Method for recycling hydrochloric acid in production process of AC foaming agent

A hydrochloric acid recycling and production process technology, applied in organic chemistry and other directions, can solve the problems of complex process, difficult recovery, low hydrochloric acid reuse rate, etc., and achieve the effects of reducing costs, reducing the content of impurities, and controlling the reaction end point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

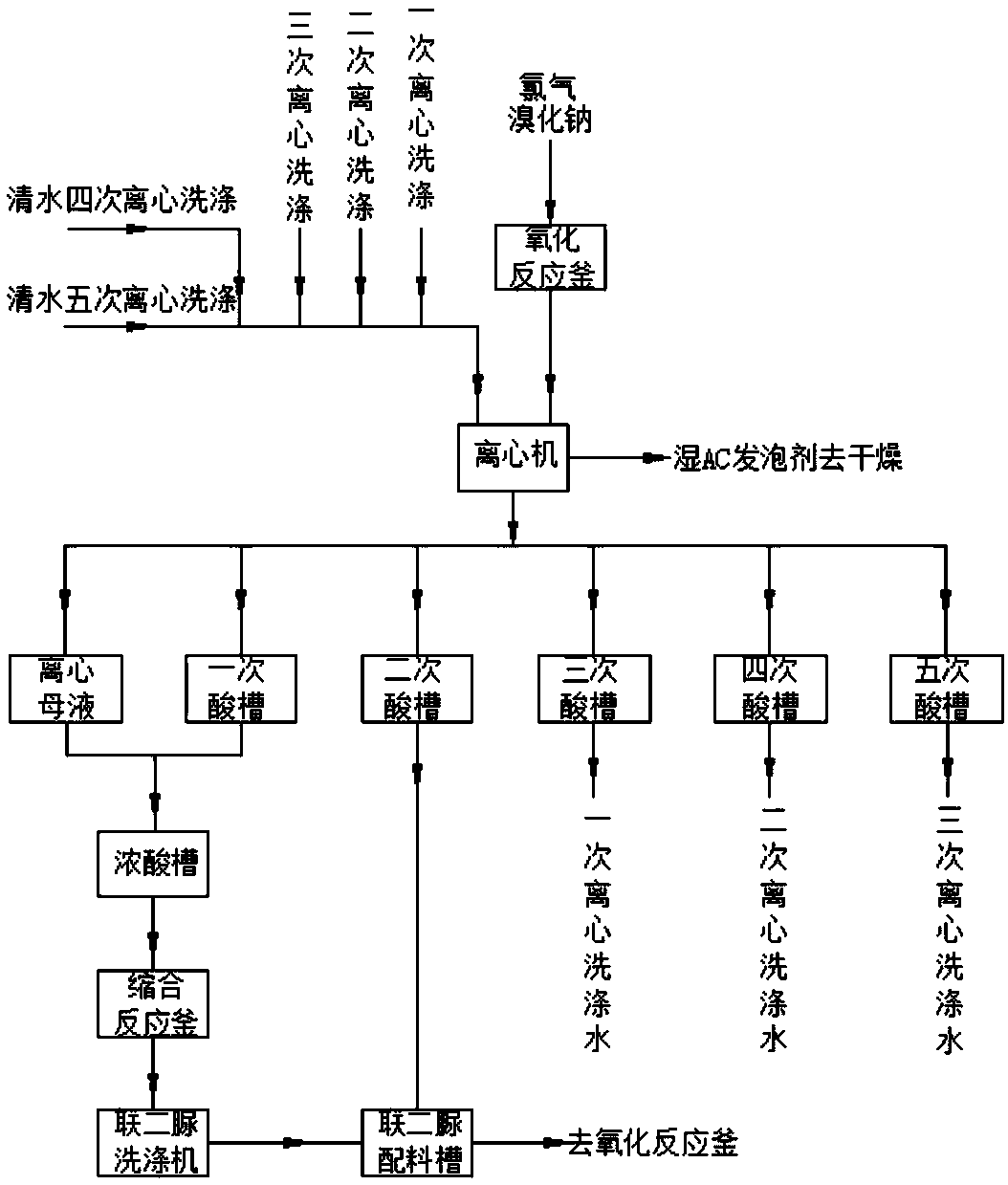

[0045] like figure 1 As shown, a method for recycling hydrochloric acid in the production process of AC foaming agent, comprising the steps of: (1) oxidizing biuret with chlorine gas to obtain oxidation mother liquor; (2) centrifuging the oxidation mother liquor to obtain AC foaming agent and Centrifuge the mother liquor; (3) carry out at least three centrifugal washings on the AC foaming agent, and recycle the removal liquids of different centrifugal washings into different containers respectively, and apply the removal liquids when different batches of AC foaming agents are centrifugally washed, The removal liquid of the first centrifugal washing is used as a primary acid, and the removal liquid of the second centrifugal washing is used as a secondary acid; (4) the centrifugal mother liquor with a hydrochloric acid mass concentration of 20% and above is directly returned to the condensation reaction , or mixing the centrifugal mother liquor with hydrochloric acid mass concen...

Embodiment 2

[0051] like figure 1 As shown, a method for recycling hydrochloric acid in the production process of AC foaming agent, comprising the steps of: (1) oxidizing biuret with chlorine gas to obtain oxidation mother liquor; (2) centrifuging the oxidation mother liquor to obtain AC foaming agent and Centrifuge the mother liquor; (3) carry out at least three centrifugal washings on the AC foaming agent, and recycle the removal liquids of different centrifugal washings into different containers respectively, and apply the removal liquids when different batches of AC foaming agents are centrifugally washed, The removal liquid of the first centrifugal washing is used as a primary acid, and the removal liquid of the second centrifugal washing is used as a secondary acid; (4) the centrifugal mother liquor with a hydrochloric acid mass concentration of 20% and above is directly returned to the condensation reaction , or mixing the centrifugal mother liquor with a hydrochloric acid mass conc...

Embodiment 3

[0055] like figure 1 As shown, a method for recycling hydrochloric acid in the production process of AC foaming agent, comprising the steps of: (1) oxidizing biuret with chlorine gas to obtain oxidation mother liquor; (2) centrifuging the oxidation mother liquor to obtain AC foaming agent and Centrifuge the mother liquor; (3) carry out at least three centrifugal washings on the AC foaming agent, and recycle the removal liquids of different centrifugal washings into different containers respectively, and apply the removal liquids when different batches of AC foaming agents are centrifugally washed, The removal liquid of the first centrifugal washing is used as a primary acid, and the removal liquid of the second centrifugal washing is used as a secondary acid; (4) the centrifugal mother liquor with a hydrochloric acid mass concentration of 20% and above is directly returned to the condensation reaction , or mixing the centrifugal mother liquor with a hydrochloric acid mass conc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com