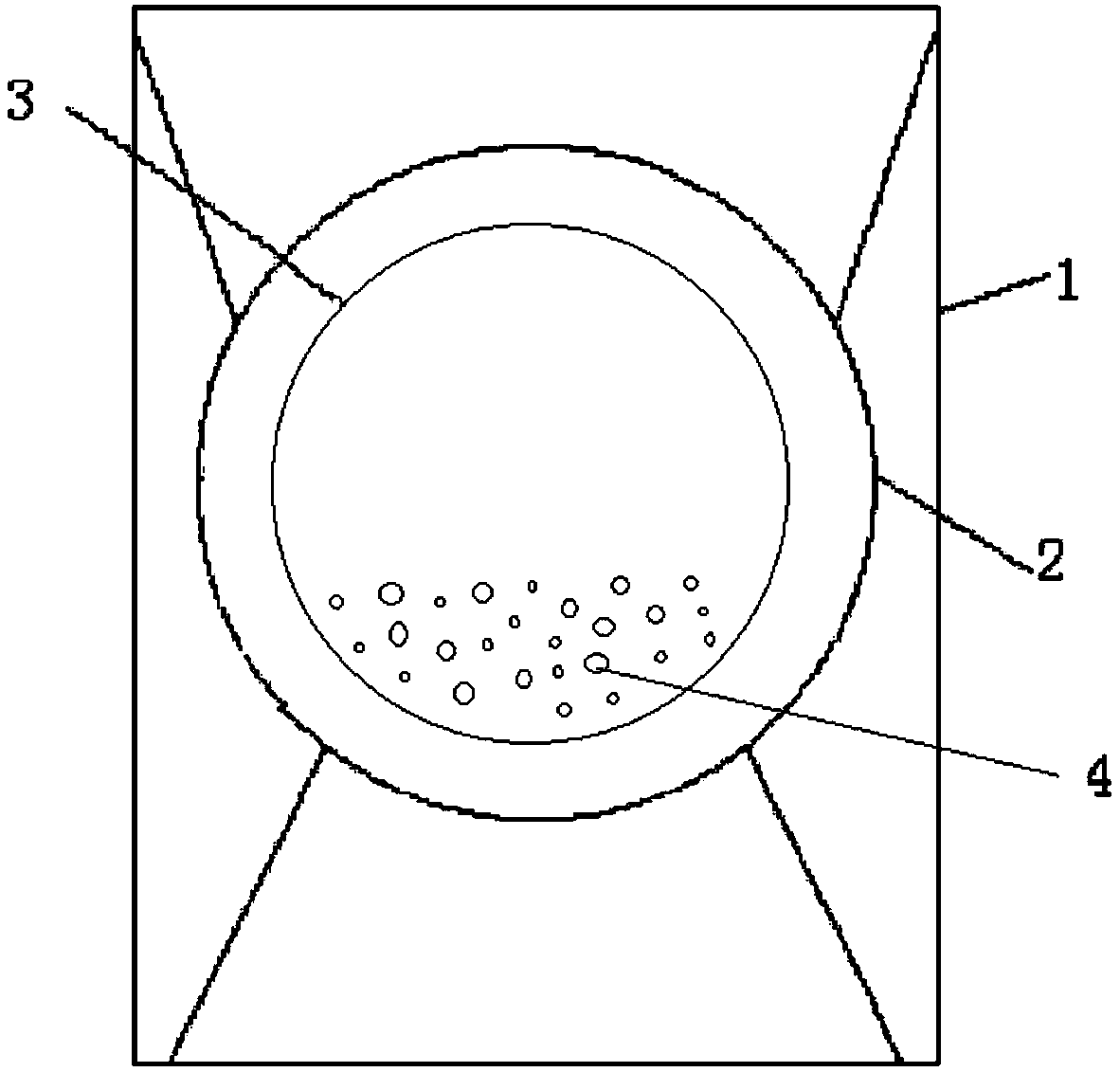

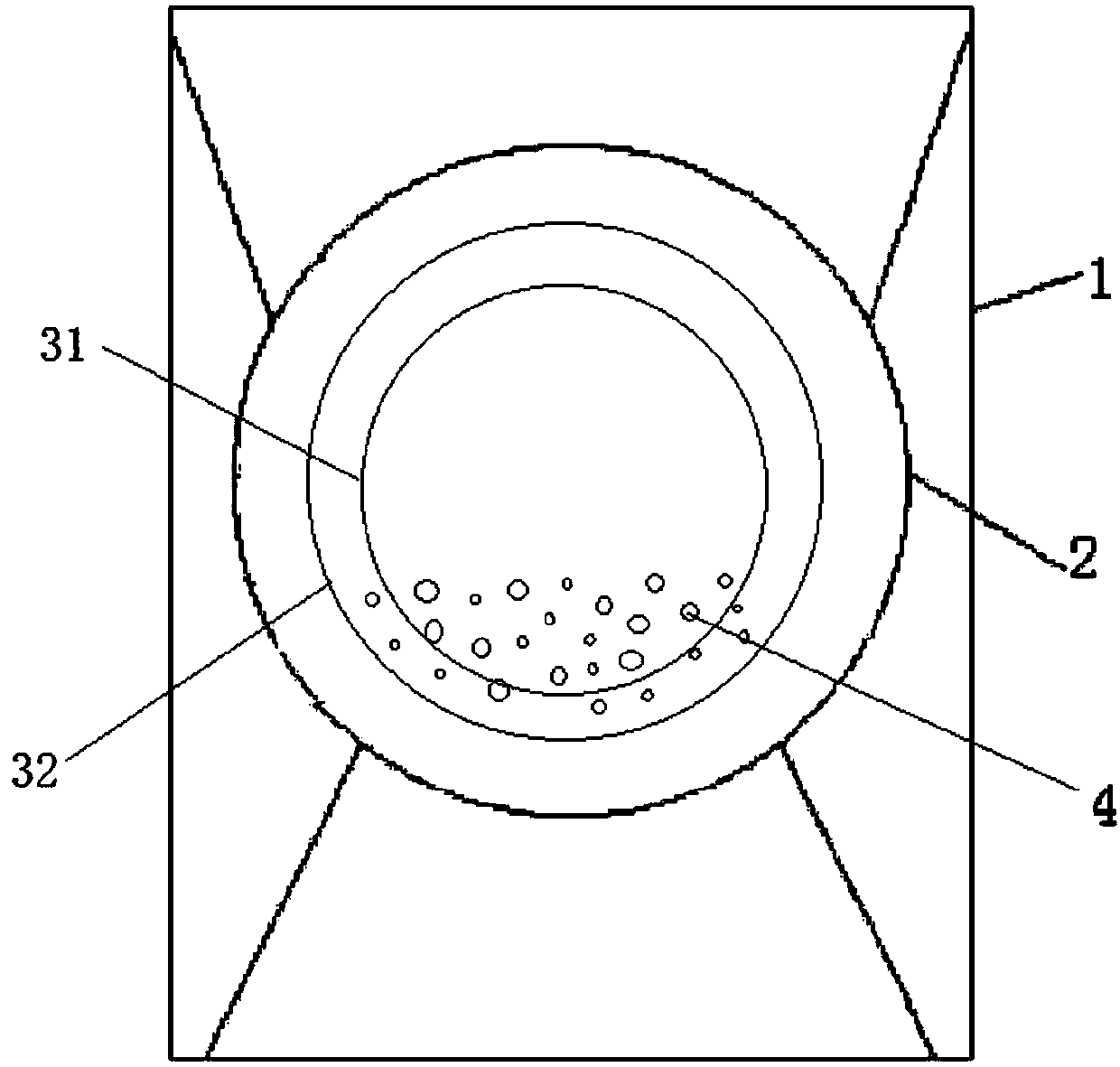

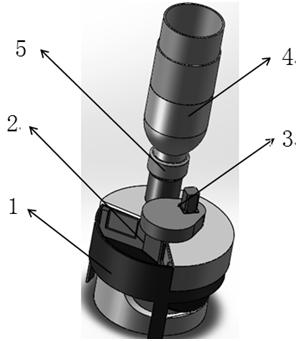

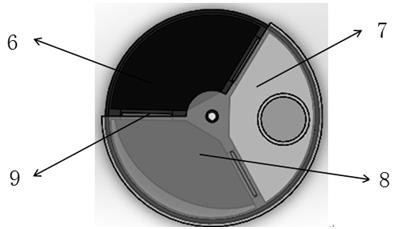

A device for automatic feeding of pets and its application method

ActiveCN108371110BImplement the cleanup functionTotal controlAnimal feeding devicesBiotechnologyAgricultural science

The invention discloses a device for automatically feeding pets and a using method thereof. The device is characterized in that a bottom fixed drum and a cylindrical cam (1) are mainly responsible forinstalling, fixing and bearing the complete device; a guide rail is responsible for opening and closing a rotary feeding plate; the rotary feeding plate (2) is mainly responsible for dividing a feeding device into three zones, i.e., a feeding zone, a loading zone and a residue cleaning zone and realizing conversion of the three zones through a rotary power mechanism and a control system (3); an adjustable material barrel (4) is mainly responsible for adding food in the rotary feeding plate and correspondingly adjusting the capacity of the adjustable material barrel according to the length oftime during a time period that no people take care of the pets; a food intake capacity adjuster (5) in a feeding inlet is mainly responsible for adjusting the amount of feed added every time accordingto the food intake amount of the pets. The device disclosed by the invention is simple in structure, all motions of automatic feeding can be realized without manual assistance, the reliability is high, and automation of an automatic pet feeding system is propelled.

