Wafer wet processing workstation

A wet processing and workstation technology, applied in the field of wafer wet processing workstations, can solve the problems of insufficient wafer soaking, wafer damage, and inability to take out the wafer, and achieve the effect of controlling the soaking time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the above and other objectives, features, and advantages of the present disclosure more comprehensible, preferred embodiments of the present disclosure will be exemplified below in detail with accompanying drawings.

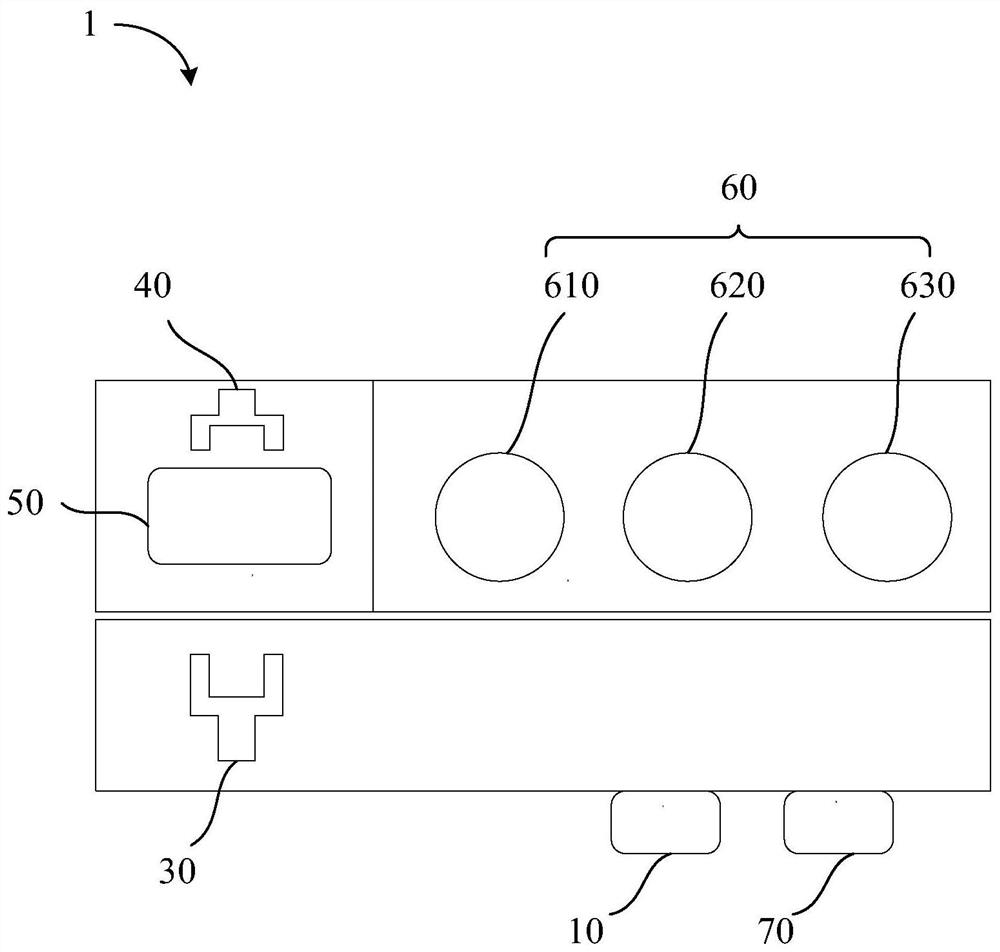

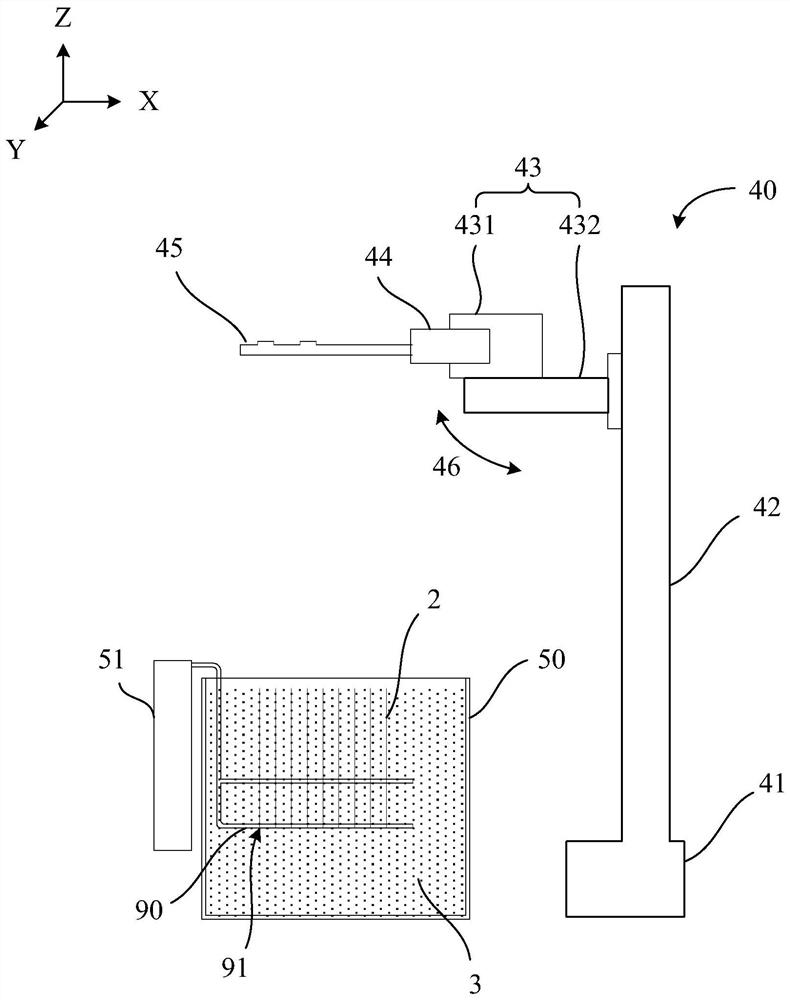

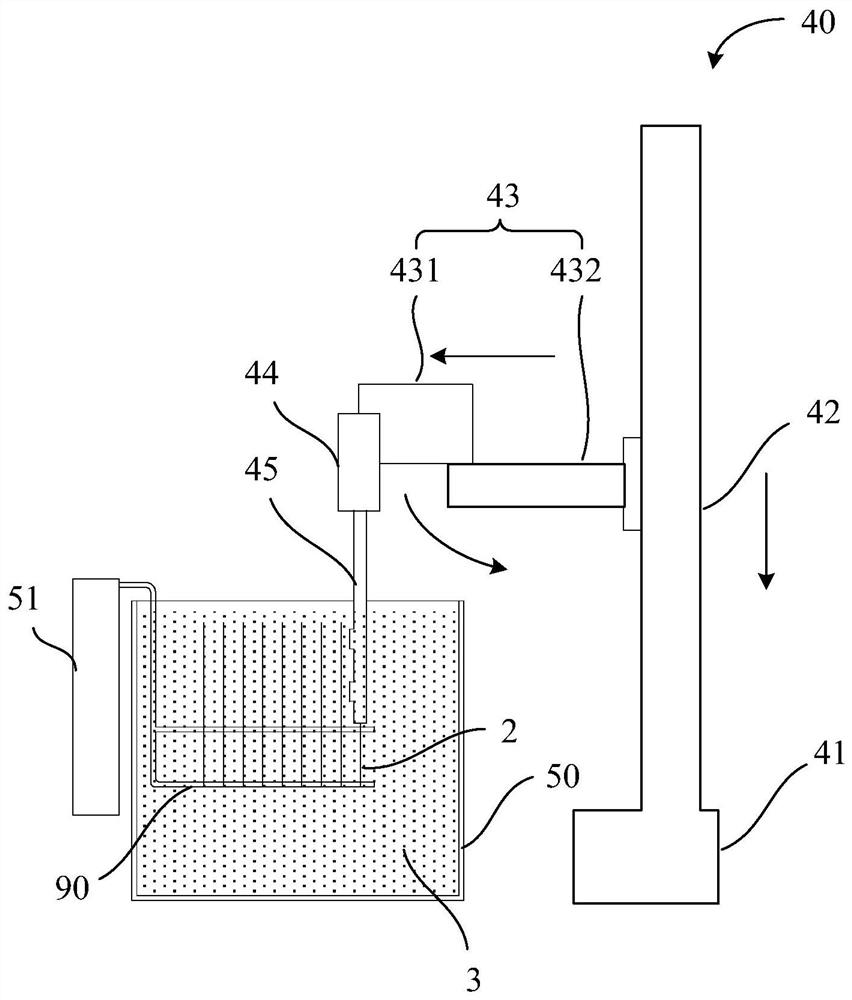

[0029] Please refer to figure 1 , which shows a schematic diagram of a wafer wet processing workstation 1 according to a preferred embodiment of the present disclosure. The wafer wet processing workstation 1 includes a material inlet 10 , a transfer device 30 , a robot arm 40 , a soaking tank 50 , a single wafer processing device 60 , and a material outlet 70 . The transfer device 30 is configured to be movable among the material inlet 10 , the soaking tank 50 , the single wafer processing equipment 60 , and the material outlet 70 . The transfer device 30 is adjacent to the robotic arm 40 . The base of the robot arm 40 is fixed on one side of the soaking tank 50, and the robot arm 40 can perform a series of actions relative to the soakin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com