Novel safe and environment-friendly coating equipment

A safe and environmentally friendly, coating equipment technology, applied in the device, coating and other directions of coating liquid on the surface, can solve problems such as adverse health, impact, etc., to reduce pollution, reduce direct contact, and uniformly coat substrates. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

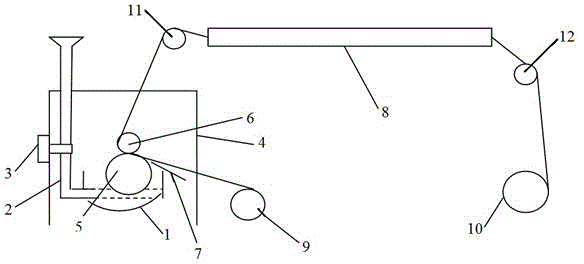

[0014] Such as figure 1 As shown, the novel safety and environmental protection coating equipment described in the embodiment of the present invention is mainly composed of an unwinding device 9, a coating device, a drying device 8, and a winding device 10. The coating device is composed of a coating roller 5, a rubber The roller 6 and the scraper 7 are composed, the coating roller 4 is connected with the rubber roller 5 rollingly, and the first traction roller 11 is arranged between the coating device and the drying device 8, and the drying device 8 and the winding device 10 A second pulling roller 12 is arranged between them.

[0015] A protective cover 4 is installed on the coating device, and a slit parallel to the coating roller 5 for film retraction is respectively arranged on the upper side and the side of the protective cover 4 . The protective cover 4 has a square structure and is made of transparent material. The protective cover 4 is a polymer composite material, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com