Owner:何禹诺

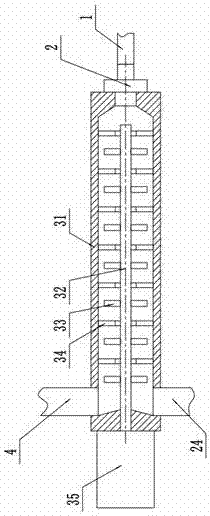

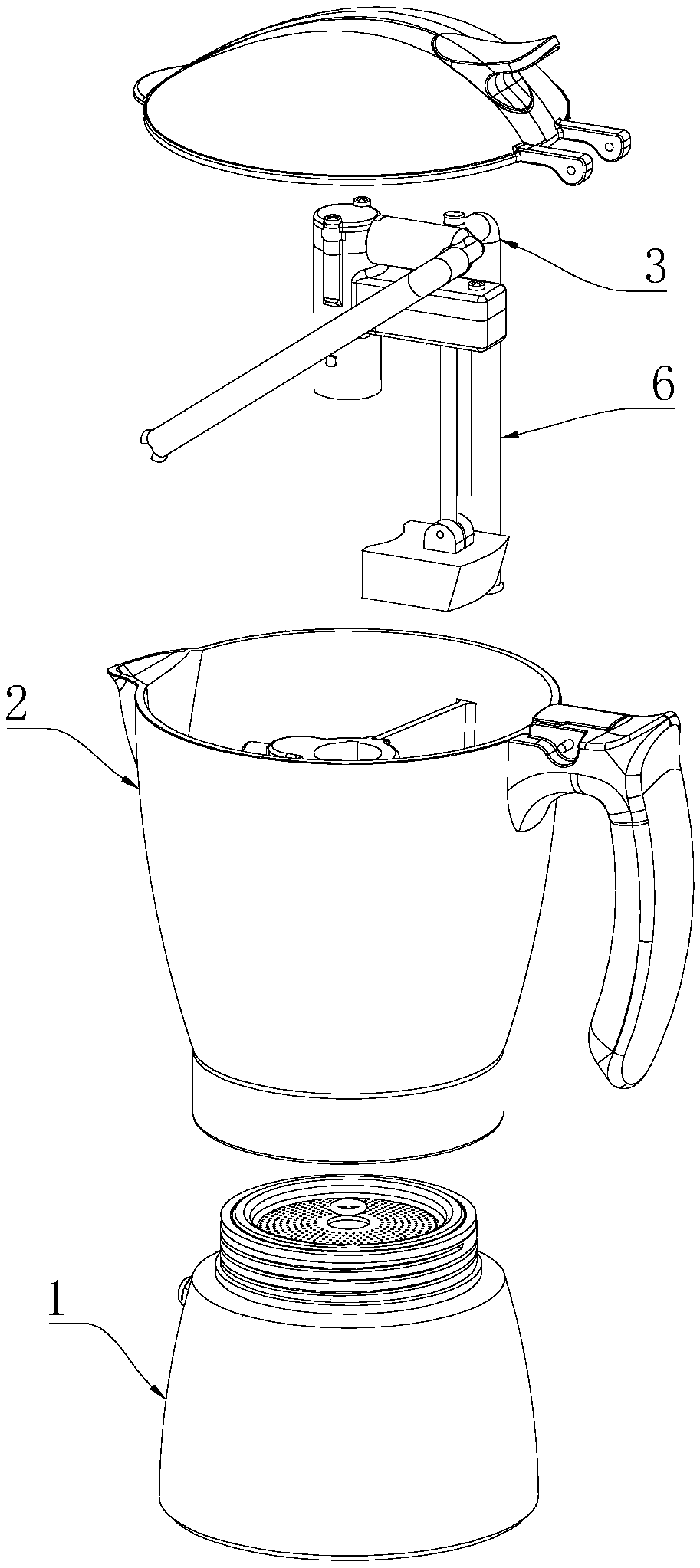

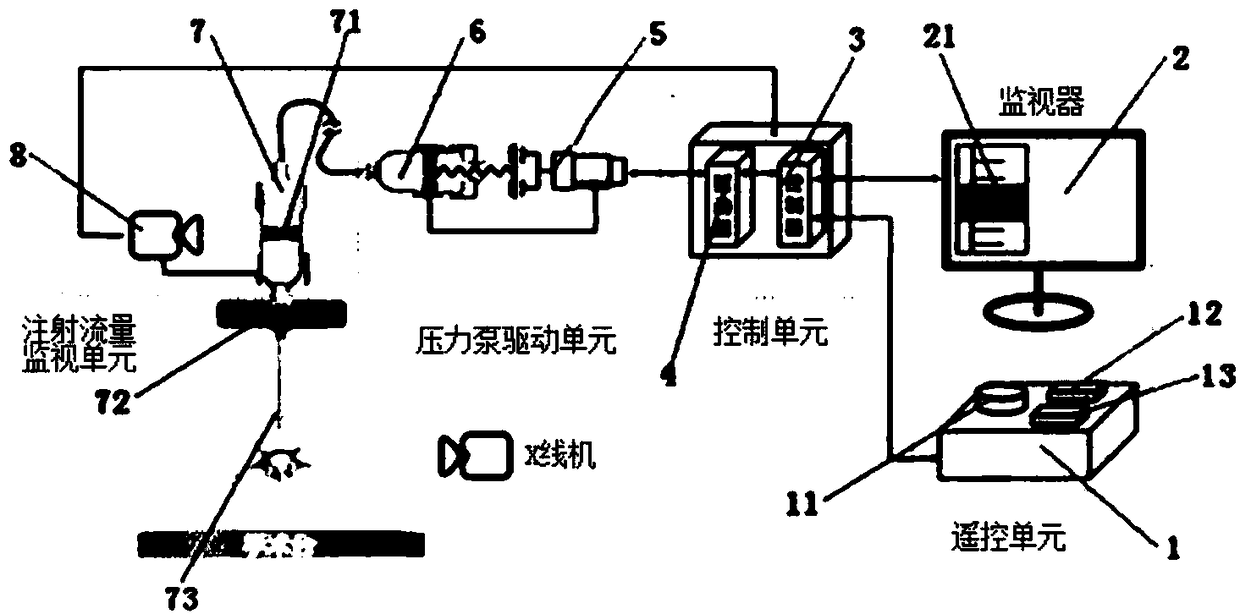

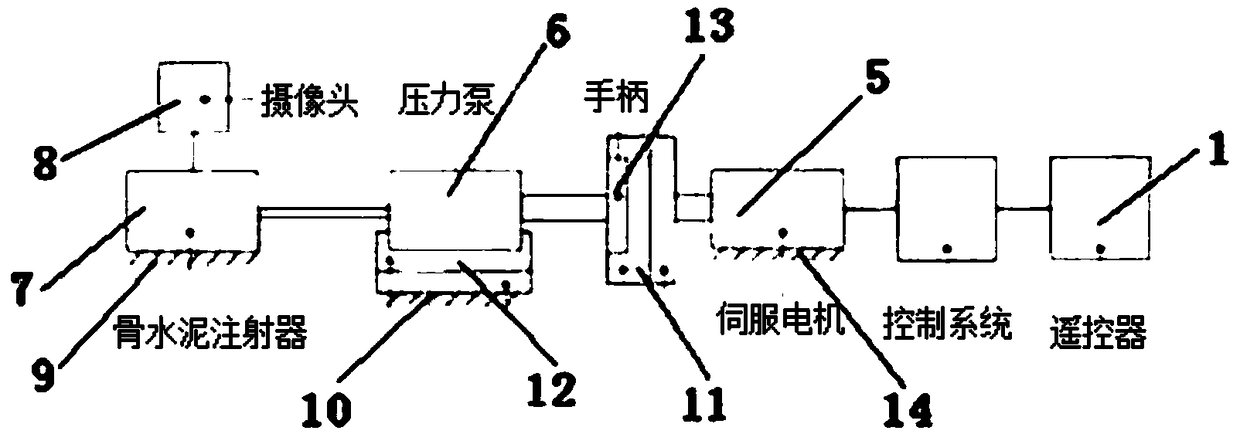

A remote control injection device for bone cement

ActiveCN106725815BTotal controlEasy to monitor in real timeOsteosynthesis devicesRemote controlEngineering

The invention provides a remotely-controlled bone cement injection device. The remotely-controlled bone cement injection device comprises a remote control unit, a control unit, a driving unit and an injection flow monitoring unit; the remote control unit comprises a remote controller and a monitor, the remote controller is connected with the input end of the control unit, and the monitor is connected with the output end of the control unit; the output end of the control unit is connected with the input end of the driving unit, and the output end of the driving unit is connected with the input end of the injection flow monitoring unit. The remotely-controlled bone cement injection device is simple in structure and convenient to operate and can not only achieve real-time monitoring on the injection dose and speed of an injector, but also effectively avoid radiation damage to a doctor in the operation process.

Owner:赵建武

A video key frame extraction method

The invention discloses a method for extracting a video key frame, and belongs to the field of video data processing. The method for extracting the video key frame comprises the steps that the gray level mass centers of video frames are calculated, a video frame sequence is segmented into a plurality of frame sequences with vision similarity continuity according to the distance of the gray level mass centers of the adjacent frames and the distance between the gray level mass center of a current video frame and the average gray level mass center of presequence vision similar frame sequences, and the key frame is selected from the vision similar frame sequences. The problems that an existing key frame extraction technology is complex in computation process and large in computation quantity are solved.

