Automatic glazing device for ceramic spoon production

An automatic glazing device and ceramic technology, which is applied in the field of ceramic production, can solve problems such as troublesome operation, low work efficiency, and long installation and disassembly time, and achieve the effects of improving work efficiency, good thickness, and reducing worker workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

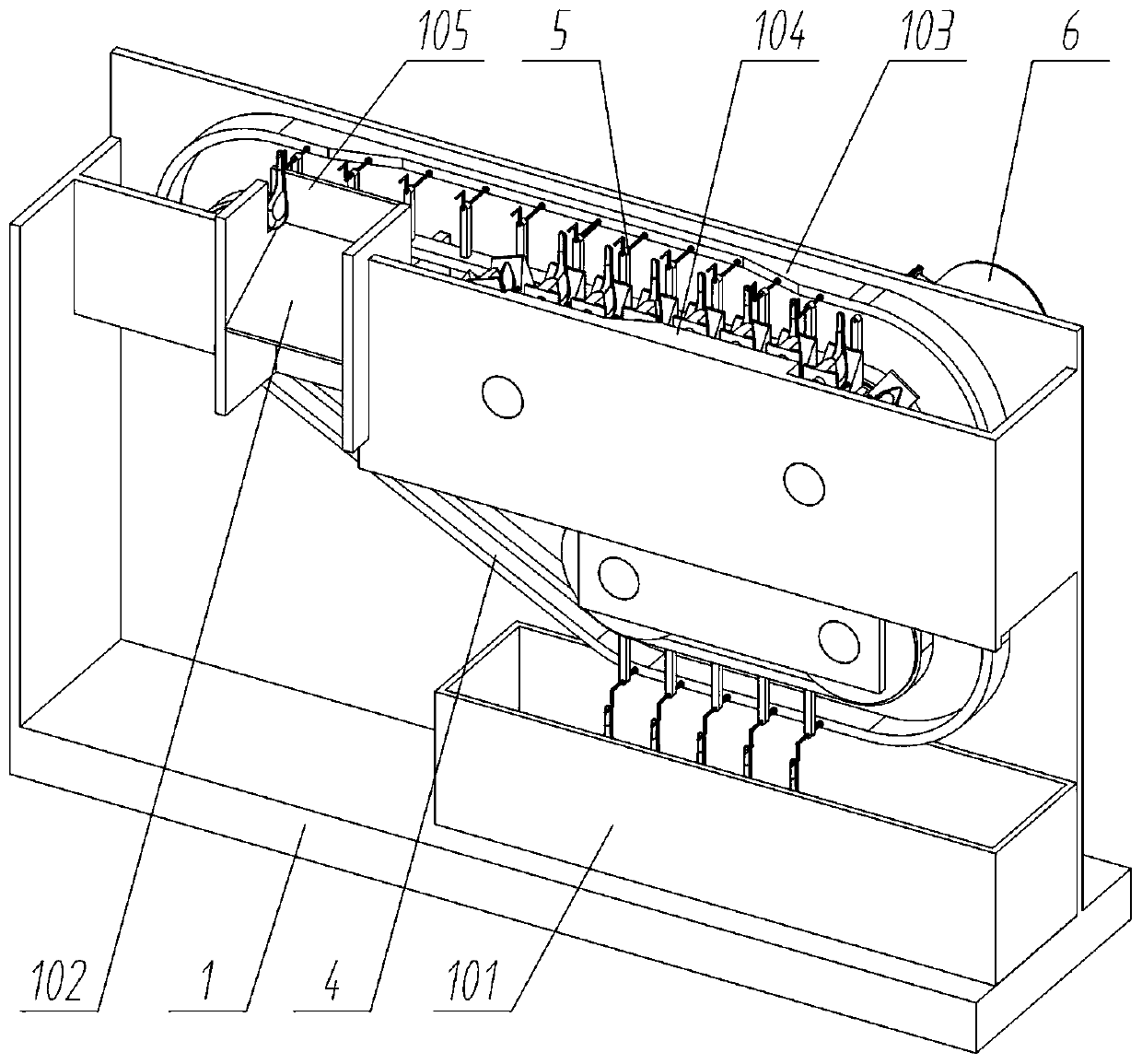

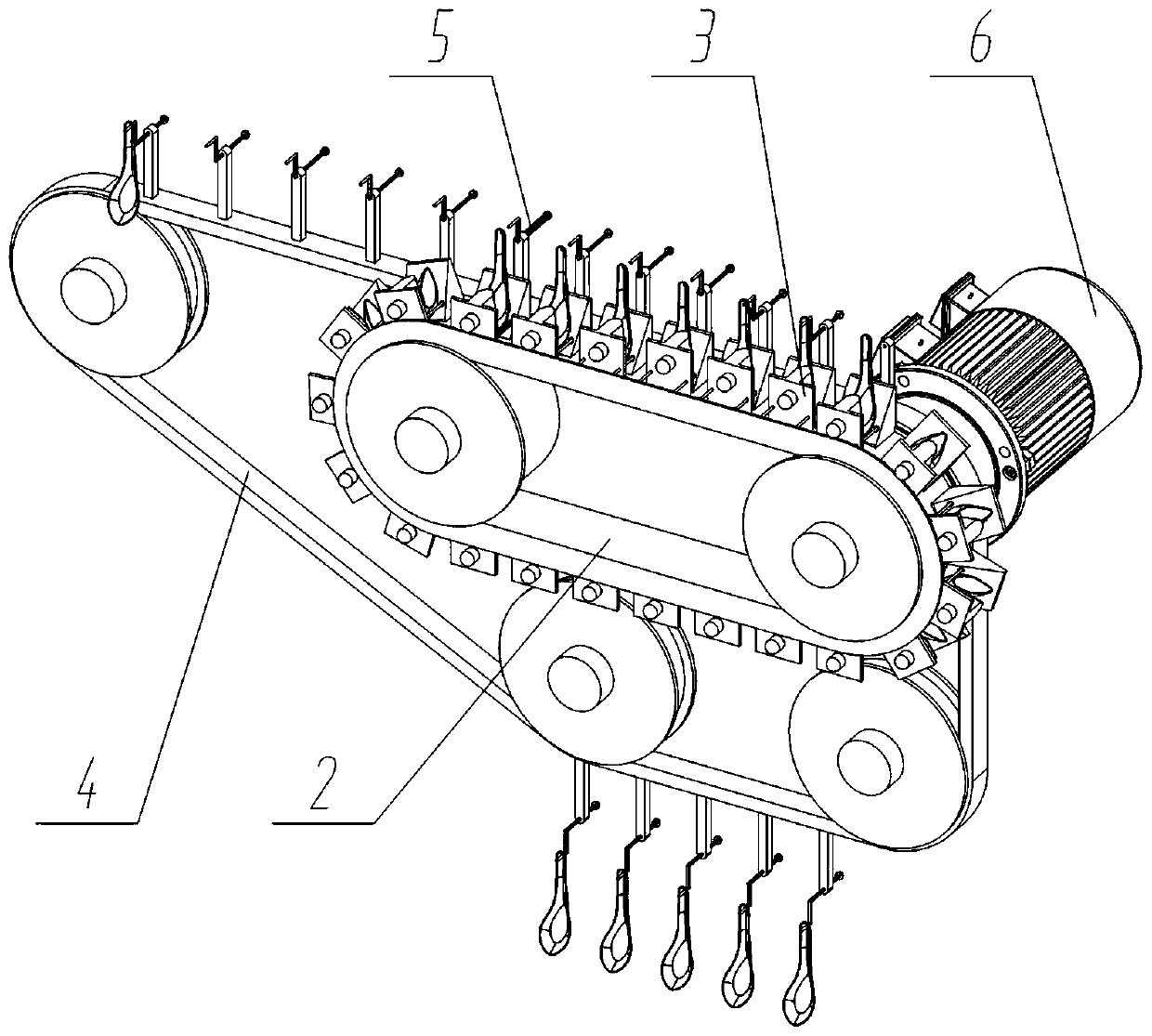

[0028] see Figure 1 to Figure 6 , an embodiment provided by the present invention: an automatic glazing device for the production of ceramic spoons, including a bracket main body 1; a group of glazing conveyor belts 4 and a group of positioning conveyor belts 2 are arranged on the upper inner rear side of the bracket body 1; A group of motors 6 are fixedly connected to the upper right side of the rear side of the bracket main body 1, and the motors 6 simultaneously drive the glazing conveyor belt 4 and the positioning conveyor belt 2 to rotate synchronously; the outside of the positioning conveyor belt 2 is evenly arranged with multiple sets of positioning devices 3; the positioning device 3 Also include fixed positioning block 301, sliding positioning block 302, fixed positioning block 301 is fixed on the bracket main body 1 of positioning device 3 rear side, the front end face of fixed positioning block 301 is slidably connected with a group of sliding positioning block 302,...

