Semi-automatic surgical instrument pretreatment machine

A technique for surgical instruments and pretreatment machines, applied in the field of medical instruments, can solve the problems of inadequate execution, large corrosion of instruments, affecting sterilization effects, etc., and achieves the effects of saving time and cost, simple production process, and easy promotion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

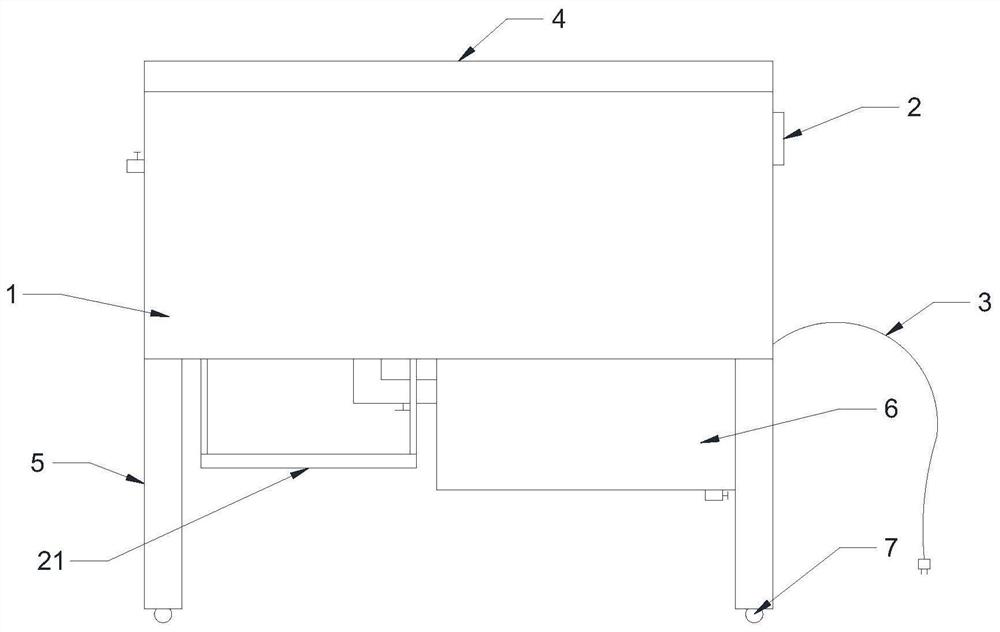

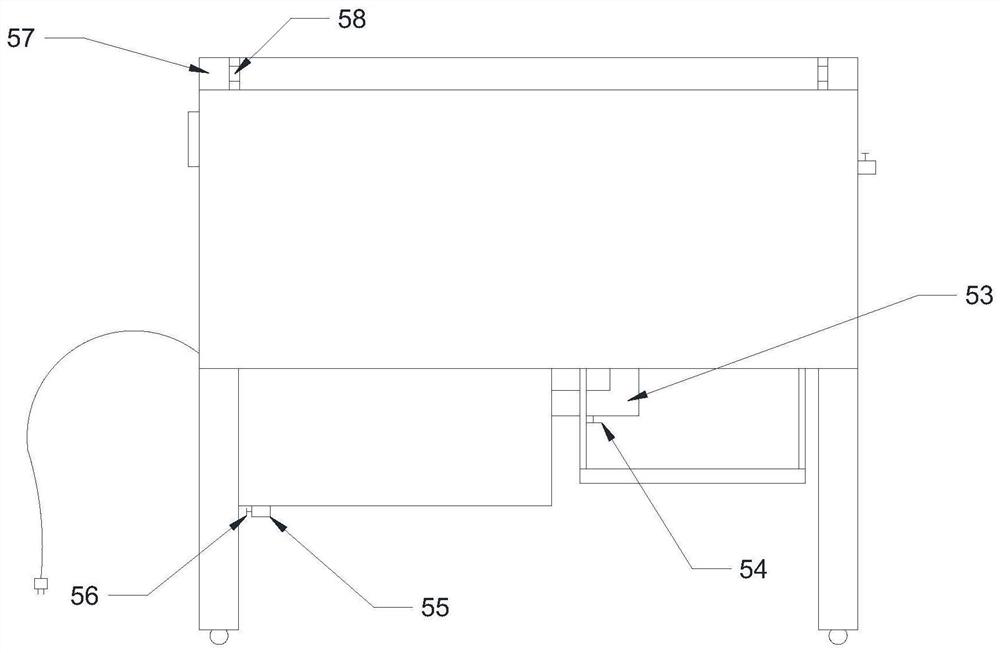

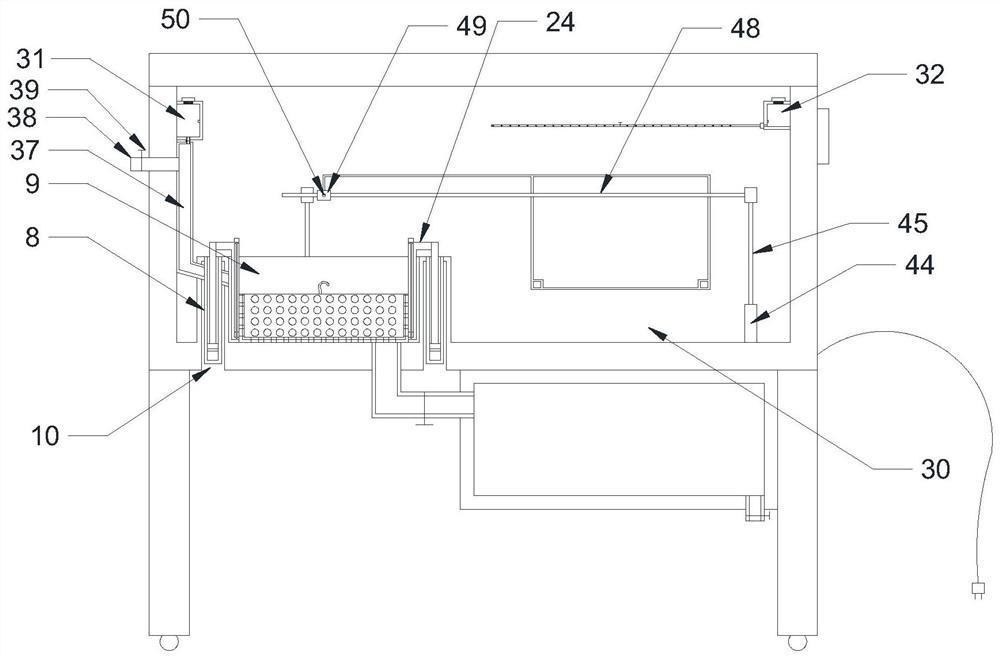

[0028] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 with Figure 10, a semi-automatic surgical instrument pretreatment machine, including a processing box 1, the outer wall of the processing box 1 is provided with a control panel 2 and a power cord 3, and the device is connected to an external power supply device through the power cord 3. The top of the processing box 1 is provided with a cover 4 that can be automatically opened and closed by the control panel 2, and the two ends of the top of the side wall of the processing box 1 of the present embodiment are provided with two rotating motors 57, and the two rotating motors 57 and the processing Box 1 is welded, and the sides of the two rotating motors 57 facing each other are provided with rotating rods 58. The cross section between the rods 58 is a semicircular driving rod 59, the driving rod 59 and the cover 4 are integrally made, and the two rotating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com