Owner:MINZU UNIVERSITY OF CHINA

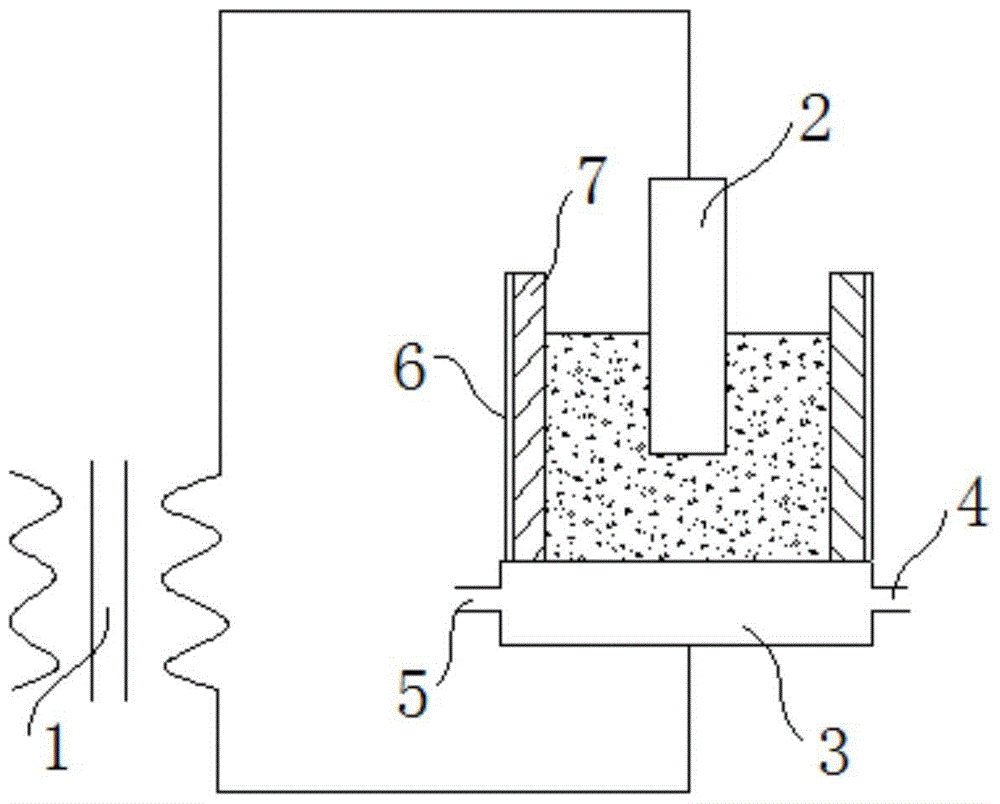

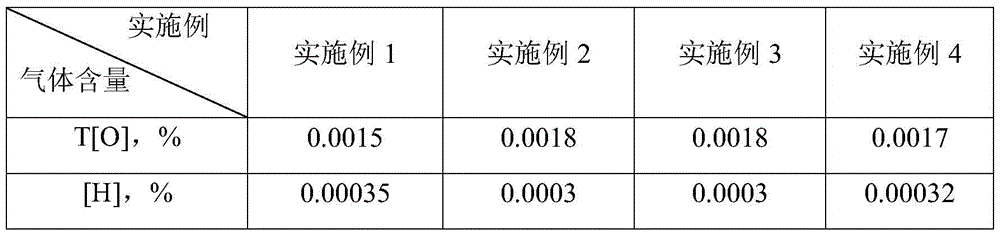

A preparation method of slag system that simultaneously controls the hydrogen-oxygen content of electroslag ingots

Owner:ANHUI FUKAI STAINLESS STEEL

Pneumatic dosing device for mine wastewater and mine wastewater treatment system

InactiveCN104291418BNot easy to damageReduce maintenance workloadWaste water treatment from quariesWater treatment parameter controlWorking environmentEconomic benefits

