A preparation method of slag system that simultaneously controls the hydrogen-oxygen content of electroslag ingots

A simultaneous control and electroslag ingot technology, applied in the field of electroslag remelting slag system, can solve the problems of low hydrogen permeability, inability to effectively control the oxygen content and hydrogen content of steel ingots, reduce the hydrogen and oxygen content of steel ingots, and achieve reduction Hydrogen content, improve production efficiency and economic benefits, and prevent moisture absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

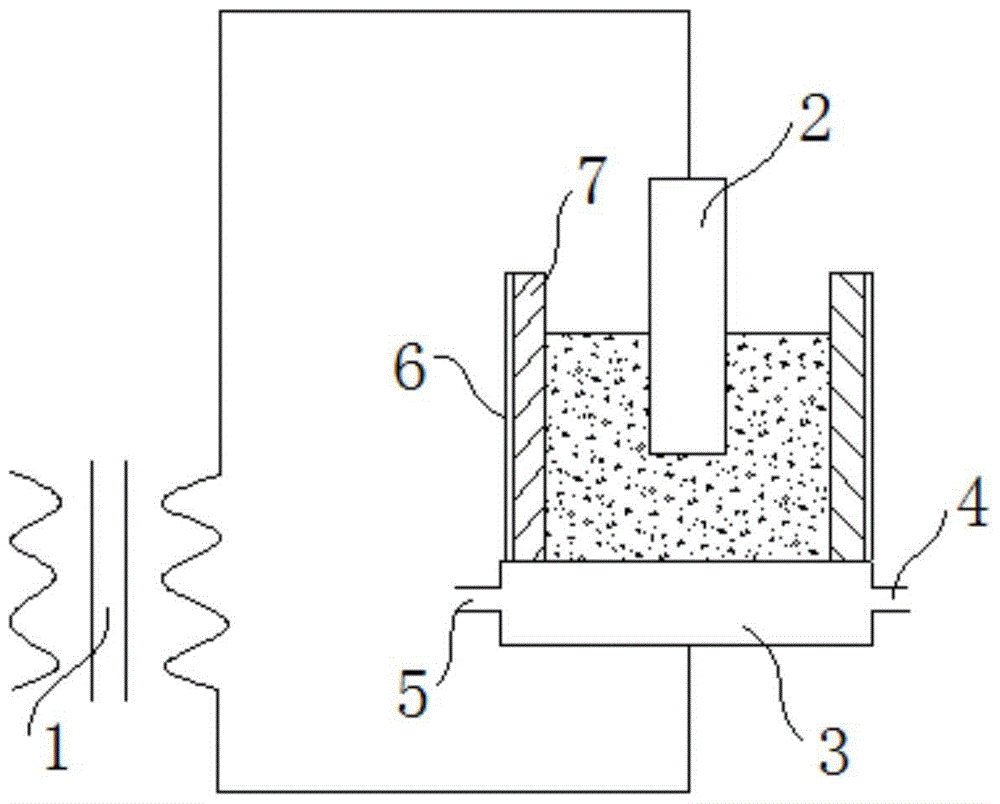

Image

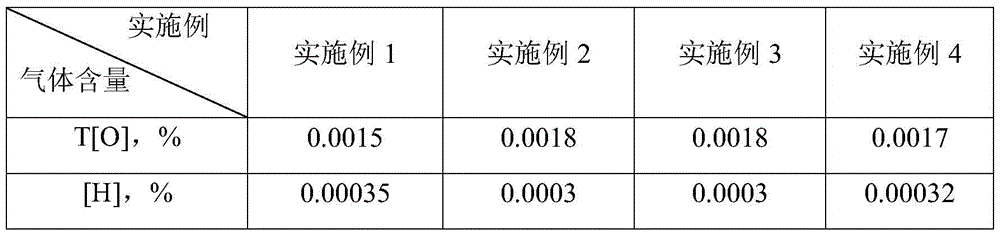

Examples

Embodiment 1

[0032] A new slag system that simultaneously controls the hydrogen-oxygen content of electroslag ingots in this embodiment, the composition and weight percentage of the slag system are: CaF 2: 43%, CaO: 22%, Al 2 o 3 : 6%, MgO: 8%, Ce 2 o 3 : 16%, La 2 o 3 : 5%. The steps of its preparation method are specifically:

[0033] Step 1. According to the requirements of preparing slag components and weight percentage, the slag material is configured in proportion and mixed evenly. The slag material is limestone, dolomite, fluorite, bauxite, cerium oxide powder and lanthanum oxide powder. In this embodiment The slag composition and weight percentage are: CaF 2 : 43%, CaO: 22%, Al 2 o 3 : 6%, MgO: 8%, Ce 2 o 3 : 16%, La 2 o 3 : 5%; Wherein: the mass percent of CaO in the limestone>54%, particle size 2~5mm; the mass percent of MgO in the dolomite>20%, the mass percent of CaO>30%, particle size 2~5mm; Medium CaF 2 The mass percentage of bauxite is >90%, and the particle s...

Embodiment 2

[0040] A new slag system that simultaneously controls the hydrogen-oxygen content of electroslag ingots in this embodiment, the composition and weight percentage of the slag system are: CaF 2 : 45%, CaO: 20%, Al 2 o 3 : 5%, MgO: 10%, Ce 2 o 3 : 14%, La 2 o 3 : 6%. The steps of its preparation method are specifically:

[0041] Step 1. According to the requirements of preparing slag components and weight percentage, the slag material is configured in proportion and mixed evenly. The slag material is limestone, dolomite, fluorite, bauxite, cerium oxide powder and lanthanum oxide powder. In this embodiment The slag composition and weight percentage are: CaF 2 : 45%, CaO: 20%, Al 2 o 3 : 5%, MgO: 10%, Ce 2 o 3 : 14%, La 2 o 3 : 6%; Wherein: the mass percent of CaO in the limestone>54%, particle size 2~5mm; the mass percent of MgO in the dolomite>20%, the mass percent of CaO>30%, particle size 2~5mm; Medium CaF 2 The mass percentage of bauxite is >90%, and the particl...

Embodiment 3

[0046] A new slag system that simultaneously controls the hydrogen-oxygen content of electroslag ingots in this embodiment, the composition and weight percentage of the slag system are: CaF 2 : 47%, CaO: 18%, Al 2 o 3 : 4%, MgO: 12%, Ce 2 o 3 : 14%, La 2 o 3 : 5%. The steps of its preparation method are specifically:

[0047] Step 1. According to the requirements of preparing slag components and weight percentage, the slag material is configured in proportion and mixed evenly. The slag material is limestone, dolomite, fluorite, bauxite, cerium oxide powder and lanthanum oxide powder. In this embodiment The slag composition and weight percentage are: CaF 2 : 47%, CaO: 18%, Al 2 o 3 : 4%, MgO: 12%, Ce 2 o 3 : 14%, La 2 o 3 : 5%; Wherein: the mass percent of CaO in the limestone>54%, particle size 2~5mm; the mass percent of MgO in the dolomite>20%, the mass percent of CaO>30%, particle size 2~5mm; Medium CaF 2 The mass percentage of bauxite is >90%, and the particl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com