Embodiment 2

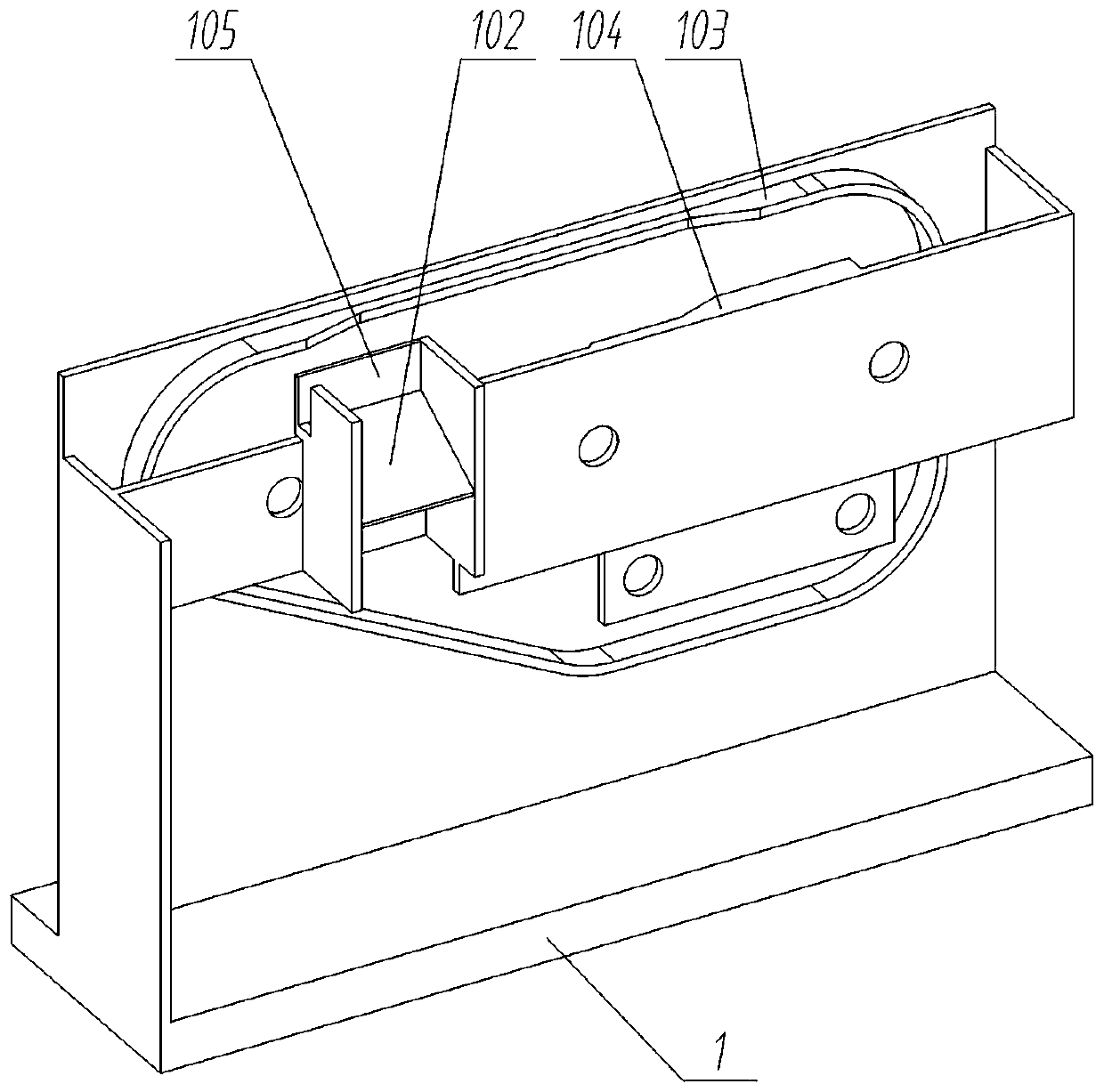

[0031] On the basis of Example 1, please refer to figure 1 , figure 2 with Figure 7 , an embodiment provided by the present invention: an automatic glazing device for ceramic spoon production, which also includes a hanging device 5, the hanging device 5 includes a hanging rod 501, a spline 502, and the hanging device The top of 5 is slidably connected with a group of hanging rods 501, the hanging rods 501 are Z-shaped structures, a group of splines 502 are arranged behind the hanging rods 501, and the hanging rods 501 are slidably connected with the hanging device 5 through the splines 502, And through the elastic connection of the spring, the hanging rod 501 is guided by the spline 502 in use; The bracket main body 1 also includes grabbing bosses 103, the rear portion of the bracket body 1 is provided with a group of ring-shaped grabbing bosses 103, the upper middle position of the grabbing bosses 103 is recessed toward the rear, and the ball head 503 is hung on the sprin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com