Fresh-locked rice noodle raw material treatment process

A technology for raw material processing and fresh rice noodles, applied in food heat treatment, food science and other directions, can solve the problems of poor quality and poor taste of locked fresh rice noodles, and achieve easy operation of processing technology, not easy to break, reduce starch content and The effect of average particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

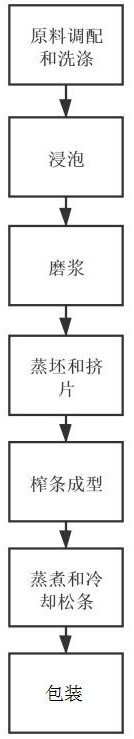

Image

Examples

Embodiment 1

[0026] A process for processing raw materials of fresh-locked rice noodles, comprising the following steps:

[0027] (1) Raw material blending and washing: Weigh the raw materials according to the following parts by weight: 65 parts of early indica rice and 35 parts of late indica rice; sieve the early indica rice and late indica rice to remove impurities and deteriorated rice, and then mix the early indica rice and late indica rice washing with water until the rice washing water becomes clear without turbidity, and then drained to obtain mixed indica rice;

[0028] (2) Soaking: Soak the mixed indica rice obtained in step (1) in water at a temperature of 22°C for 4 hours; when soaking the mixed indica rice in water, change the water every hour;

[0029] (3) Refining: Soak the mixed indica rice treated in step (2) in water at a temperature of 45°C for 1.5 hours, then dry it with hot air to control its water content to 44%, and pass the mixed indica rice through 120 mesh after r...

Embodiment 2

[0035] A process for processing raw materials of fresh-locked rice noodles, comprising the following steps:

[0036] (1) Raw material blending and washing: Weigh the raw materials according to the following parts by weight: 70 parts of early indica rice and 30 parts of late indica rice; sieve the early indica rice and late indica rice to remove impurities and deteriorated rice, and then mix the early indica rice and late indica rice washing with water until the rice washing water becomes clear without turbidity, and then drained to obtain mixed indica rice;

[0037] (2) Soaking: Soak the mixed indica rice obtained in step (1) in water at a temperature of 20°C for 5 hours; when soaking the mixed indica rice in water, change the water every hour;

[0038] (3) Refining: Soak the mixed indica rice treated in step (2) in water at a temperature of 40°C for 2 hours, then dry it with hot air to control its water content to 40%, and pass the mixed indica rice through 120 mesh after ref...

Embodiment 3

[0044] A process for processing raw materials of fresh-locked rice noodles, comprising the following steps:

[0045] (1) Raw material blending and washing: Weigh the raw materials according to the following parts by weight: 75 parts of early indica rice and 25 parts of late indica rice; sieve the early indica rice and late indica rice to remove impurities and deteriorated rice, and then mix the early indica rice and late indica rice washing with water until the rice washing water becomes clear without turbidity, and then drained to obtain mixed indica rice;

[0046] (2) Soaking: Soak the mixed indica rice obtained in step (1) in water at a temperature of 25°C for 2 hours; when soaking the mixed indica rice in water, change the water every hour;

[0047] (3) Refining: Soak the mixed indica rice treated in step (2) in water at a temperature of 50°C for 2 hours, then dry it with hot air to control its water content to 50%, and pass the mixed indica rice through 120 mesh after ref...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com