The invention relates to a pneumatic dosing device for mine wastewater and a processing system for the mine wastewater. The pneumatic dosing device for the mine wastewater comprises a tank body for loading a solution; the tank body is provided with a solution inlet, a solution outlet, and an air inlet for being connected to mine compressed air; the solution outlet is disposed at the bottom of the tank body; the solution outlet is connected to a solution-discharging tube for discharging the solution in the tank body to a wastewater pool; the outlet of the solution-discharging tube is higher than a liquid surface in the tank body when the pneumatic dosing device is in use. Since the dosing device takes use of the mine compressed air as a power, the power source has the advantages of stability, reliability, safety and convenience. Therefore, the dosing device is not liable to be damaged, is small in workload required for maintenance, is in no need of consuming electric energy, can brings about significant economic benefits, and effectively overcomes the problems of high cost for use and maintenance in a conventional dosing device. Besides, the dosing device has no noise in work and can provide a good work environment for workers.

Owner:永煤集团股份有限公司新桥煤矿

Liquid organic acid composite acidifying agent for livestock and preparation method of liquid organic acid composite acidifying agent

InactiveCN114451488AIncrease bactericidal functionThe bactericidal function hasAccessory food factorsWorking-up animal fodderPropanoic acidPhosphate

The invention relates to a liquid organic acid composite acidifier for livestock and a preparation method thereof. The composite acidifying agent is prepared from the following raw material components in parts by mass: 39 to 43 parts of citric acid, 16 to 40 parts of alkali, 92 to 108 parts of formic acid, 37 to 48 parts of acetic acid, 48 to 52 parts of propionic acid, 140 to 165 parts of lactic acid, 94 to 108 parts of ammonium formate, 8 to 12 parts of copper sulfate, 30 to 70 parts of phosphate and 400 to 496 parts of water. The invention also discloses a preparation method. The acidifying agent has the advantages that the acidifying agent can be prepared or diluted with tap water, the pH value is 3.8-4.0 after the acidifying agent is diluted with the tap water by 3000 times, and the acidifying agent diluted with the tap water by 1000 times, 2000 times and 3000 times has a good inhibition effect on escherichia coli and staphylococcus aureus, so that the breeding production cost is reduced.

Owner:JIANGNAN UNIV

A preparation system and method of high-pressure mixed gas

ActiveCN110801769BSolve the problem of excessive pressure requirementsSolve the problem of inaccurate matchingTransportation and packagingMixer accessoriesThermodynamicsMixed gas

The invention relates to the field of preparing high-pressure gas, in particular to a preparation system and a use method of high-pressure mixed gas. The preparation system includes a gas source control part, a first booster, a mixed gas container, a second booster, and a sampling chamber, and the gas source control part is used to provide various gases required for preparing the mixed gas. The gas outlet of the gas source control part communicates with the inlet of the first supercharger, the gas outlet of the first supercharger communicates with the mixed gas container, and the first supercharger and the mixed gas container cooperate with each other to control the gas source. The gas discharged by the control part is pressurized in the first stage. A gas delivery pipeline is communicated between the mixed gas container and the air inlet of the first supercharger, and the gas outlet of the first supercharger is also communicated with the air inlet of the second supercharger, and the gas outlet of the second supercharger Connected with the sampling chamber, the first supercharger, the second supercharger and the sampling chamber cooperate with each other, and are used for two-stage pressurization of the gas discharged from the mixed gas container.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

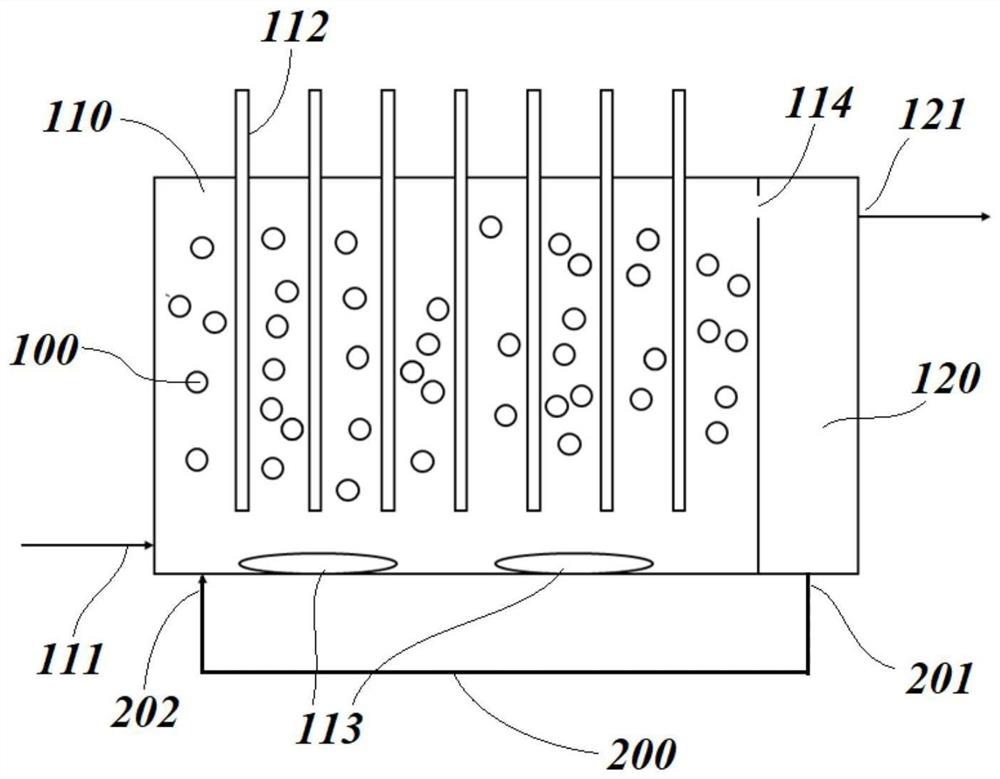

Immobilized filler, preparation method thereof as well as photosynthetic bacterium-protozoa sewage treatment device and method based on filler

ActiveCN113845236ATotal controlAvoid it happening againWater treatment parameter controlWater aerationBiotechnologyProtozoa

The invention discloses an immobilized filler, a preparation method thereof as well as a photosynthetic bacterium-protozoa sewage treatment device and method based on the filler, and belongs to the technical field of wastewater treatment. According to the immobilized filler disclosed by the invention, a starch filling and amylase etching method is adopted, so that the immobilized filler has certain mechanical strength and a substance exchange function, the internal pore diameter is large enough, a good planting space is provided for protozoa, and the protozoa can be massively propagated. According to the sewage treatment method, protozoa can prey and digest a large amount of excess sludge in the treatment area, the yield of the excess sludge in the treatment area is reduced, and the solid waste output is reduced.

Owner:NANJING INNOVATION CENT FOR ENVIRONMENTAL PROTECTION IND

A trocar for laparoscopic surgery

ActiveCN109288562BSmooth in and outGuaranteed smoothnessCannulasSurgical needlesEndoscopic surgerySilica gel

The invention discloses a puncture device for endoscopic surgery, which comprises a puncture sleeve, a seal, a puncture rod assembly and an air intake assembly, the seal is made of silica gel containing self-lubricating agent, the puncture rod assembly includes a puncture A rod base and a puncture rod, the puncture rod is an equal-diameter rod body, and the tail end of the puncture rod is connected with the puncture rod base, the head end of the puncture rod shrinks into a polygonal pyramid, and the head of the puncture rod After the end passes through the seal, it is inserted into the puncture sleeve; the puncture rod is made of medical polymer materials containing acid amide lubricants, and the acid amide lubricants use oleic acid amide. The content of oleic acid amide is 1% of the total mass of the medical polymer material. The puncture device for laparoscopic surgery of the present invention has a combined improvement of the sealing member and the puncture rod assembly, and has a self-lubricating effect, so that the puncture rod and surgical instruments can smoothly enter and exit the puncture sleeve while ensuring the sealing performance of the sealing member Tube.

Owner:SHANGHAI KANGDELAI ENTERPRISE DEV GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com